Patents

Literature

65results about How to "Guaranteed printing efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

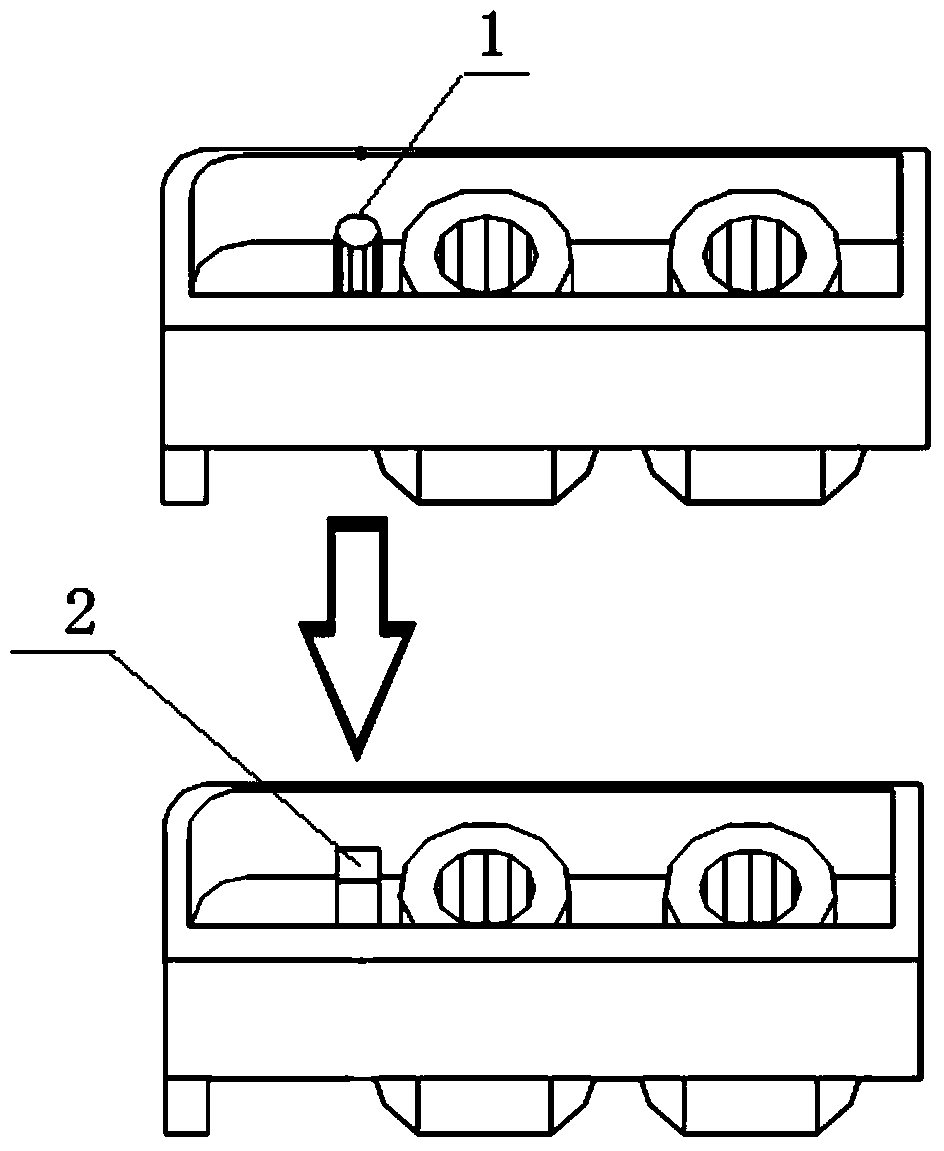

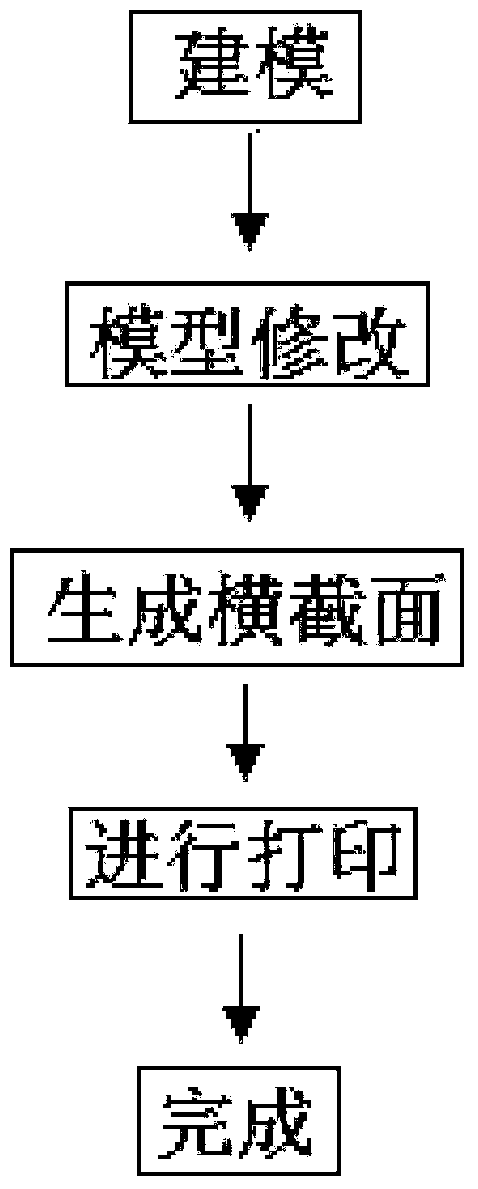

3D (3-Dimensional) printing method

InactiveCN104191619AQuality improvementGood lookingSquare cross sectionFrequency-division multiplexing

The invention discloses 3D (3-Dimensional) printing method. The 3D printing method comprises the following steps: modeling a model needed to be printed in a computer through professional three-dimensional software; amending the modeling of a small structure according to the dimensions of the model needed to be printed, and amending column bodies with circular cross sections with the diameters of smaller than or equal to 0.8 mm and greater than or equal to 0.4 mm into equal-height column bodies with square cross sections with equal side length; guiding the model in specific digital slicing printing software, and generating N Z-axis cross sections for the model; depositing raw materials on the cross sections of model data through an FDM (Frequency Division Multiplexing) printer carrier, wherein one raw material layer is deposited on each cross section layer, and depositing the cross section material layers layer by layer upwards along the Z axis from the base layer in sequence. The 3D printing method has the characteristics that minimum circular shapes or circular shapes with equal diameter that the printing forming precision is nearly 0.4 mm, 0.6 mm and 0.8 mm can be obtained in a traditional printing method; while the printing efficiency is guaranteed, high structural strength of the printed model can be guaranteed, and the model is unlikely to be damaged and deformed.

Owner:湖南梵天信息科技发展有限公司

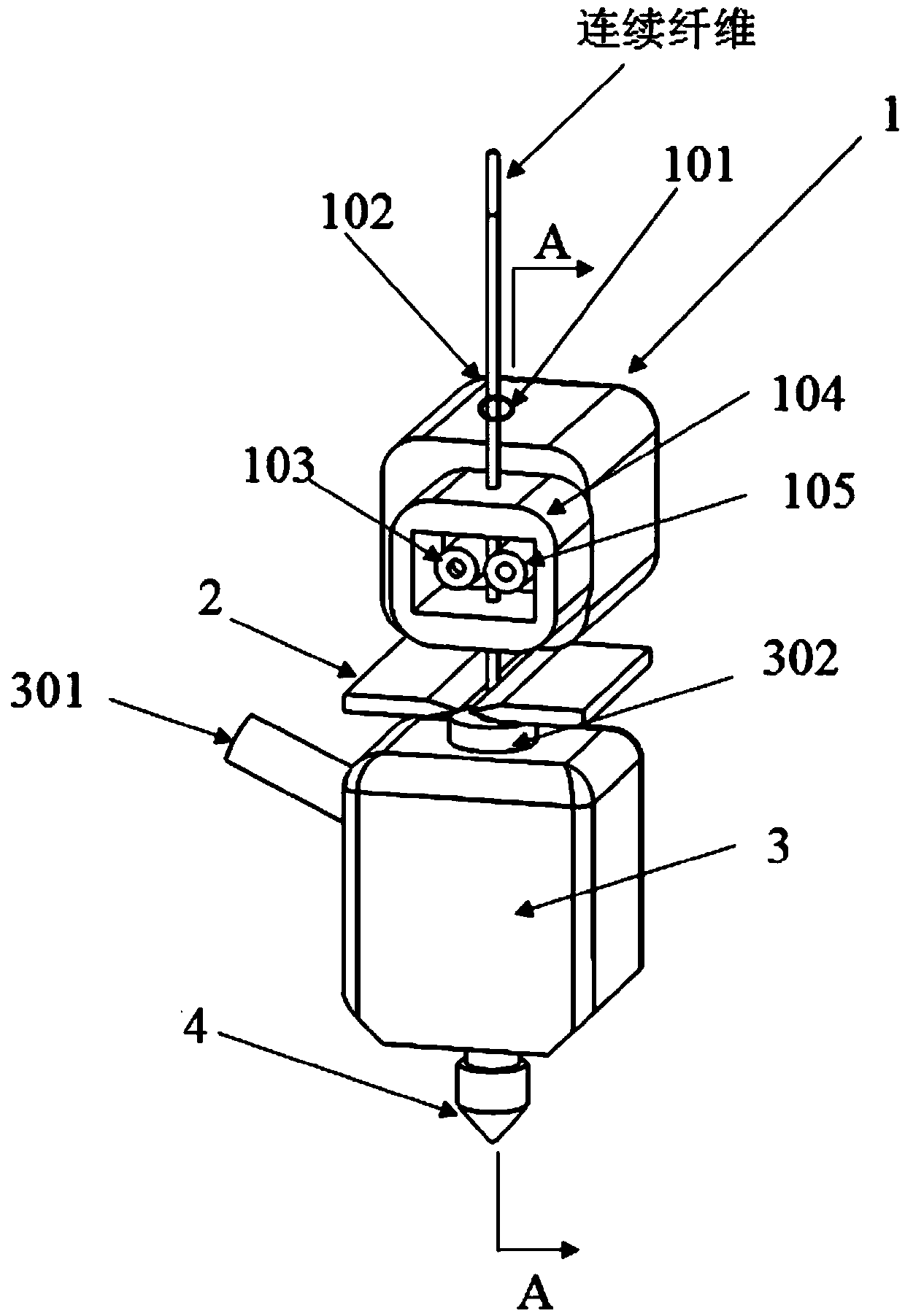

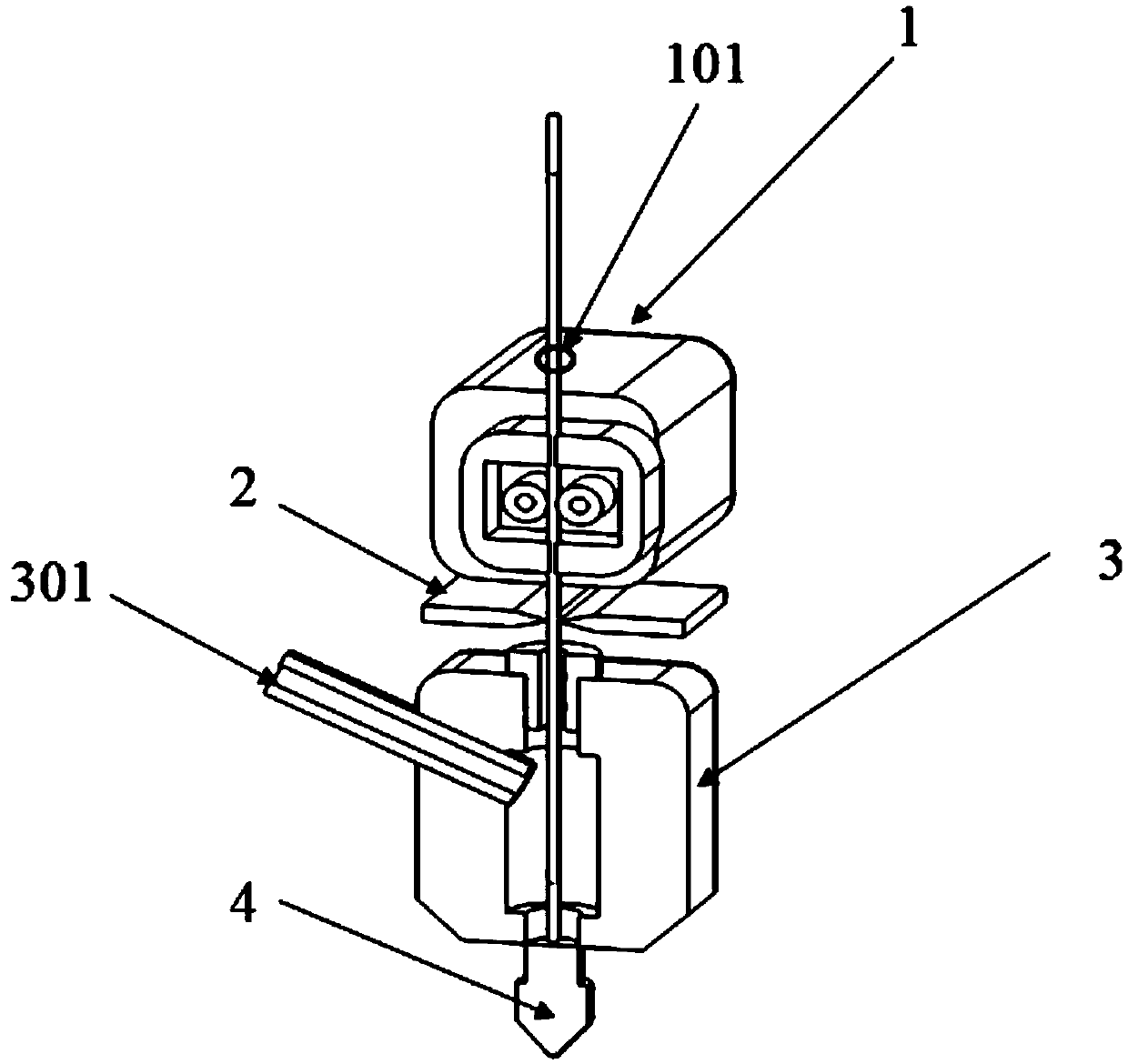

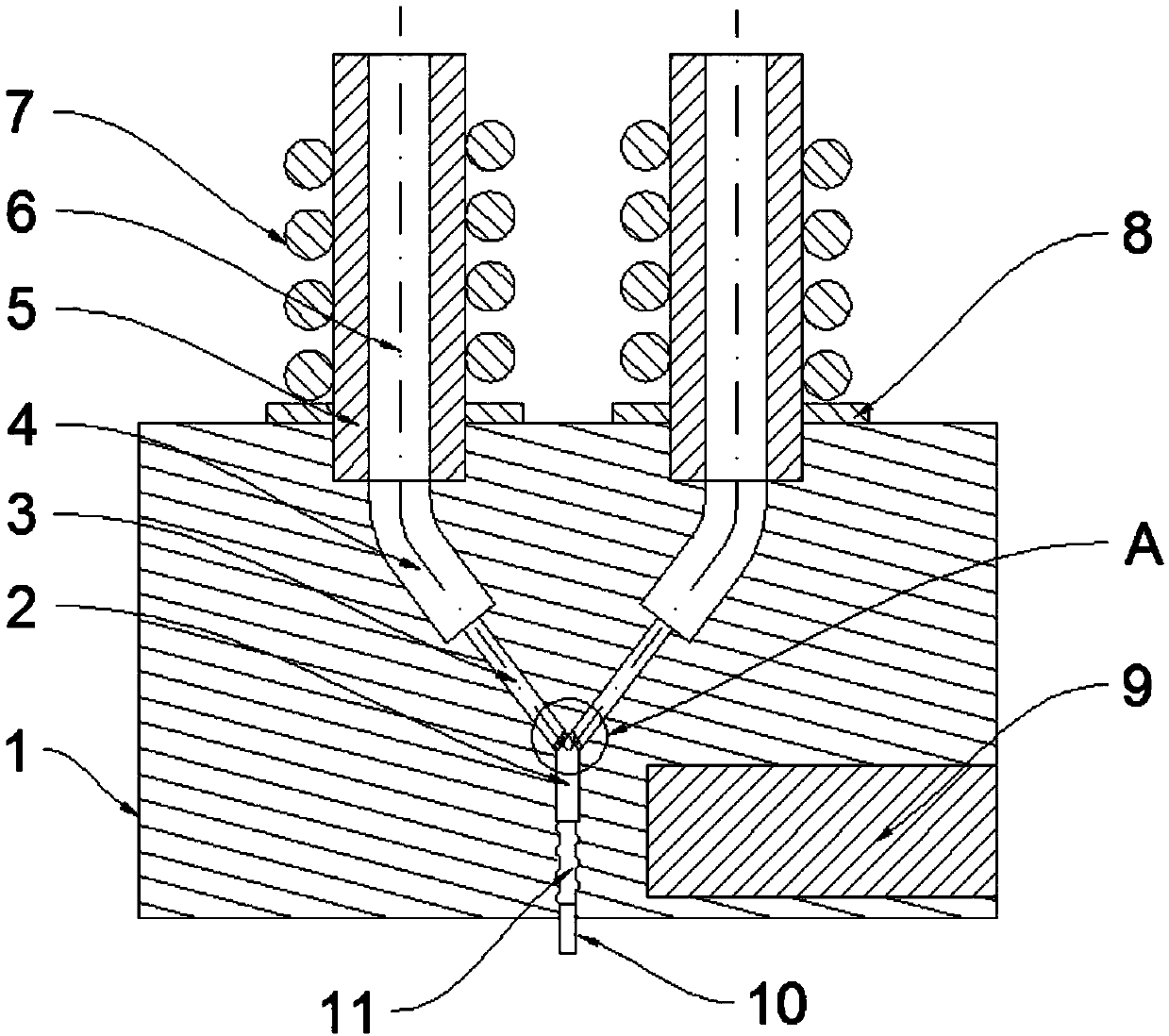

3D printing forming method of continuous fiber reinforced member

PendingCN111572016AImprove performanceImprove efficiencyAdditive manufacturing apparatus3D object support structures3d printPolymer science

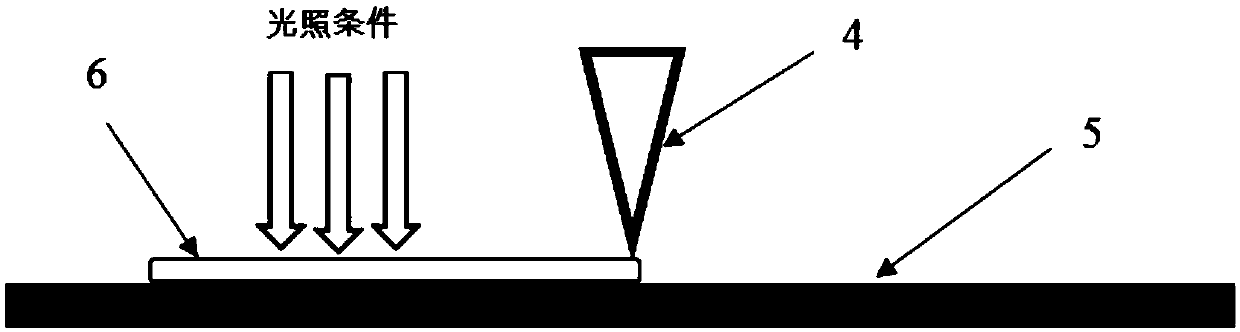

The invention discloses a 3D printing forming method of a continuous fiber reinforced member, and belongs to the technical field of 3D printing. The 3D printing forming method comprises the followingsteps that 1) photosensitive resin and continuous fibers make full contact in an extrusion head to form a composite precursor; 2) component forming is synchronously performed by using a 3D printing platform; and 3) under the illumination condition, the photosensitive resin is subjected to cross-linking curing in the printing process, composite reinforcement of the continuous fibers and the photosensitive resin is completed, and a continuous fiber reinforced component is obtained. According to the 3D printing forming method, the composite material of the continuous fibers and the photosensitiveresin is used as a raw material, component forming and accurate shearing operation are completed by means of the 3D printing platform, resin and fiber composite strengthening and the forming processare completed synchronously and coordinately, and therefore the component forming efficiency is improved while the overall performance of the component is improved; and wider applicability and associativity in the selection of photosensitive resin and continuous fibers are achieved, and components made of different materials can be selectively printed and formed.

Owner:CENT SOUTH UNIV

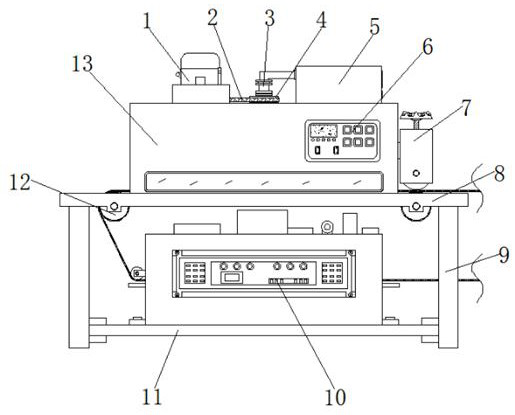

Printing machine for cable markers

InactiveCN101537729AImprove efficiencyEasy to operateRotary pressesEconomic benefitsElectrical and Electronics engineering

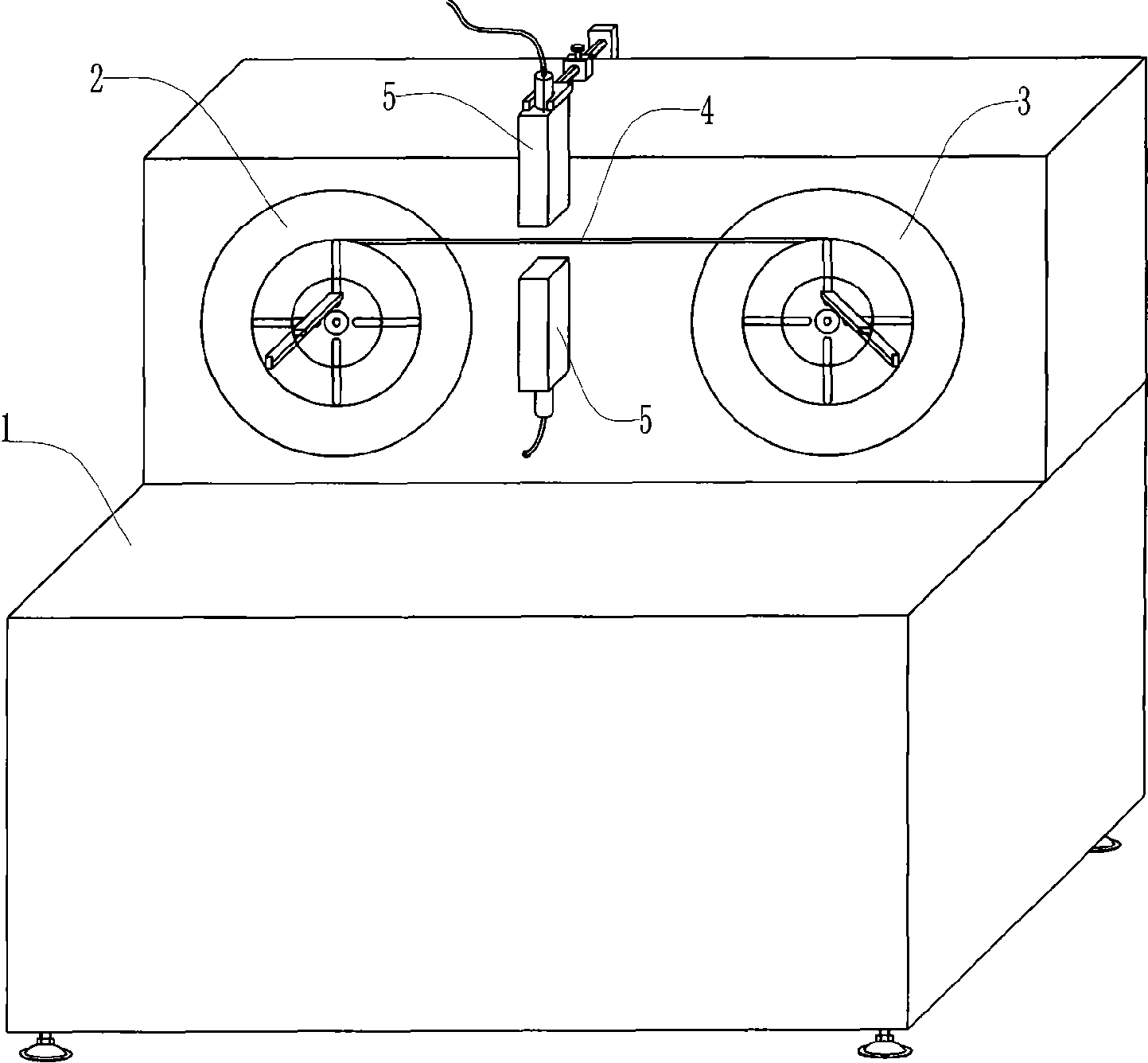

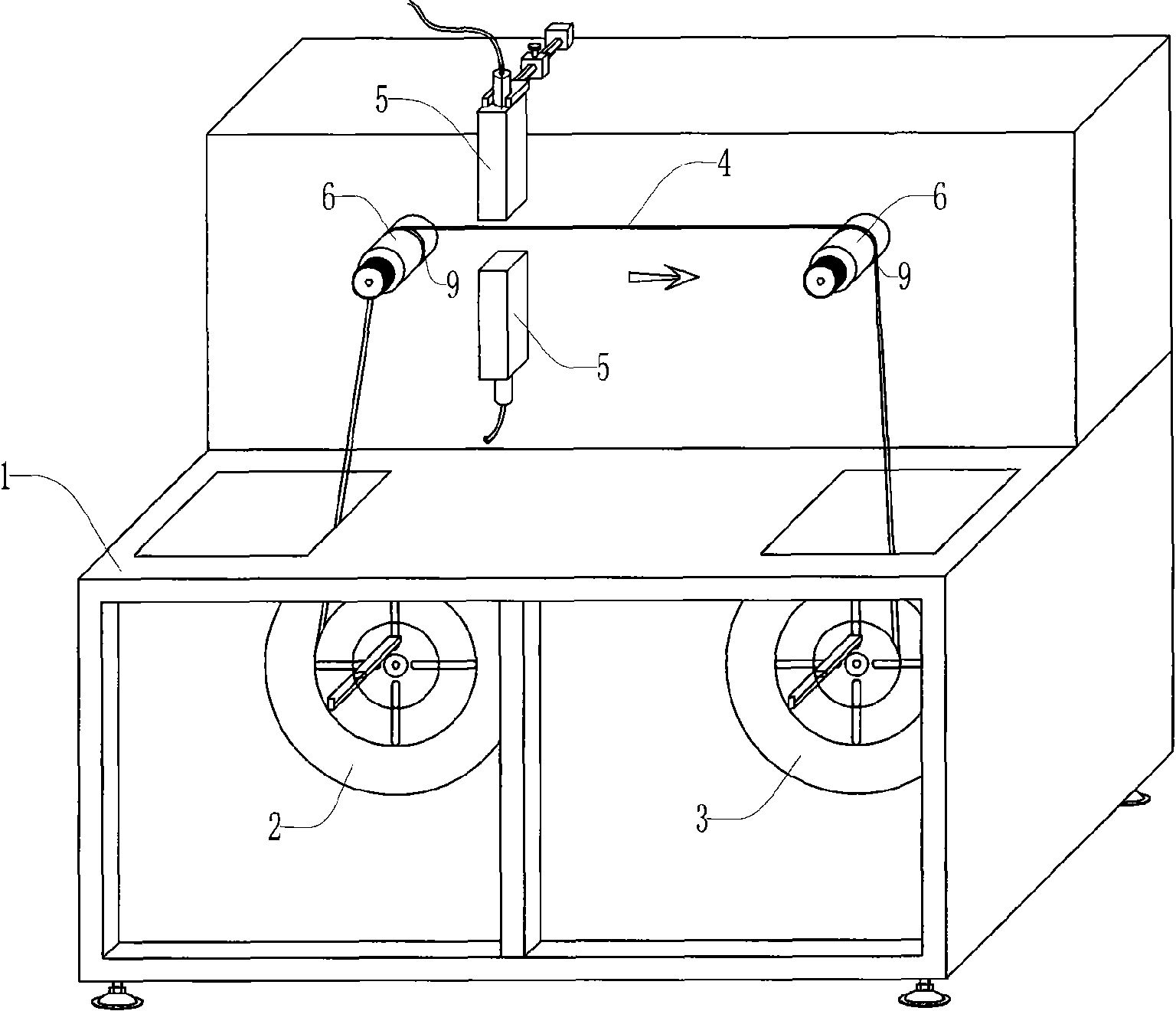

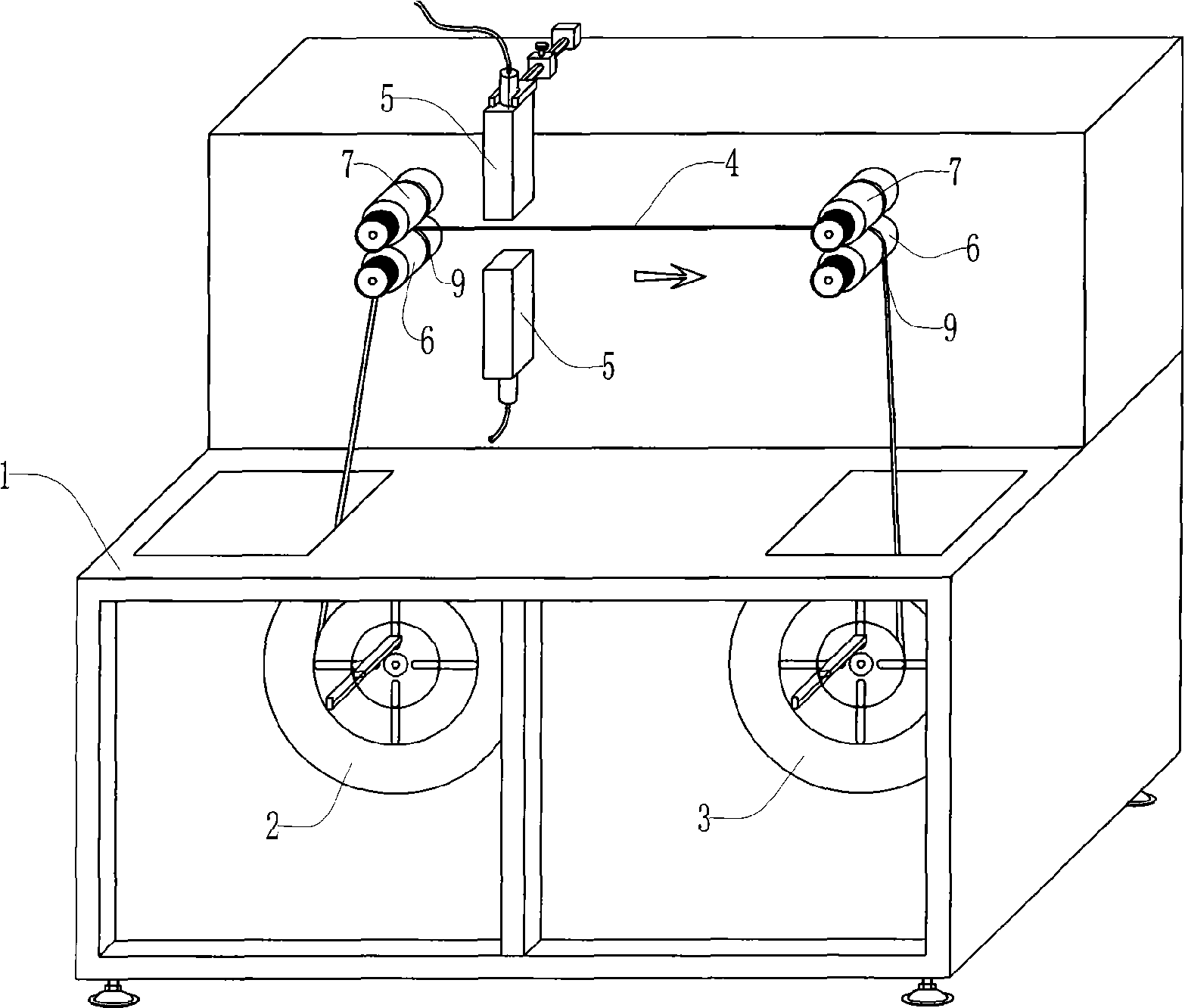

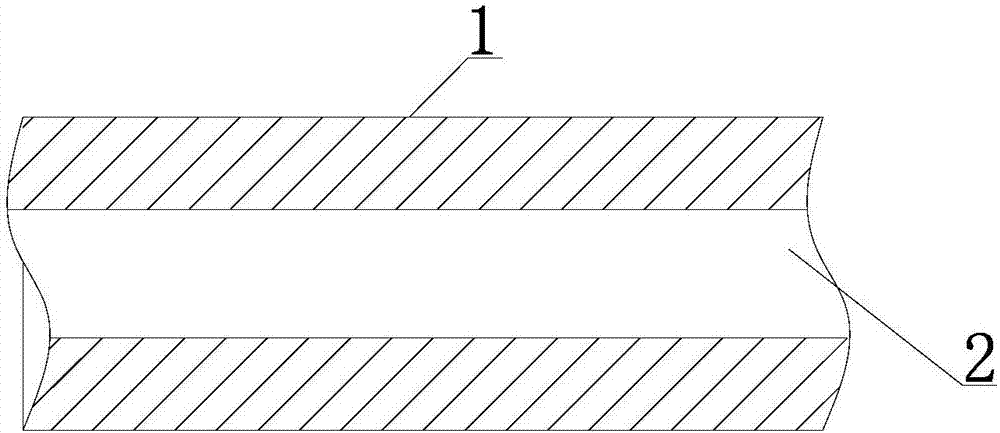

The invention discloses a printing machine for cable makers. Two code-spraying heads of two code-spraying machines which are oppositely arranged are arranged on the upper side and the lower side of the conveying path of the cable markers. When the cable markers are conveyed along with a conveying mechanism, the code-spraying heads which are arranged on the two sides spray and print numbers on the upper surface and the lower surface of the cable markers simultaneously, thus conveniently realizing the double-surface synchronous printing for the cable markers; the code-spraying and printing process can be thoroughly automatically and mechanically completed, thus having simple operation, convenience, high spraying and printing speed and high efficiency; simultaneously, the printing machine is especially designed for the most common and cheap PVC tubular products, thus greatly reducing the cost of consumptive material on the basis of guaranteeing the printing efficiency, and having obvious economic benefit.

Owner:GUANGZHOU SHIPYARD INTERNATIONAL LTD +1

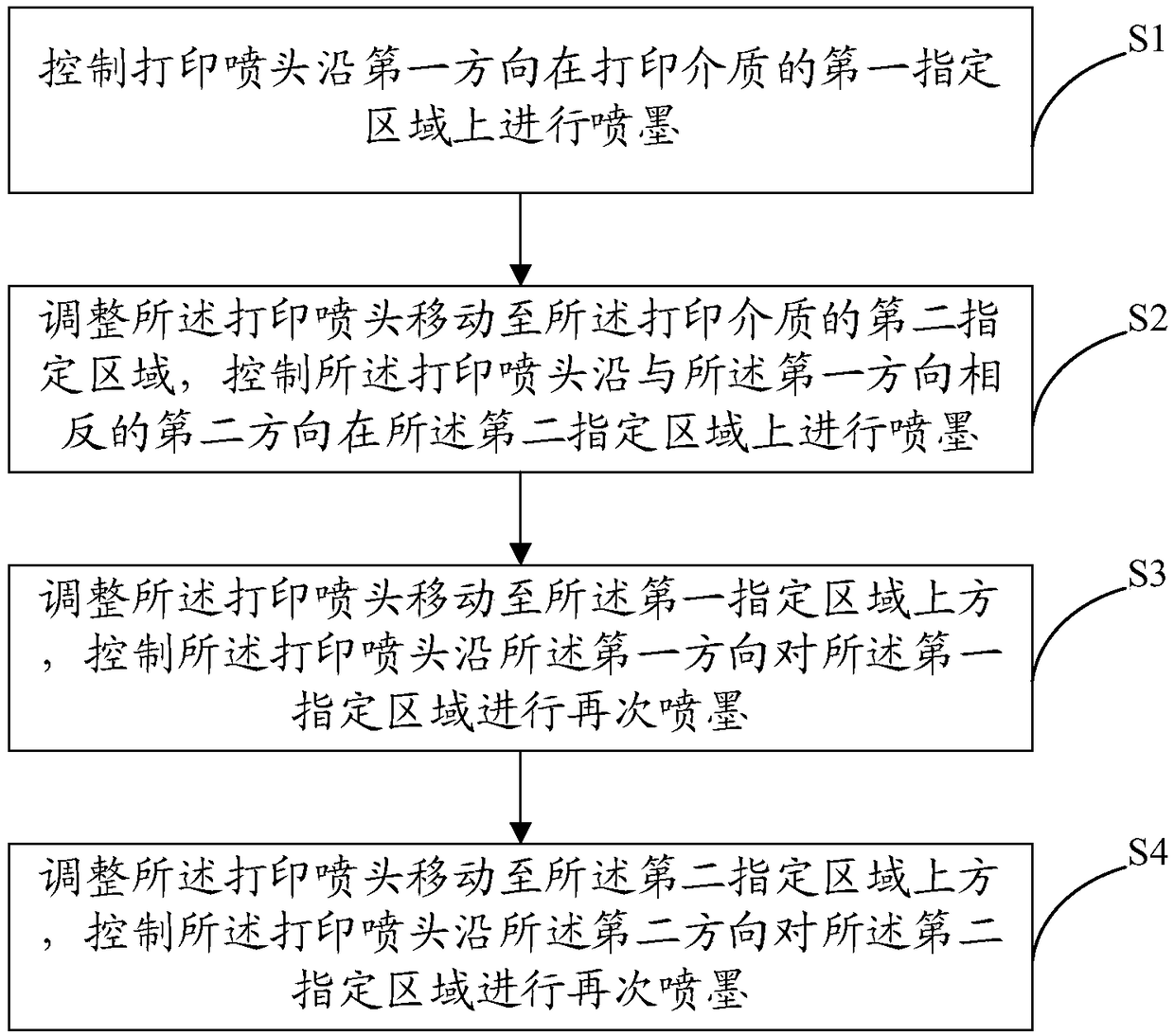

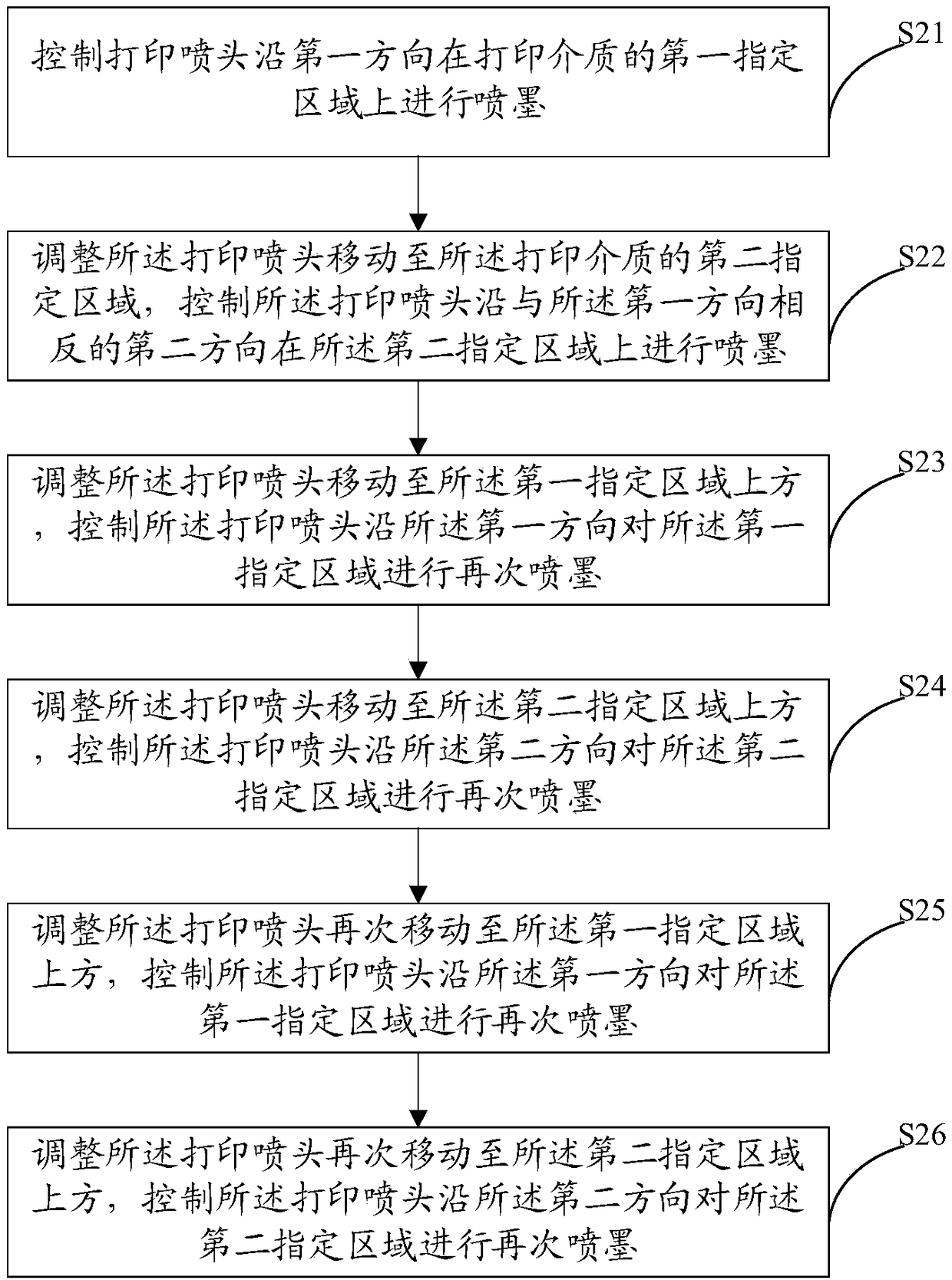

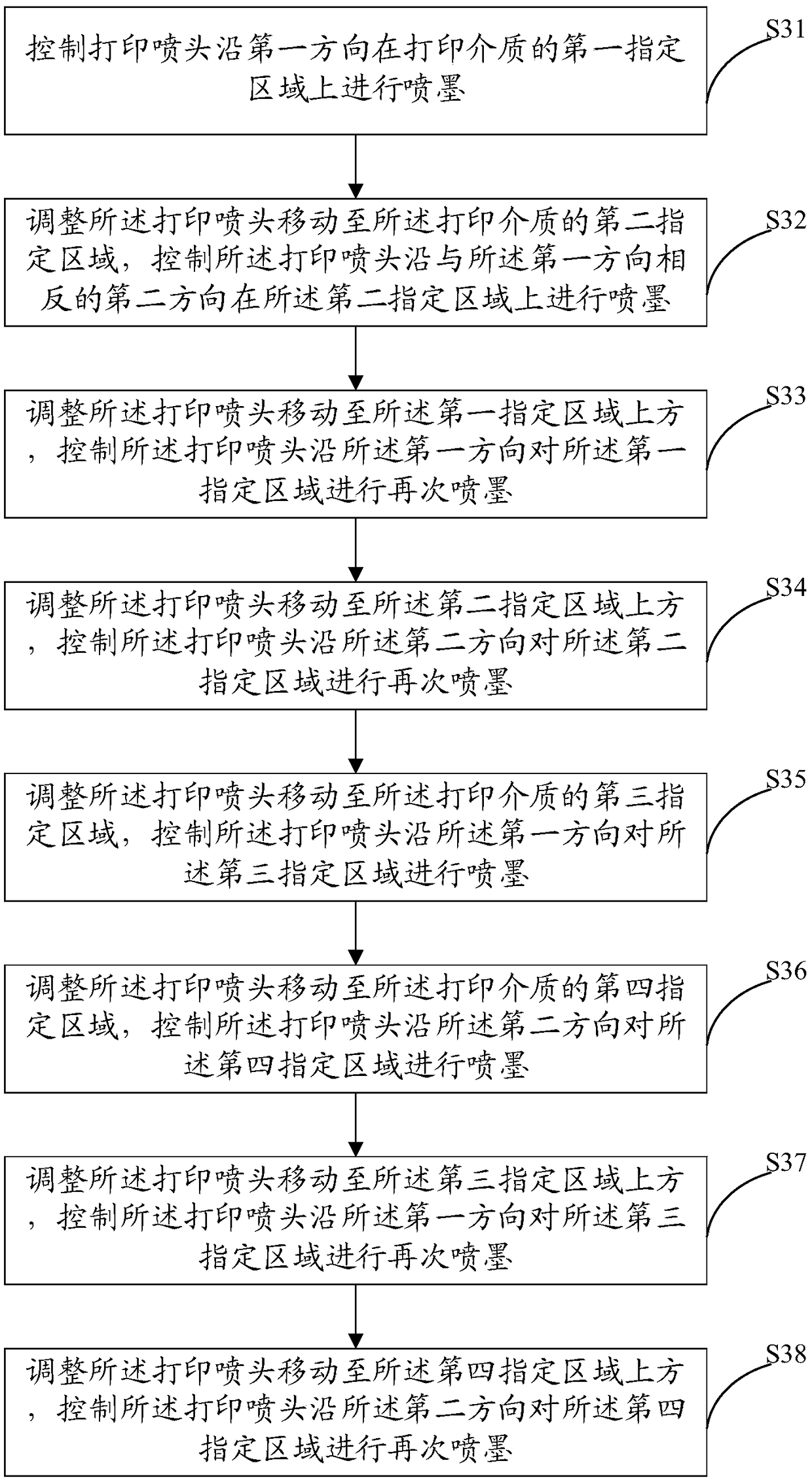

Control method and device for bidirectional rotary printing

ActiveCN109435517AGuaranteed clarityGuaranteed printing efficiencyDuplicating/marking methodsEngineeringElectrical and Electronics engineering

Owner:SHENZHEN HOSONSOFT CO LTD

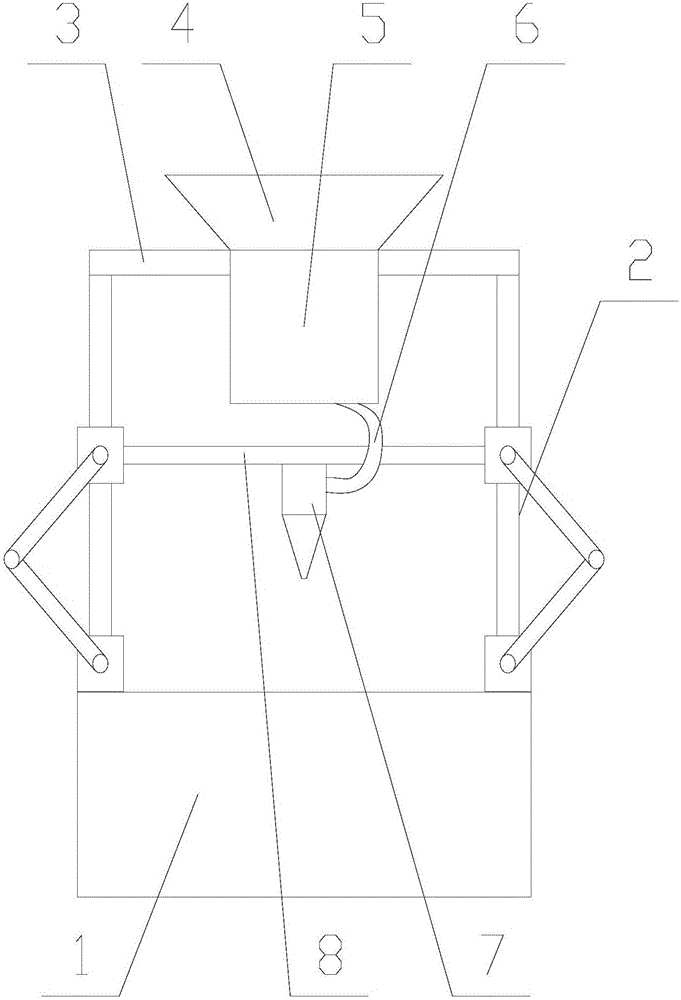

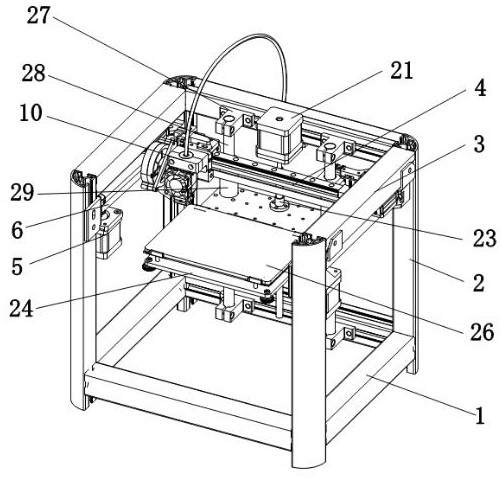

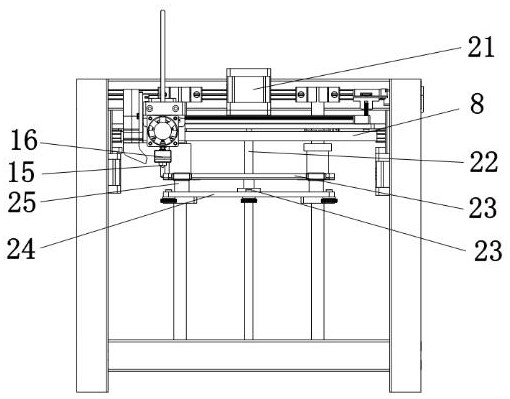

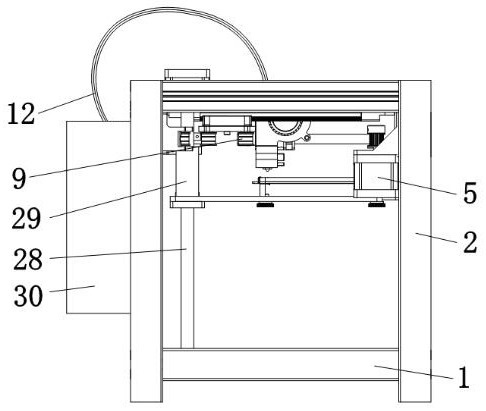

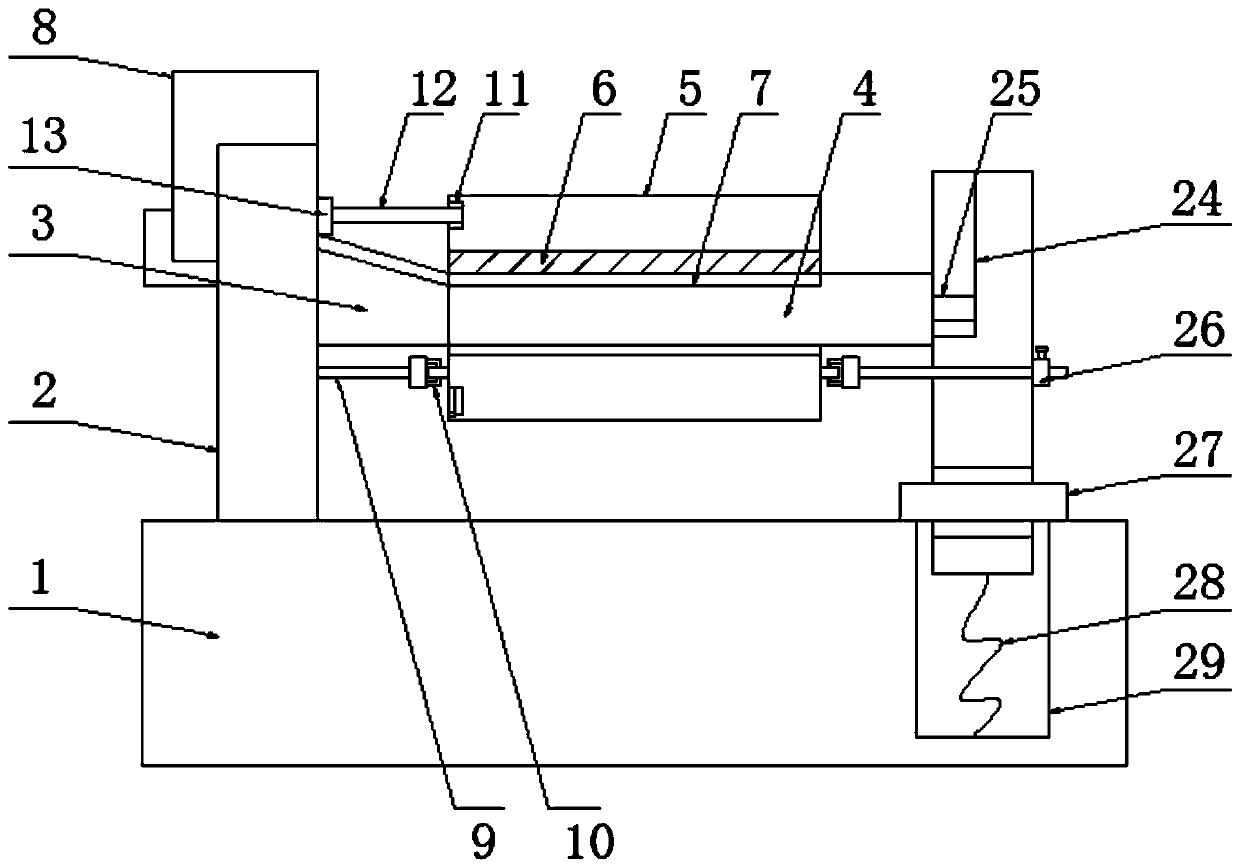

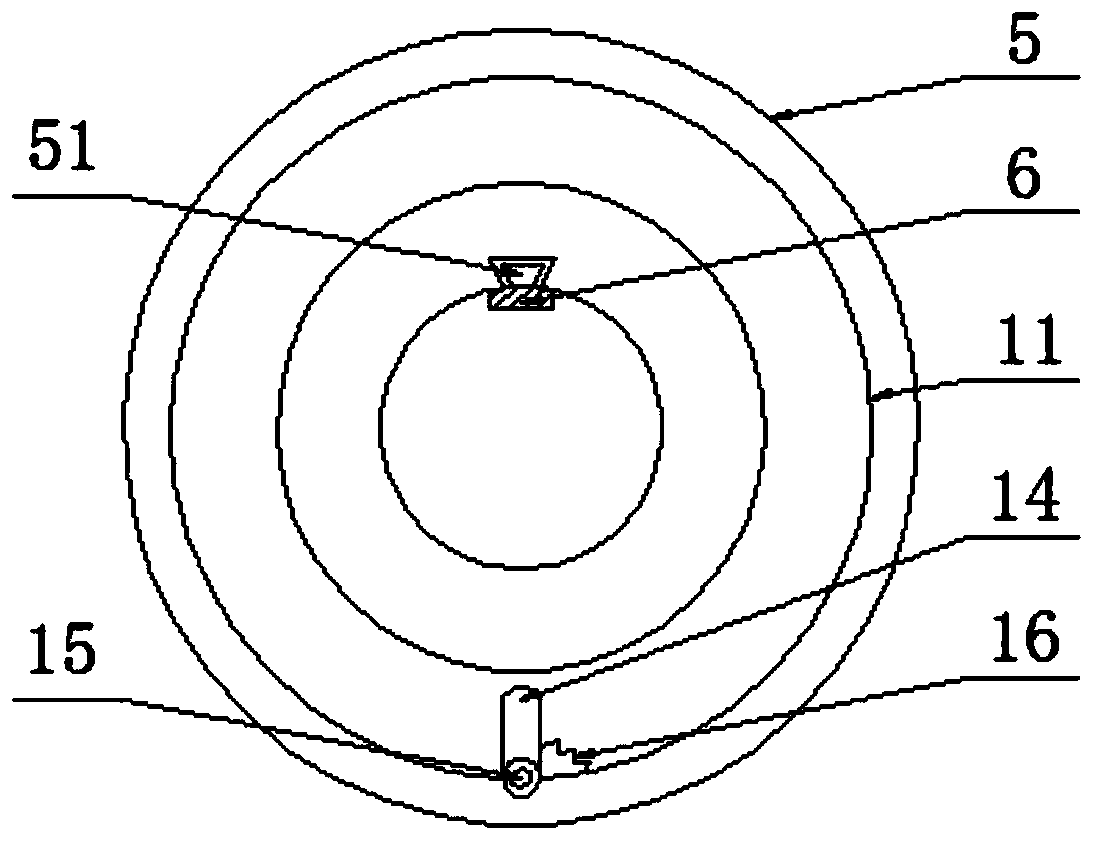

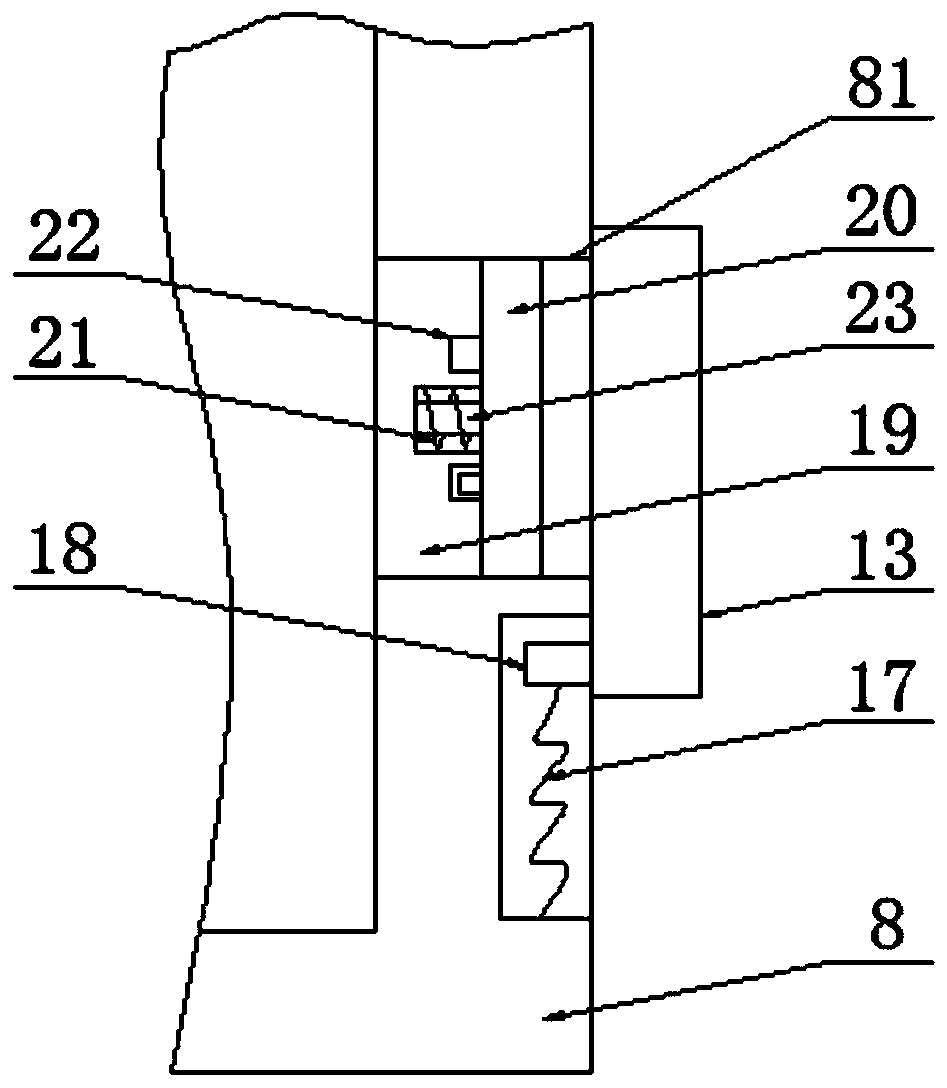

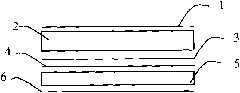

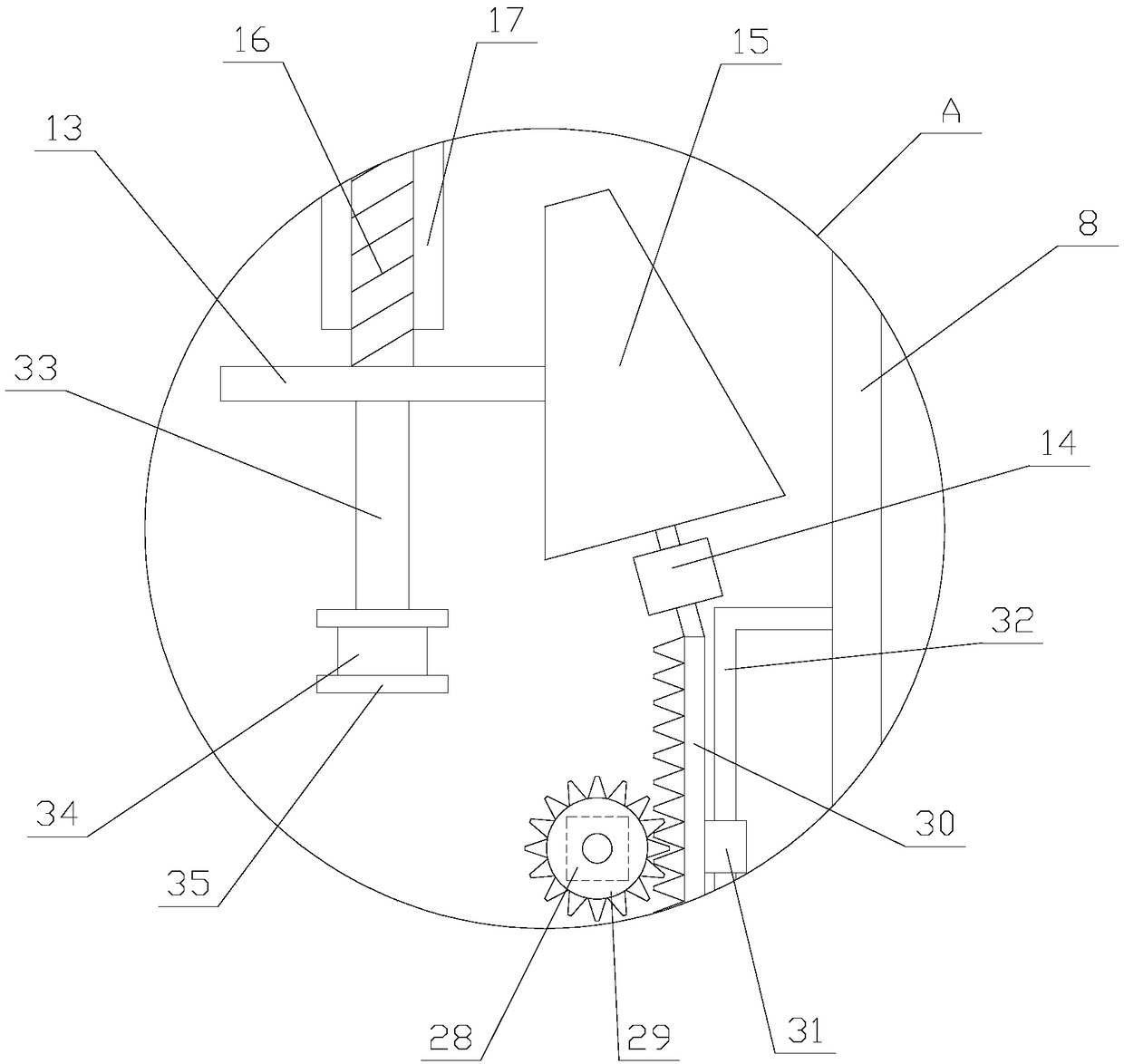

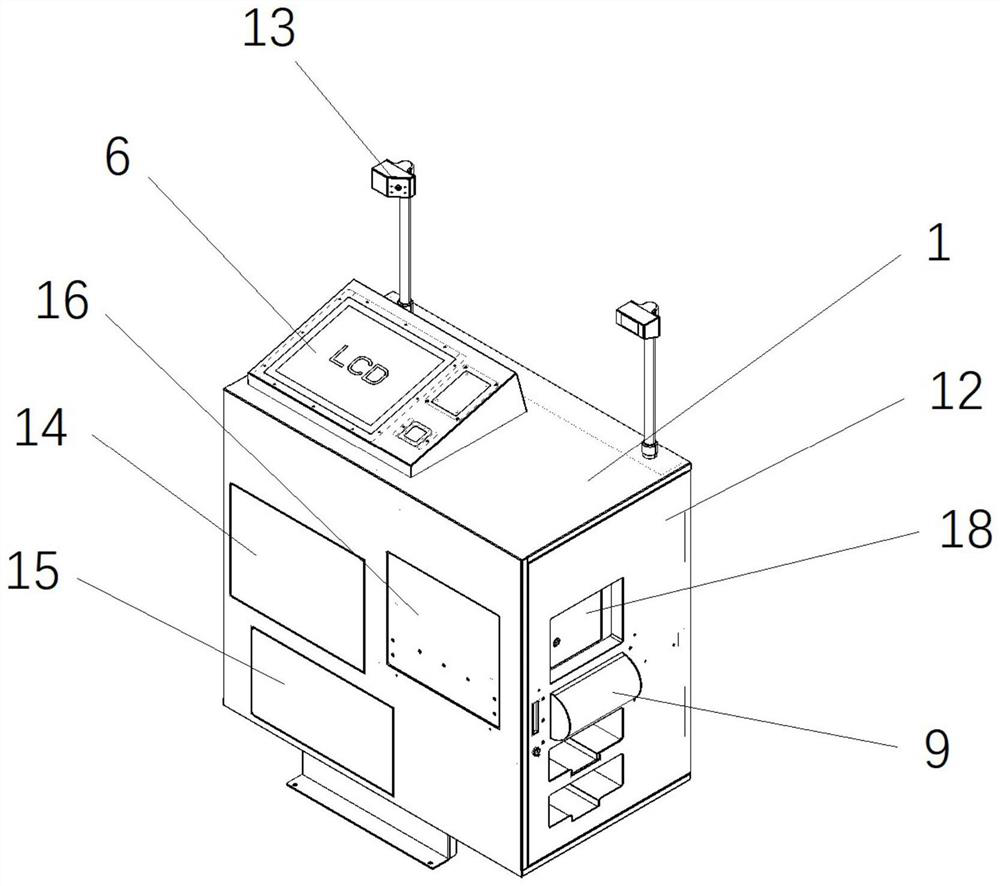

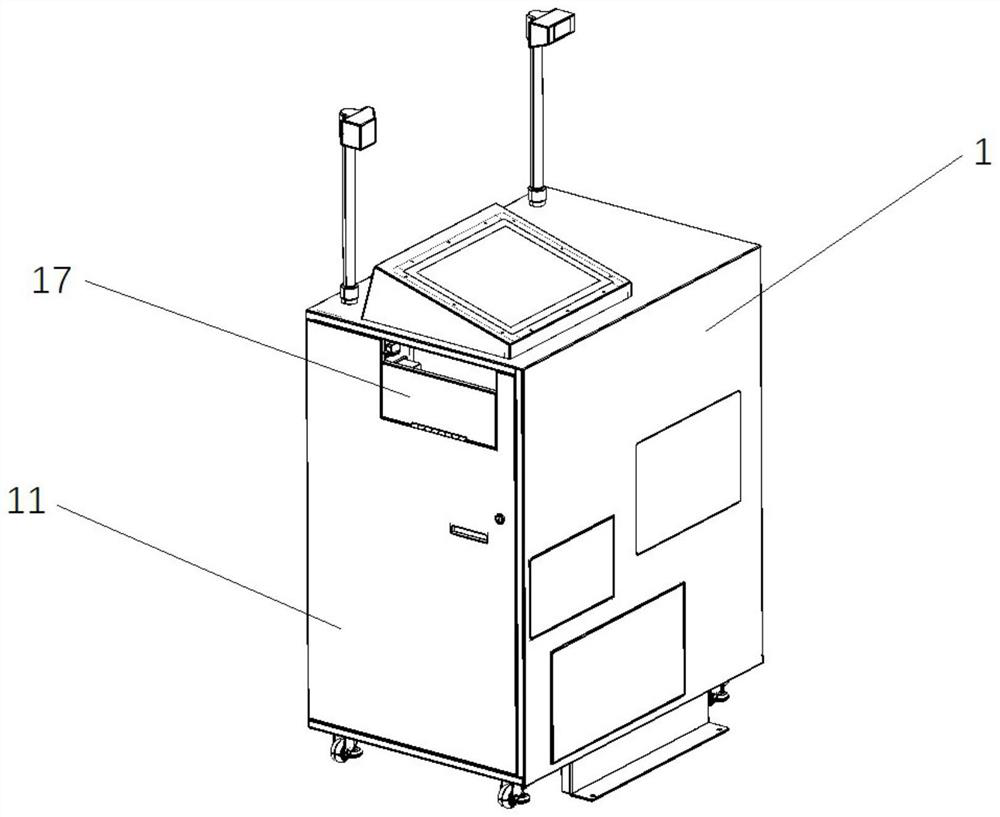

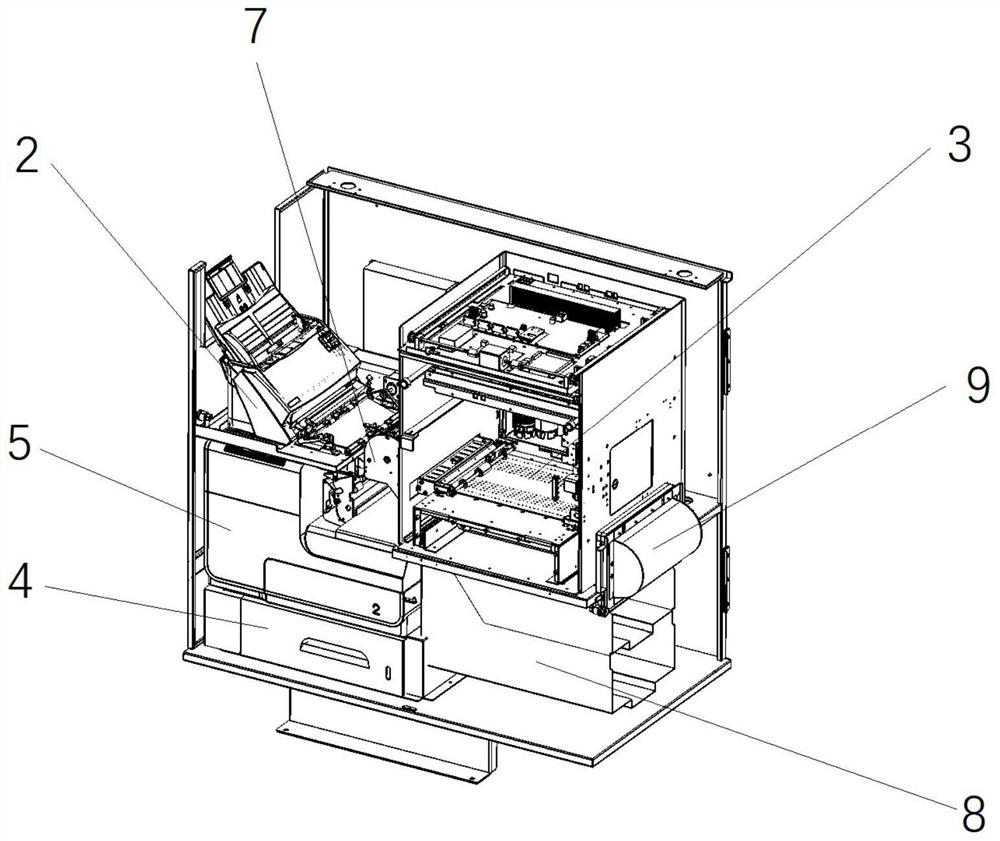

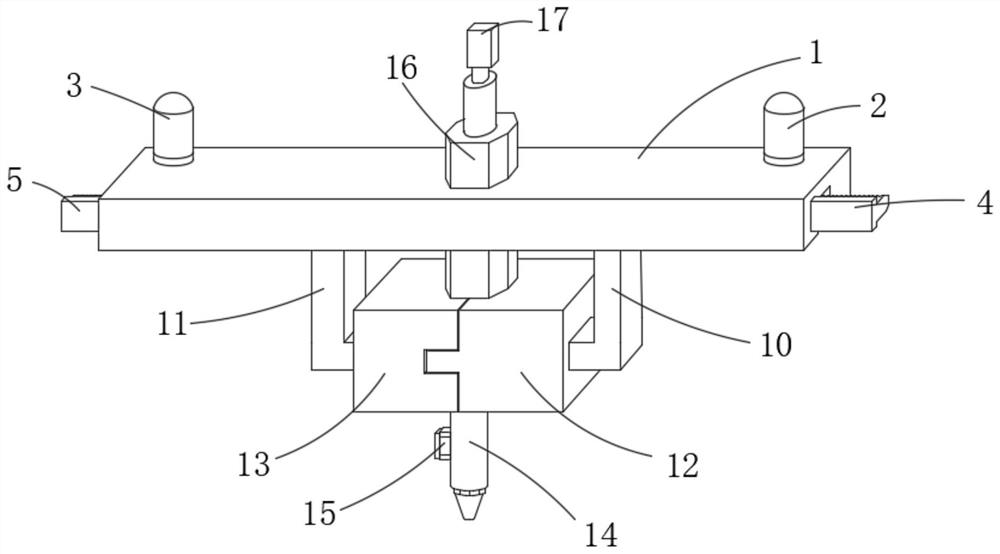

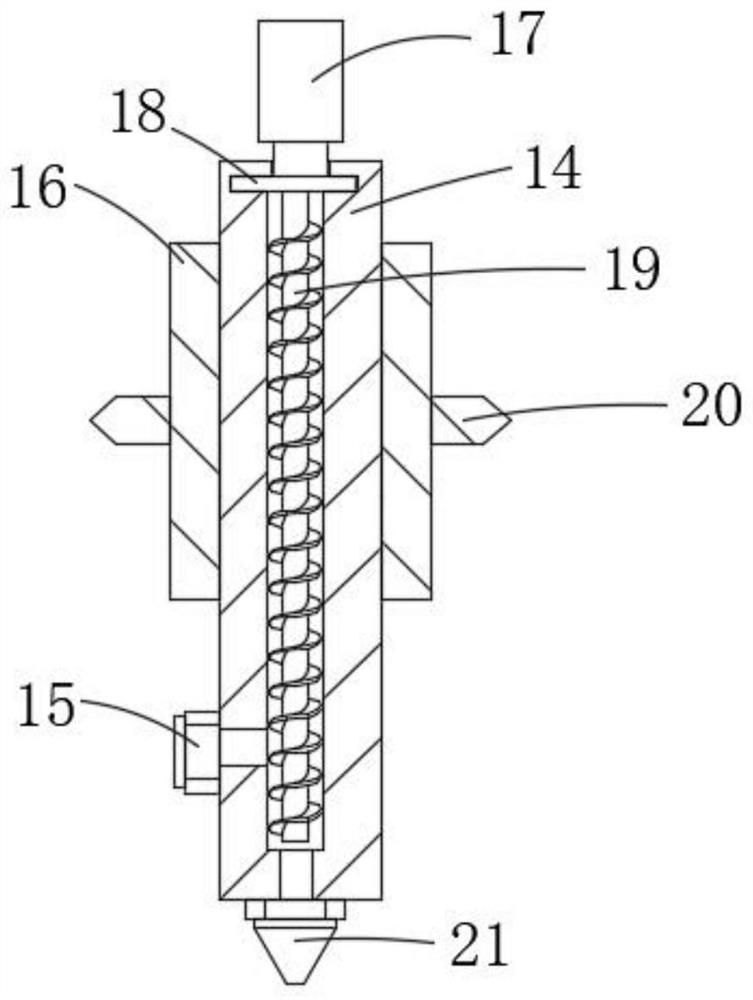

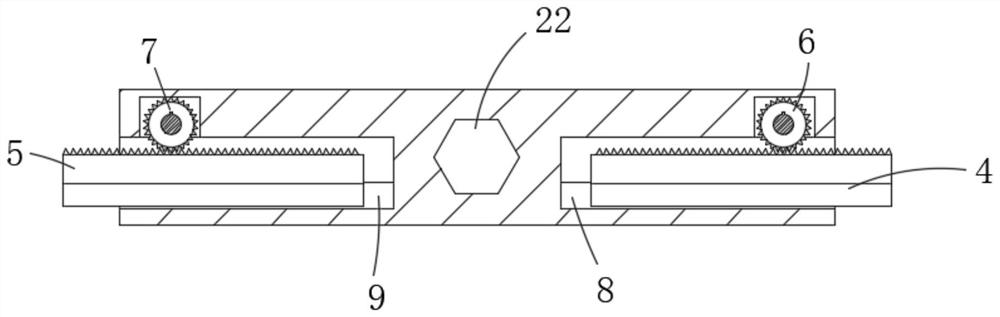

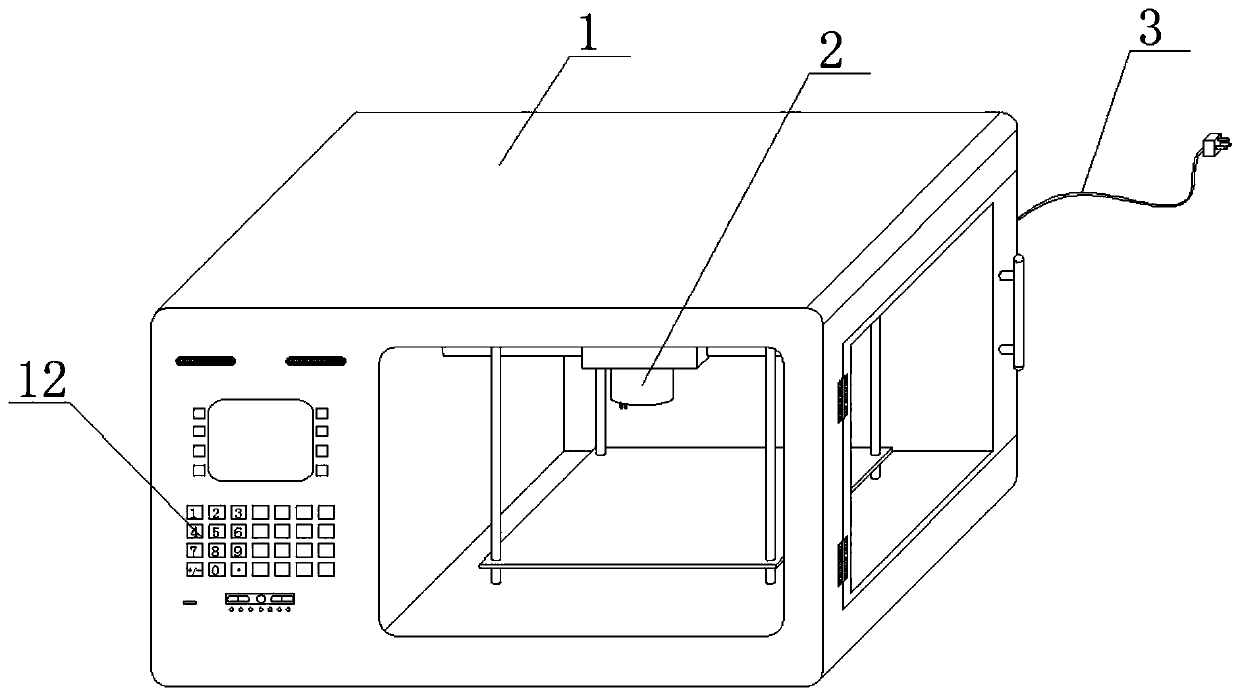

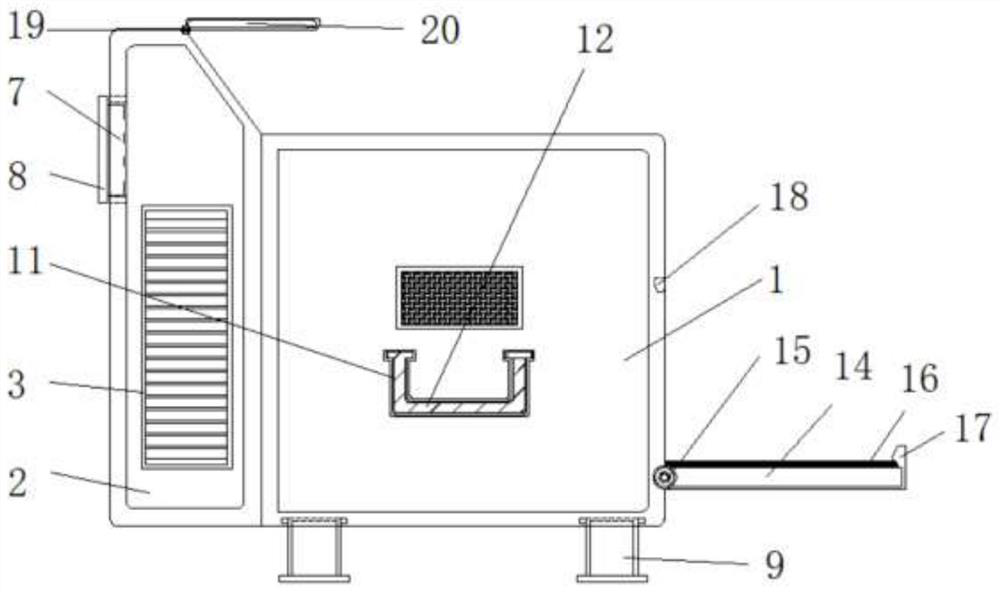

Intelligent 3D printer based on Internet of Things

InactiveCN106825564ASimple internal structureGuaranteed printing efficiencyAdditive manufacturing apparatusIncreasing energy efficiencyInternet of ThingsRaw material

The invention relates to an intelligent 3D printer based on the Internet of Things. The 3D printer comprises a recycling mechanism, a top plate, a hopper, a material conveying mechanism, a feeding pipe, a spraying head, a plane moving mechanism and two supporting units. The two supporting units are arranged at the two ends of the recycling mechanism correspondingly; the top plate is erected on the two supporting units; the plane moving mechanism is arranged between the two supporting units; the supporting units are in transmission connection with the plane moving mechanism; and the spraying head is arranged below the plane moving mechanism. According to the intelligent 3D printer based on the Internet of Things, the material conveying mechanism provides quantitative powder for the spraying head to conduct printing, and the internal structure is simple, so that the conveying efficiency is improved while the cost of equipment is reduced, and the printing efficiency is guaranteed; and in addition, the printing platform tilts through a overturning mechanism inside the recycling mechanism, and defective raw materials are left in recycling boxes inside a box body, so that convenient recycling and cyclic utilization of raw materials are achieved.

Owner:SHENZHEN XIAOKONG COMM TECH CO LTD

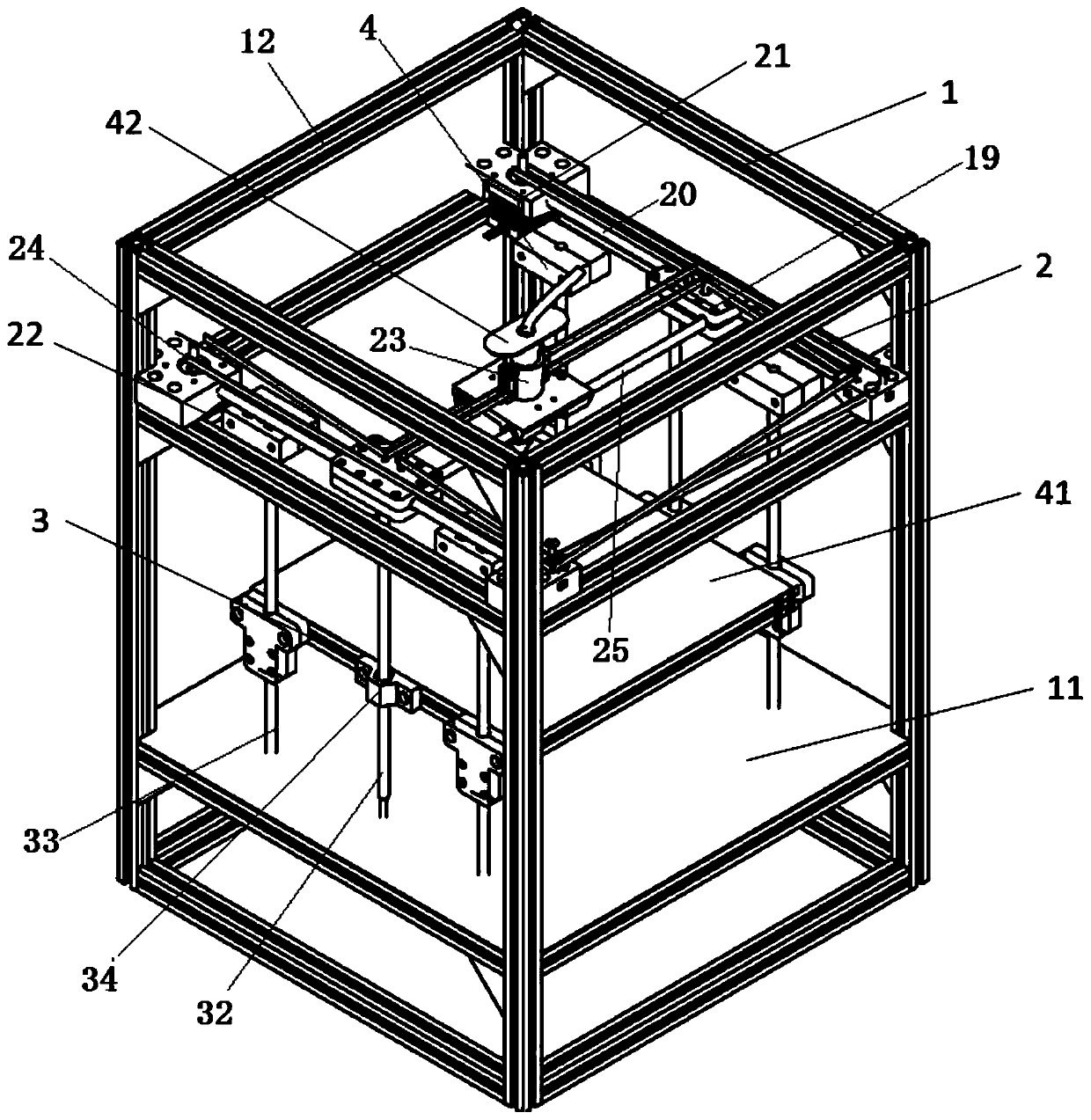

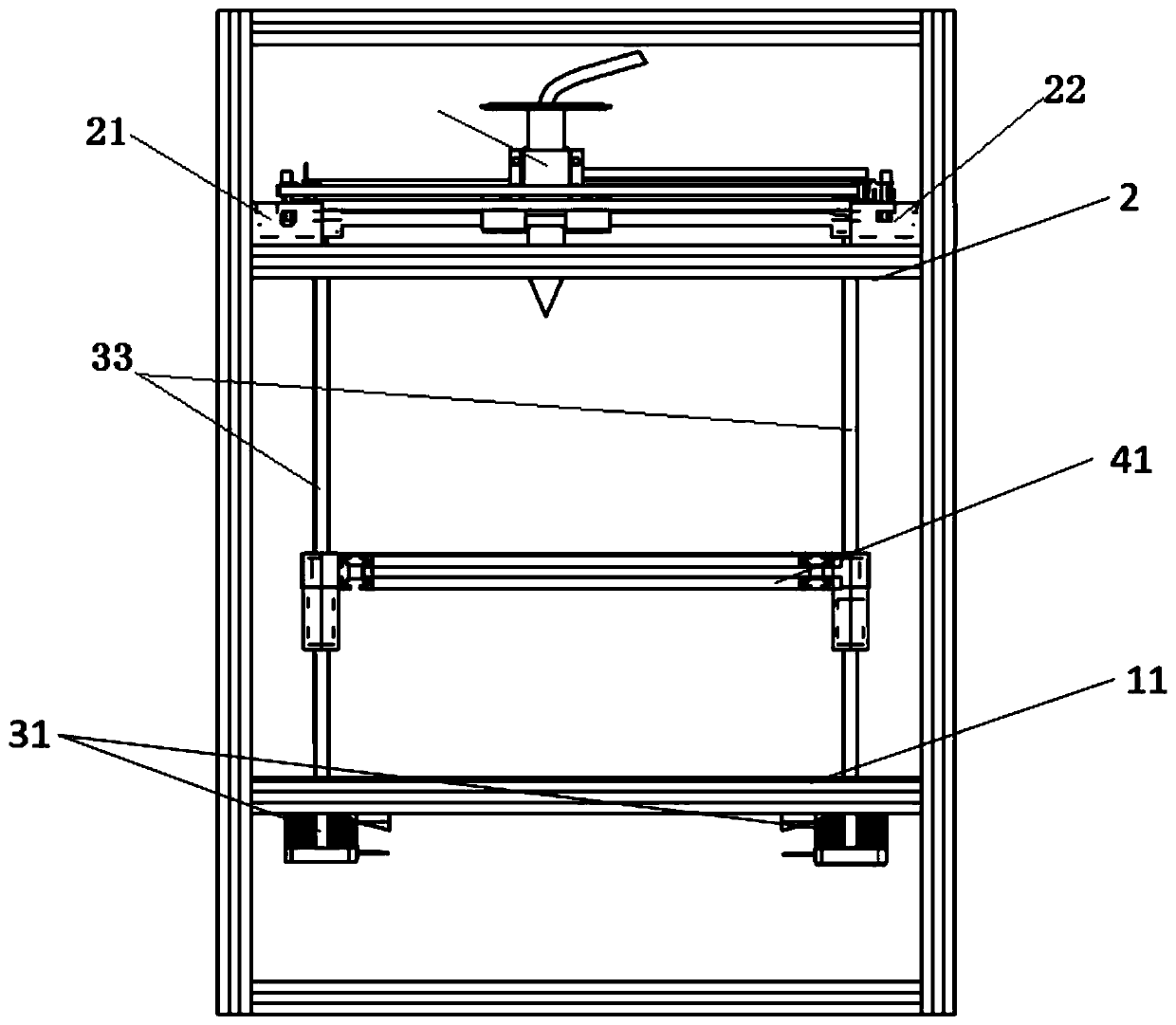

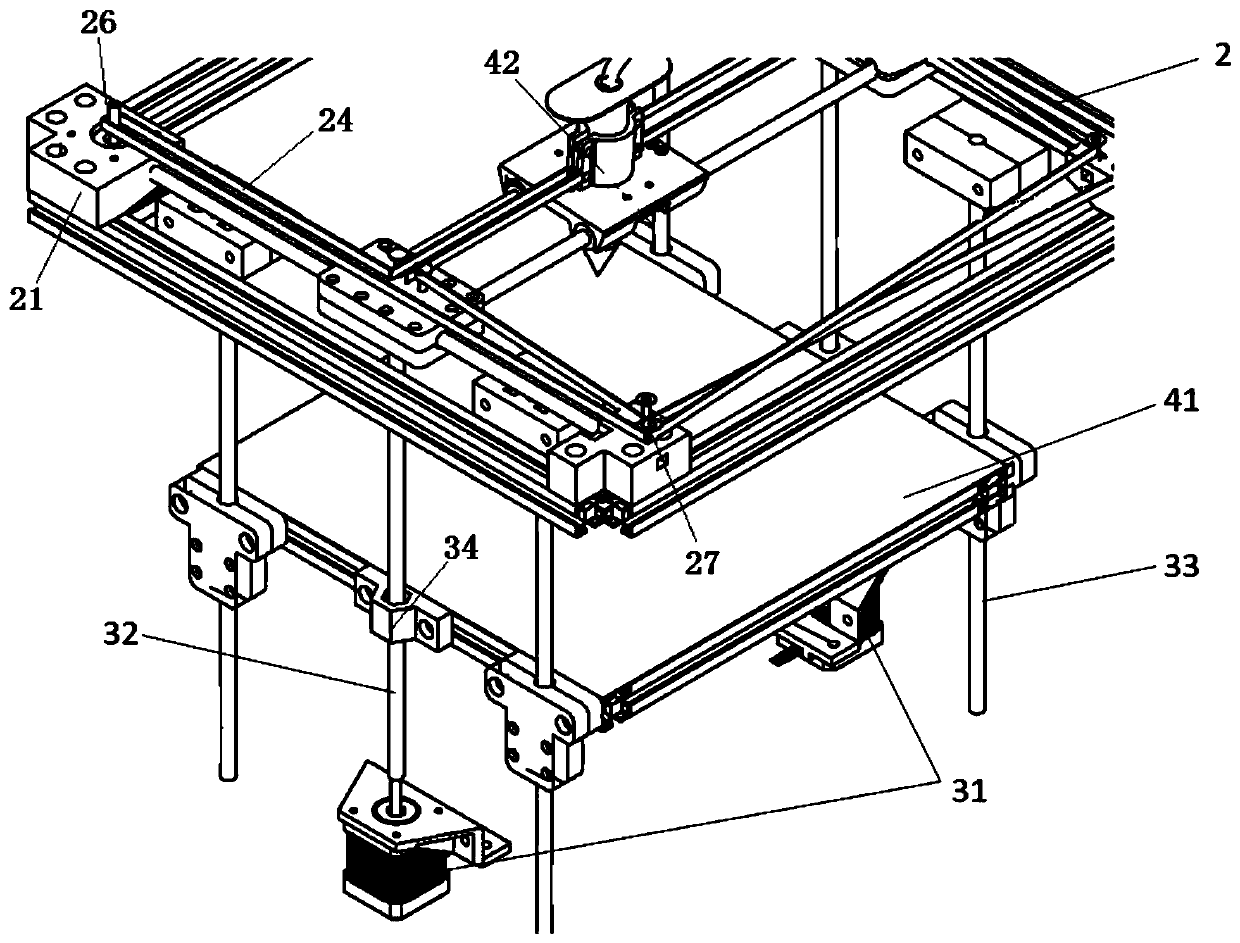

3D printer

ActiveCN112959657ASolve precise controlHigh movement accuracyManufacturing heating elements3D object support structuresThermal dilatationComputer printing

The invention relates to the technical field of printing equipment, in particular to a 3D printer which comprises a bottom frame. Multiple sets of vertical frames are arranged at the top of the bottom frame, a top frame is arranged between any two vertical frames, a cross beam is arranged between the top frames through a Y-axis controller, and an X-axis controller on the outer surface of the cross beam is slidably connected with a printing device; and a bottom plate is arranged at one side of each top frame through a Z-axis controller, the printing device comprises a booster, a raw material pipe is slidably connected into the booster, a heating cavity is formed in the bottom of the booster, the bottom of the heating cavity communicates with a flowing cavity, and a temperature sensor is arranged in the flowing cavity and used for detecting the internal temperature of the flowing cavity. According to the 3D printer, the current value of an electromagnet is controlled to change a gap between a heat-resistant magnetic ball and a spray head and change the volume of a molten material flowing out of the spray head, the material thermal expansion principle is combined, the material volume is increased when the temperature rises, the needed shape and volume are obtained after cooling, the printing effect is good, and the printing precision is high.

Owner:深圳市俩棵树科技有限公司

Printing roll paper cylinder with lubricating function and using method thereof

ActiveCN110065833AGuaranteed normal rotationGuaranteed efficiencyEngine lubricationWebs handlingOil storageRolling paper

The invention discloses a printing roll paper cylinder with a lubricating function and a using method thereof. The printing roll paper with the lubricating function comprises a base, wherein two groups of side plates are symmetrically arranged on the outer wall of the top of the base; the outer wall of the right side of the left side plate is connected with a guide block; the right end of the guide block is connected with a connecting rod; the right end of the connecting rod is slidably connected with the outer wall of the left side of the right side plate; the outer wall of the connecting rodis sleeved with a paper roll cylinder; the inner wall of the top of the paper roll is connected with a brush; and an oil storage groove is formed in the top outer wall of the connecting rod and the top of the guide block. According to the printing roll paper cylinder, lubricating oil in the oil storage groove is uniformly coated on the outer wall of the connecting rod by the brush due to rotationof the paper roll cylinder in a device, frictional force generated when the paper roll cylinder rotates is reduced, normal rotation of the paper roll cylinder is guaranteed, the situation that papercannot be pulled out or damaged due to excessive frictional force between the paper roll cylinder and the connecting rod is avoided, and printing efficiency is guaranteed.

Owner:嘉兴市民华纺织股份有限公司

Front labeling transparent tag and production method thereof

InactiveCN101823400AReduce manufacturing costShortened decorative effectDecorative surface effectsSynthetic resin layered productsSolventComputer science

The invention discloses a front labeling transparent tag and a production method thereof. The production method comprises the following steps that: PP transparent film of different specifications is selected firstly to be spread and adhered onto a working table surface, then the film is silk-screened with color and is dried, then the film is silk-screened with separation gold oil and is dried again, the film is silk-screened with white color as paint base, finally the film is silk-screened with positive-rotation viscose, after being dried, the film is arranged into a drying chamber to be statically held, and after being attached with separation paper, the film is rolled. The entire structure adopts the transparent PP film as a carrier to be sequentially attached with a pattern layer, a separation gold oil layer, a white color paint-base layer and a positive-rotation viscose layer, and the adhesion position can be observed through the PP transparent film, so the adhesion accuracy and convenience can be improved, the adhesion quality and the adhesion speed can be ensured, and the harm of the traditional solvent on the operator and the pollution on the environment can be prevented; and moreover, the front labeling transparent tag has low production cost and good decorative effect, and is particularly suitable for being directly adhered onto the top-grade light material.

Owner:刘桂清

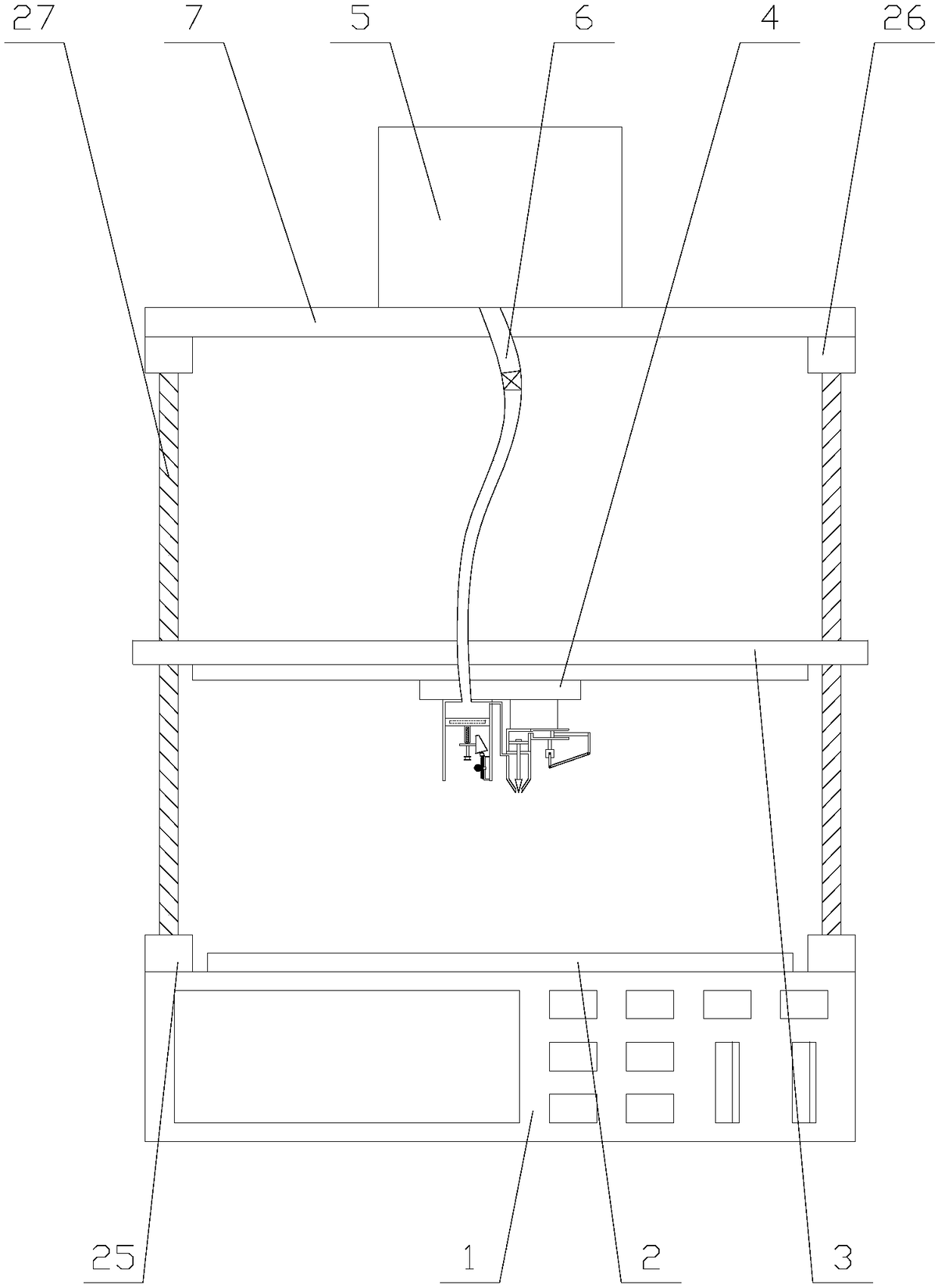

3D printer with adjusting function

ActiveCN109177157AGuaranteed uptimePrecise control of movement speedManufacturing heating elementsAdditive manufacturing with liquidsSprayerEngineering

The invention relates to a 3D printer with an adjusting function. The 3D printer comprises a host, a printing platform, a lifting plate, a planer moving device, a translation plate, a discharging device, a material box, a material pipe, a top plate and four lifting mechanisms; the discharging device comprises a heating pipe, a connecting pipe, a connecting block and a discharging mechanism; a heating plate and a speed regulating mechanism are arranged in the heating pipe; the speed regulating mechanism comprises a turntable, a support component, a first motor, a driving block, a speed regulating assembly, a rotating shaft and a sleeve; the discharging mechanism comprises a sprayer, a first cylinder, a second cylinder and a translation component; an adjusting block and a vertical rod are arranged in the sprayer. The 3D printer with the adjusting function is capable of accurately controlling the moving speed of the heating plate by the speed governing device according to the accuracy requirement of print positions, so that the printing efficiency can be guaranteed and the printing precision can be promoted. Meanwhile, the size of the gap of the opening of the sprayer can be adjustedby the discharging mechanism, so that the discharging speed can be adjusted according to the printing requirement and the practicality of the device is improved.

Owner:永康市普方铝业有限公司

Silica gel 3D printer based on Core XY structure and printing method thereof

InactiveCN111516260ASolve the technical problem of low printing accuracyAutomatic correction of printing accuracyManufacturing platforms/substratesManufacturing heating elementsComputer printingEngineering

The invention discloses a silica gel 3D printer based on a Core XY structure and a printing method thereof. The silica gel 3D printer comprises a rack, a printing module, a horizontal plane electric module, a vertical axis electric module, a horizontal track positioning module, a vertical axis track positioning module, a running track generation module and a master control module, wherein the printing module comprises a printing plane and a gel dispensing needle cylinder, the horizontal plane electric module comprises a horizontal movement platform, the horizontal plane electric module drivesthe gel dispensing needle cylinder to move in the X-axis or Y-axis direction, the vertical axis electric module drives the printing plane to move in the Z-axis direction of the rack, the horizontal track positioning module comprises a first distance sensor and a second distance sensor, the vertical axis track positioning module comprises a third distance sensor, the running track generation moduleobtains a three-dimensional running track curve of the gel dispensing needle cylinder, and the master control module is used for correcting the three-dimensional running track curve. The 3D printer has the deviation self-correcting function, improves the printing precision and the printing effect, and guarantees the stability of 3D printing.

Owner:HEFEI UNIV OF TECH

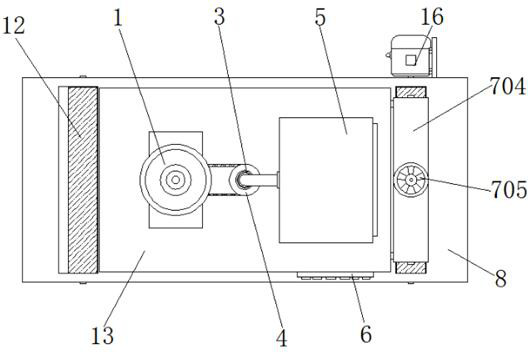

Printing machine with good drying effect

ActiveCN112009090AGuaranteed printing efficiencyAffect clarityDispersed particle separationRotary pressesTextile printerElectric machinery

The invention discloses a printing machine with a good drying effect. The printing machine comprises a mounting table. A drying cabin is mounted at the top of the mounting table; a servo motor is mounted at one end of the top of the drying cabin; a mounting pipe is arranged in the middle of the top of the drying cabin; belt wheels are mounted at the top of the outer side of the mounting pipe and the output end of the servo motor correspondingly; the outer sides of the belt wheels are jointly sleeved by a belt; a first rotary joint is mounted at the top end of the mounting pipe; and a drying assembly is arranged at the bottom end of the outer side of the mounting pipe. According to the printing machine with the good drying effect, a pressing assembly, the mounting table, supporting legs, aprinting machine body, the drying assembly, and a driving motor are used in cooperation; and heat generated by electric heating wires is used for drying printing ink on paper, the printed paper can becontinuously dried, so that the situation that the printing ink on the paper is blurred due to external factors, and consequently the printing definition of the whole paper is affected is avoided, and therefore the printing efficiency of the printing machine is guaranteed.

Owner:佛山市中联伟业纸品有限公司

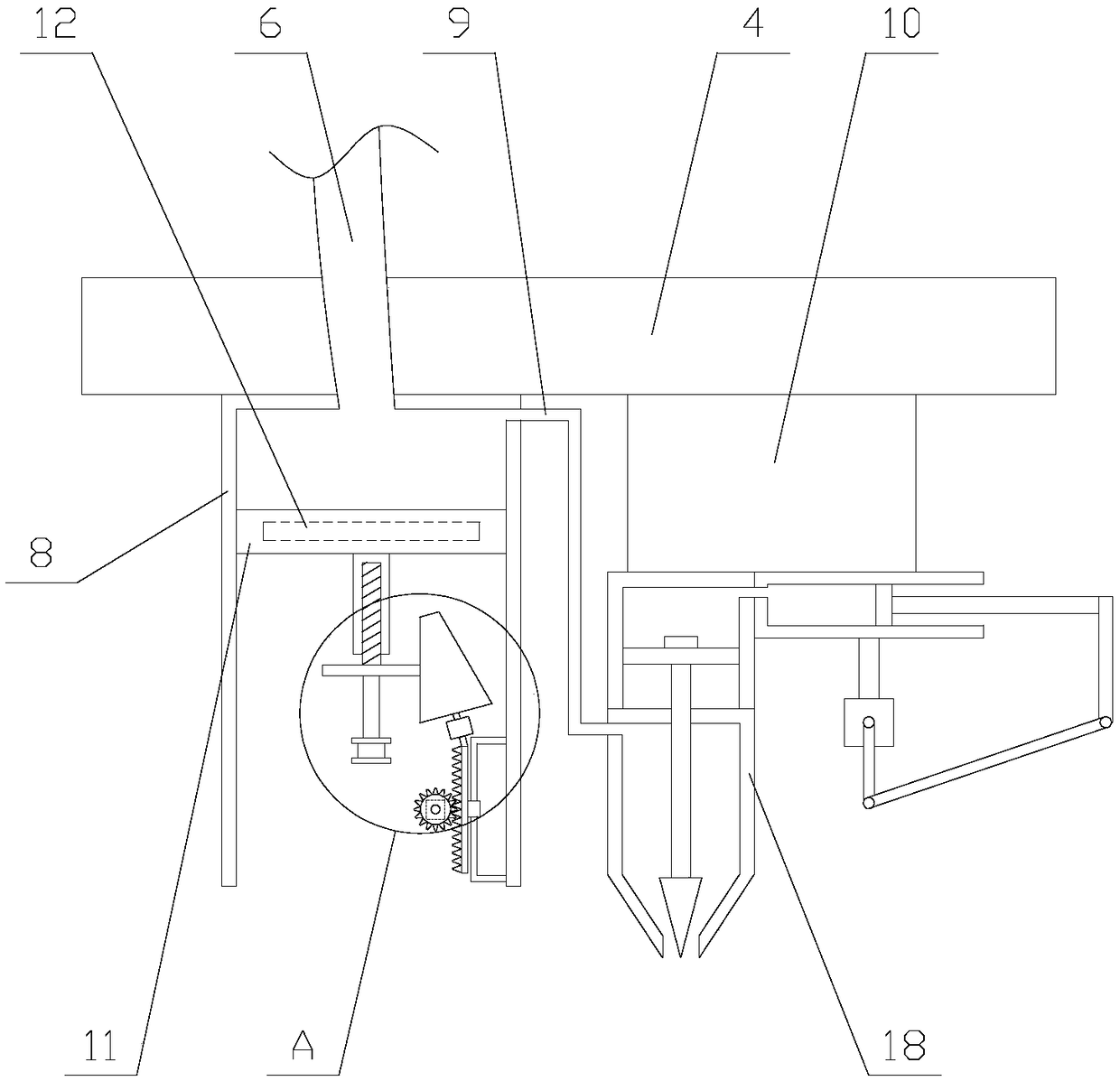

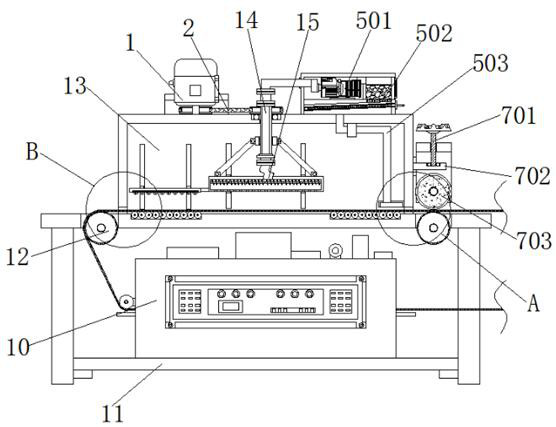

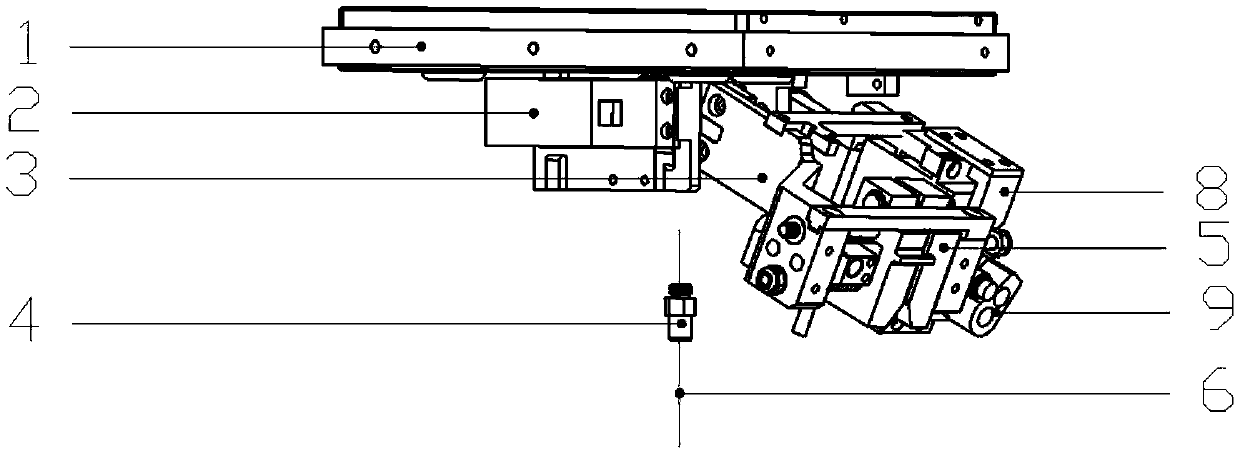

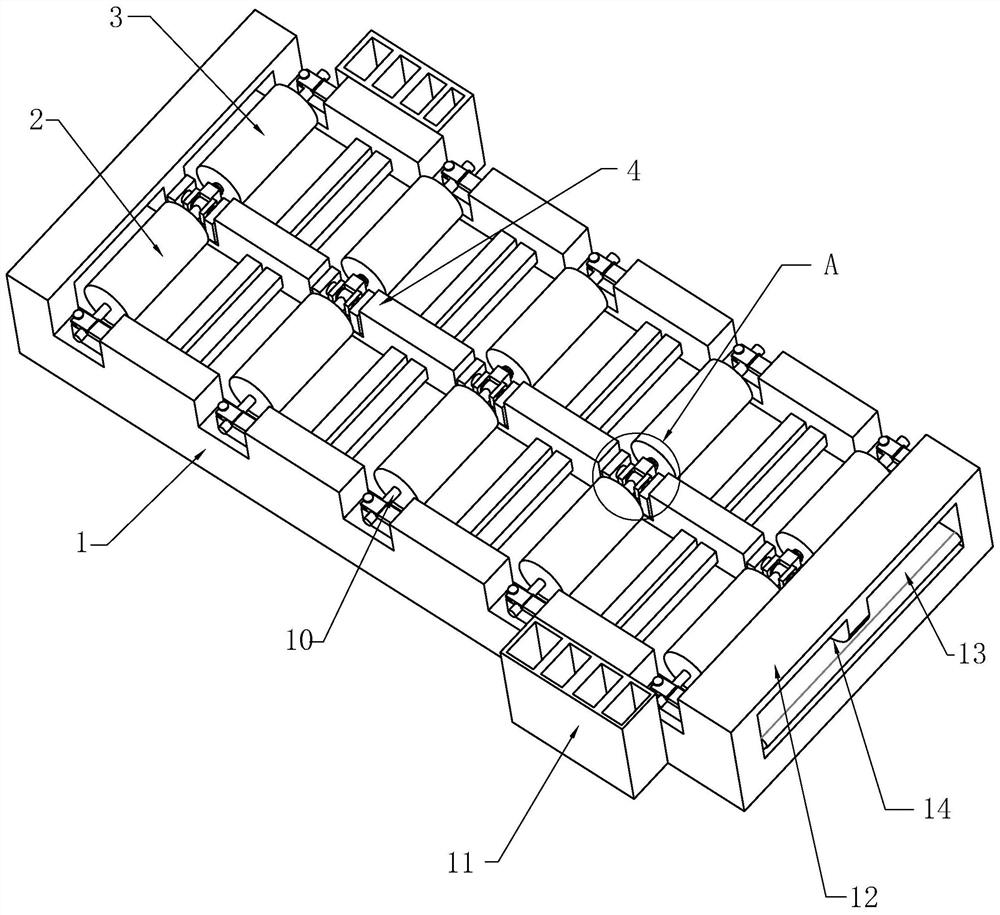

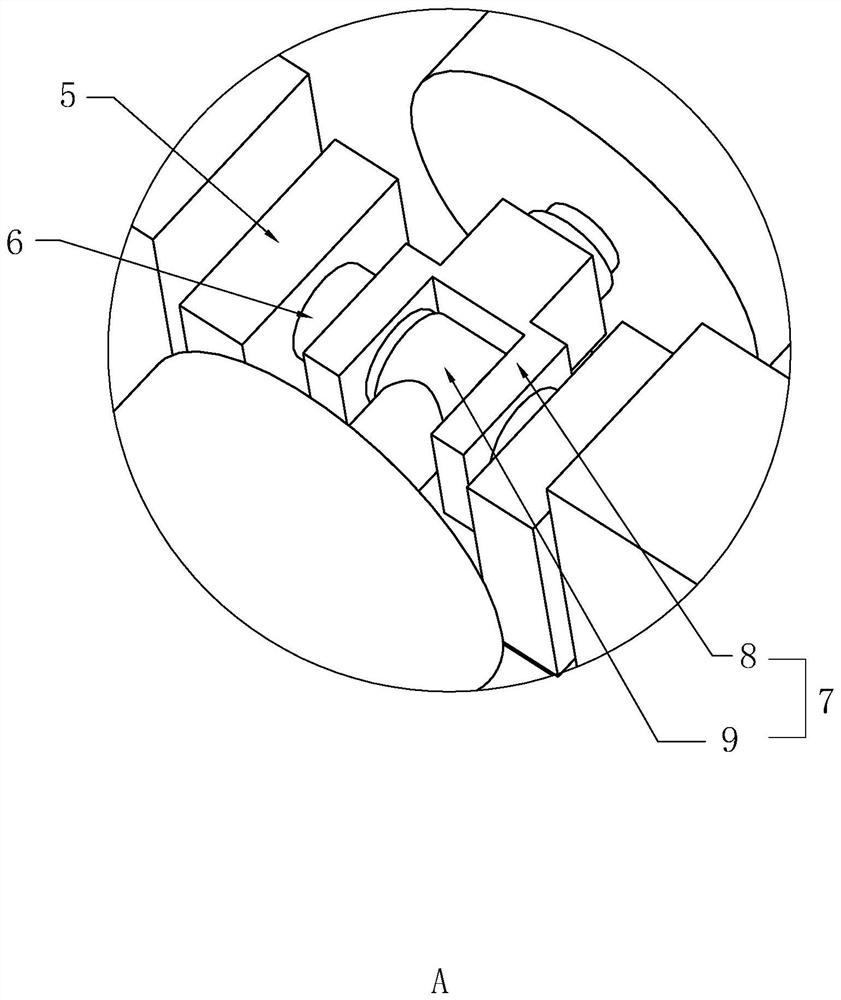

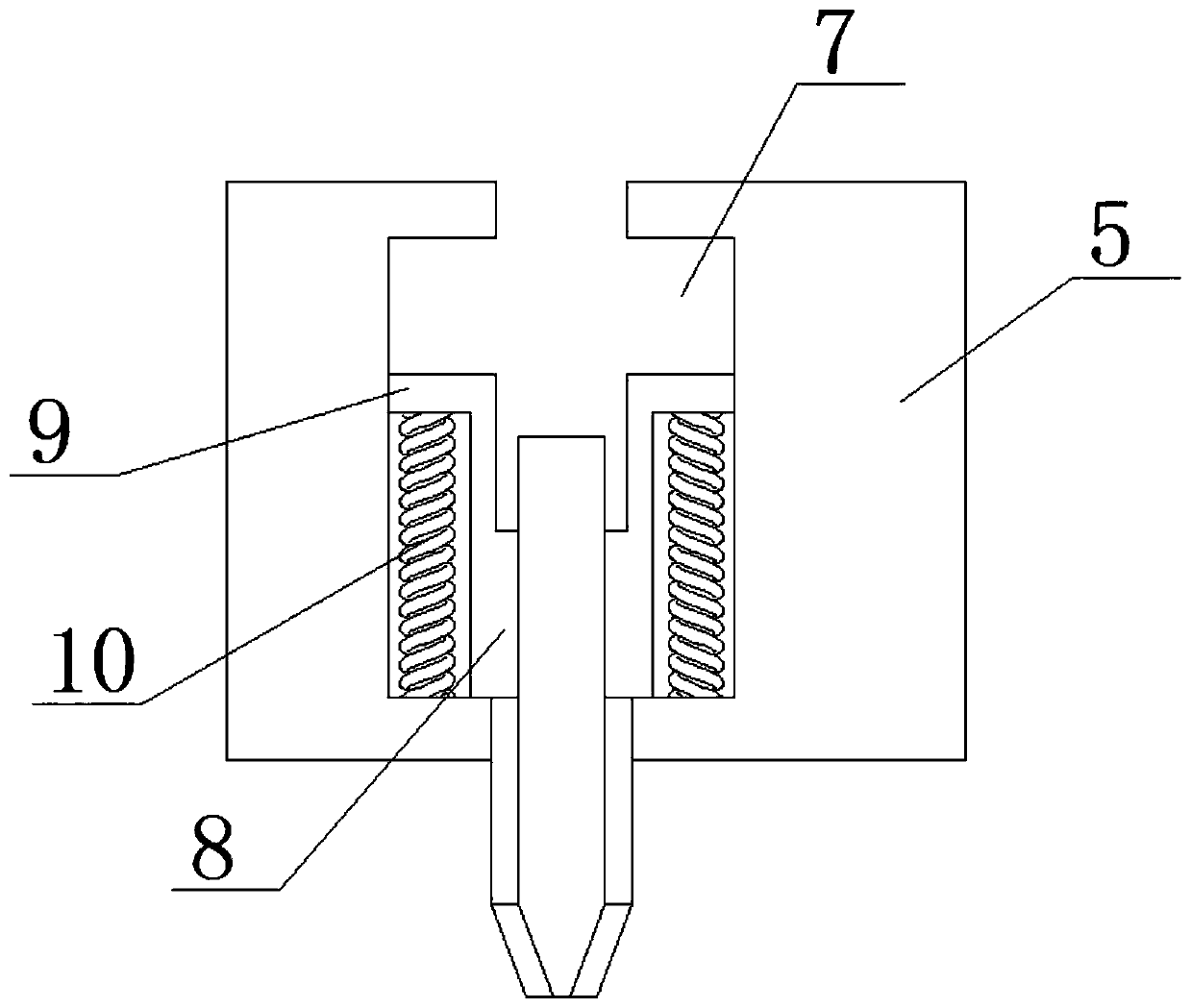

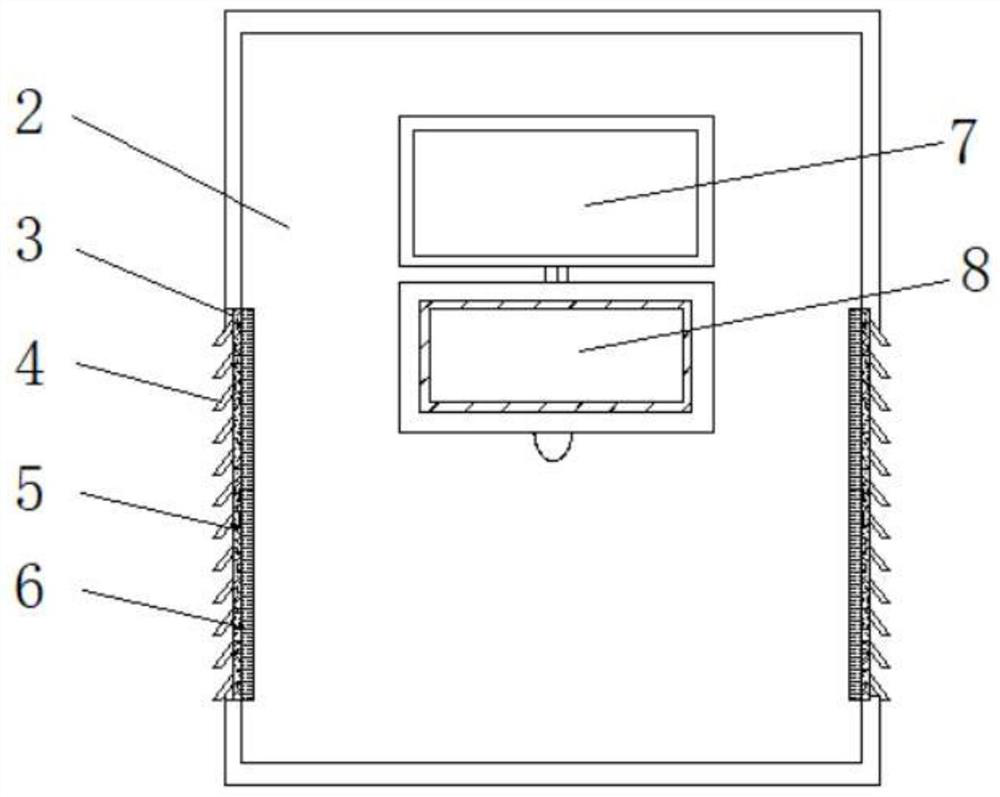

Intelligent switching double-spray-head 3D printer

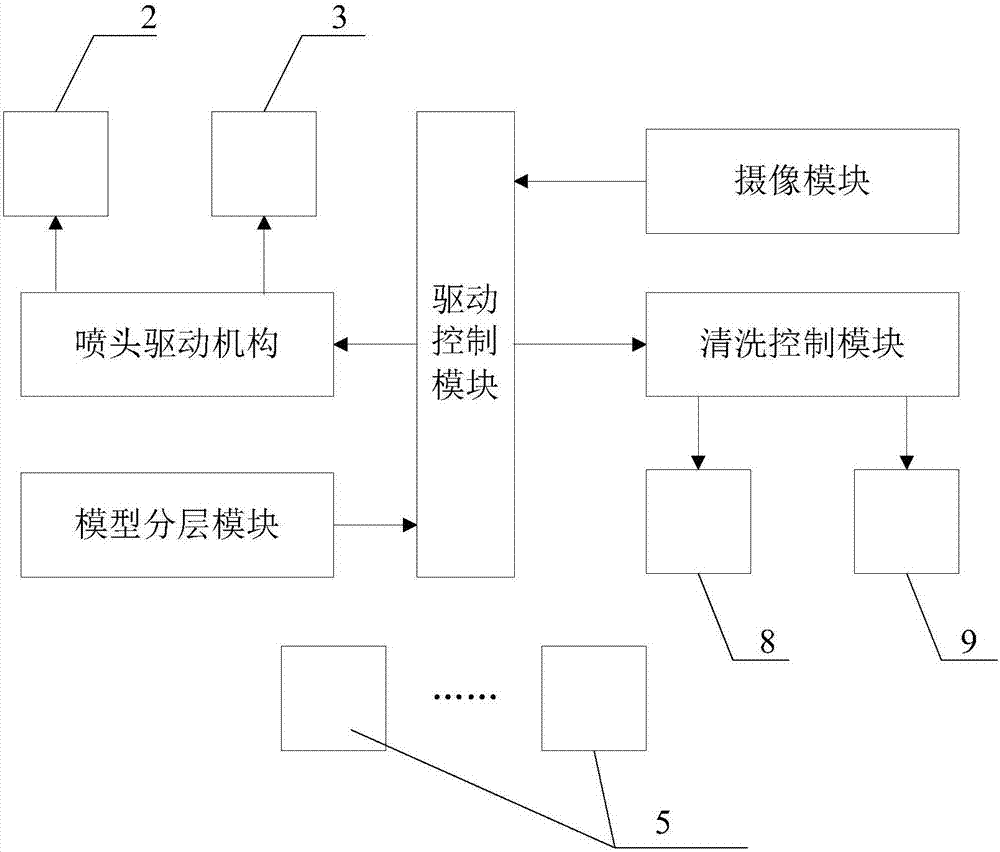

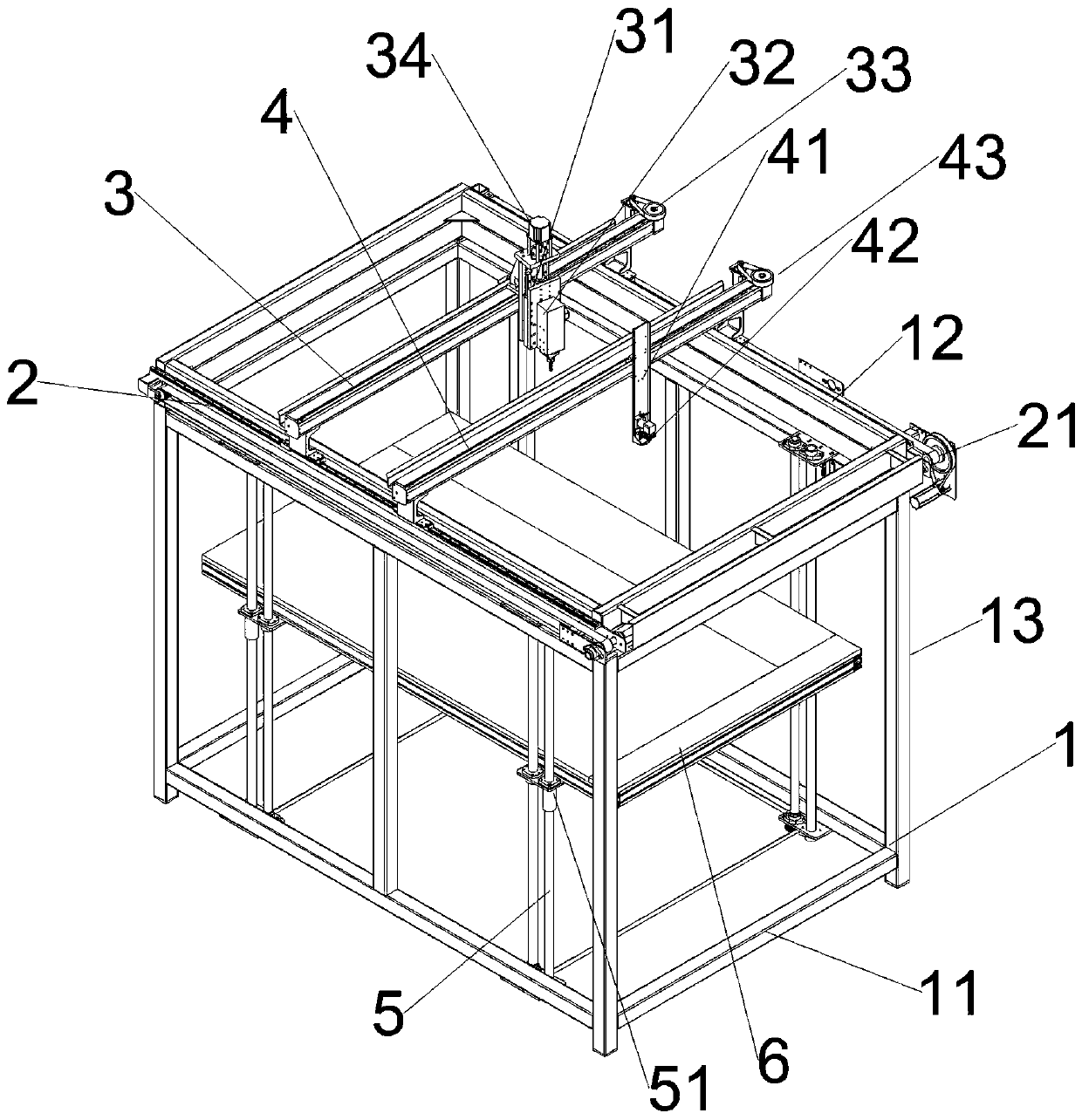

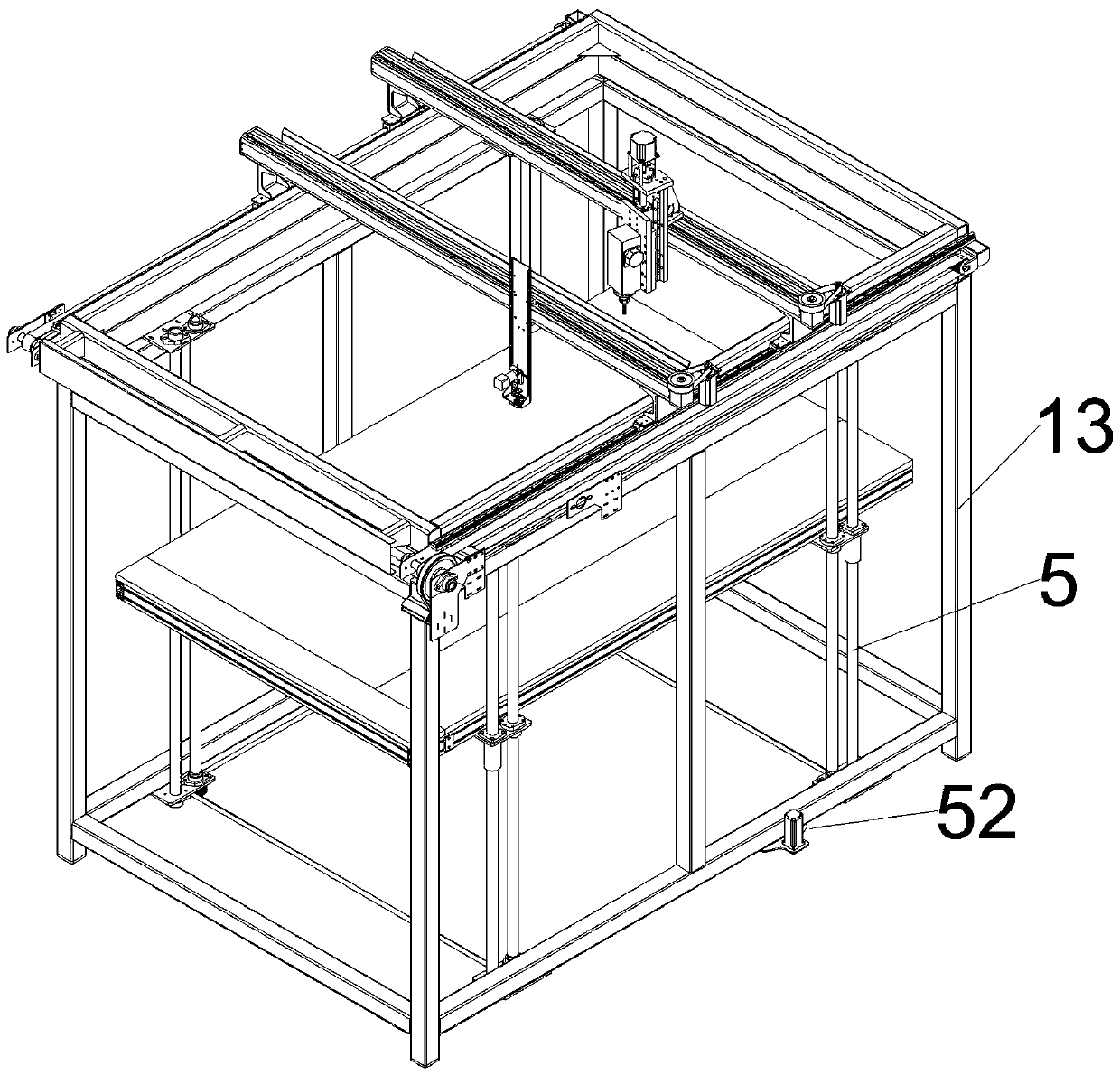

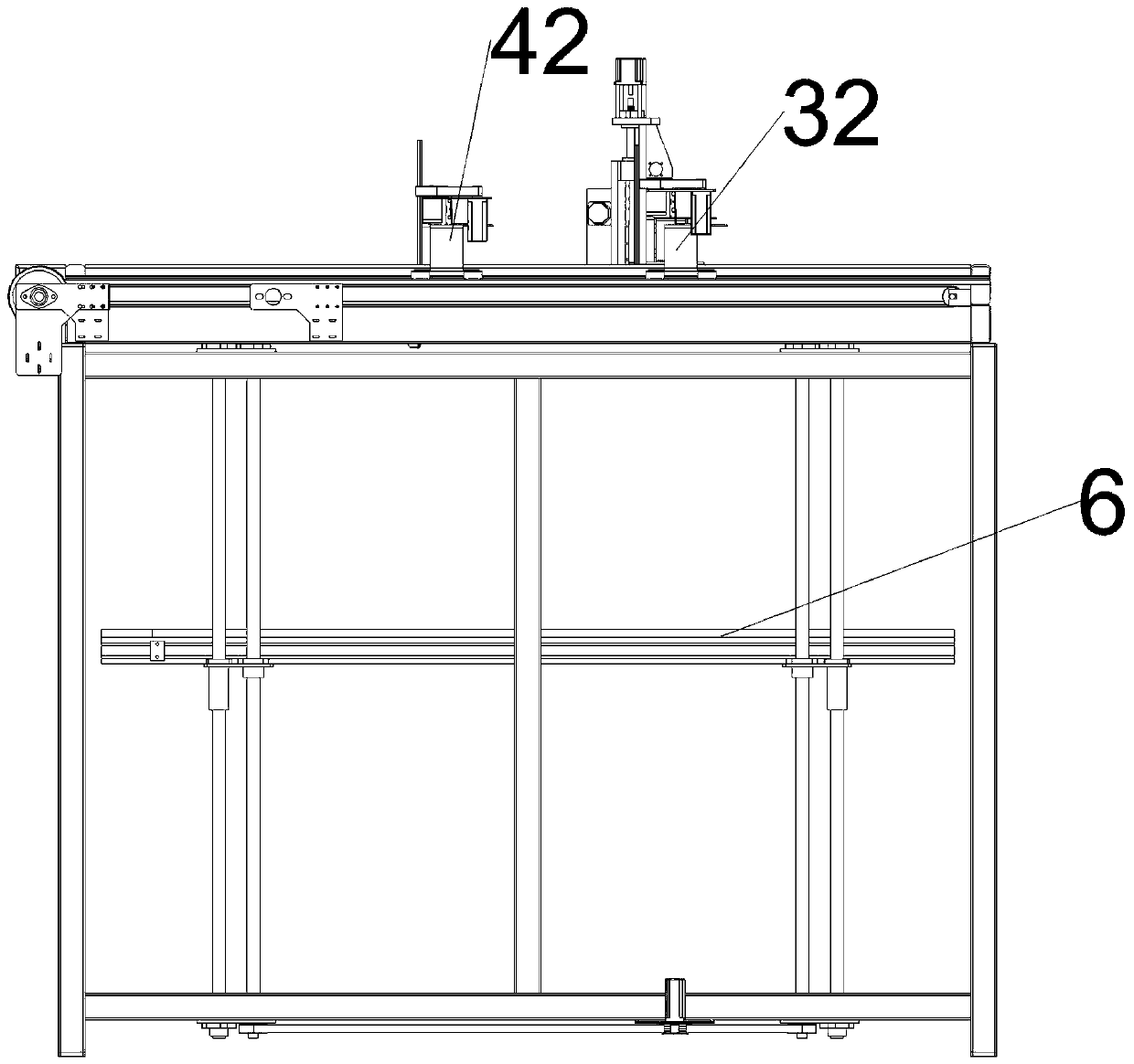

ActiveCN107139468AGuaranteed printing efficiencySave human effort3D object support structuresManufacturing data aquisition/processingEngineering3d printer

The invention discloses an intelligent switching double-spray-head 3D printer which comprises a supporting rack A, a plurality of raw material storage tanks 1, a first spray head 2, a second spray head 3, a tray B, a cleaning water tank 6, a recovery water tank 7, a first cleaning pump 8, a second cleaning pump 9, a spray head driving mechanism, a model layering module, a camera shooting module, a driving control module and a cleaning control module. The driving control module intelligently controls the first spray head and the second spray head to work through the spray head driving mechanism, so that the printing work of the first spray head and the printing work the second spray head are linked automatically, the printing efficiency is ensured, and the manpower is saved.

Owner:安徽新芜精密装备制造产业技术研究院有限公司

3D printing model forming method and 3D printer for implementing same

InactiveCN107932903AImprove the finishHigh precisionAdditive manufacturing apparatusManufacturing auxillary operationsSurface finish3d printer

The invention relates to a 3D printing model forming method and a 3D printer for implementing the same. According to the method, a 3D printing head is linked with an engraving head, the engraving headfor performing milling machining on the outer surface of a model is arranged on a machine body, and the to-be-printed model is designed to adopt upper and lower sectional printing. The method mainlycomprises steps as follows: (1) the bottom section of the model is printed by the aid of the 3D printing head; (2) the 3D printing head is removed, and milling machining is performed on the outer surface of the bottom section by the aid of the engraving head; (3) the engraving head is removed, and the adjacent section on the upper side is printed continuously in a laminated manner at the upper endof the bottom section by the aid of the 3D printing head; (4) the printing head is removed, and milling machining is performed on the outer surface of the adjacent section on the upper side by the aid of the engraving head; (5) the step (3) and the step (4) are repeated on the basis of the adjacent section on the upper side, printing is completed, and surface finish processing after printing isperformed on all sections of the model.

Owner:郑州智高电子科技有限公司

Printer and adapter work control method and device thereof, and readable storage medium

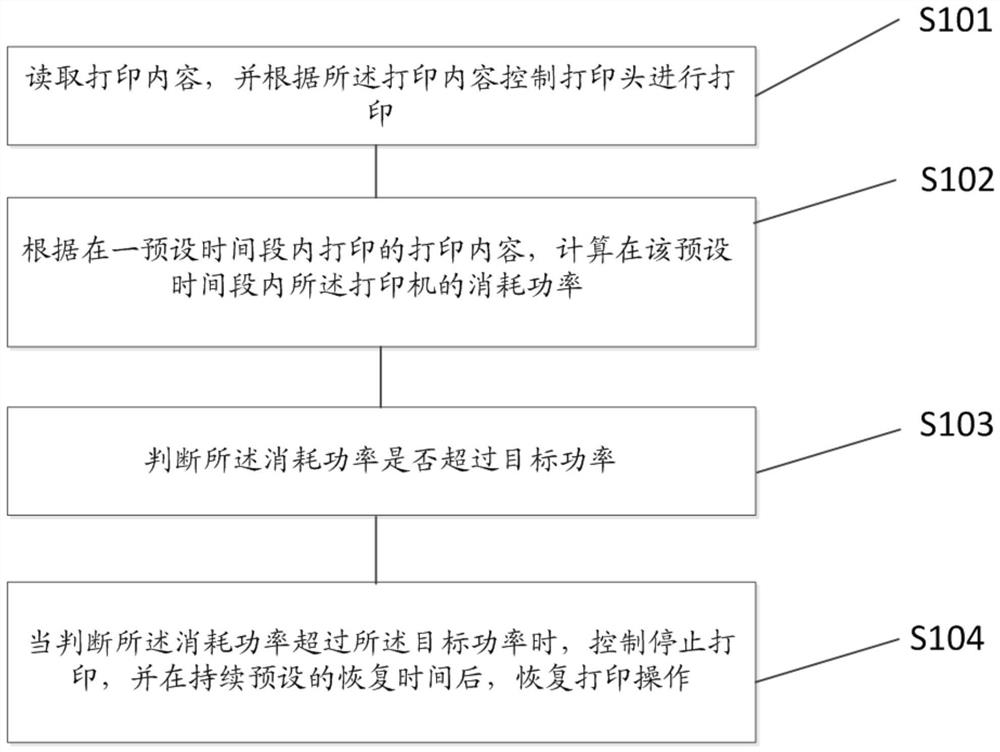

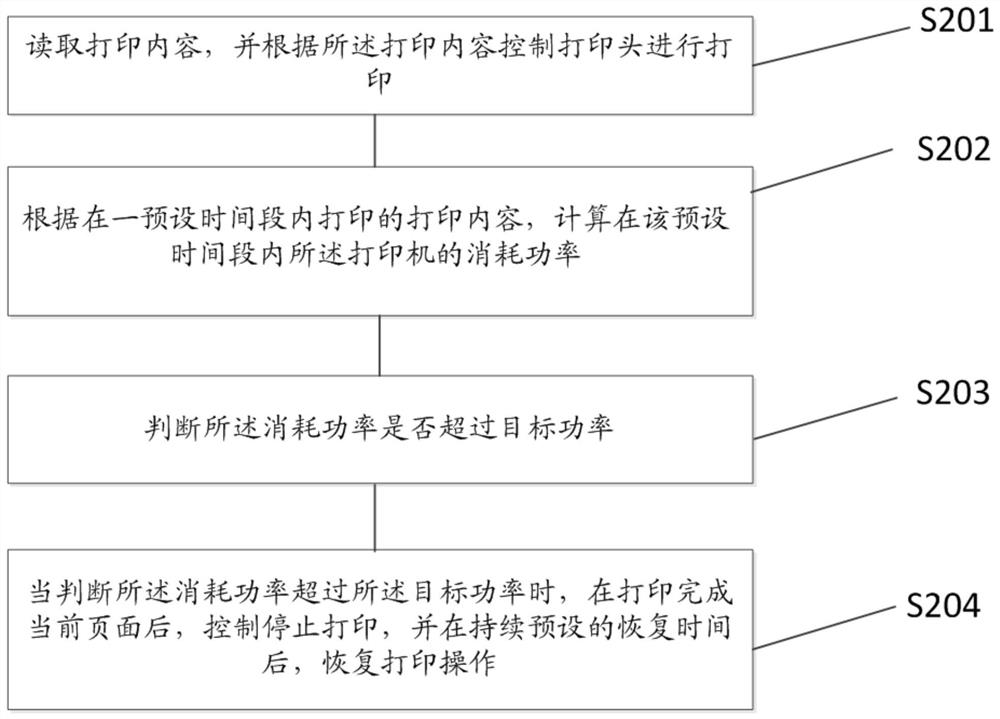

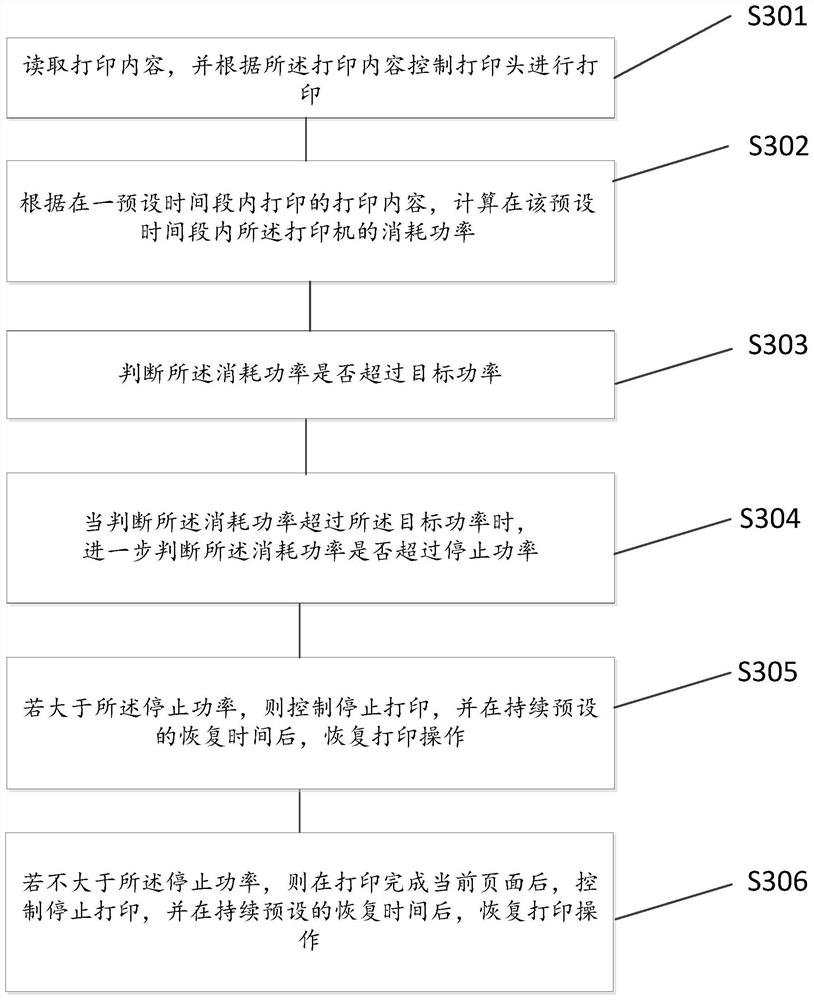

PendingCN113434096AAvoid damageLow costEnergy efficient computingDigital output to print unitsComputer printingProcess engineering

The invention discloses a printer and an adapter work control method and device thereof, and a readable storage medium, wherein the method comprises the steps of reading printing content, and controlling a printing head to print according to the printing content; calculating the consumed power of the printer in a preset time period according to the printing content printed in the preset time period; judging whether the consumed power exceeds target power or not; when it is judged that the consumed power exceeds the target power, stop printing, and continue printing when operation is recovered after preset recovery time, wherein the target power and the recovery time are determined according to parameters of an adapter of the printer. Printing requirements under different conditions can be met without adopting a high-performance adapter, and the printing efficiency is guaranteed on the premise that the cost of the whole printer is reduced as much as possible.

Owner:XIAMEN HANIN ELECTRONICS TECH CO LTD

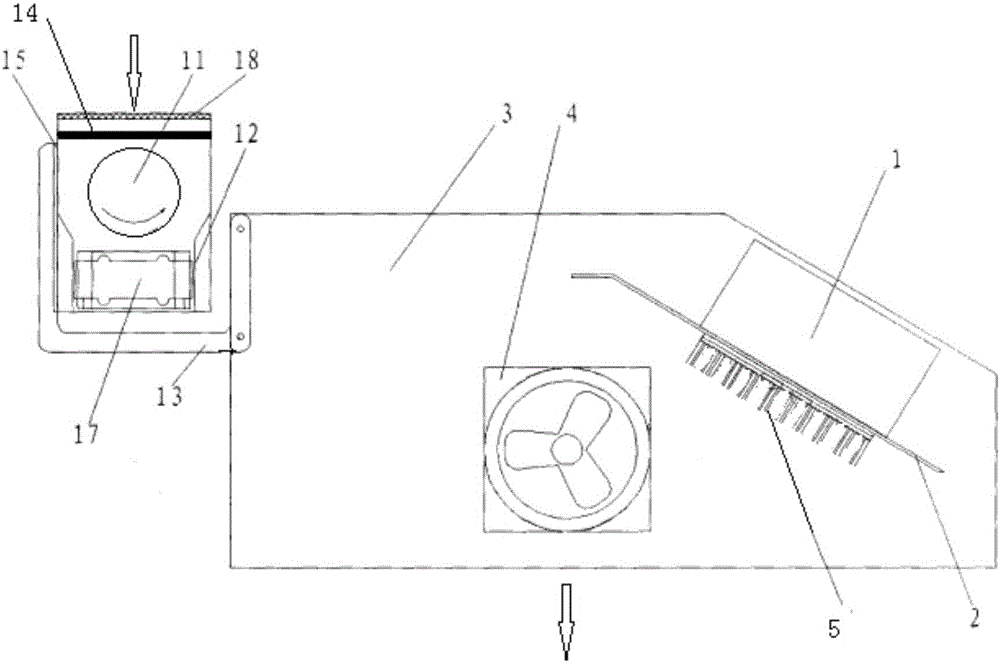

Drying assembly of medical film printer

InactiveCN106394006AKeep dryGuarantee quality and efficiencyOther printing apparatusEngineeringMechanical engineering

The invention provides a drying assembly of a medical film printer. The drying assembly of the medical film printer is characterized in that the drying assembly comprises an inner drying assembly and an outer drying assembly which is arranged above a film outlet of the printer. A printer shell comprises baffles at the left side and the right side. A printer head is installed on the inner side of one baffle. The drying assembly of the medical film printer has the beneficial effects of guaranteeing printing quality and improving printing efficiency.

Owner:HEFEI FILIM DIGITAL TECH CO LTD

Indoor and outdoor portable integrated method and device for preventing seal from being stolen

ActiveCN114103495AGuaranteed printing efficiencyGuaranteed clarityPackage recyclingTypewritersStampingComputer printing

The invention relates to an indoor and outdoor portable seal and seal stealing prevention integrated method and device. The device comprises a box body, a printer, an intelligent sealing unit, a paper storage box, a scanner and a central control processor. By arranging the multiple movable stamping machines used for storing the seals of the corresponding types, automatic stamping of the movable stamping machines in the device can be effectively achieved, and after the corresponding movable stamping machines are taken out of the device, the movable stamping machines are used for safe stamping during business outgoing, so that the seals can be efficiently used for stamping in the device and stamping outside the device; and the storage efficiency of the device for multiple seals and the storage safety efficiency of each seal are effectively improved.

Owner:SHENZHEN INFOTECH TECH

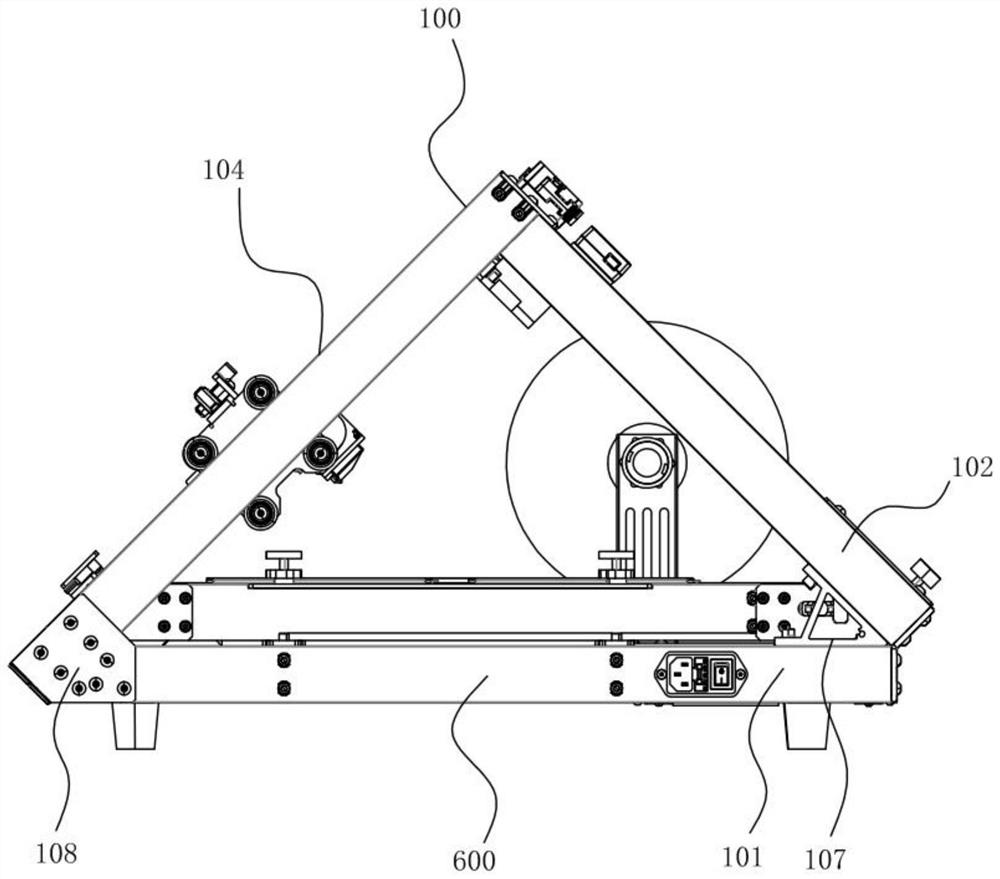

3D printer

PendingCN112046000AExtruder Assembly MovementFlexible moving processManufacturing platforms/substratesManufacturing driving meansComputer printingEngineering

The invention discloses a 3D printer. The 3D printer comprises a triangular-prism-shaped frame, a spray head moving assembly installed on the triangular-prism-shaped frame, a spray head assembly installed on the spray head moving assembly, a feeding assembly installed on the triangular-prism-shaped frame, a material breaking detection assembly, a display assembly and a power supply mainboard assembly; and the power supply mainboard assembly is electrically connected with the spray head moving assembly, the spray head assembly, the feeding assembly, the material breaking detection assembly andthe display assembly. The 3D printer is provided with the triangular-prism-shaped frame, a transmission assembly is arranged at the bottom of the triangular-prism-shaped frame, and infinite-length printing is achieved through belt conveying of the transmission assembly.

Owner:SHENZHEN CREALITY 3D TECH CO LTD

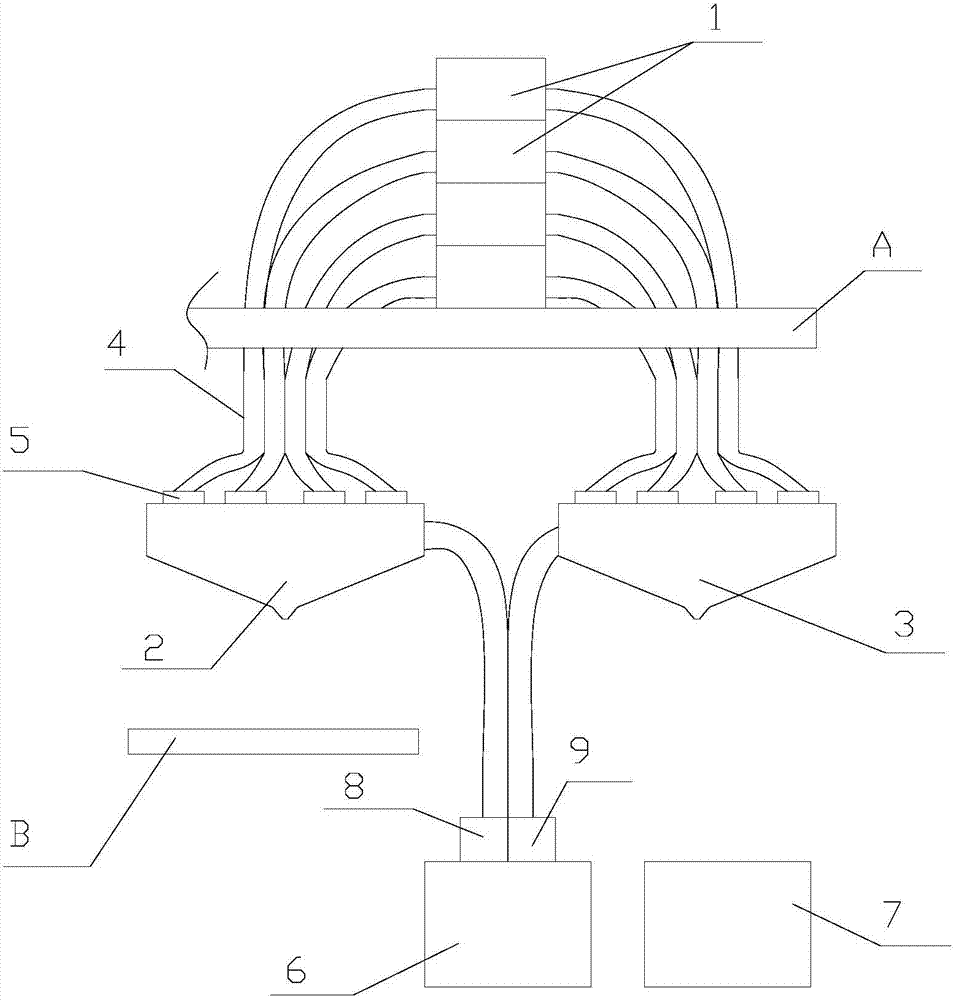

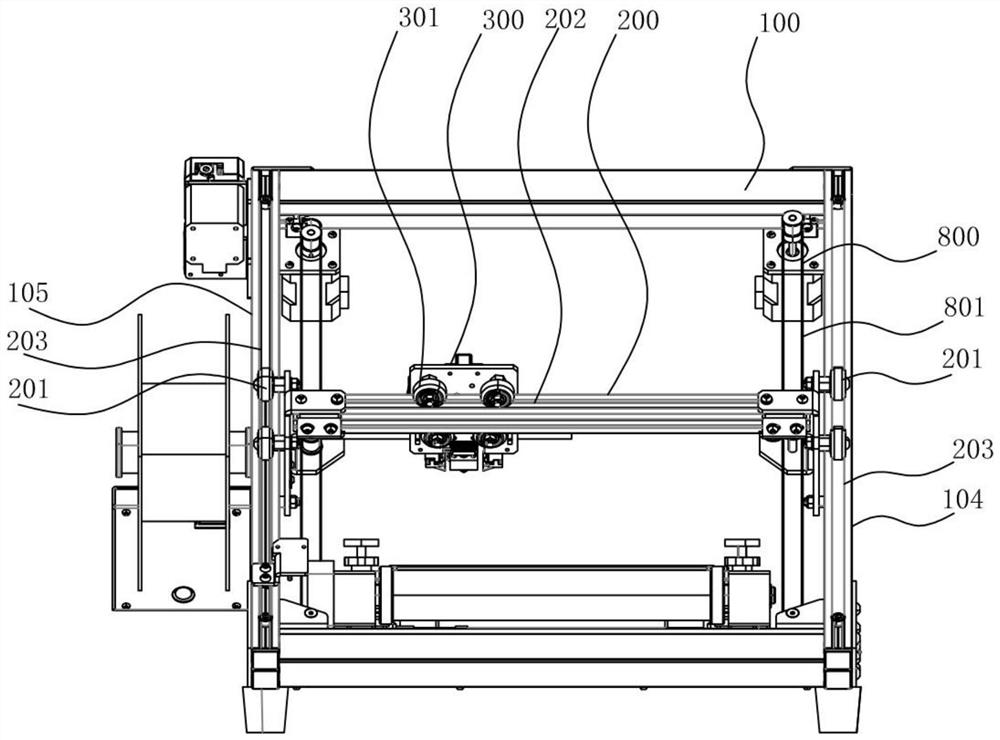

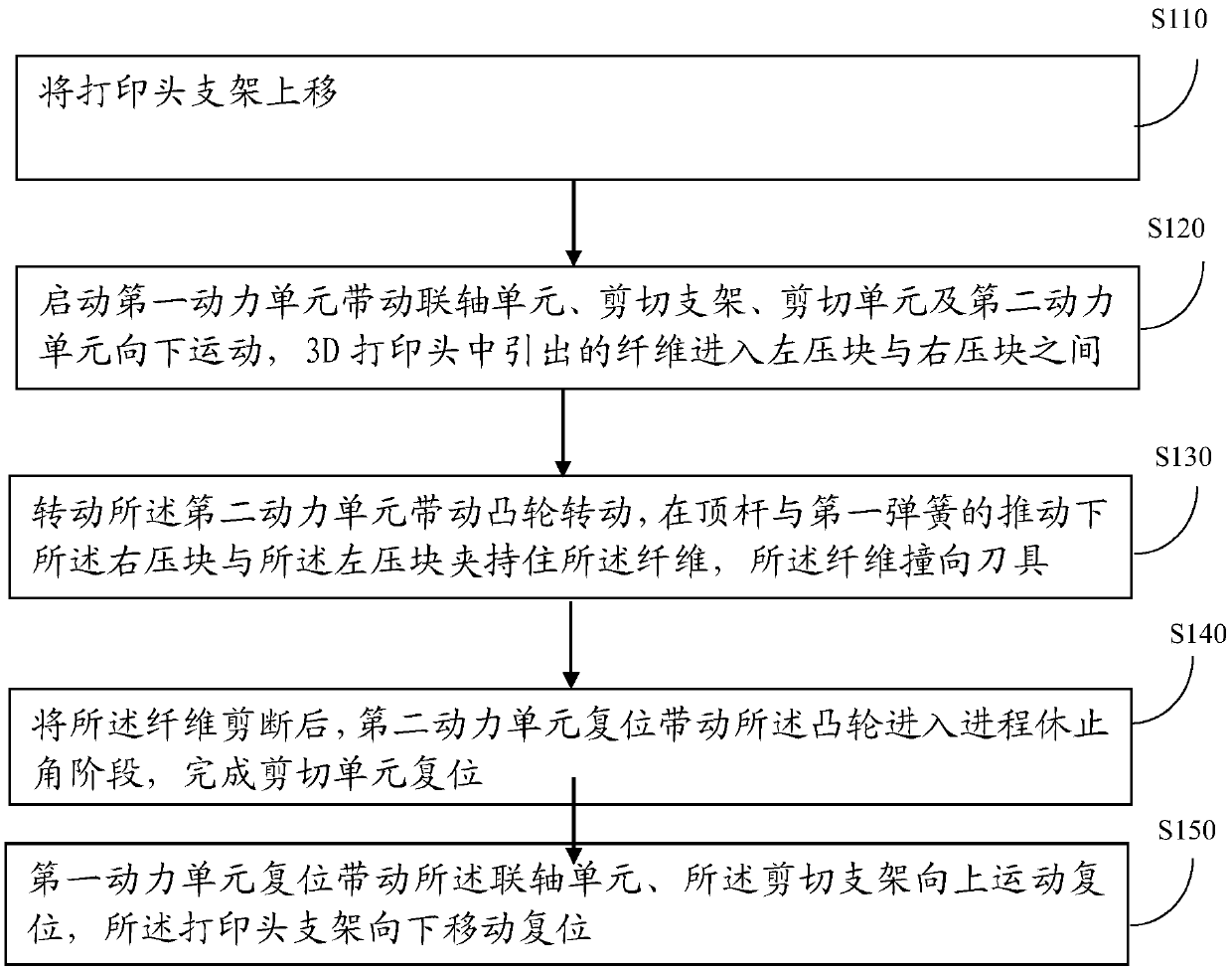

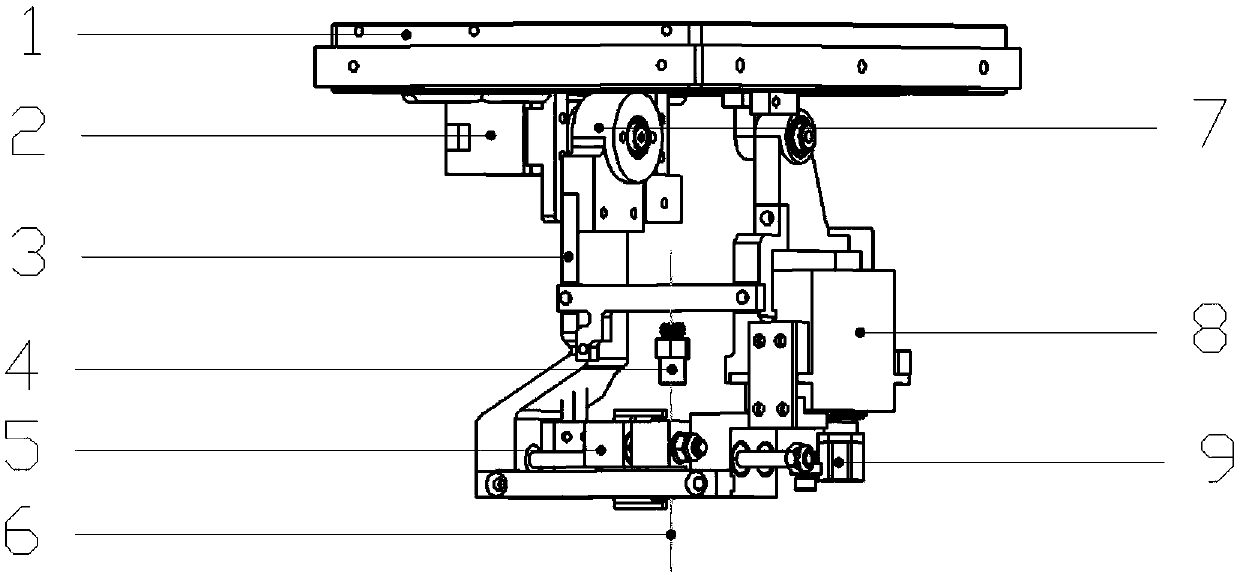

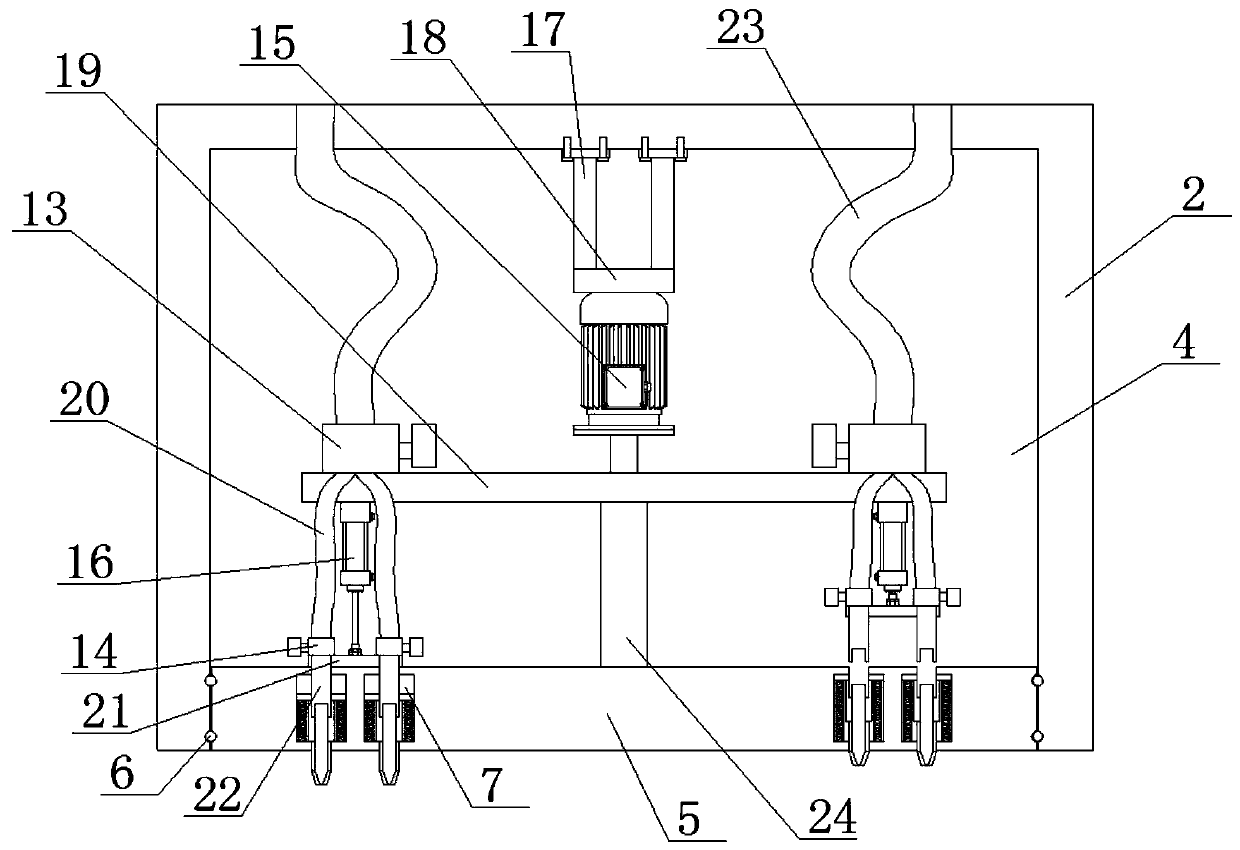

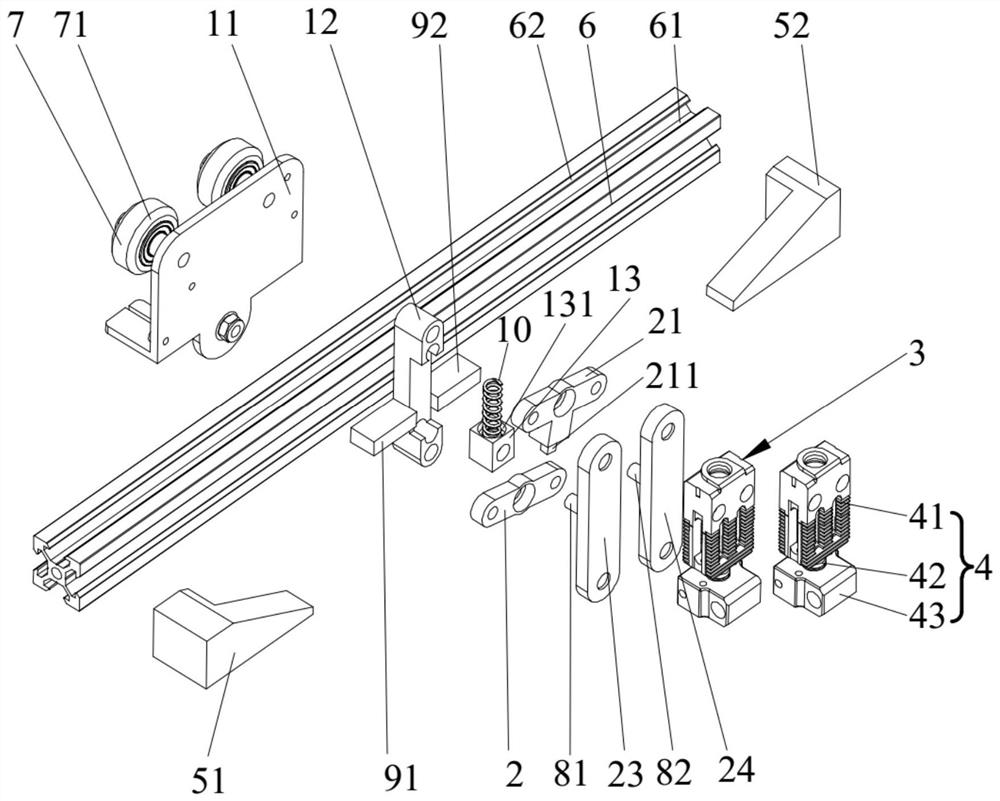

Fiber shearing method and device for 3D printing of continuous fiber reinforced composite material

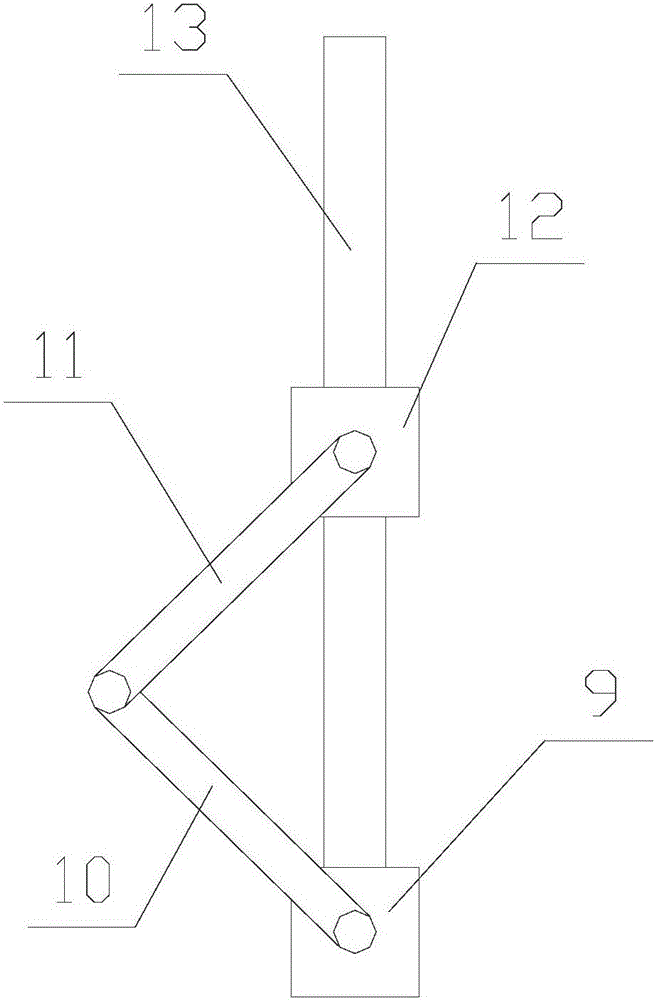

PendingCN109094016AImprove printing efficiencyImprove stabilityManufacturing driving means3D object support structuresCouplingEngineering

The invention provides a fiber shearing method and device for 3D printing of a continuous fiber reinforced composite material. The method comprises the following steps: a printing head bracket is moved upwards; a first power unit is started to drive a coupling unit, a shearing bracket, a shearing unit and a second power unit to move downwards, and fibers led out of a 3D printing head enter betweena left pressing block and a right pressing block; the second power unit is rotated to drive a cam to rotate, and the fibers are clamped by the right pressing block and the left pressing block under pushing of an ejector rod and a first spring; after the fibers are sheared, the second power unit resets to drive the cam to enter a process repose angle stage, and reset of the shearing unit is completed; the print head bracket moves downwards to reset. The technical problems that existing shearing devices have poor reliability, limited applicable material range and high requirement on calculationand control precision in the printing process are solved, and the technical effects of improving printing efficiency and stability of the composite material, reducing the requirement on calculation and control precision and saving cost are achieved.

Owner:陕西斐帛科技发展有限公司

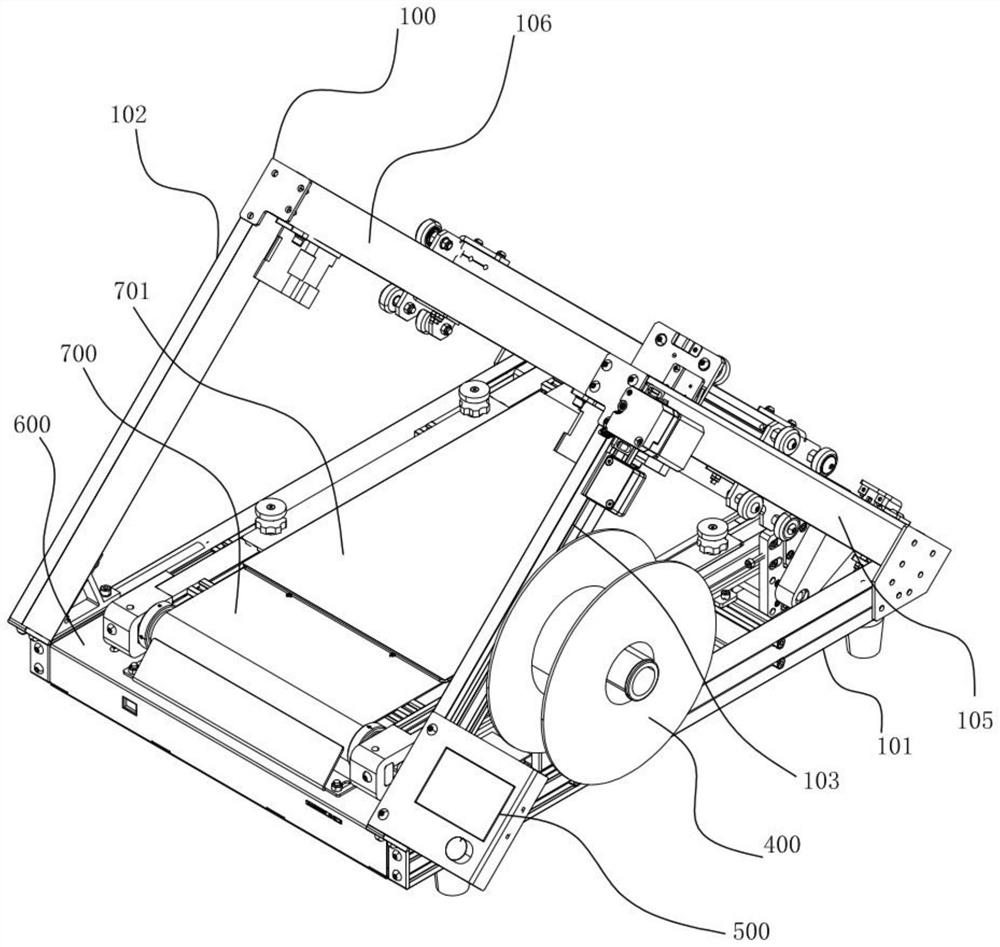

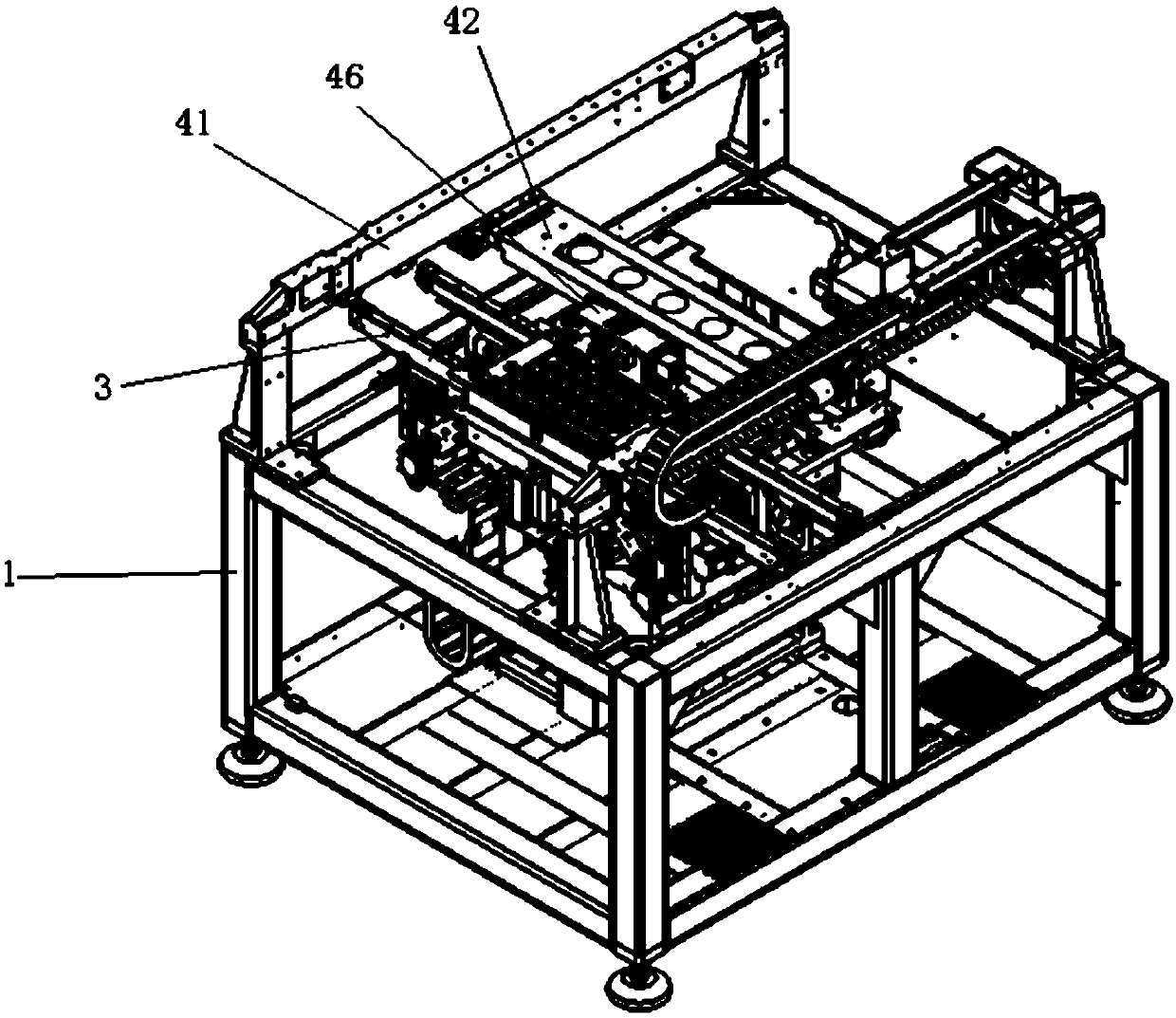

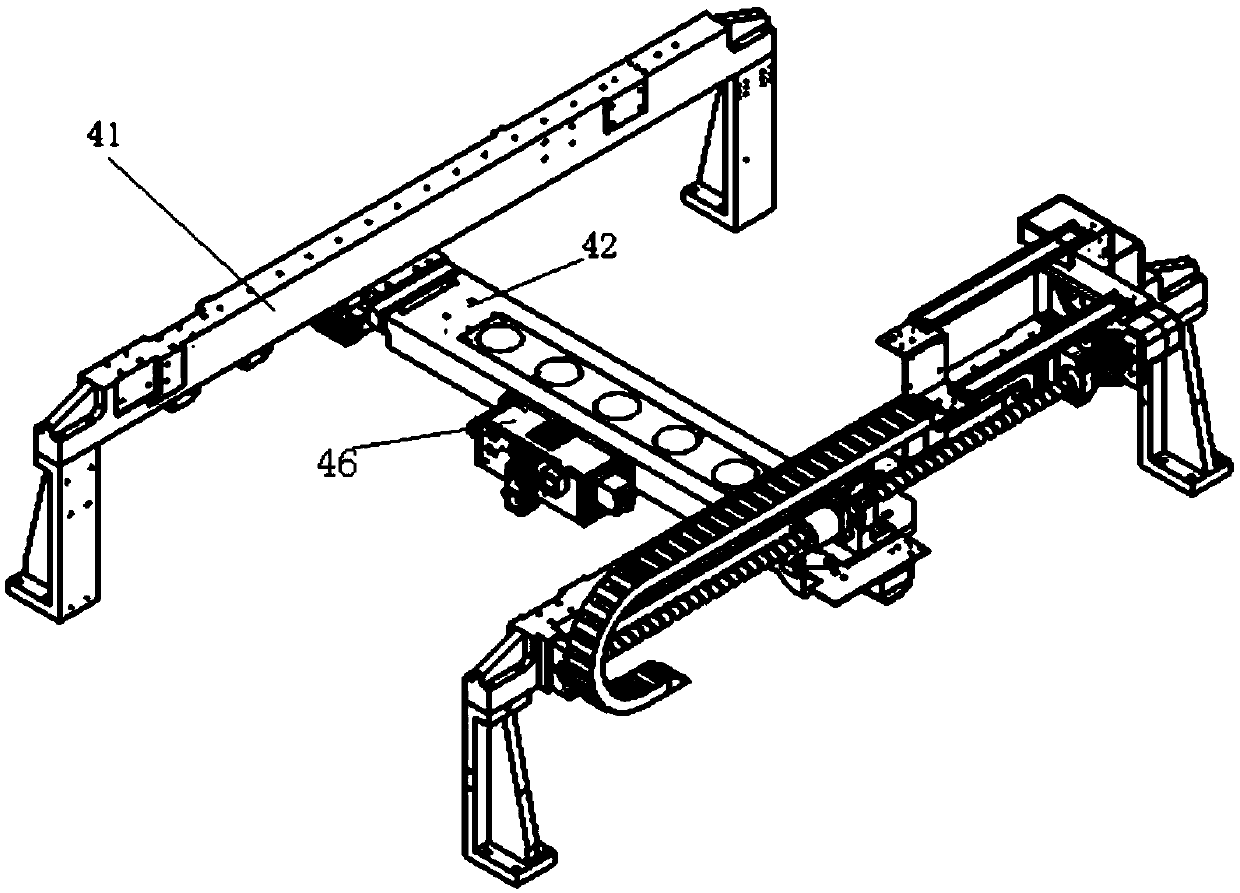

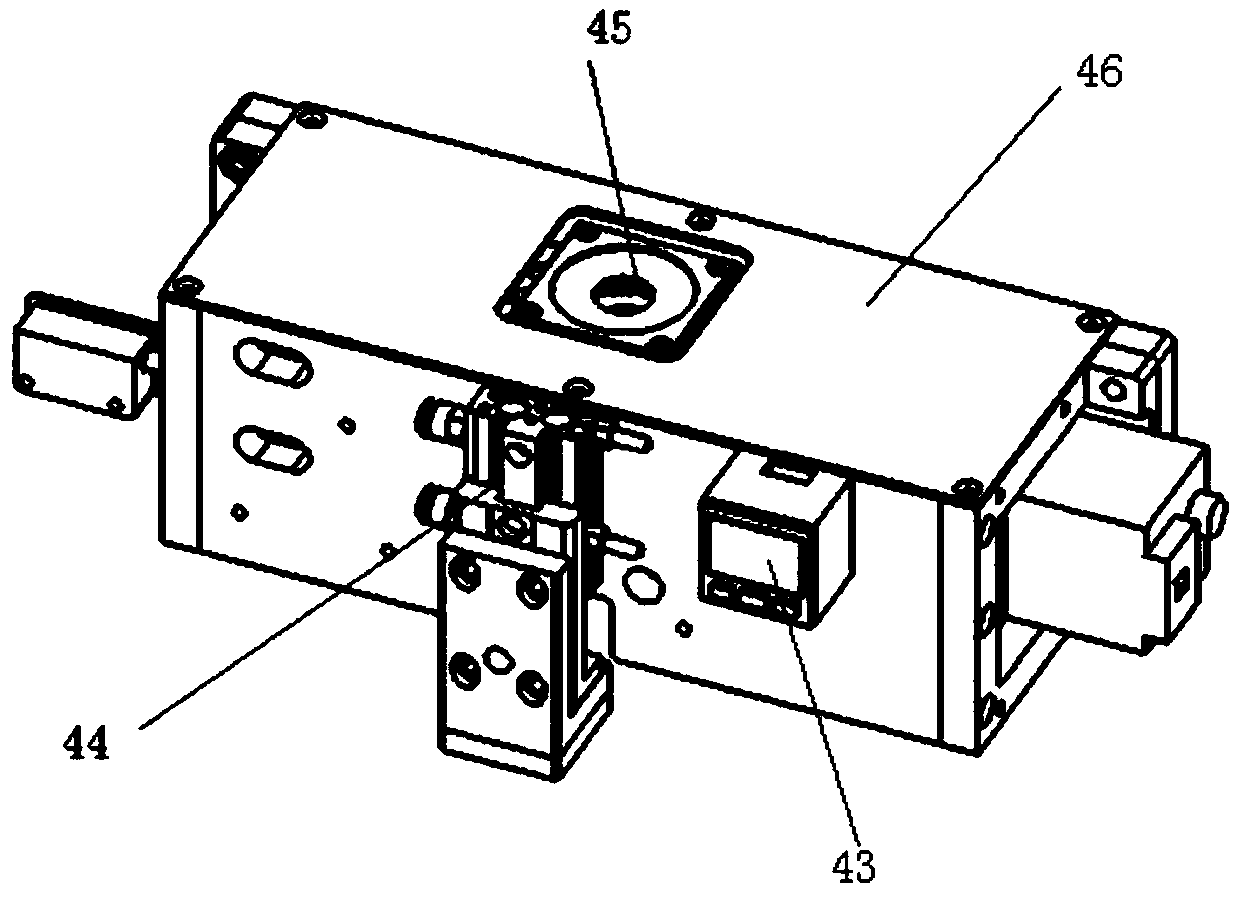

Multi-substrate alignment printing method and alignment printing machine

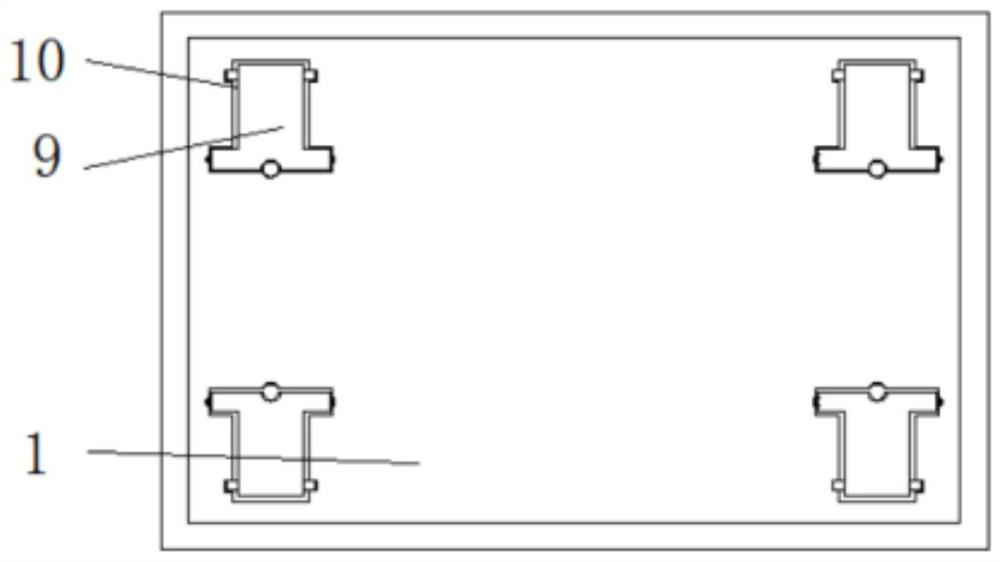

PendingCN109551871AGuaranteed printing efficiencyQuality assuranceScreen printersConductive pattern formationElectromagnetic valveNozzle

The invention discloses a multi-substrate alignment printing method and an alignment printing machine. The alignment printing machine comprises a machine frame, a platform module, conveying guide rails and a CCD module, the platform module capable of ascending and descending is arranged on the machine frame, the conveying guide rails are used for conveying a jig loaded with substrates to the center of the printing machine, the CCD module is used for sucking and positioning the substrates, a lower suction nozzle platform is arranged on the platform module, a plurality of lower suction nozzles are arranged on the lower suction nozzle platform at intervals, the lower suction nozzle platform is located between the two transportation guide rails. According to the alignment printing machine, a plurality of lower suction nozzles and a single upper suction nozzle are adopted and are independently controlled by electromagnetic valves, the adsorption adjustment of the lower suction nozzles and the upper suction nozzle needs to be used for each adjustment of the substrate, independent adjustment and printing of a plurality of substrates are realized, the product is detected and adjusted for multiple times through the CCD, the position of the base plate and the position of the steel net are repeatedly confirmed, so that the printing position of the base plate can be ensured.

Owner:GKG PRECISION MACHINE

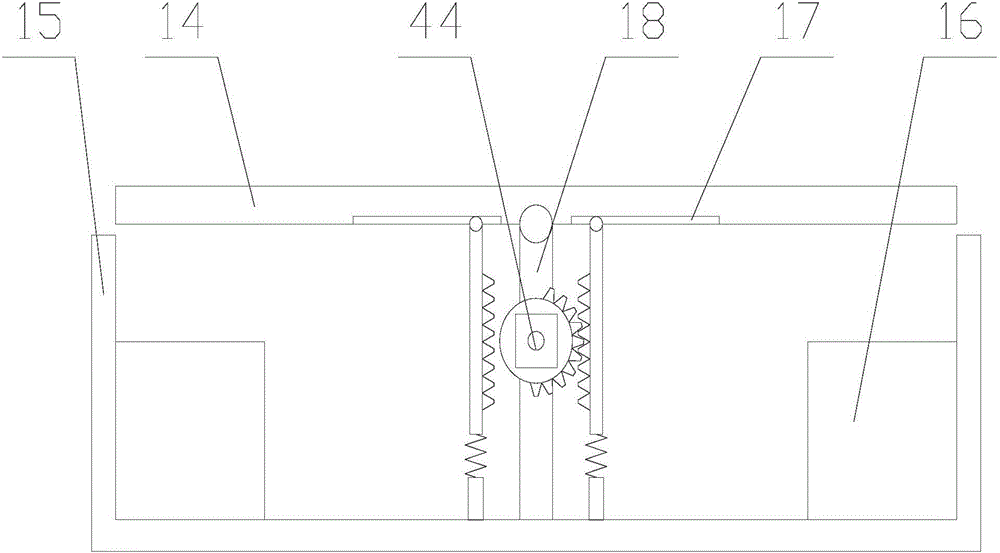

Printing nozzle convenient to replace for 3D printer

PendingCN112123771AEasy to disassembleEasy to installApplying layer meansComputer printingElectric machinery

The invention discloses a printing nozzle convenient to replace for a 3D printer, comprising a mounting plate. A first motor and a second motor are mounted on the two sides of the top surface of the mounting plate, respectively; the first motor is in key connection with a first gear through an output shaft; the second motor is in key connection with a second gear through an output shaft; the firstgear and the second gear are both arranged in the mounting plate; the interior of the mounting plate is slidably connected with a first rack and a second rack; and the first rack is connected with the side wall of the first gear in an engaged manner. The invention aims to provide a printing nozzle convenient to replace for a 3D printer; by controlling the first motor and the second motor to rotate forwards and backwards, the first rack and the second rack move in the mounting plate, and then, a first limiting block and a second limiting block are clamped and unclamped, so that mounting and dismounting of the printing nozzle are completed conveniently.

Owner:芜湖英罗智能制造有限公司

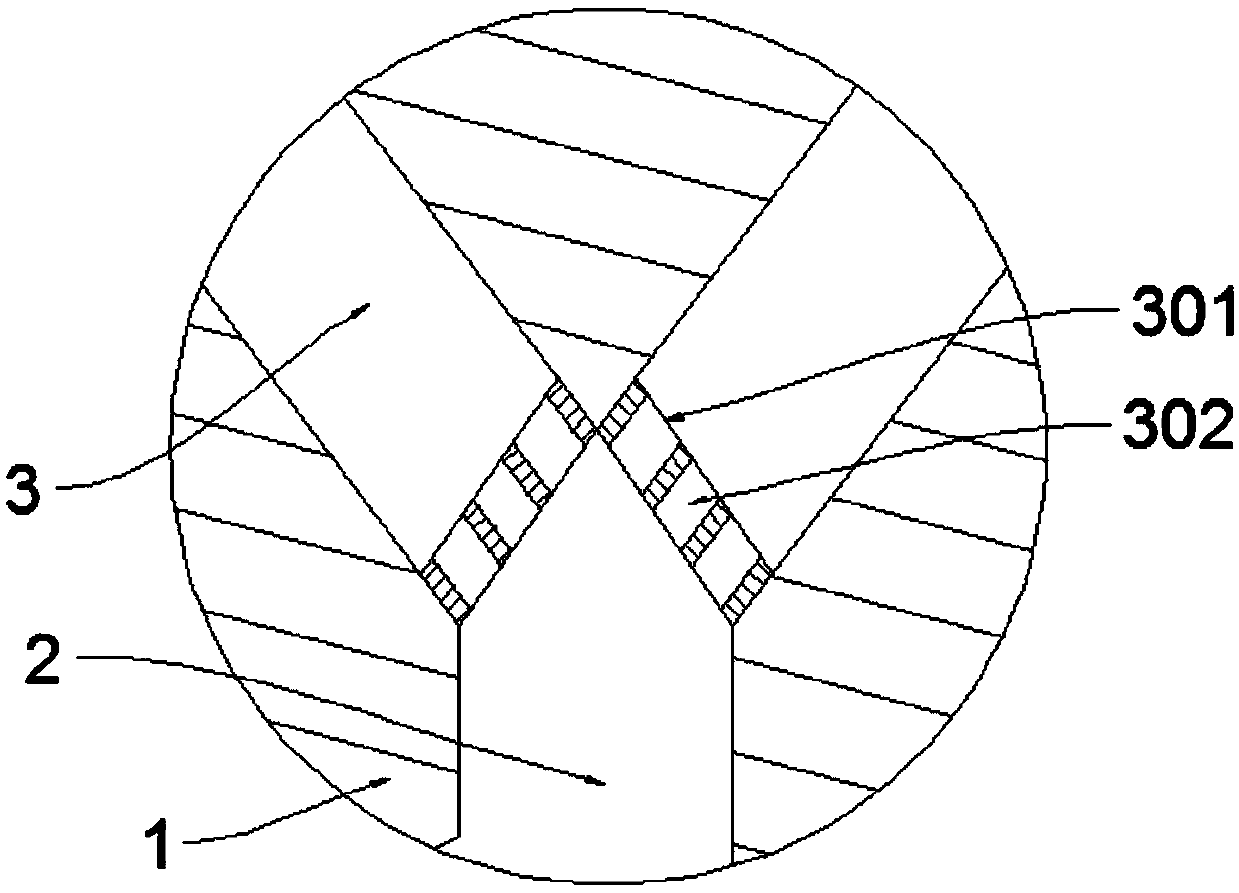

3D printing spray head system

PendingCN108673894AHigh speedGuaranteed StrengthManufacturing heating elements3D object support structuresMulti materialSpray nozzle

The invention relates to the technical field of 3D printing, in particular to a 3D printing spray head system. The 3D printing spray head system comprises a fusing spray head shell and a feeding throat pipe, and a vertical material mixing cavity is formed in the fusing spray head shell; the bottom end of the material fixing cavity communicates with a spiral discharging channel which communicates with a spray nozzle; the spray nozzle penetrates the fusing spray head shell and is connected with the fusing spray head shell in a threaded manner; the top end of the material mixing cavity communicates with a plurality of feeding channels which communicate with a connection channel; the upper surface of the fusing spray head shell is provided with an installing hole which is in threaded connection with the feeding throat pipe; the feeding throat pipe communicates with the connection channel, and is sleeved with a heating pipe; and the feeding throat pipe is provided with a heat insulating gasket which is located between the heating pipe and the fusing spray head shell. The spray head system is designed into the multi-feeding and single-discharging spray head mode, the feeding speed in theprinting process can be increased due to the multi-feeding mode, discharging manners of a plurality of materials can be in a mixed state due to the single-discharging mode, and the strength and the precision of printed finished products are guaranteed.

Owner:ZUNYI MEDICAL UNIVERSITY

Different-pattern synchronous double-amplitude printing machine

InactiveCN111688338AReduce the time for frequent rotary screen replacementShorten the timeScreen printersTextile printerEngineering

The invention discloses a different-pattern synchronous double-amplitude printing machine which comprises a rack. A rotary screen set A and a rotary screen set B different in pattern are arranged on the rack in a left row and a right row. A division wall is arranged between the rotary screen set A and the rotary screen set B. U-shaped fixed tables are arranged on the division wall at intervals. Columnar transverse bars are arranged on the fixed tables. Lifting parts towards the two sides are rotationally arranged on the transverse bars. Scraping knife rests extending into the rotary screen setA and the rotary screen set B are arranged on the lifting parts. The different-pattern synchronous double-amplitude printing machine has the following advantages and effects that through different-pattern double-amplitude printing, two different patterns can be printed at the same time, the time of frequently replacing rotary screens under the condition of a few orders of multiple batches is reduced, and printing efficiency is guaranteed.

Owner:SHAOXING YONGTONG PRINTING CO LTD

3D printing consumable and application thereof

ActiveCN107143745APrint effect interventionGuaranteed printing efficiencyAdditive manufacturing apparatusElongated constructional elementsEngineering3D printing

Owner:GUANGZHOU POTOP EXPERIMENTAL ANALYSIS INSTR

3D printing layering processing method, device and equipment and storage medium

PendingCN113306151AGood detailsImprove work efficiencyAdditive manufacturing apparatusManufacturing data aquisition/processingEngineeringLayer thickness

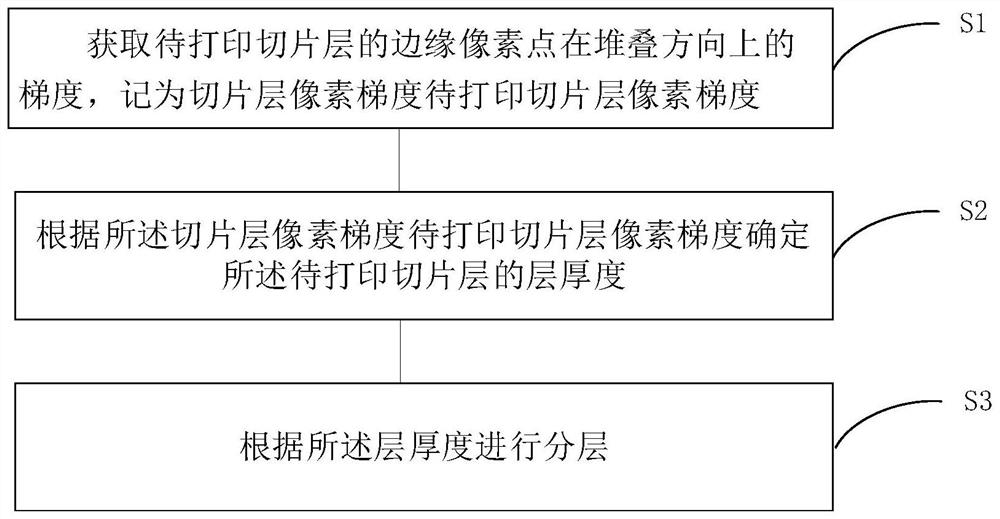

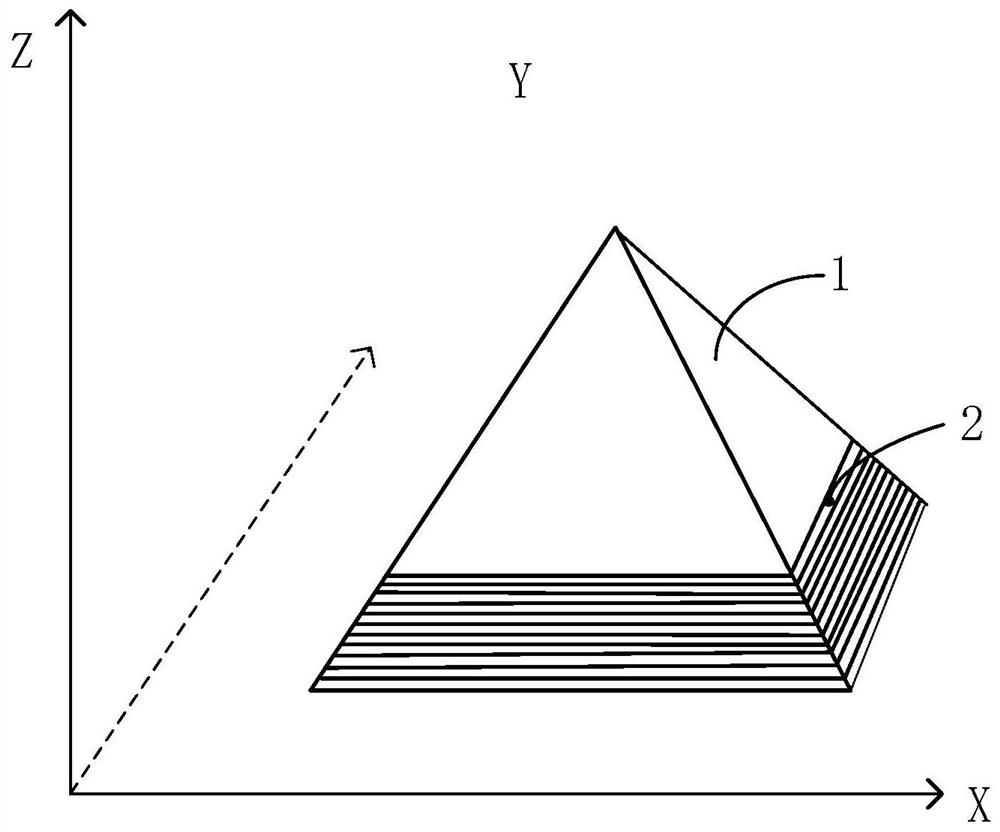

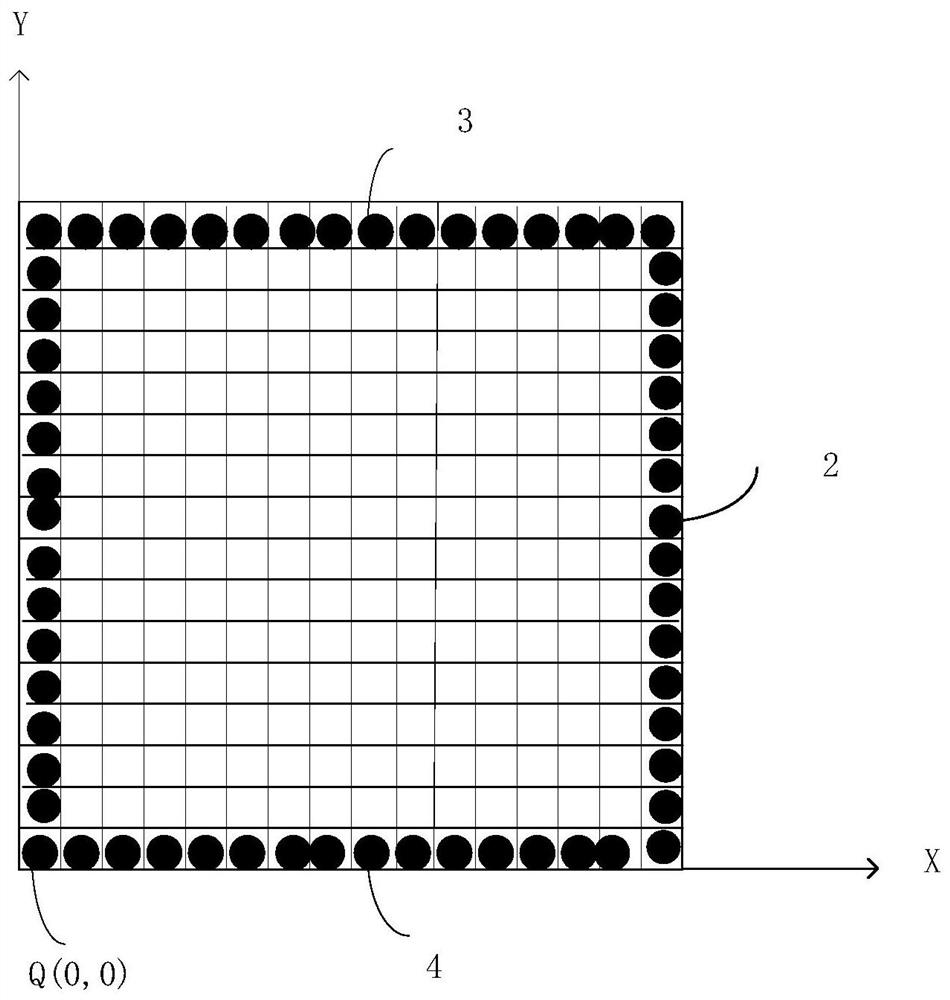

The invention discloses a 3D printing layering processing method, device and equipment and a storage medium, and relates to the technical field of 3D printing. The method comprises the steps that the gradient of edge pixel points of a slice layer to be printed in the stacking direction is obtained and recorded as the pixel gradient of the slice layer to be printed; the layer thickness of the slice layer to be printed is determined according to the pixel gradient of the slice layer to be printed; and layering is conducted according to the layer thickness. According to the method, the layer thickness of the slice layer to be printed is determined according to the gradient of the edge pixel points of the slice layer to be printed, the relatively small layer thickness is adopted for the area with the relatively large gradient, better detail performance is achieved, the relatively large layer thickness is adopted for the area with the small gradient, and therefore the working efficiency is improved, and meanwhile the printing quality and the printing efficiency are guaranteed.

Owner:SHENZHEN HOSONSOFT CO LTD

Double-injection multicolor 3D printer

ActiveCN109910303APrecise full-color printingAvoid affecting the color3D object support structuresApplying layer meansEngineering3d printer

The invention provides a double-injection multicolor 3D printer. The double-injection multicolor 3D printer comprises a 3D printer main body and an intelligent processing system; the back side of the3D printer main body is connected with a power supply wire; a printing head is arranged in the 3D printer main body; a circular groove is formed in the bottom of the printing head; a rotating base ismounted in an opening end of the circular groove; a ball is mounted between the rotating base and the inner side wall of the circular groove; multiple sets of medium through holes are formed in the rotating base; two medium through holes form one set; movable nozzles are mounted in the medium through holes; limiting flanges are fixedly arranged at the tops of the movable nozzles; springs are fixedly connected to the bottoms of the limiting flanges; and the other ends of the springs are fixedly connected with the inner side walls of the bottoms of the medium through holes. The double-injectionmulticolor 3D printer is reasonable in design, can precisely perform full-color printing, and achieves high printing efficiency.

Owner:广西电网有限责任公司防城港供电局

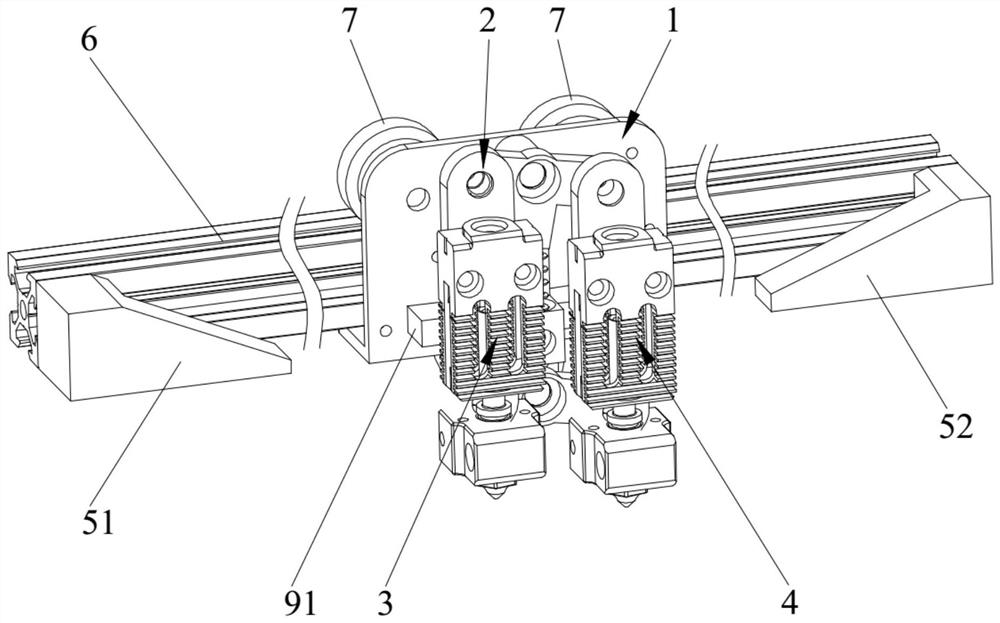

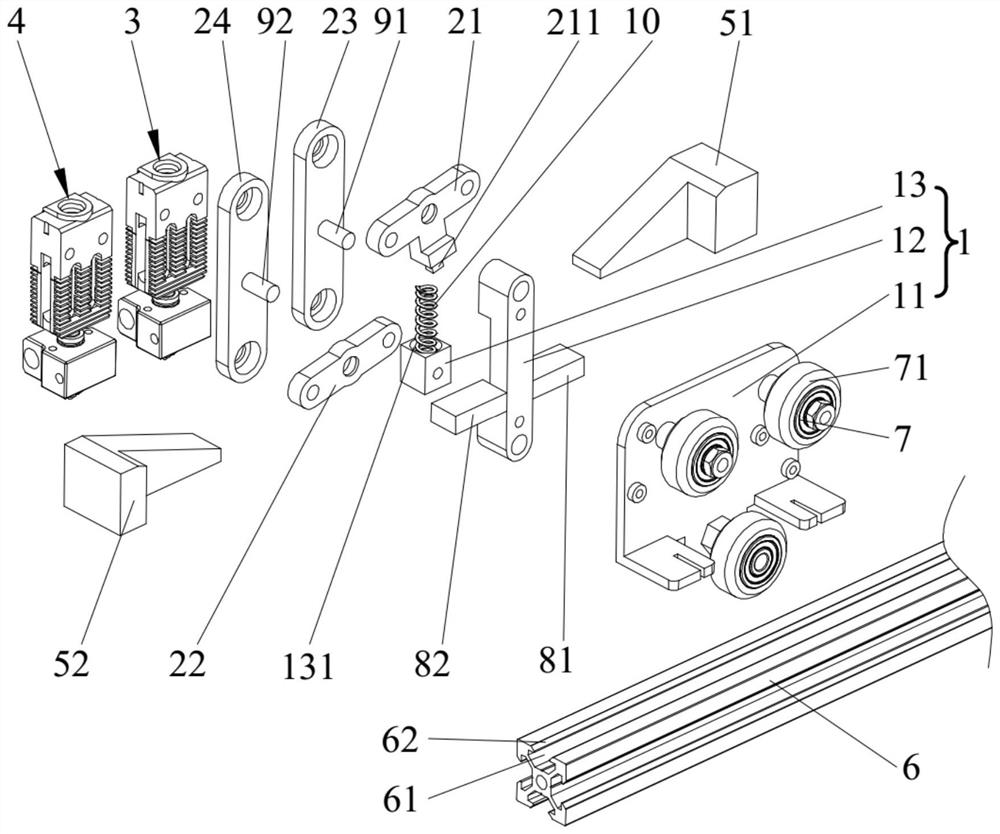

Double-nozzle switching device and 3D printer

PendingCN112757637AGuaranteed printing efficiencyGuaranteed printing accuracyApplying layer meansComputer printingGear wheel

The invention relates to the technical field of 3D printers, and particularly discloses a double-nozzle switching device and a 3D printer. The double-nozzle switching device comprises a back plate, a supporting seat, a first spray head assembly, a second spray head assembly, a first reversing block and a second reversing block. The supporting seat is rotationally arranged on the back plate; the first spray head assembly and the second spray head assembly are both arranged on the supporting seat, the supporting seat can swing between a first position and a second position relative to the back plate, and when the supporting seat is located in the first position, the first spray head assembly is located below the second spray head assembly; when the supporting seat is located in the second position, the first spray head assembly is located above the second spray head assembly, the first reversing block can abut against the supporting seat to push the supporting seat to rotate to the second position, the second reversing block can abut against the supporting seat to push the supporting seat to rotate to the first position, and thus position switching of the two spray head assemblies is achieved; structures such as a motor gear and the like are not required to be arranged on the back plate, so that the weight of components on the back plate can be reduced, and the printing efficiency and precision can be guaranteed.

Owner:SHENZHEN CREALITY 3D TECH CO LTD

Computer printing equipment with dustproof structure

InactiveCN112339456AAvoid enteringReduce spreadDispersed particle filtrationOther printing apparatusActivated carbonComputer printing

The invention discloses computer printing equipment with dustproof structure. The equipment comprises a printing equipment main body and a control plate protection cover, wherein a printing equipmentcontrol main body is arranged on the left side of the printing equipment main body, air circulation openings are formed in the front side and the rear side of the printing equipment control main bodycorrespondingly, a wire connecting port is formed in the left side of the printing equipment control main body, a rubber sealing cover is arranged on the inner side of the wire connecting port, a first rotating column is arranged on the right side of the printing equipment main body, a paper outlet baffle is arranged on the right side of the first rotating column, a sealing ring is arranged abovethe paper outlet baffle, a baffle clamping block is arranged on the right side of the sealing ring, and a second rotating column is arranged at the top of the printing equipment control main body. According to the equipment, a dustproof gauze and an activated carbon purification layer are tightly attached, so that air entering the equipment can be filtered through the dustproof gauze, and dust isprevented from entering the equipment along with the air.

Owner:广州古米科技有限公司

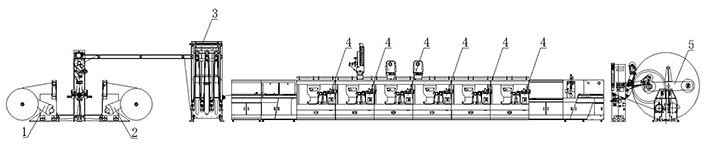

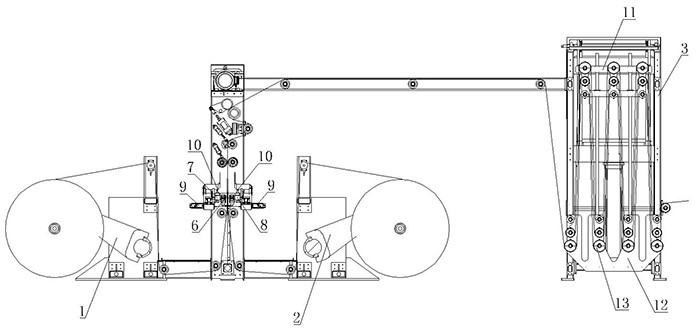

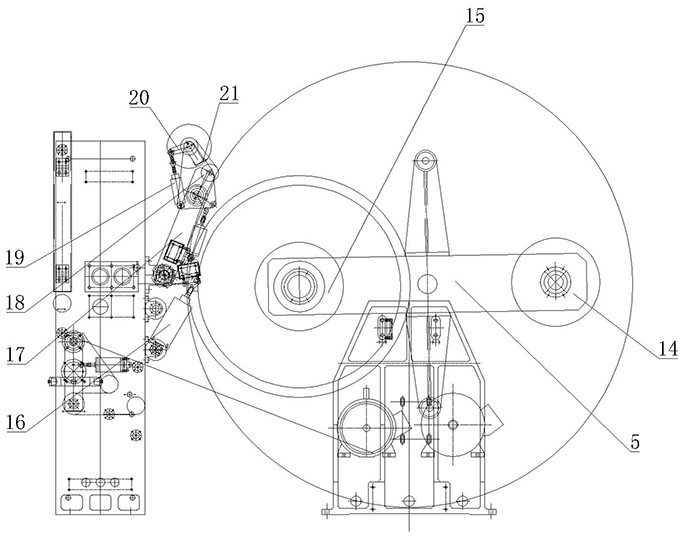

Non-stop winding and unwinding reel soft package material offset press

InactiveCN113682036AImprove fluencyGuaranteed printing efficiencyRotary lithographic machinesElectric machineryEngineering

The invention discloses a non-stop winding and unwinding reel soft package material offset press. The non-stop winding and unwinding reel soft package material offset press comprises an unwinding assembly, an offset printing unit set and a winding assembly which are sequentially arranged, wherein the unwinding assembly comprises a first unwinding base and a second unwinding base which are arranged left and right; a cut-off tool is arranged between the first unwinding base and the second unwinding base; extrusion wheels are arranged on the two sides of the cut-off tool; the extrusion wheels are arranged on corresponding moving seats; the moving seats are connected with corresponding horizontal driving assemblies; a storage assembly is arranged between the unwinding assembly and the offset printing unit set; the winding assembly comprises a rotating frame; the rotating frame is in transmission connection with a rotating motor; a first winding seat and a second winding seat are arranged on the rotating frame left and right; a swing frame is arranged close to the rotating frame and is hinged onto a rack and connected with a first swing driving assembly; a rubber roller and a swing block are arranged on the swing frame; a cutter is connected onto the swing block; and the swing block is connected with a second swing driving assembly. According to the non-stop winding and unwinding reel soft package material offset press provided by the invention, the non-stop winding and unwinding operation of the offset press can be realized.

Owner:ZHEJIANG ZHONGTE MACHINERY TECH CO LTD

3D array inkjet printing defect detection and correction system and method

ActiveCN113232300AExtended service lifeLow costAdditive manufacturing apparatusManufacturing data aquisition/processingEngineeringComputer science

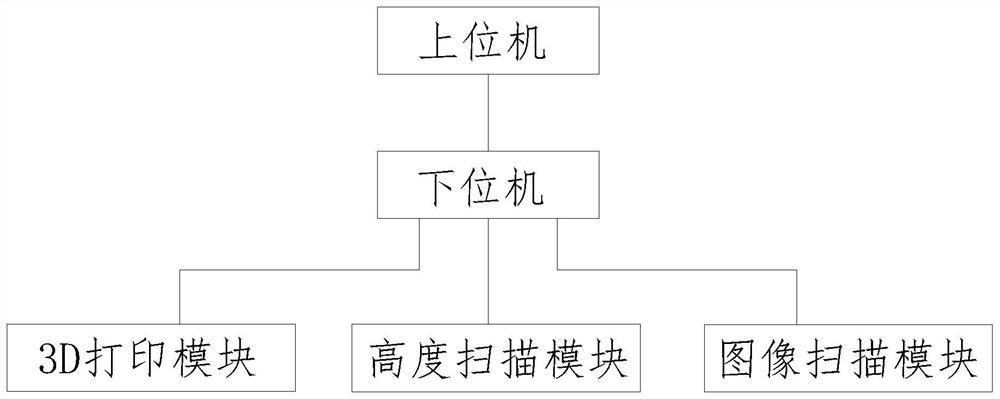

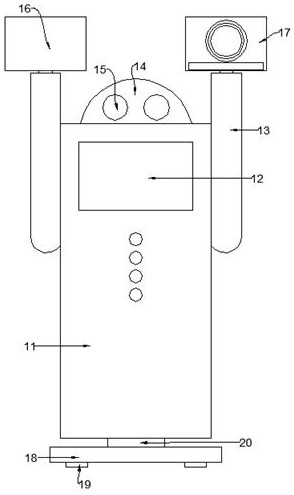

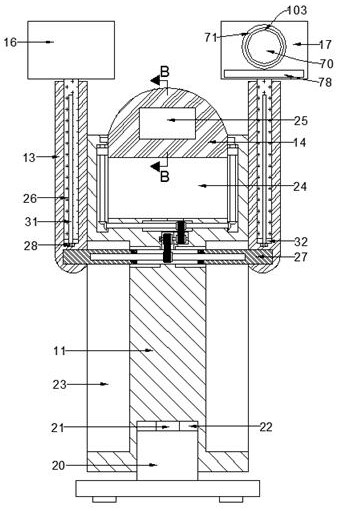

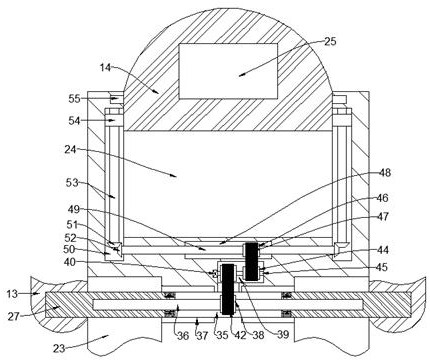

The invention discloses a 3D array inkjet printing defect detection and correction system and method. The system comprises a 3D printing module, a height scanning module, an image scanning module and a control module; the 3D printing module, the height scanning module and the image scanning module are electrically connected with the control module; the 3D printing module is used for printing of a slice layer; the height scanning module is used for scanning height information of the slice layer and uploading the height information to the control module; the image scanning module is used for scanning image information of the slice layer and uploading the image information to the control module; the control module is used for processing the height information and the image information and working out whether the slice layer has a printing defect or not; and if the printing defect is present, a repair printing instruction is automatically generated and the 3D printing module is controlled to execute the repair printing instruction for printing; By adopting the technical scheme, under the condition that a jet orifice of the 3D printing module is blocked, printing can also be implemented, so that the printing efficiency is guaranteed, the service life of the 3D printing module is prolonged, and the cost of an enterprise is reduced.

Owner:广东省珠海市质量计量监督检测所

Wall painting and printing process

InactiveCN113071213AProtection securityReduce dangerous accidentsTypewritersOther printing apparatusPrinting pressInformation processor

The invention discloses a wall painting and printing process. A shell is included, a moving groove with an upward opening is formed in the top wall of the shell, a head shell is slidably connected between the left wall and the right wall of the moving groove, and an information processor is fixedly connected in the head shell. A blocking device can completely protect the head shell when the head shell is not used, so that the information processor in the head shell is not damaged, the service life is prolonged, the working efficiency of a camera is protected, a clamping device can freely change the motion state of a first extension rod, subsequent work implementation is facilitated, machines moving to the outside in the working process are helped to be stored, damage of the machines is reduced when the machines do not work, the service time is prolonged, the maintenance cost is reduced, the occupied area is reduced, storage is convenient, uneven positions of the surface of a wall face needing to be printed can be polished through a cleaning device, the printing efficiency of the printing machine is ensured, meanwhile, the surrounding environment is kept clean, and the environment is protected.

Owner:苏州集尼露贸易有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com