Bearing assembly for pipeline

A technology for pipes and assemblies, applied in the directions of pipe supports, pipes/pipe joints/fittings, hoses, etc., can solve problems such as damage to isolation devices, difficult operation of pipe centering and adjustment, affecting service life, etc., and achieve the effect of avoiding damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

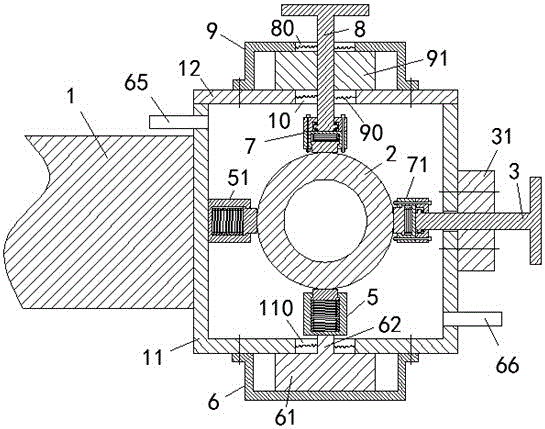

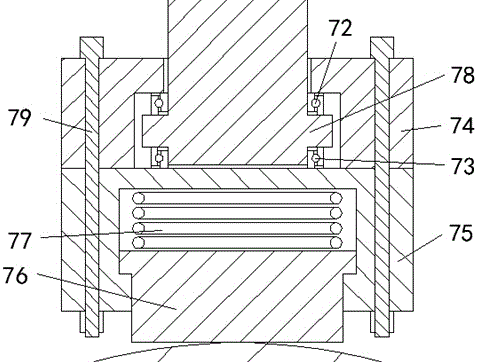

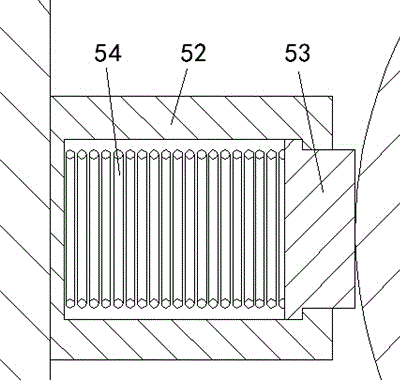

[0010] Combine below Figure 1-3 The present invention will be described in detail.

[0011] A bearing assembly for pipelines according to an embodiment, comprising a fixed base frame 1, a box body 11 fixedly connected to the fixed base frame 1, and a box body cover 12 detachably fixedly connected to the box body 11, the box body The body cover 12 covers the upper opening of the box body 11 to allow the pipeline 2 to pass through the upper opening when dismounting. The outer side of the box body cover 12 is fixedly provided with an upper slider to clamp the cover body 9 for An upper slider 91 is slidably clamped between the upper slider clamping cover 9 and the box cover 12, and a screw hole is provided in the upper slider 91 to operate the screw rod 8 with the longitudinal axis. Threaded fit, the outer part of the longitudinal axis operating screw 8 passes through the upper slider clamping cover 9 and has a first adjustment margin with the adjacent two sides of the upper sli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com