Polishing device for steel pipe machining

A technology for steel pipes and grinding wheels, which is applied in the direction of grinding drive devices, grinding/polishing safety devices, metal processing equipment, etc., can solve the problems of physical consumption, operator injury, and reducing the speed of steel pipe grinding, so as to reduce the vibration amplitude, Improve the service life and facilitate the effect of grinding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

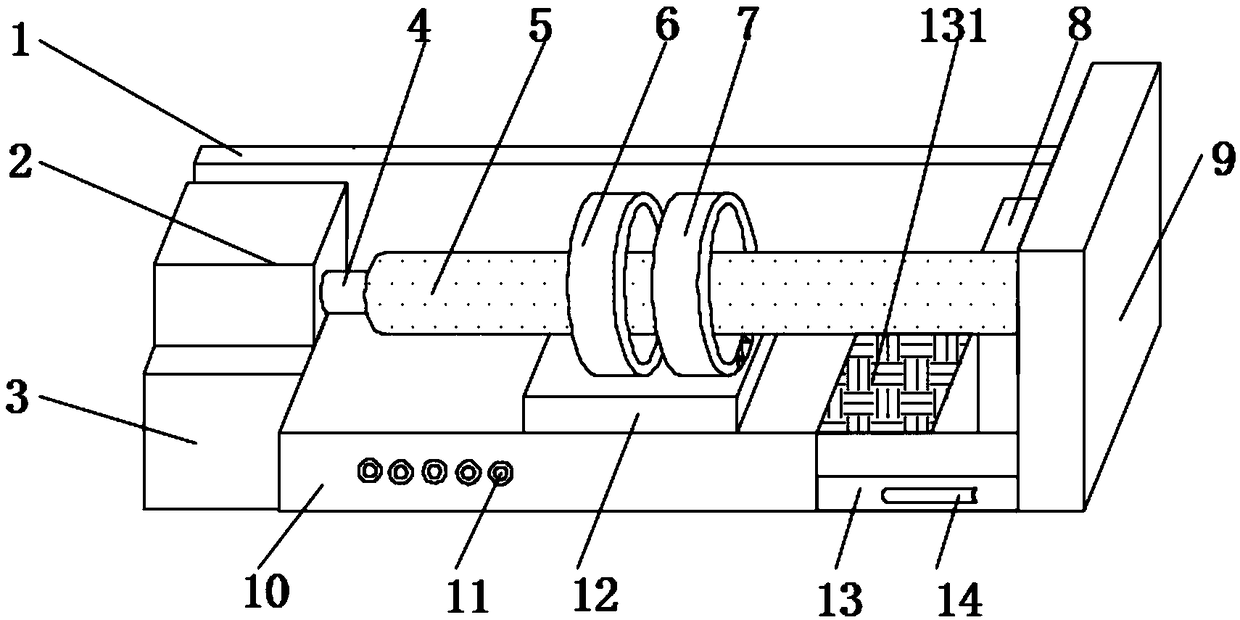

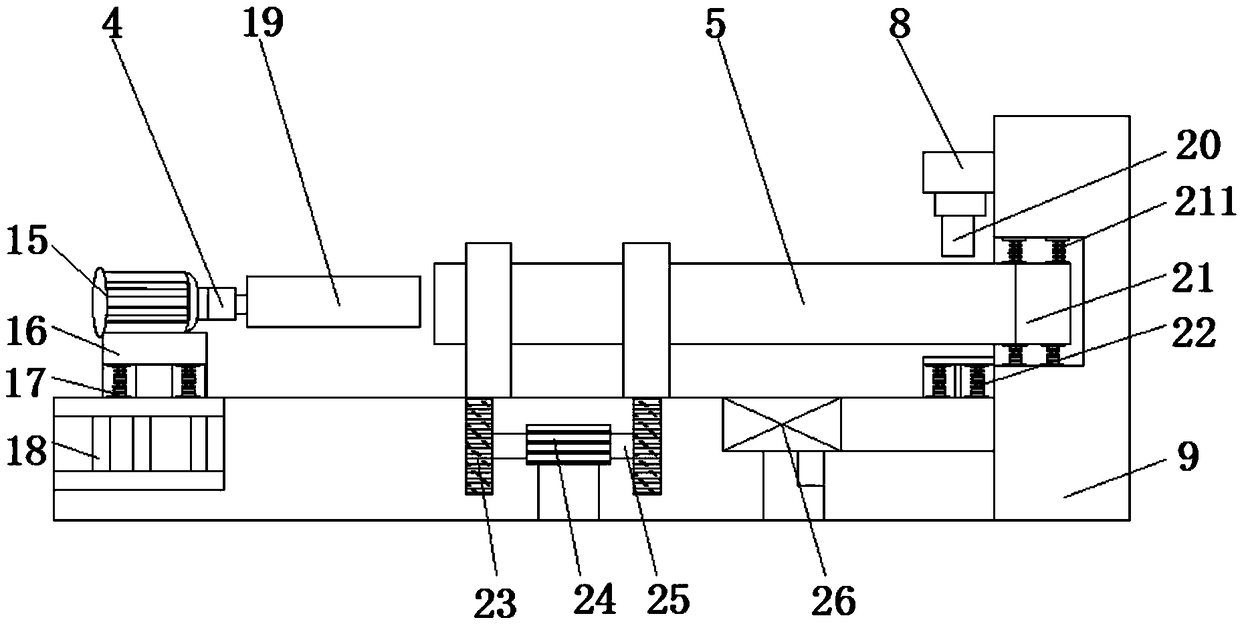

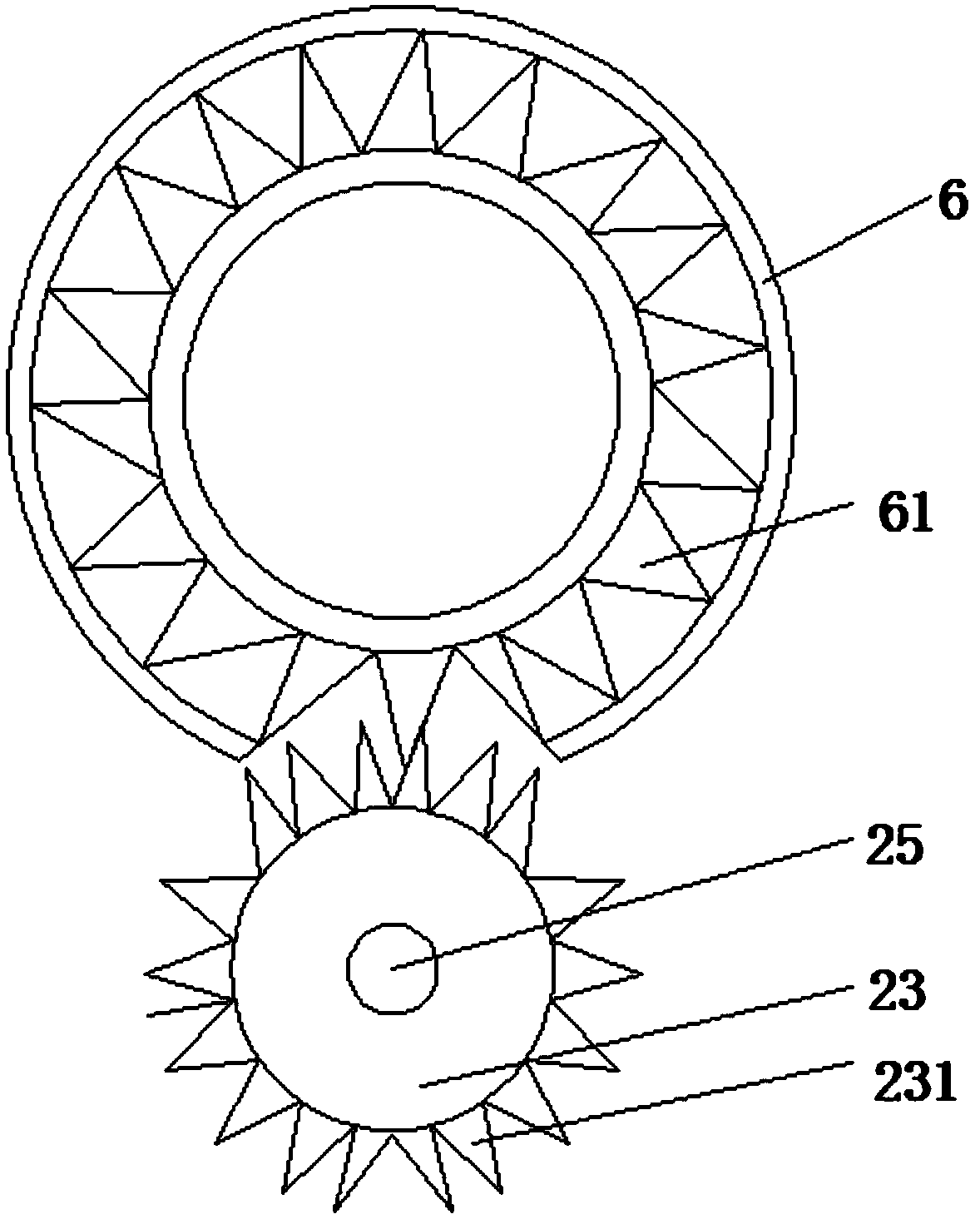

[0022] see Figure 1~3 , in an embodiment of the present invention, a grinding device for steel pipe processing includes a base 10, the side surface of the base 10 is fixedly provided with a motor base 3, and the upper surface of the motor base 3 is fixedly installed with a first motor box 2, the base 10 The rear surface of the base 10 is fixedly provided with a baffle plate 1, the other side surface of the base 10 is fixedly provided with a support seat 9, the front surface of the base 10 is embedded with a control switch 11, and the inner top of the first motor box 2 is fixedly installed with a motor 15 One side of the motor 15 is fixedly equipped with an electric telescopic rod 4, and one end of the electric telescopic rod 4 is fixedly sleeved with a third grinding wheel 19, and the middle part of the support seat 9 is fixedly provided with a groove 21, and one side of the support seat 9 A support plate 8 is fixedly installed near the upper position of the groove 21, a tele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com