Hydrogen energy annular polar plate rolling and correcting equipment

A technology for calibrating equipment and hydrogen energy, used in metal processing equipment, manufacturing tools, metal processing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

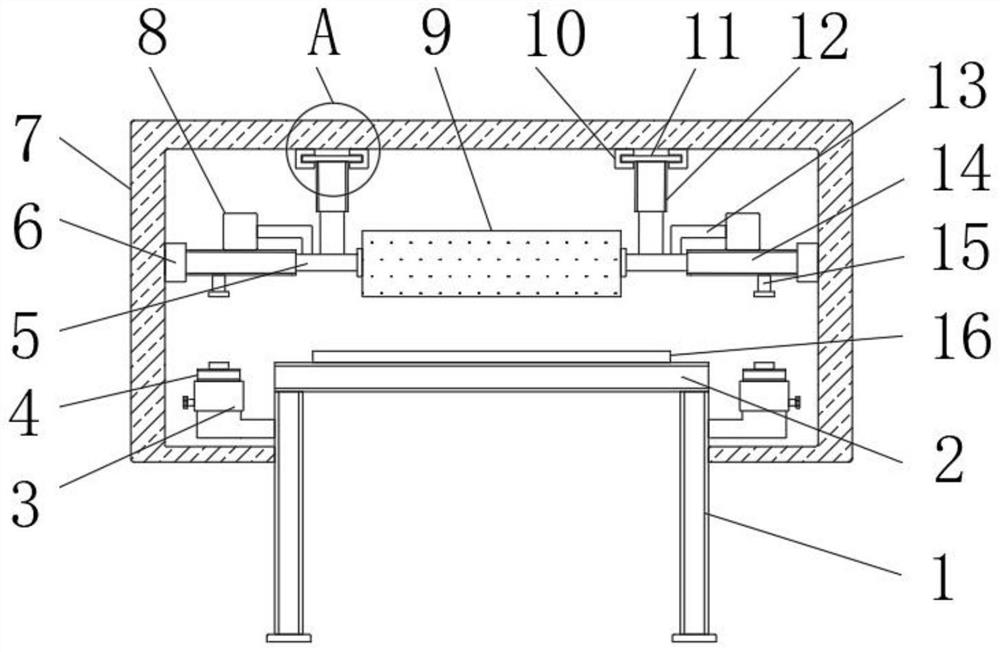

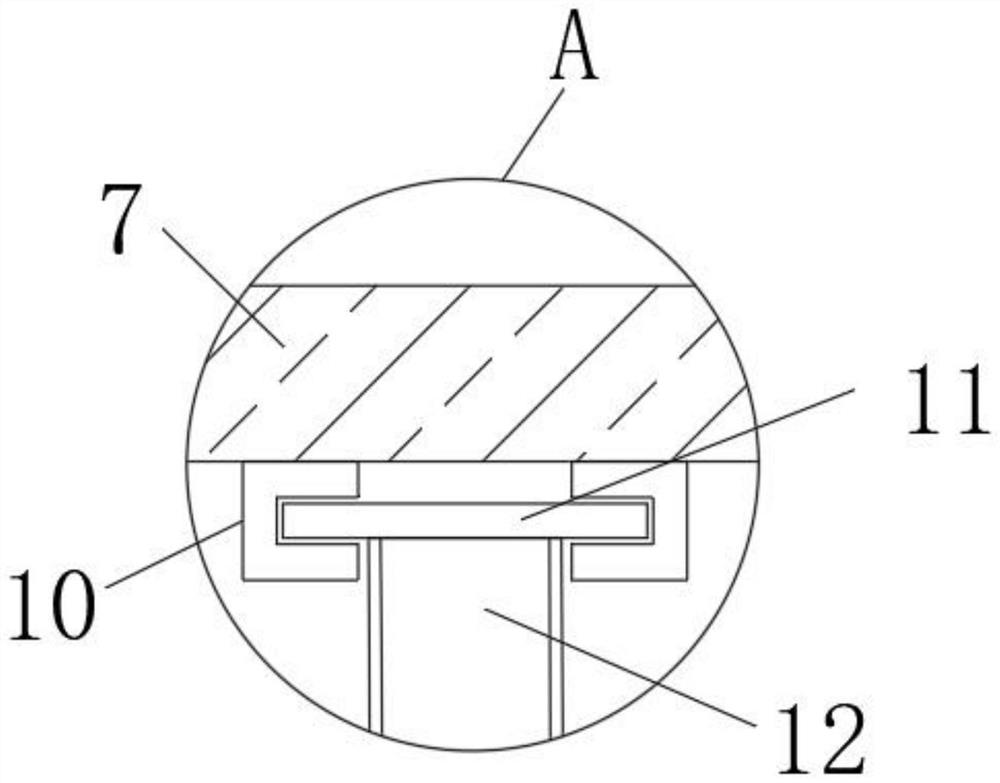

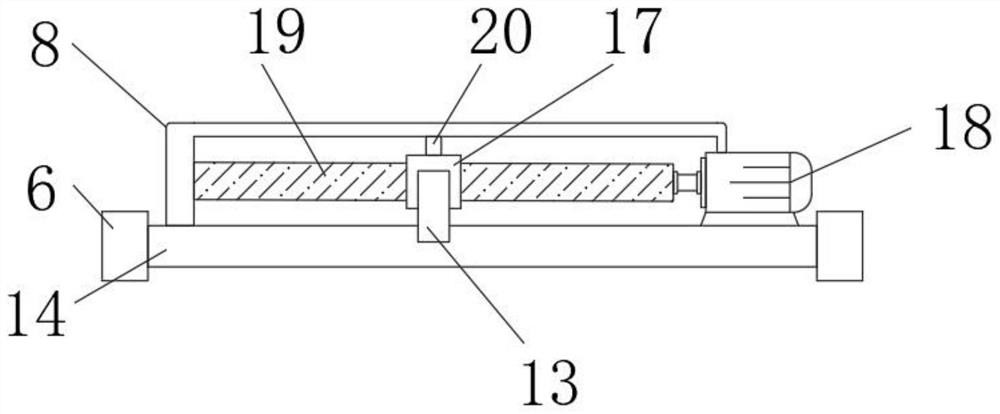

[0025] The following is attached Figure 1-5 The present invention is described in further detail.

[0026] The embodiment of the present invention discloses a hydrogen energy annular plate rolling correction device. refer to figure 1 , a hydrogen energy annular plate rolling correction device, the device is welded with support columns 1 at the four corners of the lower surface of the workbench 2, so as to ensure the stability of the device, and at the same time, both sides under the support frame 7 are A telescopic rod 12 is provided so as to facilitate the pressure roller 9 to move up and down through the telescopic rod 12, so that the telescopic length of one side of the telescopic rod 12 can be changed, so that the pressure applied to the outer surface of the fixed rod 5 can be changed accordingly, and then the pressure roller 9 can be changed accordingly. The pressure intensity of the roller 9 acting on the pole plate can be adjusted to a certain extent. At the same tim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com