3D array inkjet printing defect detection and correction system and method

A defect detection and 3D printing technology, applied in 3D printing related fields, can solve problems affecting the service life and printing efficiency of 3D array nozzles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

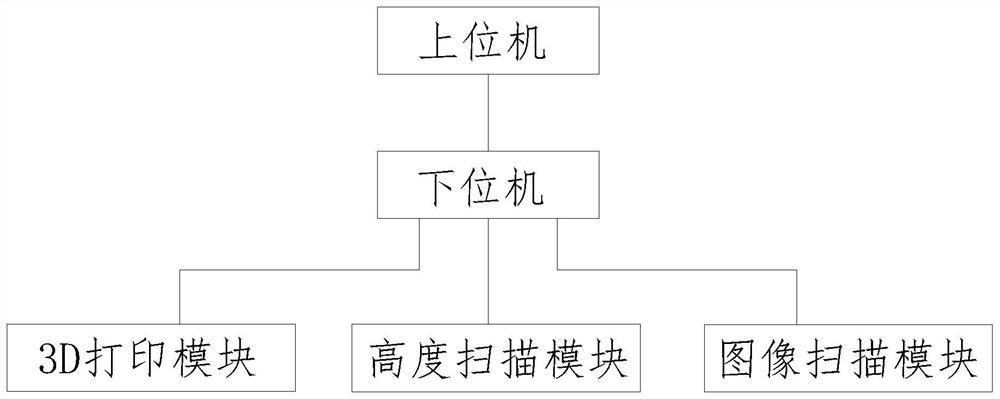

[0031] refer to figure 1 As shown, the 3D array inkjet printing defect detection and correction system provided by the present invention includes: a 3D printing module, a height scanning module, an image scanning module and a control module.

[0032] The 3D printing module, the height scanning module, the image scanning module are electrically connected with the control module. Further, the control module includes an upper computer and a lower computer, the upper computer is electrically connected to the lower computer, the lower computer is electrically connected to the 3D printing module, the height scanning module, and the image scanning module, and the upper computer is connected to the 3D printing module, the height scanning module, and the image scanning module. Realize data transmission through the lower computer. Wherein, the upper computer is a kind of in computer, industrial computer, preferably upper computer is computer, and upper computer is integrated with infor...

Embodiment 2

[0038] The 3D array inkjet printing defect detection and correction method based on the system of embodiment 1 comprises the following steps:

[0039] S1. The 3D printing module receives the printing instruction from the control module and executes the printing of the slice layer.

[0040] S2. The height scanning module receives the scanning instruction from the control module to scan each pixel of the slice layer printed by the 3D printing module, and uploads the scanned height information to the control module.

[0041]S3. The control module converts the received height information into an actual height value and subtracts it from the preset theoretical height value to calculate the missing value of the actual height of each pixel, and compares the calculated missing value of the actual height of each pixel with the Compared with the preset height missing threshold value, when the actual height missing value of each pixel in the comparison result is less than the height miss...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com