Patents

Literature

65results about How to "Guaranteed Position Adjustment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

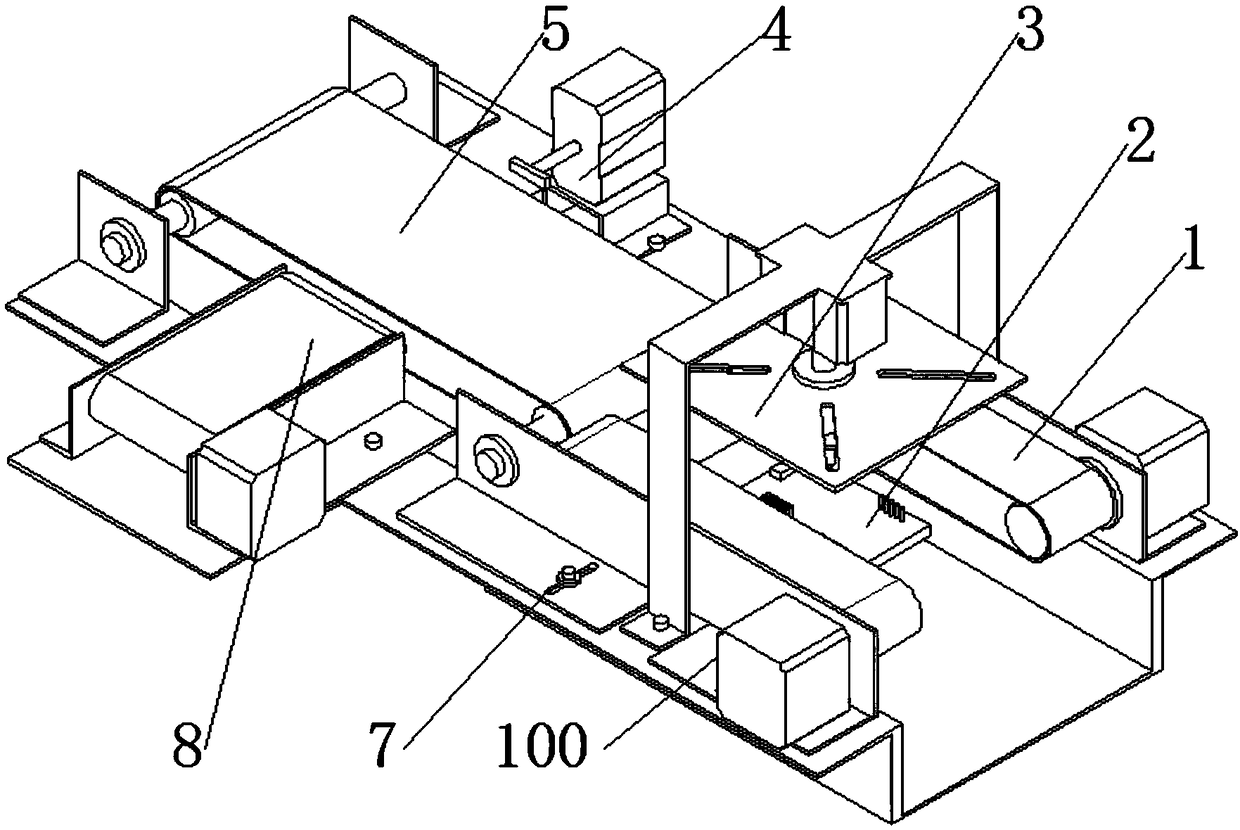

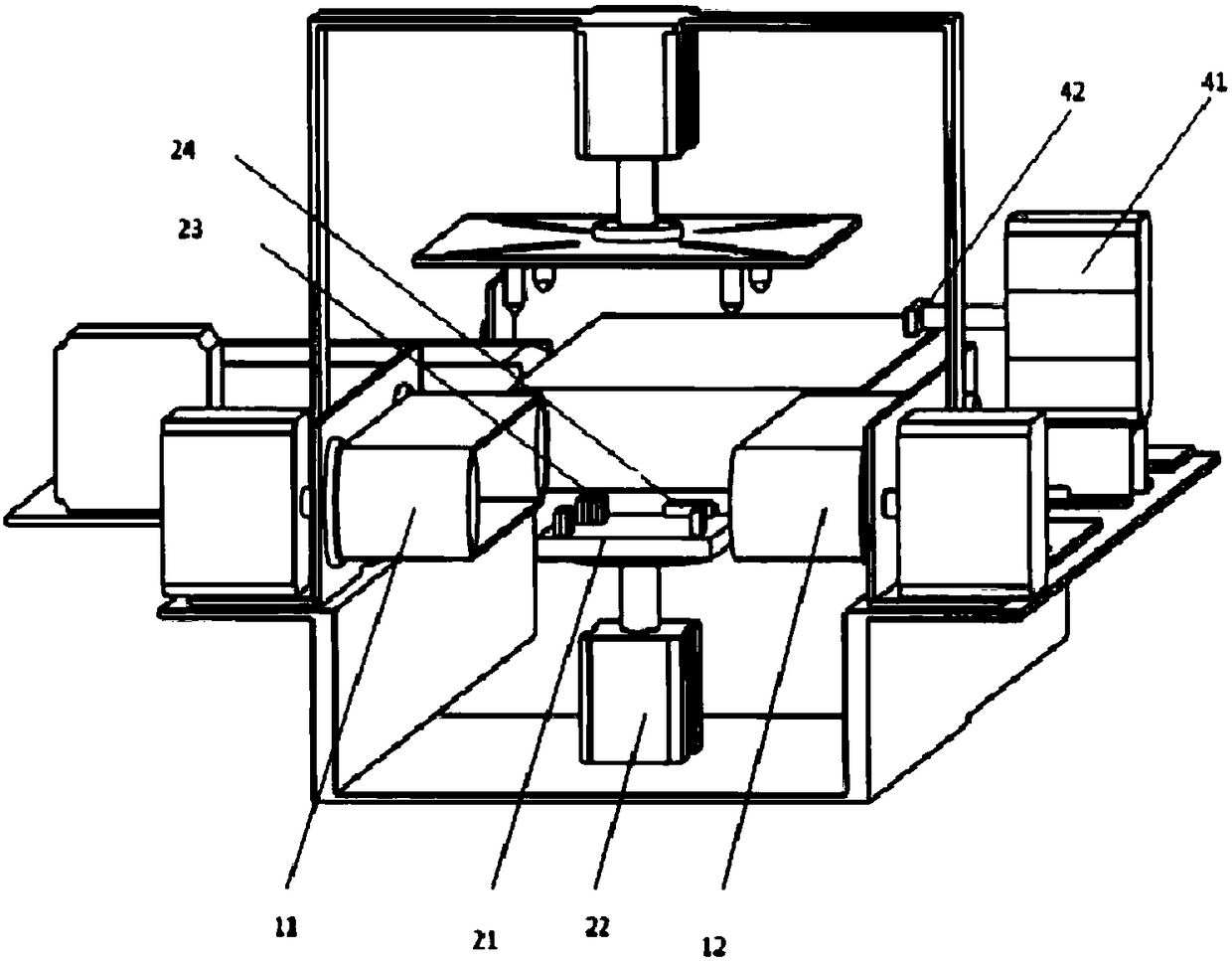

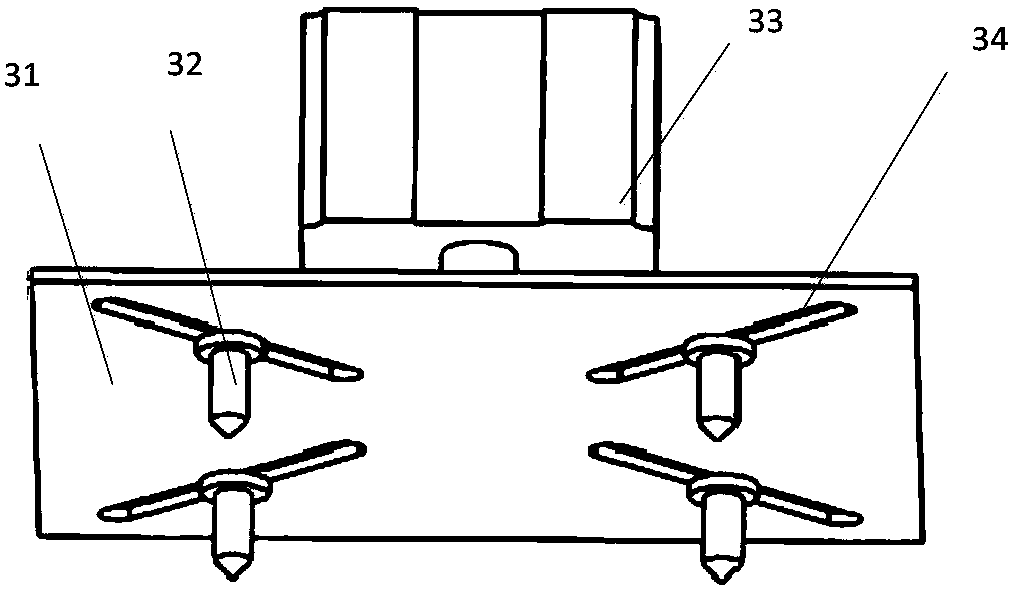

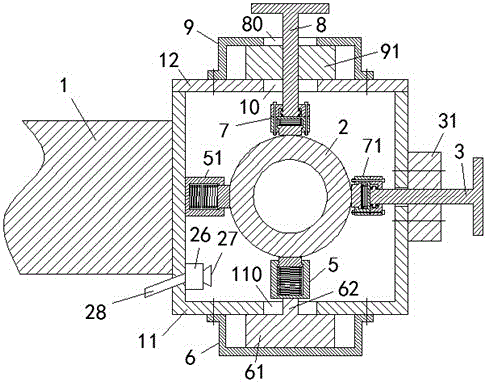

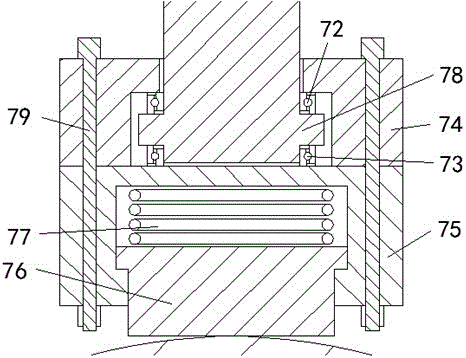

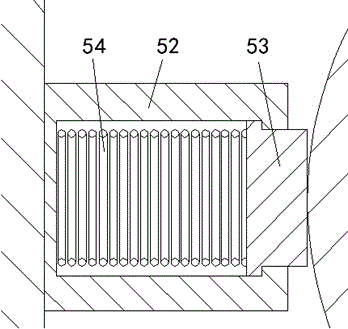

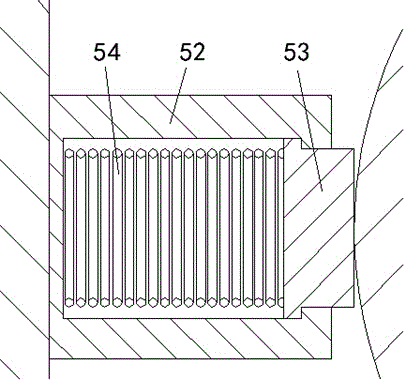

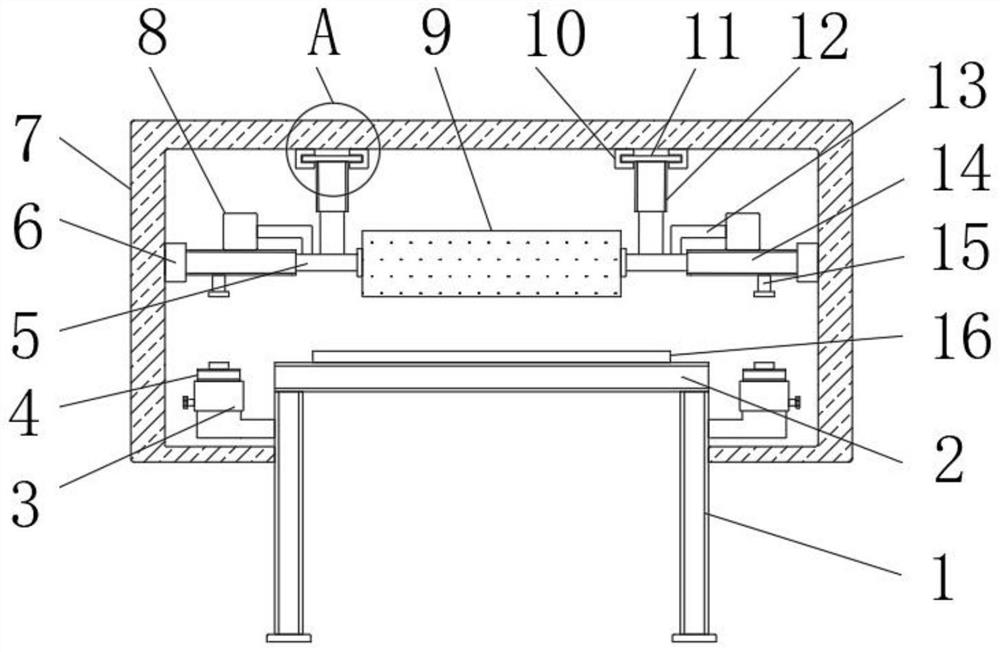

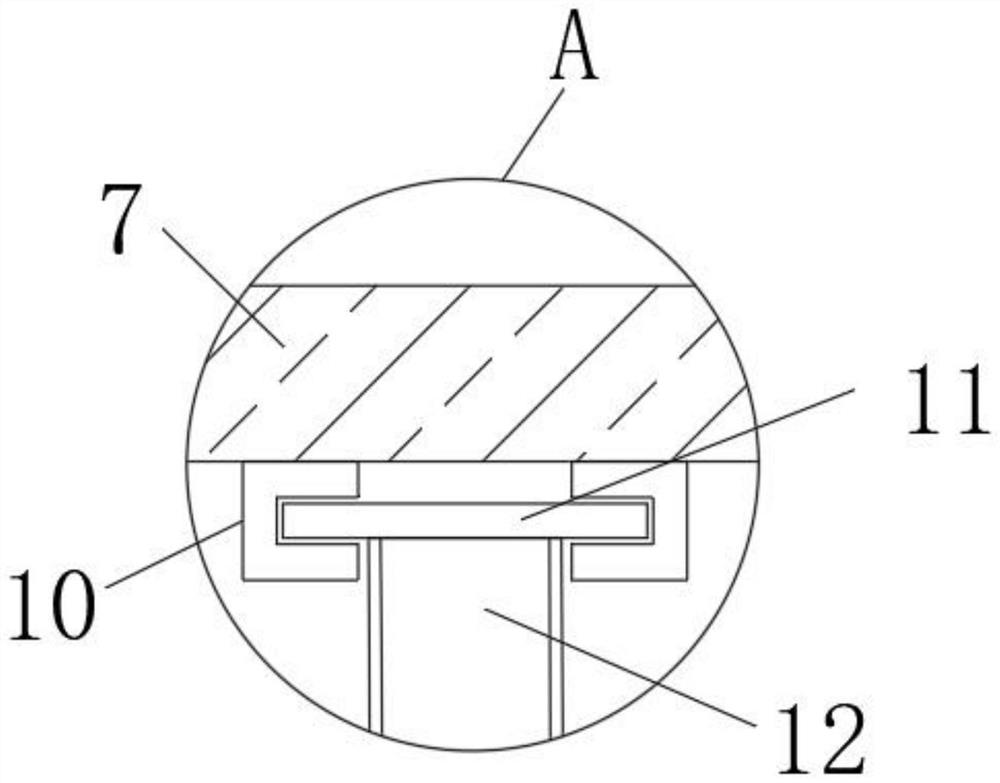

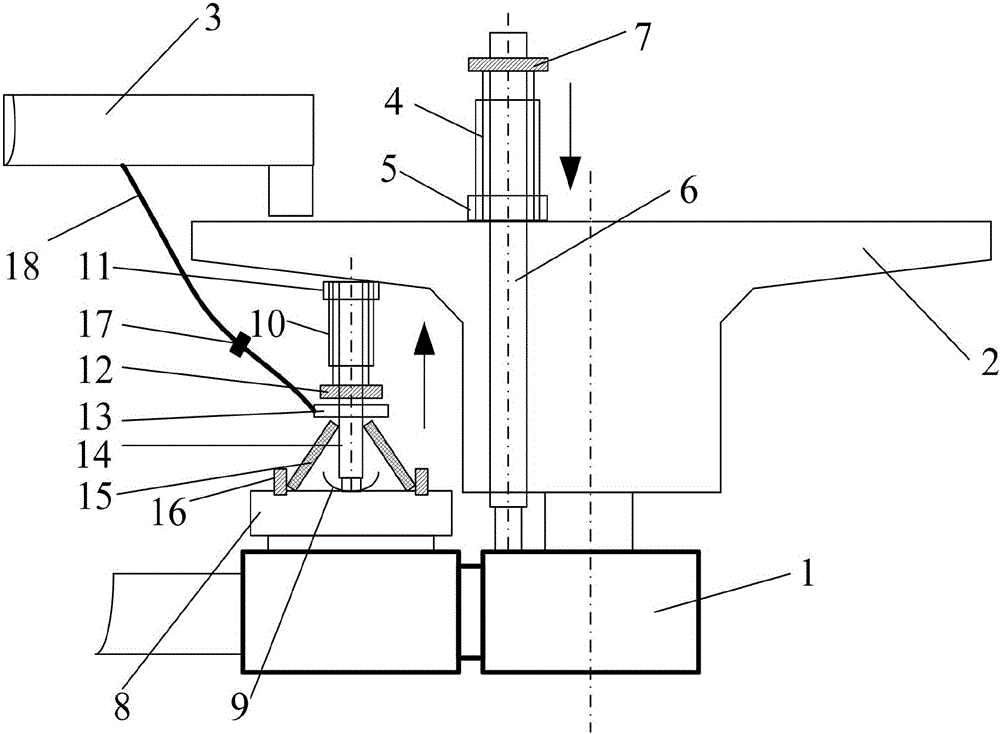

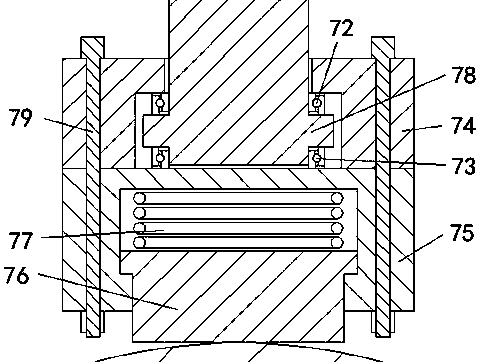

Inspection platform used in production process of EPS (Electrical Power Steering) controller and working method of inspection platform

PendingCN108318807AReduce detection error rateReduce process stepsElectronic circuit testingMeasurement instrument housingWorking setSteering control

The invention relates to the technical field of automobile steering control inspection and in particular relates to an inspection platform used in the production process of an EPS (Electrical Power Steering) controller. The inspection platform comprises a rack, wherein two groups of conveyer belts in parallel are arranged on the rack; a group of a fly needle lifting platform is arranged between the two groups of the conveyer belts; a group of positioning lifting rods are arranged above the fly needle lifting platform; the positioning lifting rods are fixed on the rack through a fixing bracket;discharge ends of the two groups of the conveyer belts are connected with a T-shaped diversion track; a diversion shift fork is arranged on one side of the T-shaped diversion track; an unqualified product guide track is arranged on the other side of the symmetric T-shaped diversion track of the diversion shift fork. By adopting the inspection platform, complex procedures that multiple times of inspection are carried out in the conventional EPS controller inspection process can be avoided, through function integration, procedures and steps can be reduced, the probability of mal-inspection in production of controllers can be reduced, and the production efficiency can be remarkably improved.

Owner:NORTHEAST FORESTRY UNIVERSITY

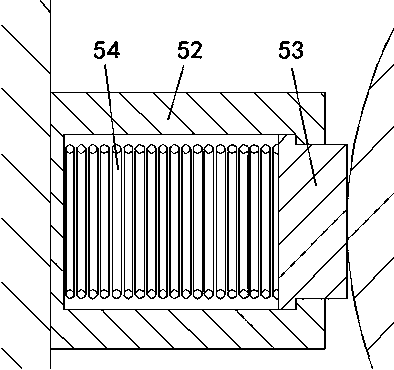

Steady pipeline supporting device

InactiveCN105864521AOvercoming top pressureAvoid damagePipe supportsEngineeringMechanical engineering

Owner:昆山市鑫泓建设工程有限公司

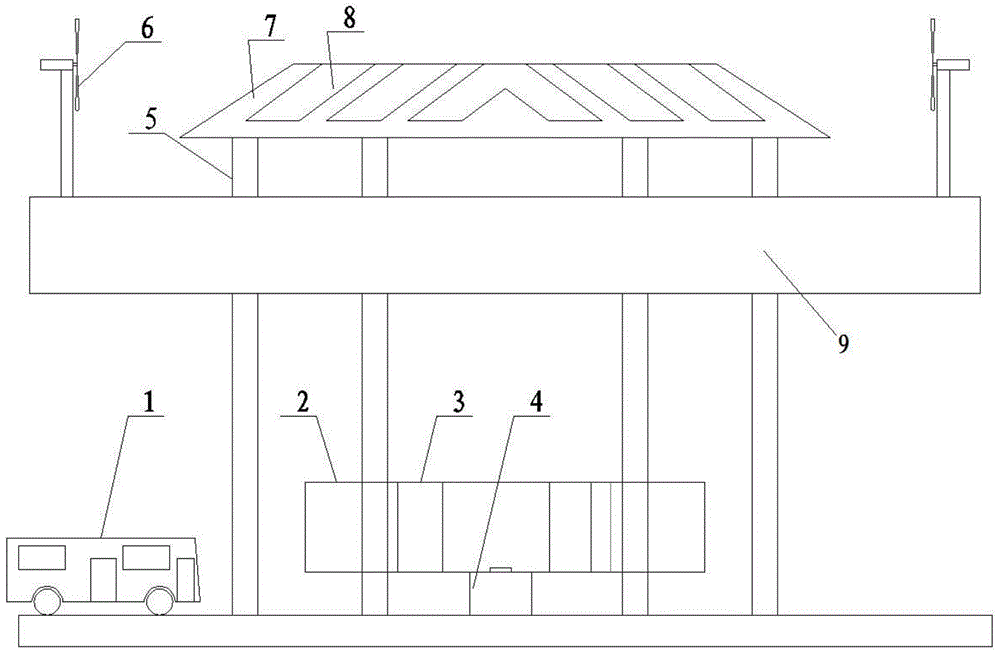

Electric passenger car charging station

InactiveCN105720624AGuaranteed Position AdjustmentHigh application valueBatteries circuit arrangementsElectric powerElectrical batteryCharging station

The invention discloses an electric passenger car charging station, and the charging station comprises a plurality of supporting columns. The tops of the supporting columns support a roof, and the roof is provided with a plurality of photovoltaic plates. The upper parts of the supporting columns are provided with an installation plate. One end of the installation plate is fixedly provided with a wind power generator. A rotating motor is disposed below the roof, and the output shaft of the rotating motor is connected with a battery charging cabin, wherein the interior of the battery charging cabin is provided with a cavity. The interior of the cavity of the battery charging cabin is provided with a charging power battery pack which is used for storing the electric quantity generated by the photovoltaic plates and the wind power generator. The charging power battery pack and a discharge power battery pack of an electric passenger car are alternately used for the charging of the electric passenger car. The roof is in a cone structure, and the supporting columns are respectively in a cylindrical structure. The installation plate is in a circular structure. The battery charging cabin is in a cylindrical structure. The charging station can quickly replace the power battery pack for the electric passenger car, is provided with a wind power generation source and a solar power generation source, saves energy, and is environment-friendly.

Owner:陕西银河网电科技有限公司

Dedusting pipeline support device

ActiveCN106015757AOvercoming top pressureAvoid damagePipe supportsDirt cleaningEngineeringMechanical engineering

Owner:江苏中康金属材料有限公司

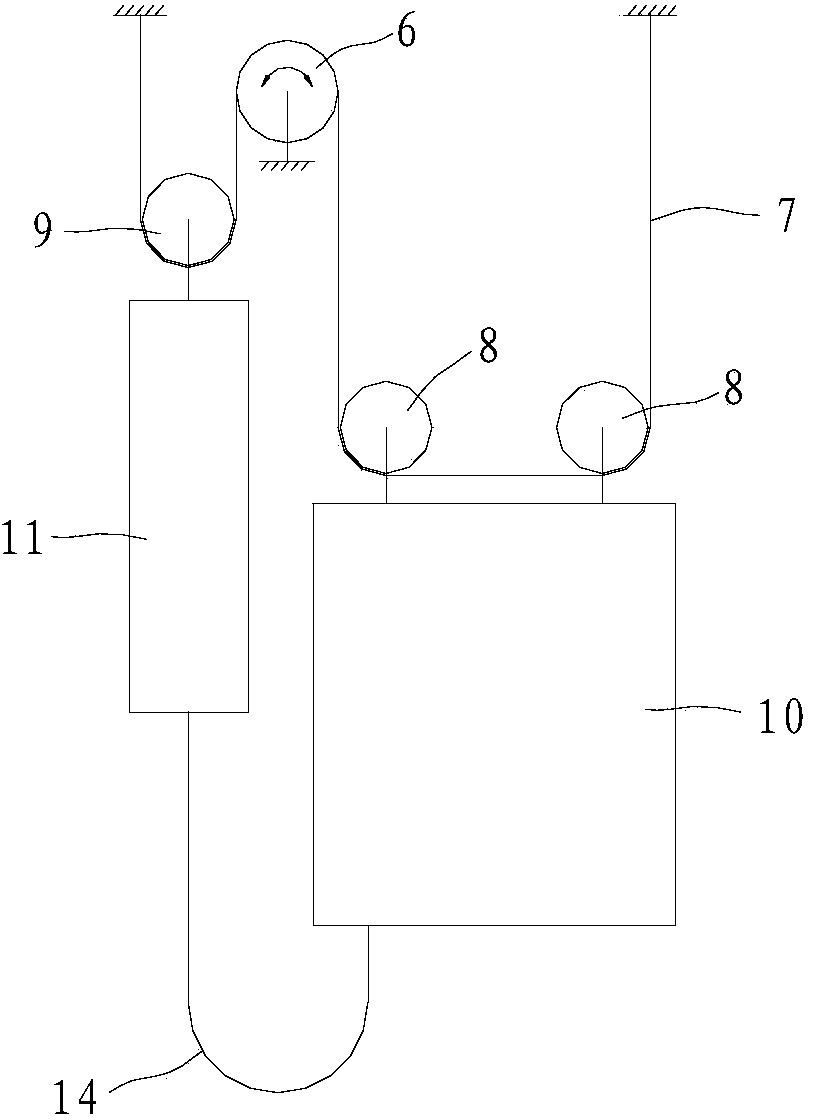

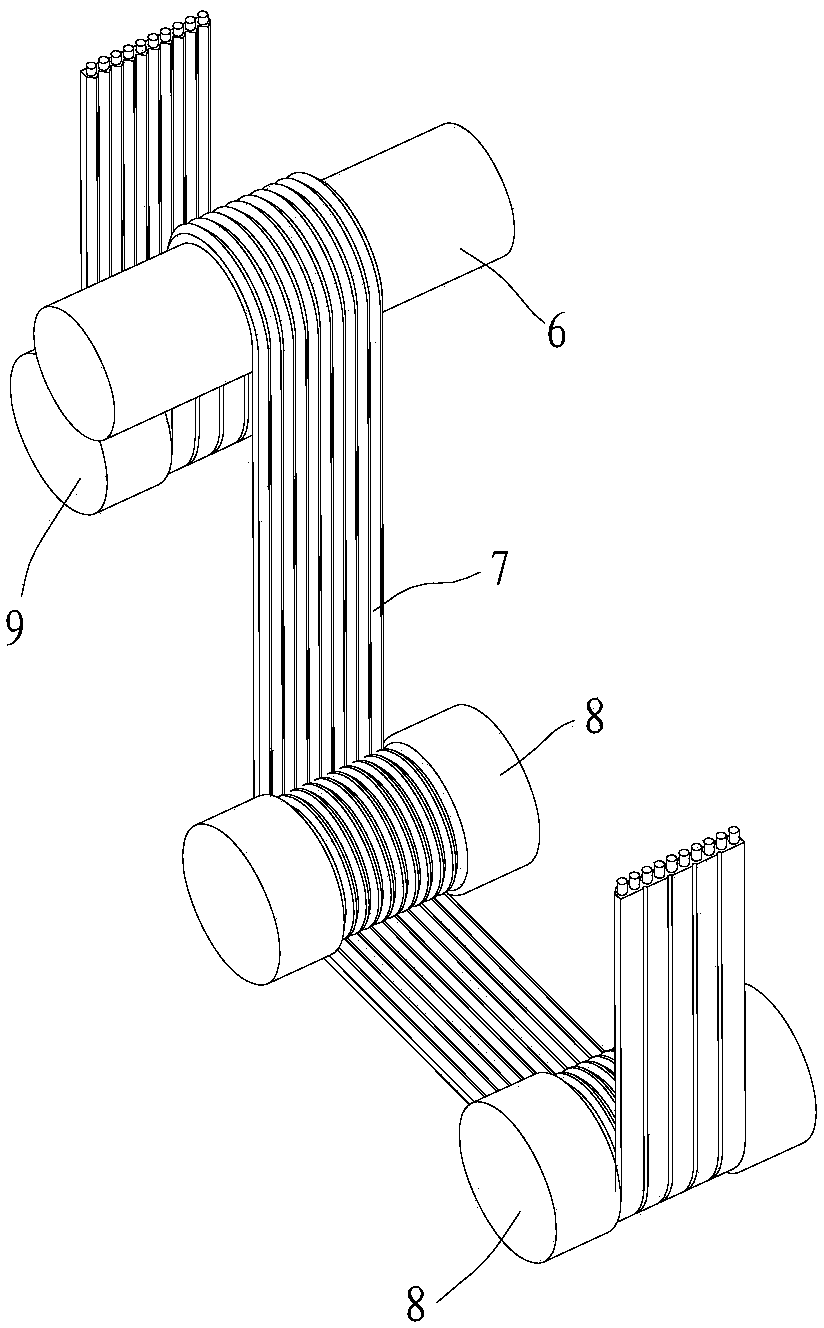

Elevator dragging and suspension system

ActiveCN104192674AEnough room to roamGuaranteed Position AdjustmentElevatorsElevator systemAutomotive engineering

The invention discloses an elevator dragging and suspension system. The elevator dragging and suspension system comprises a plurality of work wheels and a dragging and suspension rope wound on the work wheels. The work wheels comprise at least two classes, one class includes dragging wheels, and the other class includes guide wheels moving along with a lift car and a counterweight, and the dragging and suspension rope is matched with one class of work wheels in an axial limiting full-restraining mode, and matched with the other class of work wheels in an axial sliding free-restraining mode. The elevator dragging and suspension system is suitable for being used in various elevator systems with the winding ratio being 2:1 or 4:1. When an elevator operates, the dragging and suspension rope can swim and twist relative to the work surface of the guide wheels moving along with the lift car and the counterweight, abrasion of the dragging and suspension rope, caused by the dragging wheels and the guide wheels, is reduced, and the service life of the dragging and suspension rope is prolonged on the premise of safe and stable operation of the elevator.

Owner:HANGZHOU XO ELEVATOR

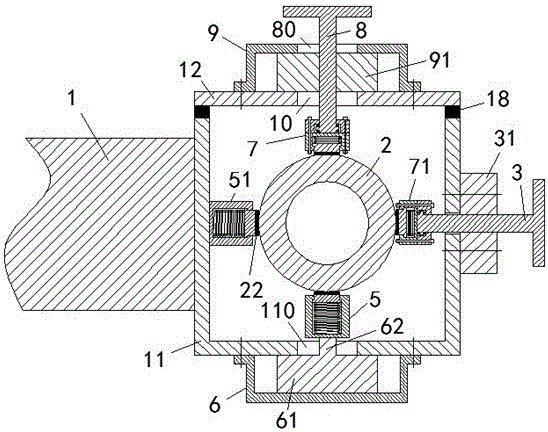

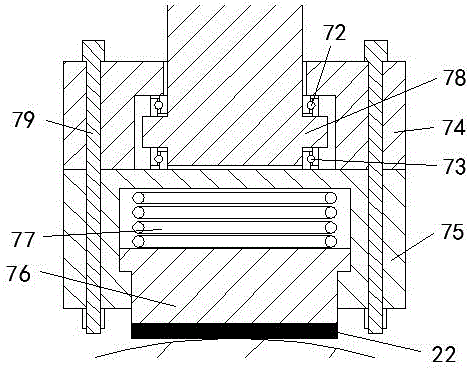

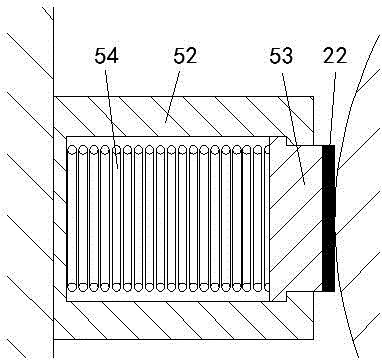

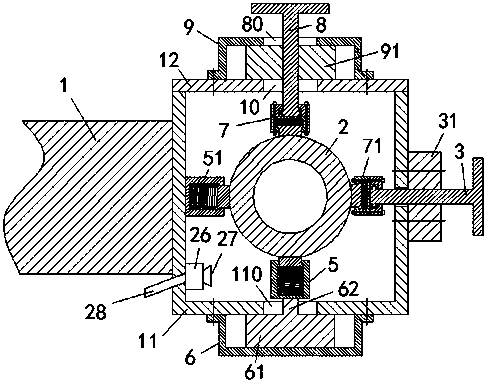

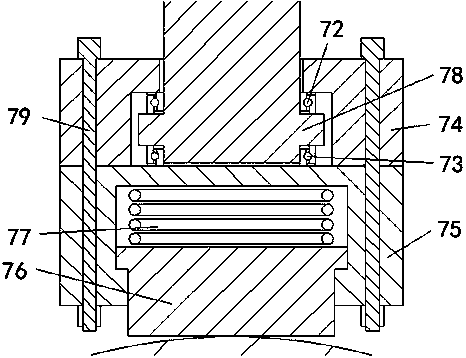

Bearing assembly for pipeline installation

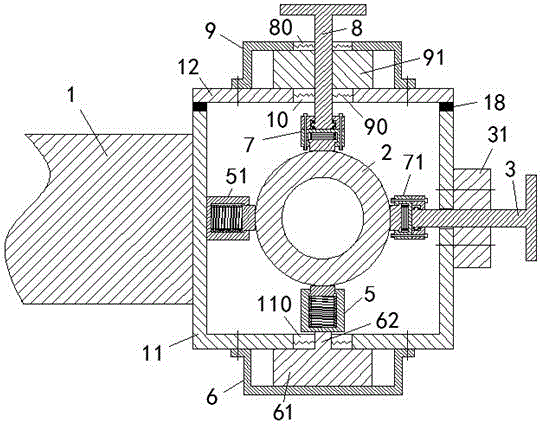

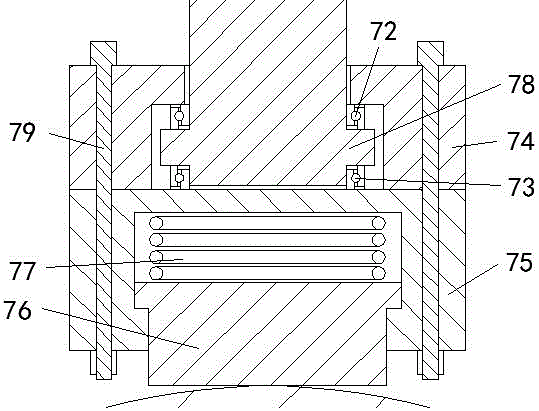

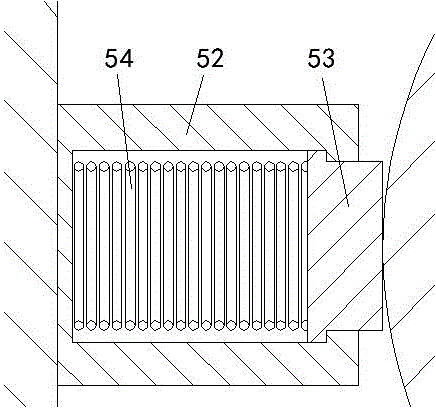

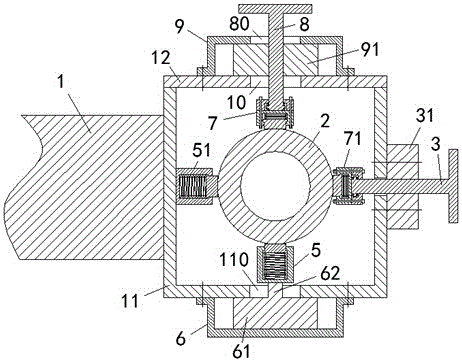

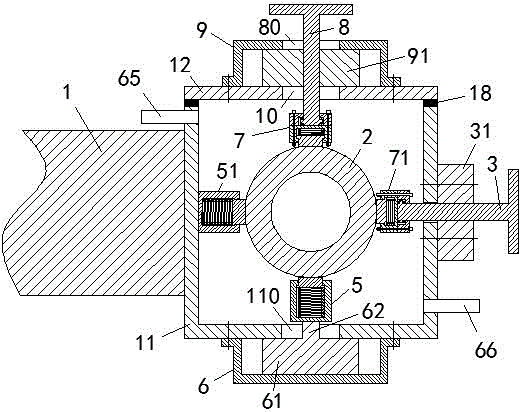

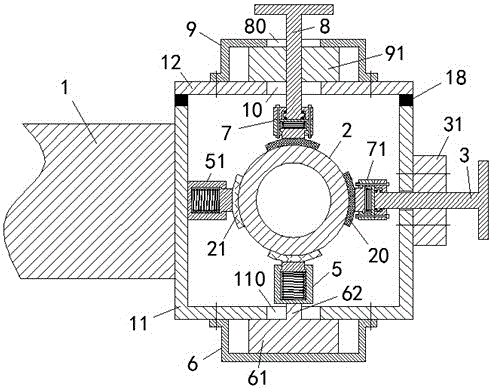

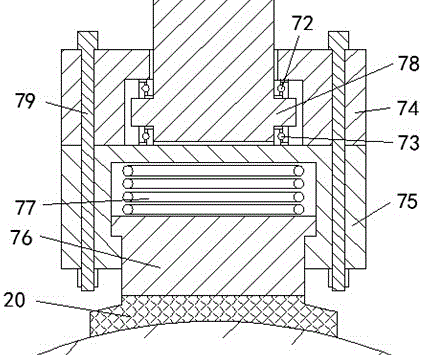

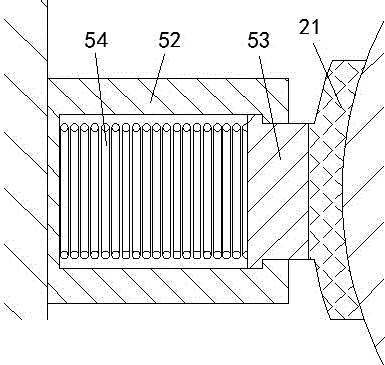

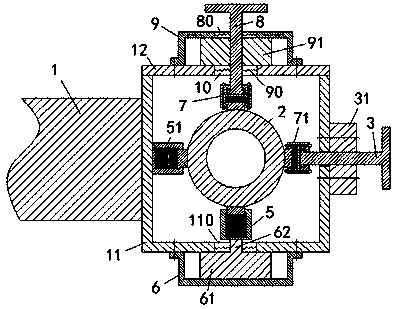

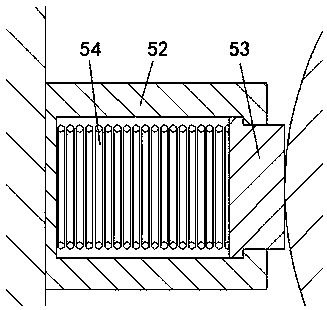

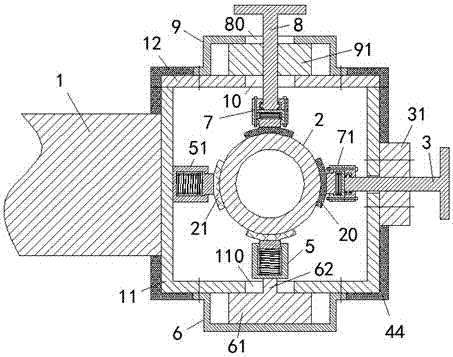

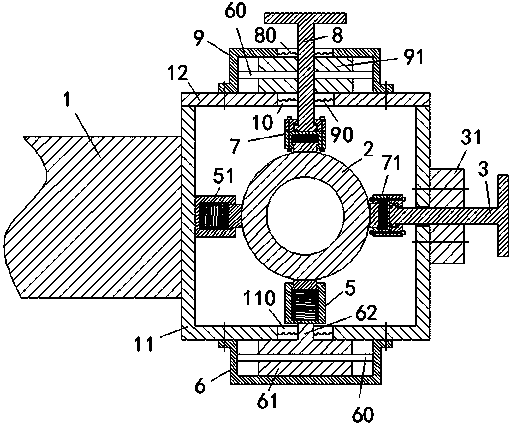

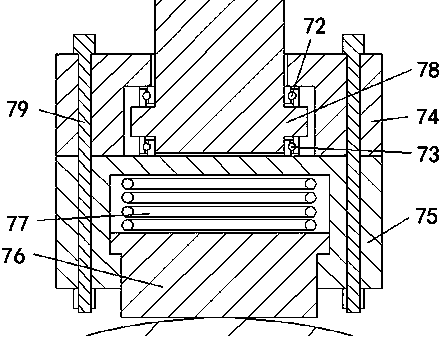

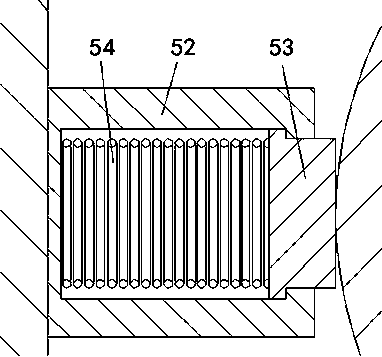

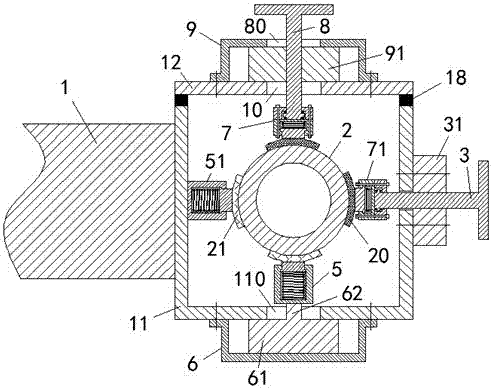

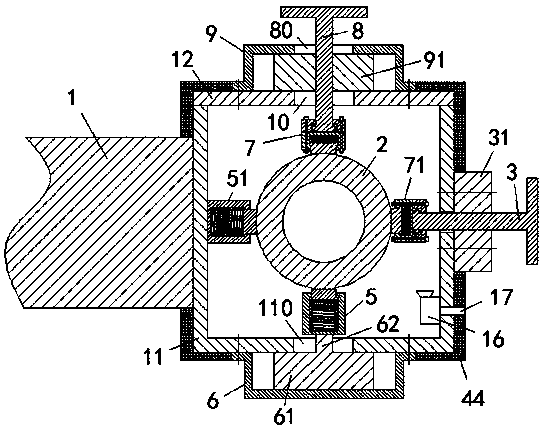

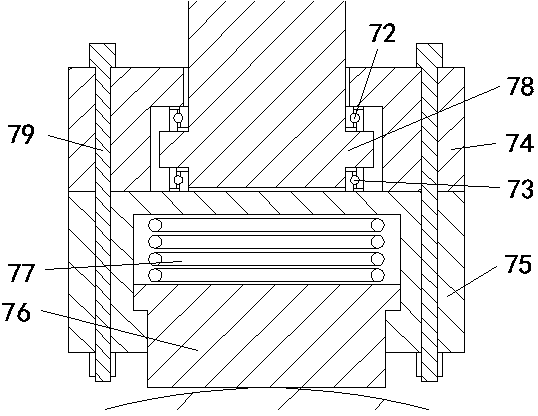

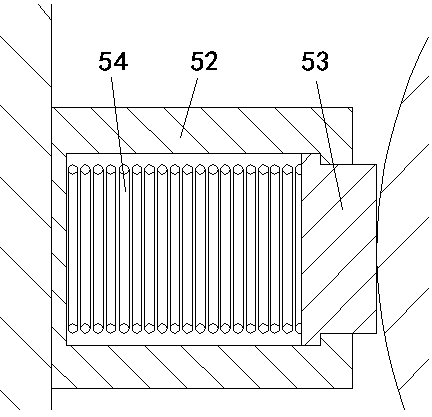

The invention discloses a bearing assembly for pipeline installation and a pipeline installation adjusting method using the assembly. The assembly comprises a fixed base frame (1), a box body (11) fixedly connected with the fixed base frame (1) and a box body cover (12) detachably and fixedly connected with the box body (11). The box body cover (12) covers the position of an opening in the upper side of the box body (11) so that a pipeline (2) can pass through the opening in the upper side during detachment. A sealing gasket (18) is fixed to the edge of the periphery of the position of the opening of the upper side of the box body (11) in a gluing manner. The sealing gasket (18) is used for being matched with the box body cover (12) so that a sealing effect can be generated between the box body (11) and the box body cover (12), and the sealing effect of the box body (11) and the box body cover (12) is better. The sealing gasket (18) is the rubber gasket made of a rubber material, and an upper sliding block clamping cover body (9) is fixedly arranged on the outer side of the box body cover (12).

Owner:何一鸣

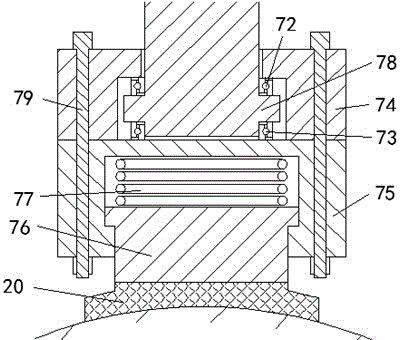

Safe industrial pipeline supporting device

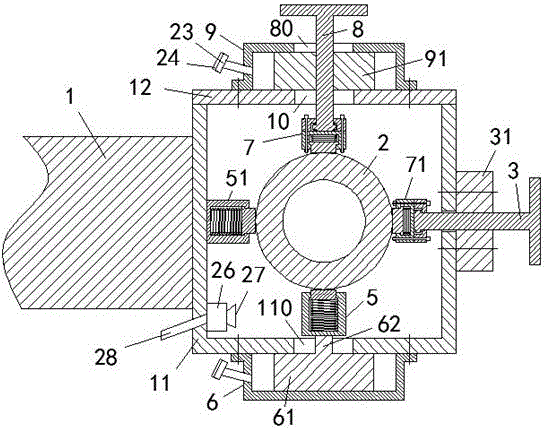

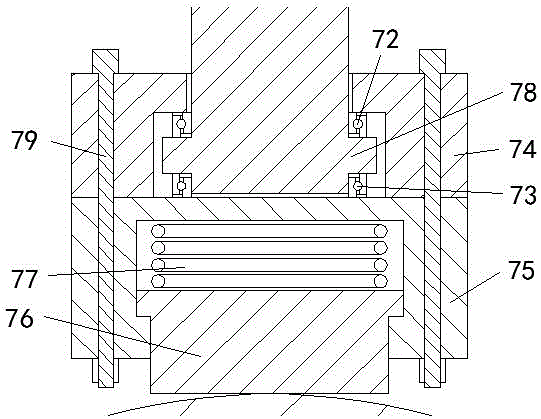

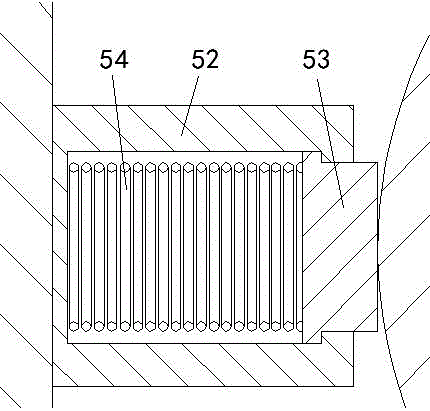

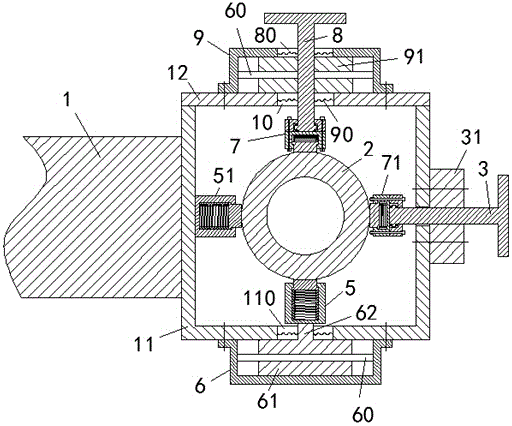

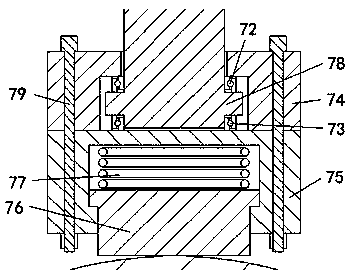

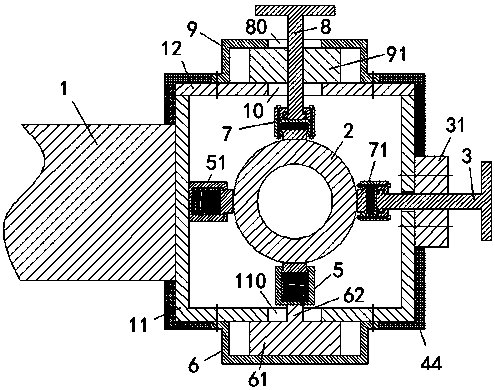

ActiveCN106078188AOvercoming top pressureAvoid damageMetal working apparatusPipe supportScrew thread

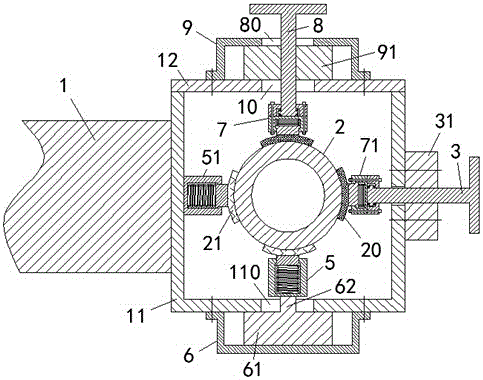

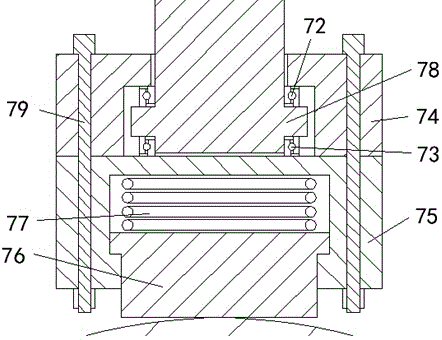

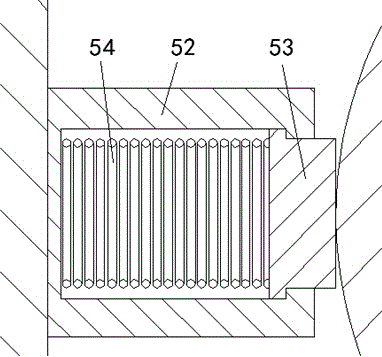

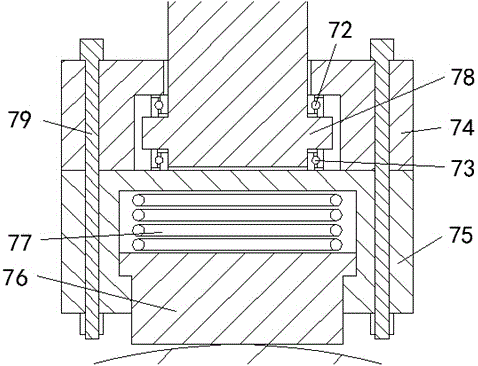

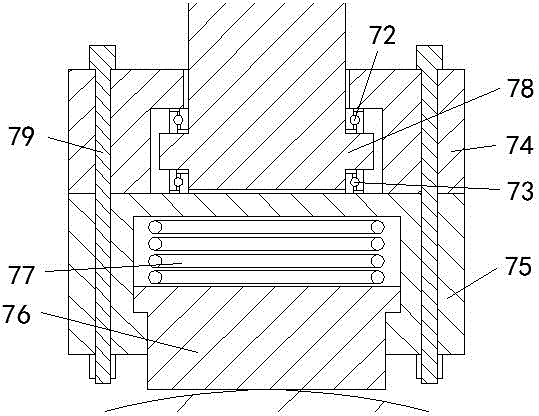

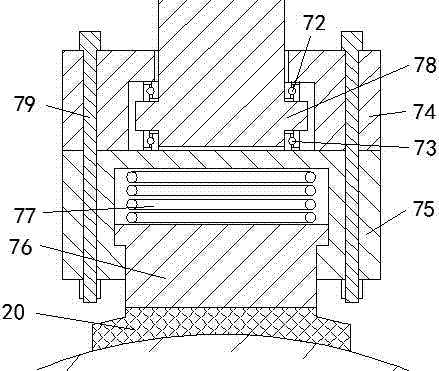

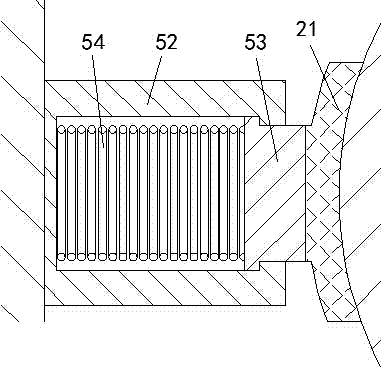

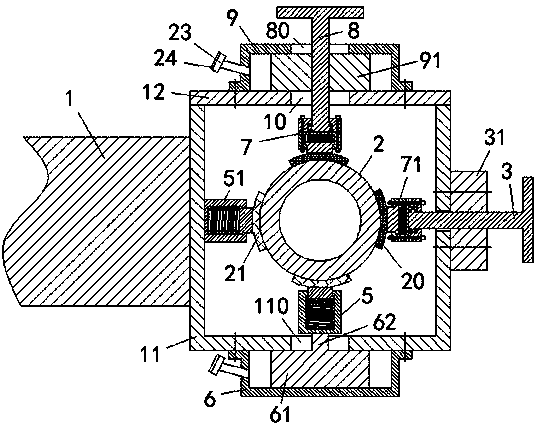

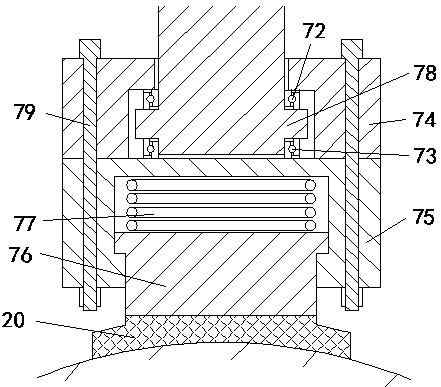

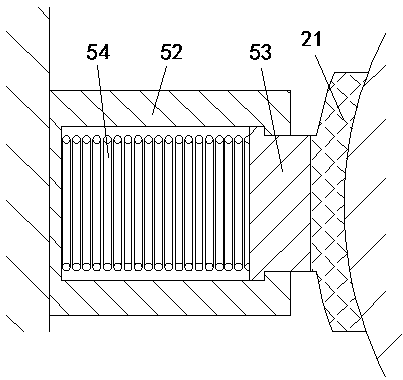

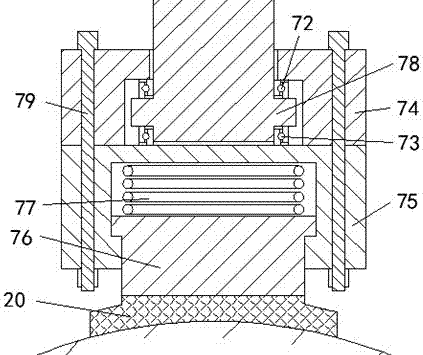

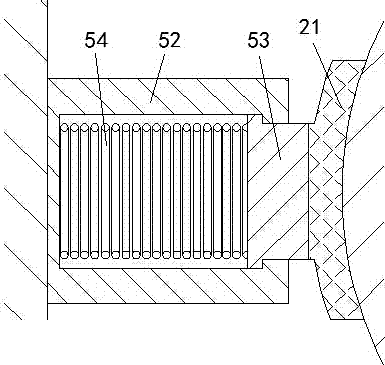

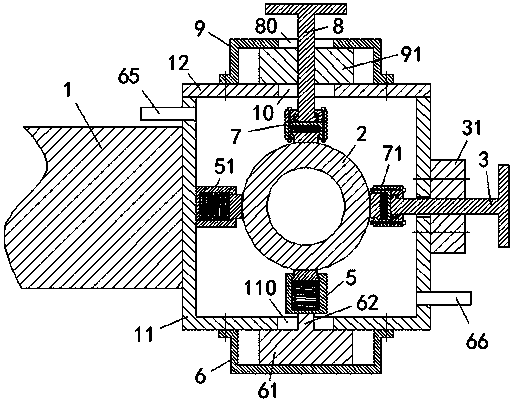

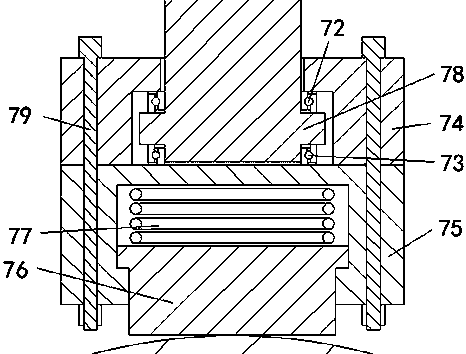

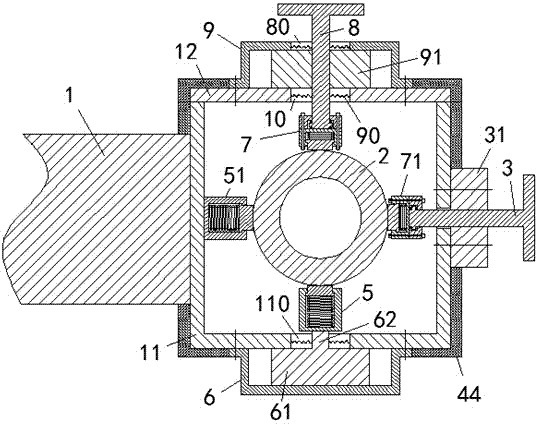

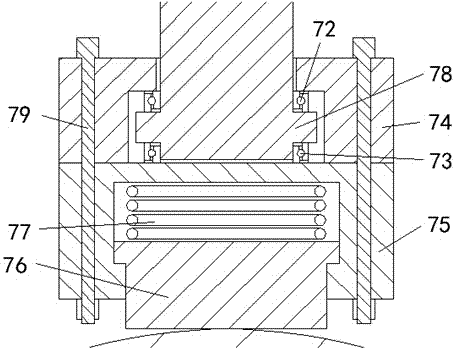

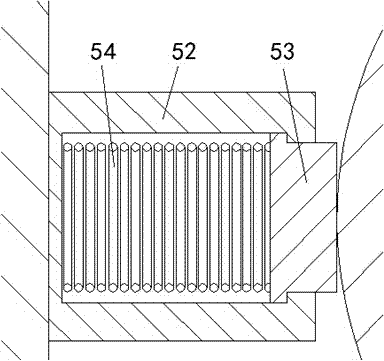

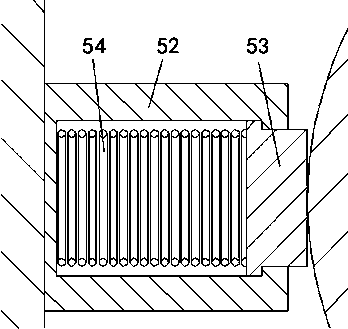

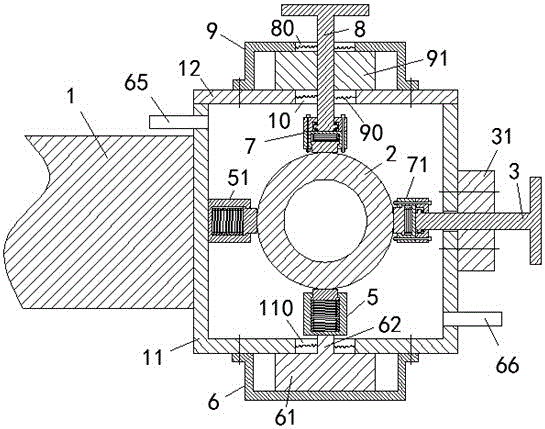

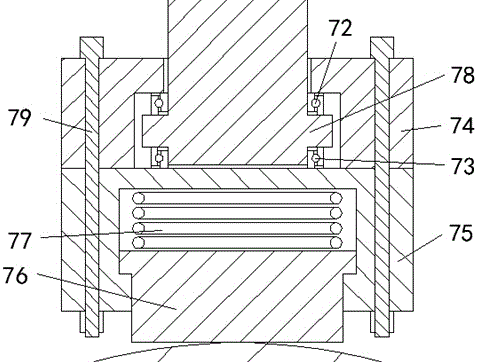

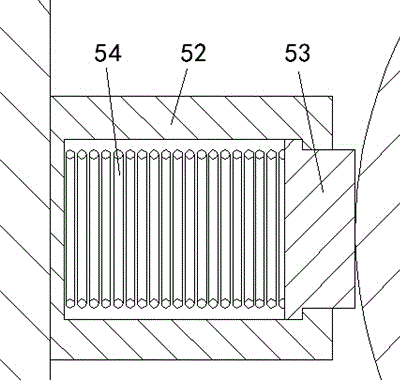

Provided are a safe industrial pipeline supporting device and a pipeline installation and adjustment method adopting the safe industrial pipeline supporting device. The safe industrial pipeline supporting device comprises a fixing base frame (1), a box (11) fixedly connected with the fixing base frame (1) and a box cover (12) detachably and fixedly connected with the box (11). The box cover (12) covers an upper opening of the box (11) so that when the box cover (12) is detached, a pipeline (2) can pass through the upper opening. An upper slide block clamping cover body (9) is fixedly arranged on the outer side of the box cover (12) and used for clamping an upper slide block (91) between the upper slide block clamping cover body (9) and the box cover (12) in a sliding manner. A threaded hole is formed in the upper slide block (91) and used for being in screw thread fit with a longitudinal axis operation threaded rod (8). The outer side of the longitudinal axis operation threaded rod (8) partially penetrates through the upper slide block clamping cover body (9), and the first adjustment overmeasure (80) exists between the two adjacent sides of the longitudinal axis operation threaded rod (8) and the upper slide block clamping cover body (9).

Owner:JIANGSU HUITONG PIPELINE EQUIP CO LTD

Bearing device used for pipeline

Owner:南京强思数字科技有限公司

Pipeline supporting device

The invention relates to a pipeline supporting device and a pipeline mounting adjusting method applying the pipeline supporting device. The pipeline supporting device comprises a fixed base frame (1), a box body (11) fixedly connected with the fixed base frame (1) and a box body cover (12) detachably and fixedly connected with the box body (11), wherein the box body cover (12) covers an opening in the upper side of the box body (11) so as to be passed through by a pipeline (2) during dismounting, an upper sliding block clamping cover body (9) is fixedly arranged outside the box body cover (12) and used for slidably clamping an upper sliding block (91) between the upper sliding block clamping cover body (9) and the box body cover (12), a screw hole is formed in the upper sliding block (91) and used for being in screw thread fit with a longitudinal axis operation screw (8), the outside part of the longitudinal axis operation screw (8) passes through the upper sliding block clamping cover body (9), and first adjustment allowance (80) is kept between two adjacent sides of the upper sliding block clamping cover body (9) and the longitudinal axis operation screw (8).

Owner:智管家(天津)科技有限公司

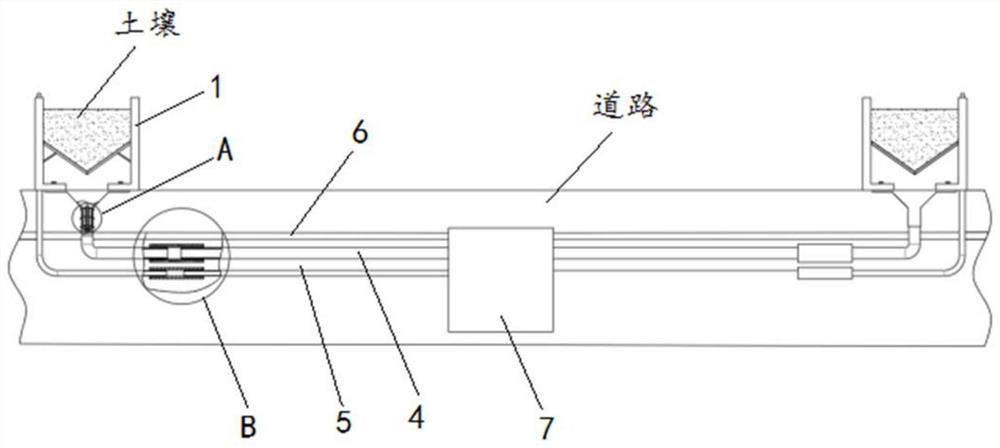

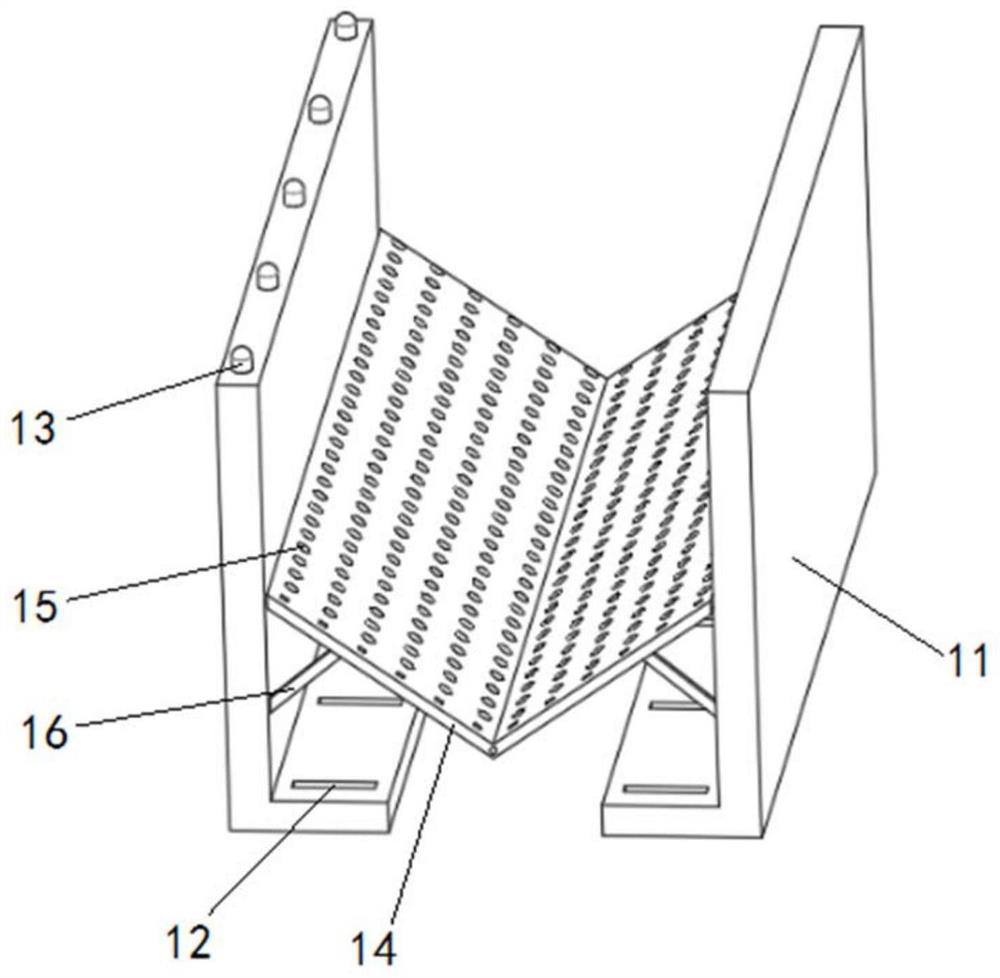

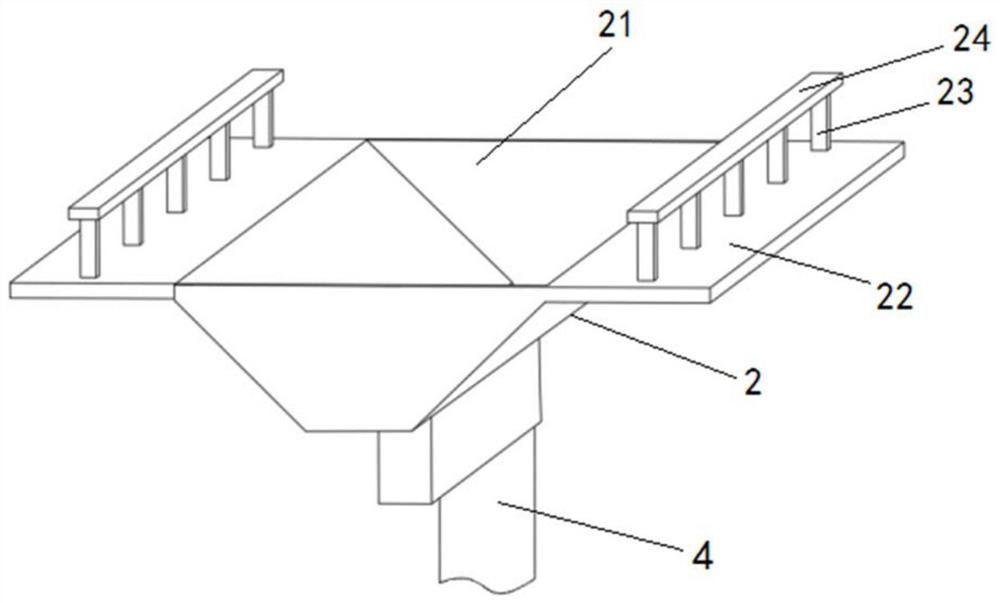

Greening isolation belt construction method based on constructional engineering

ActiveCN113261446AGuaranteed Position AdjustmentAvoid planting width adjustmentsSewerage structuresGeneral water supply conservationEnvironmental resource managementWater storage tank

The invention discloses a greening isolation belt construction method based on constructional engineering. The greening isolation belt construction method specifically comprises the following steps: installing a water storage tank, respectively installing isolation water collecting devices on two sides of a main road, connecting an isolation water collecting seat with a water inlet of the water storage tank by adopting a water collecting pipe, installing a filtering and impurity removing device at the upper end of the water collecting pipe, installing greening isolation side plates, one side of a water supply pipe communicates with a water spraying head through a water conveying pipeline on the greening isolation side plates, the other side of the water supply pipe communicates with a water outlet of the water storage tank, matching a width limiting supporting plate with an inserting hole in a filtering plate to fix the distance between the two greening isolation side plates, and filling the space between the two greening isolation plates with soil. The greening isolation belt construction method particularly relates to a greening isolation belt, through installation and structural design of a greening isolation device and the isolation water collection devices, rainwater in a greening belt is collected and filtered, the planting width of the greening isolation belt is adjusted, the adaptability of the greening isolation belt is improved, and the protection on the plants is improved.

Owner:广东韩江工程总承包有限公司

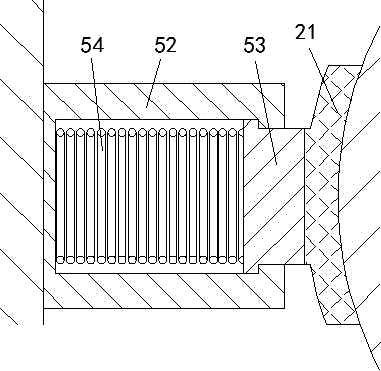

Support apparatus for bearing pipeline

InactiveCN105909876AOvercoming top pressureAvoid damagePipe supportsRubber materialMechanical engineering

The invention discloses a support apparatus for bearing a pipeline and a pipeline mounting and adjusting method using the apparatus. The apparatus comprises a fixing base frame (1), a box body (11) fixedly connected with the fixing base frame (1) and a box body cover (12) removably and fixedly connected with the box body (11); the box body cover (12) covers an upper side opening of the box body (11) so as to allow a pipeline (2) to go through the upper side opening during disassembly; a sealing washer (18) is glued and fixed at the peripheral edge of the upper side opening of the box body (11); the sealing washer (18) is used for cooperation with the box body cover (12), so as to produce sealing between the box body (11) and the box body cover (12), and enable the sealing effect between the box body (11) and the box body cover (12) to be better; the sealing washer (18) is a rubber washer made of a rubber material; and an upper slider clamping cover body (9) is fixedly arranged on the outer side of the box body cover (12).

Owner:何一鸣

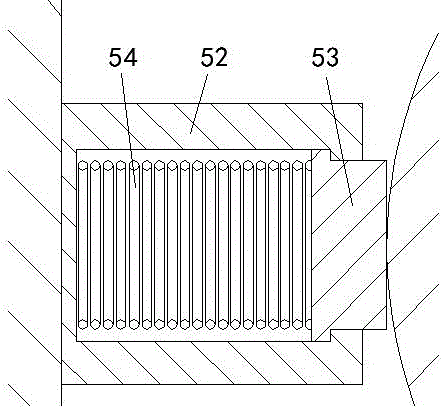

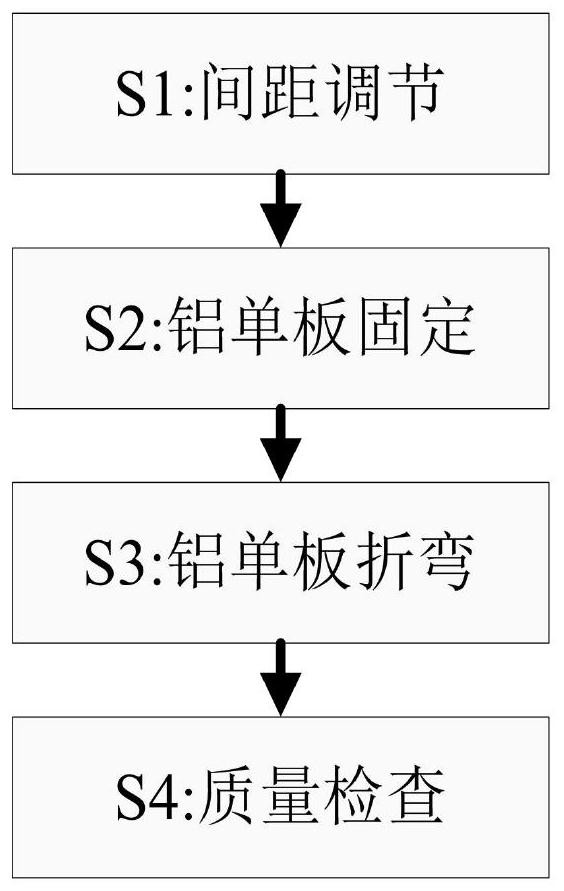

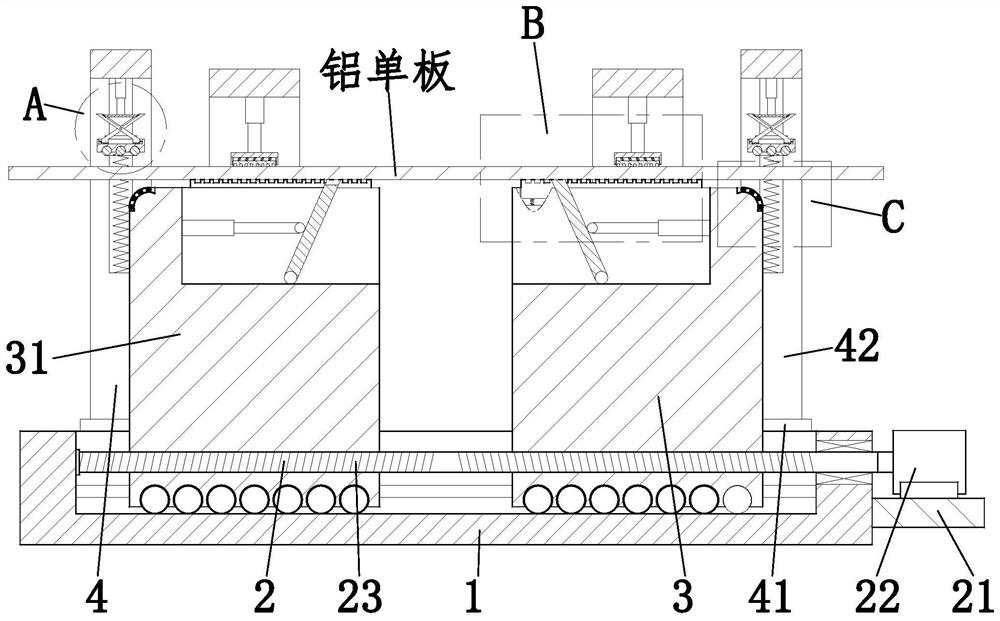

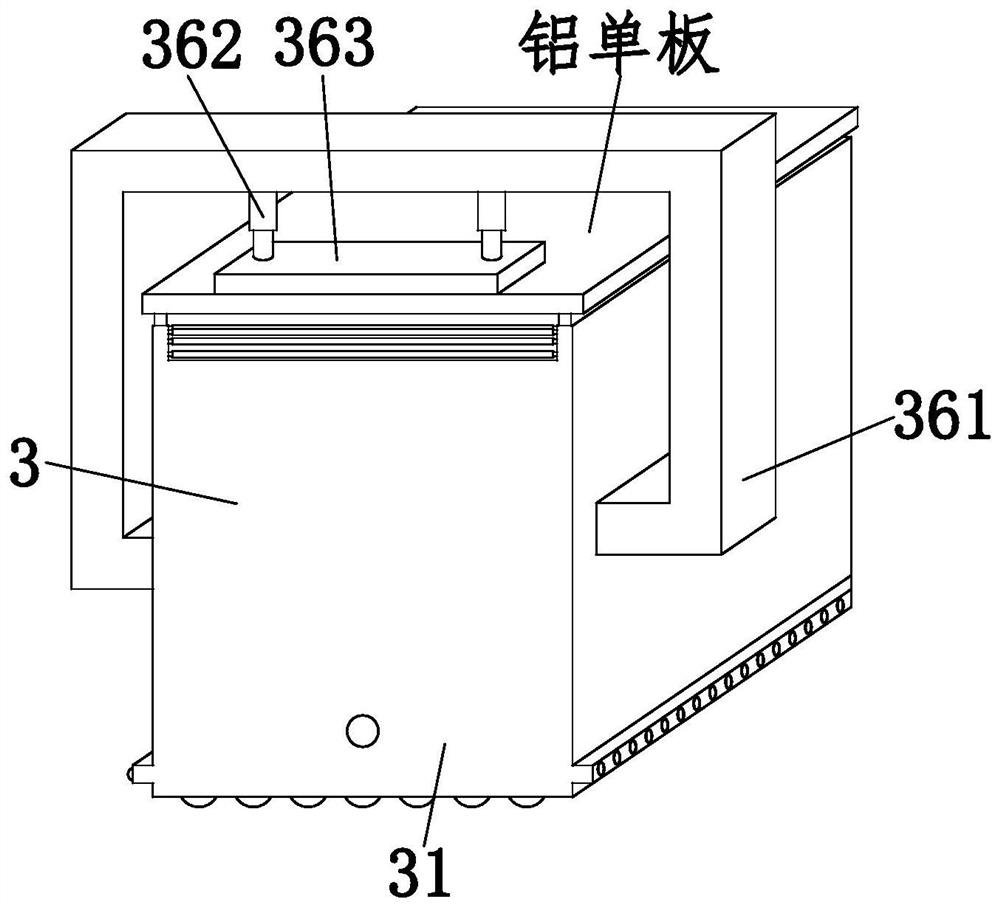

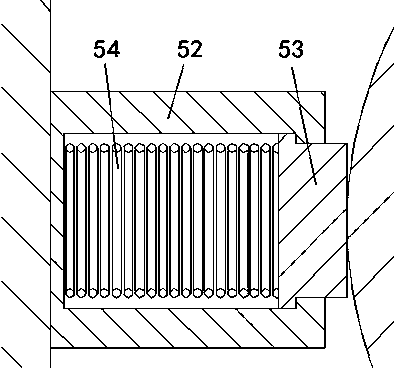

Curtain wall aluminum veneer machining method

ActiveCN112536345AConvenient bending workIncrease pressureMetal-working feeding devicesMetal working apparatusSingle plateMachining

The invention provides a curtain wall aluminum veneer machining method. According to the method, a bottom plate, an adjusting device, a fixing device and an executing device are matched to complete machining of a curtain wall aluminum veneer. The method can solve the following problems that in the existing curtain wall aluminum veneer fixing and bending process, due to the fact that fixing is unstable in the aluminum veneer bending process, the aluminum veneer is prone to shaking in the aluminum veneer bending process, and then the bending quality of the aluminum veneer is further influenced;and in the current aluminum veneer bending process, the bending quality of the bending position of the aluminum veneer is affected due to non-uniform force control, so that the bending position of thealuminum veneer is prone to breakage, cracks are generated and the like.

Owner:安徽银泰铝业有限公司

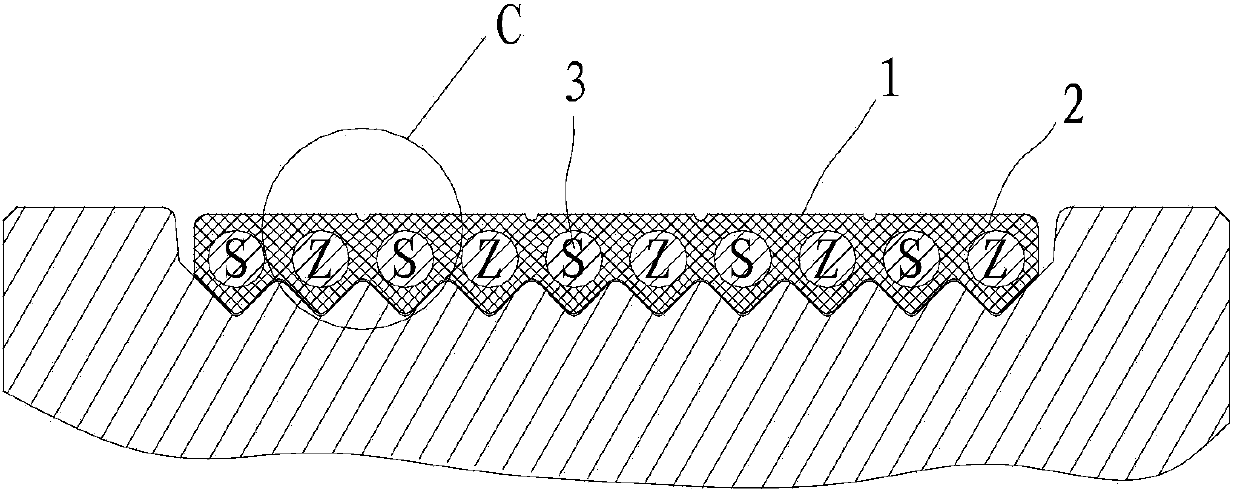

Hydrogen energy annular polar plate rolling and correcting equipment

The invention relates to the field of rolling and correcting equipment, and discloses hydrogen energy annular polar plate rolling and correcting equipment which comprises a supporting column, a workbench and a supporting frame. A pressing roller is arranged above the workbench, fixed rods are rotationally connected to the two sides of the interior of the pressing roller through bearings, a telescopic rod is arranged below the supporting frame, one side of the outer surface of the telescopic rod is welded to the corresponding sides of the outer surfaces of the fixed rods, a supporting plate is connected to the outer surfaces of the fixed rods in a clamped mode, a protruding block is welded to the lower surface of the supporting plate, and the telescopic length of one side of the telescopic rod is changed, so that the pressure applied to the outer surfaces of the fixed rods can be correspondingly changed, the pressure intensity of the pressing roller acting on polar plates can be adjusted to a certain degree, and the requirements of the pressure intensity of the polar plates of different specifications can be better met. According to the hydrogen energy annular polar plate rolling and correcting equipment, when the pressing roller moves downwards, the protruding block can be driven to move downwards, so that one side of the outer surface of the protruding block is tightly attached to the corresponding position of the upper surface of a pressure sensor.

Owner:安徽容众自动化设备有限公司

Sealed type pipeline supporting device

Provided are a sealed type pipeline supporting device and a pipeline installation and adjustment method adopting the sealed type pipeline supporting device. The sealed type pipeline supporting device comprises a fixing base frame (1), a box (11) fixedly connected with the fixing base frame (1) and a box cover (12) detachably and fixedly connected with the box (11). The box cover (12) covers an upper opening of the box (11) so that when the box cover (12) is detached, a pipeline (2) can pass through the upper opening. A seal gasket (18) is fixed to the peripheral edge of the upper opening of the box (11) in a gluing manner. The seal gasket (18) is used for being matched with the box cover (12), so that seal is generated between the box (11) and the box cover (12), and therefore the seal effect between the box (11) and the box cover (12) is better. The seal gasket (18) is a rubber gasket made of a rubber material. An upper slide block clamping cover body (9) is fixedly arranged on the outer side of the box cover (12).

Owner:何晓明

Pipe carrying equipment

The invention provides pipe carrying equipment and a pipe mounting adjusting method using the equipment. The equipment comprises a fixed base frame (1), a box (11) and a box cover (12), wherein the box (11) is fixedly connected with the fixed base frame (1); the box cover (12) is fixedly connected with the box (11) detachably and covers an opening of the upper side of the box (11) so that a pipe (2) passes through the opening of the upper side during disassembling; sealing washers (18) are fixed at the edges of the periphery of the opening of the upper side of the box (11) in a gluing manner and are matched with the box cover (12), so that the box (11) and the box cover (12) are sealed, and the sealing effect of the box (11) and the box cover (12) is good; the sealing washers (18) are rubber washers made of a rubber material; and an upper sliding block clamping cover (9) is fixedly arranged on the outer side of the box cover (12).

Owner:JIANGSHAN HAIWEI TECH

A dust-proof pipeline support device

Owner:南京市燃气工程设计院有限公司

A durable pipe support device

Owner:泰兴市东城水处理工程有限公司

A support device for pipes

The invention provides a pipeline supporting device and a pipeline installation and adjustment method using the pipeline supporting device. The pipeline supporting device comprises a fixed bed frame (1), a box (11) fixedly connected with the fixed bed frame (1) and a box cover (12) detachably and fixedly connected with the box (11). The box cover (12) covers an upper opening of the box (11), and the upper opening allows a pipeline (2) to pass through during dismantling. An upper sliding block clamping cover body (9) is fixedly arranged on the outer side of the box cover (12), and an upper sliding block (91) is slidably clamped between the upper sliding block clamping cover body (9) and the box cover (12). A screw hole is formed in the upper sliding block (91) and used for being in screw-thread fit with a vertical axis operation screw rod (8). The outer side part of the vertical axis operation screw rod (8) penetrates through the upper sliding block clamping cover body (9), and first adjustment margins (80) are formed between the vertical axis operation screw rod (8) and the two sides, adjacent to the vertical axis operation screw rod (8), of the upper sliding block clamping cover body (9).

Owner:广东赛福智能装备有限公司

A bearing device for pipelines and a pipeline installation and adjustment method using the same

Owner:南京强思数字科技有限公司

Bearing equipment for pipelines and pipeline installation and adjustment method using the equipment

ActiveCN105937657BOvercoming top pressureAvoid damagePipe supportsRubber materialMechanical engineering

The invention provides pipe carrying equipment and a pipe mounting adjusting method using the equipment. The equipment comprises a fixed base frame (1), a box (11) and a box cover (12), wherein the box (11) is fixedly connected with the fixed base frame (1); the box cover (12) is fixedly connected with the box (11) detachably and covers an opening of the upper side of the box (11) so that a pipe (2) passes through the opening of the upper side during disassembling; sealing washers (18) are fixed at the edges of the periphery of the opening of the upper side of the box (11) in a gluing manner and are matched with the box cover (12), so that the box (11) and the box cover (12) are sealed, and the sealing effect of the box (11) and the box cover (12) is good; the sealing washers (18) are rubber washers made of a rubber material; and an upper sliding block clamping cover (9) is fixedly arranged on the outer side of the box cover (12).

Owner:JIANGSHAN HAIWEI TECH

Pipe support device and pipe installation and adjustment method for maintaining internal air circulation

Owner:山东天安健生物制品有限公司

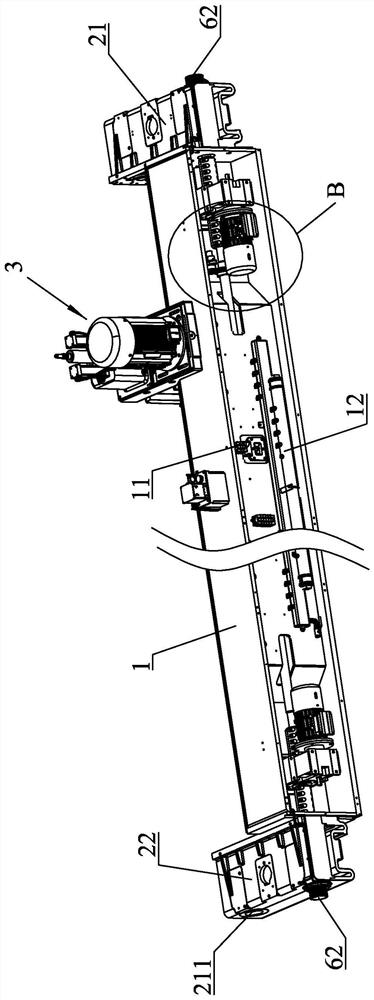

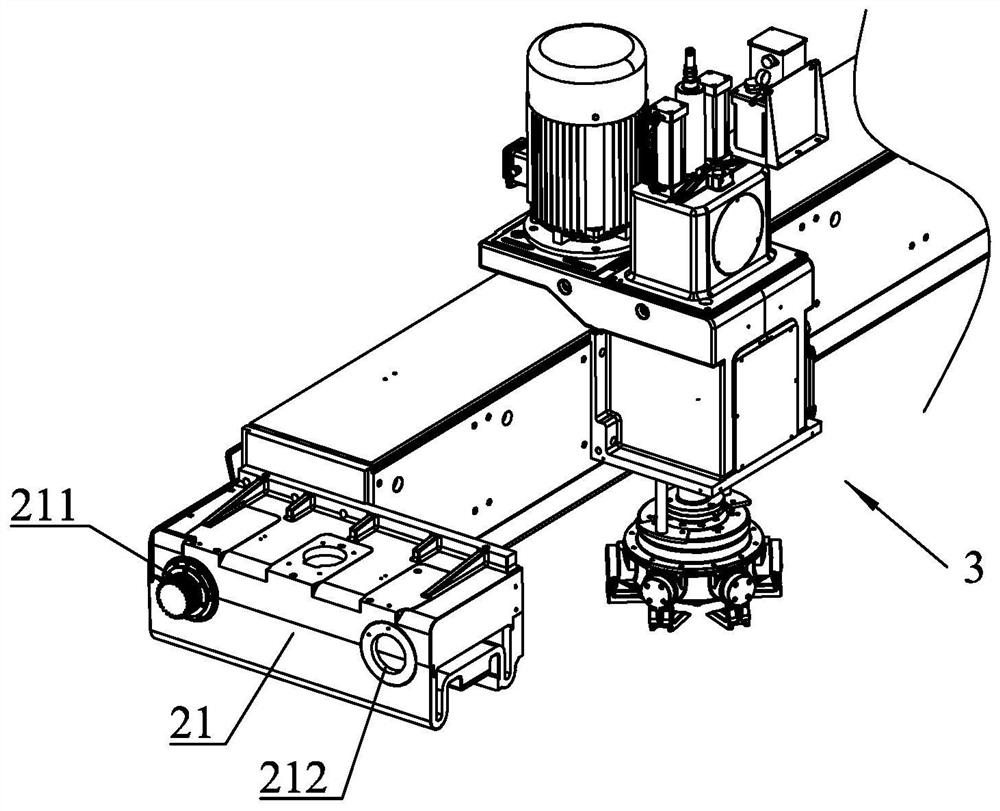

A pendulum beam structure for grinding and polishing equipment

ActiveCN112247755BReduce shakingEasy to GrindGrinding carriagesPolishing machinesPolishingEngineering

The invention discloses a swing beam structure of grinding and polishing equipment, which comprises a main beam, a first moving seat and a second moving seat respectively connected to two ends of the main beam; at least one grinding host is installed on the main beam; the The first mobile seat is slidably arranged on the first support seat, and the second mobile seat is slidably arranged on the second support seat; the first mobile seat and / or the second mobile seat are provided with an adjustment mechanism; and the existing Compared with technology, the present invention avoids the swaying of the main beam along the length direction due to external force by arranging the abutting wheel and the abutting guide rail to abut against and cooperate, thereby improving the overall stability and improving the grinding effect.

Owner:QUANZHOU HAIENDE ELECTROMECHANICAL TECH DEV

Front fulcrum hanging basket reverse preloading device

ActiveCN105714688BAchieve cooperationGuaranteed accuracyBridge erection/assemblyCable stayedJackscrew

The invention discloses a reverse prepressing device for a front-support movable suspended scaffolding. The device comprises reverse hydraulic jack adjustment systems mounted on two bridges, wherein a precast beam is initially erected through a hoisting stander; the front-support movable suspended scaffolding is arranged on a web plate and a top plate of the precast beam; a first reverse prepressing device is used for adjusting a deviation of the precast beam along the vertical direction; the second reverse prepressing device is used for adjusting a deviation of the precast beam along the horizontal direction. According to the reverse prepressing device for the front-support movable suspended scaffolding, two reverse prepressing jack devices are provided; due to independent matching of two jacks, the deviations of the precast beams in the horizontal direction and the longitudinal direction can be adjusted, to realize matching between the precast beam and a cable-stayed bridge, and the construction precision is guaranteed. The second reverse prepressing device is fastened by a spherical pair, so that relative positions of the second reverse prepressing device and a flange of the precast beam can be adjusted, and the position adjustment in the horizontal direction is guaranteed. By the adoption of reverse prepressing, the precast beam and an adjustment mechanism can be connected more tightly, and the whole precast beam can be adjusted more flexibly and conveniently.

Owner:中交中南工程局有限公司

Pipeline support equipment and pipeline installation and adjustment method using the equipment

Owner:JIANGSHAN HAIWEI TECH

A support device for pipeline installation

Owner:珠海市金德通讯设备有限公司

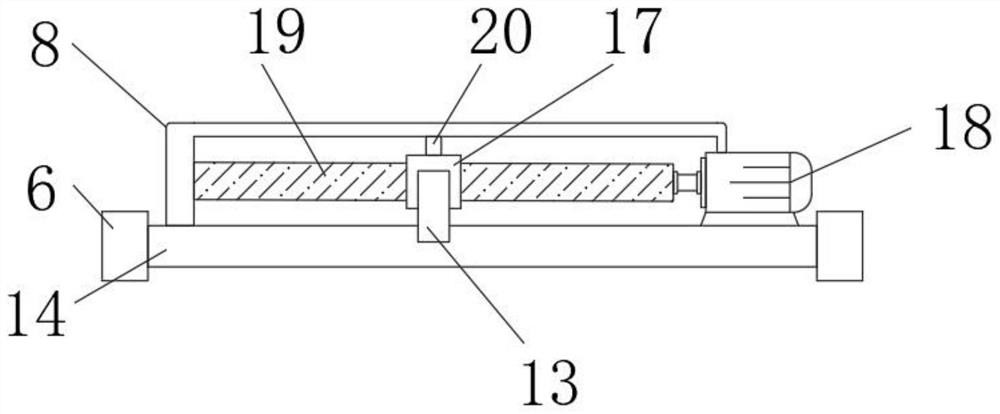

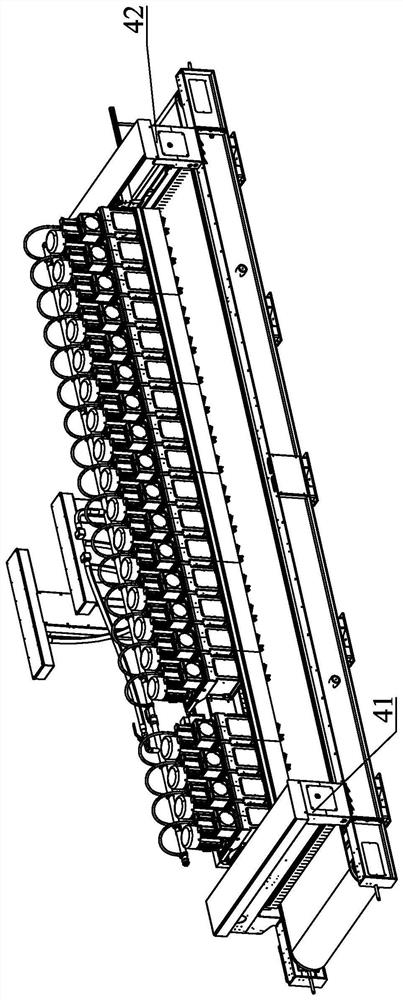

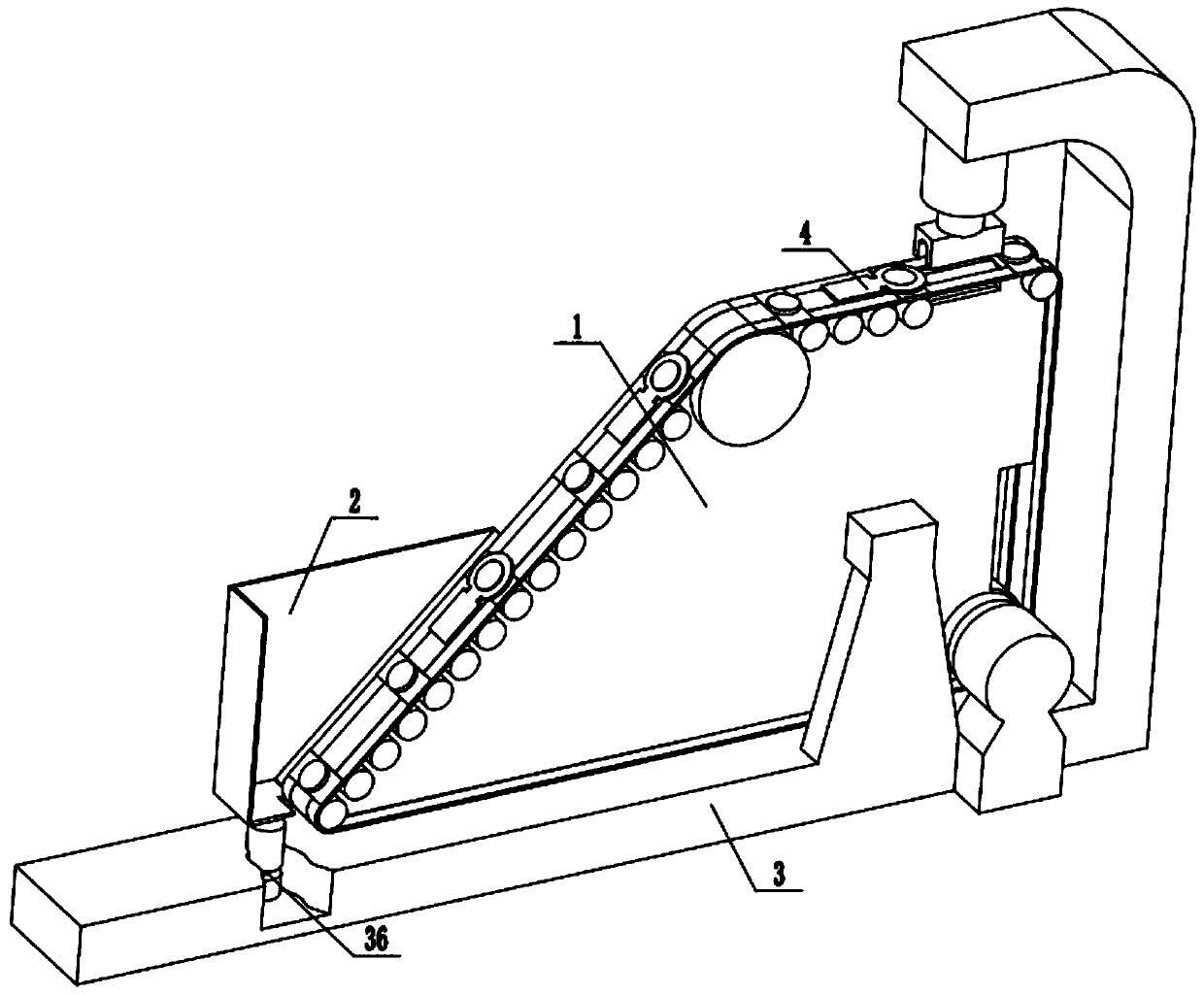

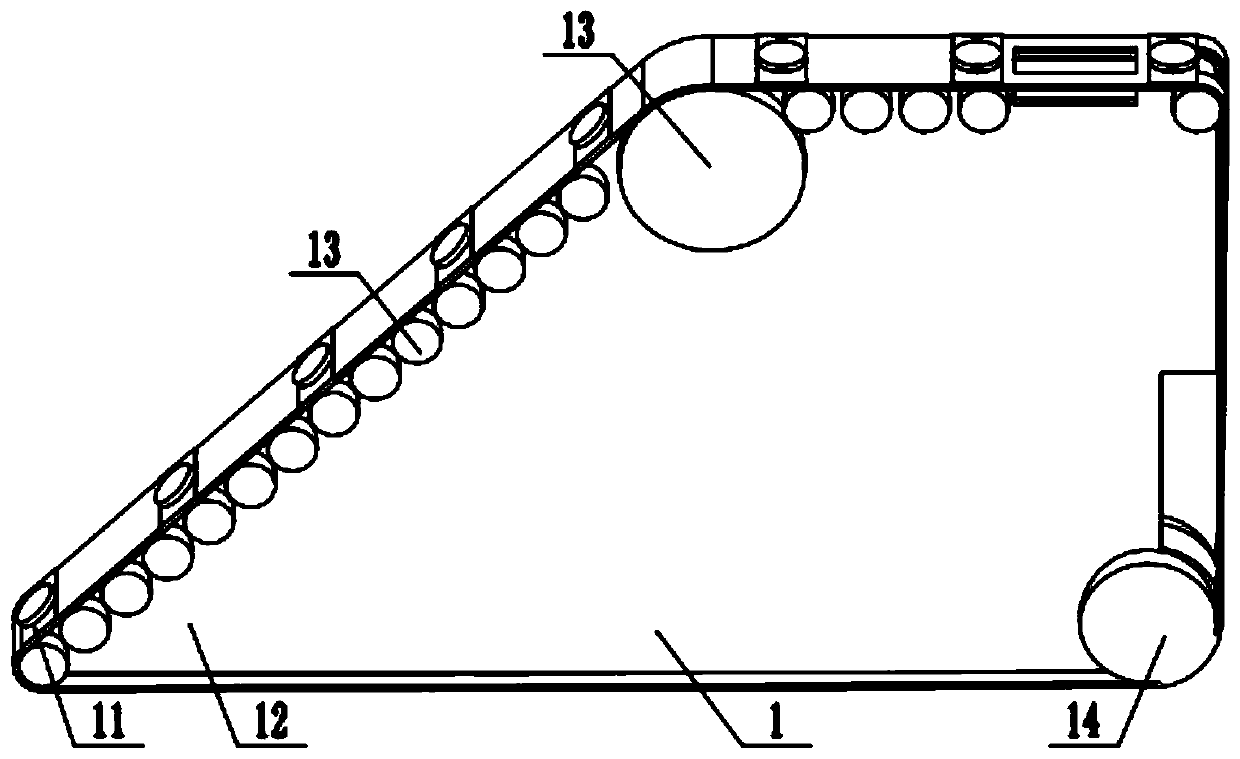

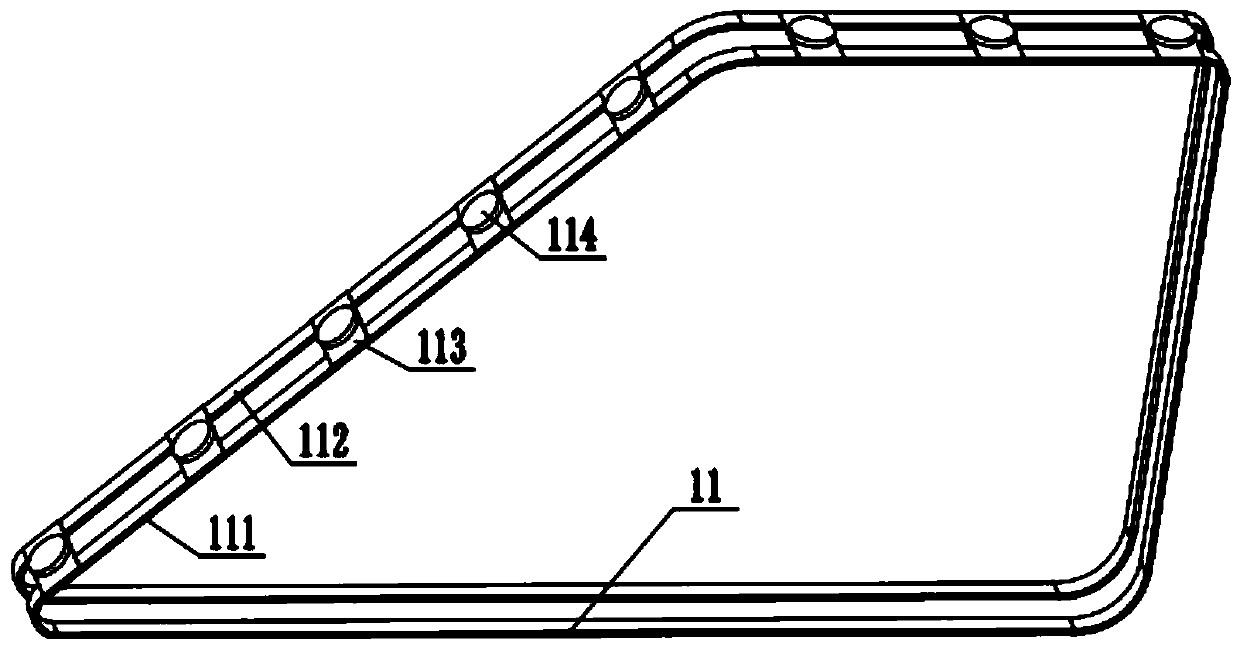

A wire crimping piece bending machine

ActiveCN108906951BRealize automatic stampingGuaranteed Position AdjustmentShaping toolsMetal-working feeding devicesJoint componentEngineering

The invention discloses a conducting wire compression joint component bending machine which comprises a conveying mechanism and the like. The conveying mechanism is fixed onto a support by the aid ofa fixing frame, a hopper is mounted on the support via a vibrator, the conveying mechanism comprises a conveyor belt and a support component, the support component comprises a support plate, roll shaft holes are formed in a middle line edge and a top line edge of the support plate, support rolls are arranged on the support plate via the roll shaft holes, the axes of the support rolls are perpendicular to planes of the support plate, the support rolls are arranged on two sides of the support plate, a driving friction wheel is arranged at an edge of the support plate, and the conveyor belt is arranged on the support component and can be tensioned by the support rolls and the driving friction wheel; a motor is arranged on the support and is connected with the driving friction wheel in a driving manner. The conducting wire compression joint component bending machine has the advantages that the problems of inconvenience in manual operation and long time consumption due to large quantities of small components can be solved by the aid of the conducting wire compression joint component bending machine; the conducting wire compression joint component bending machine is provided with automatic feeding, automatic loading and automatic stamping devices, accordingly, manual intervention can be omitted, and conducting wire compression joint components only need to be placed in the hopper andcan be automatically stamped by the conducting wire compression joint component bending machine.

Owner:ZHANGQIU POWER SUPPLY CO OF STATE GRID SHANDONG ELECTRIC POWER CO +1

A dust-removable pipeline support device and pipeline installation and adjustment method

ActiveCN106015757BOvercoming top pressureAvoid damagePipe supportsDirt cleaningEngineeringScrew thread

Owner:江苏中康金属材料有限公司

Bearing assembly for pipeline

ActiveCN105927793AOvercoming top pressureAvoid damagePipe supportsFlexible pipesMechanical engineeringMental detachment

The invention discloses a bearing assembly for a pipeline and a pipeline installation adjusting method using the assembly. The assembly comprises a fixed base frame (1), a box body (11) fixedly connected with the fixed base frame (1) and a box body cover (12) detachably and fixedly connected with the box body (11). The box body cover (12) covers the position of an opening in the upper side of the box body (11) so that a pipeline (2) can pass through the opening in the upper side during detachment. An upper sliding block clamping cover body (9) is fixedly arranged on the outer side of the box body cover (12) so that an upper sliding block (91) can be clamped between the upper sliding block clamping cover body (9) and the box body cover (12) in a sliding manner. A threaded hole is formed in the upper sliding block (91) and is used for being in threaded fit with a longitudinal shaft operation screw rod (8). The outer side portion of the longitudinal shaft operation screw rod (8) penetrates the upper sliding block clamping cover body (9), and a first adjustment allowance (80) is arranged between the two adjacent sides of the upper sliding block clamping cover body (9).

Owner:盐城市圣泰机械有限公司

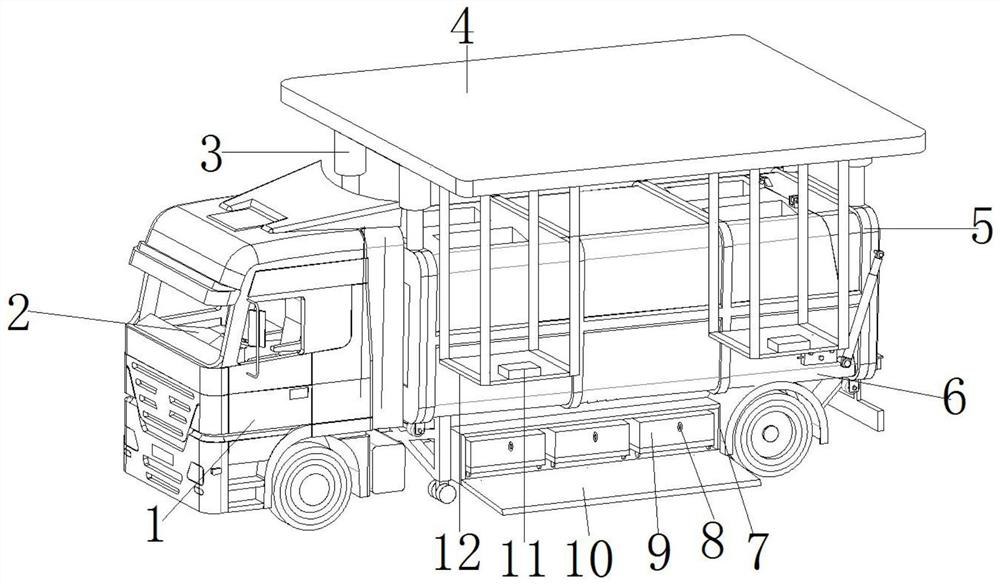

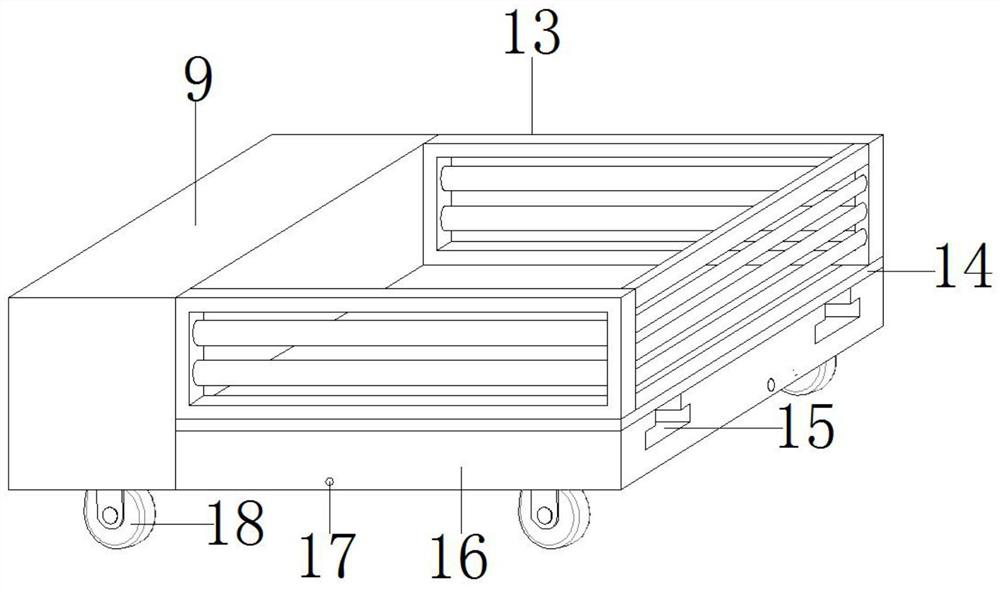

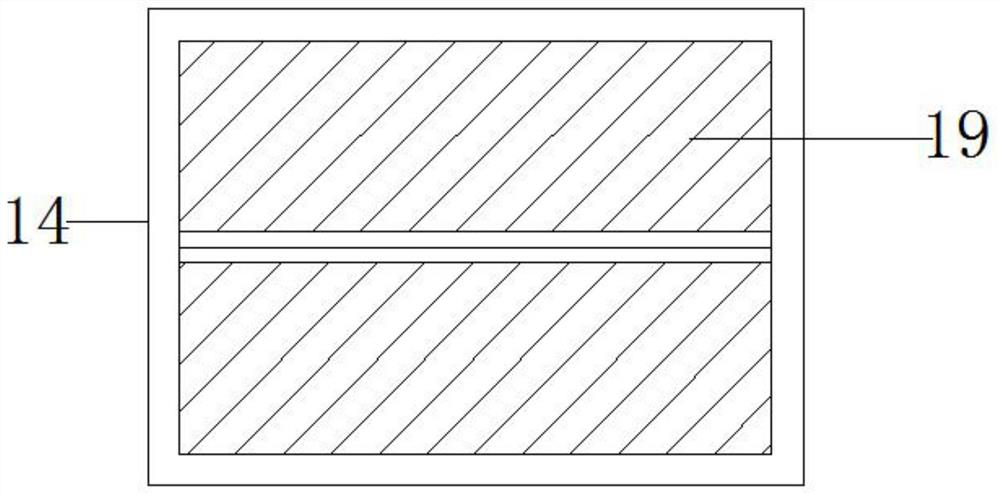

A door-to-door recycling vehicle for garbage sorting

Owner:供销环境科技有限公司

A pipeline support device with protective function

Owner:衡水汇能路桥工程材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com