Patents

Literature

50results about How to "Realize automatic stamping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Intelligent seal system and method

ActiveCN107967593AEnsure safetyImplement remote authorizationOffice automationIndividual entry/exit registersEngineeringControl circuit

The invention discloses a safe seal sleeve internally provided with a driving device which has the advantages of simple structure, convenient use and high safety. The safe seal sleeve internally provided with the driving device is arranged inside an intelligent seal machine for fixedly mounting a seal, and comprises a shell, a driving device and a protective cover, wherein the driving device comprises a driving block, a guiding rod and a connecting block arranged inside the shell sequentially from top to bottom; the driving block and the guiding rod are respectively connected onto two ends ofthe guiding rod; the guiding rod is sleeved with a spring; the spring is located between the driving block and the connecting block; the upper end of the shell is internally provided with a first electronic lock matched with the driving block; the first electronic lock is electrically connected with a control circuit of the intelligent seal machine; the protective cover is fixedly connected onto the lower end of the shell; and the seal is mounted inside the protective cover and is connected with the connecting block. The safe seal sleeve internally provided with the driving device is applied to the technical field of intelligent seal machines.

Owner:珠海思格特智能系统有限公司

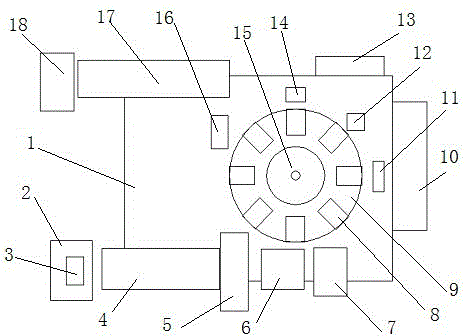

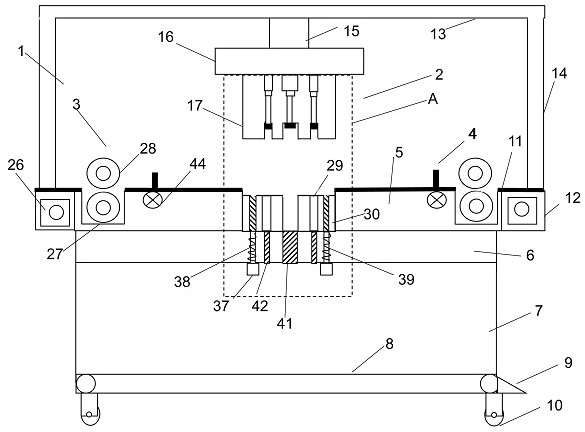

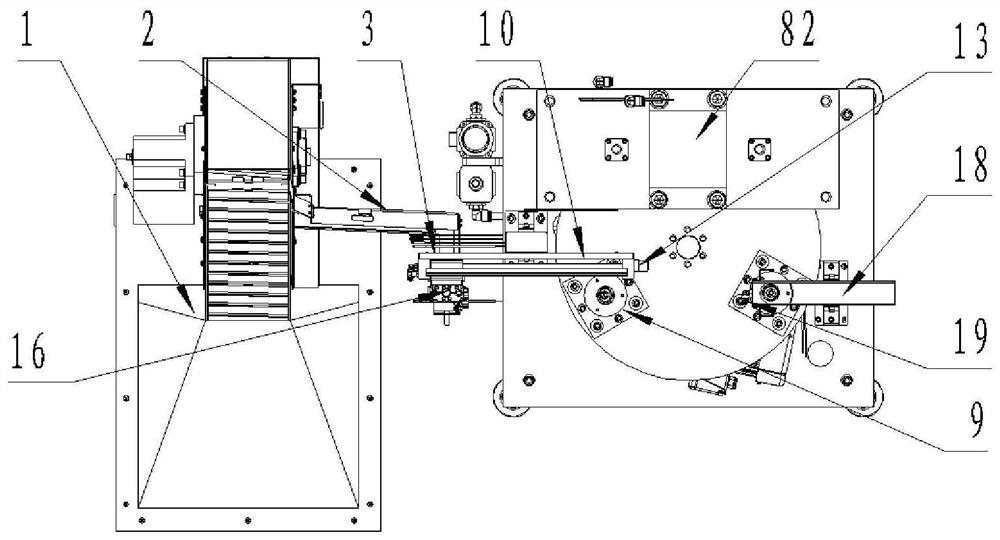

Automatic stamping machine

InactiveCN104553400ARealize automatic stampingReduce labor intensityStampingTransmission systemEngineering

The invention relates to an automatic stamping machine and belongs to the field of office equipment. The automatic stamping machine comprises a frame, a credential bin, a credential delivering device, a credential conveyor, a credential identification device, a credential position adjusting device, a credential feeding device, a credential positioning device, a rotary disc system, a control system, an official seal stamping device, a principle seal stamping device, a pneumatic system, a steel seal stamping device, a transmission system, a credential discharge device, a discharge conveyor and a credential collecting device. By the automatic stamping machine, automatic stamping of graduation credentials and student identity credentials, stamping of several different seals is completed at the same time, labor intensity is lowered, and work efficiency is increased.

Owner:ZHONGZHOU UNIV

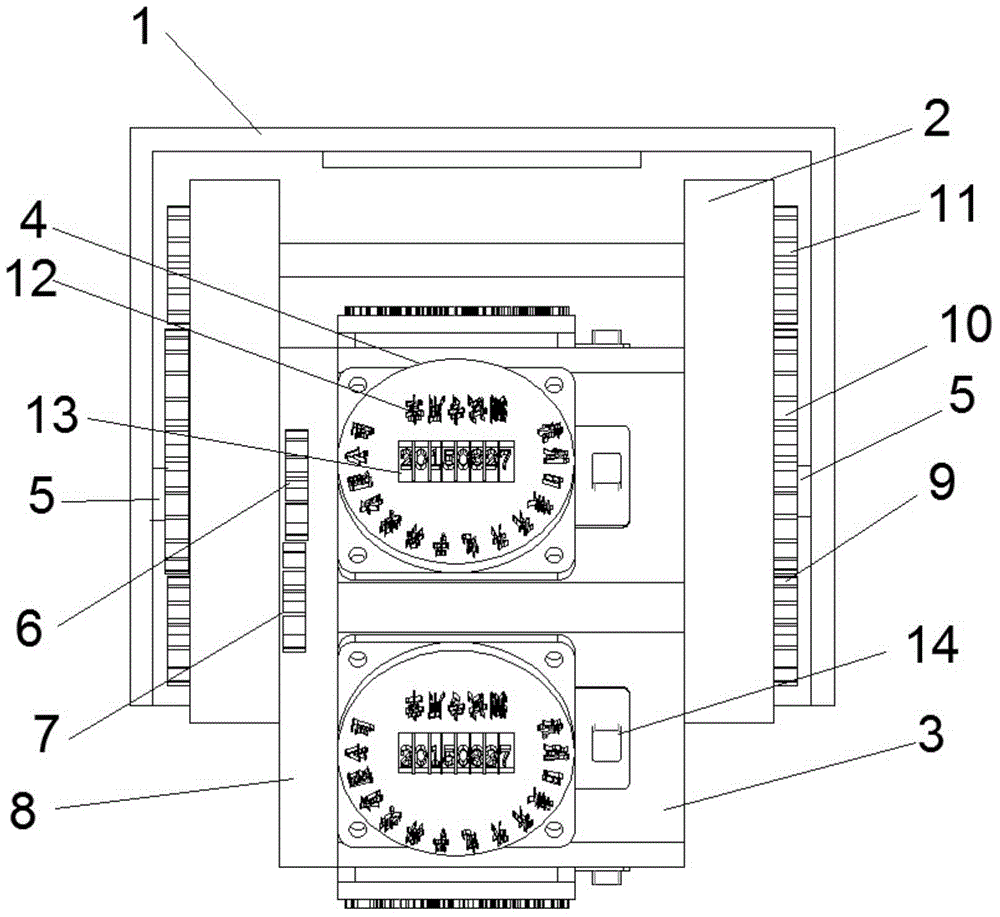

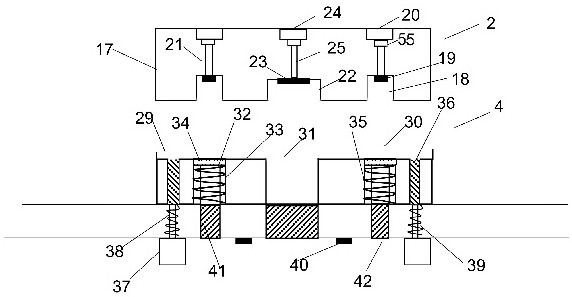

Multiple stampers and automatic date adjusting device thereof

The invention relates to multiple stampers and an automatic date adjusting device thereof. The device comprises a support, sliding blocks, a motor and one or more stamper modules; the inner side walls, corresponding to the sliding blocks, of the support are provided with rail wall grooves; each sliding block is slidably connected with the matched rail wall groove through a bearing column; the two ends of the motor are fixed to a sliding block guide bearing capable of moving vertically; the motor is in transmission connection with a first gear and a second gear in sequence in the anti-clockwise direction; the first gear is in transmission connection with a third gear through a cross shaft; the motor is in transmission connection with a fourth gear, a fifth gear and a sixth gear in sequence in the clockwise direction; each stamper module is provided with a stamper body, date numbers, a mechanical arm used for controlling the date numbers and a date adjusting button. By means of the multiple of stampers and the automatic date adjusting device thereof, stamping can be conducted automatically, and the purposes of adjusting the position of the stampers automatically and adjusting the date automatically are achieved; in addition, by means of the multiple stampers and the automatic date adjusting device thereof, the problems that one month includes 28 days or 31 days, and it is difficult to adjust the numbers of days and months are solved through reasonable application.

Owner:HANGZHOU RIMEI KAIKAI ELECTRONICS TECH CO LTD

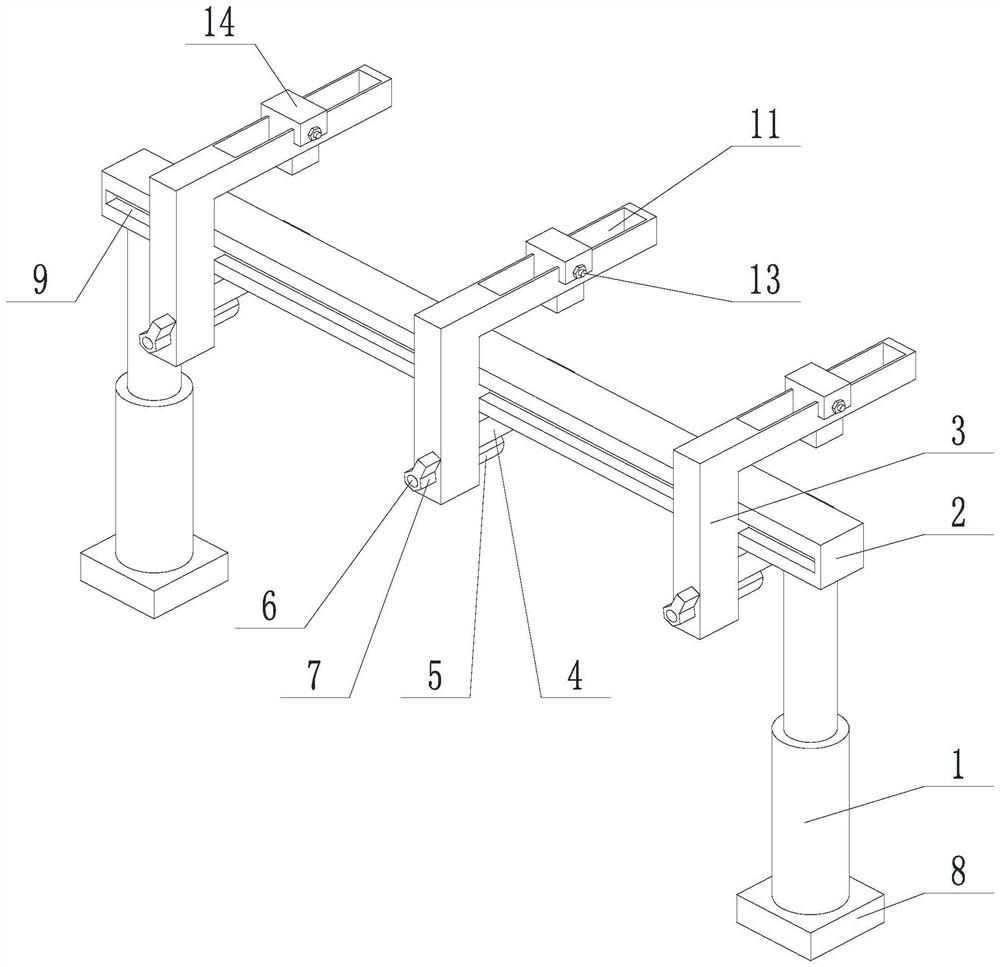

Automatic stamping device

ActiveCN106004132ARealize automatic stampingImprove work efficiencyStampingElectricityMechanical engineering

The invention discloses an automatic stamping device. The automatic stamping device comprises a vertical column which is connected to a bottom plate, wherein the top end of the vertical column is spliced with a first supporting beam by welding; a second supporting beam is arranged below the first supporting beam; a third supporting beam is arranged below the second supporting beam; the second supporting beam and the third supporting beam are spliced with the vertical column by welding; the first supporting beam is used for supporting a slide rail; the second supporting beam is used for supporting a shaft and a cam; a downward pressing motor is suspended and fixed through the third supporting beam; the slide rail is connected to an outer clamping head through first springs; a slide pin sleeved by a slide sleeve is fixed to the outer clamping head; a second spring sleeves the slide sleeve and the slide pin; and an inner clamping head is mounted in the outer clamp. According to the automatic stamping device, electricity is taken as the power to replace manual stamping, and as a result, the automatic stamping can be realized; and the technical problems such as clamping and replacing of an official seal, automatic mechanical downward pressing during stamping, and adjustable stamping height can be solved. Therefore, stamping workers can be released from the heavy repeating work, and as a result, the working efficiency can be improved.

Owner:SUZHOU INST OF TRADE & COMMERCE

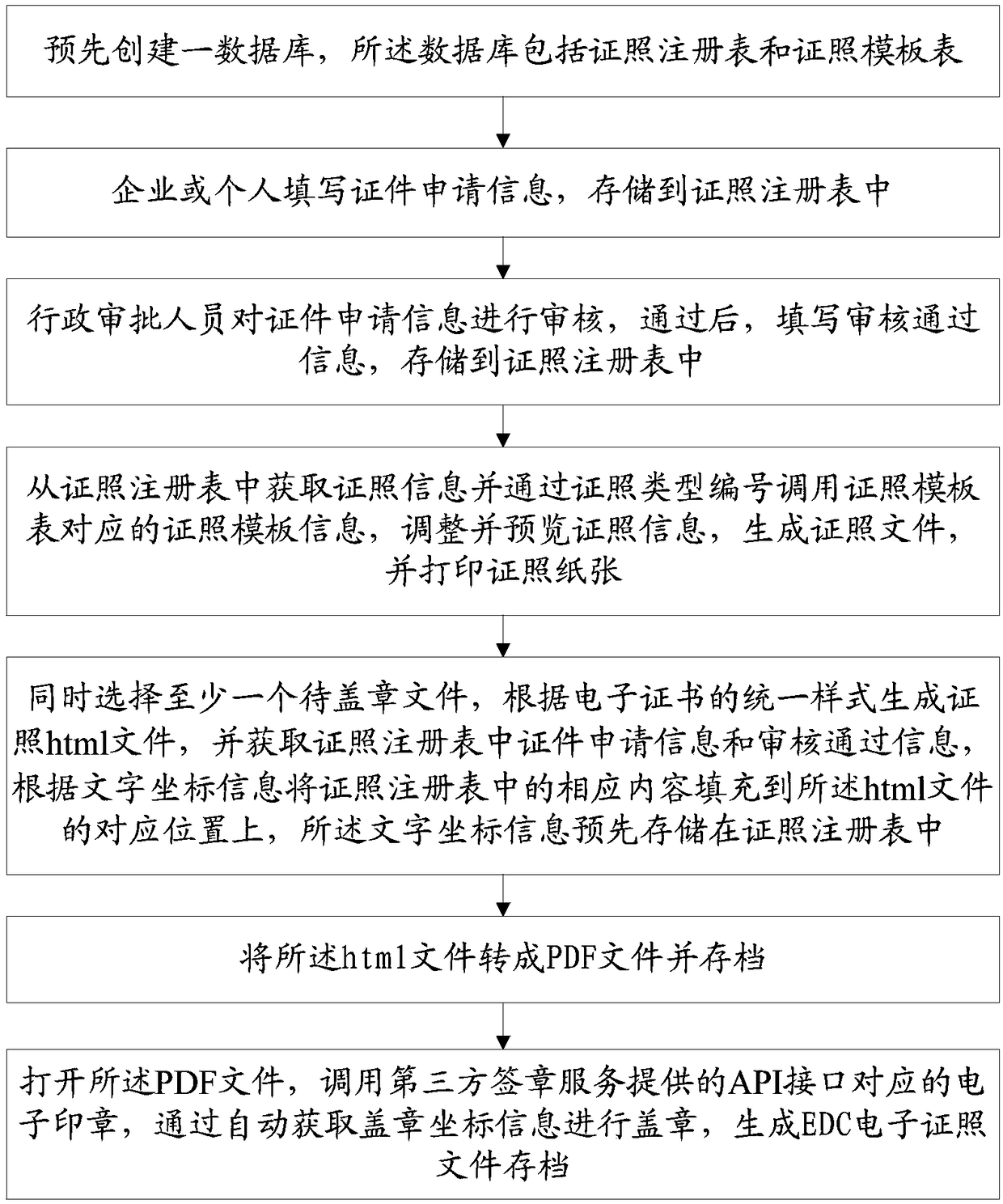

Method for sealing electronic certificate

InactiveCN109118229ASimplify user operationsReduce workloadElectronic credentialsType numberFilling-in

The invention provides an electronic license signing method, which comprises the following steps: a database is created in advance; the database comprises a license registration table and a license template table; the associated transfer of the two tables is realized by the license type number; the electronic license signing method comprises the following steps: a database is created in advance; the database comprises a license registration table and a license template table; the associated transfer of the two tables is realized by the license type number. The enterprise or individual fills inthe certificate application information and stores it in the certificate registration form; The administrative examining and approving personnel shall examine and approve the certificate applicationinformation, fill in the approved information and store it in the certificate registration form; Adjust and preview license information, generate license documents, and print license paper; Generatinglicense html file according to the uniform pattern of electronic certificate, obtaining records in license registration table, and filling corresponding contents in license registration table into corresponding positions of html file according to pre-stored text coordinate information; Convert html file to PDF file and archive; Automatically obtain the stamp coordinate information, call the electronic seal to automatically stamp, and generate the EDC electronic license document for archiving. The invention can realize the automatic stamping of a large number of electronic certificates, greatly reduces manual workload and improves stamping efficiency.

Owner:长威信息科技发展股份有限公司

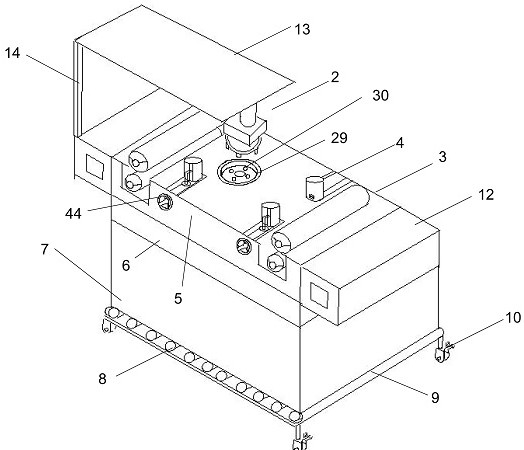

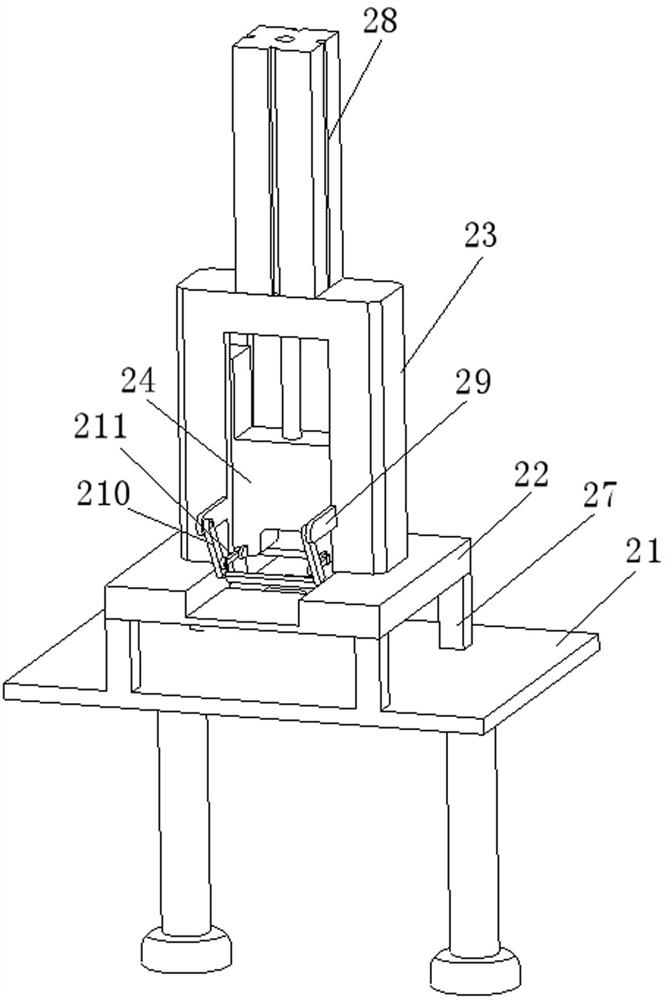

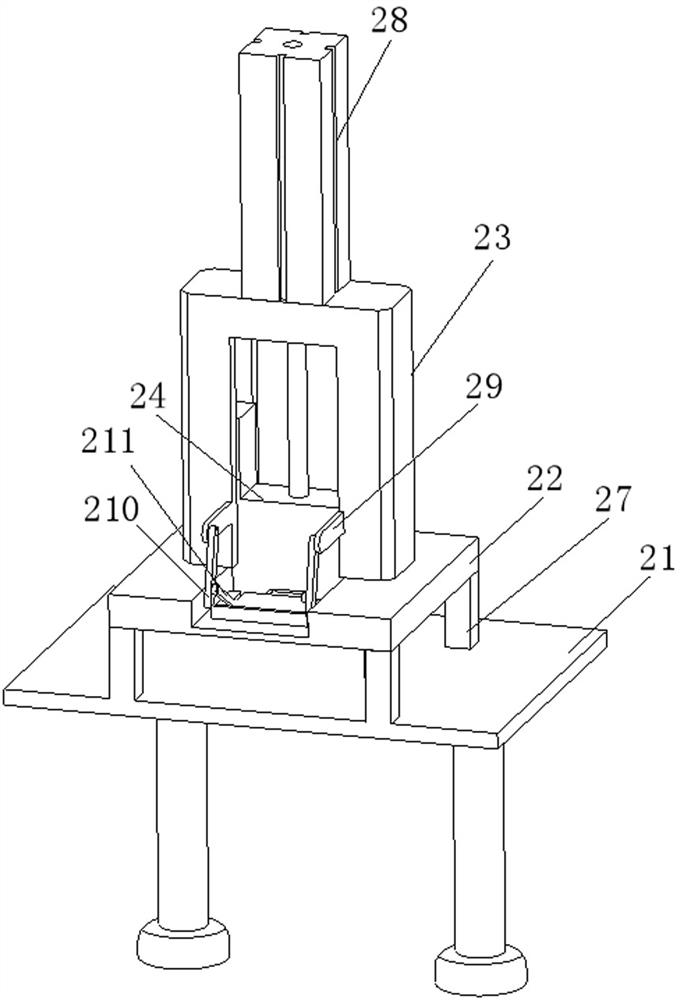

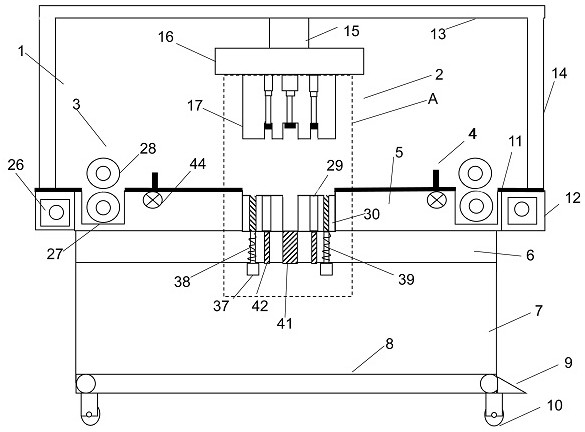

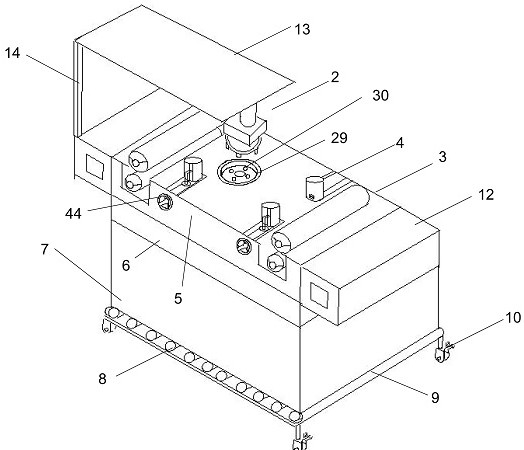

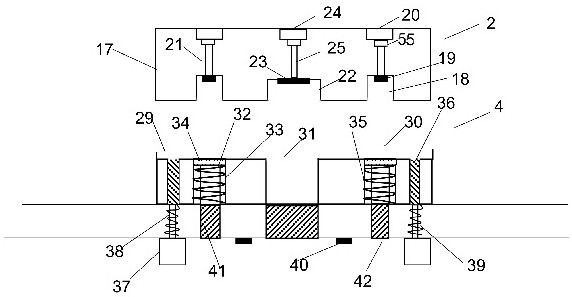

Machining tool for metal sealing gasket

ActiveCN114054591ASolve the waste of manpowerRealize the punching operationShaping toolsPerforating toolsMachine toolMachining

The invention discloses a machining tool for a metal sealing gasket. The machining tool comprises a stamping cavity, a die cavity, a bearing box and a workbench and further comprises a stamping mechanism, a feeding mechanism and a clamping mechanism, wherein the stamping cavity is formed in the workbench and composed of a top plate and four brackets located on the workbench, the stamping mechanism is located on the top plate, the bottom surface of the workbench is connected with the die cavity, control boxes are arranged on the left side and the right side of the die cavity, a die groove is formed in the die cavity, the upper portion of the die groove is not covered by the workbench, the feeding mechanism and the clamping mechanism are further arranged on the workbench and in the die cavity, the bearing box is arranged below the die cavity, the bearing box communicates with a waste box, a conveying belt is arranged in the waste box, a discharging port is formed in the joint of the conveying belt and the waste box, and universal wheels are connected to the bottom surface of the waste box. According to the invention, automatic feeding of metal plates, stamping machining of sealing gaskets and automatic ejection and taking can be achieved, waste materials are automatically discharged, manpower is saved, and the machining efficiency is improved.

Owner:烟台长鑫密封产品有限公司

Full-automatic punch press

InactiveCN108237170AGuaranteed continuous dischargeAvoid multiple fetchesMetal-working feeding devicesStripping-off devicesPunch pressEngineering

The invention discloses a full-automatic punch press. A working table is movably connected to a lower movable punching die through a fixed base, and the lower movable punching die is movably connectedto an oscillating rod through a passive pin; the side of the working table is provided with a fixed pin, and the oscillating rod is movably connected to the working table through the fixed pin; the right side of the oscillating rod is provided with a blanking cylinder fixedly connected to an active pin through a sliding block; the active pin is movably connected to the oscillating rod, and an upper punching die is arranged right above the lower movable punching die; the upper punching die is fixedly connected to the main body of the punch press through a punching cylinder, and the left side of the lower movable punching die is provided with a material storage box fixedly connected to the working table; and the left side of the material storage box is provided with a feeding cylinder fixedly connected to a material pushing plate. The full-automatic punch press has the advantages of high machining speed, automatic feeding, punching and discharging, convenient use and easy operation, andis worthy of popularizing.

Owner:惠州市绿之蓝再生科技有限公司

Processing device for copper pipe outer convex point for air conditioner

PendingCN110883175AEnsure the limitPrevent movementMetal-working feeding devicesPositioning devicesEngineeringElectric control

The invention discloses a processing device for a copper pipe outer convex point for an air conditioner in the technical field of copper pipe outer convex point machining. Fixing plates are fixedly arranged at a top and a bottom of a left side wall of a machining base. First electric telescopic rods are fixedly arranged on side walls of facing sides of the two sets of fixing plates. Clamping plates matched with an outer wall of a pipe body are fixedly assembled at output ends of the two sets of first electric telescopic rods, a second electric telescopic rod is fixedly assembled on a right side wall of an inner cavity of a protective shell, a push plate is fixedly assembled at an output end of the second electric telescopic rod, a stamping device matched with an inner cavity of the pipe body is fixedly arranged at a left end of the protective shell, and an electric control box is fixedly arranged on a left side wall of a first base. The automatic punching of protruding points can be achieved, the manufacturing of the protruding points on the outer wall of the pipe body in the circumferential direction and the length direction can be completed in sequence, the automation degree is high, the positions of the protruding points can be accurately controlled, the manufacturing quality of the protruding points is improved, and the pipe body is not damaged.

Owner:GUIXI HUATAI COPPER IND CO LTD

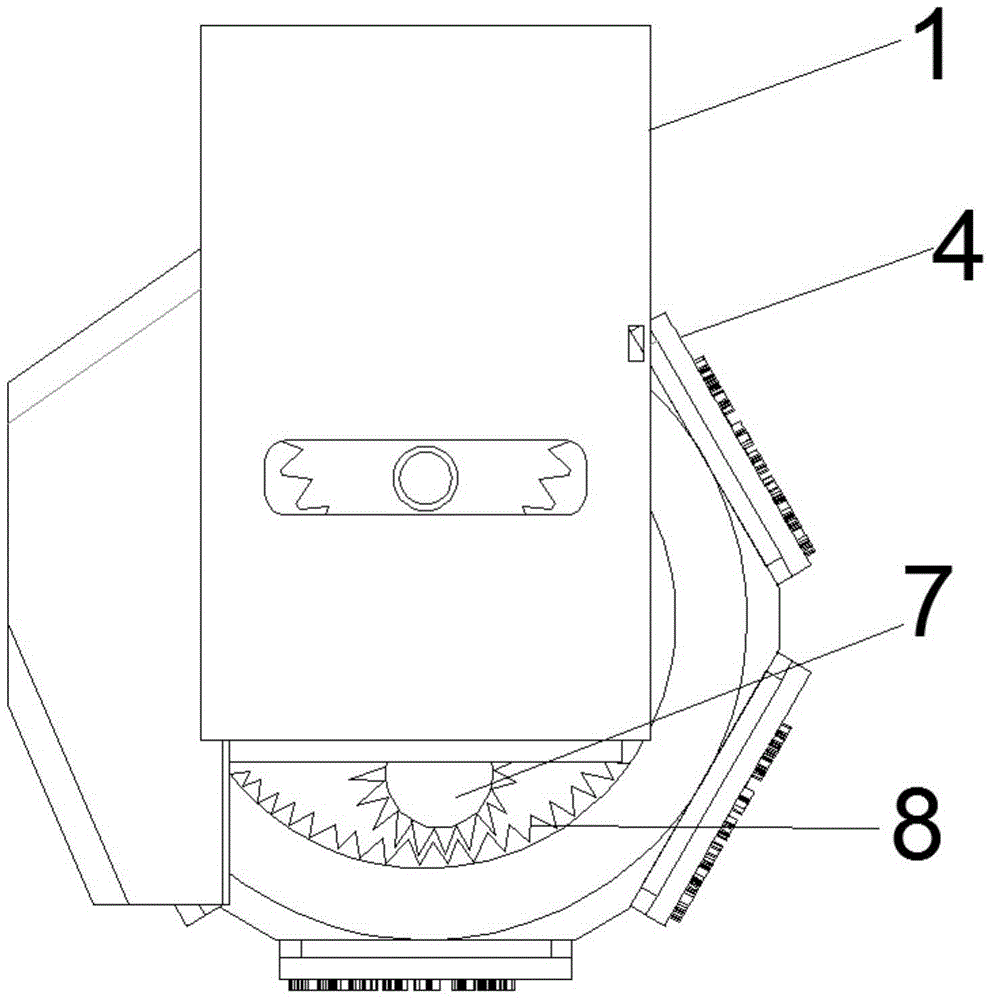

Rotary hardware lock body buckle plate punching device

InactiveCN108655240ARealize automatic stampingImprove securityShaping toolsMetal-working feeding devicesPunchingMaterial removal

The invention discloses a rotary hardware lock body buckle plate punching device. The device comprises a frame and a main chassis; a main shaft is hinged to the middle part of the top surface of the main chassis; a rotating plate is fixed at the top end of the main shaft; the frame is fixed on the top surface of the left side of the rotating plate; a transmission gear is fixed at the middle part of the main shaft; a main driving motor is fixed on the bottom surface of a top plate of the main chassis; an output shaft of the main driving motor penetrates through the top surface of the top plateof the main chassis, and is fixedly provided with a driving gear; the driving gear is engaged with the transmission gear; a vertical main plate is fixed on the top surface of the right side of the main chassis; a main top plate is fixed on the top surface of the vertical main plate; a main punching oil cylinder is fixed on the top surface of the middle part of the main top plate; and a push rod ofthe main punching oil cylinder penetrates through the main top plate, and is fixedly provided with a lifting connection plate. Through rotation of the frame, a lower mold corresponds to an upper mold, so that automatic punching is realized; and punching wastes automatically fall into a discharging through hole through falling of a positioning block, so that more convenience is achieved, and manual material removal at each time is not needed.

Owner:FOSHAN DAPUGUANG ELECTROMECHANICAL TECH CO LTD

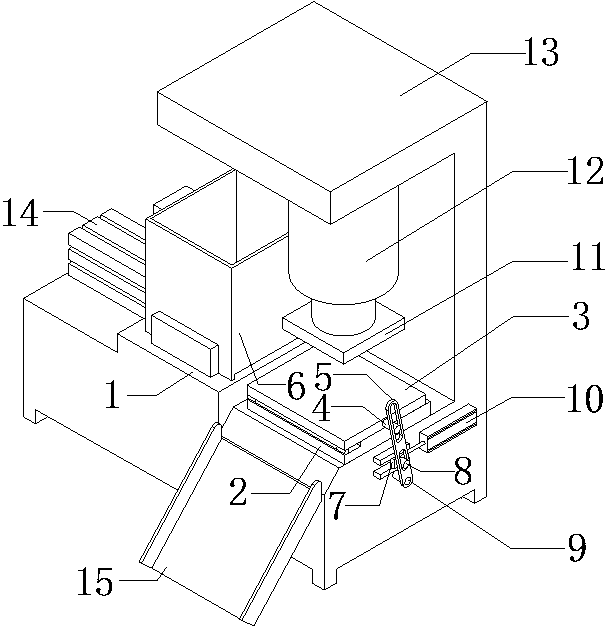

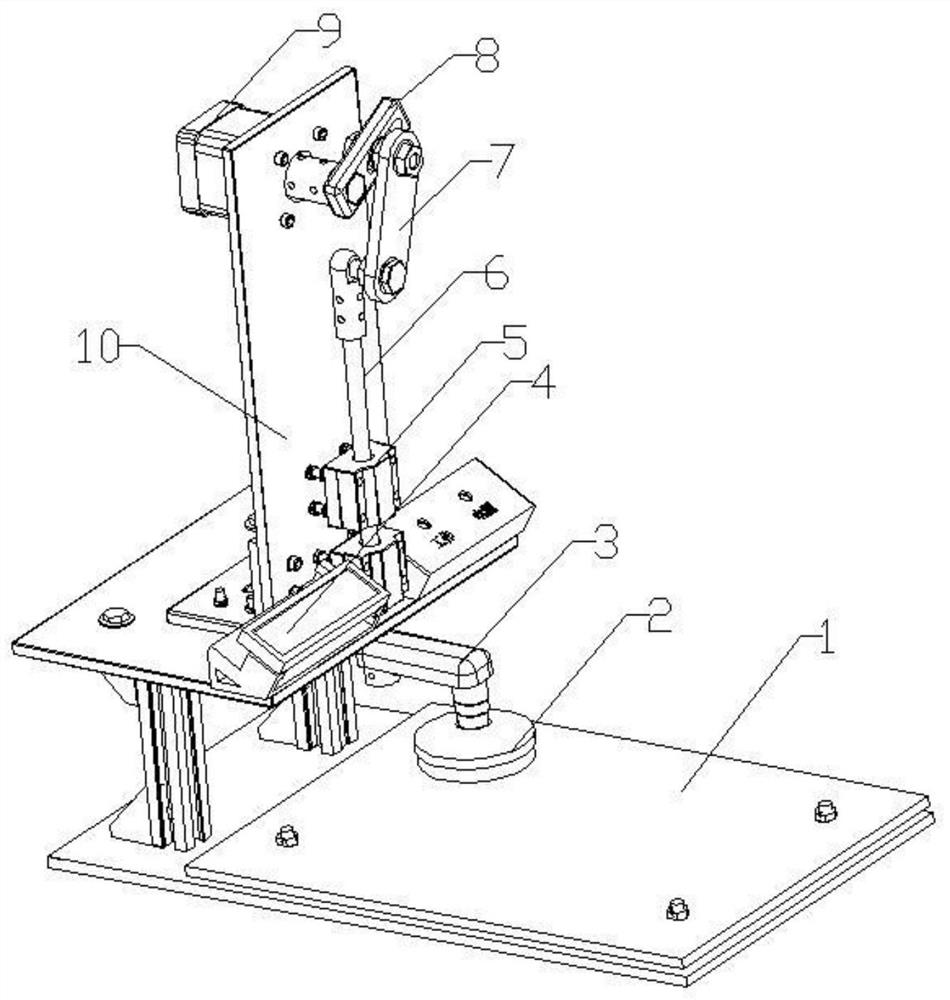

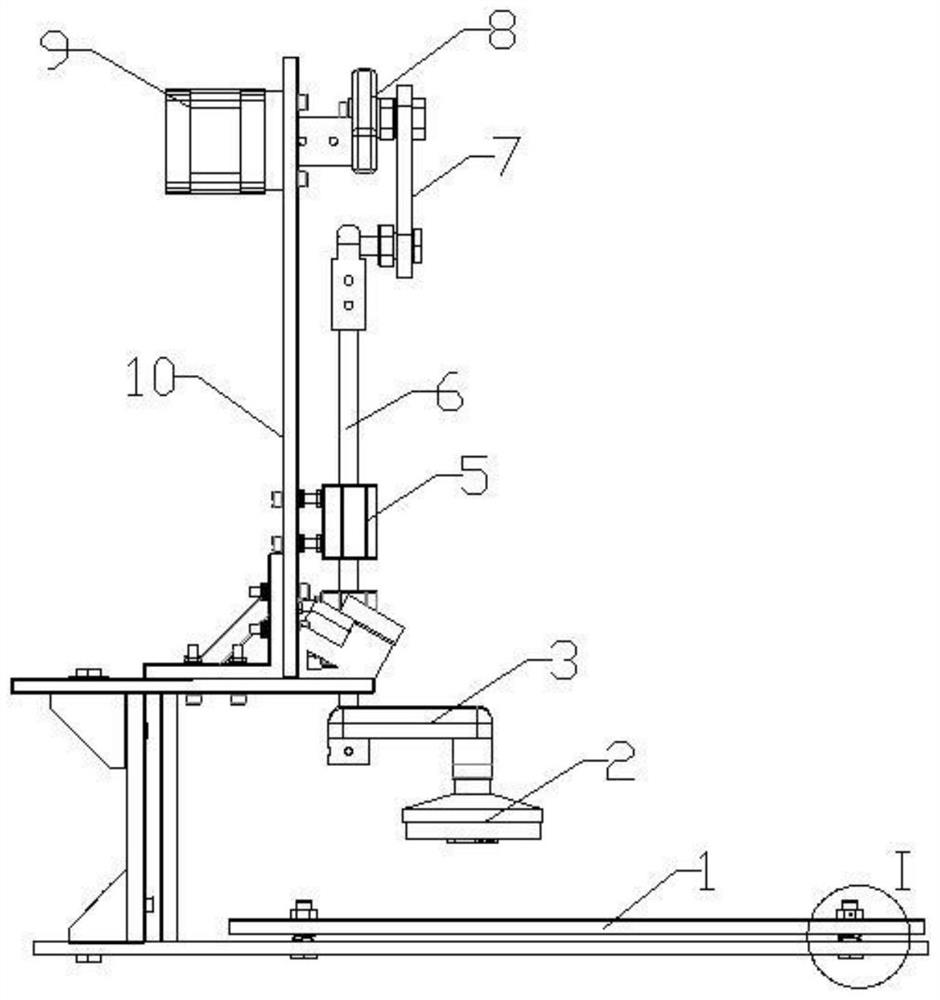

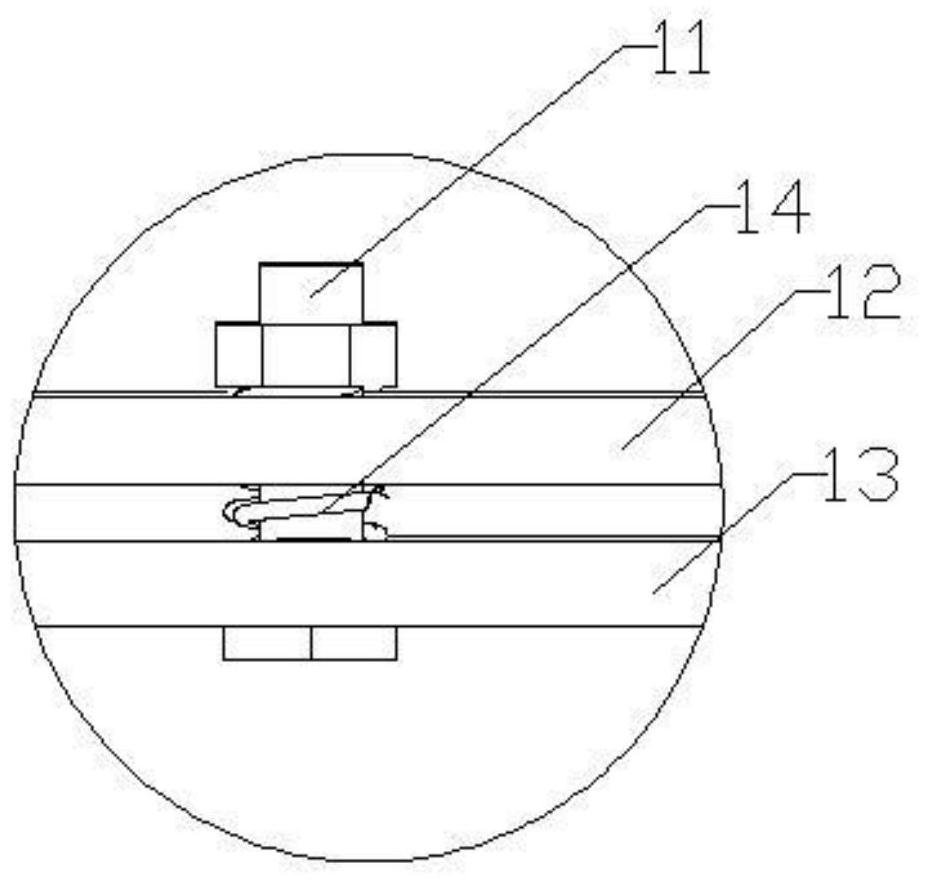

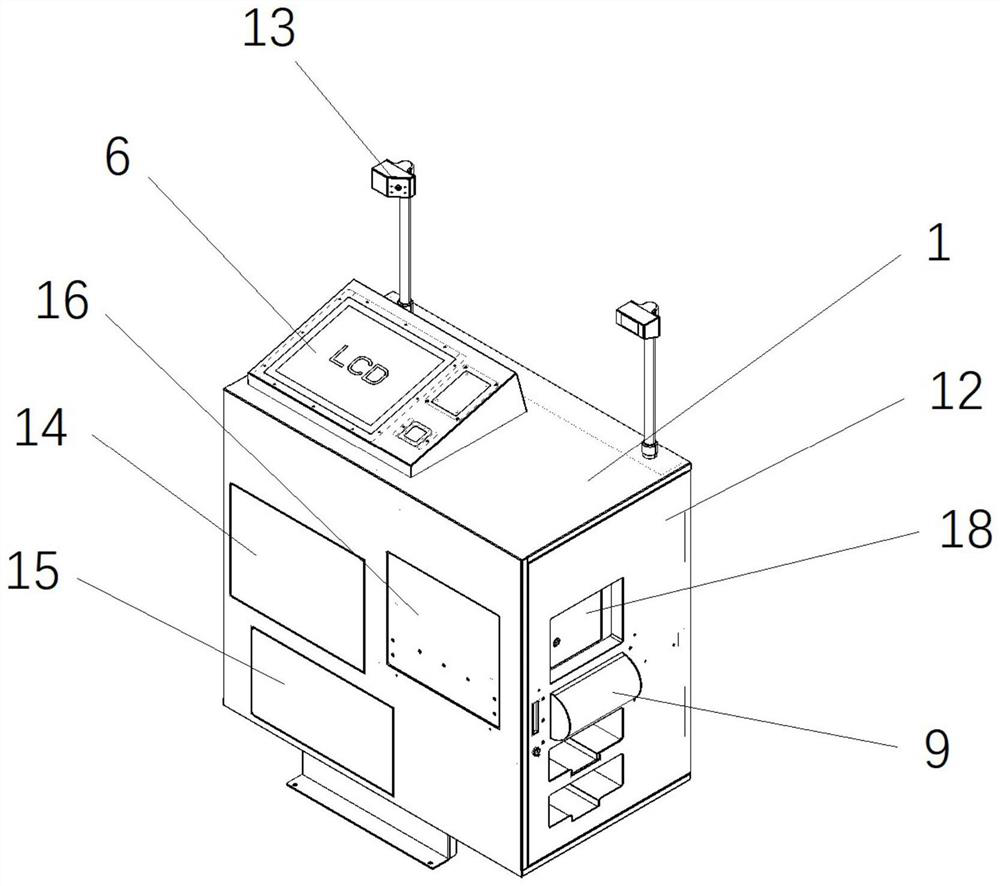

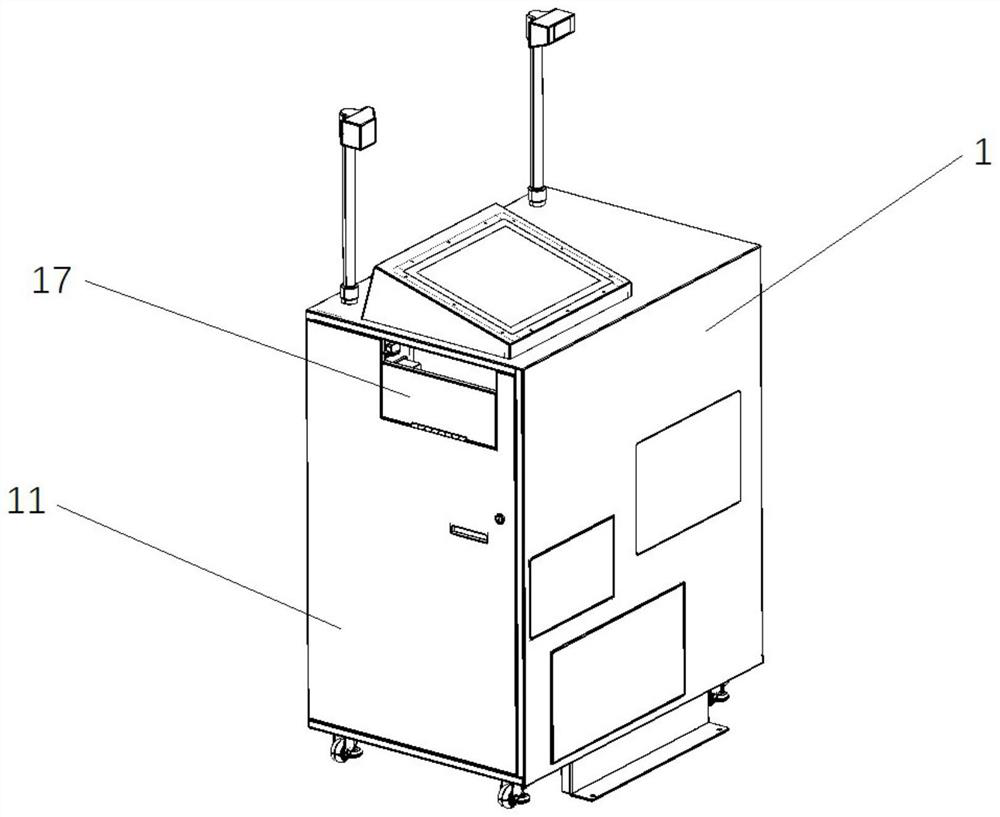

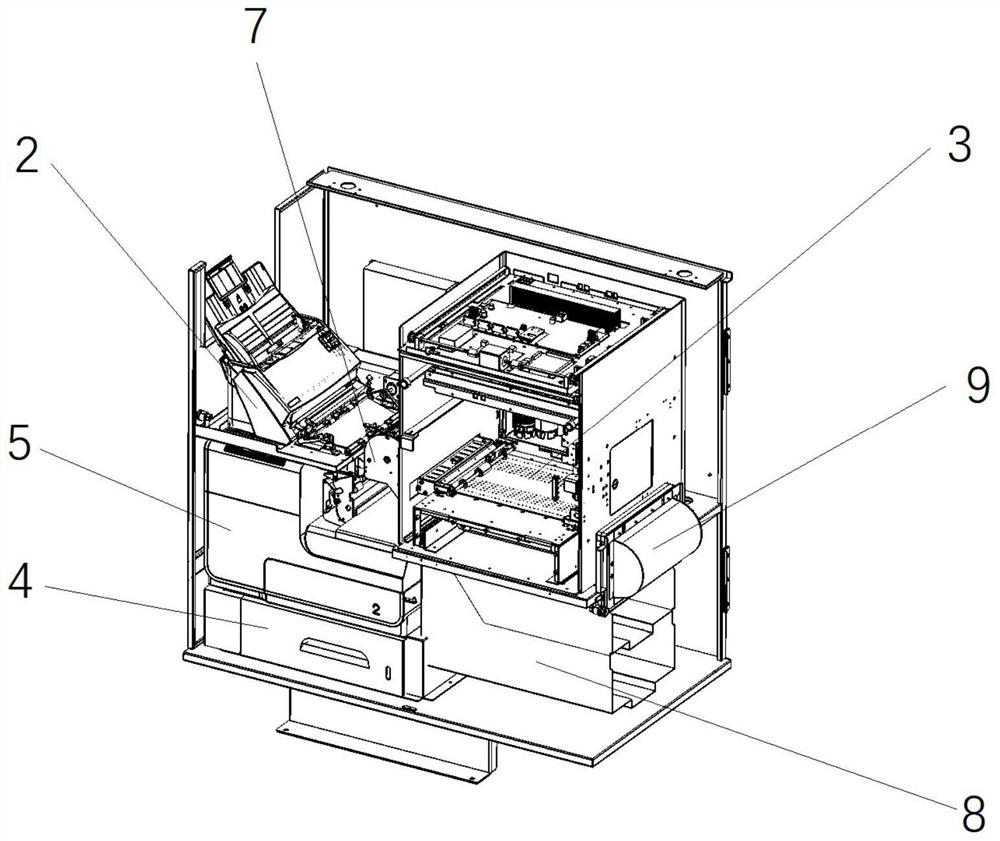

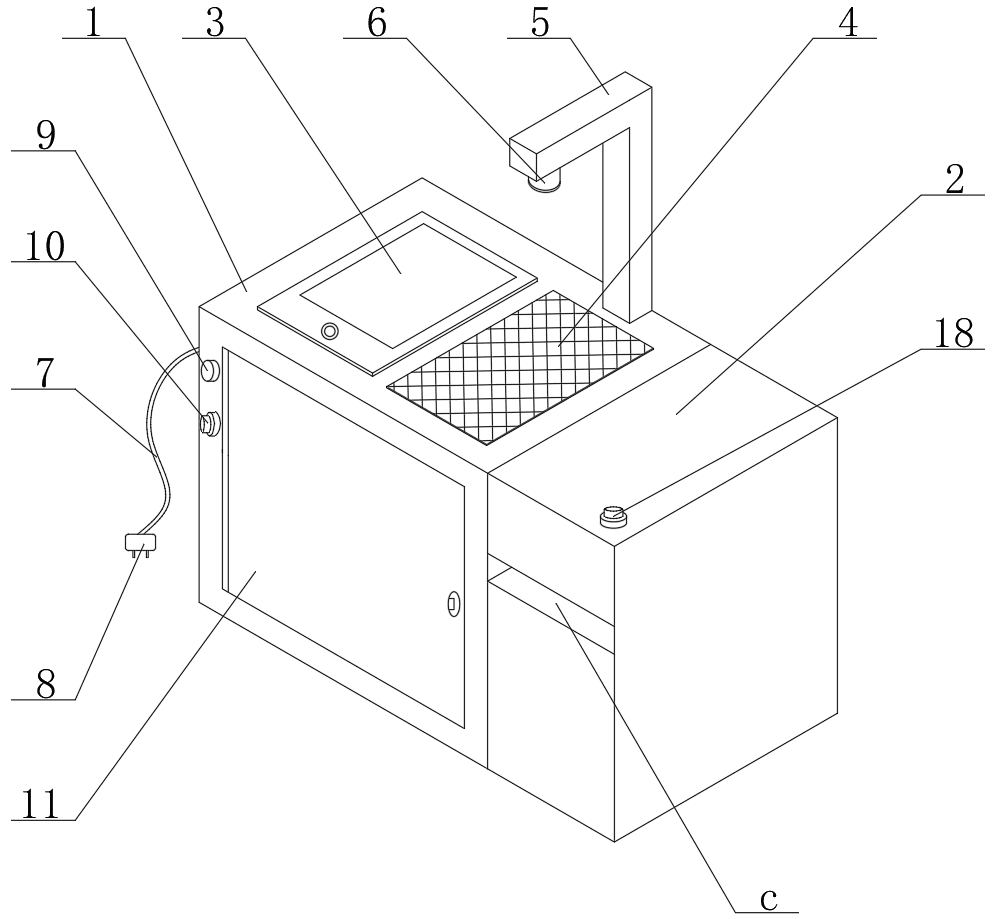

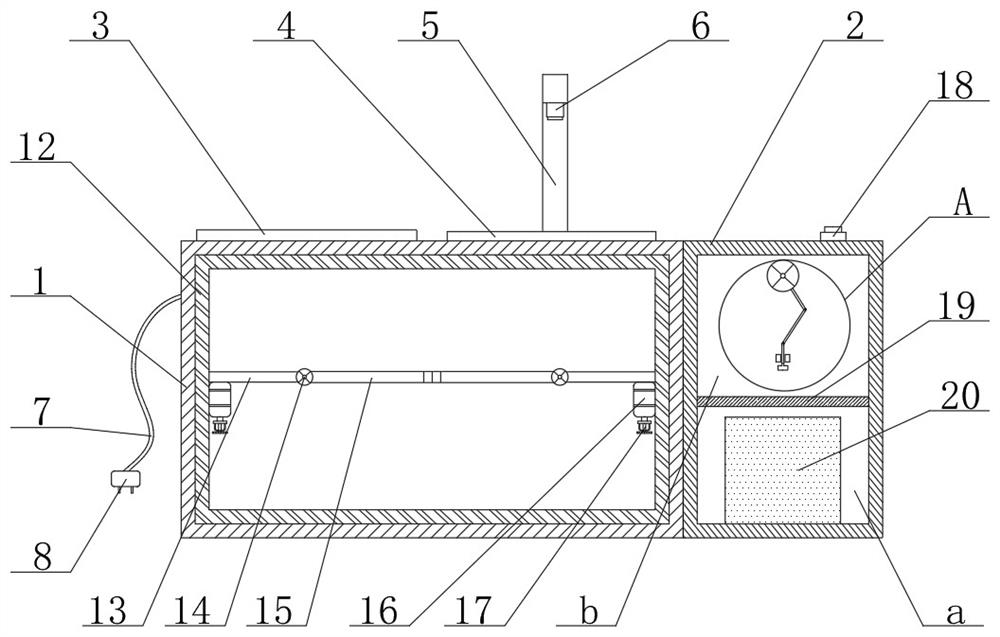

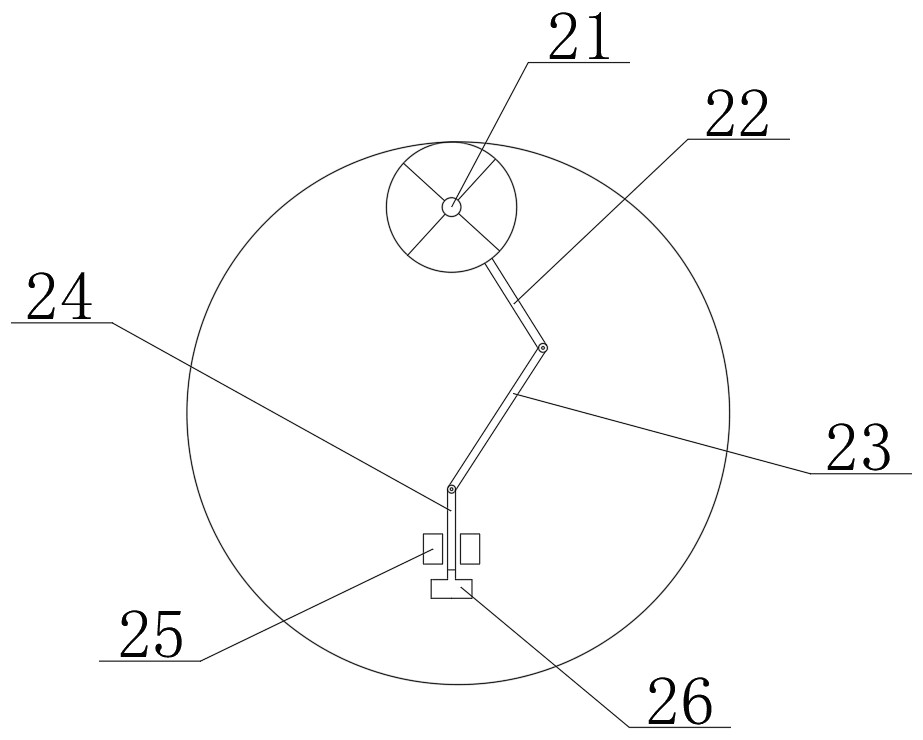

Automatic stamping machine

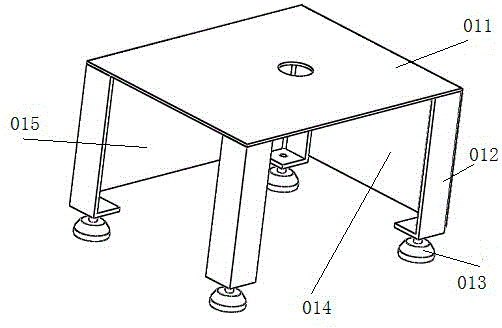

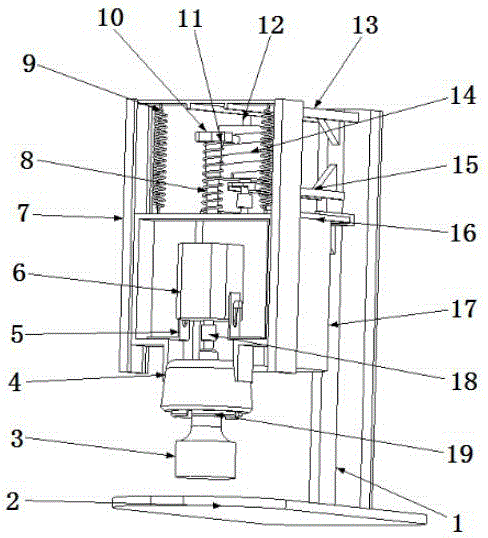

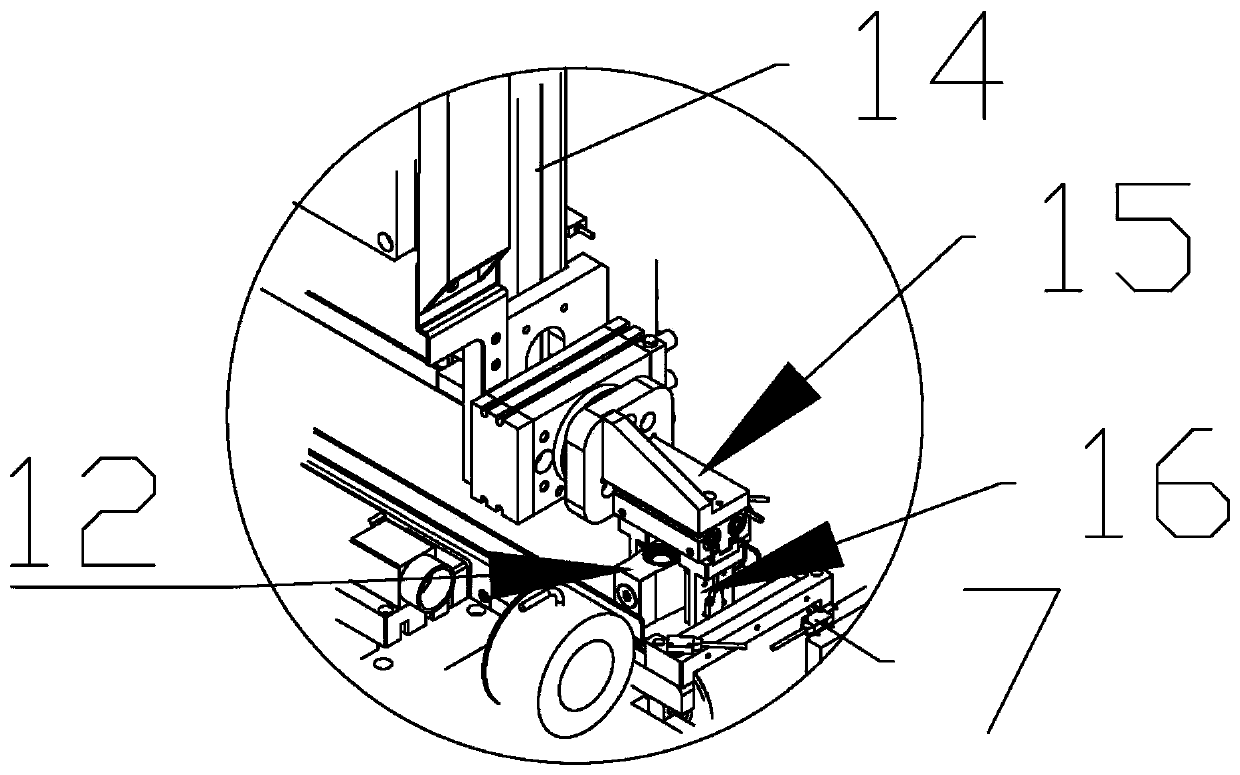

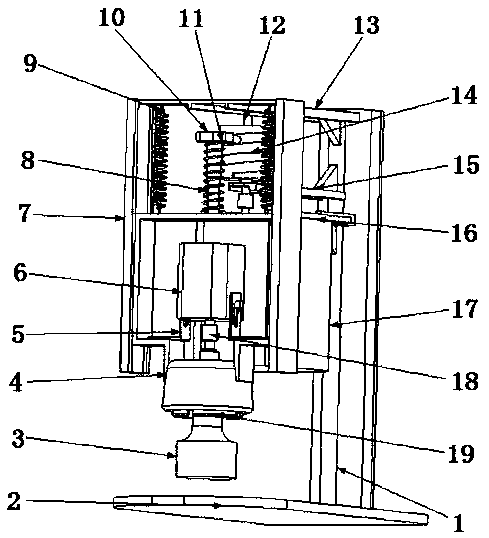

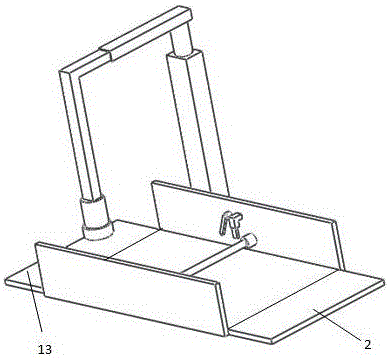

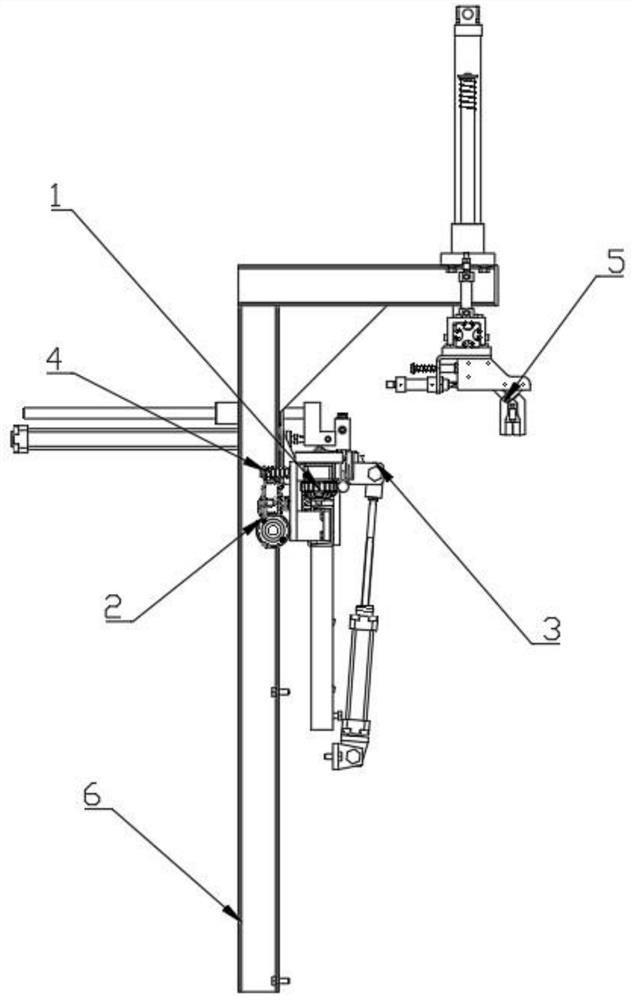

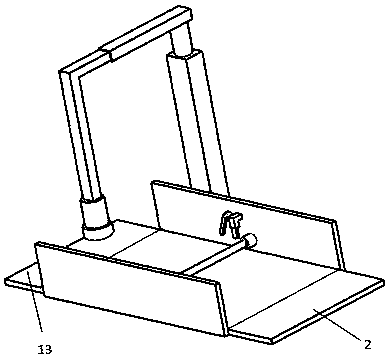

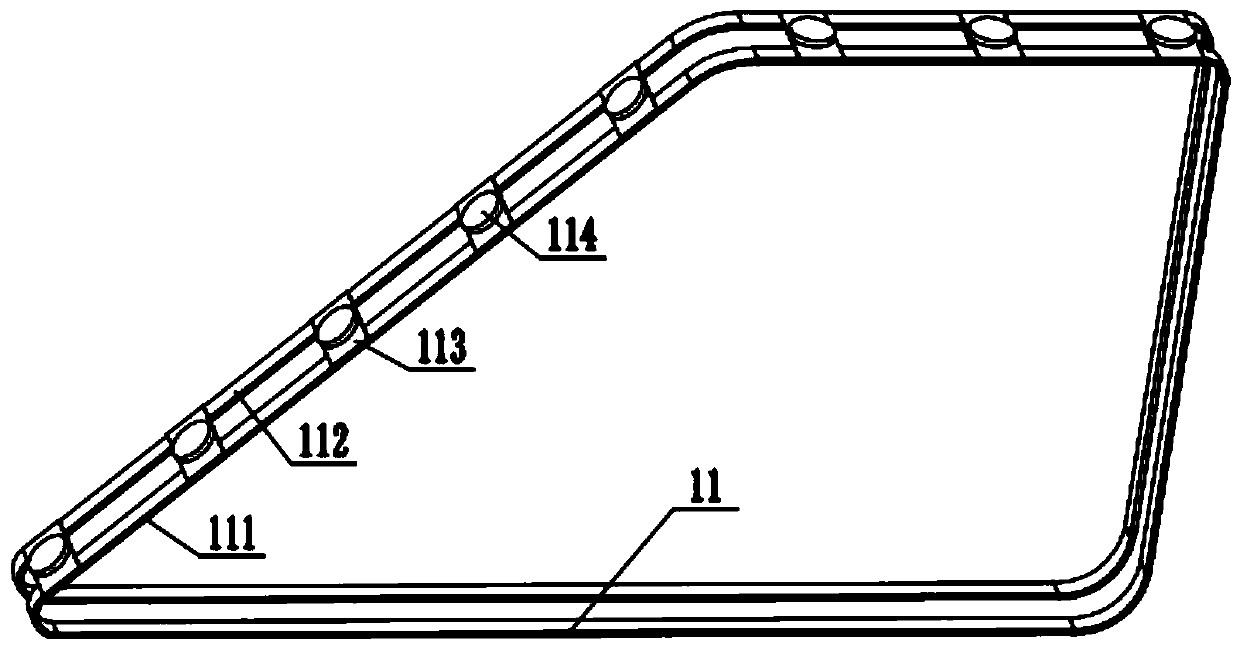

PendingCN113442613ARealize up and down movementImprove accuracyVibration suppression adjustmentsStampingStampingCrank

The invention discloses an automatic stamping machine, and belongs to the technical field of seal auxiliary equipment. The automatic stamping machine comprises a machine frame(10), a rotating part (9), a middle rod (7) and a connecting rod (6), the rotating part (9) is arranged on the machine frame(10), one end of the middle rod (7) is connected with an output rotating shaft of the rotating part (9), the other end of the middle rod (7) is connected with the connecting rod (6), the other end of the connecting rod (6) can be connected with a seal (2), and the rotating part (9) is rotated to enable the seal (2) to move up and down. According to the device, the seal (2) can move up and down by rotating the rotating part (9) through a crank connecting rod mechanism composed of the rotating part (9), the middle rod (7) and the connecting rod (6), and the purpose of automatic stamping is achieved. The problem that an existing stamping machine achieves stamping through a gear and a rack, manufacturing precision is high, and production cost is high is solved.

Owner:PANZHIHUA UNIV

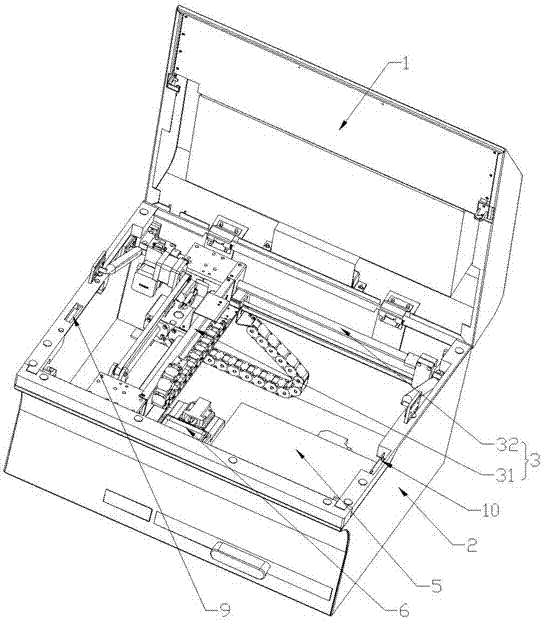

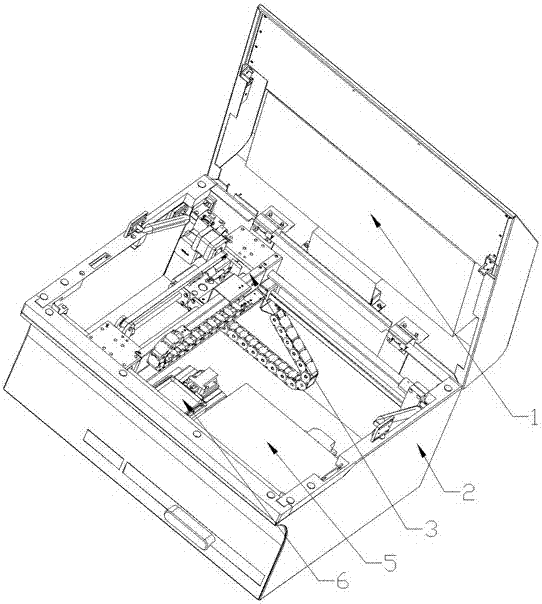

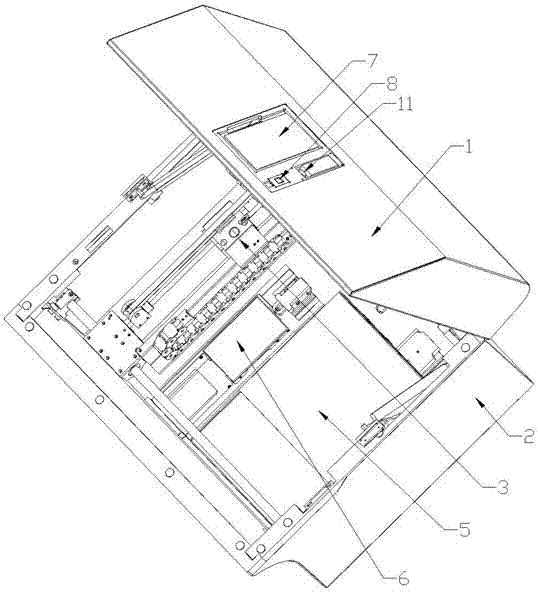

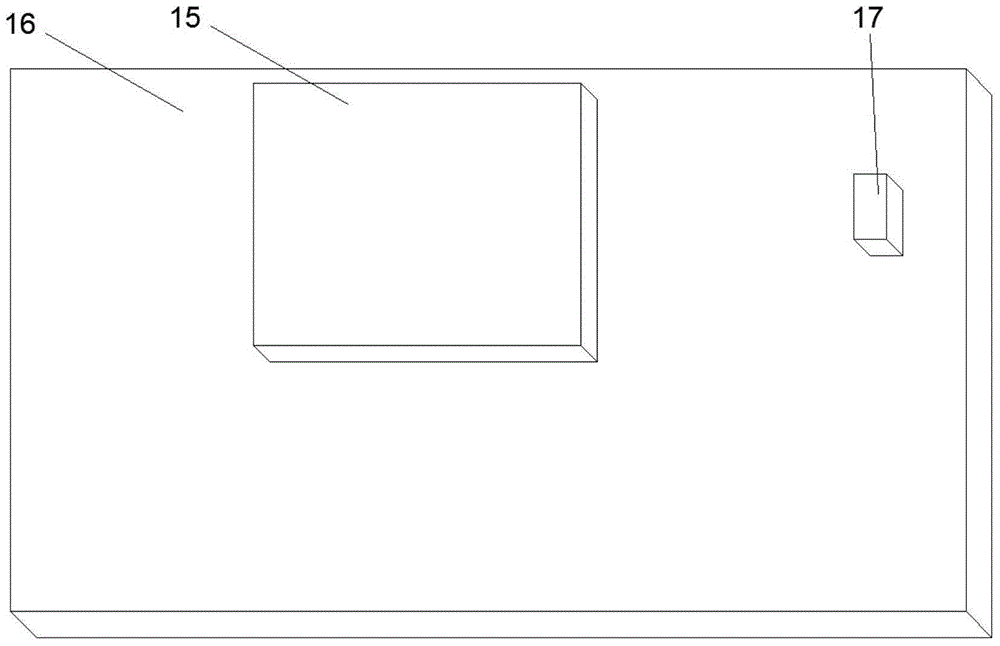

Indoor and outdoor portable integrated method and device for preventing seal from being stolen

ActiveCN114103495AGuaranteed printing efficiencyGuaranteed clarityPackage recyclingTypewritersStampingComputer printing

The invention relates to an indoor and outdoor portable seal and seal stealing prevention integrated method and device. The device comprises a box body, a printer, an intelligent sealing unit, a paper storage box, a scanner and a central control processor. By arranging the multiple movable stamping machines used for storing the seals of the corresponding types, automatic stamping of the movable stamping machines in the device can be effectively achieved, and after the corresponding movable stamping machines are taken out of the device, the movable stamping machines are used for safe stamping during business outgoing, so that the seals can be efficiently used for stamping in the device and stamping outside the device; and the storage efficiency of the device for multiple seals and the storage safety efficiency of each seal are effectively improved.

Owner:SHENZHEN INFOTECH TECH

Automobile buckle stamping device

ActiveCN112893681ARealize automatic stampingStamping precisionMetal-working feeding devicesVehicle componentsStructural engineeringIndustrial engineering

The invention discloses an automobile buckle stamping device, and belongs to the technical field of stamping equipment. The automobile buckle stamping device comprises feeding equipment and stamping equipment, wherein the feeding equipment is arranged on the right side of the stamping equipment, and the stamping equipment comprises a stamping base, a stamping plate, a stamping shell, an upper stamping die, a lower stamping die and a feeding plate; when the feeding equipment conveys buckle raw materials to the stamping plate, a stamping machine works to drive the upper stamping die to slide upwards in the stamping shell, and at the moment, the feeding plate works to push the buckle raw materials on the stamping plate to the top of the lower stamping die; and the stamping machine reversely works to drive the upper stamping die to move downwards to be matched with the lower stamping die to complete stamping, at the moment, the feeding plate is reset, during repeated work, the feeding plate drives the next buckle raw material to move to the top of the lower stamping die, the stamped automobile buckle is extruded out of the lower stamping die, and automatic stamping is achieved.

Owner:湖北天成汽车配件有限公司

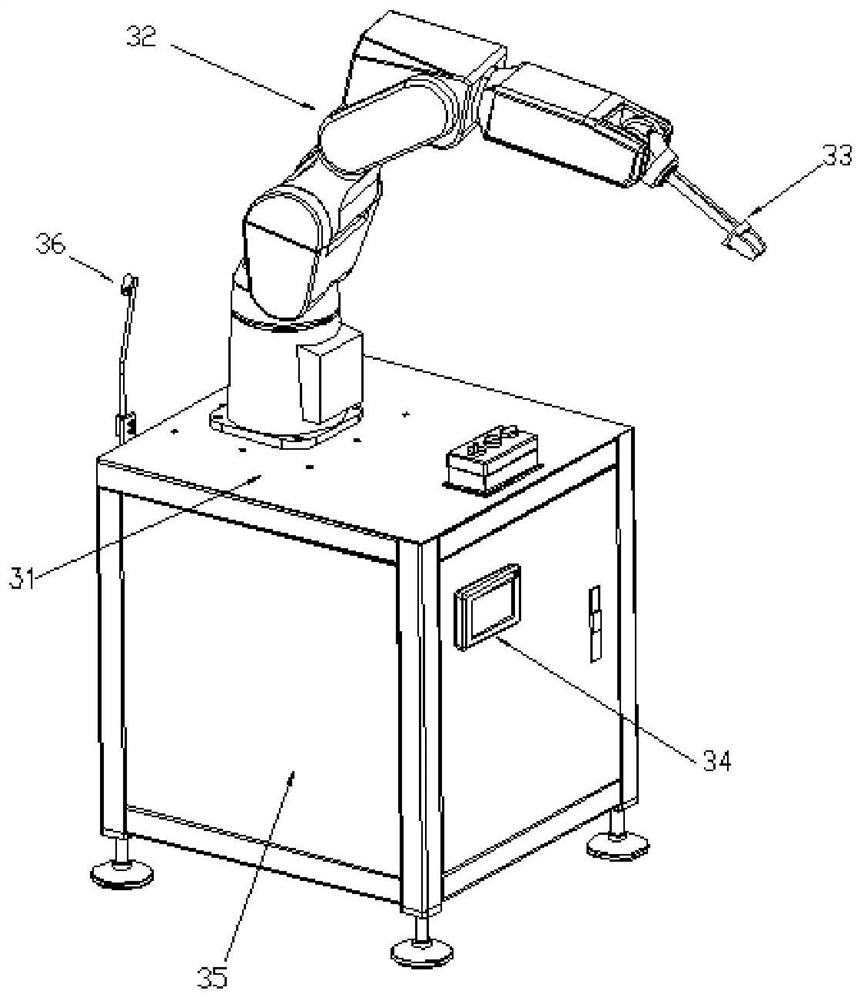

Automatic stamping and stamping detection mechanism

PendingCN111137025AReduce in quantityRealize automatic stampingTypewritersOther printing apparatusStampingRobot hand

The invention discloses an automatic stamping and stamping detection mechanism. The automatic stamping and stamping detection mechanism comprises a bottom plate, a conveying unit, an ink jetting mechanism, a camera detection mechanism, an OK discharging flat belt line, a mechanical arm discharging mechanism, a product position detection mechanism and an NG discharging flat belt line. By means of the mode, the automatic stamping and stamping detection mechanism achieves automatic stamping and stamping detection on products, original manual operation is replaced, the number of operators is reduced, the production cost is lowered, the production efficiency is improved, and personal errors are avoided.

Owner:林育键

Wooden plate stamping mechanism for store decoration

InactiveCN107599657ARealize automatic stampingImprove stamping efficiencyStampingEngineeringWood plank

The invention discloses a wooden plate stamping mechanism for store decoration. The wooden plate stamping mechanism for store decoration comprises an installation frame and a stamping device. The stamping device is installed on the installation frame. The installation frame comprises a top plate, a bottom plate and a connecting shaft. The top plate is connected with the bottom plate through the connecting shaft. The stamping device comprises a first stamping assembly and a second stamping assembly. The first stamping assembly comprises a first lifting driving part, an output shaft, a first guide shaft, a second guide shaft, a first linear bearing, a second linear bearing, a first limiting ring, a second limiting ring and a first pressing plate. The first lifting driving part is installed on the lower surface of the top plate. According to the wooden plate stamping mechanism for store decoration, by arranging the installation frame and the stamping device, a traditional manual wooden plate stamping mode is replaced, wooden plates are automatically stamped, thus the stamping efficiency of the wooden plates is improved, and the manpower cost is saved.

Owner:惠州市美呈空间装饰设计工程有限公司

An automatic stamping device

Owner:SUZHOU INST OF TRADE & COMMERCE

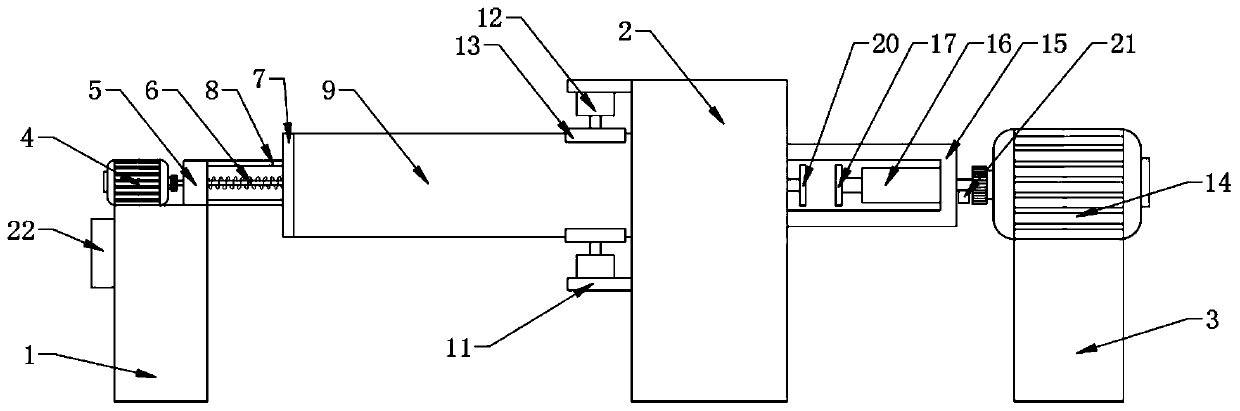

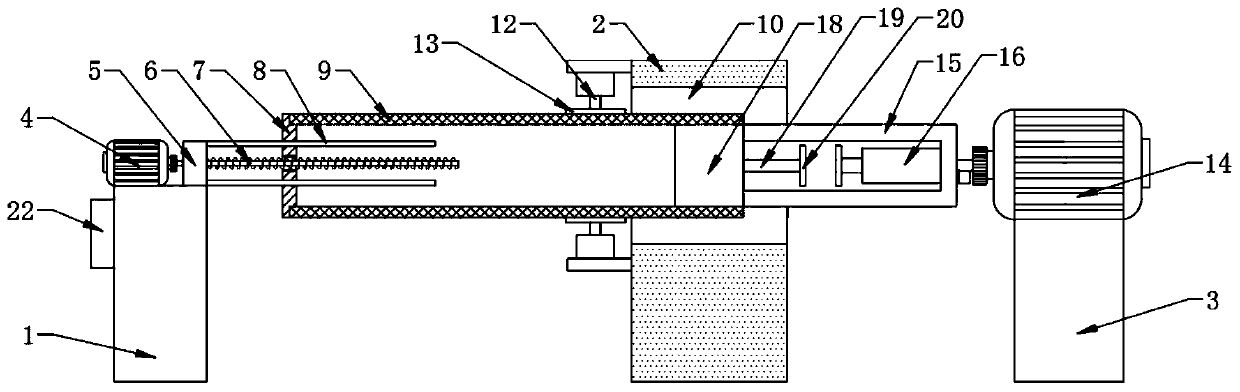

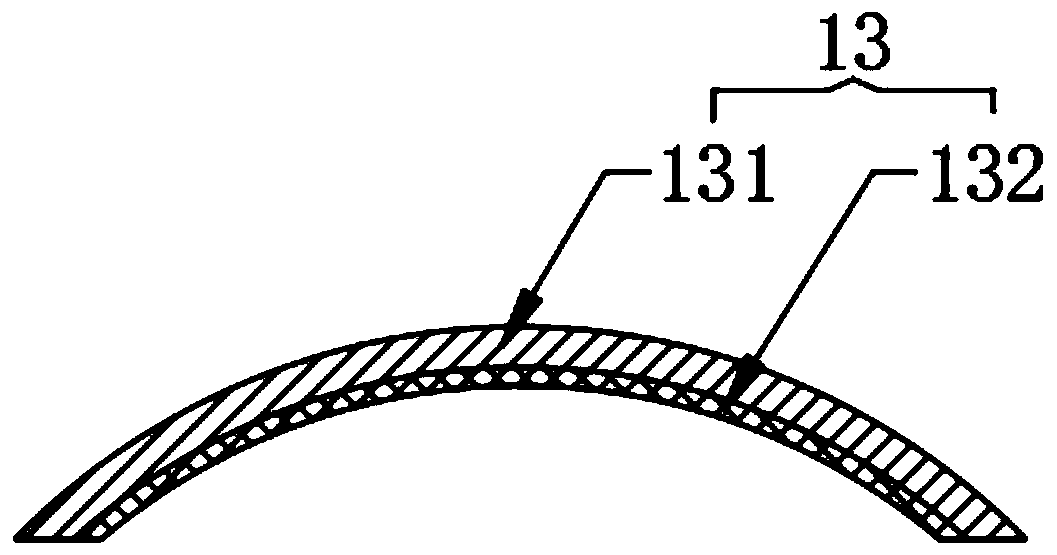

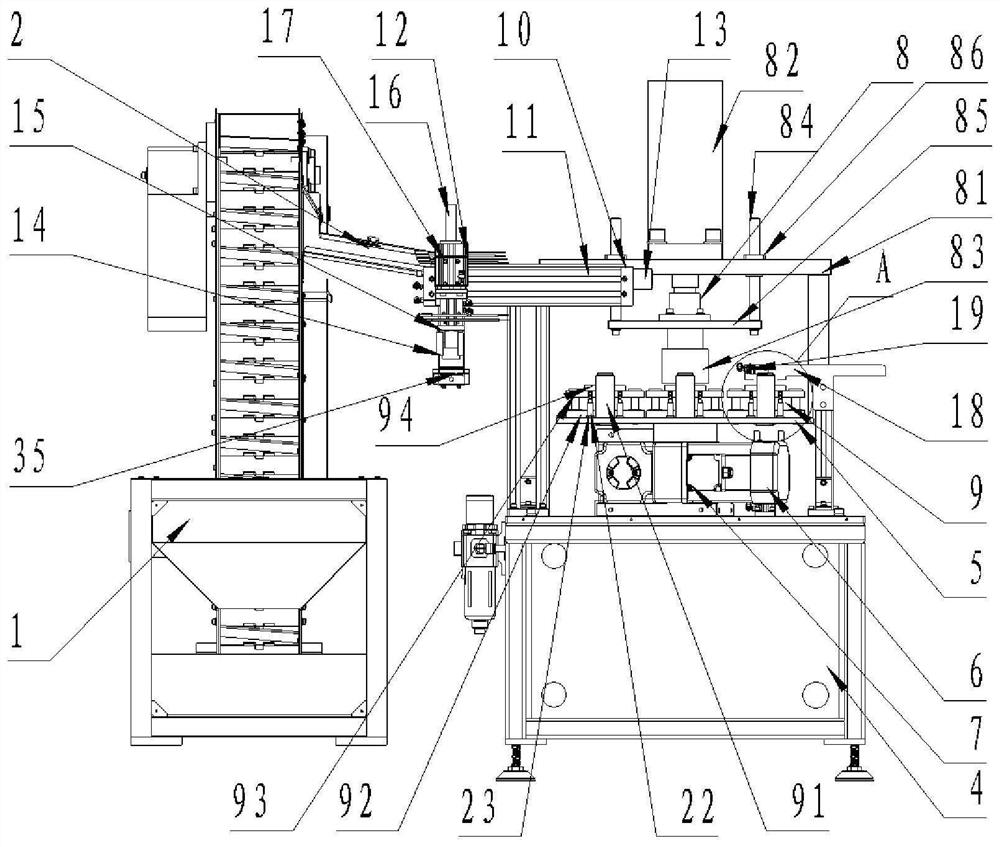

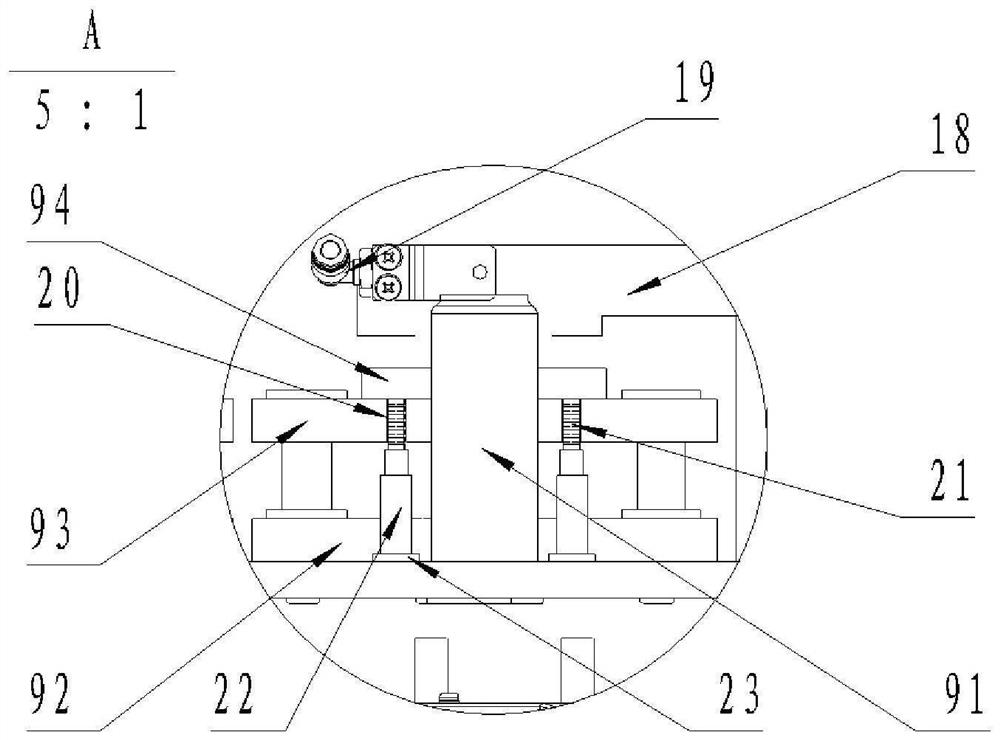

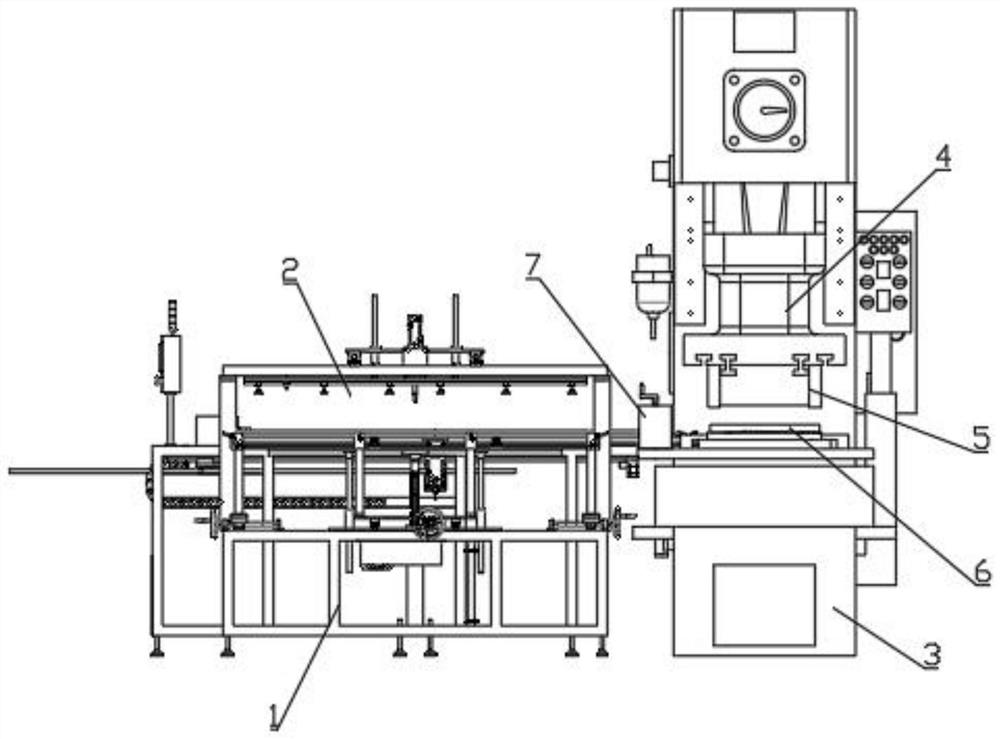

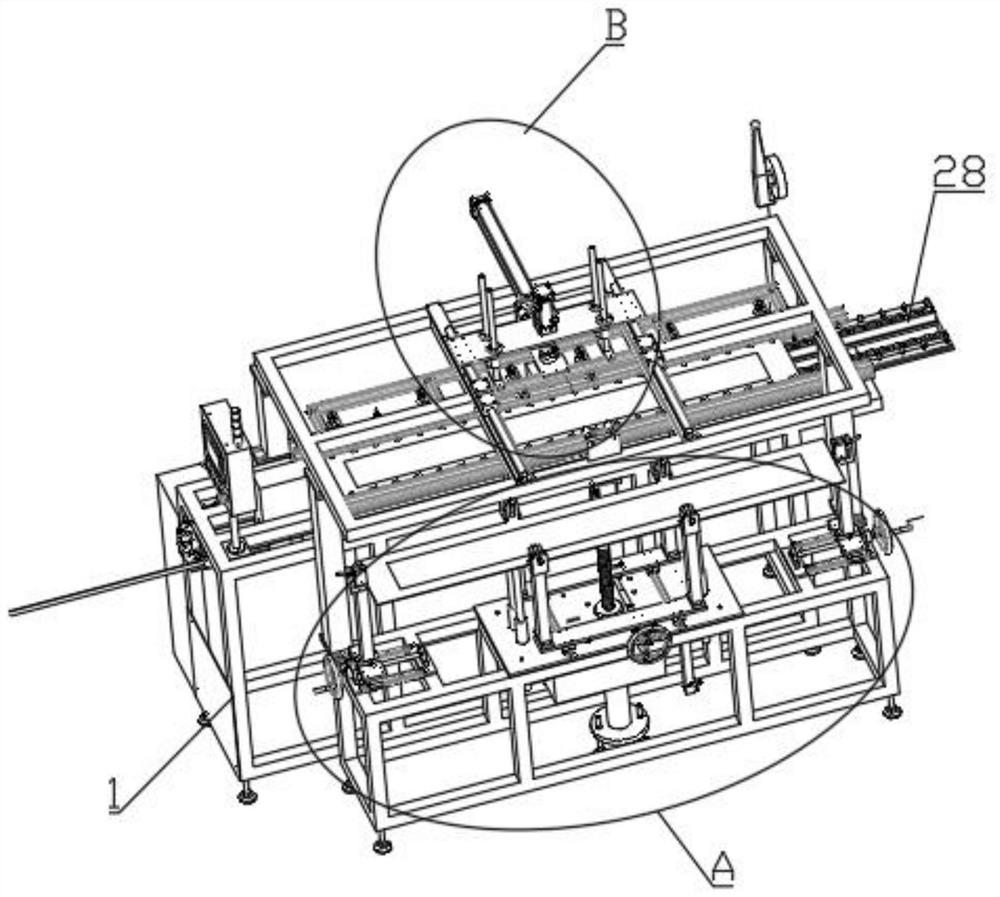

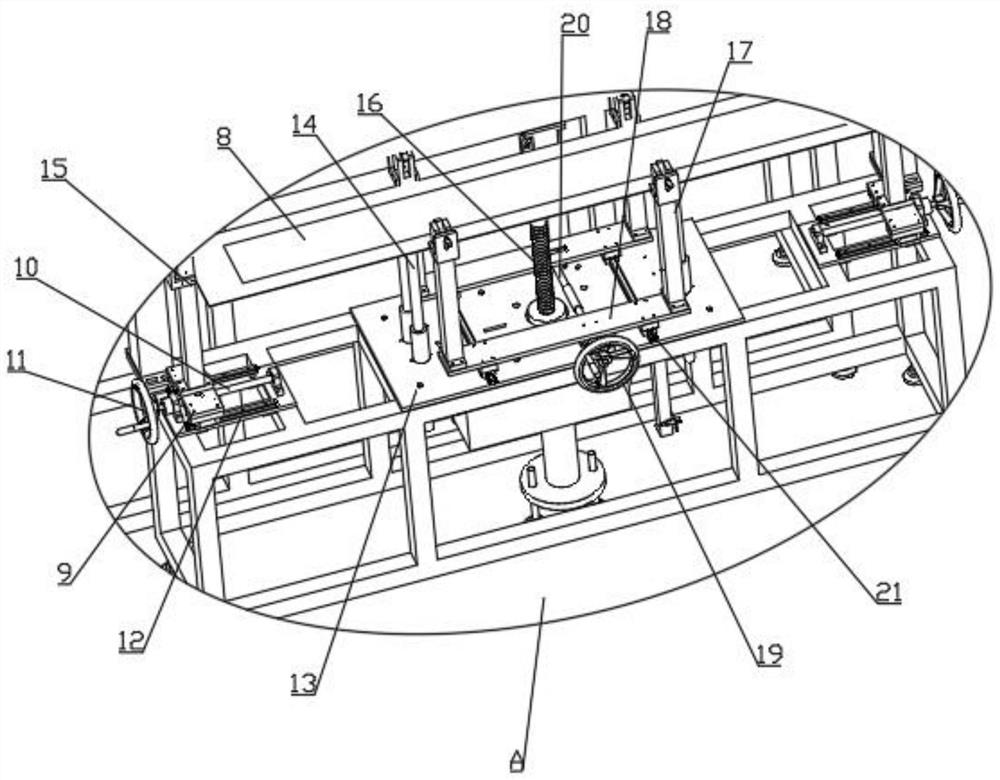

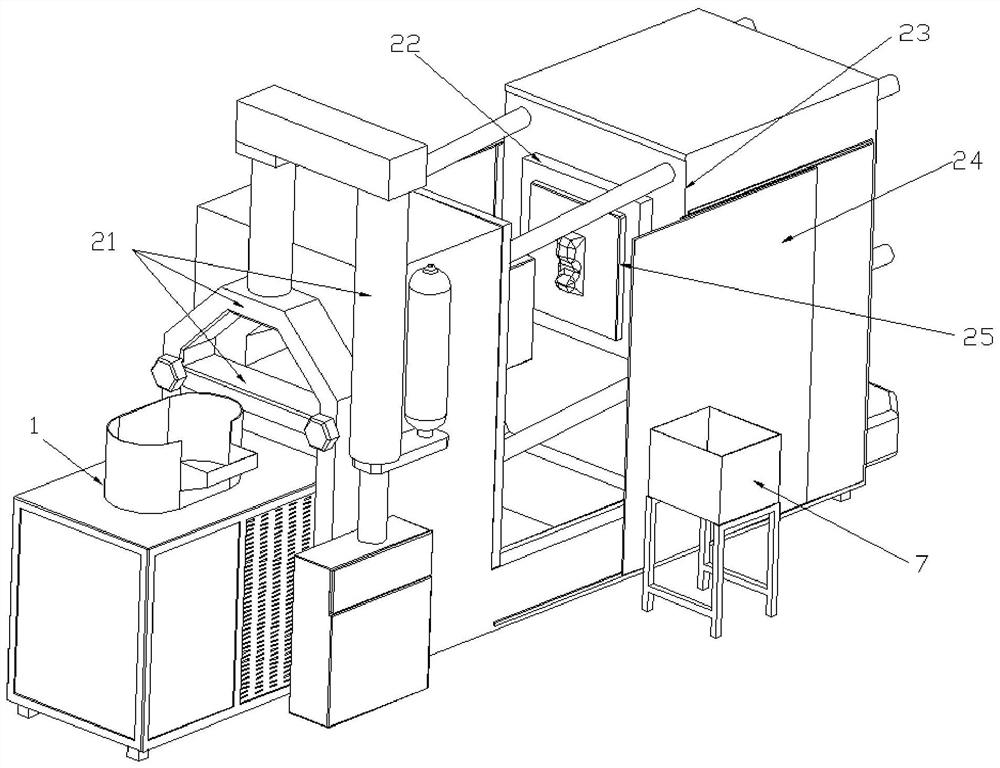

Automatic stamping facility for stainless steel outer retaining ring for fire-fighting metal hose

InactiveCN112974611ARealize automatic feeding processRealize automatic stampingShaping toolsMetal-working feeding devicesStampingReinforced concrete

The invention discloses an automatic stamping facility for a stainless steel outer retaining ring for a fire-fighting metal hose. The automatic stamping facility for the stainless steel outer retaining ring for the fire-fighting metal hose comprises a stainless steel outer retaining ring blank lifting machine installed on a reinforced concrete platform, a stainless steel outer retaining ring blank constraining and conveying device, a stainless steel outer retaining ring blank clamping and conveying device and a stainless steel outer retaining ring blank stamping device. The stainless steel outer retaining ring blank stamping device comprises a square machine frame, a rotary disc installed on the square machine frame and a rotary disc rotation driving device, further comprises a stainless steel outer retaining ring blank stamping power and stamping upper die device and three stainless steel outer retaining ring blank stamping lower die devices, and further comprises a stainless steel outer retaining ring discharging device. Automatic stamping of the stainless steel outer retaining ring for the fire-fighting metal hose is achieved, the specification and size precision of the stainless steel outer retaining ring for the fire-fighting metal hose is improved, and the welding procedure requirement of the fire-fighting metal hose is met.

Owner:玫德艾瓦兹(济南)金属制品有限公司

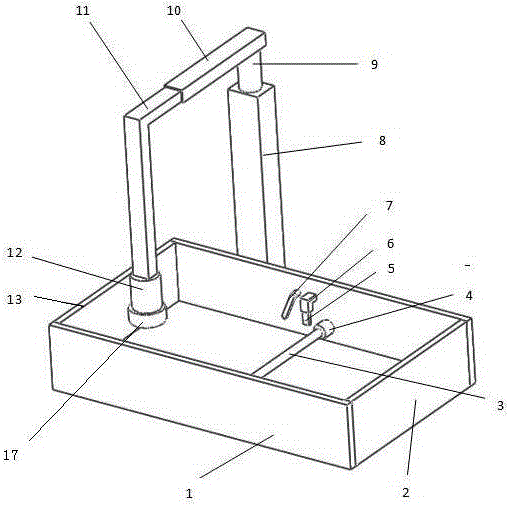

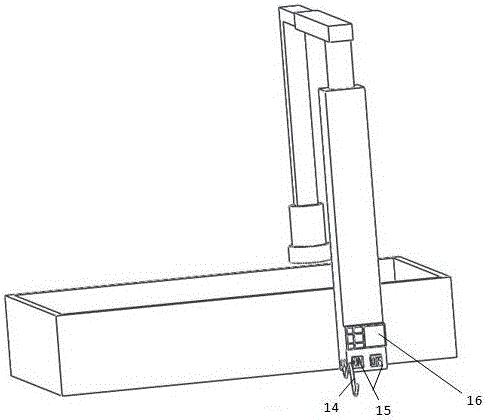

Automatic stamping machine

ActiveCN106394028ALow costSolve the shortcomings of not widely usedStampingPulp and paper industryControl principle

The invention provides an automatic stamping machine. According to the application, a roller shaft is arranged in a paper placing groove, the side wall of the middle of the paper placing groove is provided with a paper sucking rod fixed rod, a paper sucking rod telescopic rod is arranged in the lower end of the paper sucking rod fixed rod, one side of the paper sucking rod fixed rod is provided with a paper shifting swinging rod, a motor of the paper shifting swinging rod is plugged on the inner wall of the paper placing groove, a vertical rod is fixed to the outer side of the paper placing groove, a rotating shaft is plugged at the upper end of the vertical rod, the end part of the rotating shaft is connected with a rotating shaft of a motor in the upper end of the vertical rod, the upper end of the rotating shaft is connected with the part below one end of a transverse rod, a transverse telescopic rod is plugged at the other end of the transverse rod, the end part of the transverse telescopic rod is connected with a cylinder in the transverse rod, the lower end of the bent part of the transverse telescopic rod is provided with a longitudinal telescopic rod, the upper end of the longitudinal telescopic rod is connected with a cylinder in the lower end of the bent part of the transverse telescopic rod, and a stamp is plugged in the lower end of the bent part of the transverse telescopic rod. After a stamping position is determined, through the combination of mechanical movement and a control principle, paper is precisely fed through a stamping clearance, and stamping action is carried out after the paper is fed, so that automatic stamping is realized.

Owner:JINLING INST OF TECH

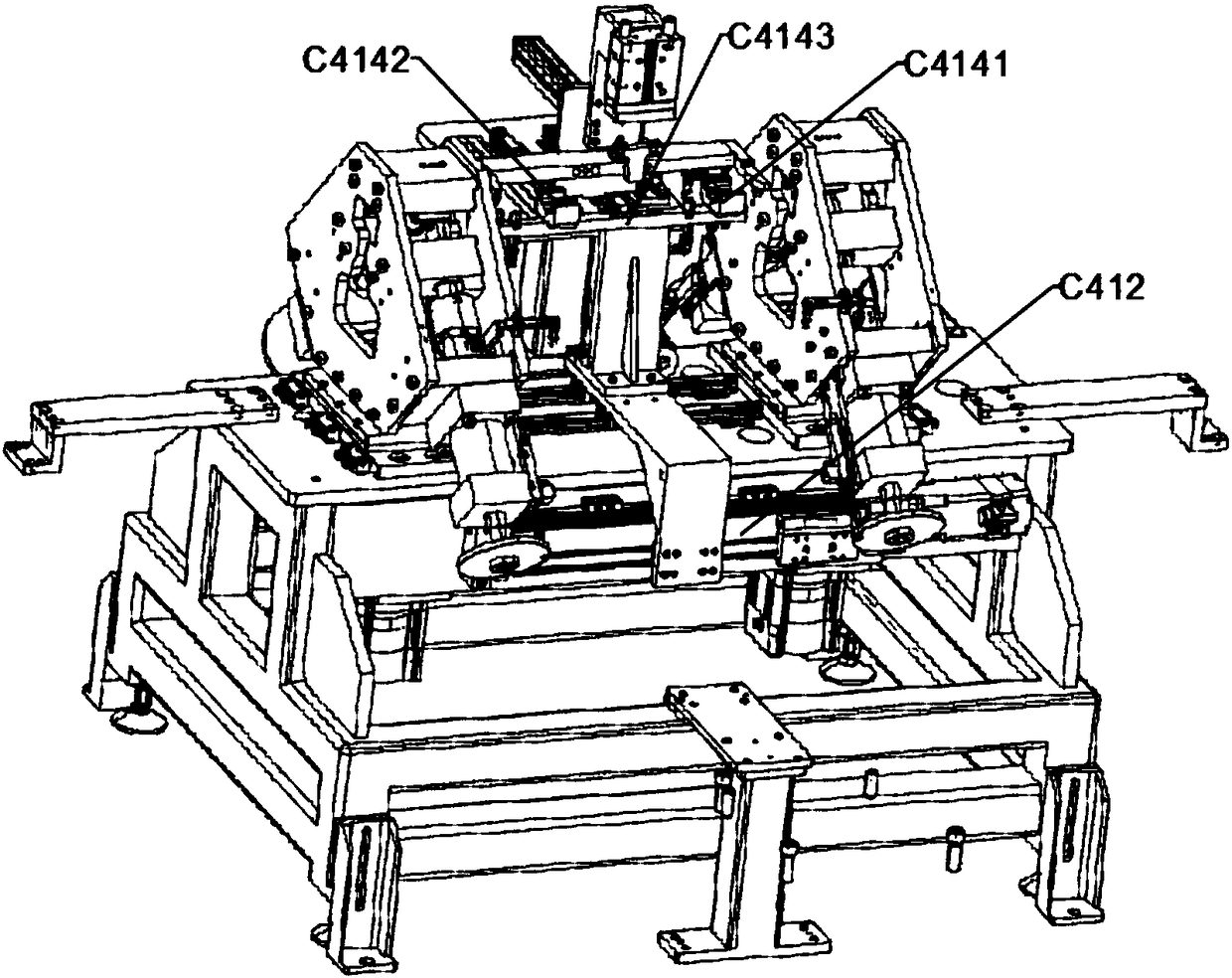

Punching unit for retainer gear points of car seat sliding rail

InactiveCN108176748AStrengthen the degree of automatic stampingKeep stamping automatedVehicle componentsMetal working apparatusCar seatEngineering

The invention discloses a punching unit for retainer gear points of a car seat sliding rail. The punching unit is fixed to a punching rack; the punching rack is fixed to a unit seat; an outer rail profiling block is fixedly arranged on the top of the punching rack; the punching unit comprises a first punching machine and a second punching machine which are of the same structure and are perpendicular mutually; and the punching rack comprises a first punching rack side face and a second punching rack side face which are of the same structure and are symmetrically arranged along the punching machines. The punching machines special for punching the retainer gear points are designed, and thus automatic punching of the retainer gear points can be achieved; and meanwhile, by arranging infrared sensors of the punching machines, punching detection and error correction can be achieved, and thus the automatic punching degree of the retainer gear points is strengthened further.

Owner:重庆飞适动力汽车座椅部件有限公司

Stamping device for machining storage battery shell and stamping method thereof

PendingCN112705638APlace stableThe L-shaped placement to the first pole is stableMetal-working feeding devicesStripping-off devicesStructural engineeringMachine

The invention discloses a stamping device for machining a storage battery shell. The stamping device comprises a support, a feeding mechanism, a machining table, a stamping machine, an upper die, a lower die and a positioning mechanism, a positioning mechanism is arranged at one end, close to the stamping machine, of a conveyor belt, a fixing frame is of a U-shaped structure and is mounted on the conveyor belt, the bottom end of a third screw rod penetrates through the top surface of the fixing frame and is in threaded connection with the fixing frame, the bottom end of the third screw rod is rotatably connected with a limiting plate, the limiting plate is in sliding connection with an inner wall of the fixing frame, the top end of the third screw rod is connected with a handle, the feeding mechanism comprises a jacking mechanism, a material taking mechanism and the conveyor belt, the conveyor belt is horizontally arranged on the support, the conveyor belt and the lower die of the machining table are located on the same plane, the material taking mechanism is arranged above the conveyor belt, and the jacking mechanism is arranged in front of the conveyor belt. According to the stamping device, automatic stamping is achieved when the storage battery shell is machined, material plates of different sizes can be stamped according to the production requirement, and the storage battery shells of different sizes are manufactured.

Owner:安徽强旭塑业科技有限公司

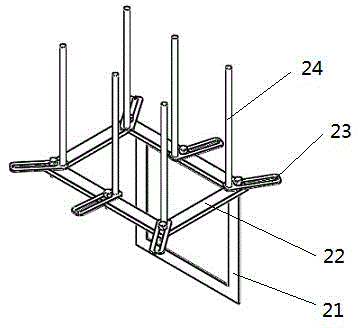

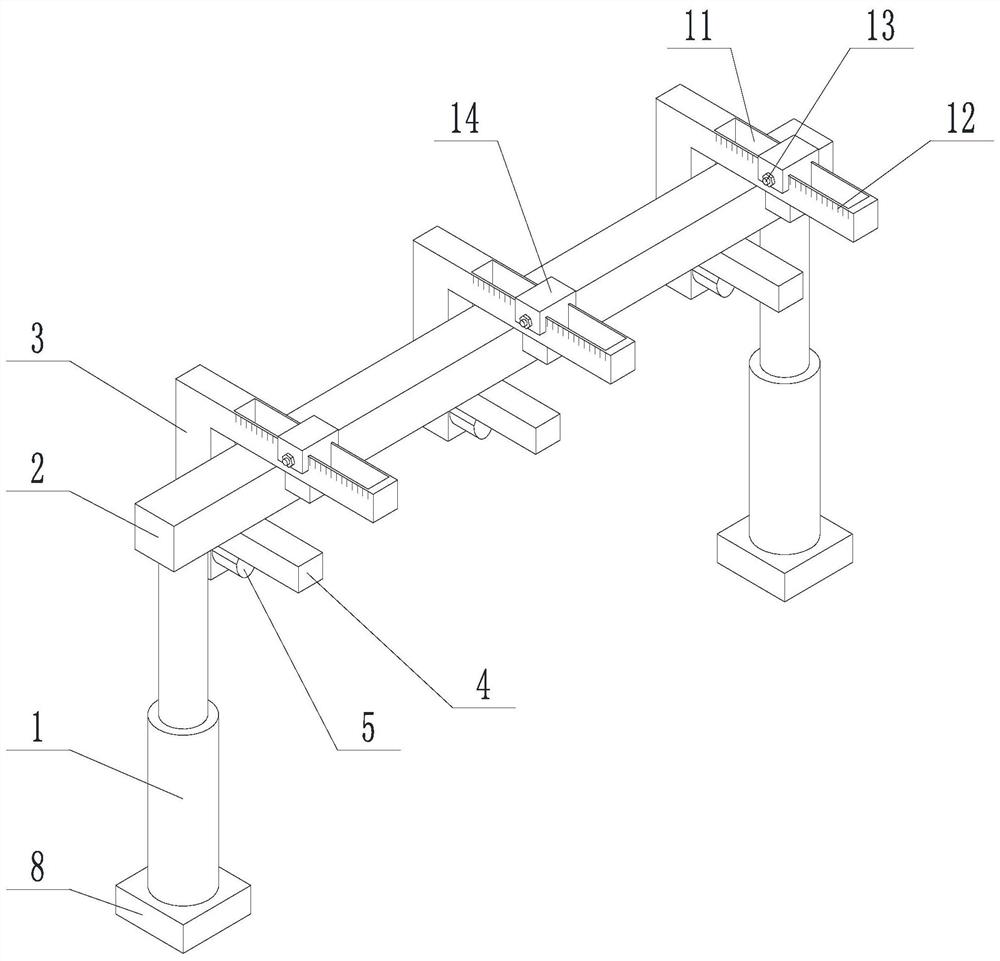

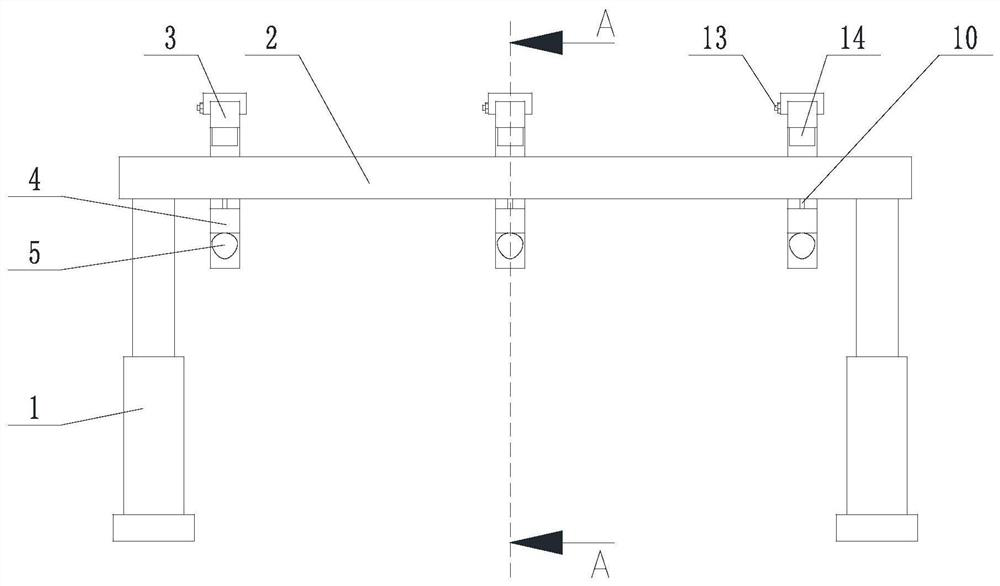

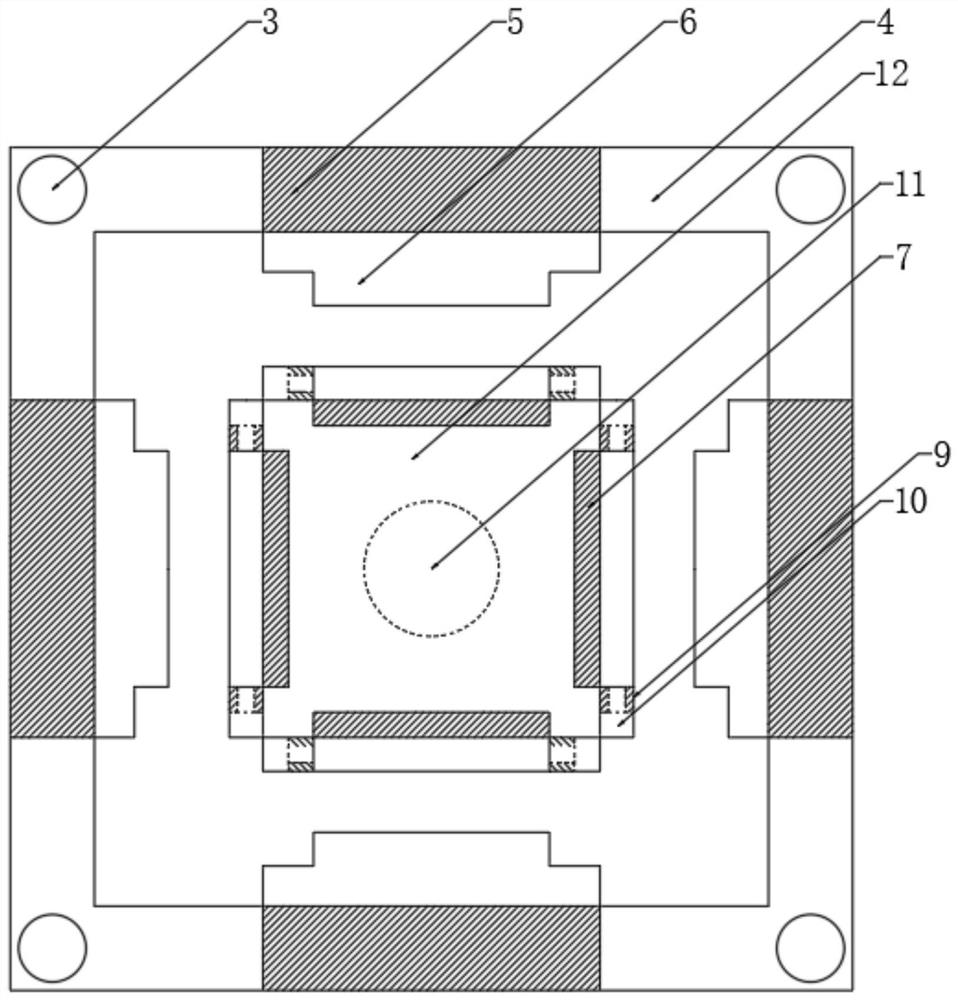

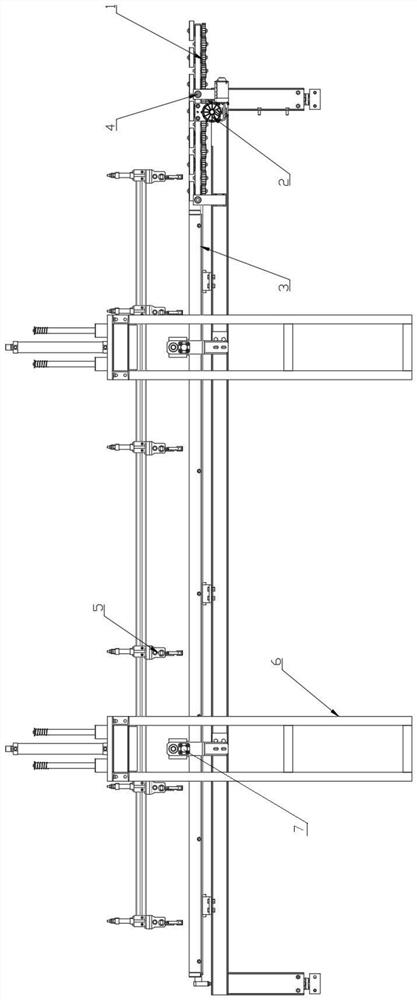

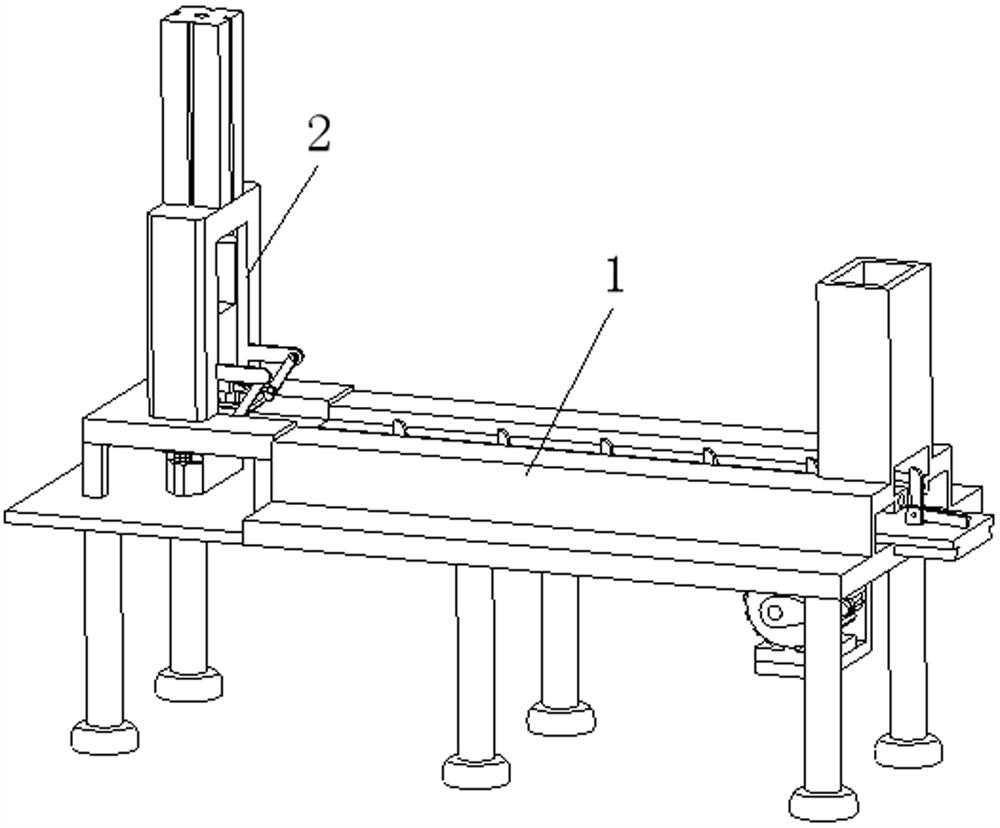

Batch marking equipment for triangular marks of oil casing screwed joints

ActiveCN112248661AOvercoming the problem of root-by-root markingImprove work efficiencyTypewritersCamScrew joint

The invention discloses batch marking equipment for triangular marks of oil casing pipe screwed joints. The equipment comprises two supporting legs and a transverse rod fixed between the two supporting legs; a plurality of L-shaped pieces are connected onto the transverse rod; one end of each L-shaped piece is in sliding fit with the side surface of the transverse rod, the other end is located above the transverse rod and strides over the transverse rod; the L-shaped pieces can slide along the axis of the transverse rod; the equipment further comprises clamping pieces in sliding fit with the L-shaped pieces; the clamping pieces can slide in the longitudinal direction; the clamping pieces are located below the transverse rod and stride across the transverse rod; cams are arranged below theclamping pieces; the cams are driven by a driving mechanism to rotate; the end, located above the transverse rod, of each L-shaped piece is further provided with a marking assembly. According to the batch marking equipment for the triangular marks of the oil casing pipe screwed joints, the technical problem of low efficiency due to the fact that casing pipes are required to be marked one by one inthe prior art is solved, and the purpose that the triangular marks are printed on a row of laid casing pipes in batches at the same time is achieved.

Owner:熊勇

Stamping die with in-die rotary forming structure

InactiveCN114130897AImplement auto-rotationRealize automatic stampingShaping toolsStampingElectric machine

The invention discloses a stamping die with an in-die rotary forming structure. The stamping die comprises a base, a polygonal stamping assembly and one or more polygonal stamping push blocks. A rotating motor is embedded in the surface of the base; the rotating motor is connected with the polygonal stamping assembly. Supporting leg assemblies are installed at all corners of the upper surface of the base. A polygonal fixing ring is mounted above the supporting leg assembly; more than one polygonal stamping push block is arranged on the inner surface of the polygonal fixing ring; more than one polygonal stamping push block is arranged on the outer side of the polygonal stamping assembly and is vertically opposite to the polygonal stamping assembly; the rotary motor is installed on the surface of the base in an embedded mode and connected with the polygonal stamping assembly, and after a product is stamped in the stamping die, automatic rotation is achieved, and next-step stamping is conducted; a first hydraulic pushing element is installed between a polygonal fixing ring and a polygonal stamping pushing block, and a second hydraulic telescopic element is arranged between a base and the polygonal fixing ring; and automatic stamping of products is achieved.

Owner:深圳市鹏瑞精密钣金制品有限公司

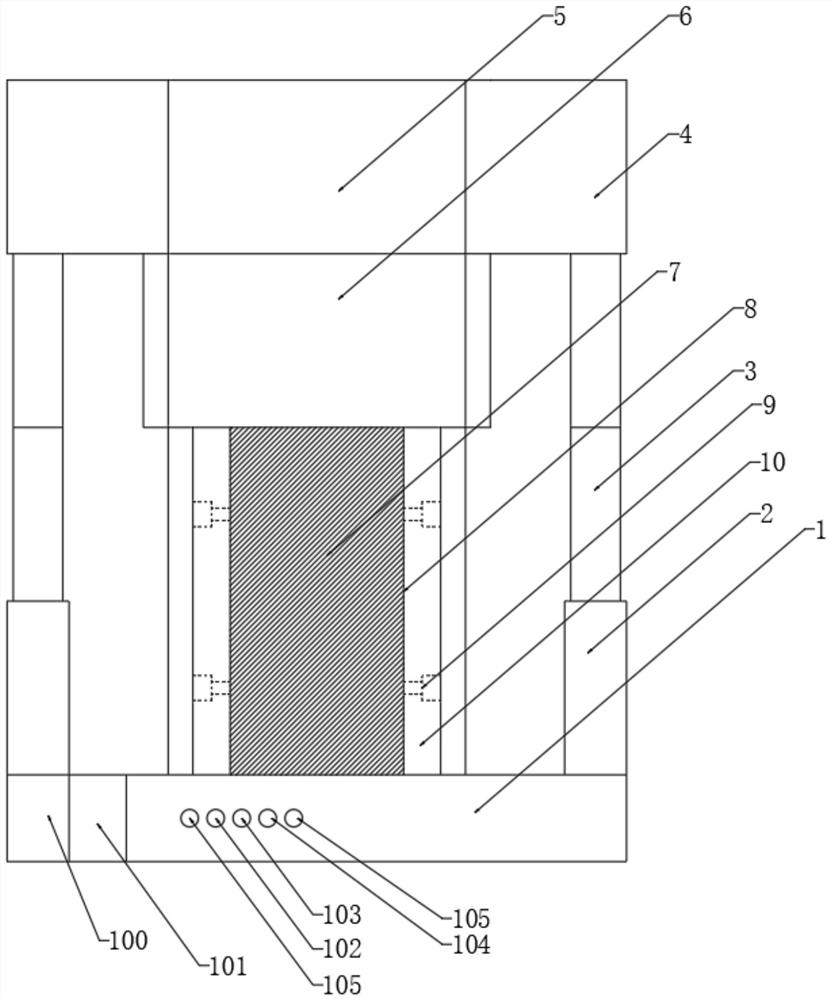

A processing tool for metal sealing gasket

ActiveCN114054591BSolve the waste of manpowerRealize the punching operationShaping toolsPerforating toolsProcess engineeringConveyor belt

The invention discloses a processing tool for a metal sealing gasket, which comprises a stamping cavity, a mold cavity, a receiving box, a workbench, and a stamping mechanism, a feeding mechanism and a clamping mechanism. The cavity is composed of a top plate and four brackets on the workbench. The stamping mechanism is located on the top plate. The bottom surface of the workbench is connected to the mold cavity. Control boxes are arranged on the left and right sides of the mold cavity, and mold grooves are arranged in the mold cavity. And the upper part of the mold groove is not covered by a workbench, and a feeding mechanism and a clamping mechanism are also provided on the workbench and in the mold cavity, and a receiving box is located below the mold cavity, and the receiving box is connected to a waste box, and the waste box is provided with a A conveyor belt, an outlet is provided at the interface between the conveyor belt and the waste box, and universal wheels are connected to the bottom surface of the waste box. The invention can realize automatic feeding of metal plates, stamping processing of sealing gaskets, automatic ejection and retrieving of materials, and automatic discharge of waste materials, which saves manpower and improves processing efficiency at the same time.

Owner:烟台长鑫密封产品有限公司

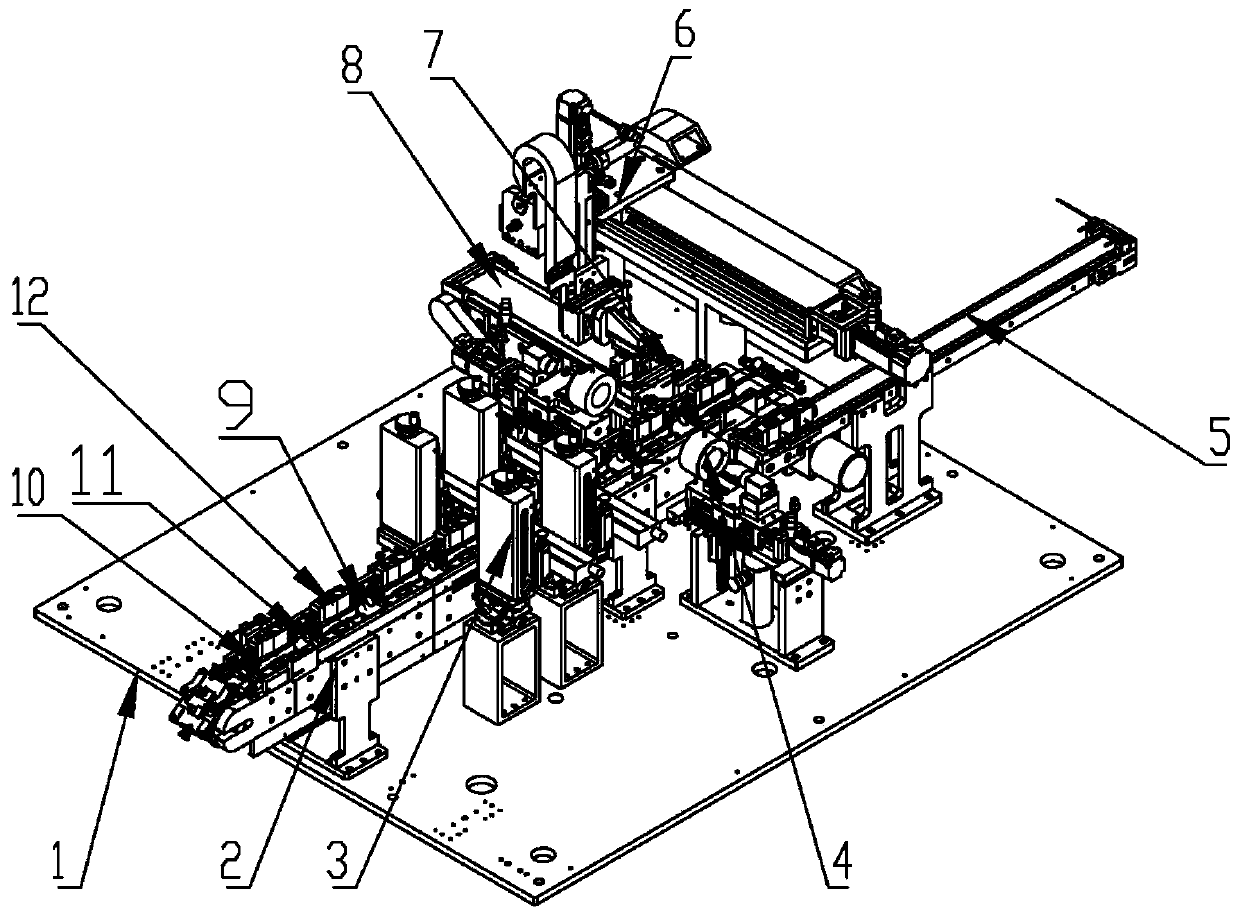

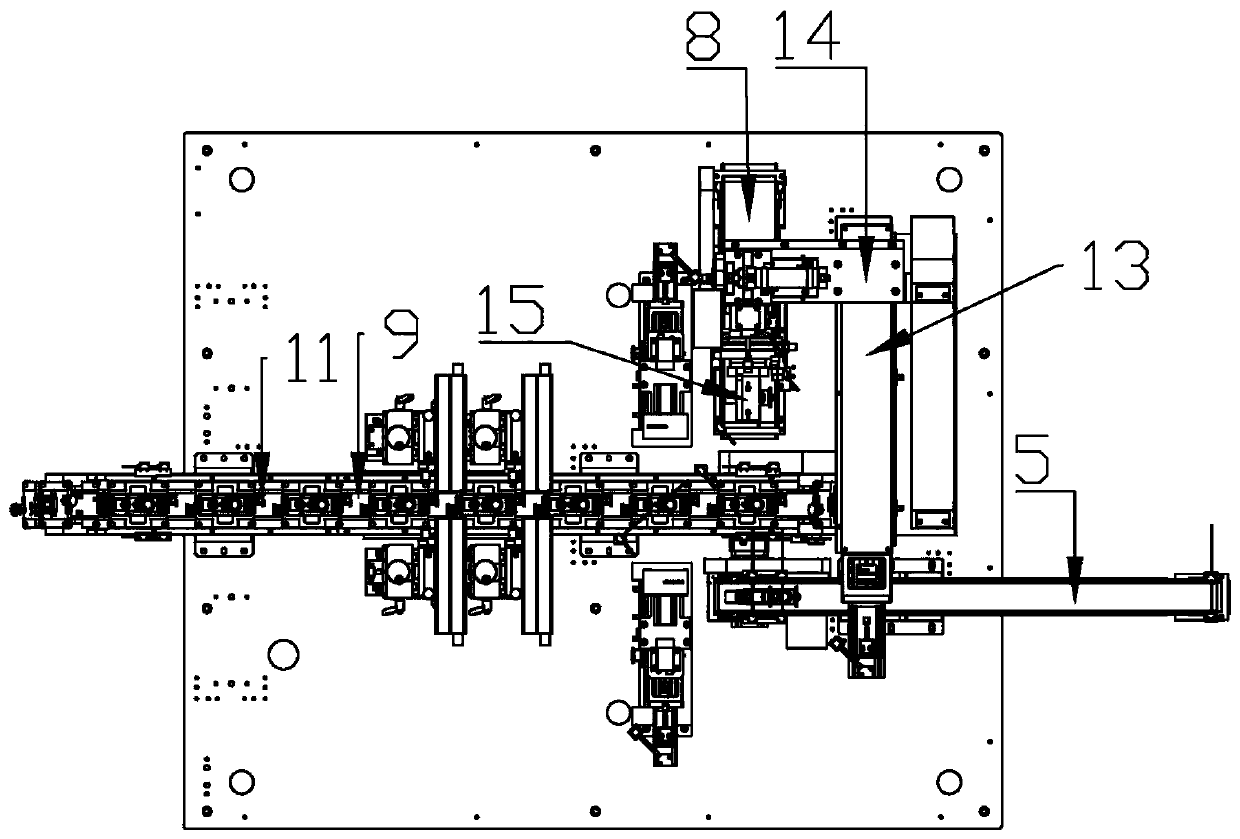

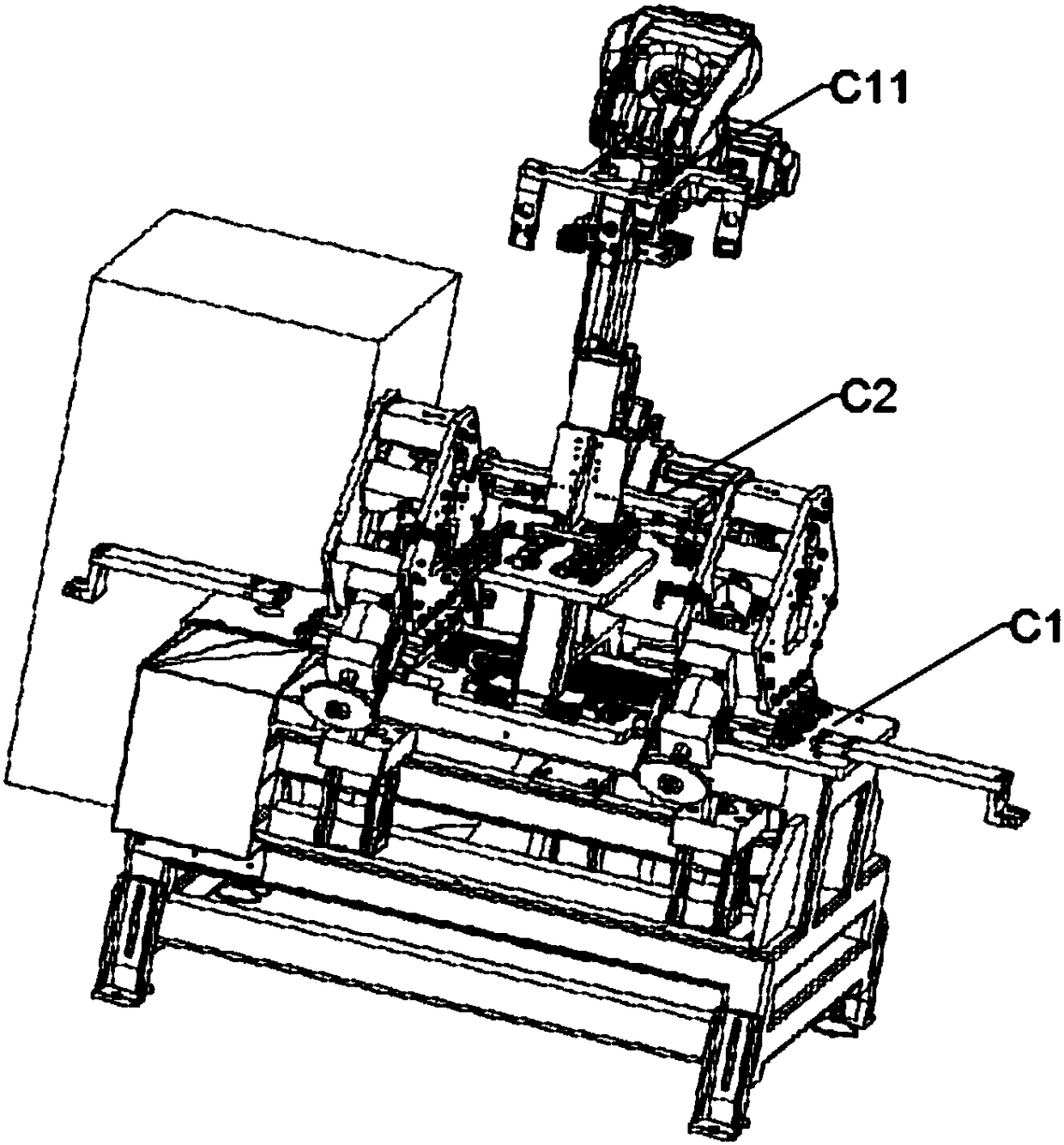

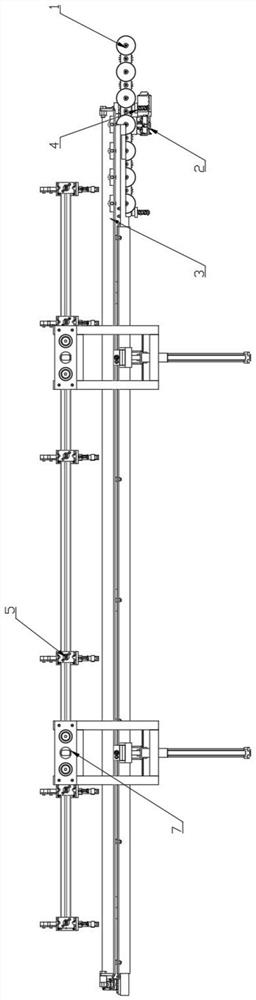

Automatic stamping assembly line for processing bulk container bottom plates

PendingCN112756494ARealize automatic stampingIngenious designHollow articlesStructural engineeringAssembly line

The invention discloses an automatic stamping assembly line for processing bulk container bottom plates. The automatic stamping assembly line comprises a traction mechanism, a tensioning mechanism is arranged on the traction mechanism, the traction mechanism is connected with a driving device, a bearing mechanism is arranged beside the traction mechanism, the bearing mechanism is connected with a supporting component, and a redirection mechanism is arranged above the bearing mechanism. A plurality of stamping mechanisms are arranged on the bearing mechanism. The automatic stamping assembly line is ingenious in design, capable of achieving automatic stamping of the ton barrel bottom plate, safe and stable.

Owner:镇江远海包装有限公司

An automatic stamping machine

ActiveCN106394028BLow costSolve the shortcomings of not widely usedStampingPulp and paper industryControl principle

The invention provides an automatic stamping machine. According to the application, a roller shaft is arranged in a paper placing groove, the side wall of the middle of the paper placing groove is provided with a paper sucking rod fixed rod, a paper sucking rod telescopic rod is arranged in the lower end of the paper sucking rod fixed rod, one side of the paper sucking rod fixed rod is provided with a paper shifting swinging rod, a motor of the paper shifting swinging rod is plugged on the inner wall of the paper placing groove, a vertical rod is fixed to the outer side of the paper placing groove, a rotating shaft is plugged at the upper end of the vertical rod, the end part of the rotating shaft is connected with a rotating shaft of a motor in the upper end of the vertical rod, the upper end of the rotating shaft is connected with the part below one end of a transverse rod, a transverse telescopic rod is plugged at the other end of the transverse rod, the end part of the transverse telescopic rod is connected with a cylinder in the transverse rod, the lower end of the bent part of the transverse telescopic rod is provided with a longitudinal telescopic rod, the upper end of the longitudinal telescopic rod is connected with a cylinder in the lower end of the bent part of the transverse telescopic rod, and a stamp is plugged in the lower end of the bent part of the transverse telescopic rod. After a stamping position is determined, through the combination of mechanical movement and a control principle, paper is precisely fed through a stamping clearance, and stamping action is carried out after the paper is fed, so that automatic stamping is realized.

Owner:JINLING INST OF TECH

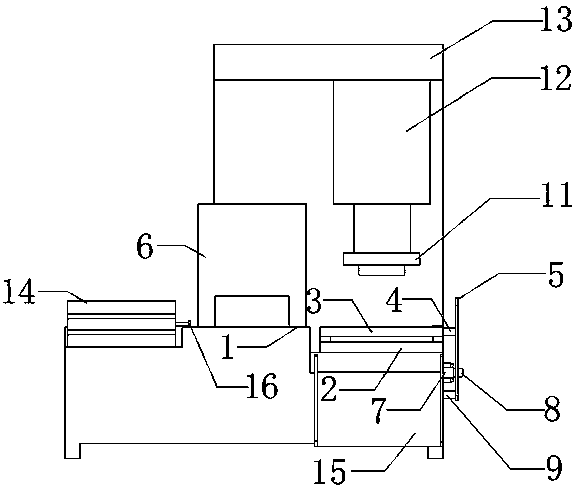

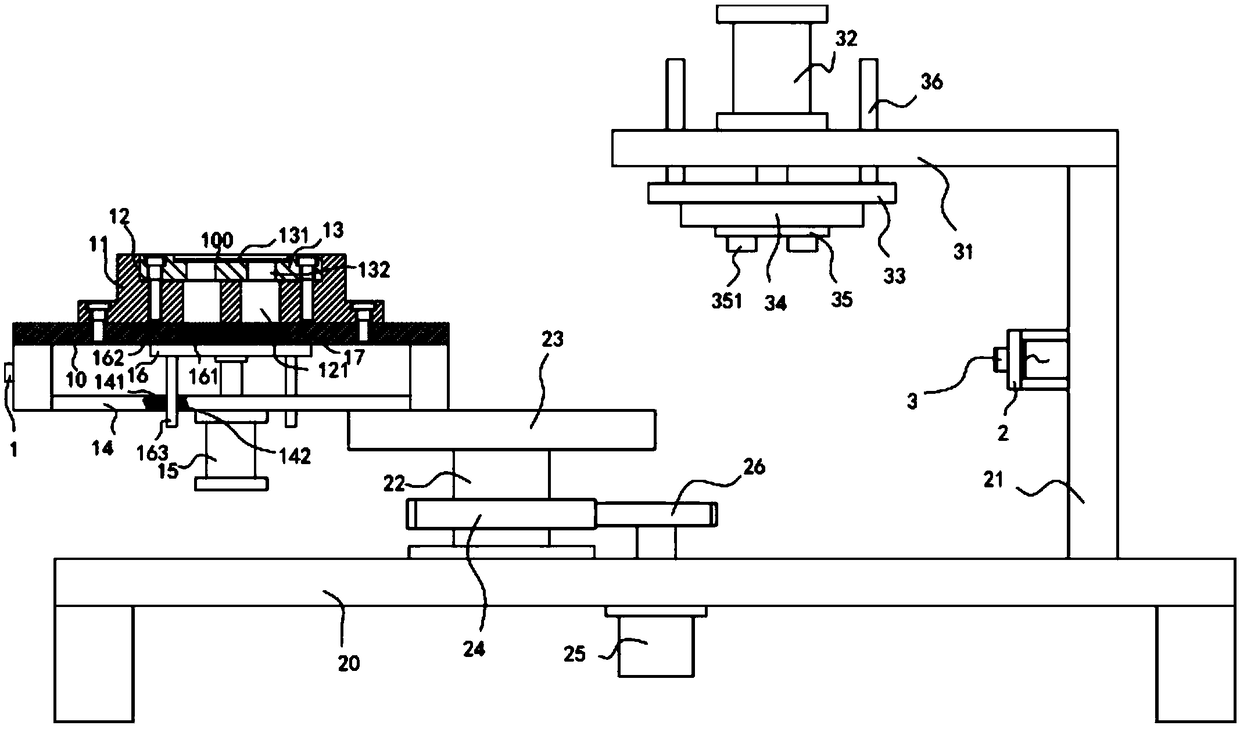

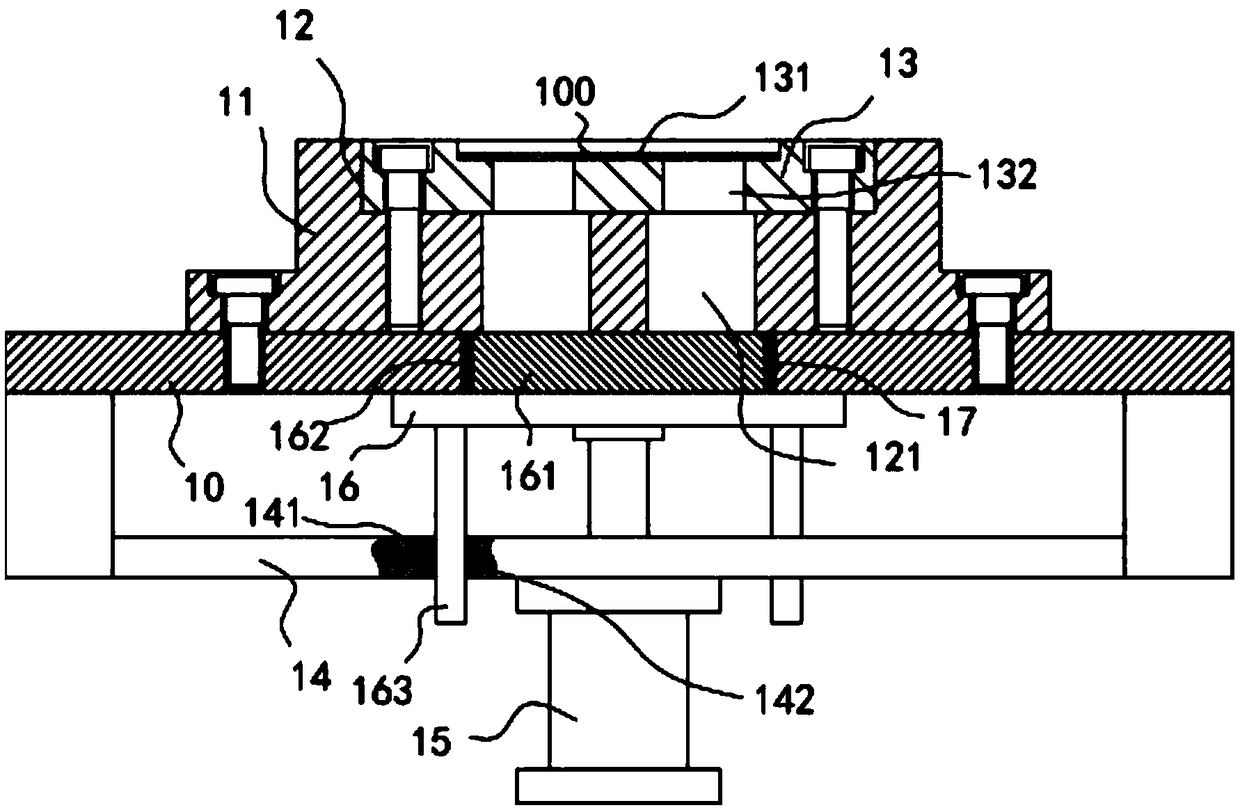

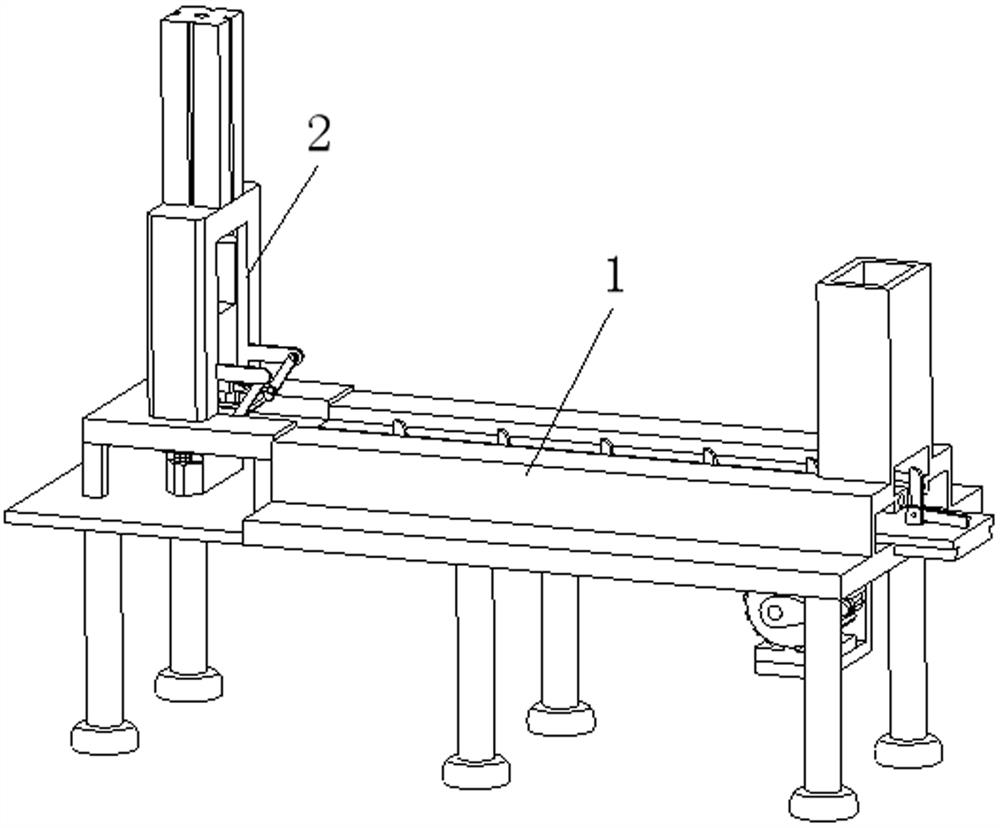

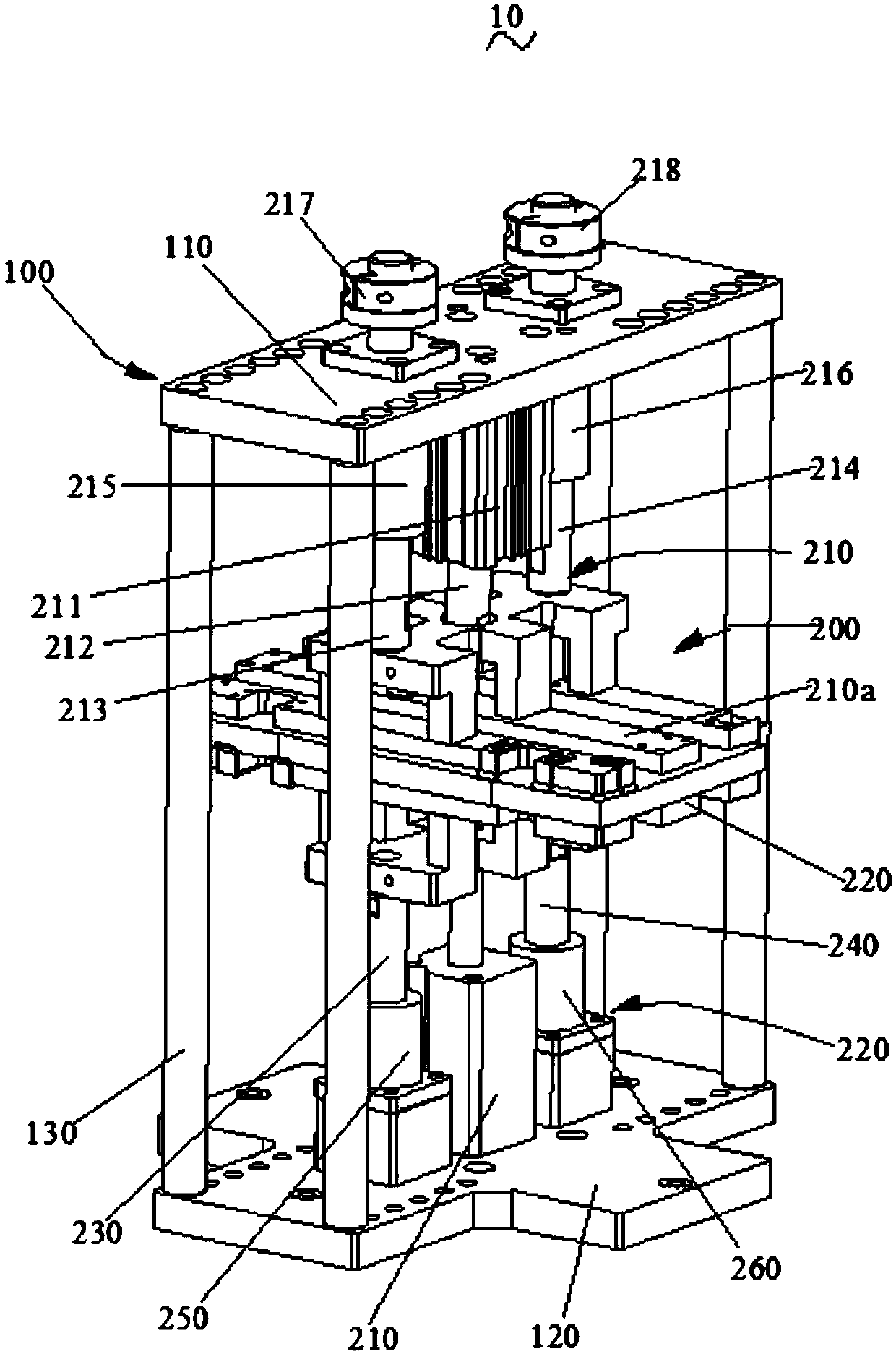

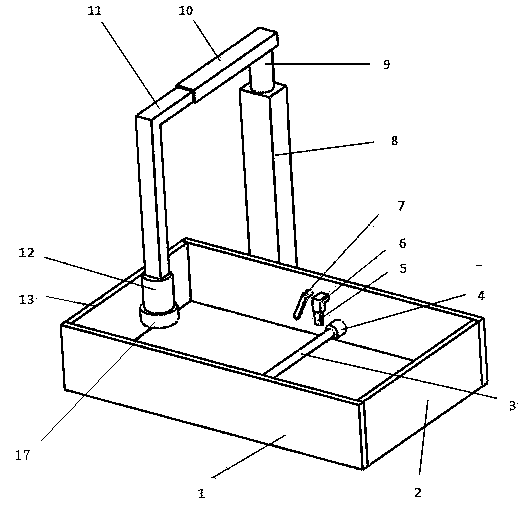

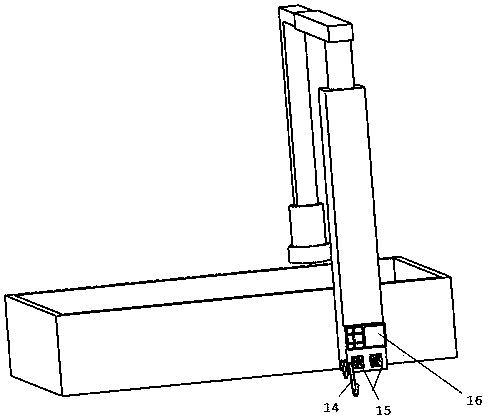

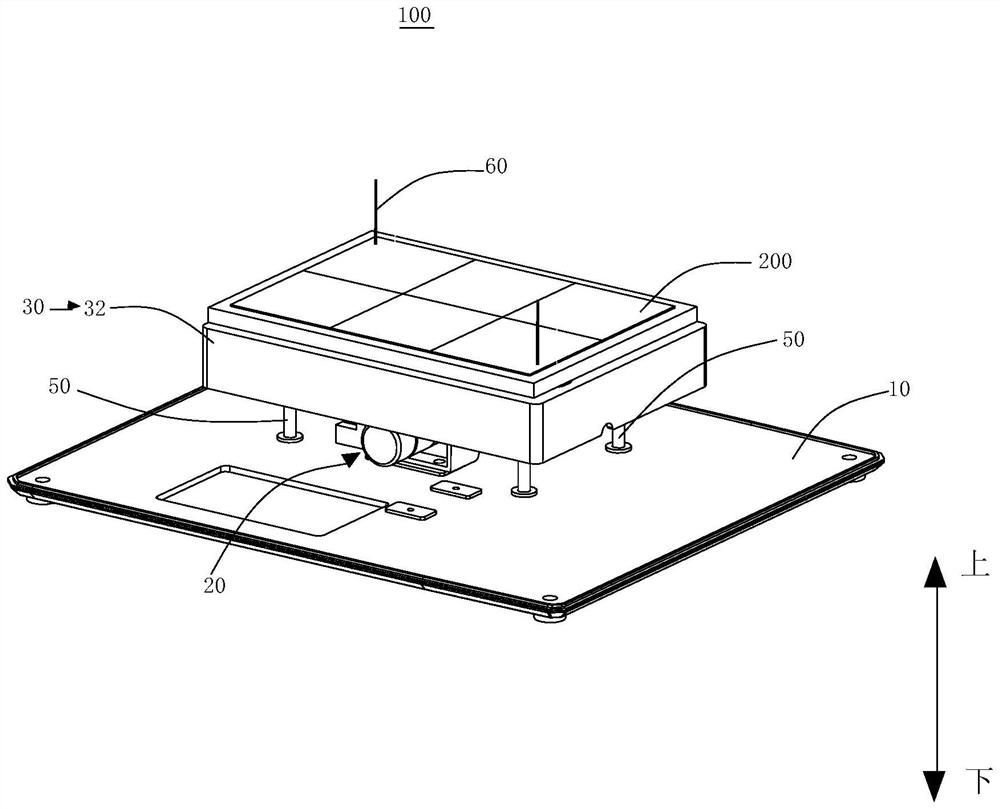

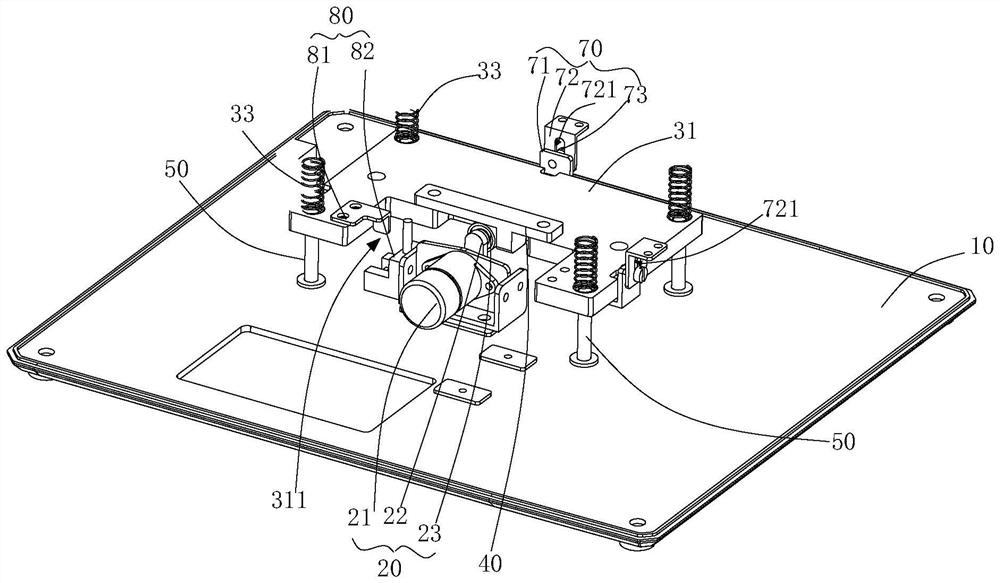

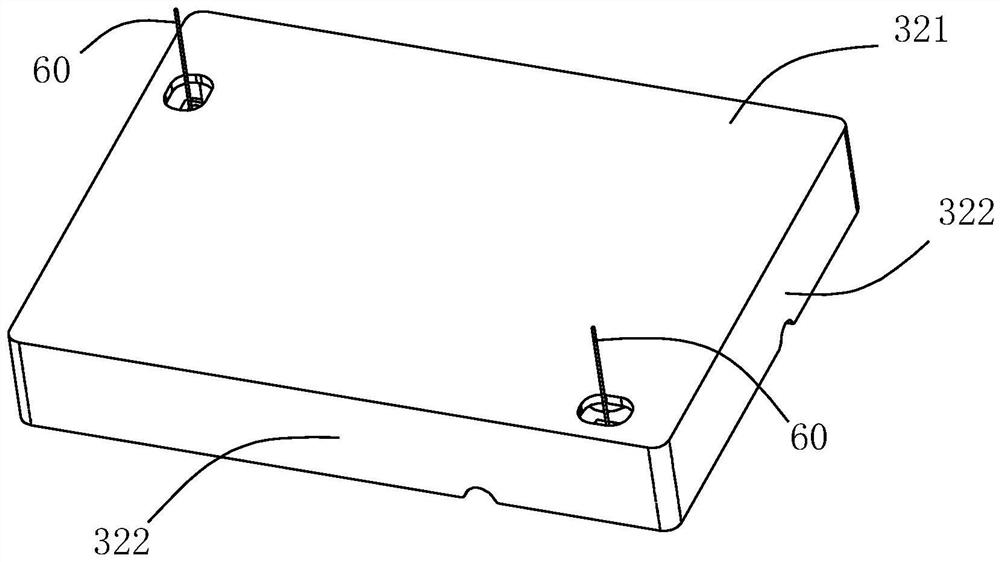

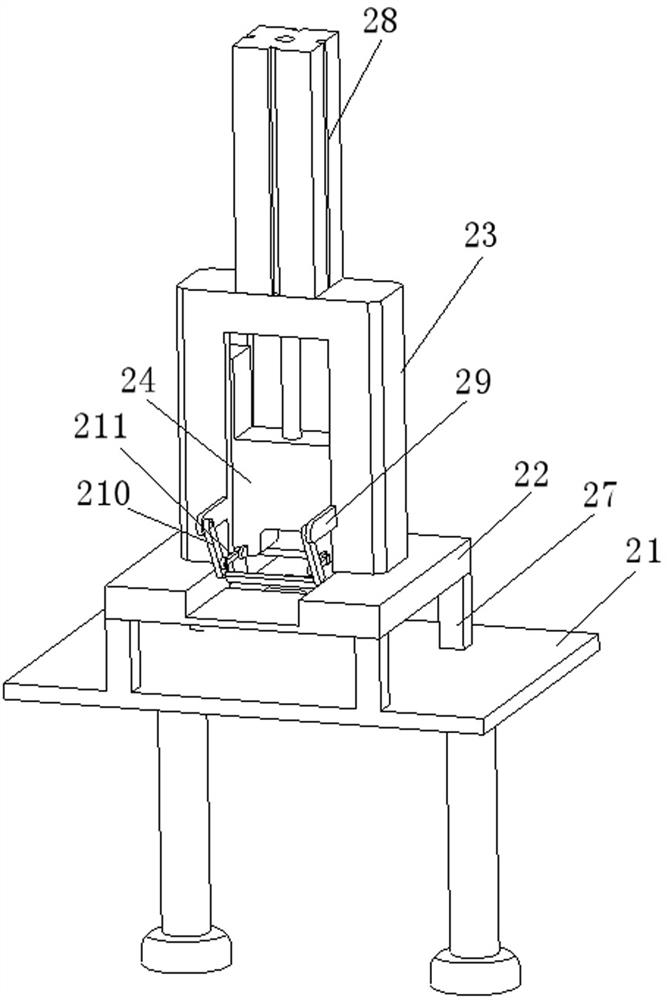

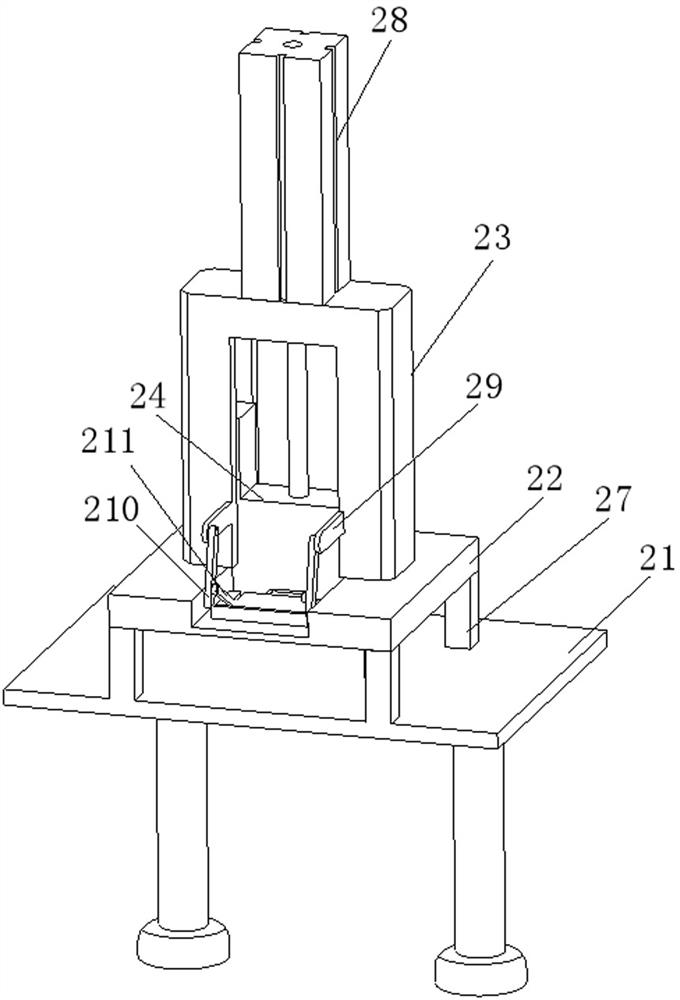

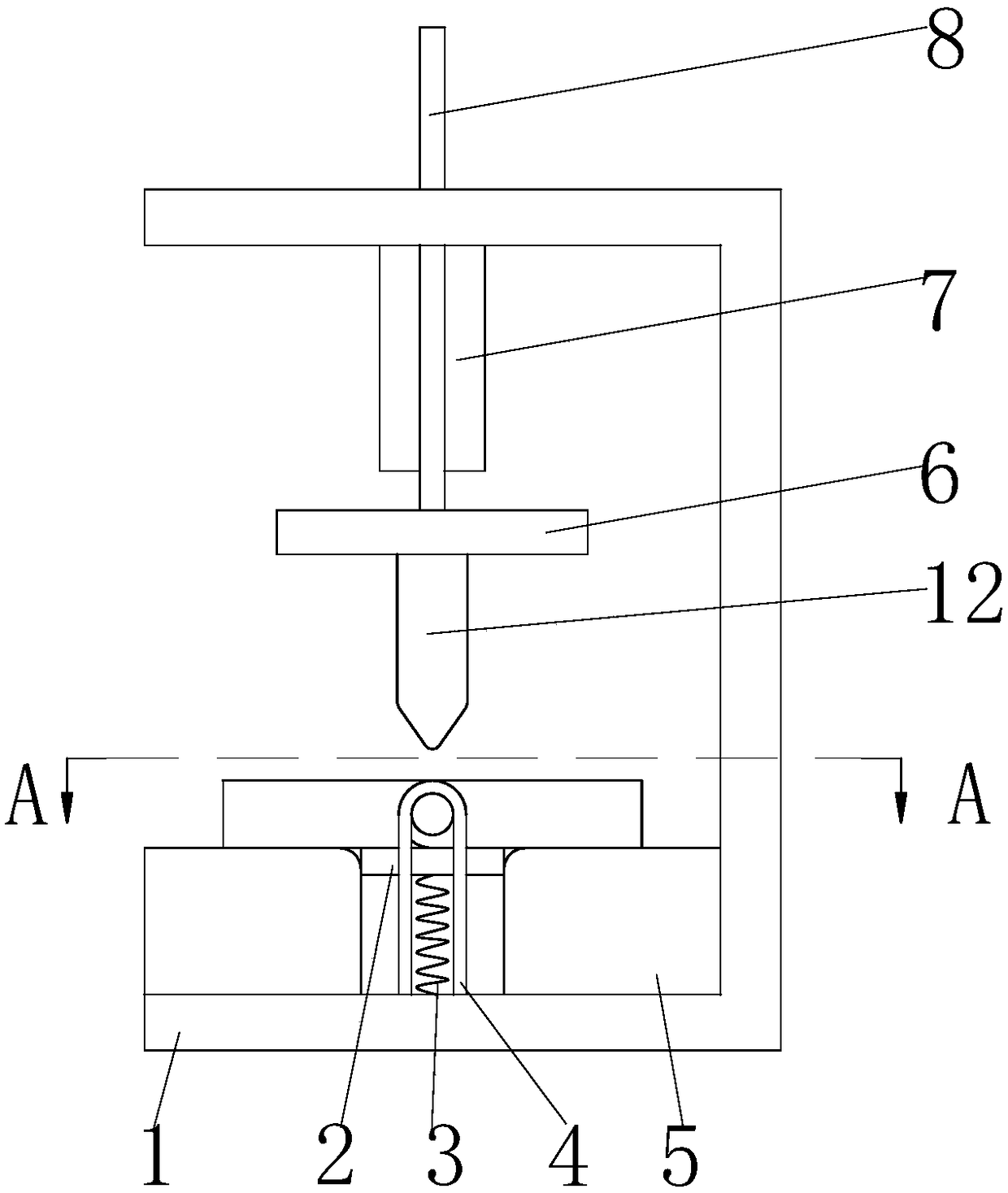

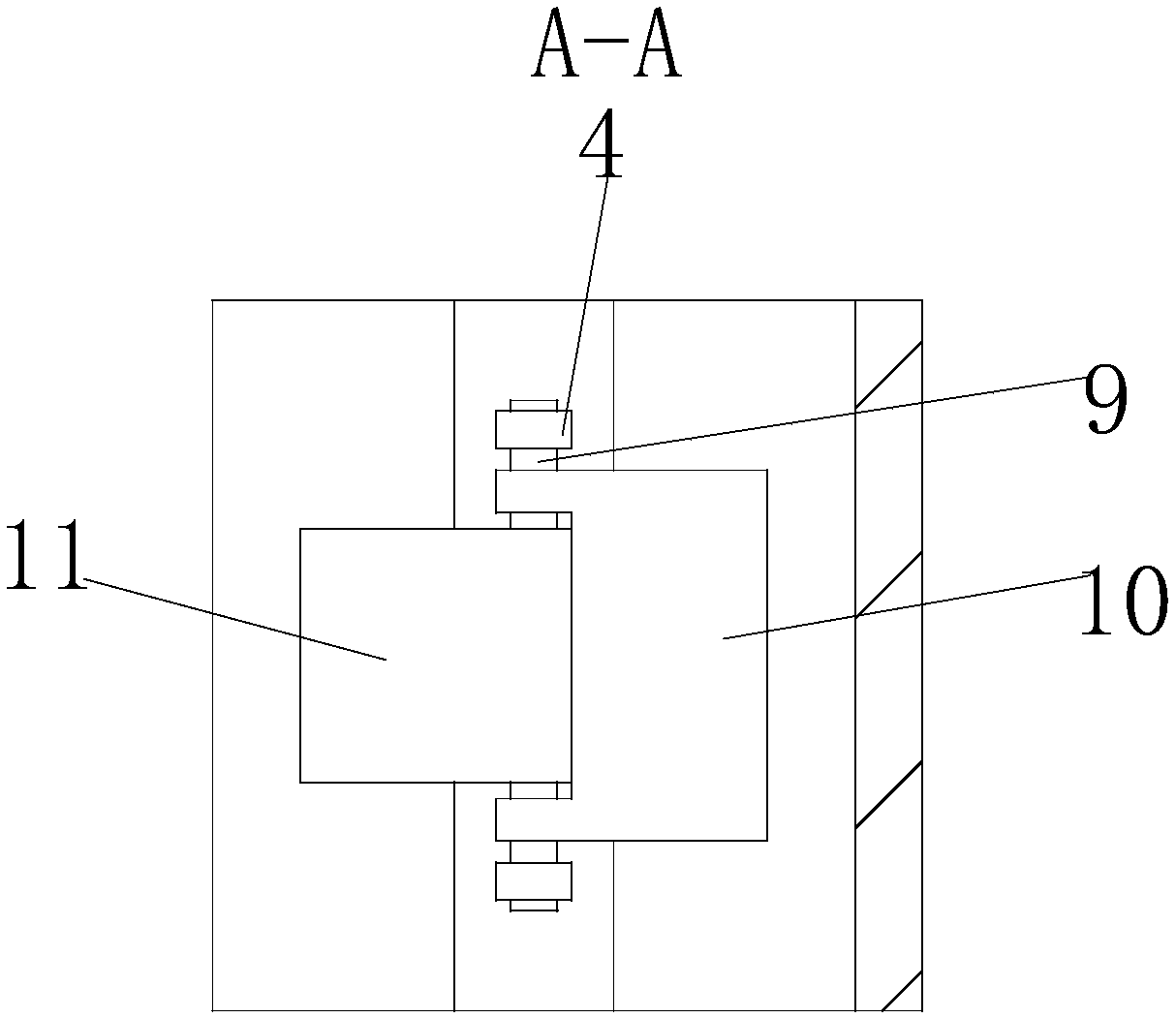

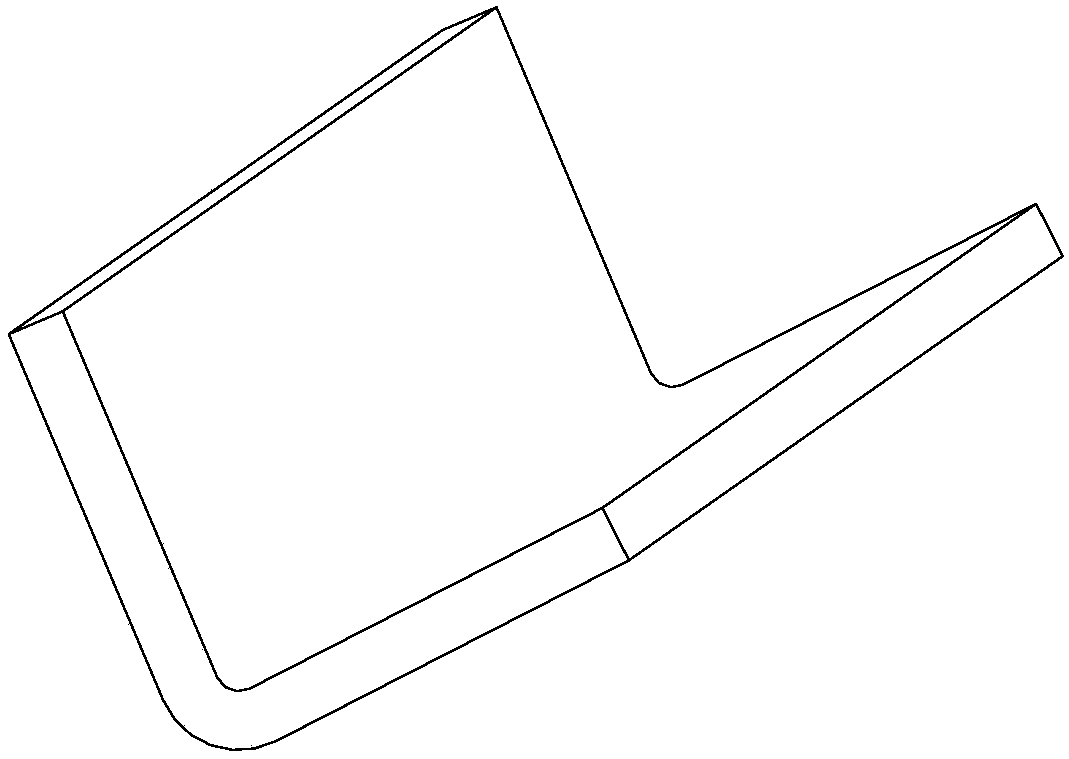

Jacking mechanism of stamping machine and stamping machine

PendingCN114161852ARealize automatic stampingReduce manual involvementStampingStructural engineeringStamping process

The invention discloses a jacking mechanism of a stamping machine. The jacking mechanism comprises a base, a jacking driving mechanism arranged on the base, a jacking piece, a limiting block fixedly arranged on the jacking piece and in surface contact with the jacking driving mechanism, and a plurality of guide rods perpendicular to the jacking piece. Specifically, one end of each guide rod is fixedly arranged on the base, and the other end of each guide rod is connected with the jacking piece in a sliding mode. A certificate to be stamped is arranged on the jacking piece, and the jacking driving mechanism is used for driving the jacking piece fixedly connected with the limiting block to slide up and down along the multiple guide rods so as to drive the certificate on the jacking piece to move up and down. The invention further provides the stamping machine applying the jacking mechanism. According to the jacking mechanism and the stamping machine, the certificate to be stamped can be effectively and automatically driven to slide up and down, the certificate can be automatically jacked to the stamping position, automatic stamping is facilitated, and manual participation in the stamping process is reduced.

Owner:SHENZHEN MAXVISION TECH

A car buckle stamping device

ActiveCN112893681BRealize automatic stampingStamping precisionMetal-working feeding devicesVehicle componentsStamping pressFastener

The invention discloses an automobile buckle stamping device, which belongs to the technical field of stamping equipment and includes a feeding equipment and a stamping equipment. The feeding equipment is arranged on the right side of the stamping equipment. The stamping equipment includes a stamping base, a stamping Plate, stamping shell, stamping upper die, stamping lower die and loading plate, when the feeding equipment transports the buckle raw materials to the stamping plate, the punching machine drives the stamping upper die on the stamping Slide upward in the housing, at this time, the work of the loading plate pushes the buckle raw material on the stamping plate to the top of the lower punching die, and the punching machine reverses to drive the upper punching die to move downward to meet with the lower punching die Cooperate to complete the stamping. At this time, the feeding plate is reset. When the work is repeated, the loading plate drives the next buckle raw material to move to the top of the stamping die, and the stamped automobile buckle is extruded from the stamping die to realize automatic stamping. .

Owner:湖北天成汽车配件有限公司

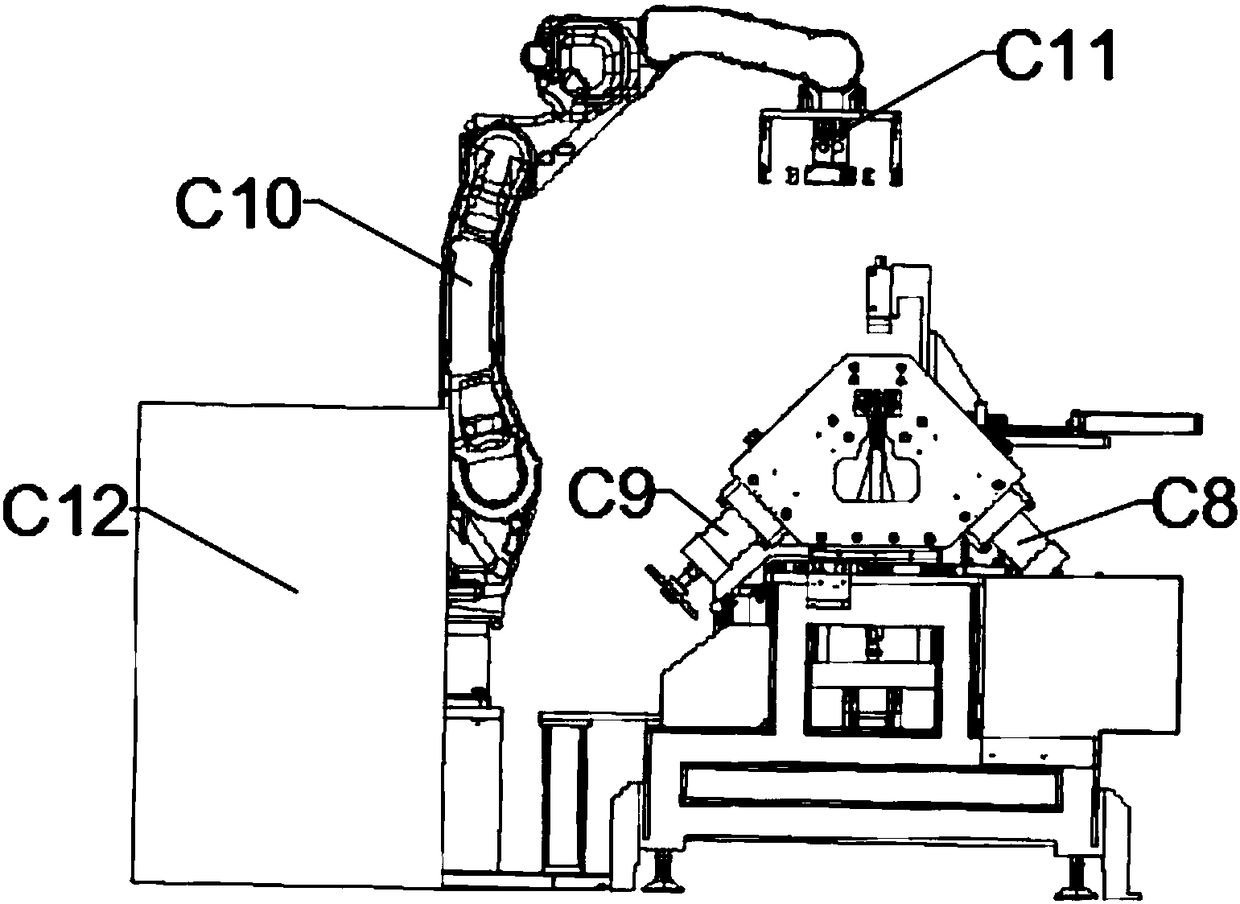

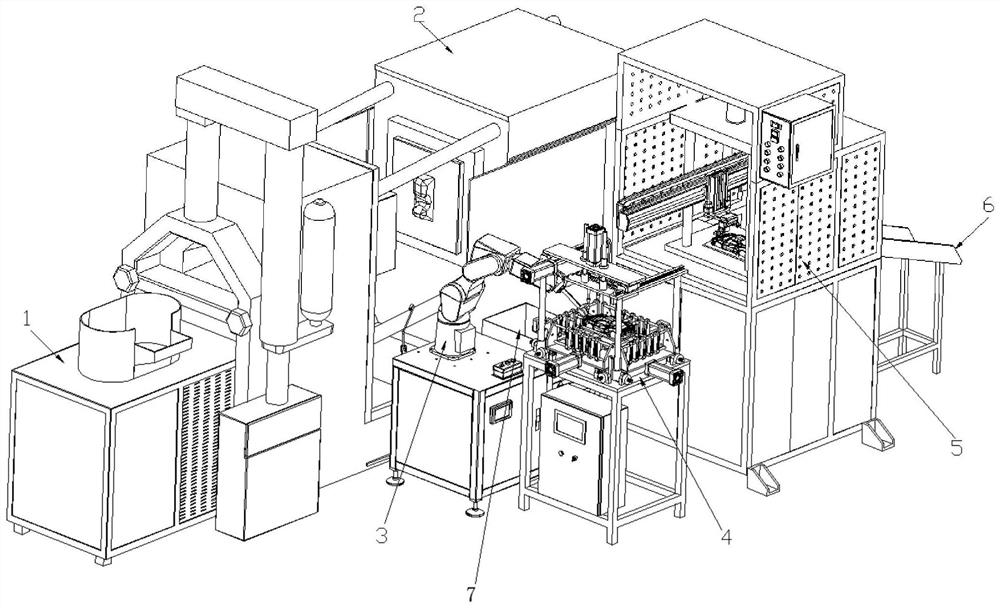

Automatic machining device for rim charges of alloy facing die-pressed pieces

PendingCN112846134AImprove automatic processing technologyRealize automatic stampingCar modelPunching

The invention discloses an automatic machining device for rim charges of alloy facing die-pressed pieces, and relates to the technical field of automobile model production. The automatic machining device comprises an alloy melting device, a die-casting device, a six-axis grabbing device, an air flushing and arranging device and a punching device which are connected in sequence, a discharging port of the alloy melting device is connected with a feeding port of the die-casting device, and the die-cast alloy facing die-pressed pieces are placed on the air flushing and arranging device through the six-axis grabbing device at the discharging port of the die-casting device; and a plurality of punching clamping blocks are arranged on the air flushing and arranging device, the punching clamping blocks carry out air exhausting position punching on a vehicle body casting, the punched vehicle body casting is grabbed by the six-axis grabbing device to cooperate with a transfer manipulator to enter the punching device for water gap punching, and a discharging port of the punching device is connected with a discharging groove. According to the automatic machining device, automatic punching of exhaust position and water gap rim charges can be achieved, manual operation of production workers is not needed, the turnover machining frequency is reduced, and mold stripping and picking, exhaust position punching and water gap punching of vehicle body castings are completed at a time.

Owner:万达工业(始兴)有限公司

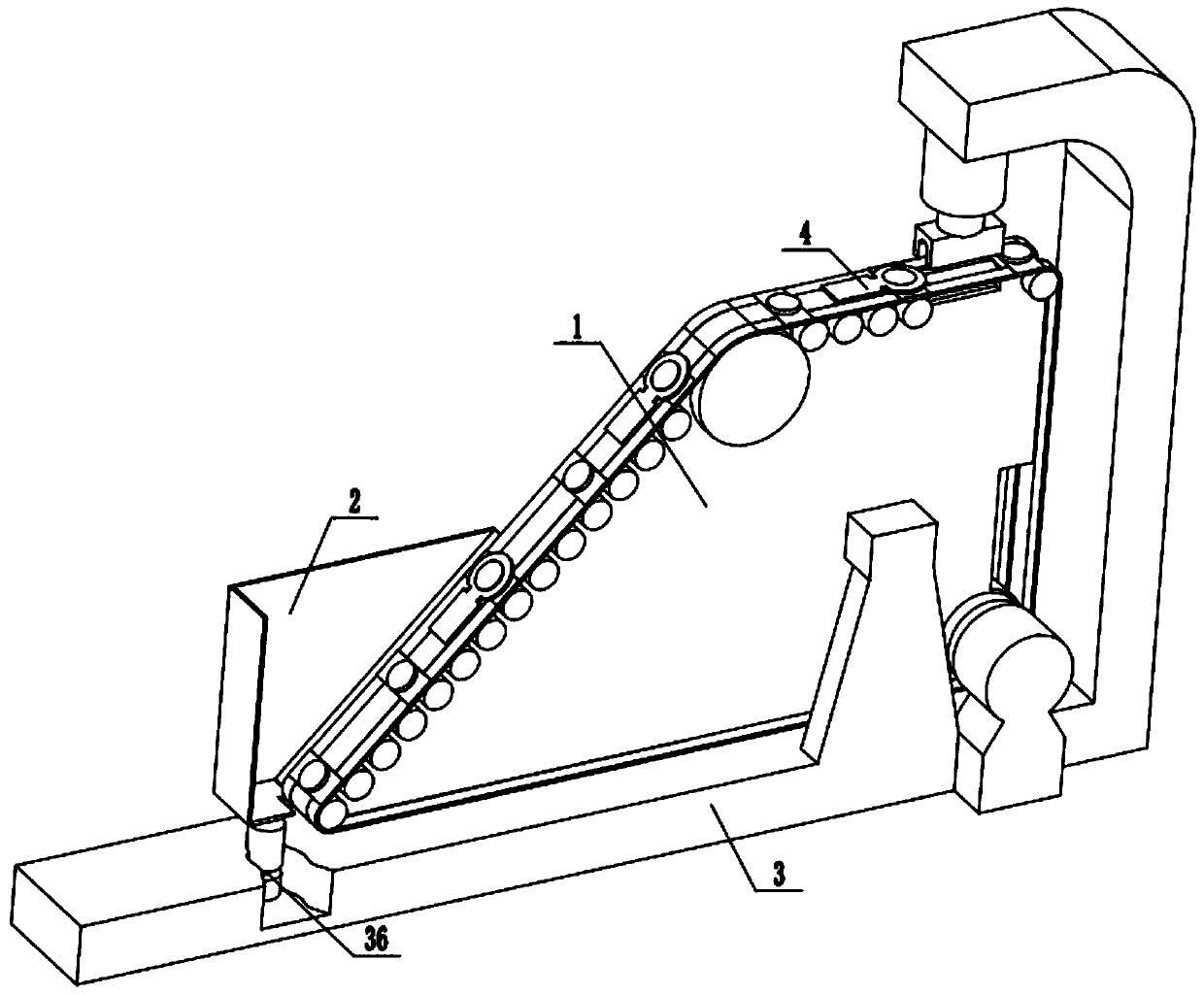

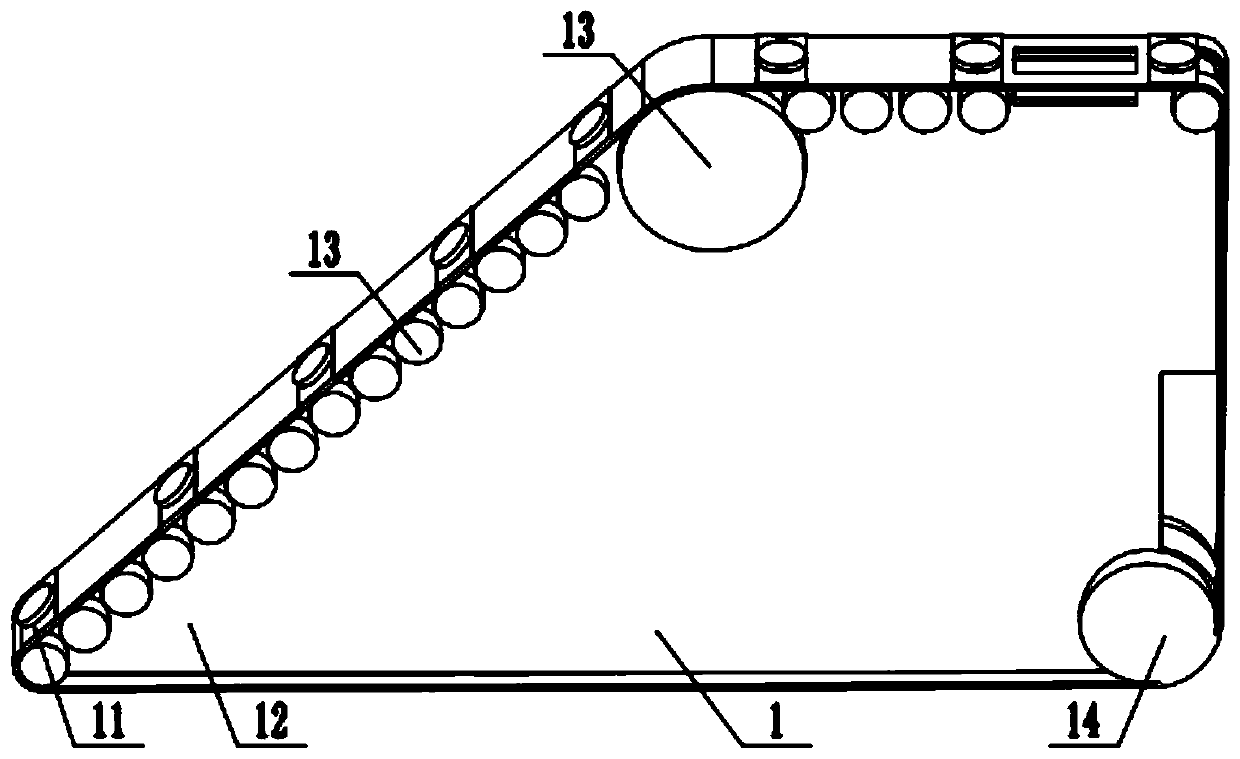

A wire crimping piece bending machine

ActiveCN108906951BRealize automatic stampingGuaranteed Position AdjustmentShaping toolsMetal-working feeding devicesJoint componentEngineering

The invention discloses a conducting wire compression joint component bending machine which comprises a conveying mechanism and the like. The conveying mechanism is fixed onto a support by the aid ofa fixing frame, a hopper is mounted on the support via a vibrator, the conveying mechanism comprises a conveyor belt and a support component, the support component comprises a support plate, roll shaft holes are formed in a middle line edge and a top line edge of the support plate, support rolls are arranged on the support plate via the roll shaft holes, the axes of the support rolls are perpendicular to planes of the support plate, the support rolls are arranged on two sides of the support plate, a driving friction wheel is arranged at an edge of the support plate, and the conveyor belt is arranged on the support component and can be tensioned by the support rolls and the driving friction wheel; a motor is arranged on the support and is connected with the driving friction wheel in a driving manner. The conducting wire compression joint component bending machine has the advantages that the problems of inconvenience in manual operation and long time consumption due to large quantities of small components can be solved by the aid of the conducting wire compression joint component bending machine; the conducting wire compression joint component bending machine is provided with automatic feeding, automatic loading and automatic stamping devices, accordingly, manual intervention can be omitted, and conducting wire compression joint components only need to be placed in the hopper andcan be automatically stamped by the conducting wire compression joint component bending machine.

Owner:ZHANGQIU POWER SUPPLY CO OF STATE GRID SHANDONG ELECTRIC POWER CO +1

V-shaped sheet metal part punch forming device

InactiveCN108580598AHigh degree of automationRealize automatic stampingMetalArchitectural engineering

The invention relates to a V-shaped sheet metal part punch forming device. The V-shaped sheet metal part punch forming device comprises a substrate; a guide rod is mounted at the upper end of the substrate in a vertical sliding manner; the lower end of the guide rod is fixedly connected with an upper mold base; a V-shaped punch is fixedly mounted at the lower end of the upper mold base; and the upper end of the upper mold base is connected with a hydraulic cylinder fixedly mounted on the substrate. Fixed mold bases are fixedly mounted on the left side and the right side of the lower part of the substrate; a guide sleeve and a spring are fixedly mounted in the center of the lower part of the substrate; the upper end of the spring is fixedly connected with a lower table plate; a table columnis slidingly mounted on the guide sleeve in the vertical direction; and the table column is hinged with a left mold base and a right mold base. The V-shaped sheet metal part punch forming device is high in automation degree, and can automatically punch aluminum alloy plates as V-shaped sheet metal parts through controlling the V-shaped punch to press down to cooperate with the left mold base andthe right mold base.

Owner:WUHU HENGHAO MACHINERY MFG

A method for backing up, sealing and preserving financial statements

InactiveCN107491365BWon't slip off easilyConvenient queryRedundant operation error correctionStampingSoftware engineeringTablet pc

The invention relates to a method for backing up, stamping and storing financial statements. The method comprises the steps that 1, the financial statements are managed orderly on an anti-slip plate on financial statement integration equipment; 2, a photo is taken by a camera and sent to a tablet computer, and the backup of the financial statements is completed; 3, the financial statements which need to be stamped are conveyed into a paper feeding port and placed on a second clapboard, and stamping is completed; 4, for the uncompleted statements, a door plate is opened, the financial statements are placed on a baffle, and a warning lamp is lighted on to remind staff that the financial statements are not completed; 5, when the financial statements are completed, a first button is pressed, and a first motor is turned on, so that the baffle moves downwards to make the completed financial statements automatically fall into the lower layer of a first shell to be saved, and the storage of the financial statements is completed.

Owner:黄泽华

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com