Printing machine with good drying effect

A kind of printing machine, good technology, applied in the direction of printing machine, rotary printing machine, general parts of printing machinery, etc., can solve the problems of long delay, energy waste, difference, etc., to ensure printing efficiency, reduce energy consumption, improve The effect of utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

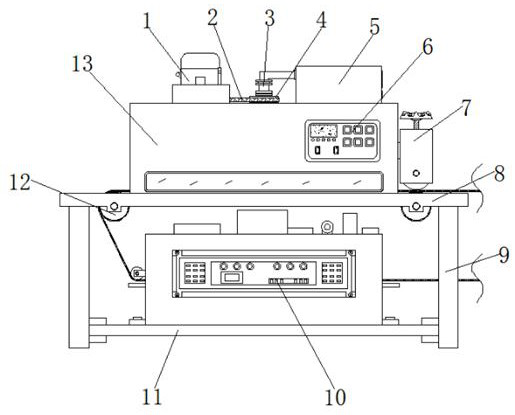

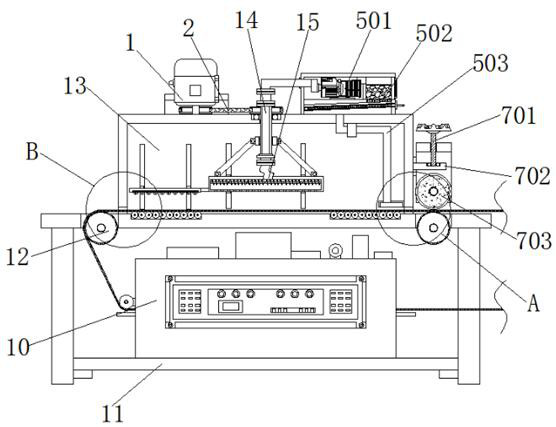

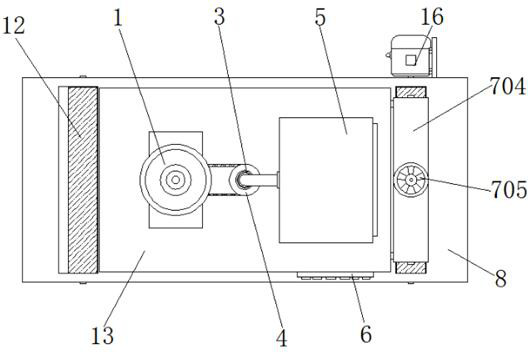

[0036] Example 1, such as figure 1 , 2 , 3, 4, 6, 7 and 8, before starting to print, the paper at the outlet of the main body 10 of the printing machine is stretched, bent and passed through the first set of solid guide rollers 12 and then passed through the inside of the drying chamber 13 , finally pass through the surface of the second group of solid guide rollers 12, and then manually turn the hand wheel 705, because the thread on the surface of the threaded rod 701 forces the U-shaped frame 704 to gradually descend until the surface of the hollow guide roller 703 and a group of solid guide rollers 12 below it The surface is close to the surface, the paper is sandwiched between the two, and then the servo motor 1 is controlled to rotate clockwise. The servo motor 1 drives the installation pipe 14 to rotate through the belt 2 and the pulley 4. Due to the effect of the thread, the internal thread ring 151 is forced to The outer side of the installation tube 14 descends, whic...

Embodiment 2

[0037] Example 2, such as Figure 1-8 As shown, when printing is started, the drive motor 16 is controlled by the control panel 6 to drive a set of solid guide rollers 12 to rotate, thereby driving the paper to pass through the inside of the drying chamber 13 continuously, and at the same time, the air pump 501 is turned on through the control panel 6 1. The electric heating wire 154 and the heating lamp 159 start to work, and the heat generated by the heating lamp 159 is radiated to the paper that has just entered the inside of the drying chamber 13, and the paper is initially preheated, and the electric heating wire 154 also generates heat when it works , the air pump 501 blows the air into the first rotary joint 3, the installation pipe 14, the second rotary joint 157 and the soft conduit 156 in sequence, and then enters the inside of the heating chamber 155, so that the heat generated by the electric heating wire 154 passes through the second through hole 153 blows to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com