3D printing spray head system

A 3D printing and nozzle technology, applied in the direction of 3D object support structure, additive manufacturing, coating device, etc., can solve the problems of low product strength and precision, and achieve the effect of ensuring efficiency, consistency, strength and precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Further detailed explanation through specific implementation mode below:

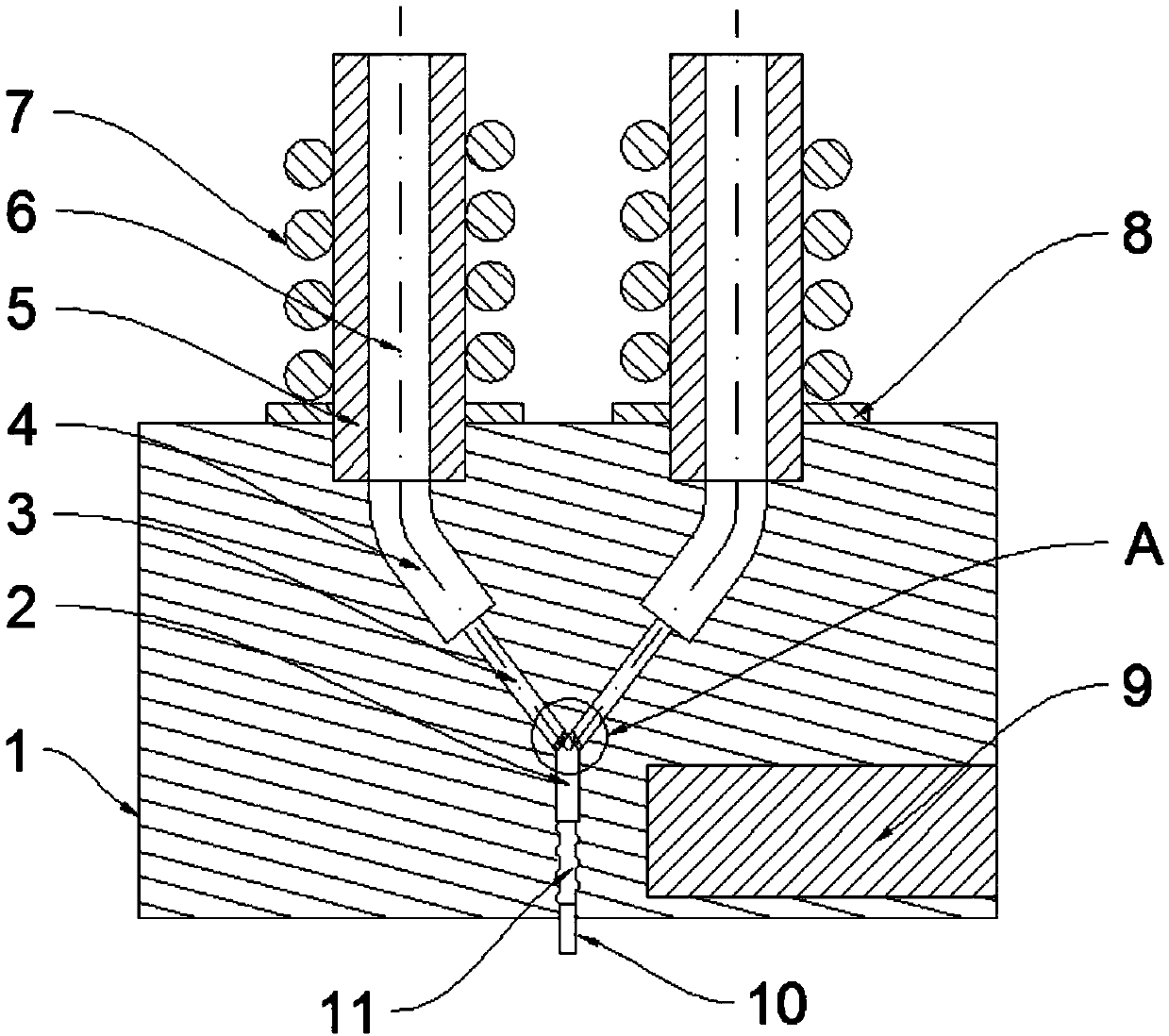

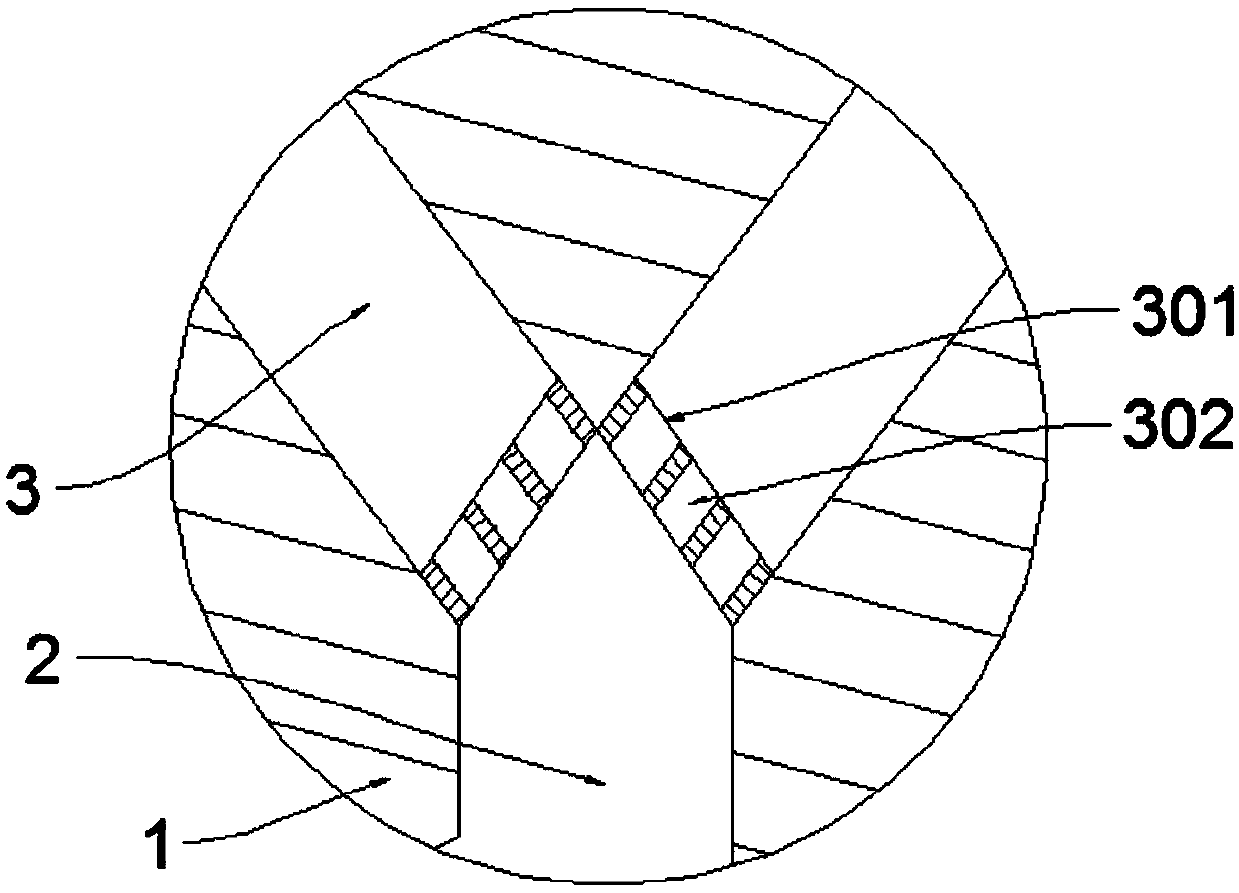

[0017] The reference signs in the accompanying drawings of the description include: fusion nozzle housing 1, mixing chamber 2, feed channel 3, diverter plate 301, diverter hole 302, connecting channel 4, feed throat 5, inner cavity 6, annular A heater 7, a heat insulating gasket 8, an ultrasonic vibrator 9, a nozzle 10, and a spiral discharge channel 11.

[0018] The embodiment is basically as attached figure 1 and figure 2 Shown: a 3D printing nozzle system, including a fusion nozzle housing 1 and a feed throat 5, the fusion nozzle housing 1 is provided with a vertical mixing chamber 2, and the bottom of the mixing chamber 2 is connected with a spiral outlet Material passage 11, spiral discharge passage 11 is connected with nozzle 10, and nozzle 10 runs through fusion shower head shell 1 and is connected with it by thread, and the top of mixing chamber 2 is communicated with 2 feeding passage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com