3D printing model forming method and 3D printer for implementing same

A 3D printer and molding method technology, applied in the auxiliary operation, processing and manufacturing of the additional layer, manufacturing auxiliary devices, etc., can solve the problems of surface wave folds, etc., and achieve the effects of convenient operation, improved product quality, and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

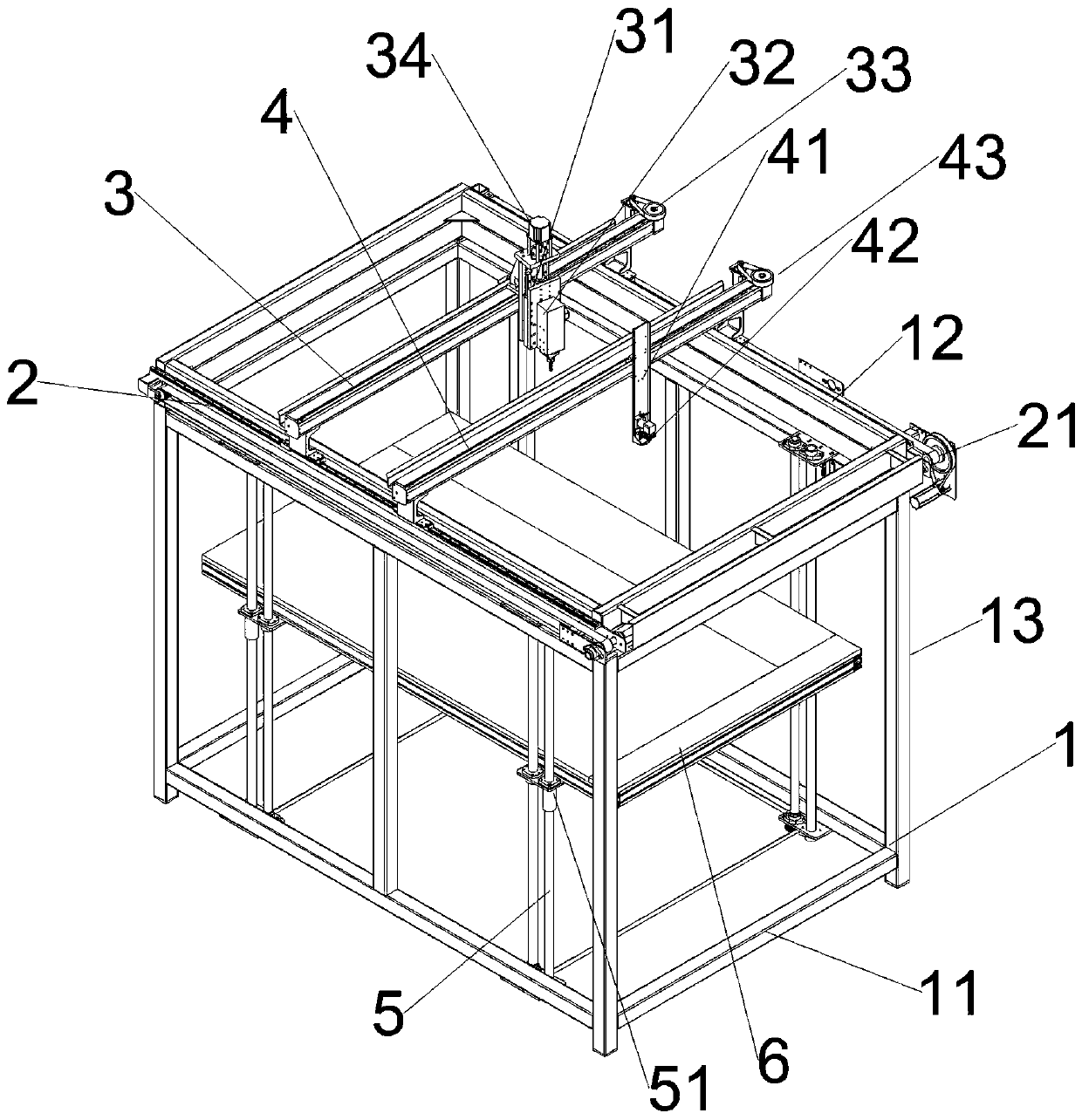

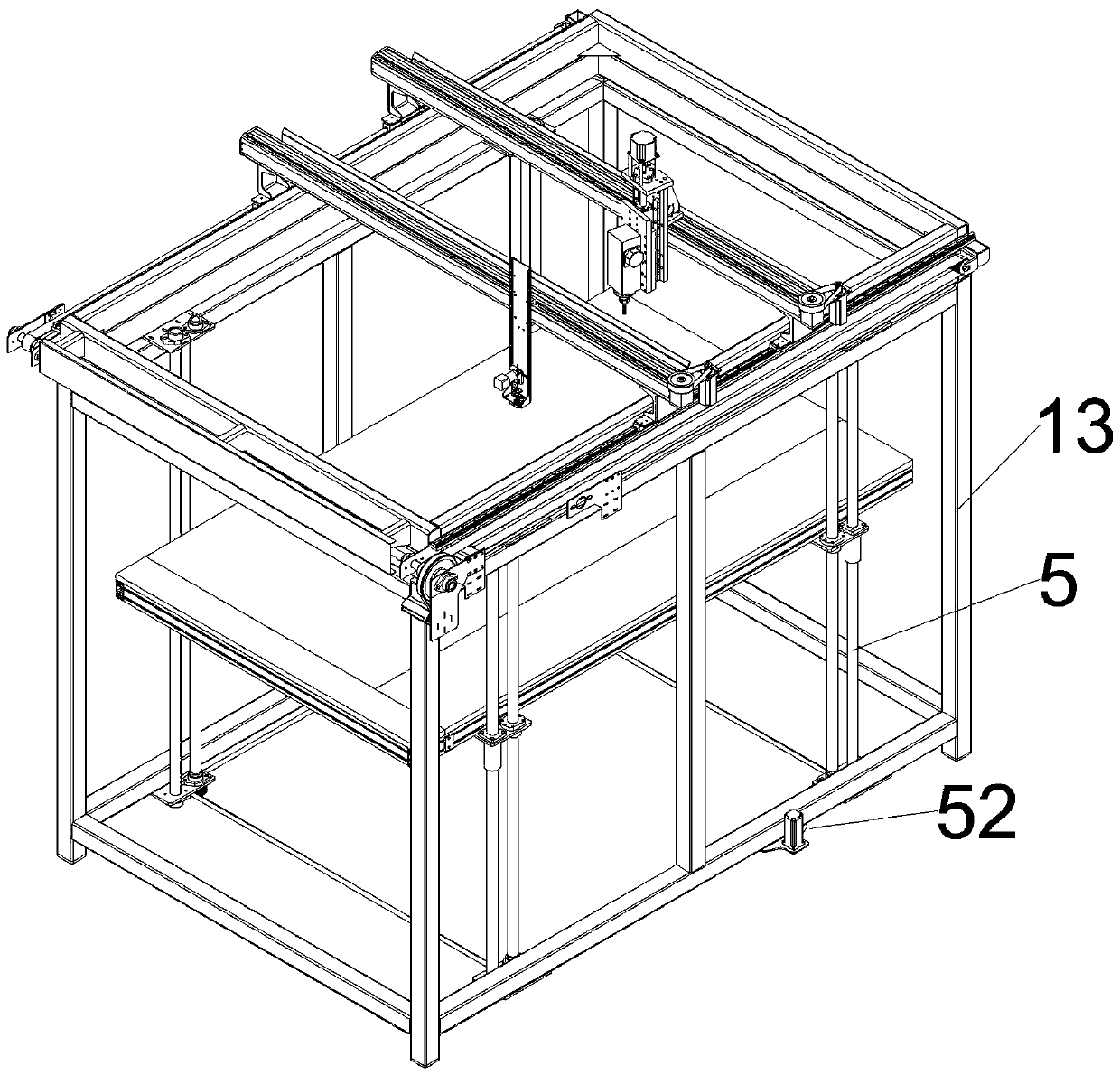

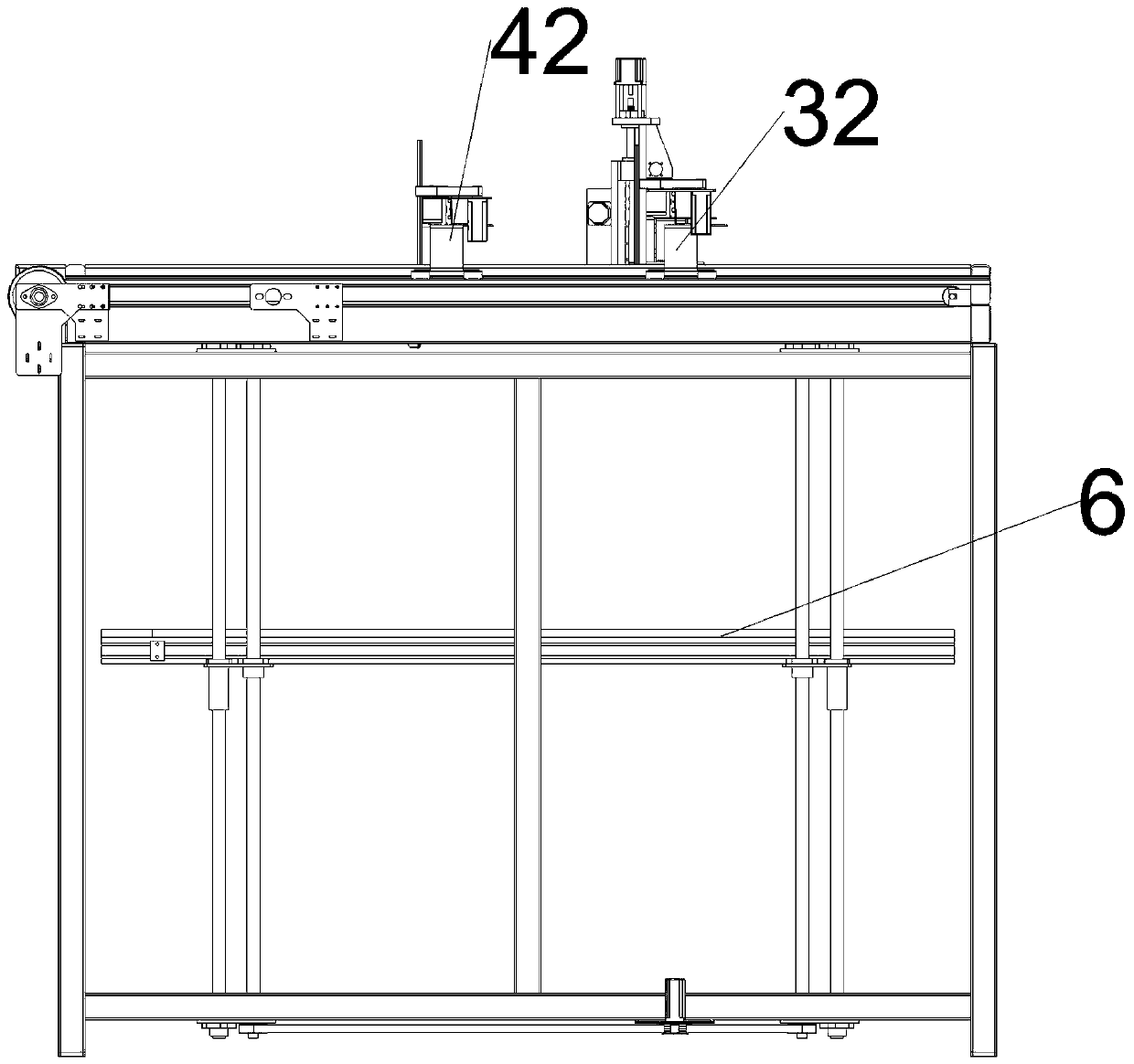

[0020] The specific embodiment of 3D printer of the present invention, as Figure 1 to Figure 3 As shown, the 3D printer is used in the 3D model printing process that requires high finish and high precision, and it includes a body 1. In this embodiment, the body 1 is a rectangular frame, which includes more than four columns 13 and supported on the columns. The lower cross brace 11 on the bottom side of 13 and the upper cross brace 12 fixed on the upper side of the column 13, the upper cross brace 12 and the lower cross brace 11 respectively enclose a rectangular frame, define the front and rear direction as the X direction, and the left and right direction as the Y direction , the up and down direction is the Z direction.

[0021] In this embodiment, the two upper cross braces 12 in the X direction are provided with a horizontal guide rail 2, and the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com