A pendulum beam structure for grinding and polishing equipment

A beam structure and equipment technology, applied in grinding/polishing equipment, surface polishing machine tools, grinding/polishing safety devices, etc., can solve the problems of low swing precision and easy shaking, so as to improve the grinding effect, avoid shaking, The effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

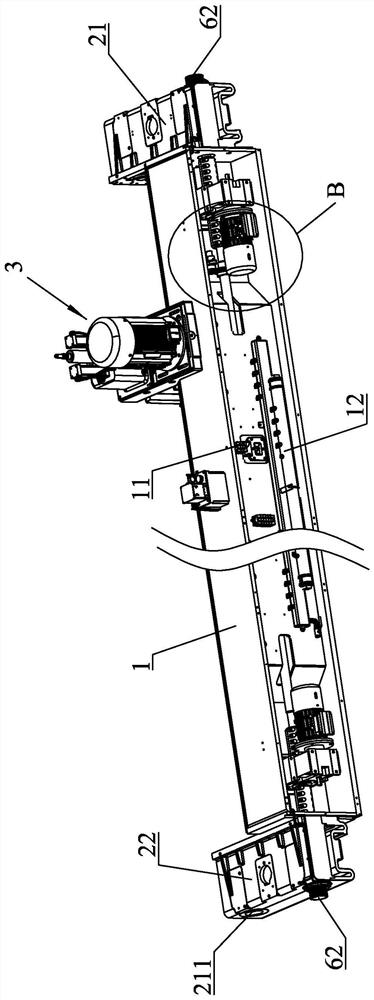

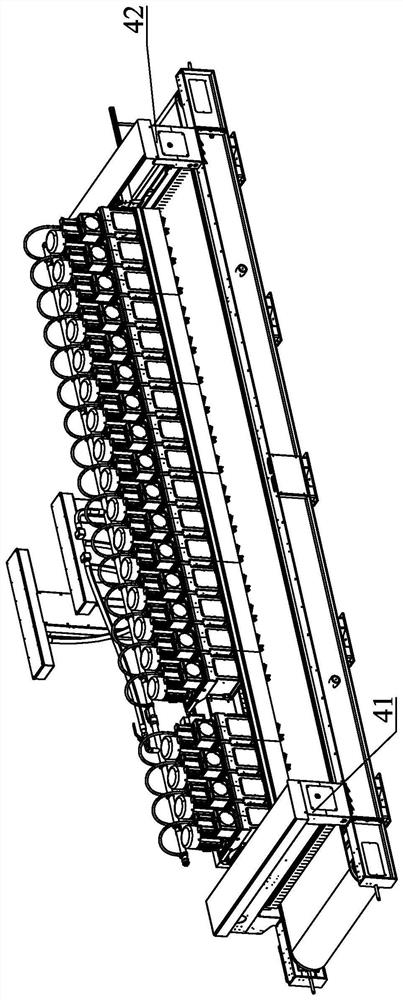

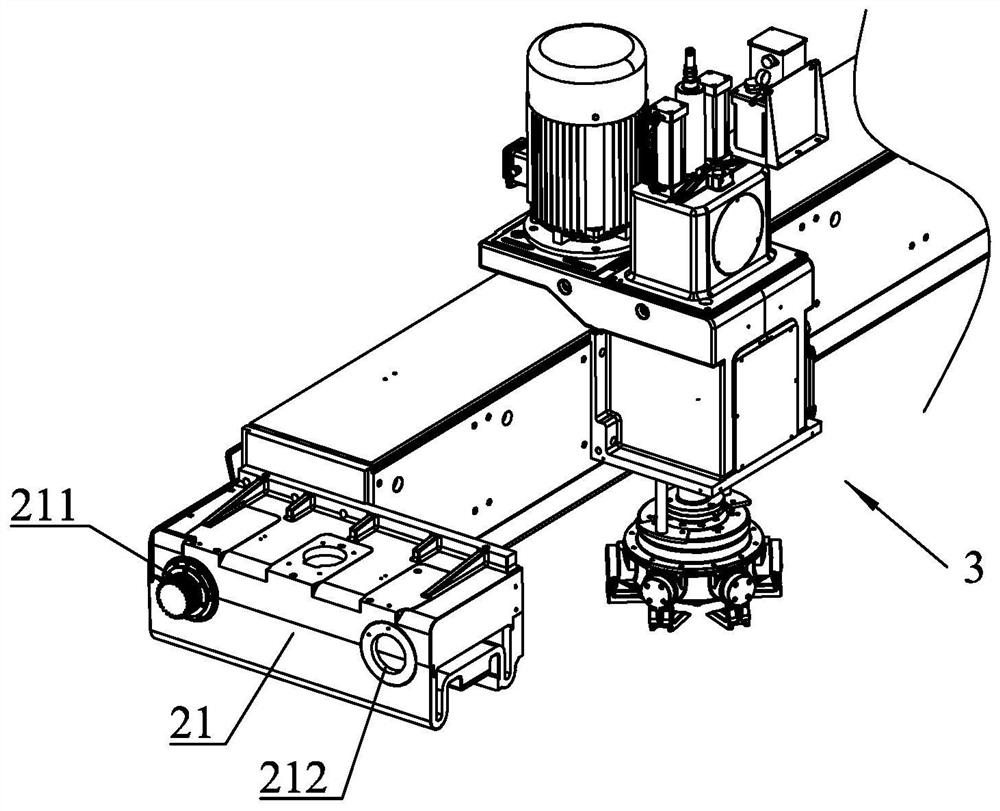

[0045] Such as Figure 1 to Figure 14 As shown, it is a swing beam structure of a kind of grinding and polishing equipment involved in the present invention, including a main beam 1, a first moving seat 21 and a second moving seat 22 respectively connected to the two ends of the main beam 1; 1 is installed with at least one grinding host 3; the first moving seat 21 is slidably arranged on the first supporting seat 41, and the second moving seat 22 is slidably arranged on the second supporting seat 42; the first moving seat 21 and / or the second mobile seat 22 is provided with an adjustment mechanism; the adjustment mechanism includes an adjustment hole 51 formed on the first mobile seat 21 or the second mobile seat 22, and the adjustment mechanism also includes an adjustment seat 52 and an abutment The top whee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com