Bearing assembly for pipeline installation

A technology of pipeline installation and assembly, applied in the direction of pipeline supports, pipes/pipe joints/pipes, mechanical equipment, etc., it can solve the problems of isolation device damage, impact on service life, vibration, etc., and achieve the effect of avoiding damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

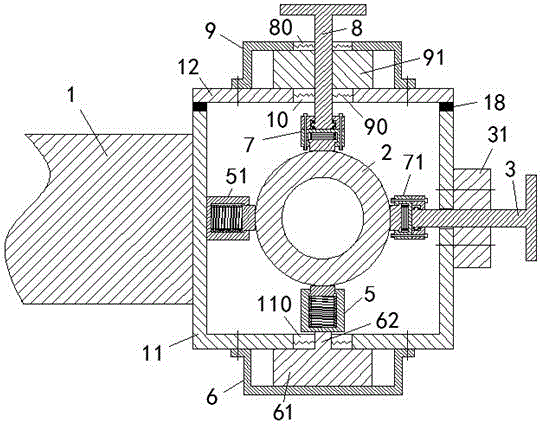

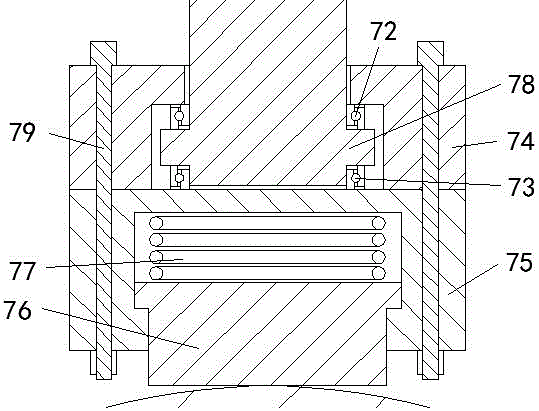

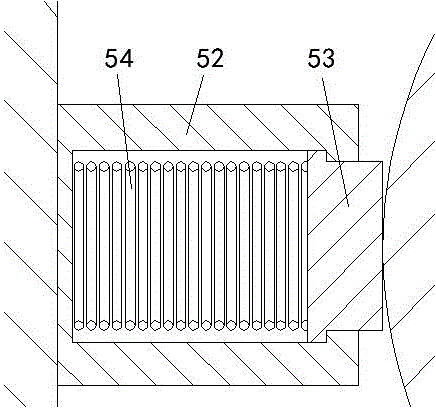

[0010] Combine below Figure 1-3 The present invention will be described in detail.

[0011] A support assembly for pipeline installation according to an embodiment, comprising a fixed base frame 1, a box body 11 fixedly connected to the fixed base frame 1, and a box body cover 12 detachably connected to the box body 11, the The box cover 12 covers the upper opening of the box 11 to allow the pipeline 2 to pass through the upper opening when disassembled, and the outer peripheral edge of the upper opening of the box 11 is glued and fixed with a sealing gasket 18, The sealing gasket 18 is used to cooperate with the box cover 12, so that a seal is formed between the box 11 and the box cover 12, so that the sealing between the box 11 and the box cover 12 The effect is better, the sealing gasket 18 is a rubber gasket made of rubber material, and the outer side of the box cover 12 is fixedly provided with an upper slider to clamp the cover body 9 for clamping the cover on the uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com