Inspection platform used in production process of EPS (Electrical Power Steering) controller and working method of inspection platform

A production process and controller technology, which is applied in the parts, instruments, and measuring electricity of electrical measuring instruments to reduce the probability of false detection, improve production efficiency, and reduce process steps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0040] Working process of the present invention:

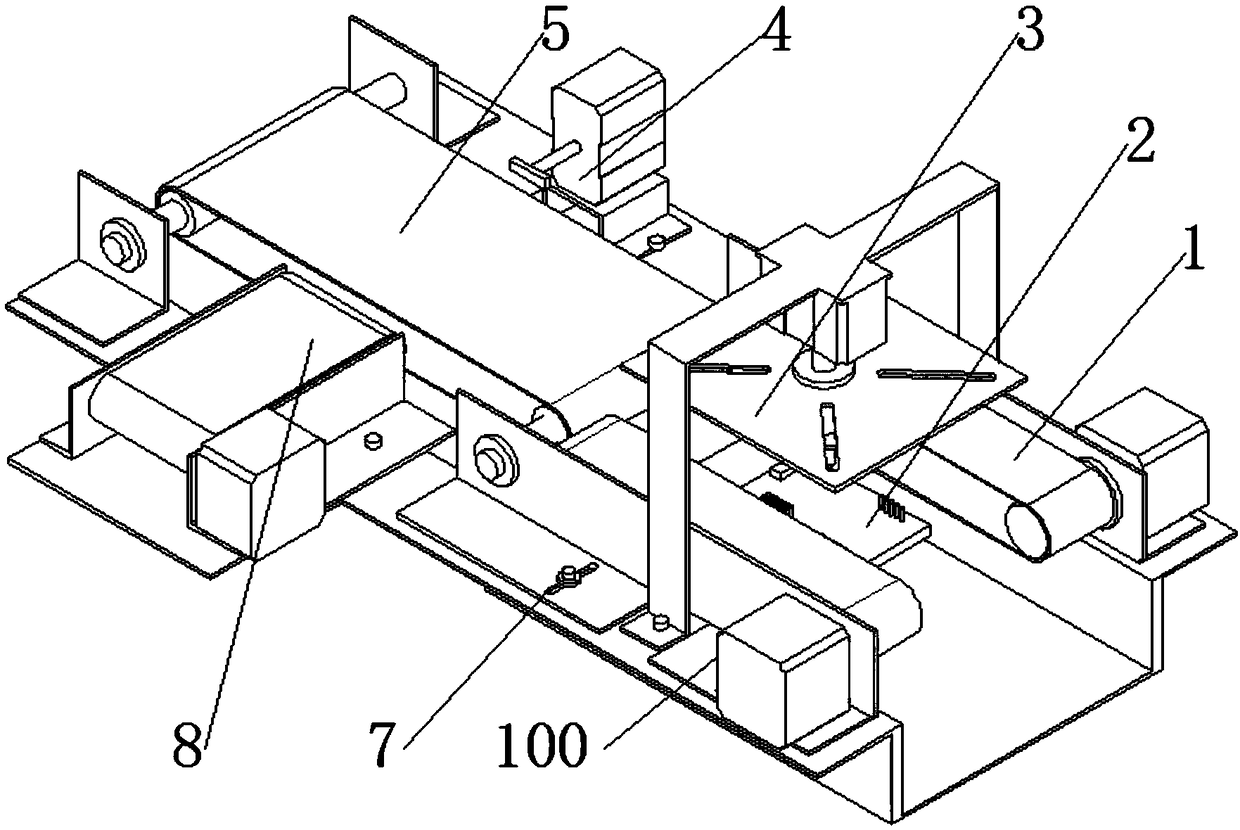

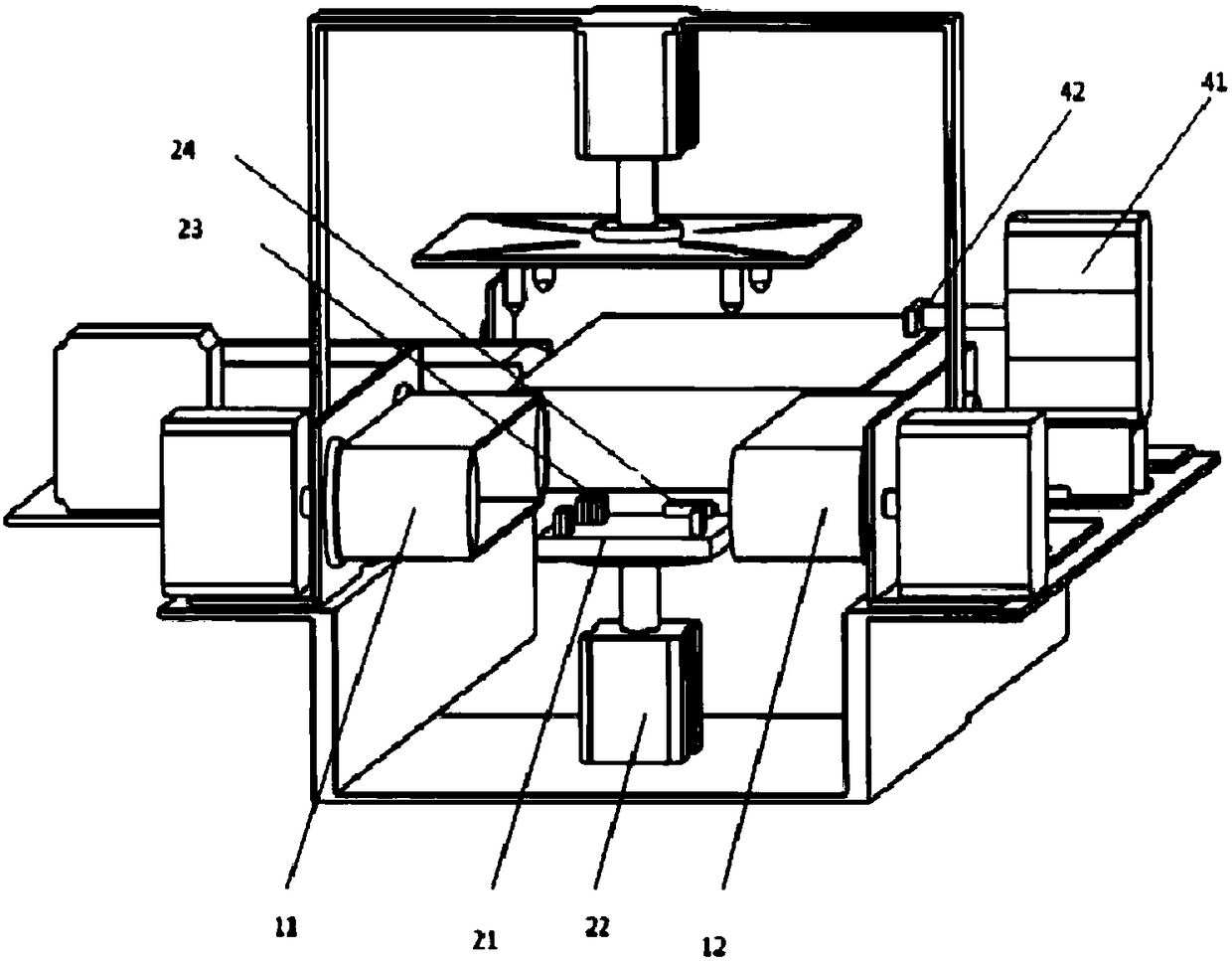

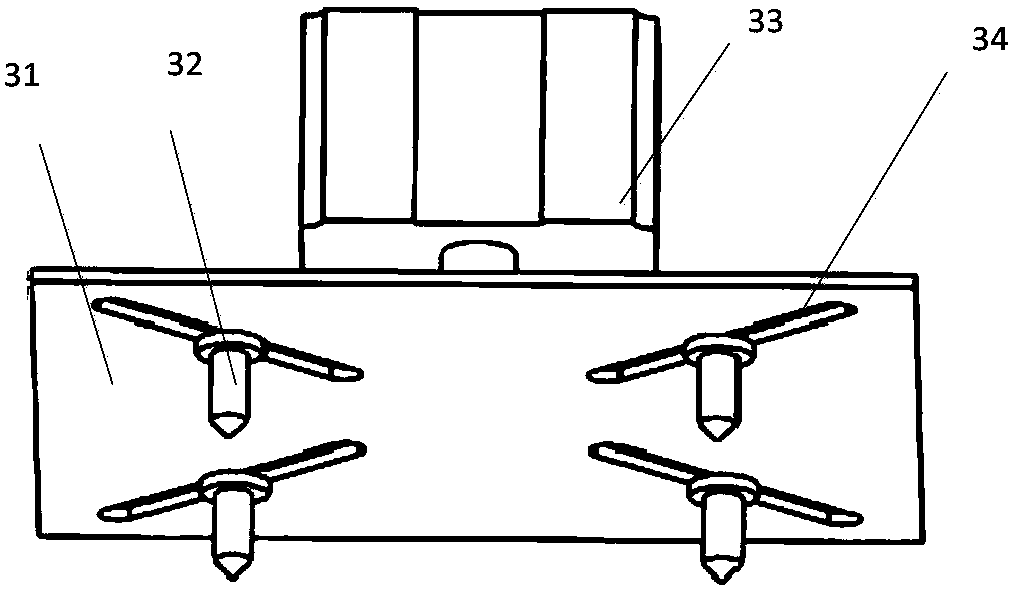

[0041] Step a: Positioning of the EPS controller: The EPS controller that has completed the placement process is shoveled to the parallel conveyor belt 1 through the barge of the placement machine, and after it reaches the predetermined position through the parallel conveyor belt, the conveyor belt stops running and is installed on the flying probe The photoelectric sensor 24 on the lifting platform 2 receives the arrival signal of the EPS controller. At this time, the positioning lifting rod 3 located directly above the EPS controller is driven down by the second telescopic cylinder 33, and the movable spring thimble 32 on the rectangular positioning plate 31 is inserted. Insert it into the installation holes at the four corners of the EPS controller to realize the positioning of the EPS controller;

[0042] Step b: Flying probe detection, program programming and function detection: The flying probe lifting platform 2 rises u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com