Non-stop winding and unwinding reel soft package material offset press

A technology of rewinding and unwinding, offset printing machine, applied in printing, printing machine, rotary printing machine and other directions, can solve the problems of single setting, equipment processing is not smooth, affecting offset printing processing efficiency, etc., to improve fluency and ensure printing efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

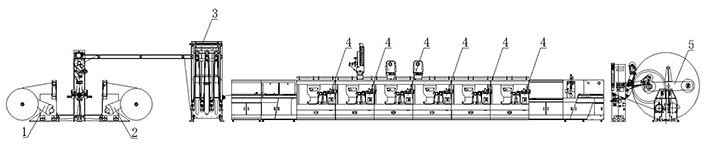

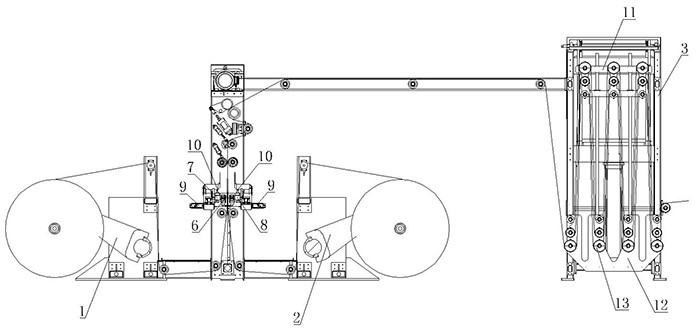

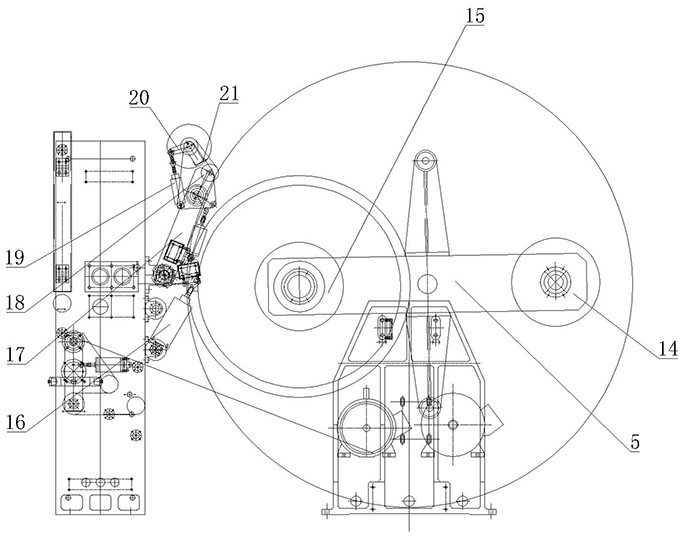

[0014] As shown in the figure, the non-stop rewinding and unwinding roll soft package material offset printing machine disclosed by the present invention includes an unwinding assembly, an offset printing unit group and a winding assembly arranged in sequence, and the offset printing unit group is an offset printing unit 4 arranged in an arrangement. The roll assembly includes a first unwinding seat 1 and a second unwinding seat 2 arranged left and right, a cutting knife 6 is arranged between the first and second unwinding seats, and there are extrusion wheels 10 on both sides of the cutting knife 6, Squeeze wheel 10 is arranged on corresponding moving seat 7, and moving seat 7 is connected with corresponding horizontal driving assembly, and horizontal driving assembly is first air cylinder 9, and the piston rod of first air cylinder 9 is connected with moving seat 7. A material storage assembly is arranged between the unwinding assembly and the offset printing unit group, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com