Patents

Literature

32results about How to "Increase the collision area" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A bridge anti-collision guardrail and a construction method thereof

InactiveCN109056523AIncrease impact forcePlay a protective effectBridge structural detailsBridge erection/assemblyCushioningArchitectural engineering

The invention discloses a bridge anti-collision guardrail and a construction method thereof, Collision barriers include columns, An upper rail and a low rail are respectively sleeved with a buff cylinder and a swirling ring on that upright column, the two ends of the upright column are fix on the upper rail through a limiting seat, the lower rail is provided with a fixing ring on the upright column, the fixing ring is in contact with the limiting seat located below, an L-shaped mounting plate is provided on the upper rail, an L-shaped mounting plate is provided with an anti-collision plate, and a cushioning guardrail plate is provided on the anti-collision plate; The construction method comprises the following steps: (a) route marking; (b) Post positioning; (c) Installation of lower railings; (d) installation of an upper railing; (e) Installation of cushion shields; (f) Installation of bumper plates; (g) Installation of remaining uprights. The anti-collision guardrail of the inventionhas the advantages of high stability, convenient installation, cushioning and anti-collision, high safety, easy operation, orderly and reasonable construction, fast and convenient construction, time and labor saving, low construction intensity and convenient maintenance in the later period. The invention has the advantages of high stability, convenient installation, cushioning and anti-collision,high safety, easy operation, orderly and reasonable construction method, fast and convenient construction, and low construction intensity.

Owner:ZHEJIANG COLLEGE OF CONSTR

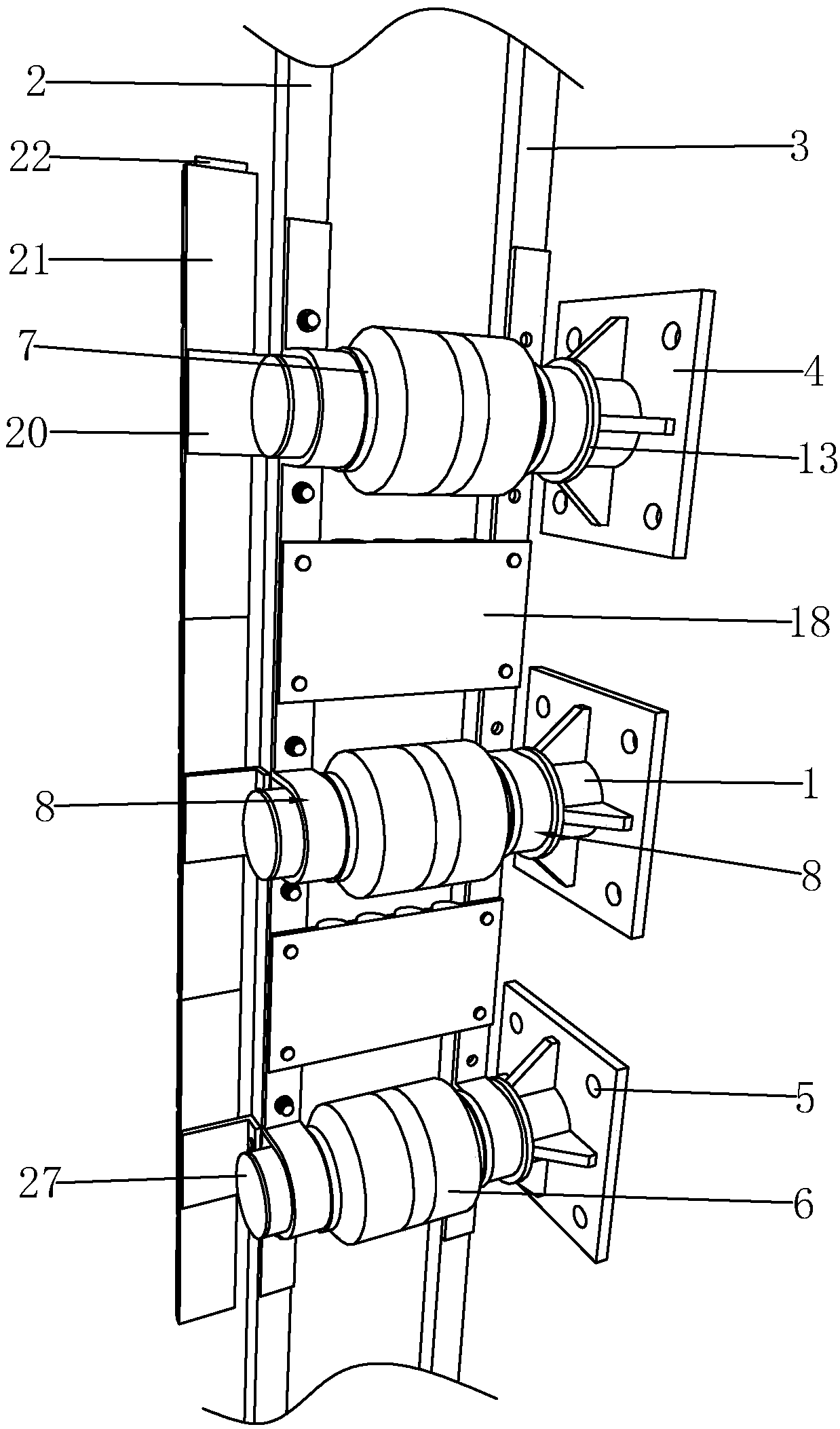

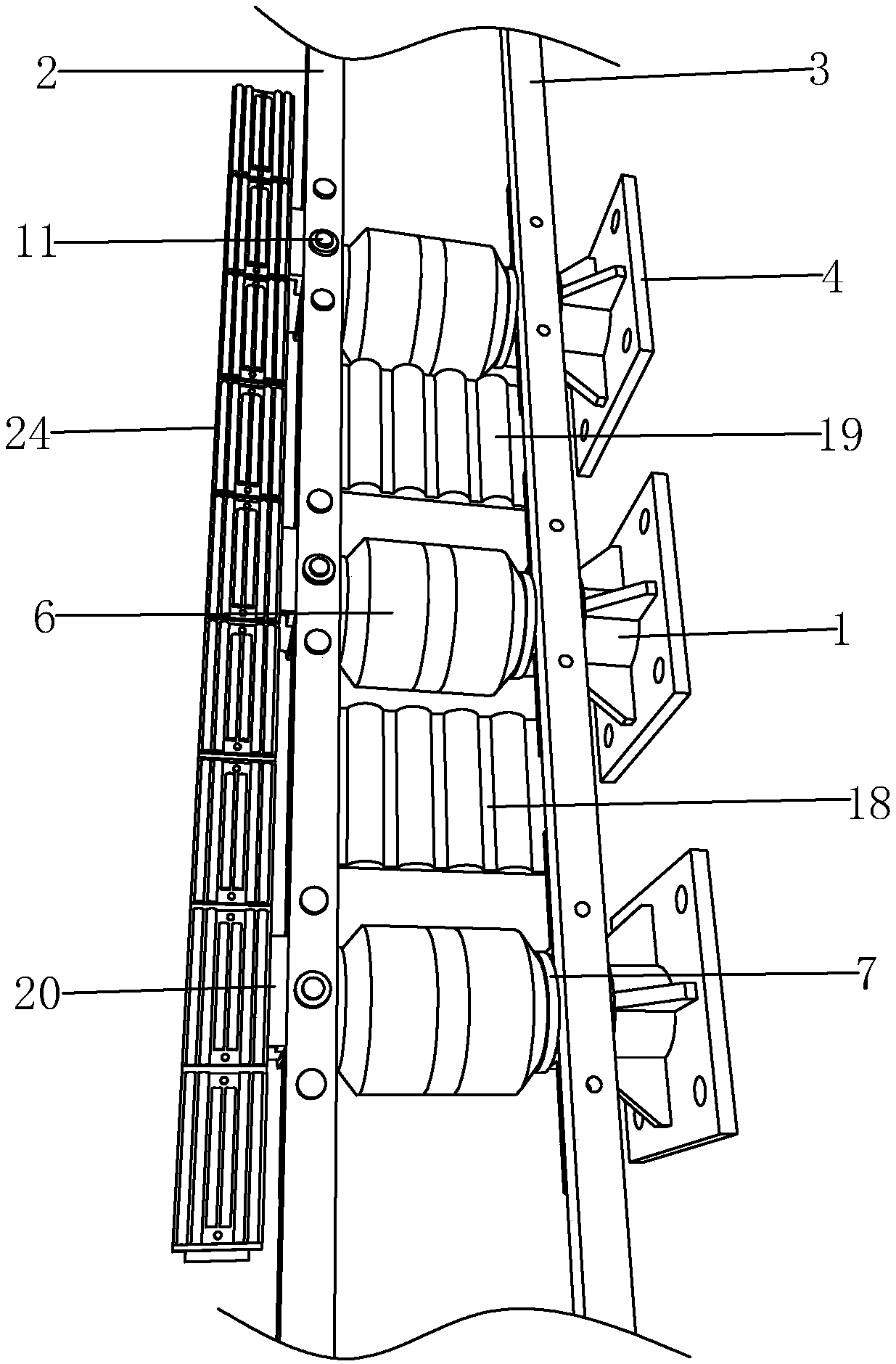

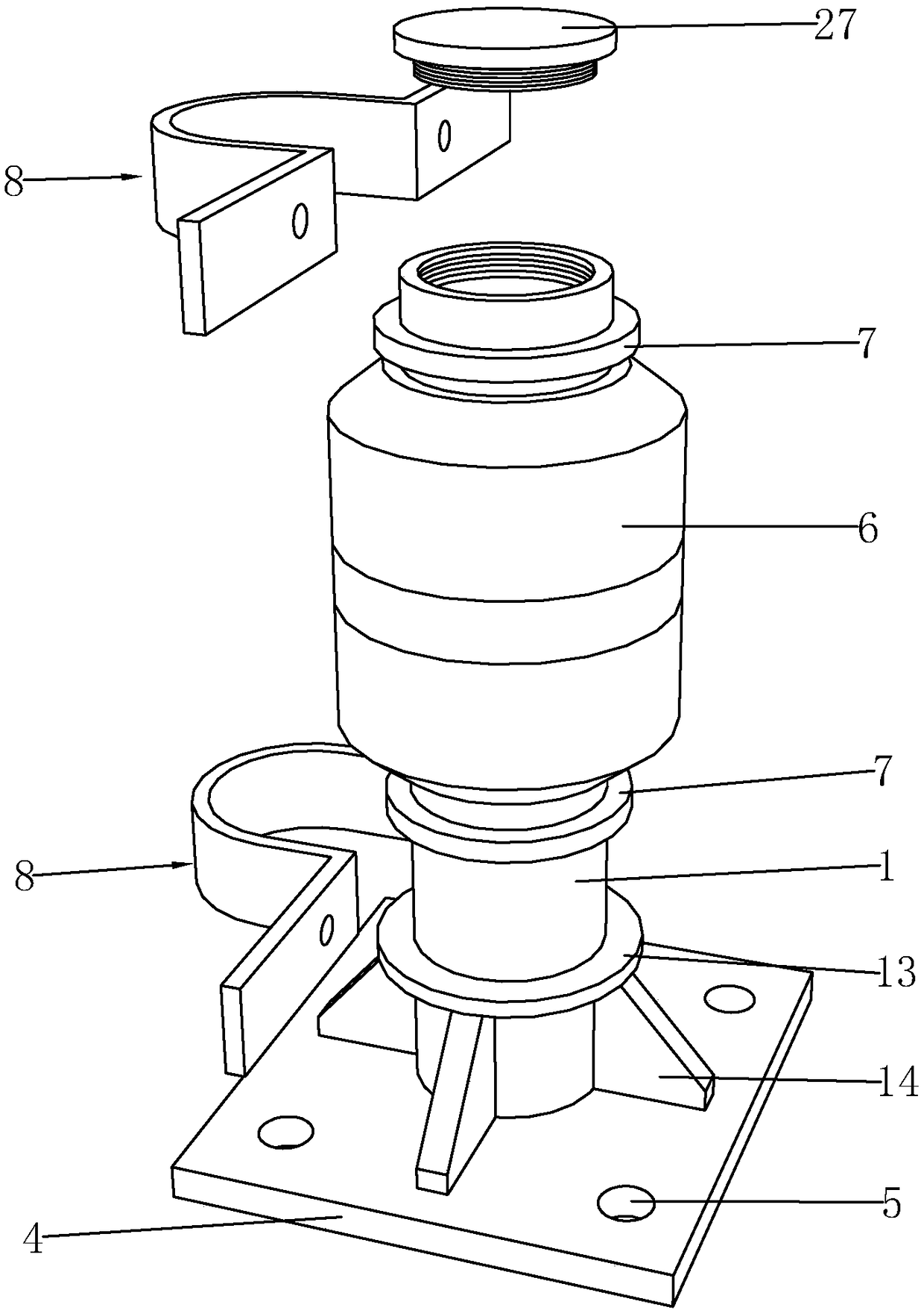

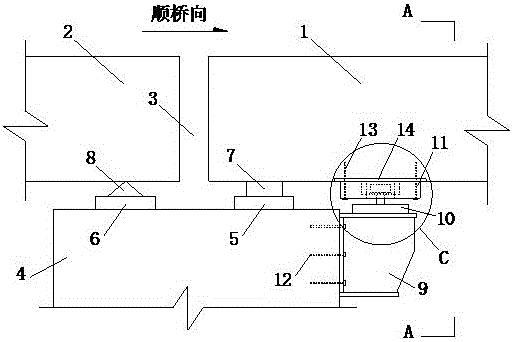

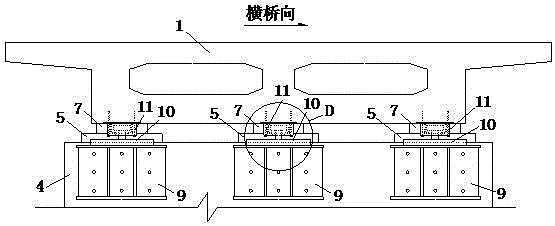

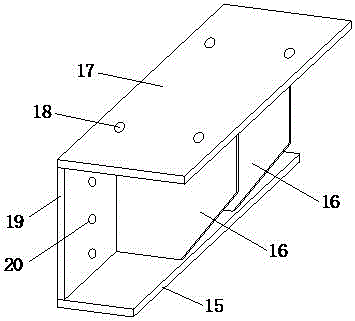

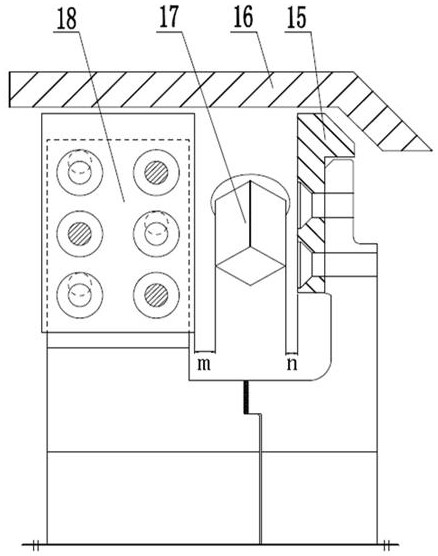

Three-way limiting buffering bridge anti-seismic stop dog structure and arranging and installing method

InactiveCN106436558AFree from damageAvoid damageBridge structural detailsExpansion jointCanis lupus familiaris

The invention discloses a three-way limiting buffering bridge anti-seismic stop dog structure and an arranging and installing method. The bridge anti-seismic stop dog structure comprises a steel corbel, a stop dog lower structure and a stop dog upper structure; the steel corbel is fixed to the side face, in the bridge axial direction, of the top of a pier close to a bridge movable supporting base, the stop dog lower structure is fixed to the top of the steel corbel through bolts, a groove is formed in the lower portion of the stop dog upper structure, the stop dog upper structure is fixed to the bottom of a main beam of the bridge through bolts, and an impact block is arranged on the upper portion of the stop dog lower structure. Relative large displacement between a beam body and the pier in the bridge axial direction, bridge transverse direction and vertical direction can be effectively limited, damage to the movable supporting base and expansion joints is reduced, and the beam body is prevented from falling in the bridge axial direction and bridge transverse direction and prevented from vertically getting away from the supporting base to cause damage on the supporting base, beam cocking damage and vertical impact damage between the beam body and the supporting base. The three-way limiting buffering bridge anti-seismic stop dog structure is simple in structure, convenient to construct, easy to repair and replace and suitable for new and old bridges.

Owner:NANCHANG UNIV

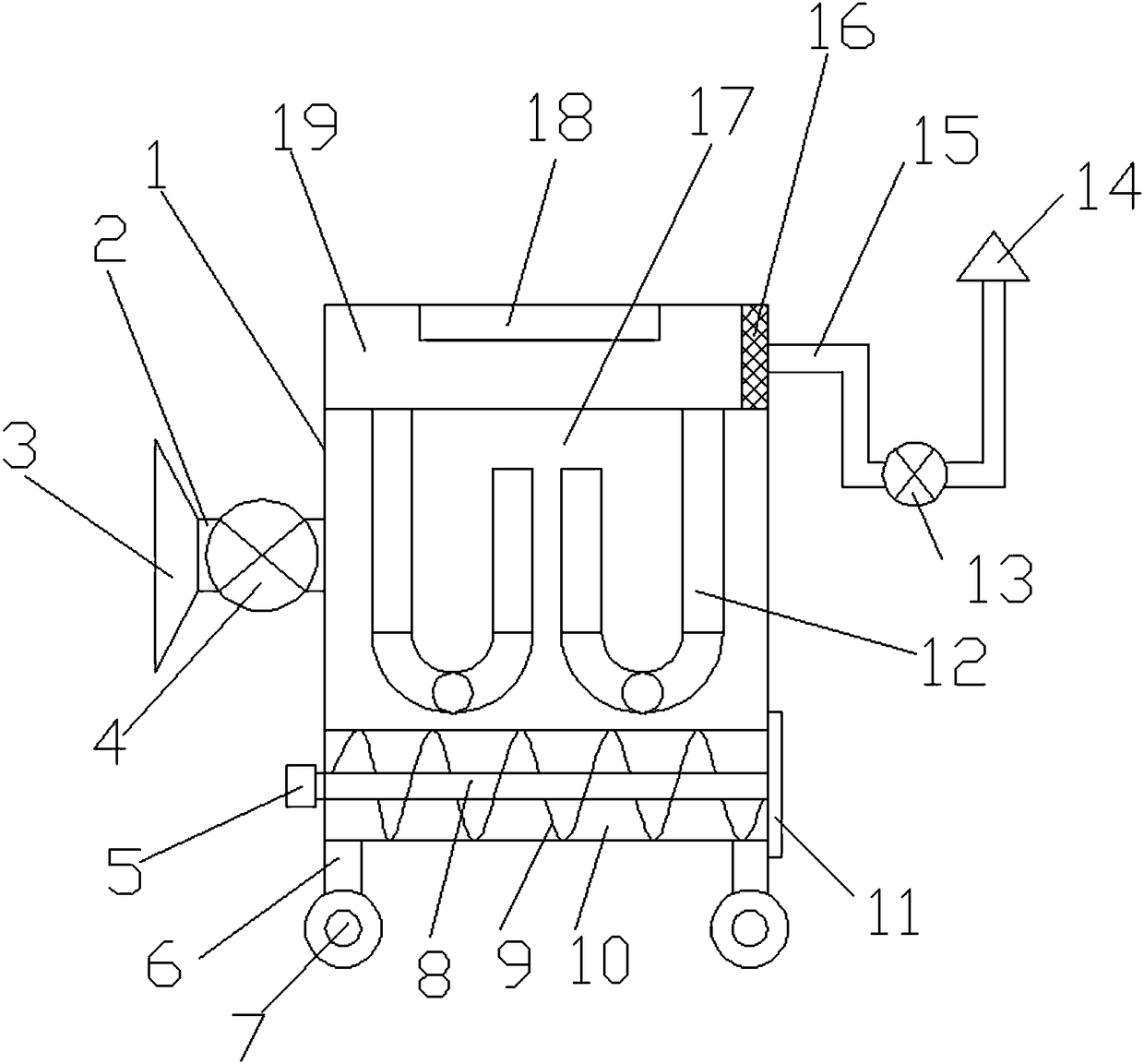

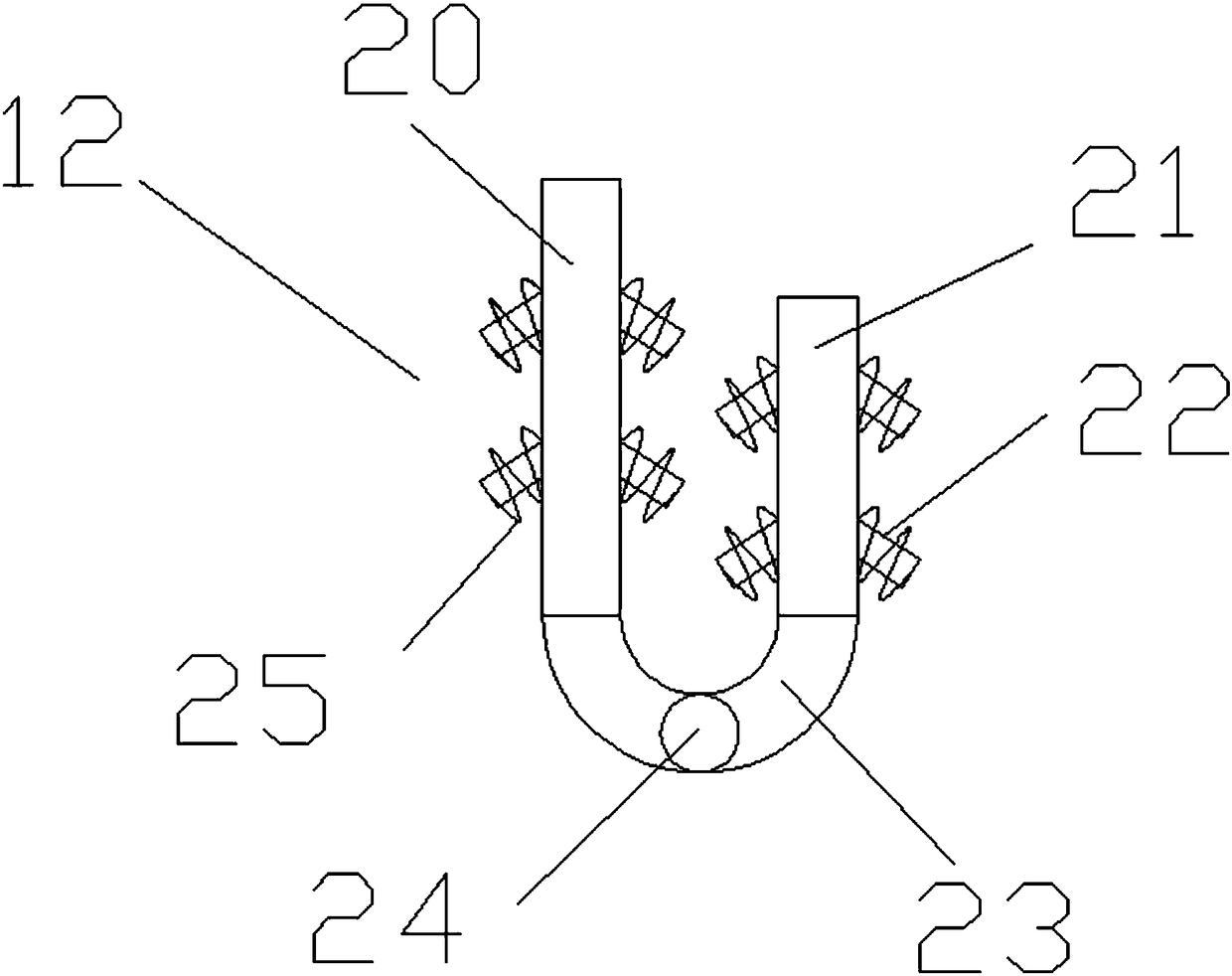

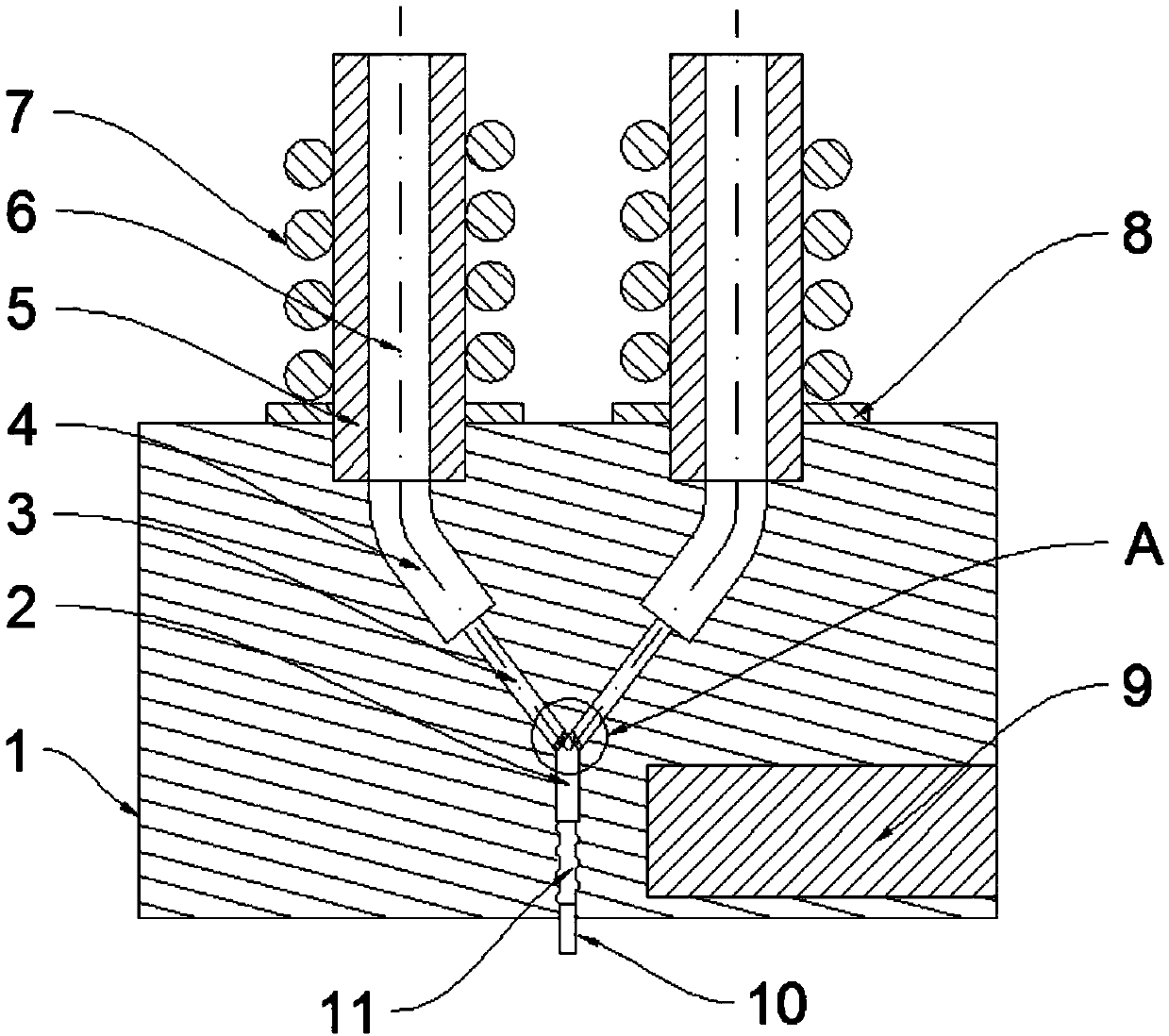

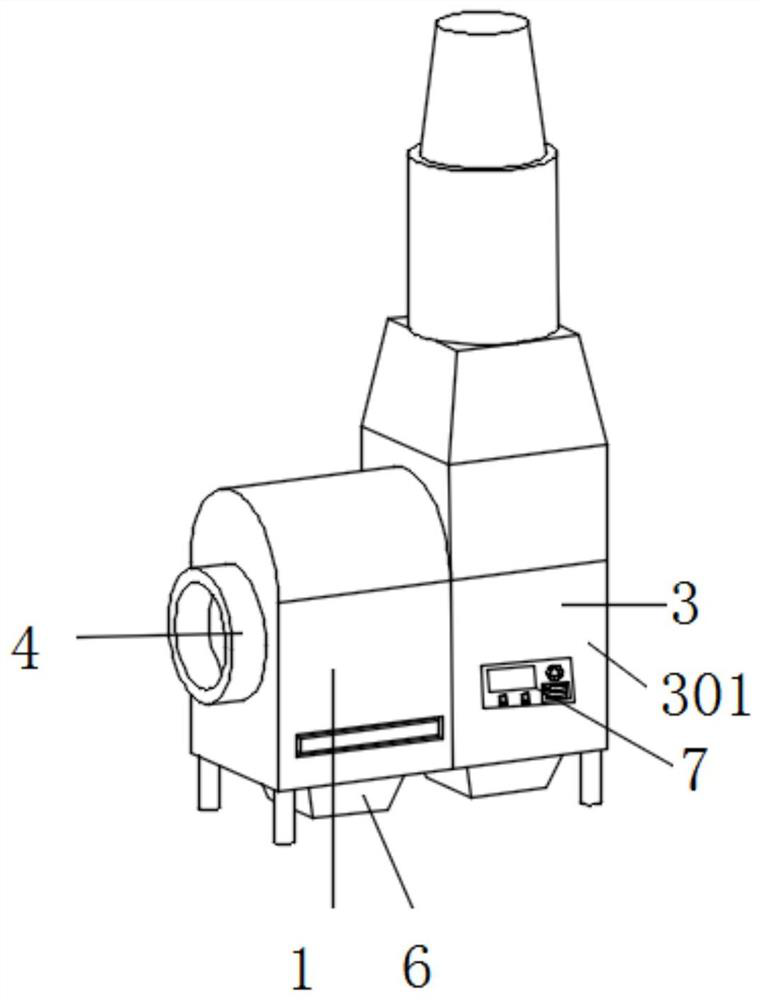

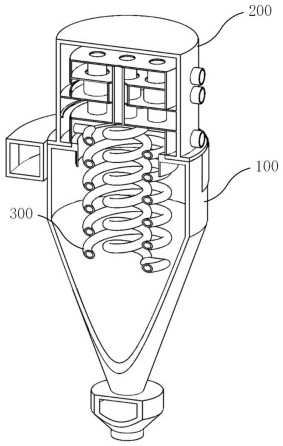

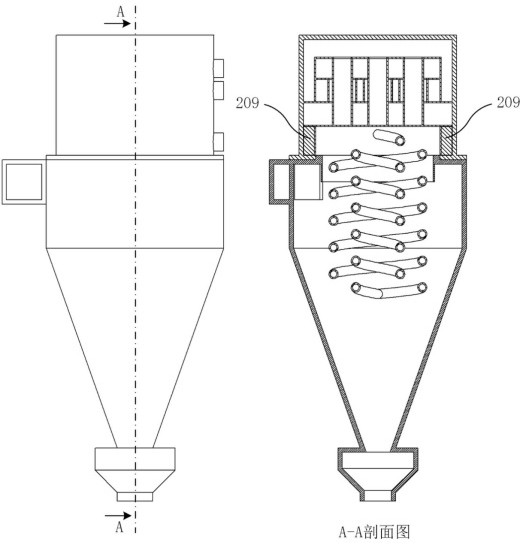

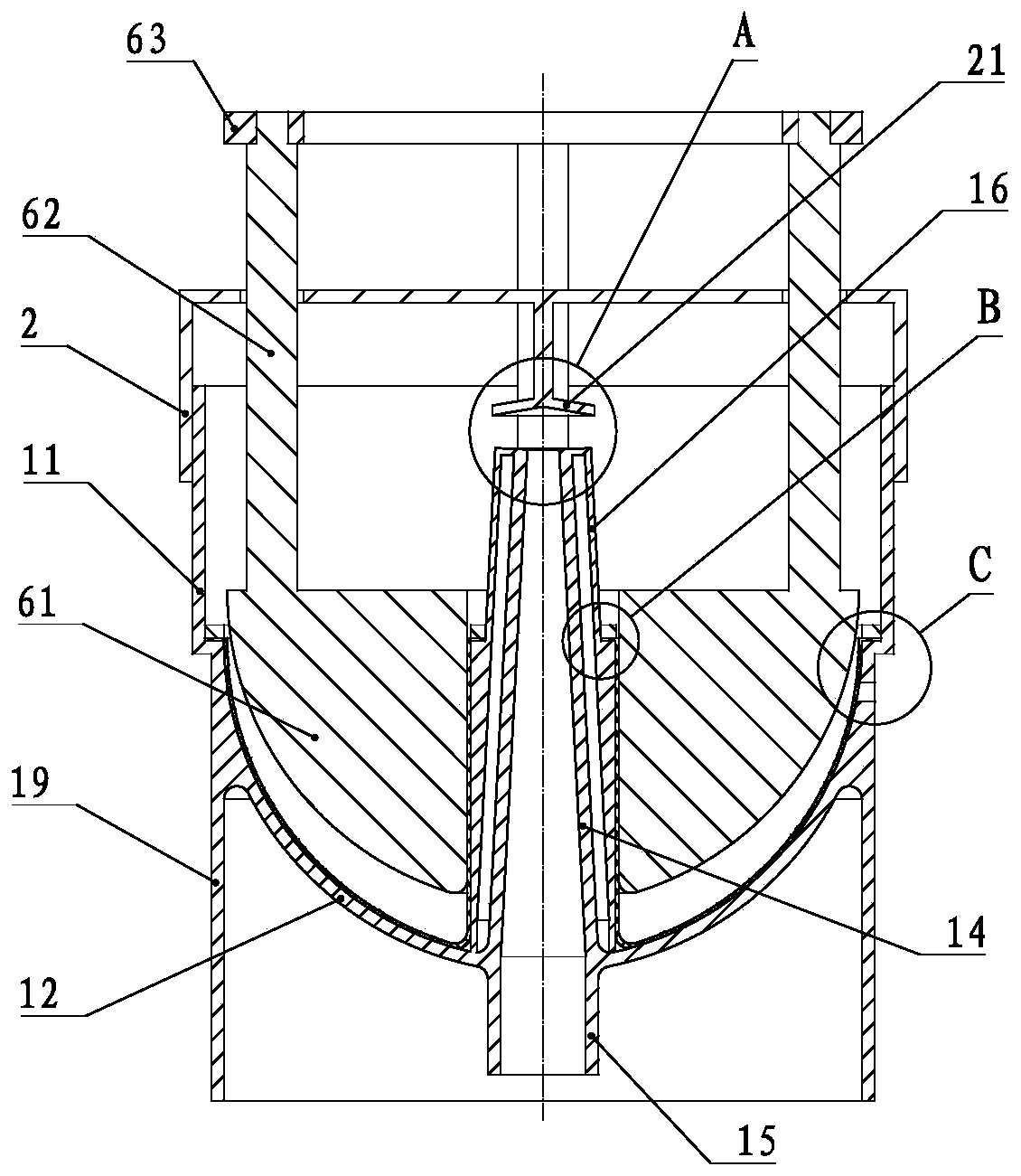

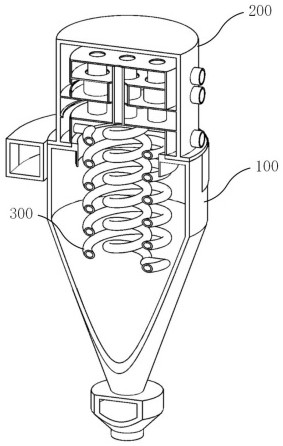

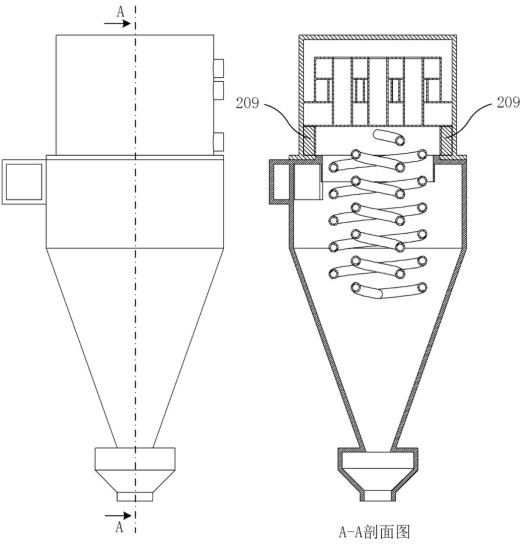

Waterless airborne-dust processing apparatus used for building engineering

InactiveCN108211625AIncrease the collision areaIncrease the frequency of collisionsCombination devicesWater resourcesArchitectural engineering

The invention discloses a waterless airborne-dust processing apparatus used for building engineering. The waterless airborne-dust processing apparatus comprises a housing, and has an ingenious structure to realize waterless processing, a water resource is saved, airborne dust on a building construction place is sucked in a purifying bin by a suction fan through an air-supply pipe, an electrostaticprecipitation net is arranged at the bottom of a material discharge canister, fine airborne dust particles are sucked in a suction housing, the large airborne dust particles in the housing are bumpedwith a sidewall of a dedusting pipeline in the purifying bin and then fall into a material-collection groove and are introduced into the material discharge canister, and then are discharged from thedischarge mechanism in the material discharge canister, dedusting efficiency is high, the dedusting pipeline is set as an U shape, a bump area of the airborne dust particles is increased, the airbornedust is introduced into the dedusting pipeline and then is intercepted, the intercepted airborne dust passes through a material-guiding pipe and then is introduced into a storage bin, the dedusting effect is increased, a heating wire at a flow deflector outside the dedusting pipeline is energized for heating air in the housing, the bump frequency of the airborne dust in air and the outer wall ofthe dedusting pipeline is increased, and the dedusting effect is increased.

Owner:郑东亮

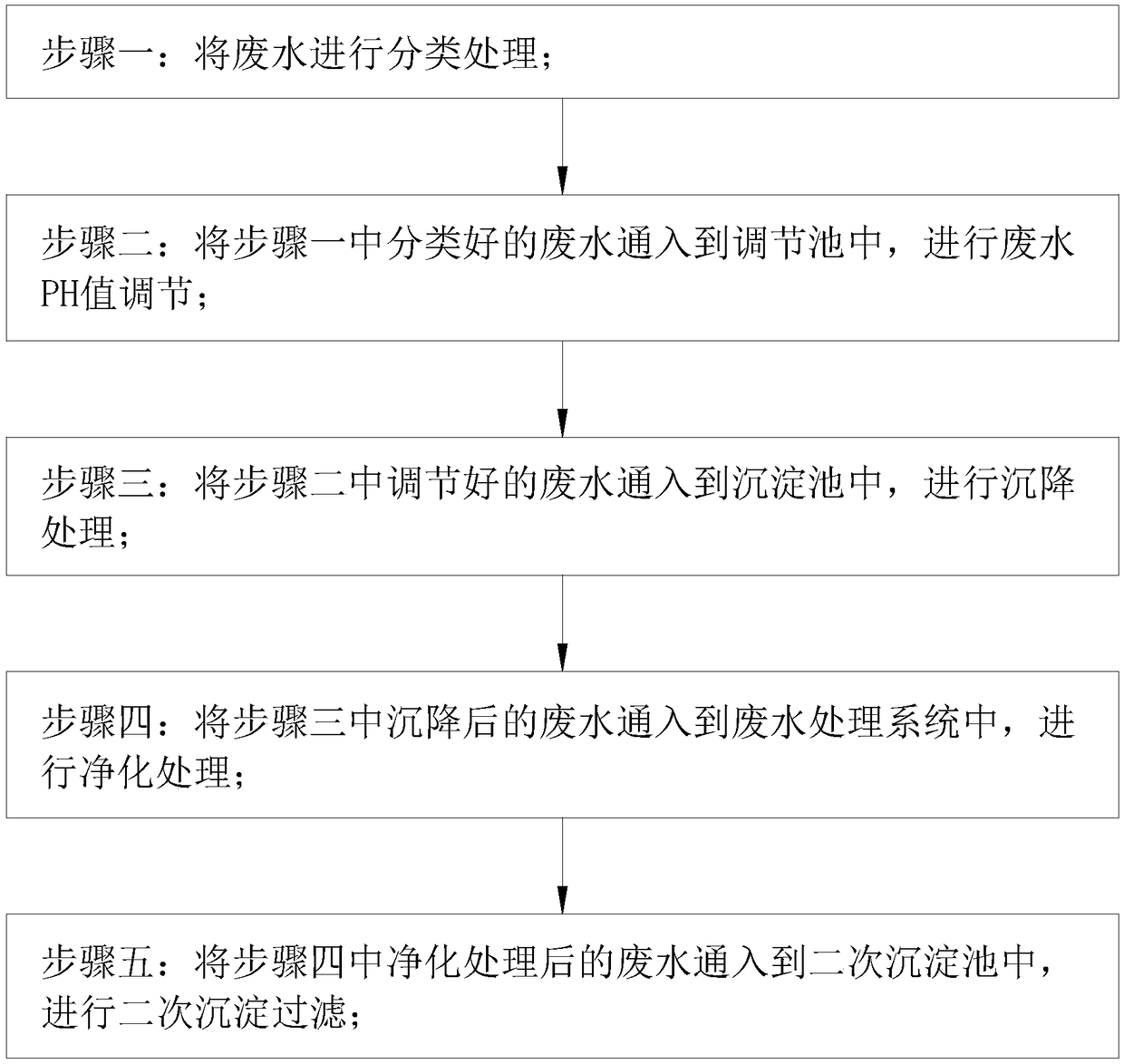

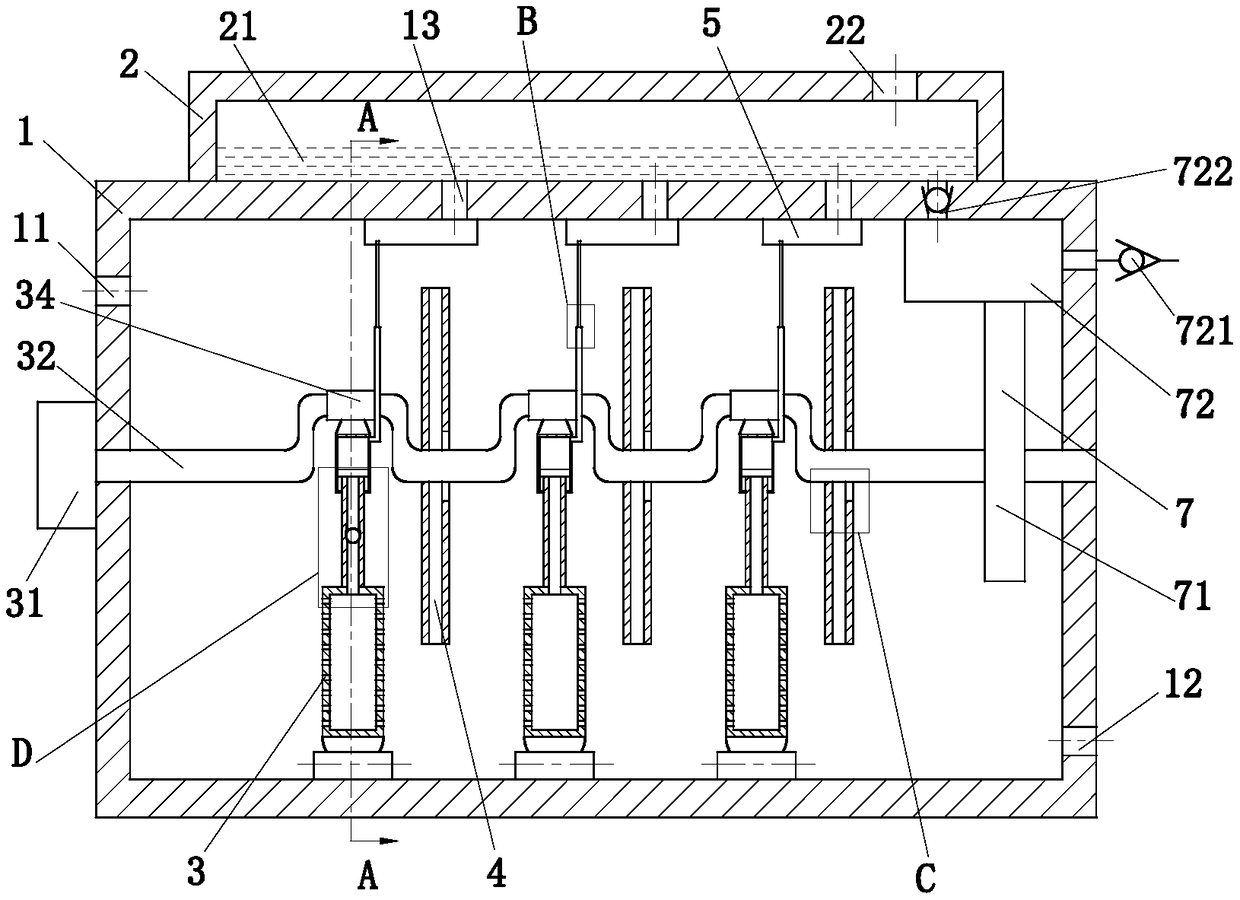

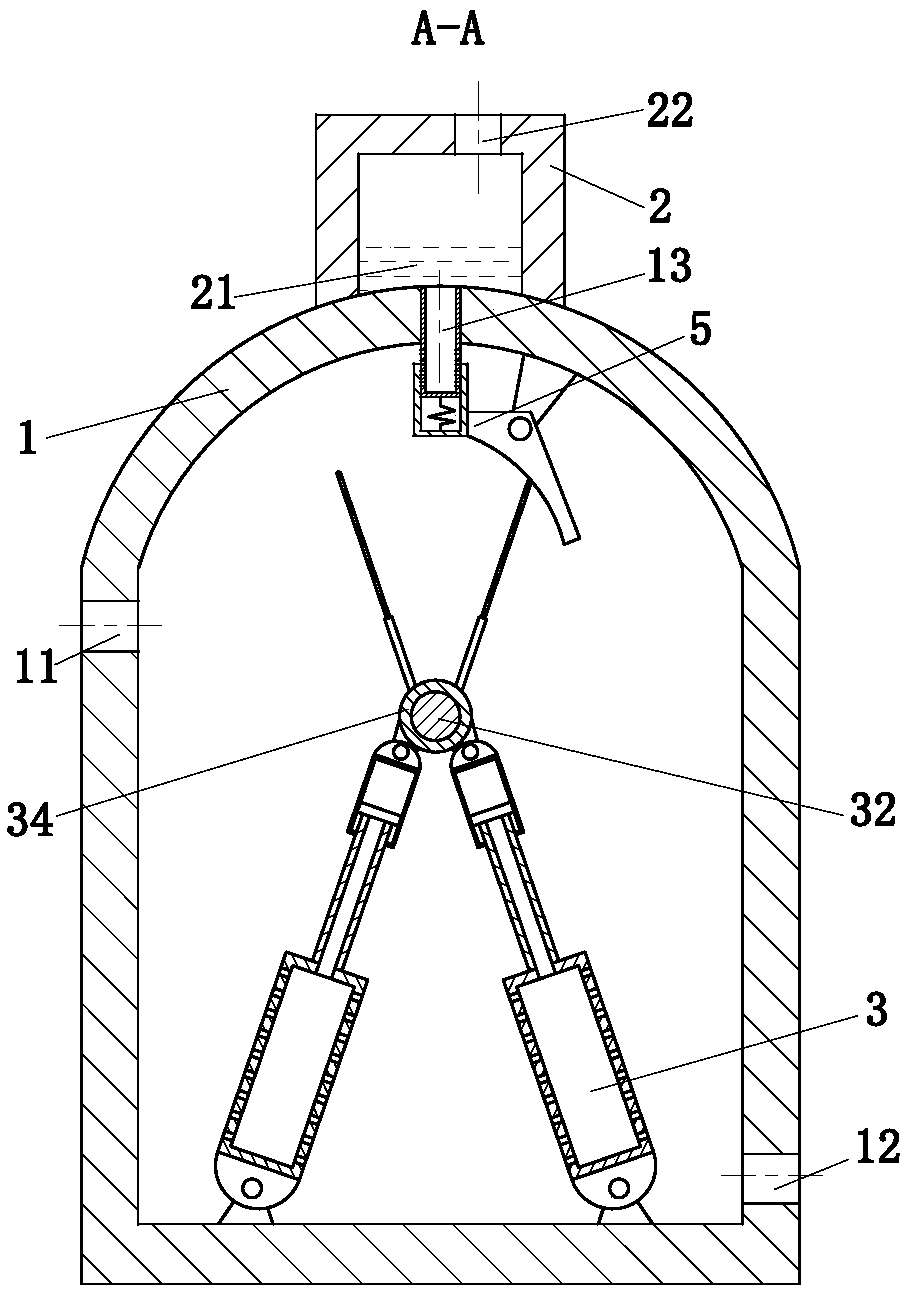

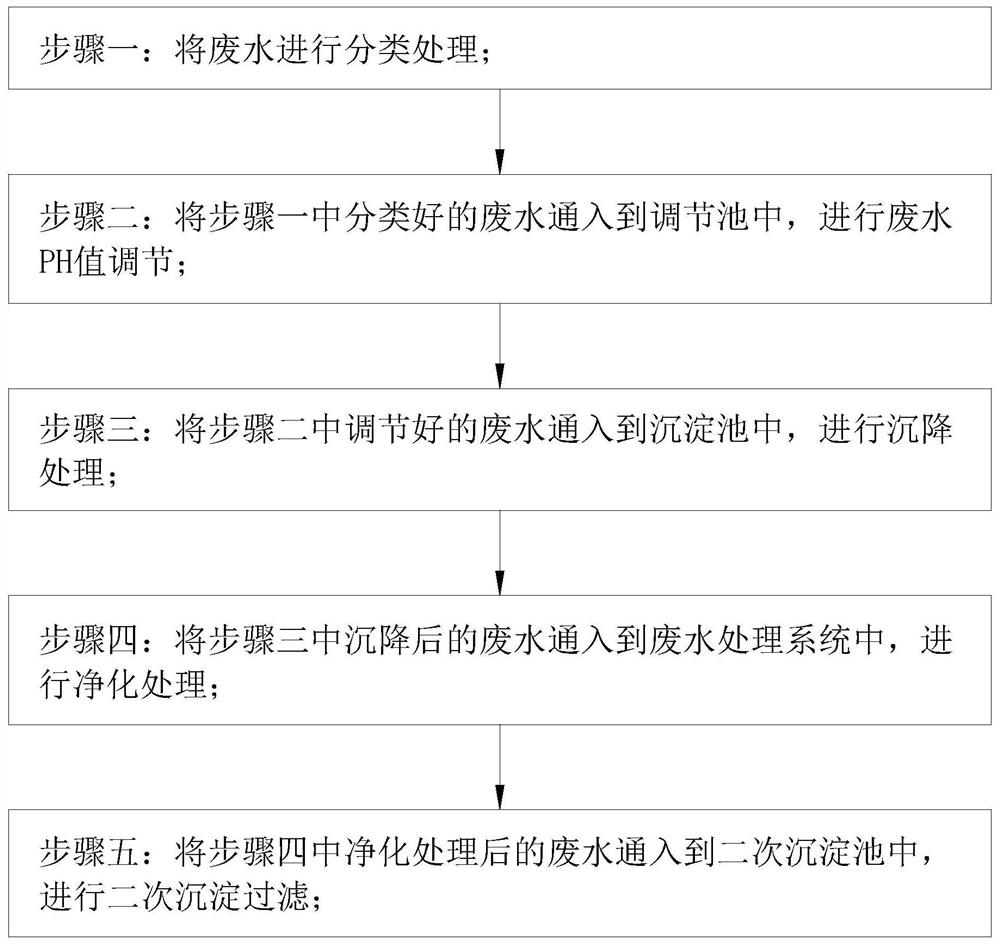

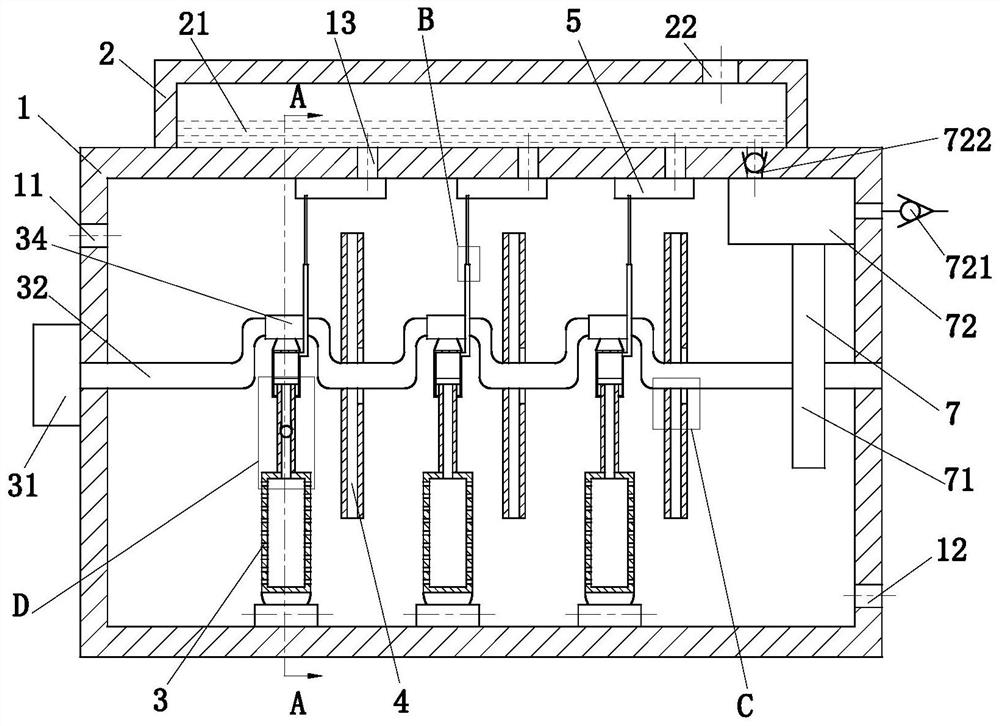

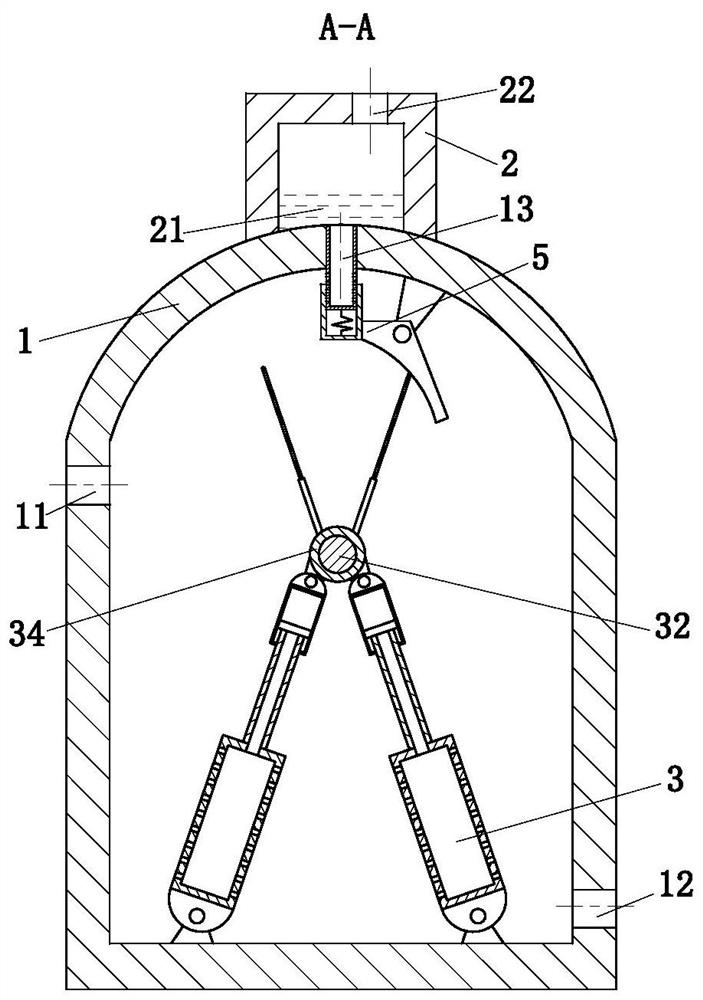

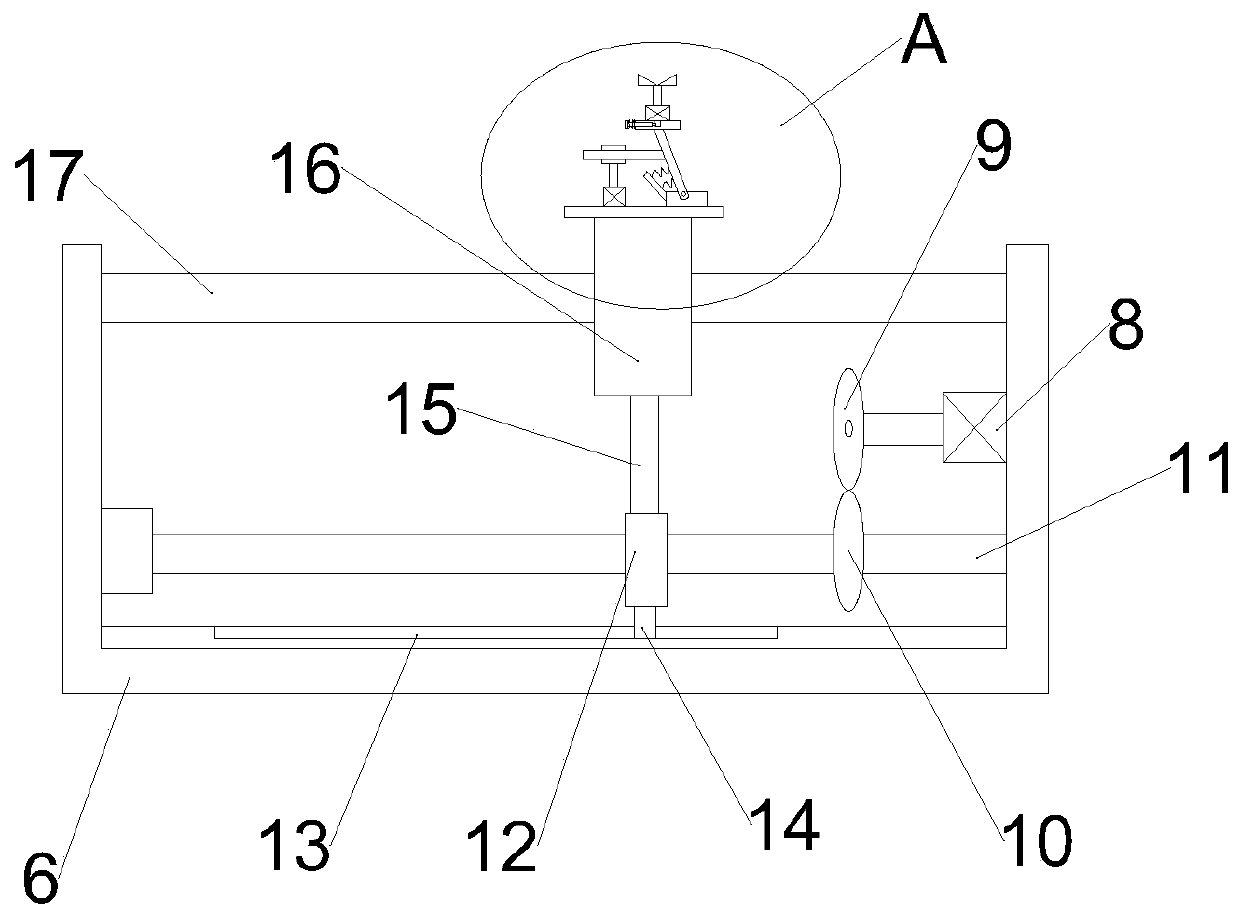

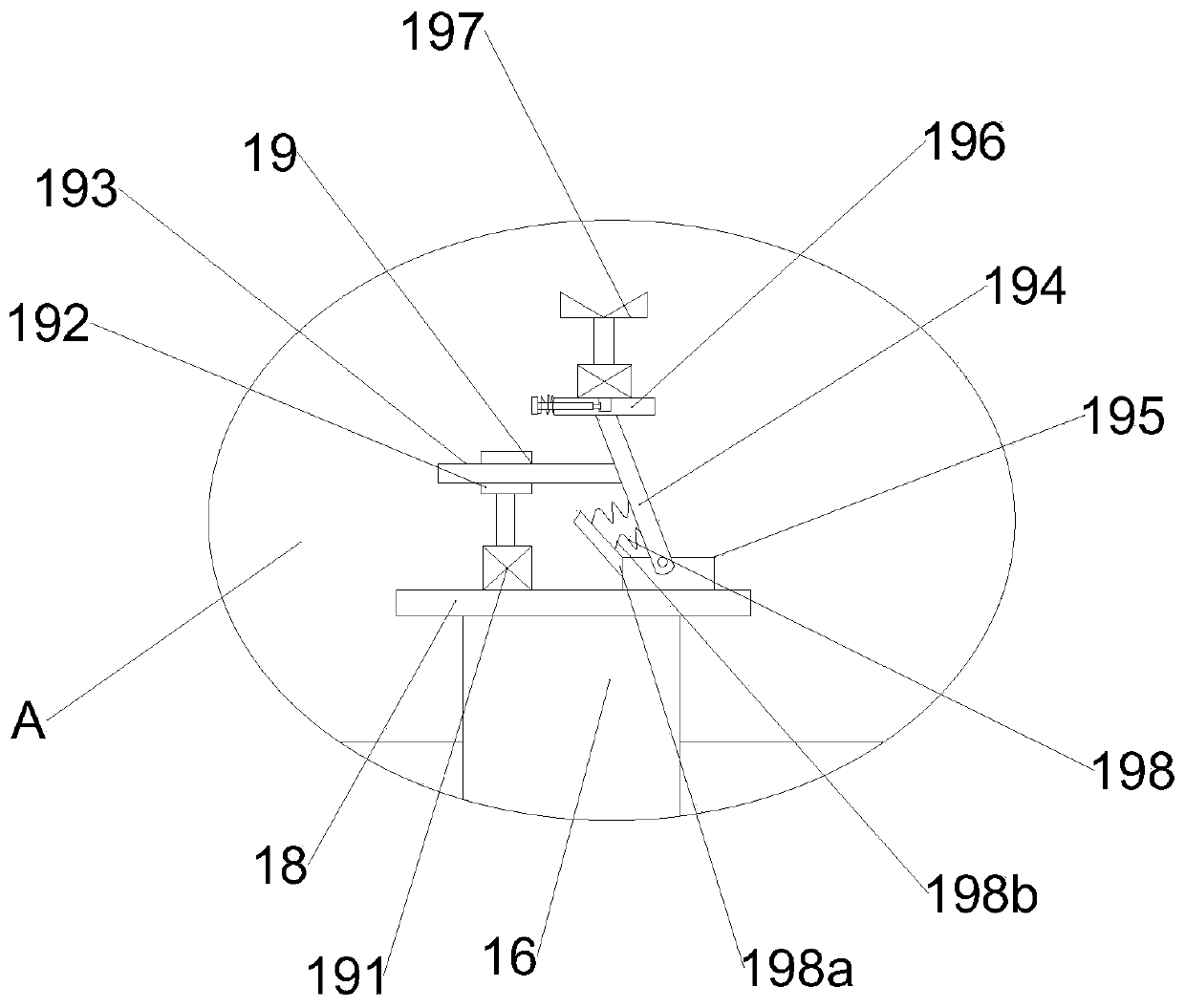

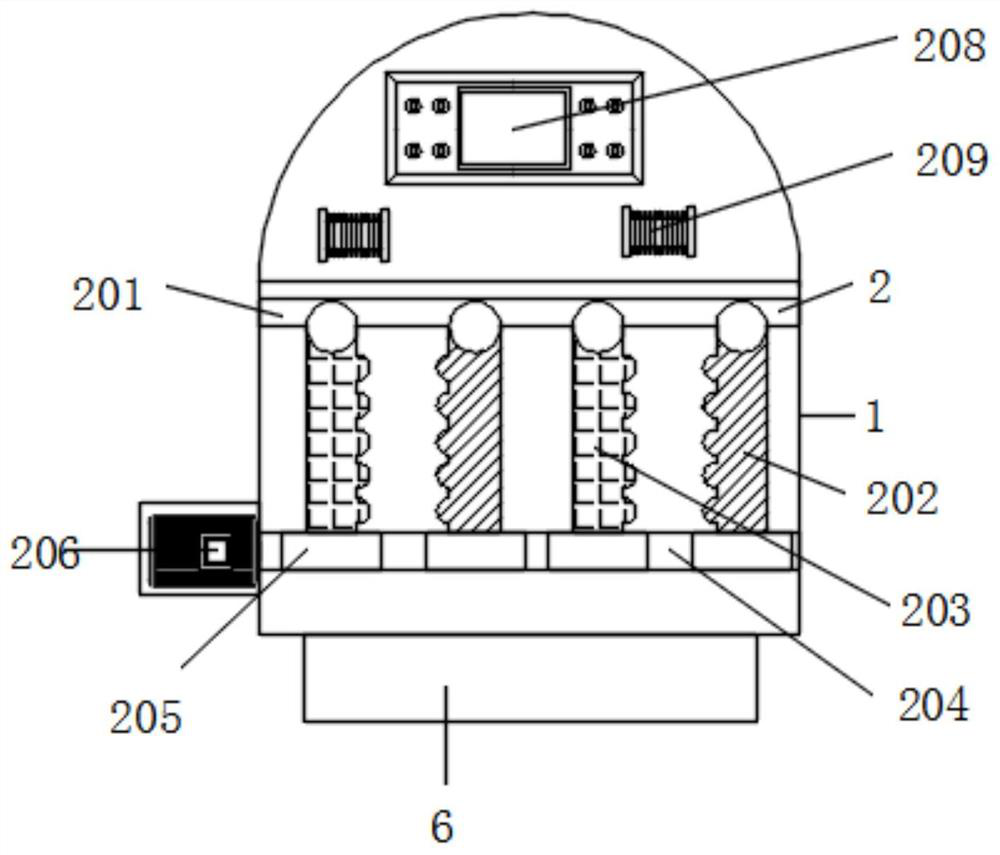

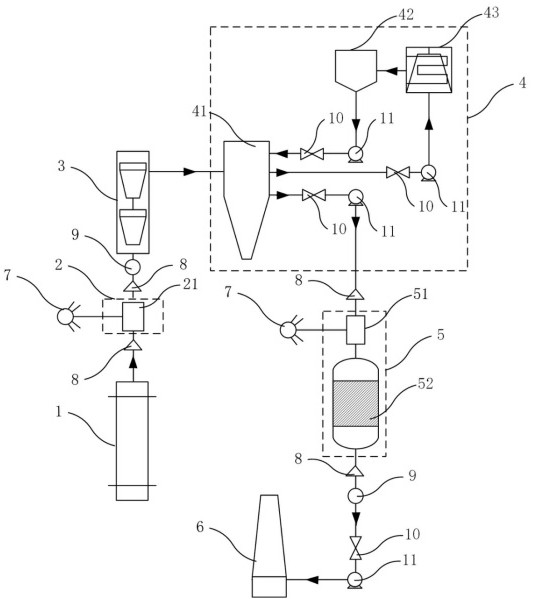

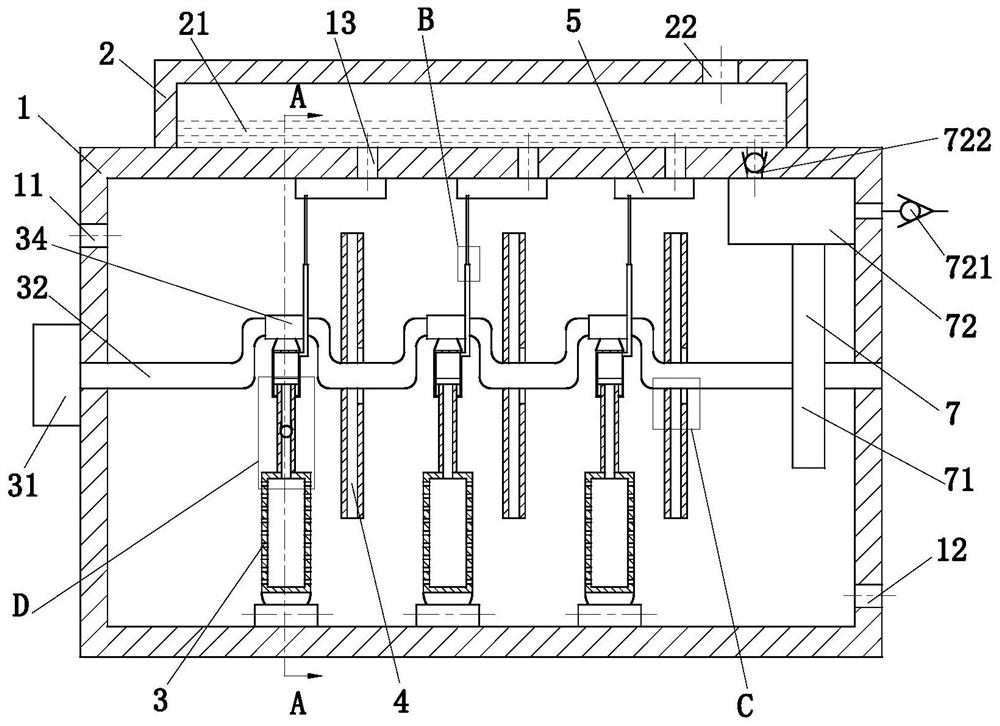

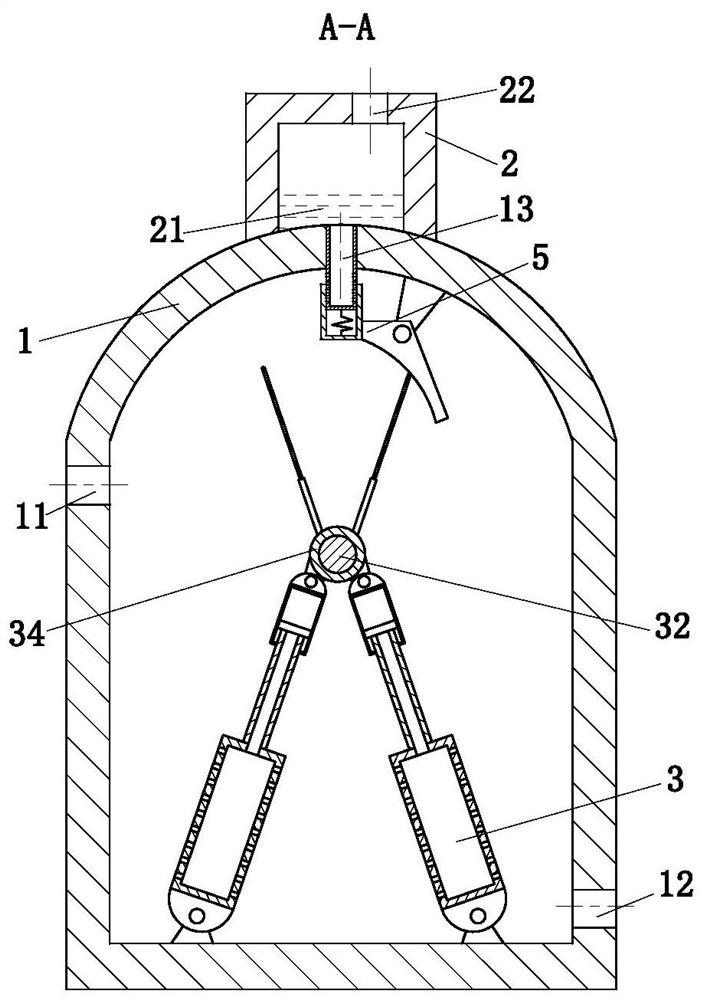

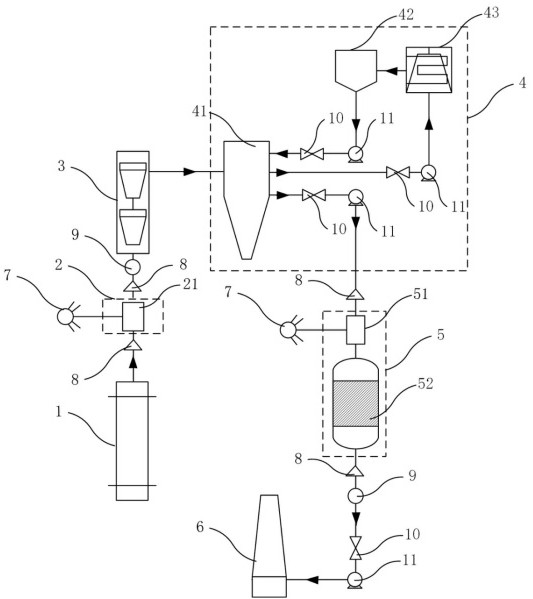

Coal chemical industry wastewater purification treatment method

ActiveCN108996753AImprove purification efficiencyIncrease the collision areaTreatment involving filtrationMultistage water/sewage treatmentLow speedCoal chemical industry

The invention belongs to the technical field of environmental protection, and particularly relates to a coal chemical industry wastewater purification treatment method. In the method, a wastewater treatment system is adopted, and the wastewater treatment system comprises a treatment box and a reagent box; the wastewater treatment system further comprises first stirring units, second stirring unitsand reagent spray heads; the first stirring units are used for dissolving a flocculating agent into wastewater during low-speed stirring; the second stirring units are used for dissolving the flocculating agent in the wastewater during high-speed stirring; and the reagent spray heads are used for spraying the flocculating agent into the treatment box. In low-speed stirring and high-speed stirring, the first stirring units and the second stirring units are used for stirring complementarily; on one hand, the collision area of the flocculating agent with impurities in the wastewater is increased, so that the dissolving efficiency of the flocculating agent into the wastewater is accelerated, and the purification efficiency of the wastewater is improved; and on the other hand, the flocculatingagent is sprayed into the treatment box reasonably according to requirements, so that the flocculating agent is dissolved into the wastewater, the waste of the flocculating agent is avoided, and theutilization rate of resources is improved.

Owner:中汇金源(北京)科技发展有限公司

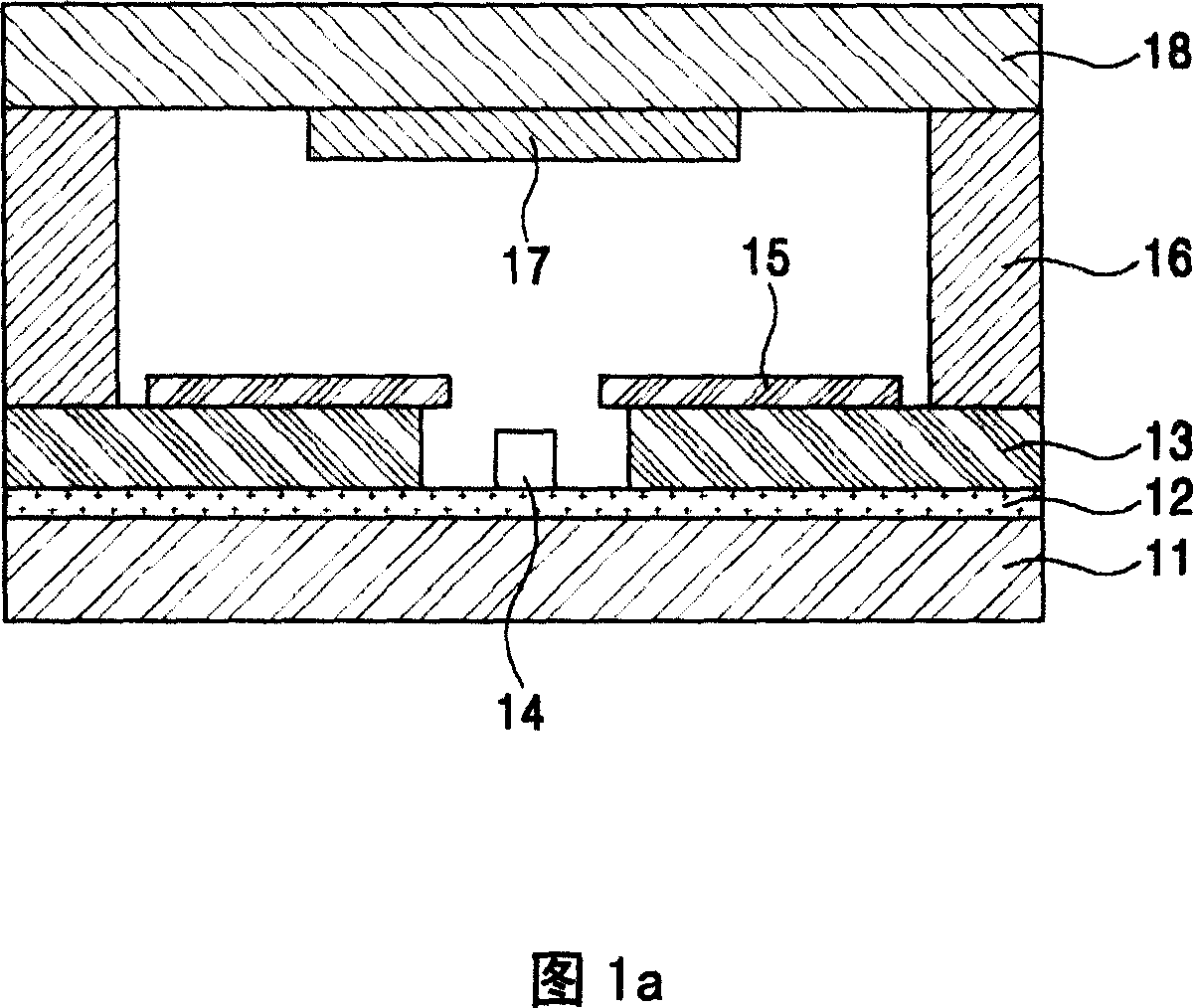

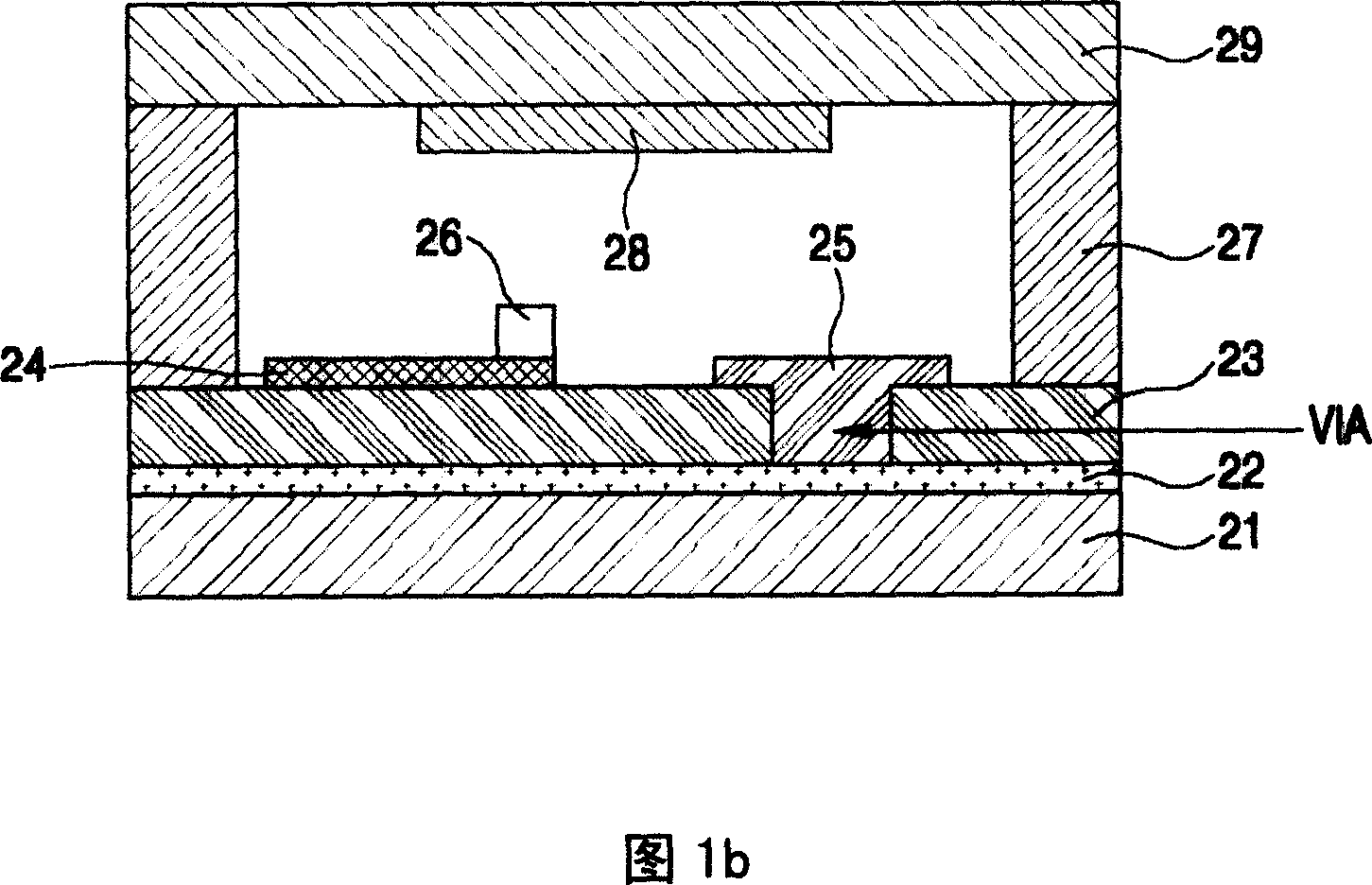

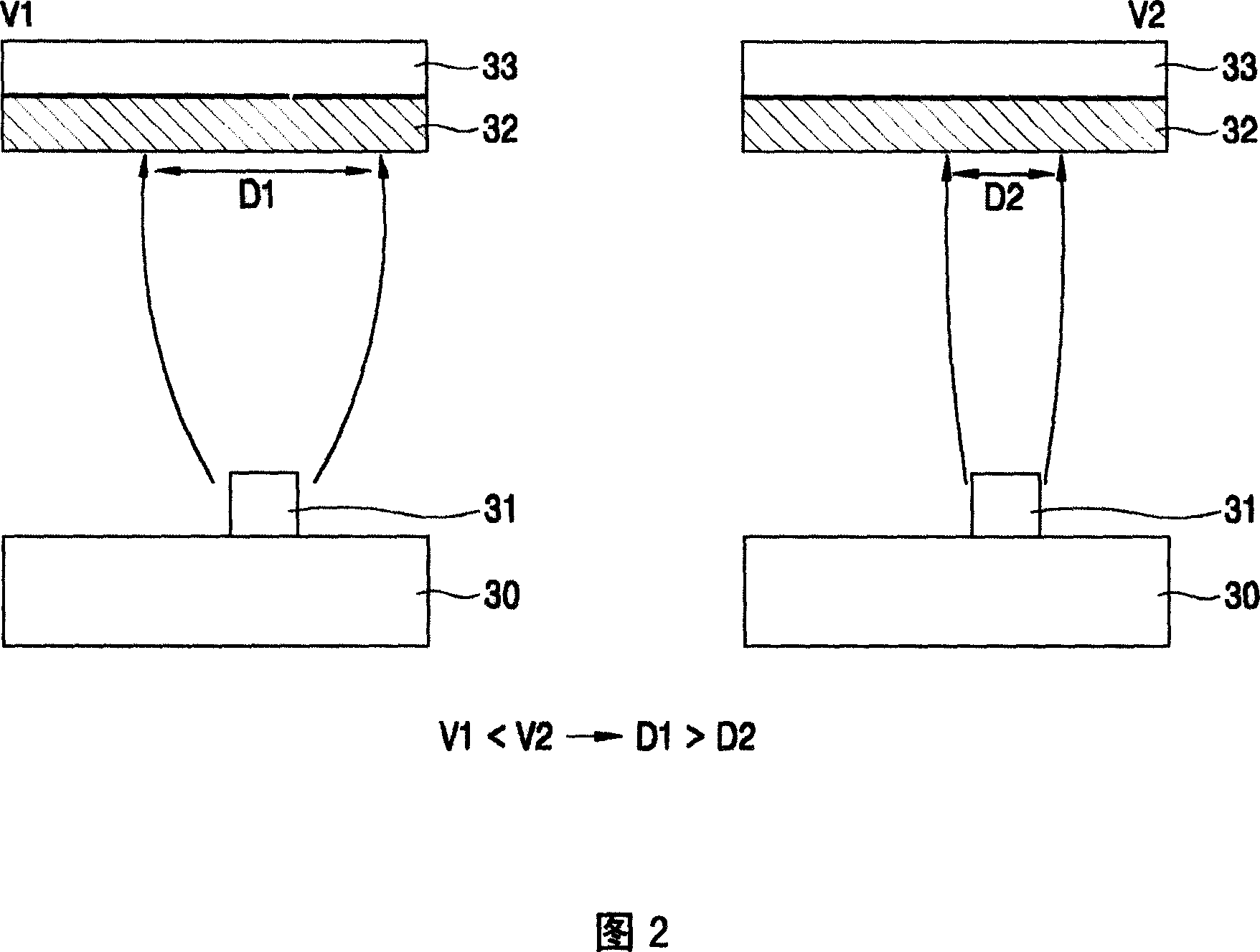

Field emission element in use for background light

InactiveCN1959503AIncrease the collision areaIncrease the areaDischarge tube cold cathodesNon-linear opticsCarbon nanotubeField electron emission

A field emission element used on background lamp makes form of fluorescent surface on fluorescent body be a projected surface in order to increase coating area of fluorescent body for raising efficiency of field emission element utilizing carbon nanotube as electronic emission source.

Owner:LG ELECTRONICS(NANJING) PLASMA CO LTD

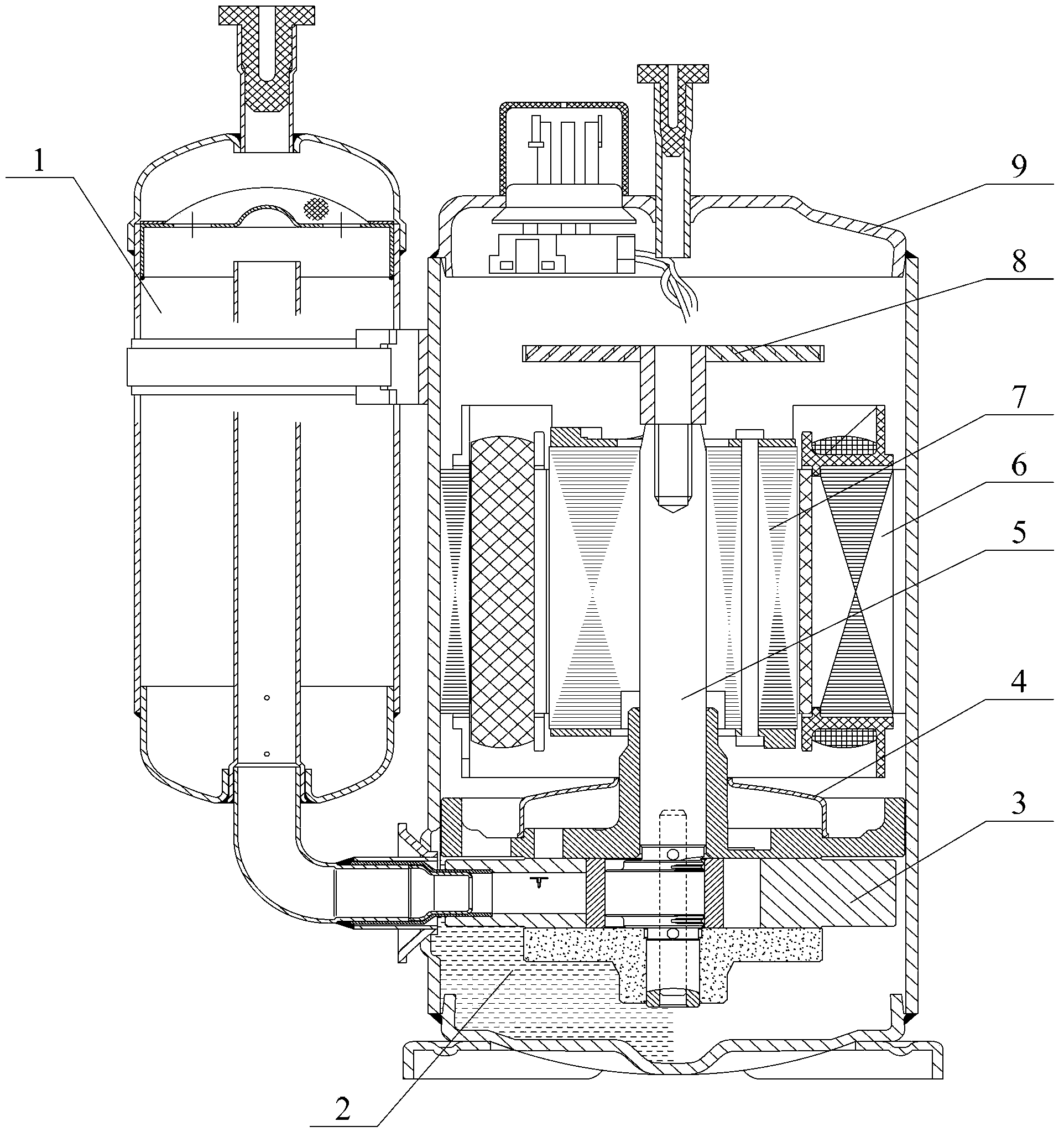

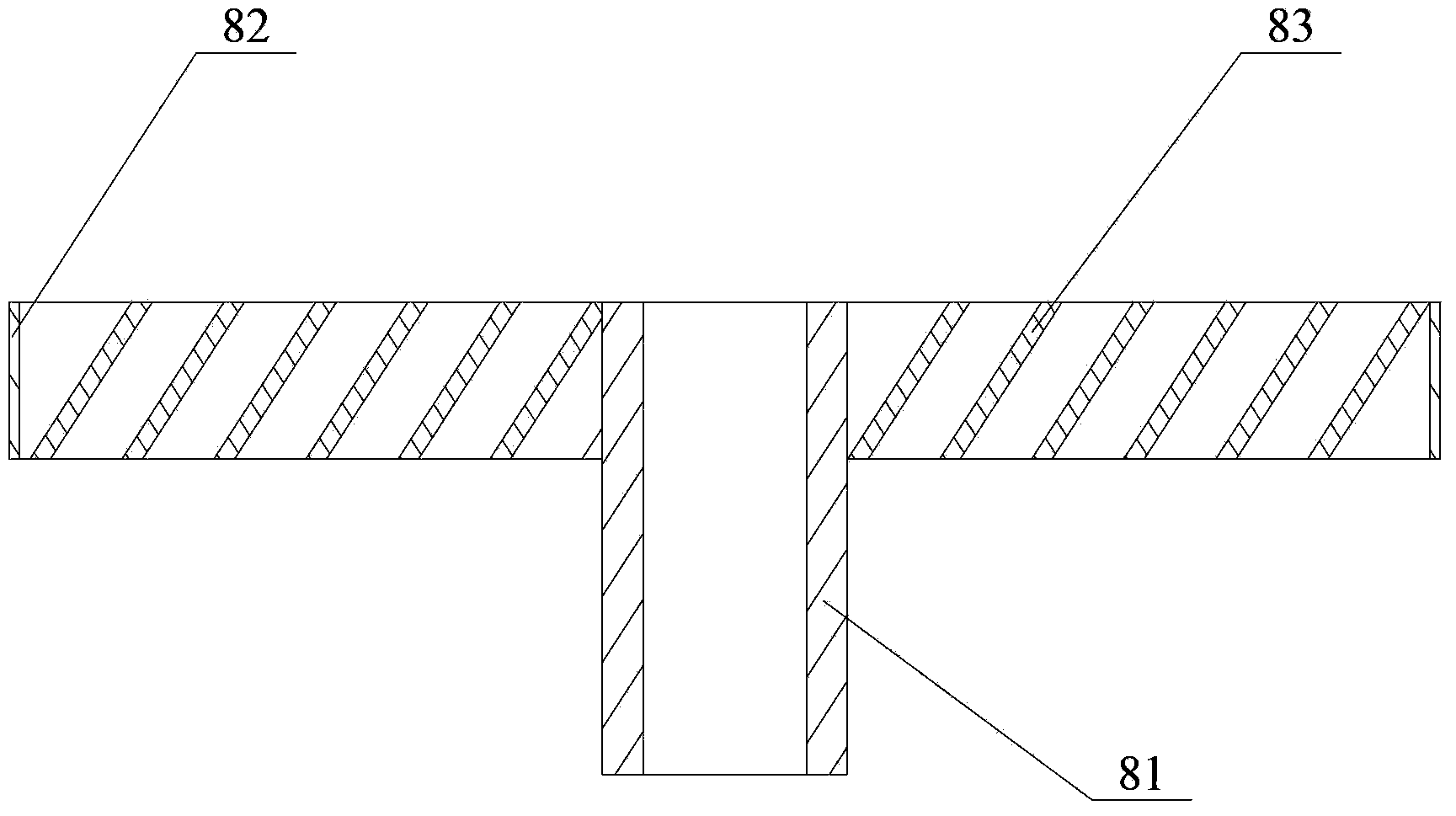

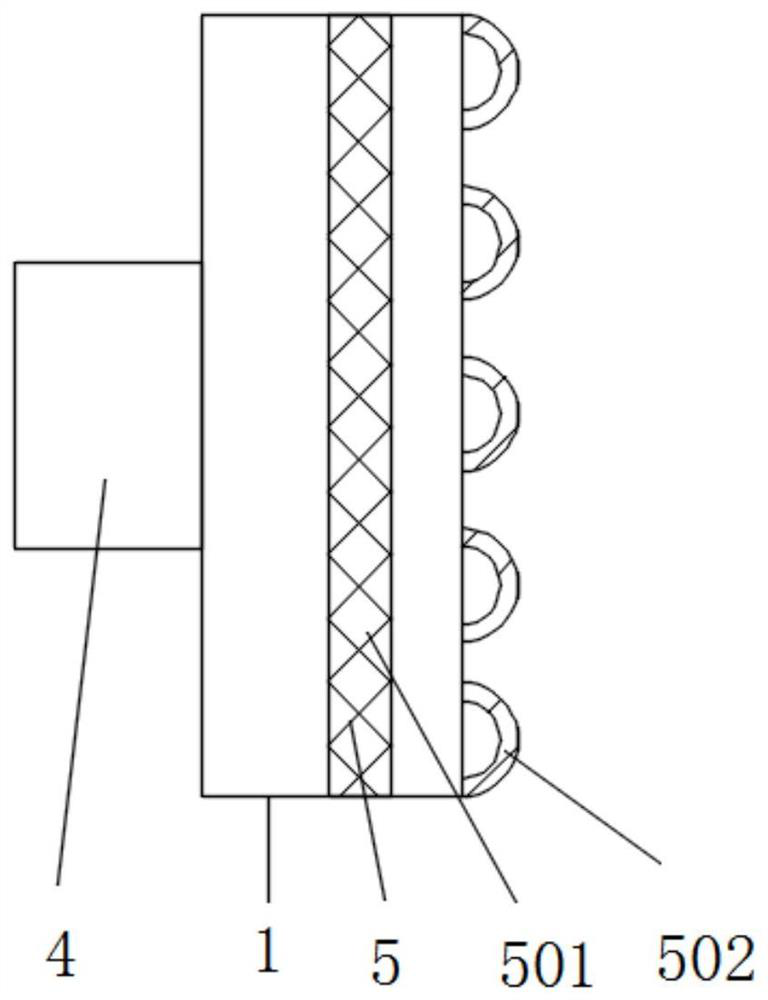

Oil baffle plate and compressor applying oil baffle plate

InactiveCN103573634AReduce outflowIncrease the collision areaRotary/oscillating piston pump componentsLiquid fuel engine componentsHigh pressureCentrifugal force

The invention discloses an oil baffle plate. The oil baffle plate is connected to the upper end of a crank shaft and comprises a transmission part fixedly connected with the crank shaft and an oil-gas separation part vertically arranged at the upper end of the transmission part, wherein the oil-gas separation part is provided with a plurality of strip-shaped fan blades which are obliquely distributed relative to the axis of the crank shaft. After the oil baffle plate is connected to the upper end of the crank shaft and an oil-gas mixture flows through the oil baffle plate, the oil-gas mixture suffers from a centrifugal force under the rotary effect of each strip-shaped fan blade; the mass of freezing oil is obviously greater than that of high-pressure gas so that the freezing oil is thrown to the outer edge of the oil baffle plate and the high-pressure gas is gathered at the central position of the oil baffle plate; meanwhile, the collision area of the oil-gas mixture and the oil baffle plate is enlarged under the effect of each strip-shaped fan blade so that the high-pressure gas and the freezing oil are easy to separate. The oil baffle plate provided by the invention can be used for easily separating the freezing oil mixed with the high-pressure gas so as to reduce the freezing oil flowing out from a compressor. The invention further discloses the compressor with the oil baffle plate.

Owner:ZHUHAI GREE REFRIGERATION TECH CENT OF ENERGY SAVING & ENVIRONMENTAL PROTECTION

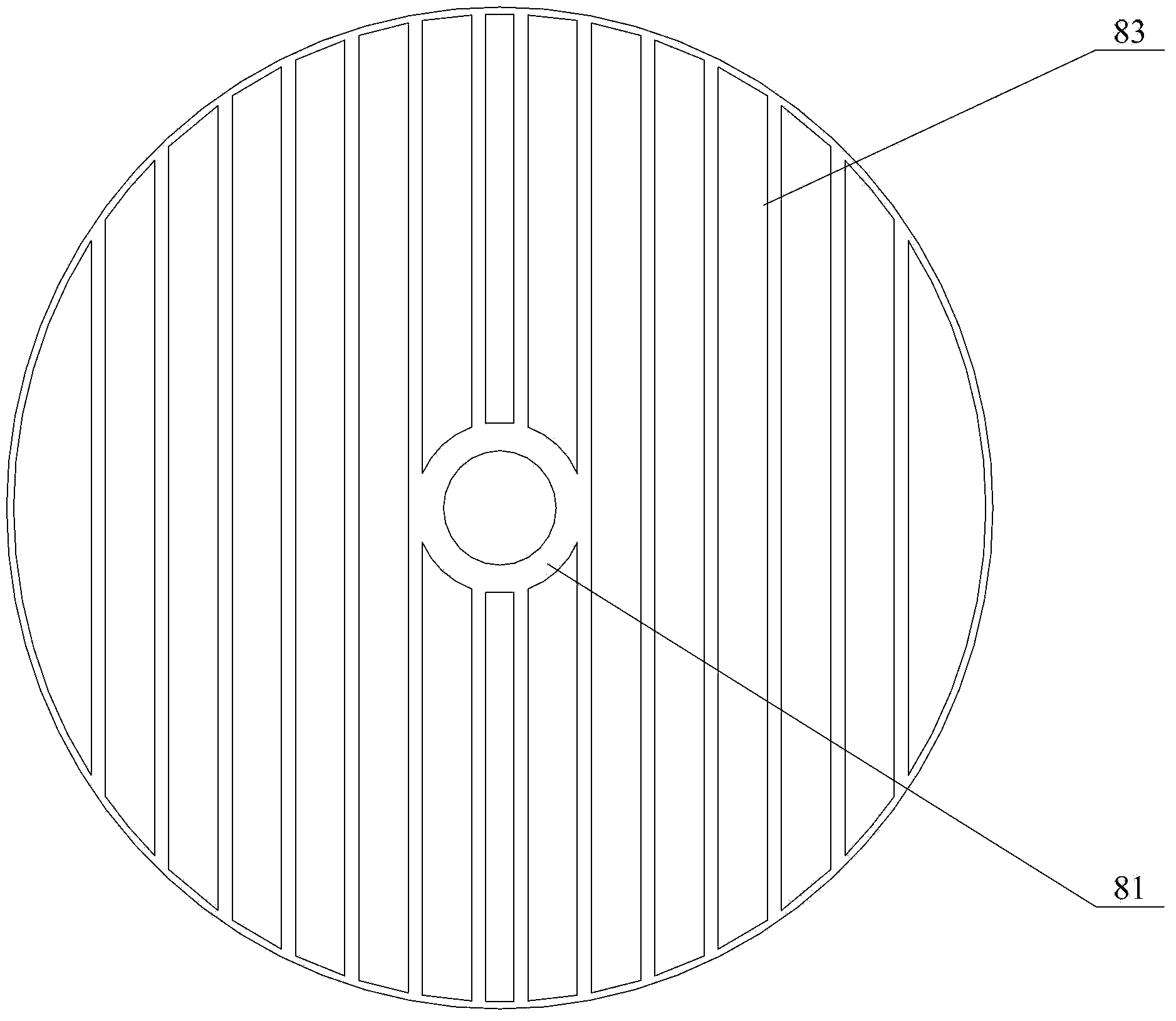

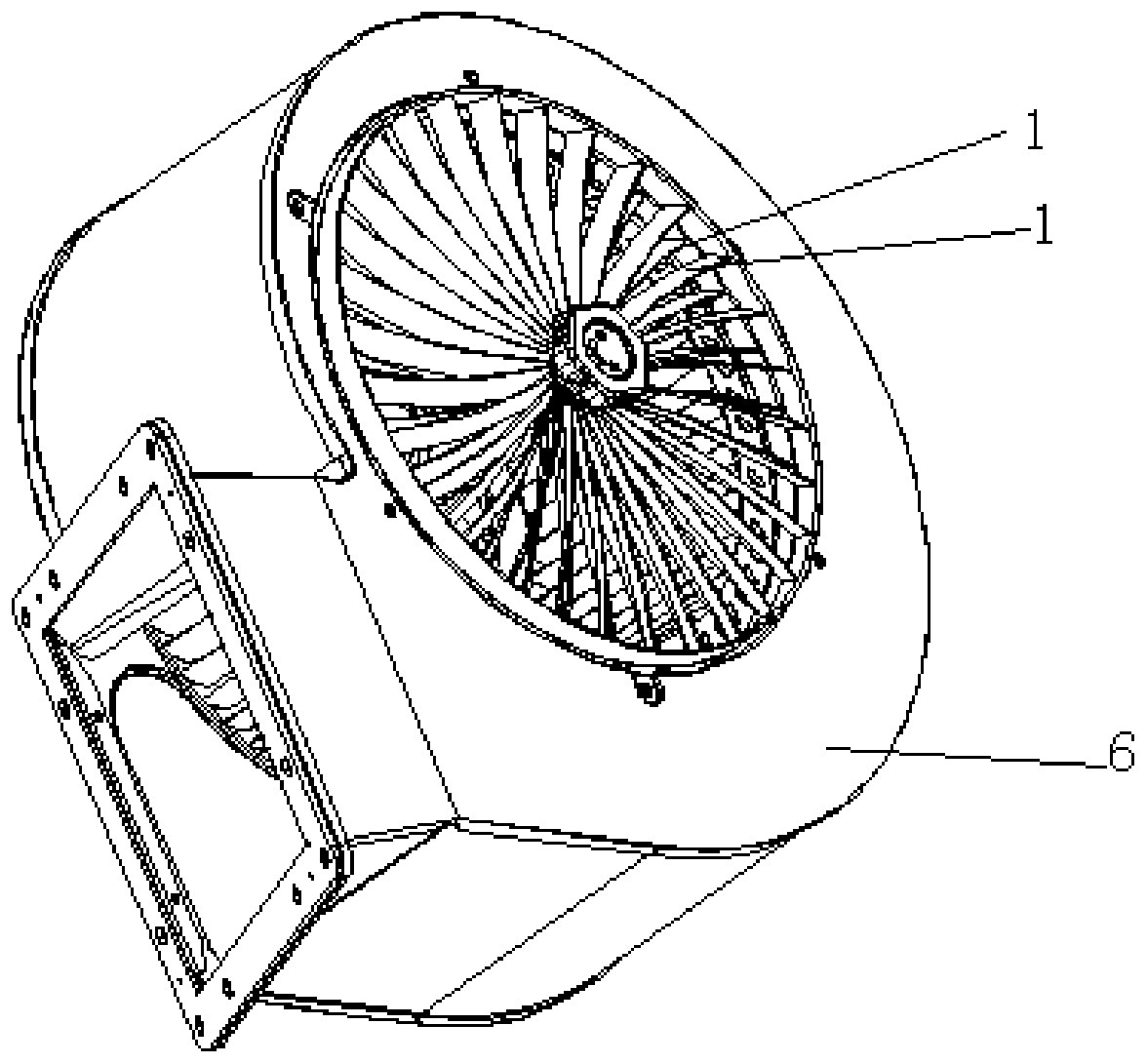

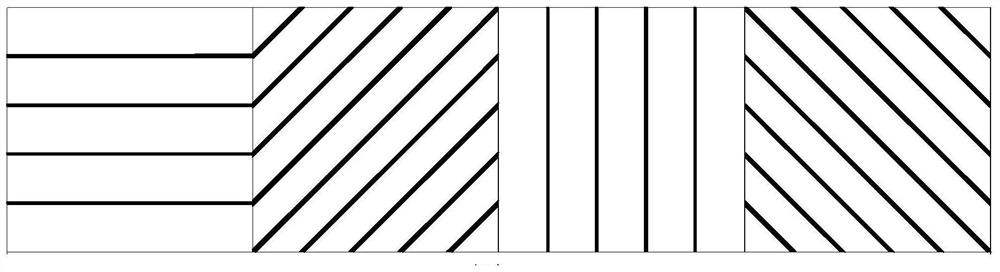

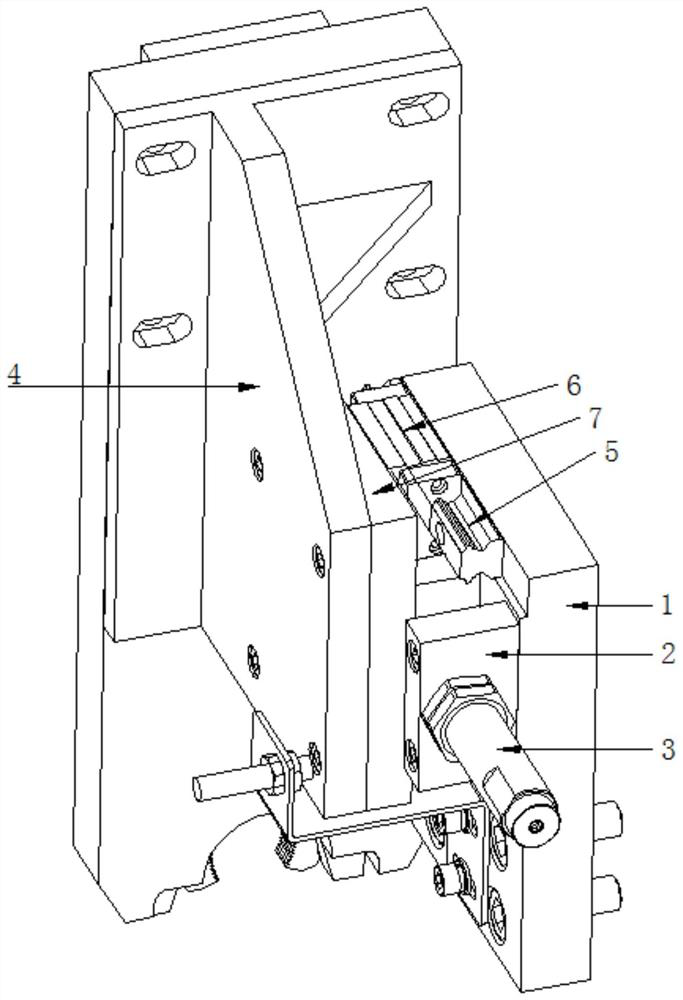

Filter screen of range hood, air inlet system of range hood and range hood

PendingCN110173734AIncrease the areaIncrease contact areaDomestic stoves or rangesLighting and heating apparatusEngineeringMechanical engineering

The invention discloses a filter screen of the range hood. The filter screen comprises a mounting disc, a rim and a quality of blades; the mounting disc is suitable for being mounted on an output shaft of a motor; the rim is arranged around the mounting disc; and a quality of the blades are arranged between the mounting disc and the rim in a radial manner by taking the center of the mounting discas a circle center, the root part of the blade is arranged on the mounting disc, the end part of the blade is mounted on the rim, at least one blade and the projection of the root of the adjacent blade on the outer peripheral wall of the mounting disc are arranged at intervals in the axial direction of the mounting disc, or the projection of the end part on the outer peripheral wall of the mounting disc is separated from the axial direction of the mounting disc. The total area of the blades can be increased as much as possible, then the contact area between the oil fume and the filter screen is increased, therefore, the oil smoke can be filtered as much as possible, the range hood can be reduced to enter the range hood, when the motor is driven by the motor to rotate, the function of air supply and pressurization is achieved, and the oil fume suction effect can be ensured.

Owner:GREE ELECTRIC APPLIANCES INC

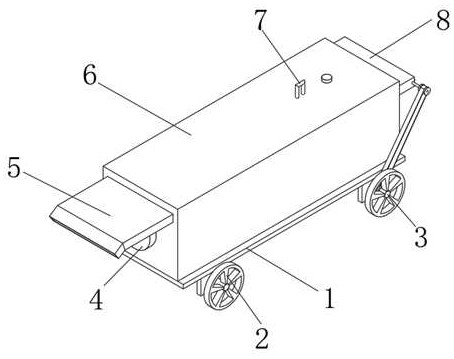

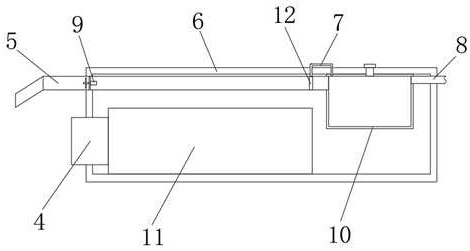

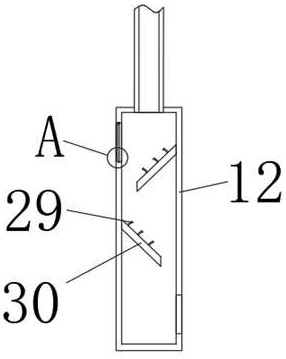

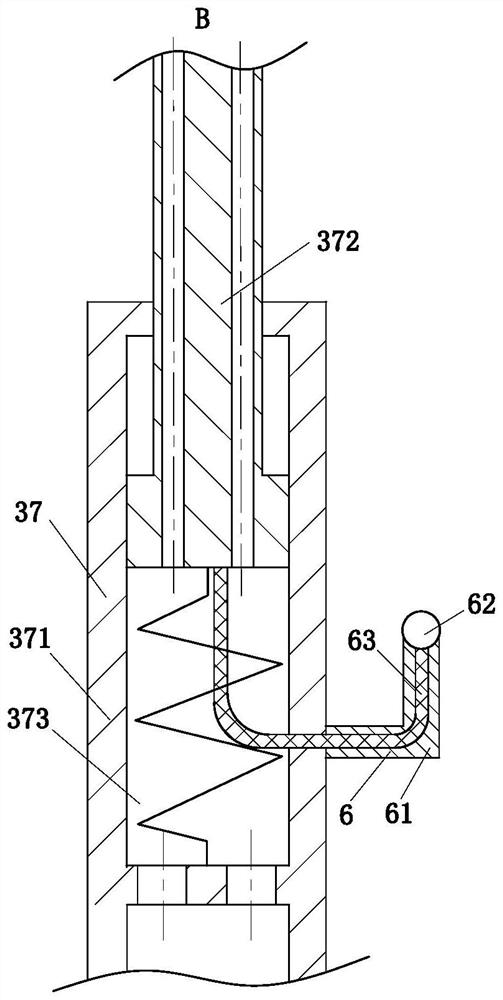

3D printing spray head system

PendingCN108673894AHigh speedGuaranteed StrengthManufacturing heating elements3D object support structuresMulti materialSpray nozzle

The invention relates to the technical field of 3D printing, in particular to a 3D printing spray head system. The 3D printing spray head system comprises a fusing spray head shell and a feeding throat pipe, and a vertical material mixing cavity is formed in the fusing spray head shell; the bottom end of the material fixing cavity communicates with a spiral discharging channel which communicates with a spray nozzle; the spray nozzle penetrates the fusing spray head shell and is connected with the fusing spray head shell in a threaded manner; the top end of the material mixing cavity communicates with a plurality of feeding channels which communicate with a connection channel; the upper surface of the fusing spray head shell is provided with an installing hole which is in threaded connection with the feeding throat pipe; the feeding throat pipe communicates with the connection channel, and is sleeved with a heating pipe; and the feeding throat pipe is provided with a heat insulating gasket which is located between the heating pipe and the fusing spray head shell. The spray head system is designed into the multi-feeding and single-discharging spray head mode, the feeding speed in theprinting process can be increased due to the multi-feeding mode, discharging manners of a plurality of materials can be in a mixed state due to the single-discharging mode, and the strength and the precision of printed finished products are guaranteed.

Owner:ZUNYI MEDICAL UNIVERSITY

Nonmetallic ore pulverizing mill

The invention provides a nonmetallic ore pulverizing mill, which comprises two rows of grinding hammer heads; four strike posts, each of which being of a tetrahedron structure, are arranged between the two rows of the grinding hammer heads and are annularly and uniformly distributed on a mill shell; and slag discharge holes are formed in the second row of the grinding hammer heads and the lower part of a lining plate for synchronously discharging impurities as well as difficultly ground particles and foreign matters in ores, so that nonmetallic ore ultrafine pulverizing is realized, and the purity and the pulverizing efficiency of ore powder are improved.

Owner:咸阳非金属矿研究设计院有限公司

A non-metallic ore grinding machine

Owner:咸阳非金属矿研究设计院有限公司

Fireproof shell for fire-fighting video transmitter

InactiveCN113422886AAchieve the purpose of eliminatingIncrease contact timeTelevision system detailsColor television detailsCamera lensEngineering

The invention belongs to the technical field of fire fighting, particularly relates to a fireproof shell for a fire-fighting video transmitter, and aims to solve the problem that smoke around a camera lens is not dispersed. The fireproof shell comprises a base, wherein the outer wall of the top of the base is fixedly connected with a fireproof shell body; a smoke suction square pipe is fixedly connected to the outer wall of one side of the fireproof shell body; a smoke suction fan is fixedly arranged between the inner wall of the top and the inner wall of the bottom of the smoke suction square pipe; a water tank is fixedly connected to the inner wall of the top of the fireproof shell body; a water inlet pipe is fixedly arranged on the outer wall of the top of the water tank; a smoke outlet square pipe is fixedly connected to the inner wall of one side of the water tank; and the smoke outlet square pipe is bent. According to the invention, during working, because the smoke outlet square pipe is bent, smoke around the camera lens is absorbed through one end of the smoke outlet square pipe, and then is discharged to the tail part of the device through the smoke outlet square pipe, so that the purpose of removing the smoke around the camera lens is achieved.

Owner:李玉红

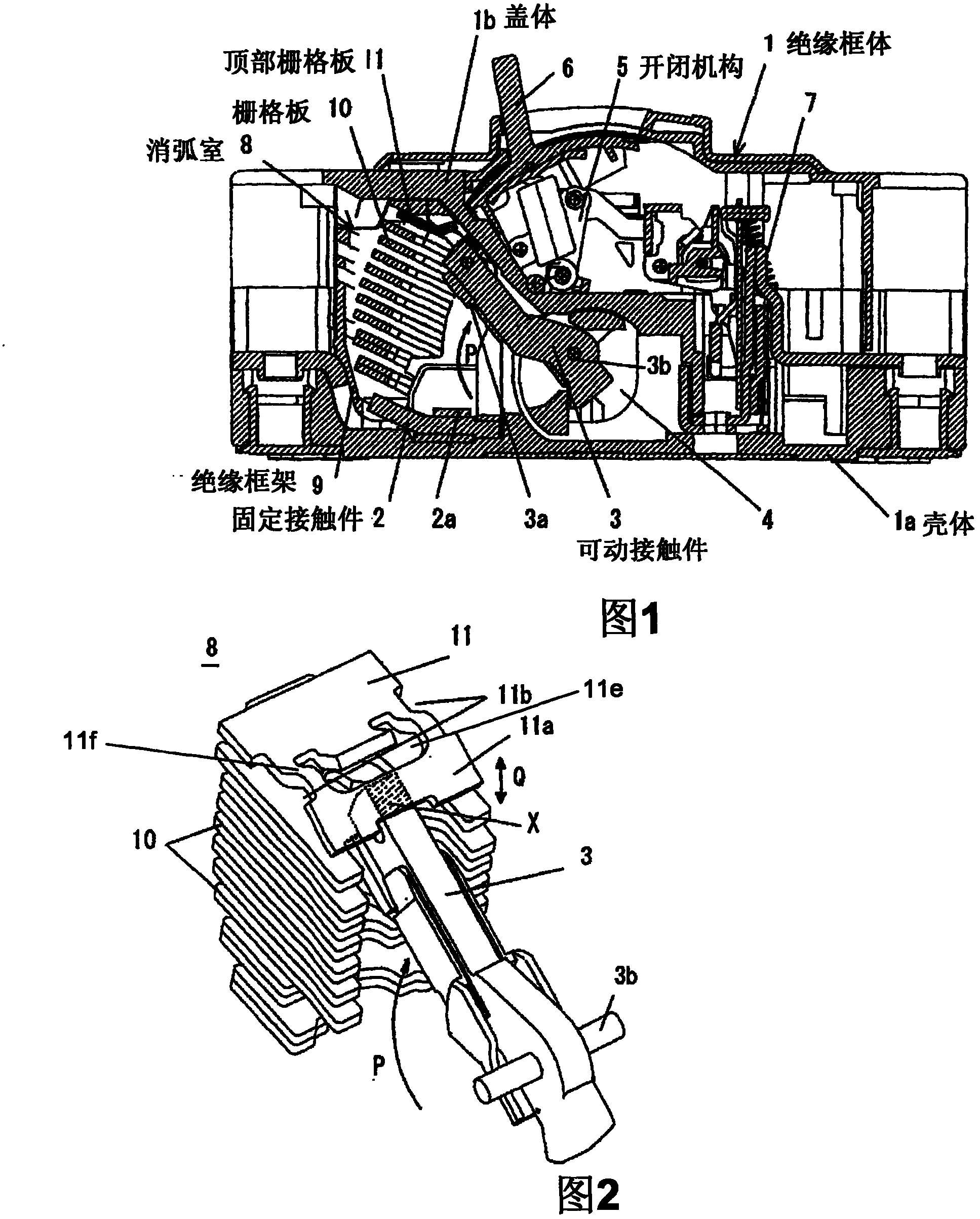

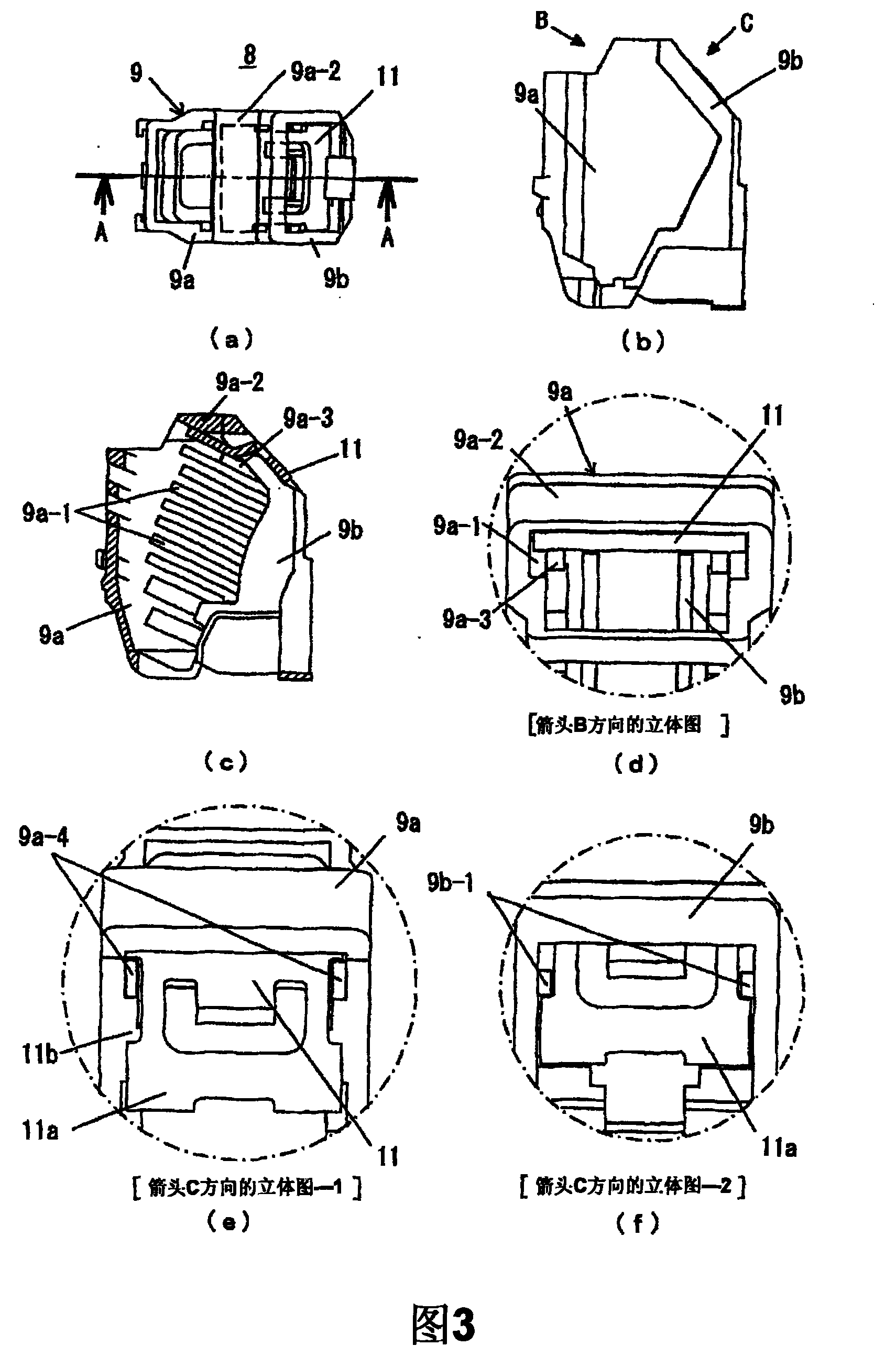

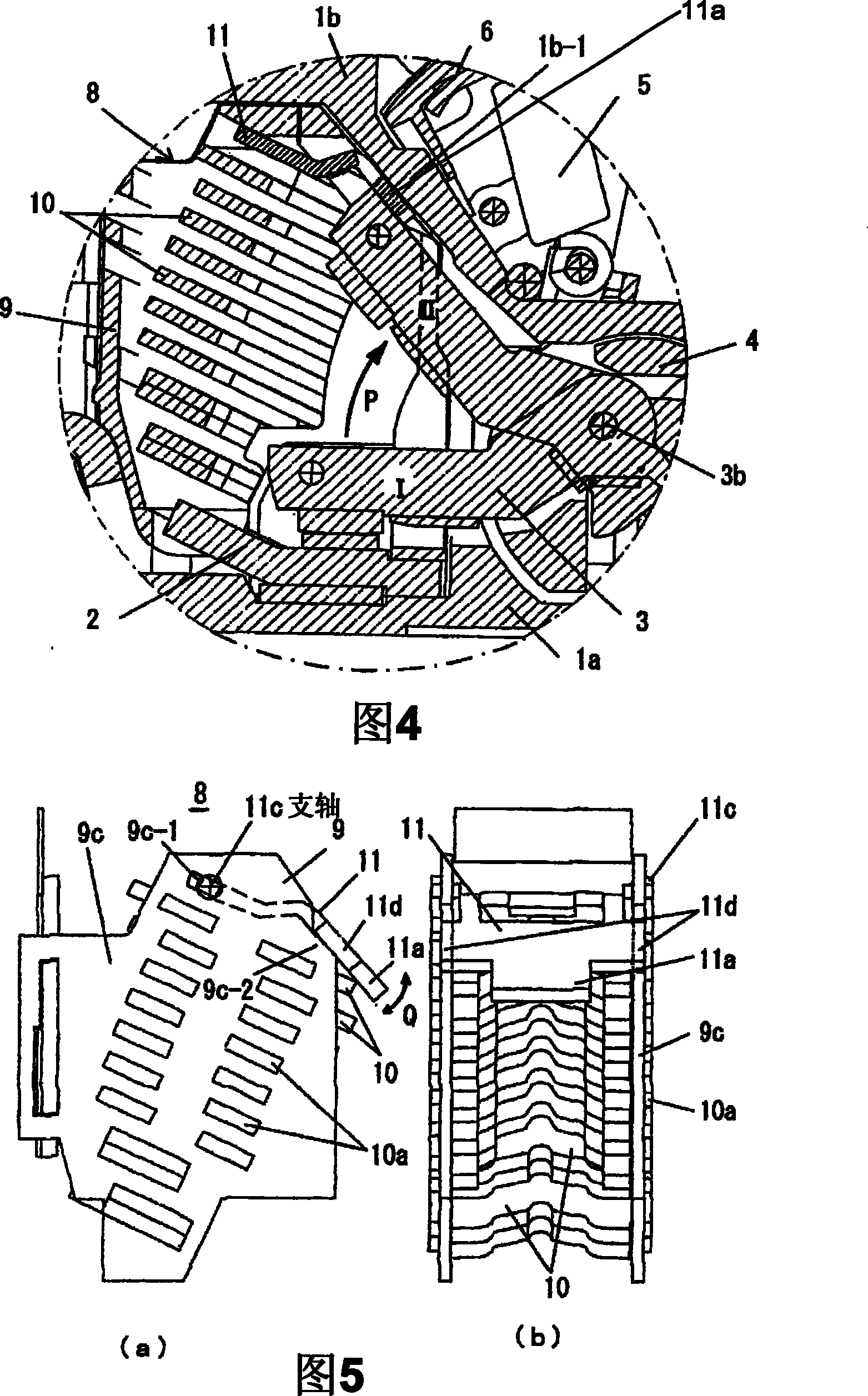

Circuit breaker

InactiveCN1953122BPrevent shock loadsAvoid bouncingProtective switch operating/release mechanismsEngineeringCircuit breaker

Provided is a circuit breaker, wherein a fixing contact piece, a rotation movable contact piece connected with the switch mechanism and an arc extinguish chamber are disposed on the interior of the frame which is consisted of a shell and a cover. The arc extinguish chamber is configured of a box-shaped insulating frame and a multilayer grid plates in the same which is arranged on the switch path of the movable contact piece, the top of the insulating frame is disposed to face and approach the inner surface of the cover, the collision component of the movable contact piece which limits the terminal position of the movable contact piece as a stop component, is arranged on the top grid plate of the arc extinguish chamber for extending, therefore, the top grid plate is movably stopped on the top of the insulating frame. The back of the movable contact piece is configured to contact with the collision component during the cutoff action, therefore dispersing the impact load on the top grid plate and the cover of the circuit breaker which stops the jumping displacement of the top grid plate, and stops the action of the movable contact piece on the cutoff-terminal position.

Owner:FUJI ELECTRIC ASSETS MANAGEMENT

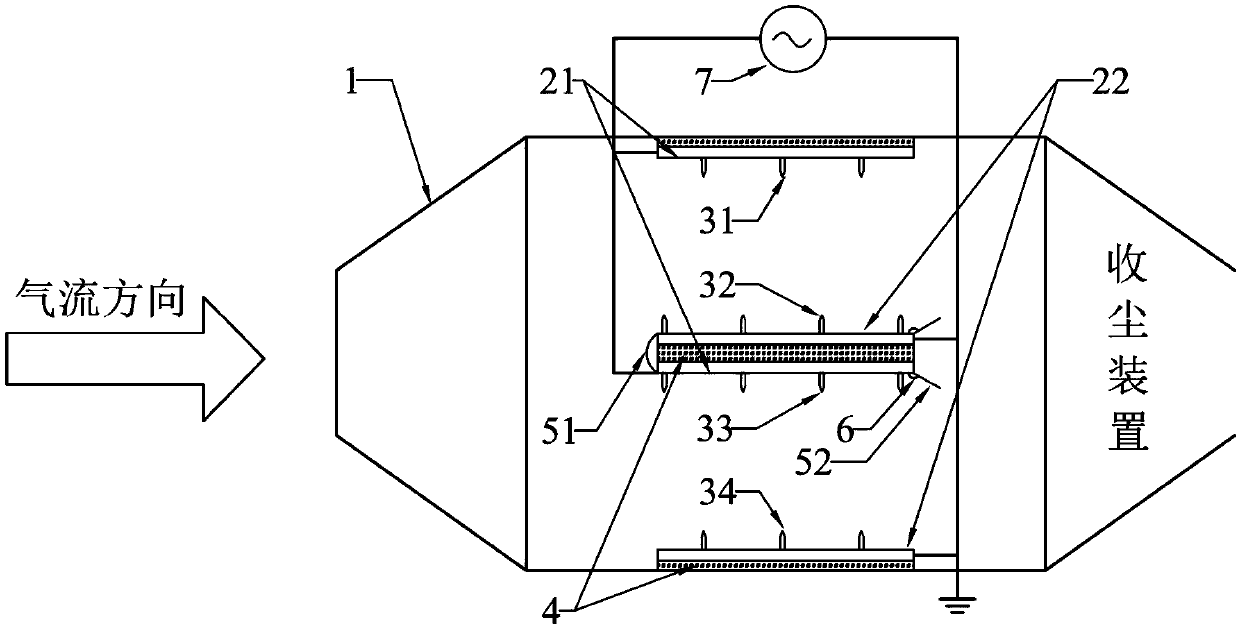

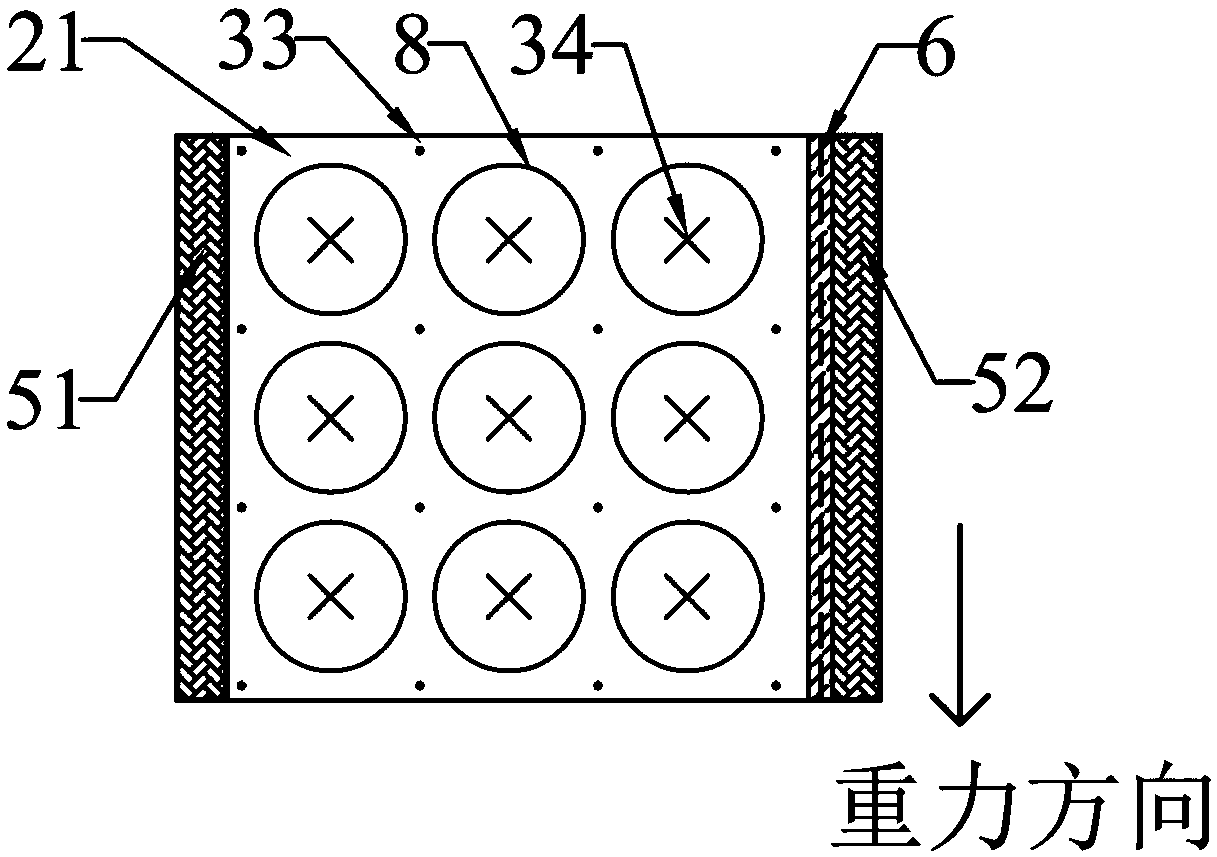

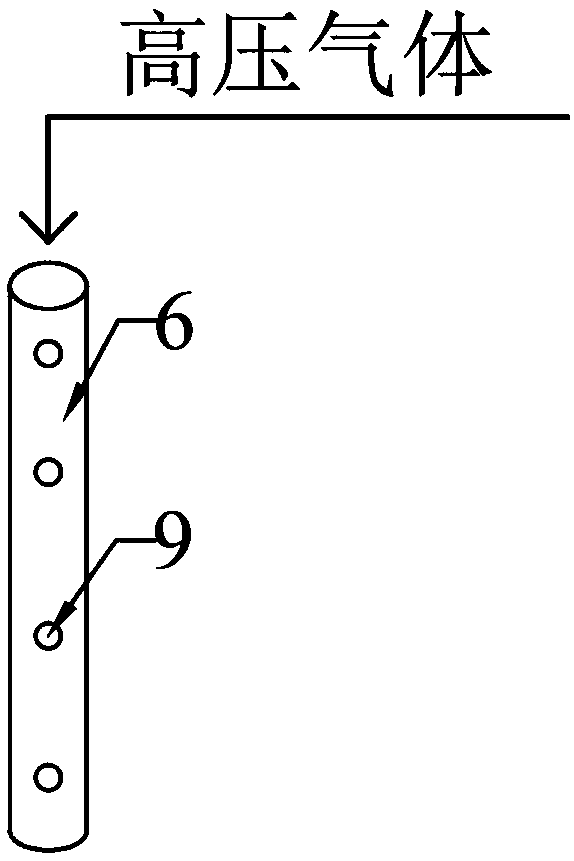

Alternating electric field fine dust electrocoagulation explosion suppression device and method

InactiveCN109569884AFacilitate dust collection efficiencySuppression or reduction of explosion intensityElectrostatic separationElectrocoagulationDouble phase

The invention discloses an alternating electric field fine dust electrocoagulation explosion suppression device and method. The device mainly comprises a shell, high-voltage plates, grounding plates,prickles on the high-voltage plates and the grounding plates, insulating plates, middle plates and a high-voltage AC power supply. The high-voltage plates are connected to the high-voltage AC power supply, the grounding plates are connected to the ground, the high-voltage plates and the grounding plates are alternately distributed with intervals, the plates are equipped with the prickles, the middle plates comprise the high-voltage plates, the grounding plates, the insulating plates between the high-voltage plates and the grounding plates, guiding plates before and behind the middle plates, and a high-pressure ventilation pipe at the ends of the middle plates, and the middle plates are provided with round through holes distributed in a rectangular array. According to the invention, throughfine dust in an electrocoagulation gas-solid double-phase air flow, the particle size of dust can be effectively increased, the explosion is suppressed or the explosion intensity is reduced, the structure is simple, the flow resistance is small, and the improvement of the dust removal and collection efficiency of a subsequent dust collecting device is facilitated at the same time.

Owner:CHANGZHOU UNIV

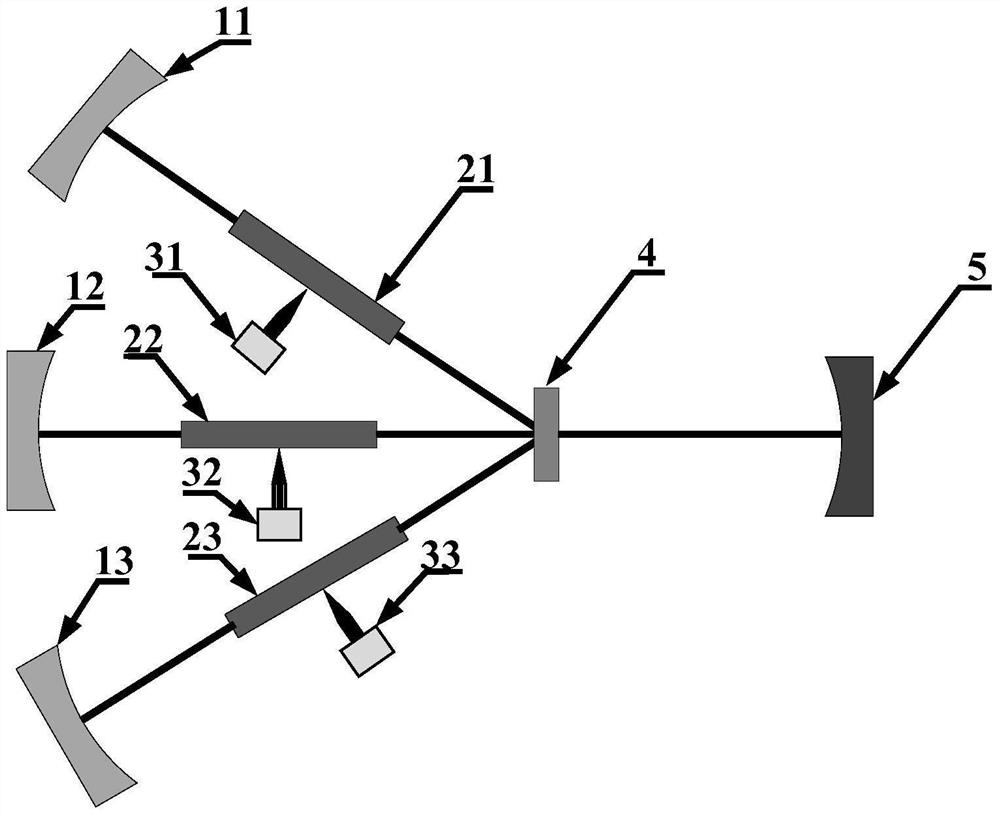

A laser coherent beam combining coupling resonator with polarization diffraction grating

ActiveCN106025776BAvoid thermal effectsResolve nonlinear effectsLaser detailsOphthalmologyBeam splitting

The invention discloses a laser coherent beam combining coupling resonator of a polarization diffraction grating, which includes a semiconductor laser, a gain unit, a polarization diffraction grating, a reflection mirror, and an output mirror. The coupling resonator includes a gain unit, a polarization diffraction grating, a reflection mirror and The output mirrors are distributed at both ends of the coherent beam combining system; the semiconductor laser is the pump light, and its central wavelength matches the absorption line of the gain unit in the resonator; the polarization diffraction grating is a beam splitting / combining device, and its theoretical beam splitting / The beam combining efficiency reaches 99%. The invention can overcome the thermal effect and nonlinear effect caused by the increase of the output power of the traditional laser system, and the high efficiency of the grating device can reduce the cost and volume of the coherent beam combining system, and can realize high power and high beam combining efficiency at the same time Laser output.

Owner:HUAZHONG UNIV OF SCI & TECH

A method for purifying and treating wastewater from coal chemical industry

ActiveCN108996753BImprove purification efficiencyIncrease the collision areaTreatment involving filtrationMultistage water/sewage treatmentWater treatment systemProcess engineering

The invention belongs to the technical field of environmental protection, and specifically relates to a method for purifying and treating coal chemical wastewater. The method adopts a wastewater treatment system, and the wastewater treatment system includes a treatment box and a medicine box; it also includes No. 1 stirring unit, No. 2 stirring unit and Drug nozzle; the No. 1 stirring unit is used for dissolving the flocculant into the wastewater at low speed; the No. 2 stirring unit is used for dissolving the flocculant into the wastewater at high speed; the drug nozzle is used for spraying the flocculant into the treatment tank . In the low-speed stirring, the No. 1 stirring unit and the No. 2 stirring unit are complementary to stir, on the one hand, the collision area between the flocculant and the impurities in the wastewater is increased, thereby accelerating the dissolution efficiency of the flocculant and the wastewater, thereby improving the purification of the wastewater Efficiency; on the other hand, the flocculant is sprayed into the treatment tank reasonably according to the needs, so that the flocculant and the wastewater are dissolved, avoiding the waste of the flocculant, thereby improving the utilization rate of resources.

Owner:中汇金源(北京)科技发展有限公司

Intelligent timekeeping perpetual calendar

PendingCN111402704AGood dispersionIncrease the area of air outlet and heat dissipationPerpetual calendersGear wheelElectric machinery

Owner:ZENTIME FUJIAN ELECTRONICS

Flue gas treatment device for environmental protection engineering

InactiveCN113648765AReduce consumptionImprove dust removal efficiencyCombination devicesGas treatmentEngineeringFlue gas

The invention discloses a flue gas treatment device for environmental protection engineering. The flue gas treatment device comprises a shell, and further comprises a dust removal mechanism and a desulfurization mechanism. The dust removal mechanism is specifically composed of a cross rod, a positive electrode plate, a negative electrode plate, a rotating rod, sliding blocks, a motor, an eccentric block, a boosting transformer and a rectifier. The cross rod is welded to the inner wall of the shel. One side of the surface of the cross rod is rotatably connected with the positive electrode plate in a matched mode, and one side of the surface of the cross rod is rotatably connected with the negative electrode plate in a matched mode. The surfaces of the positive electrode plate and the negative electrode plate are fixedly connected with the sliding blocks which are made of an insulating material. The inner wall of the shell is rotatably connected with the rotating rod in a matched mode, and the eccentric block is welded to the surface of the rotating rod. The motor is installed on the inner wall of the shell. The boosting transformer is installed on one side of the inner wall of the shell, and the rectifier is installed on one side of the inner wall of the shell. The whole device can achieve automatic filtering, the filtering cost is low, the overall filtering efficiency is high, and the device can be suitable for filtering flue gas of factories in the manufacturing industry on a large scale.

Owner:滁州市鑫鑫建筑安装有限公司

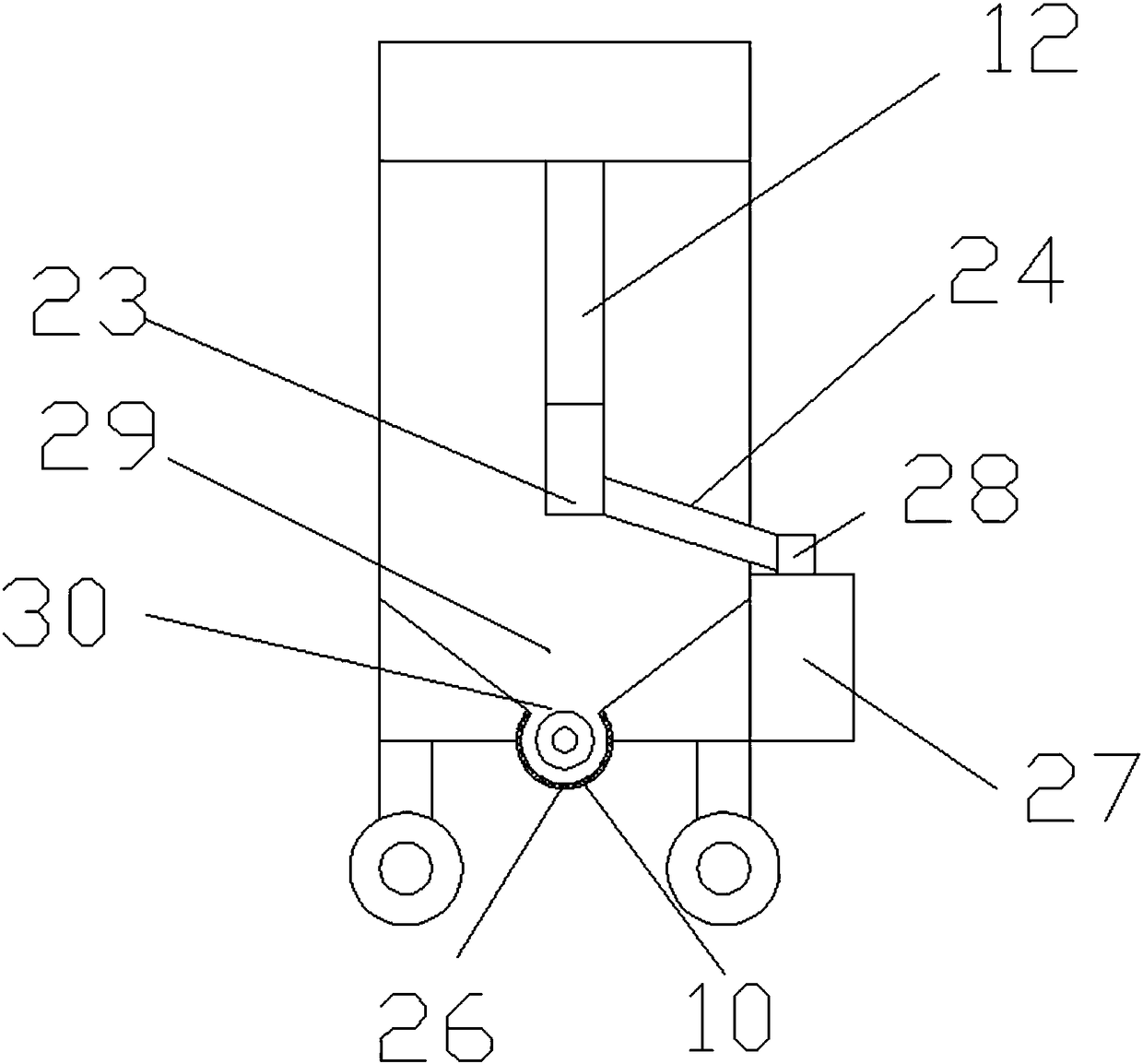

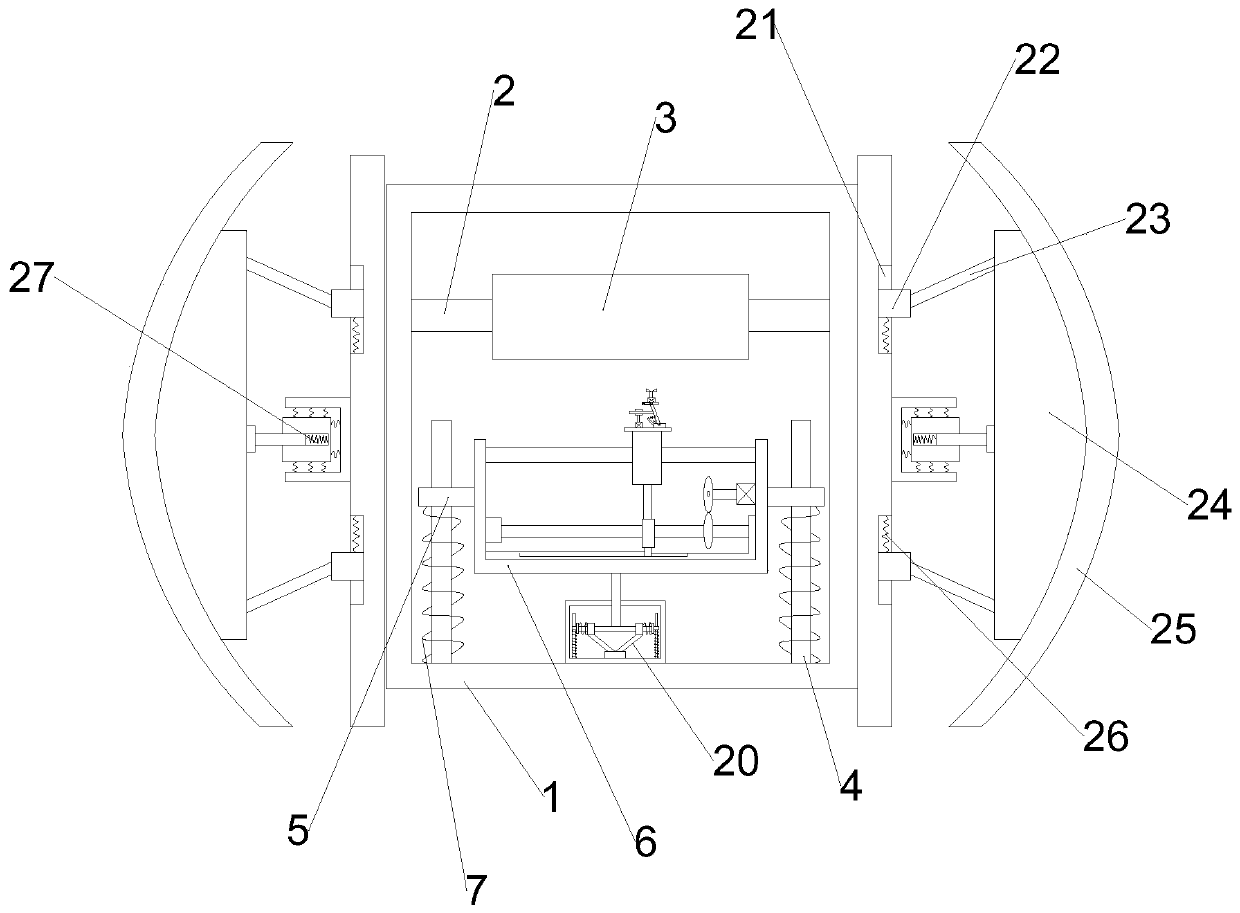

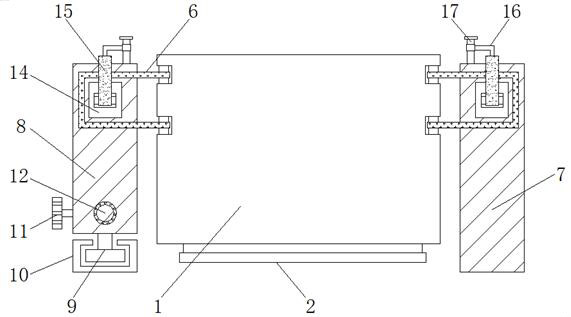

A vehicle crash test device and test method based on 5G Internet of Vehicles

ActiveCN110864907BIncrease the collision areaEasy to achieve multi-angle collisionVehicle testingShock testingStructural engineeringCollision test

The invention discloses a vehicle collision test device and a test method based on 5G Internet of Vehicles, including a barrier and a pressure sensor. The lower surface of the barrier is provided with a fixed block, and a connection groove is opened inside the top of the barrier. Fastening bolts are installed at the rear of the barrier, and a pressure sensor is arranged on the inner side of the fastening bolts, a connecting block is arranged on the outer side of the barrier, and a first fixing plate is fixed on the right side of the barrier, and the barrier A second fixed plate is installed on the left side of the second fixed plate, and a guide block is arranged under the second fixed plate, a locking block is connected to the left side of the second fixed plate, and a threaded rod runs through the inside of the second fixed plate, so An installation block is fixed in front of the second fixing plate, and a limit rod is arranged at the end of the compact block. The vehicle collision test device based on the 5G Internet of Vehicles is convenient to increase the collision area according to the volume of the vehicle, to realize multi-angle collision, and to reduce the shaking degree of the device during the collision.

Owner:吉林大学盐城智能终端产业研究中心

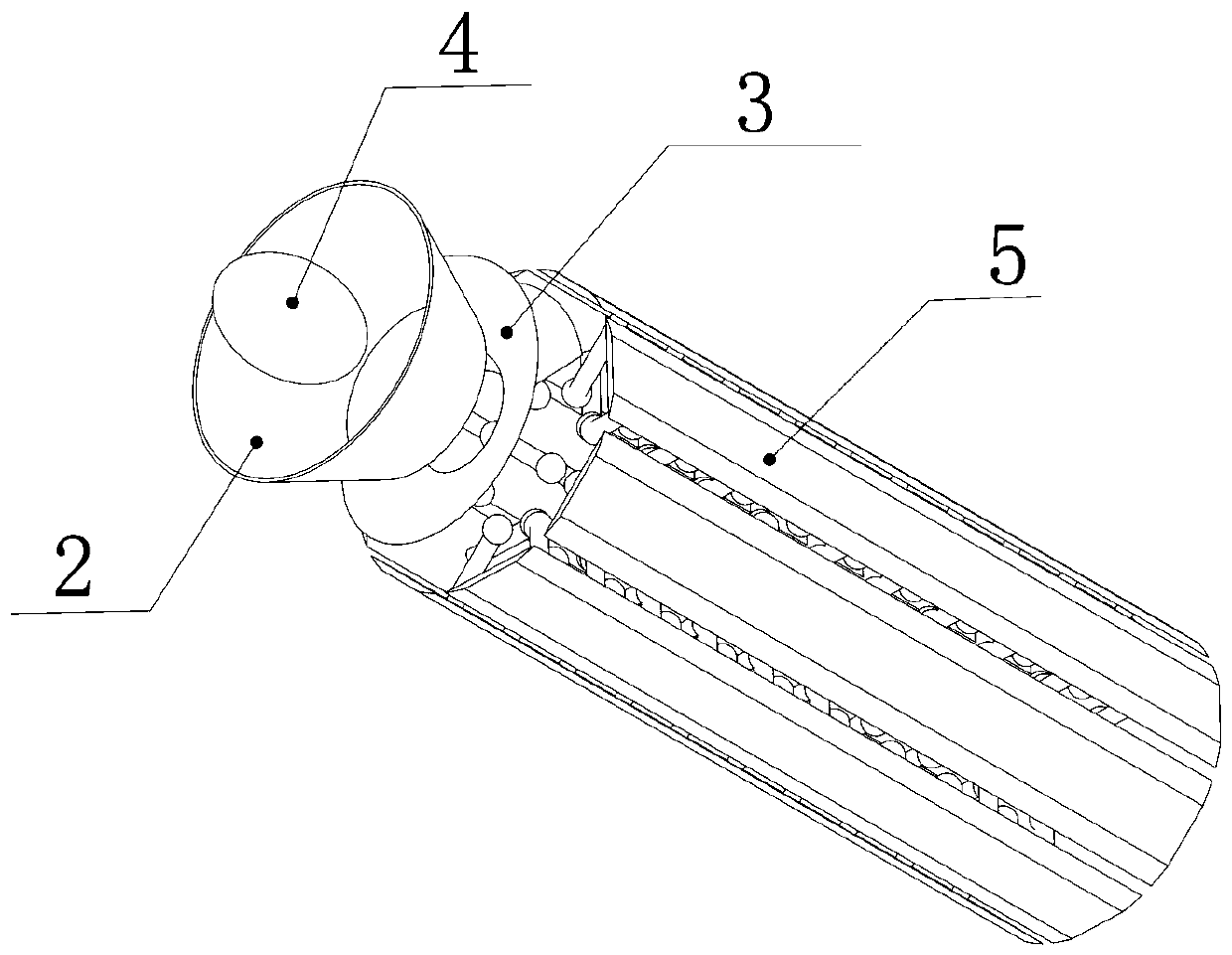

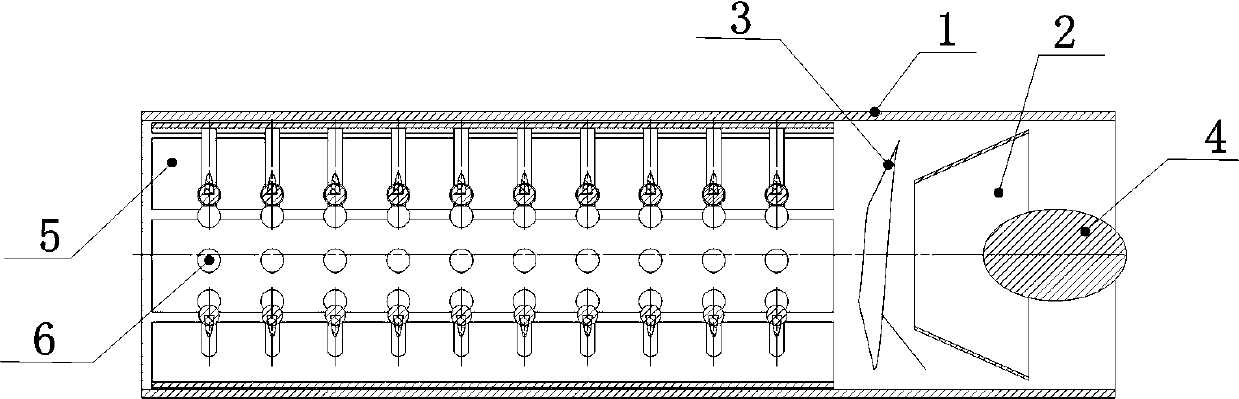

Water flow mixing heater and water flow mixing heating method thereof

The invention discloses a water flow mixing heater, which comprises a box body, a water-scattering part and a fixing plate, the water-scattering part is fixed inside the front end of the box body, eight fixing plates are evenly distributed on the inner surface of the box body and close to the The water distribution part is provided with several columns on the fixed plate; the water distribution part includes a diverter block, a conical bucket and a spiral water distribution pan, the diverter block is located in front of the conical bucket and the rear part is located in the conical bucket, and the conical bucket The rear is a spiral diffuser. The diameter of the largest outer circle of the tapered bucket is the same as the diameter of the inner circle of the box; the spiral water pan is in contact with the inner surface of the box; the top of the column is provided with a ball head, and the diameter of the ball head is larger than the diameter of the column; the invention is installed in heating , heat is generated by the collision of water against the column, which realizes the feature of energy saving of the present invention. At the same time, the present invention is simple in structure, reasonable in design, and very convenient to operate in the process of maintenance.

Owner:冉碧玉

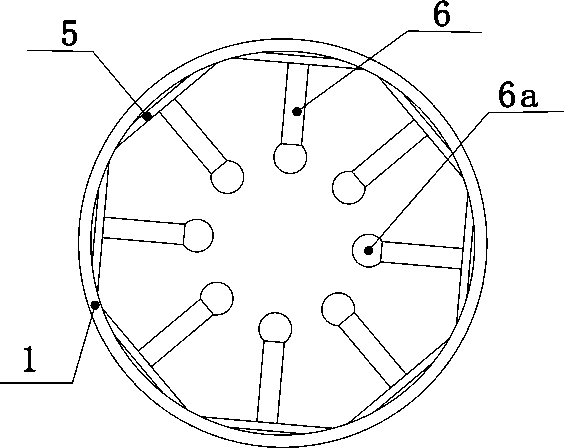

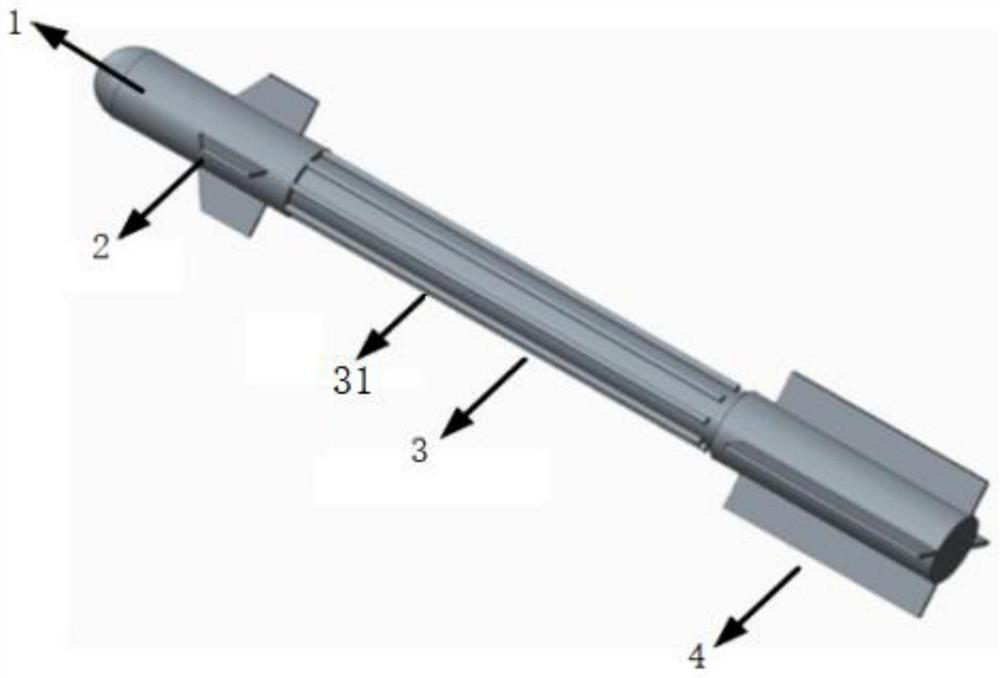

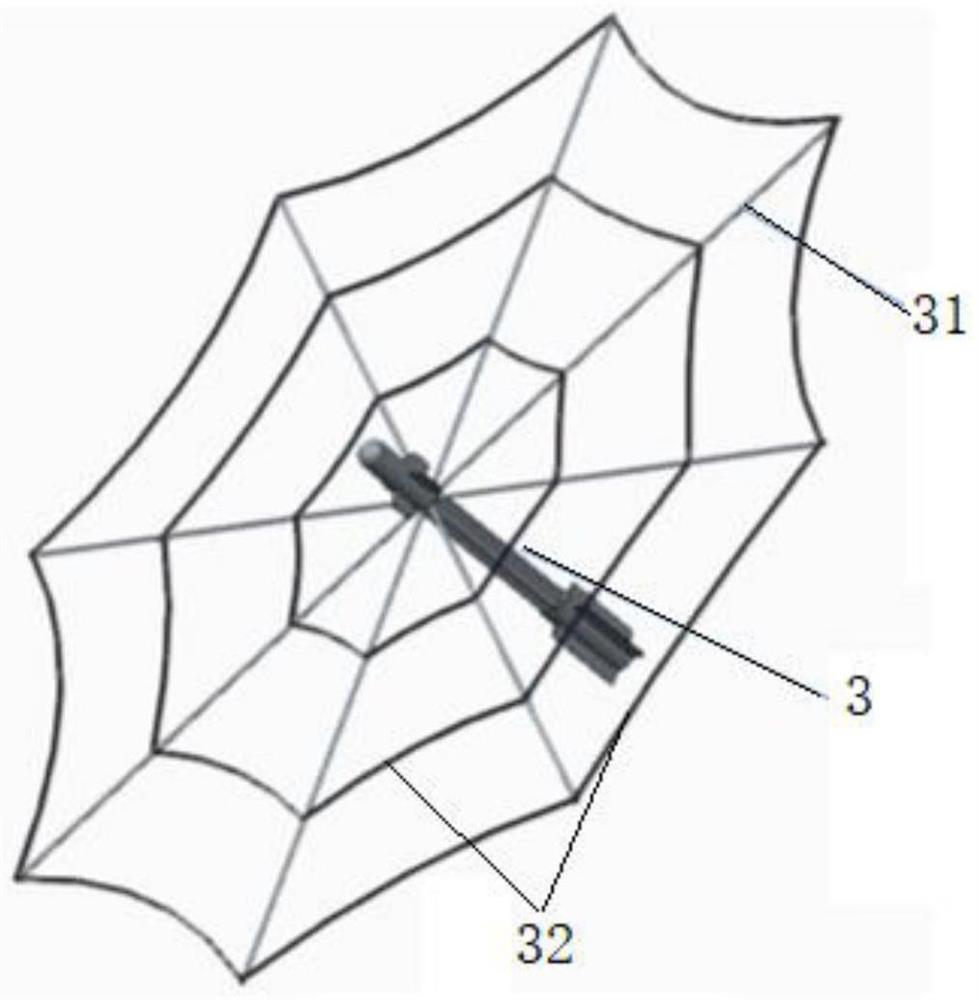

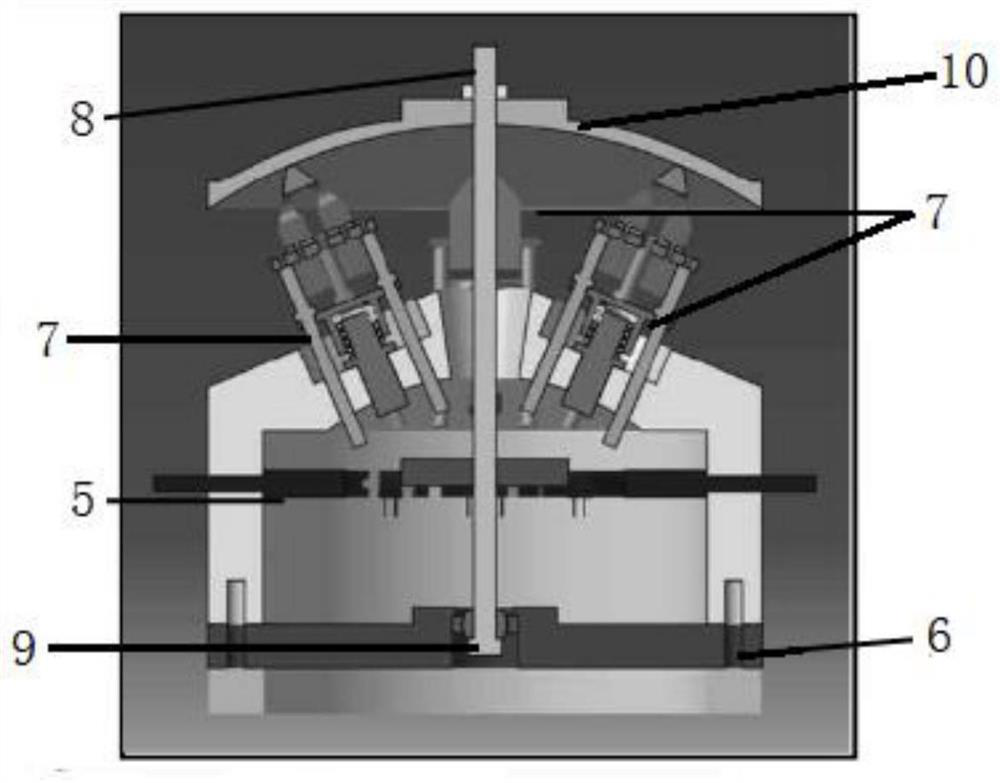

Kinetic energy interceptor based on head deflection

PendingCN114279268AIncrease the output speedQuick responseDefence devicesElectrical batteryData information

The invention relates to a kinetic energy interceptor based on head deflection. In order to overcome the defects that an existing kinetic energy interceptor is poor in hit precision and large in hit deviation for a low-altitude target, the kinetic energy interceptor providing lateral overload by means of head deflection is designed and sequentially comprises a guide cabin, an instrument cabin, a kinetic energy combat cabin and a tail section which are connected in series from front to back, and an integrated comprehensive control machine and a battery are installed in a head cone cabin. Each electrical single machine arranged in the cabin section is connected with a battery through a power supply cable, and data information is transmitted through a control cable; a head deflection mechanism is installed at the rear end of the guide cabin, the integrated comprehensive control machine rudder control module sends a deflection instruction, and the head deflection mechanism deflects in the pitching direction and the yawing direction according to the instruction and provides lateral pneumatic capacity; the kinetic-energy combat cabin is connected with the instrument cabin through a center main shaft, an electric thrust rod is installed in the center main shaft, a kinetic-energy intercepting folding rod is installed outside the center main shaft, a three-section folding mode is adopted, and the folding rod is placed on the surface of the projectile body after being folded.

Owner:AEROSPACE SCI & IND MICROELECTRONICS SYST INST CO LTD

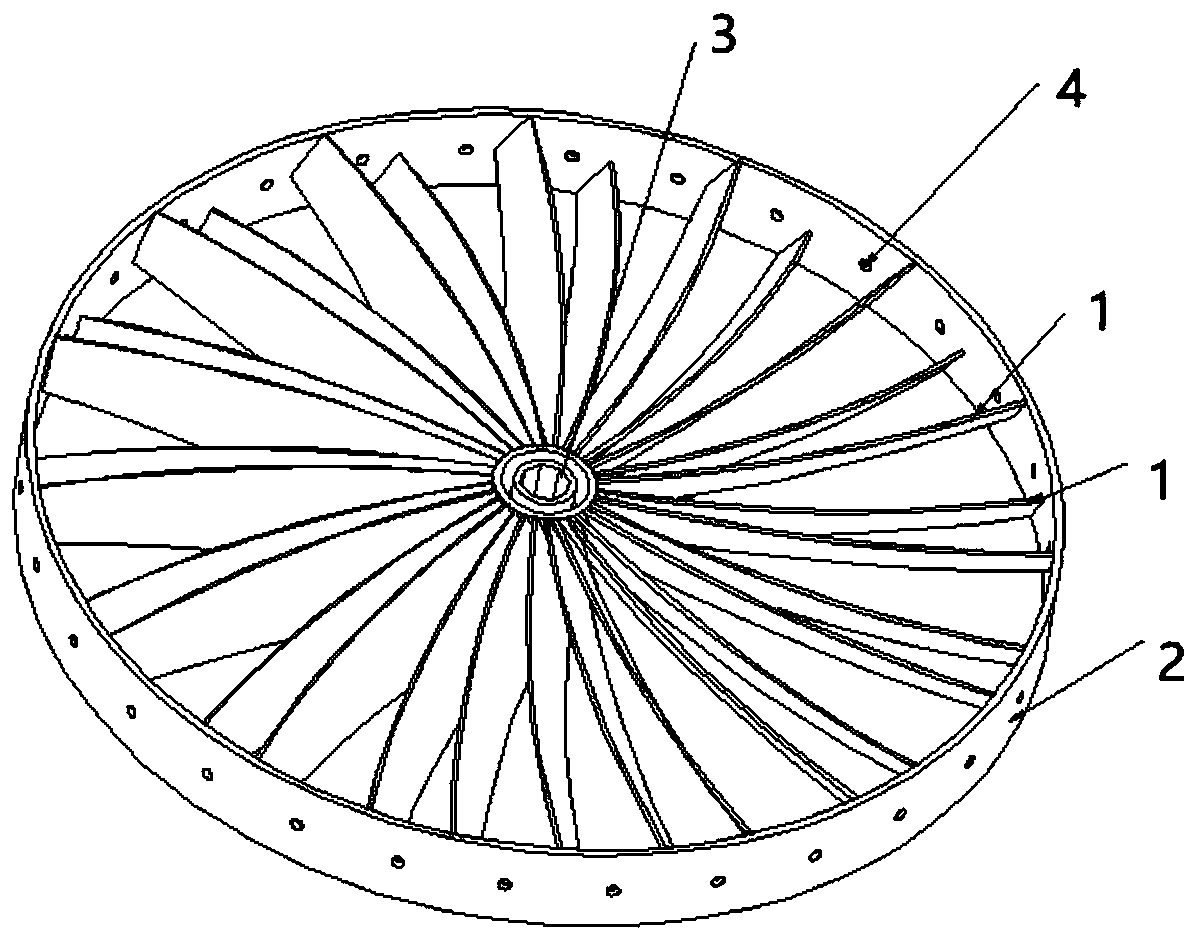

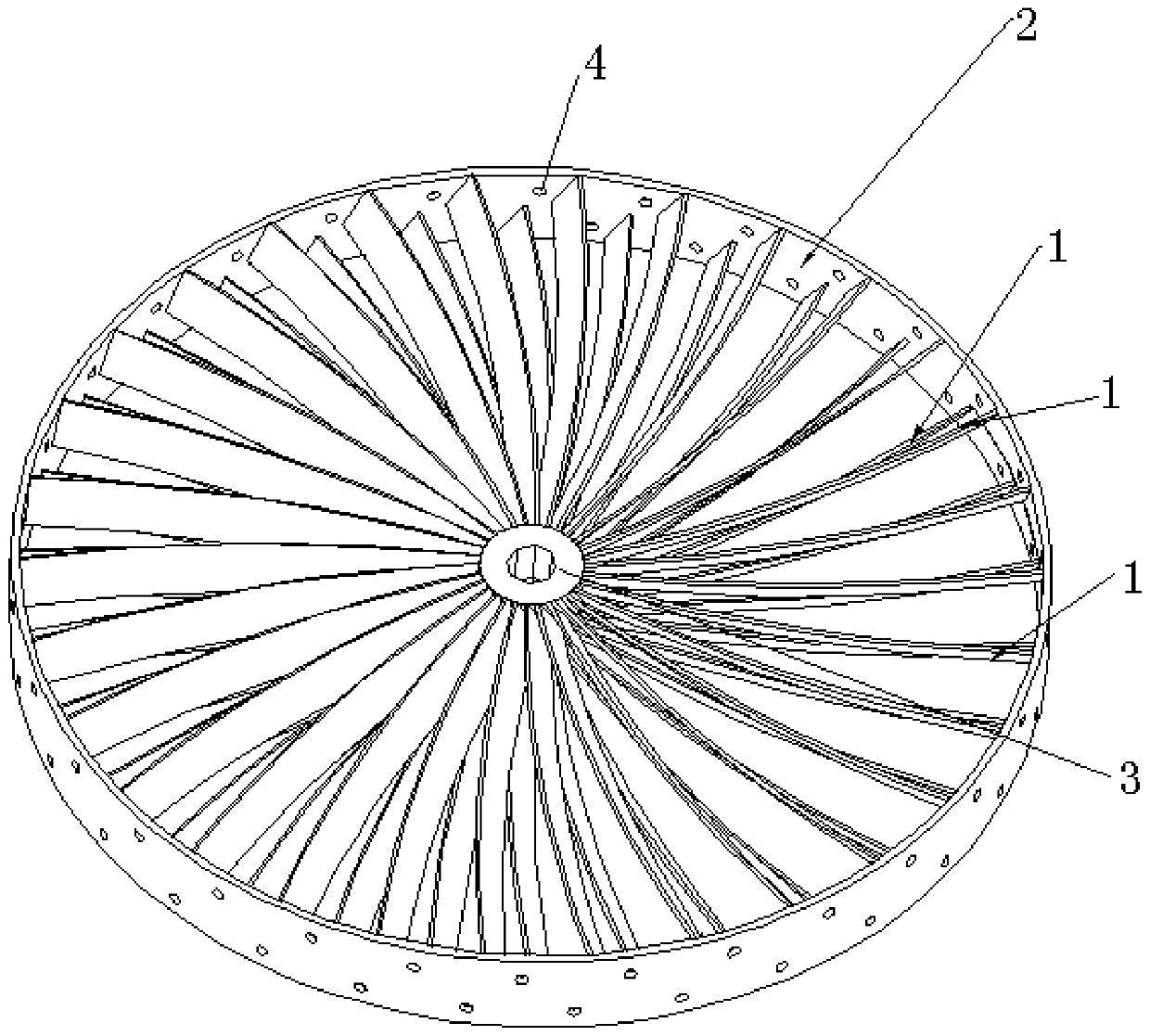

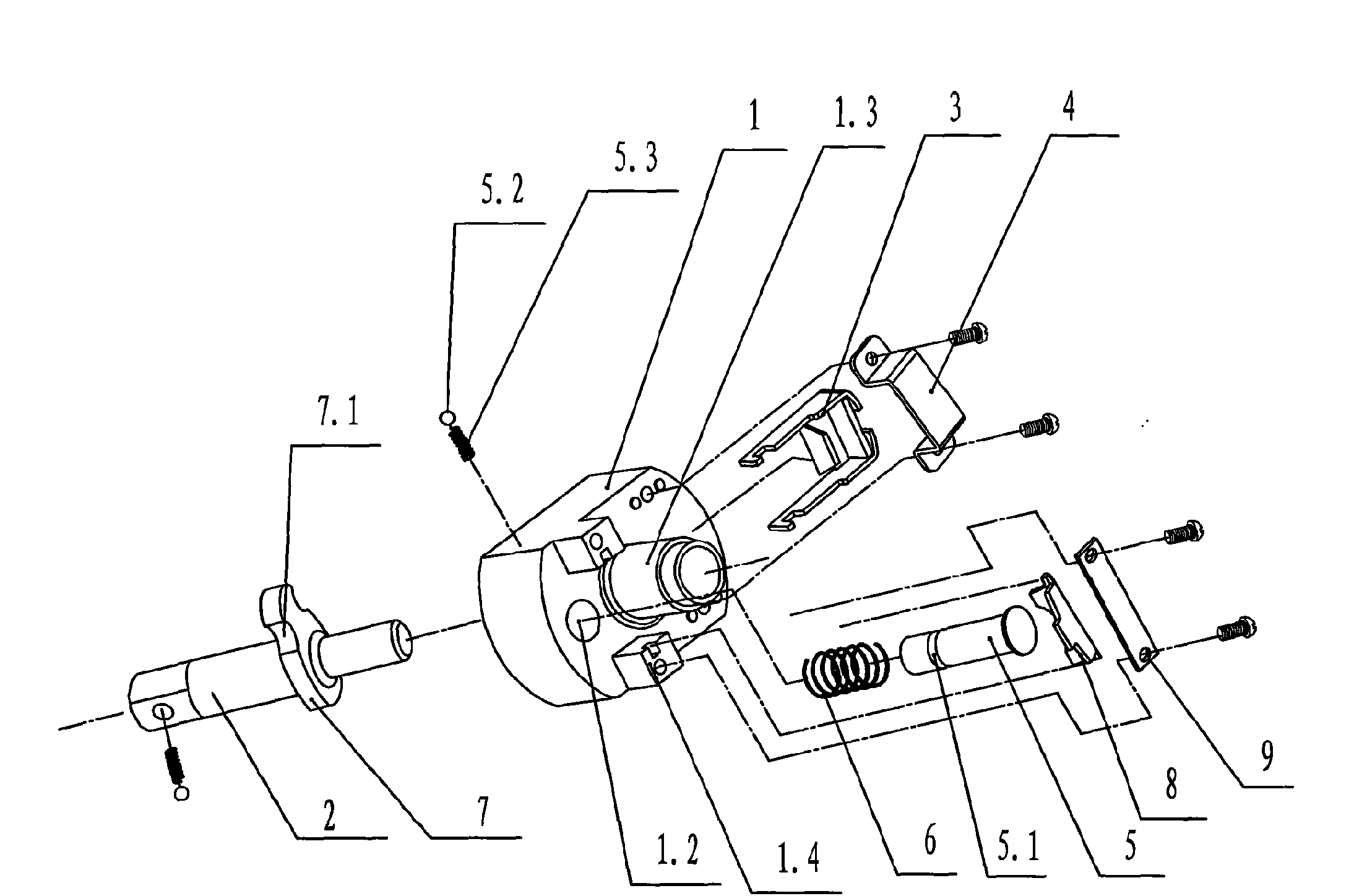

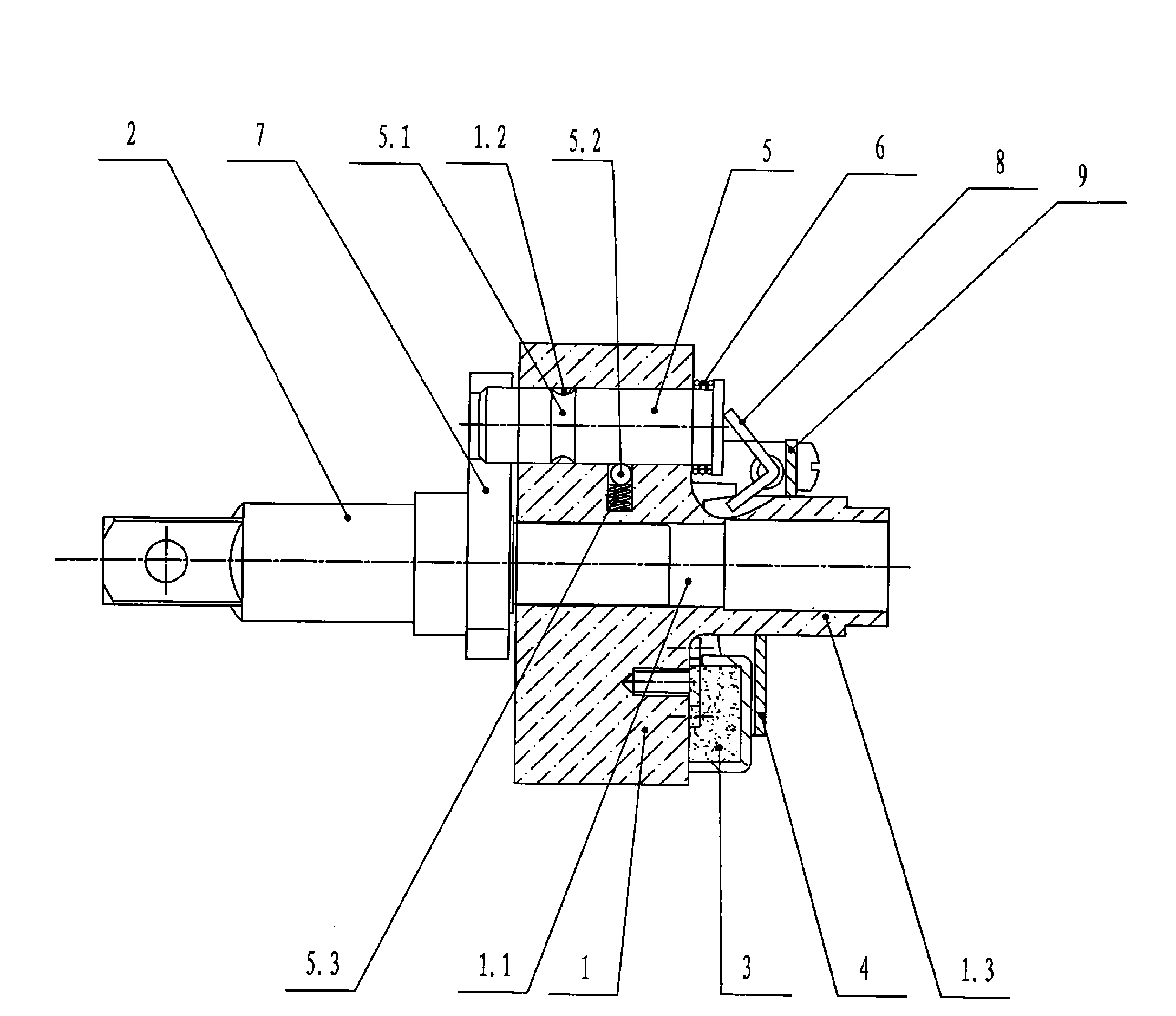

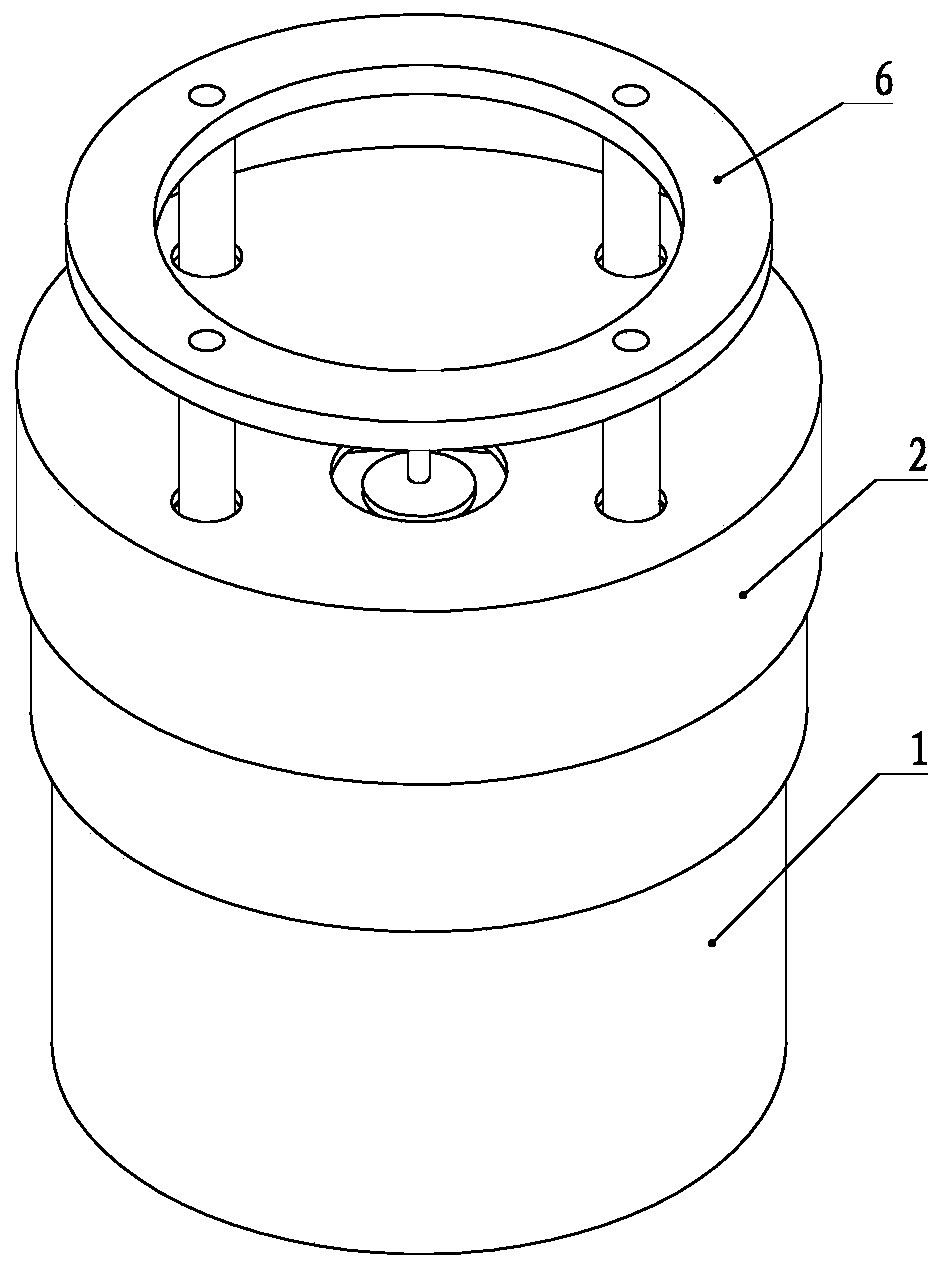

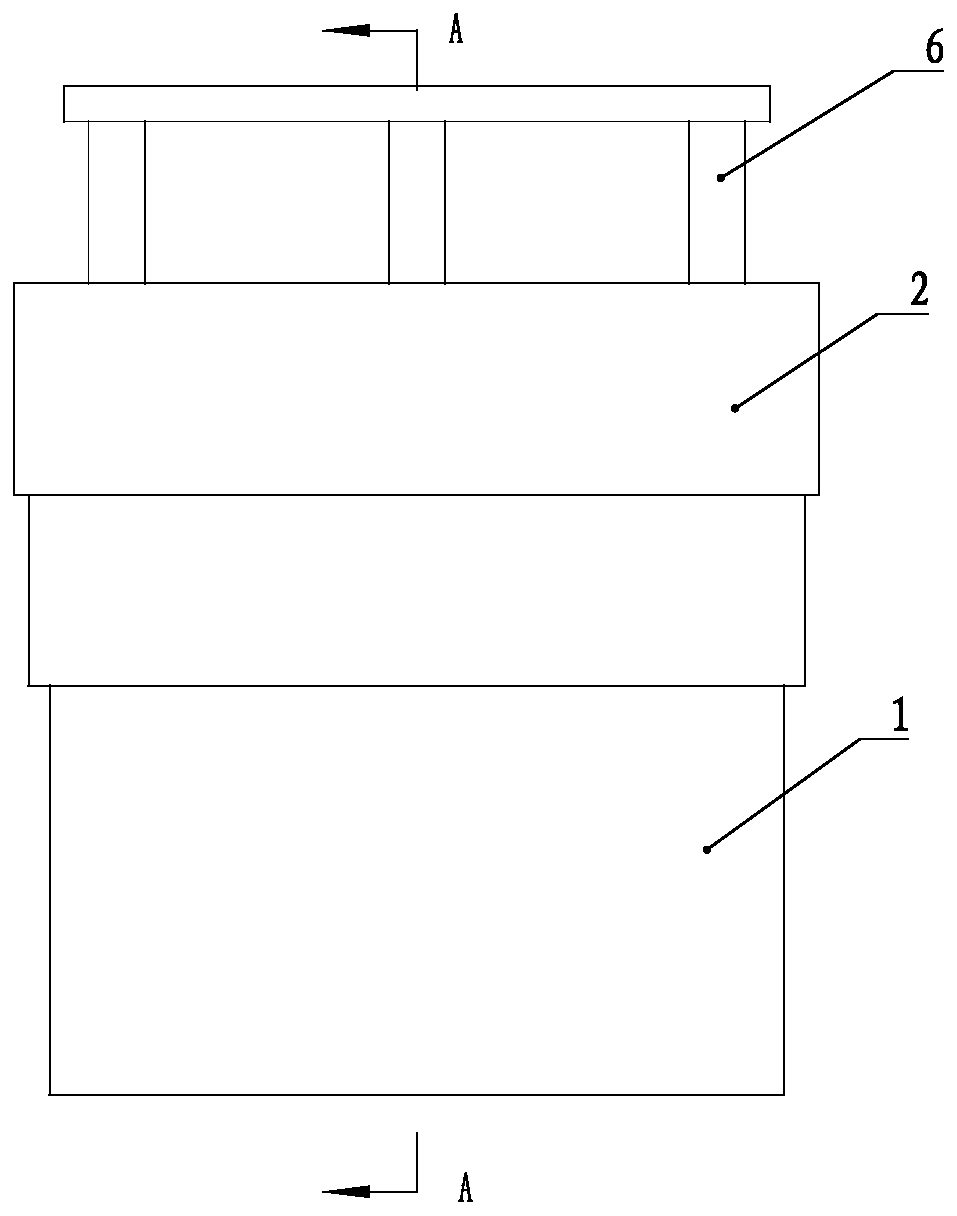

Centrifugal clutching transmission mechanism

The invention discloses a centrifugal clutching transmission mechanism which comprises a ratchet wheel (1) and an output eccentric shaft (2) which is arranged at the rear end of the ratchet wheel (1)and rotationally matched with a central hole (1.1) of the ratchet wheel (1), wherein the front end face of the ratchet wheel (1) is provided with a shaft sleeve (1.3) which is fixed into a whole withthe ratchet wheel (1) and coaxial with the central hole (1.1) of the ratchet wheel (1); the front end face of the ratchet wheel (1) is also provided with longitudinally distributed pulling plate components and transversely distributed pressing plate components and a guide post (5) which is matched in an eccentric hole (1.2) of a flywheel (1) in a sliding way, wherein the longitudinally distributedpulling plate components and the transversely distributed pressing plate components perform centrifugal motions; a return spring (6) is sleeved on the guide post (5); the output eccentric shaft (2) is provided with a connection block (7) which is fixed into a whole with the output eccentric shaft (2) and provided with symmetrical grooves (7.1); the pulling plate components and the pressing platecomponents are mutually buckled; the pressing plate components are abutted against the end face of the head part of the guide post (5); and the outer cylindrical surface of the tail part of the guidepost (5) is abutted against one corresponding groove (7.1) according to the steering of a motor. The invention has stable performance, less energy consumption, high working efficiency, long service life and difficult damage.

Owner:钱贤峰

A cement cellar flue gas denitrification device and its application method

ActiveCN113908678BGuaranteed denitrification efficiencyReduce denitrification operating costsDispersed particle separationDust controlCement kiln

Owner:山东东源新材料科技有限公司

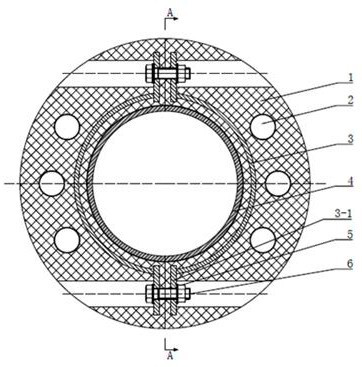

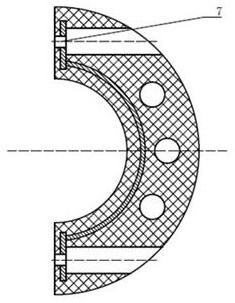

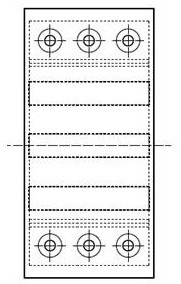

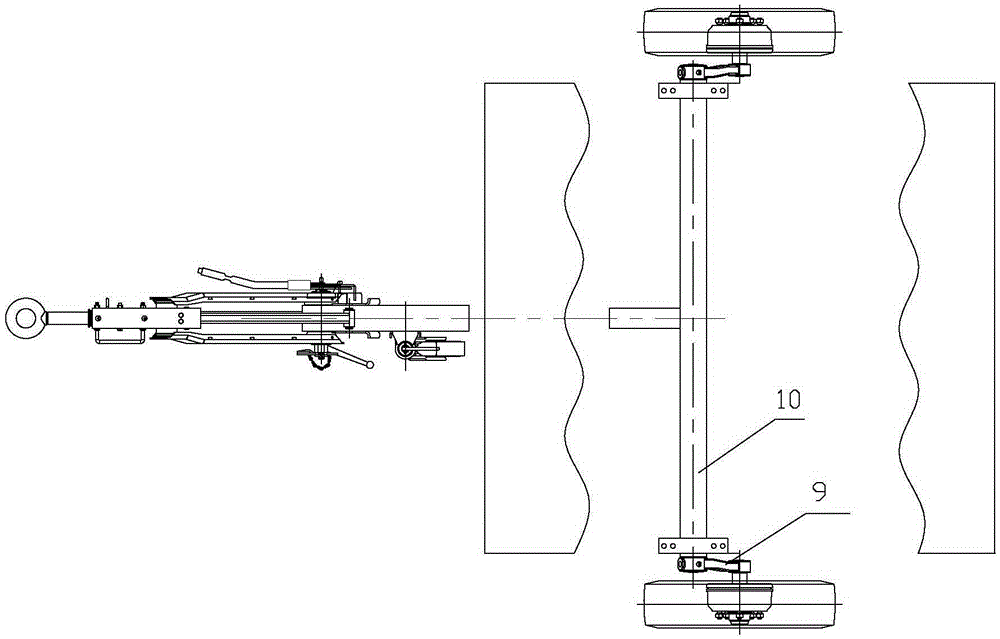

Combined anti-collision device for external wellhead riser of offshore fixed oil production platform

PendingCN112681989AImprove buffering effectEnsure the height of protectionDrilling rodsDrilling casingsOil productionMechanical engineering

The invention discloses a combined anti-collision device for an external wellhead riser of an offshore fixed oil production platform. The device comprises a left semi-circular rubber block and a right semi-circular rubber block, wherein the inner wall of the left semi-circular rubber block is the left arc-shaped surface; the inner wall of the right semicircular rubber block is the right arc-shaped surface; the left semi-circular rubber block and the right semi-circular rubber block are buckled together; and the outer wall of the riser is tightly wrapped by the left arc-shaped surface and the right arc-shaped surface. According to the invention, direct damage of accidental collision of a ship to the riser of an oil-water well of the offshore fixed oil production platform can be reduced; and the device has the characteristics of being easy to install, convenient to replace and maintain, low in cost, long in service life and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

A nebulizer that can meet any use angle

InactiveCN106730185BEasy to useReduce usage requirementsMedical devicesMedical atomisersConical tubeEngineering

Owner:QIANFOSHAN HOSPITAL OF SHANDONG

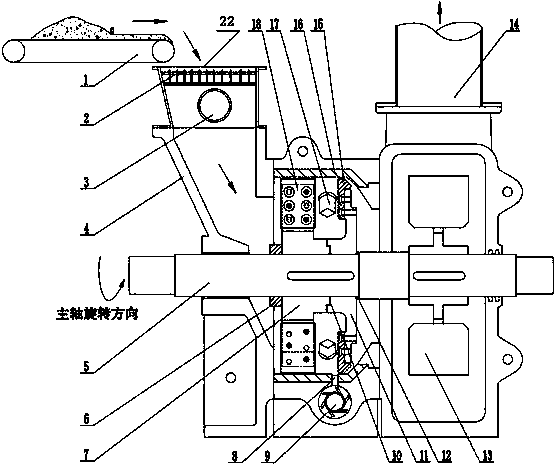

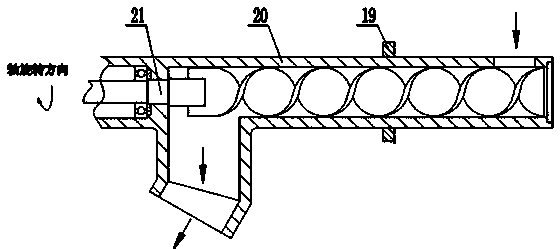

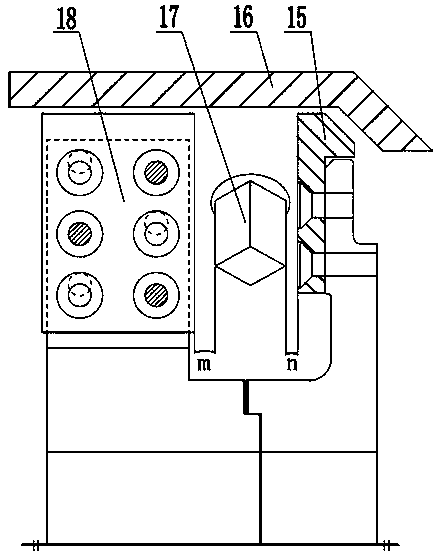

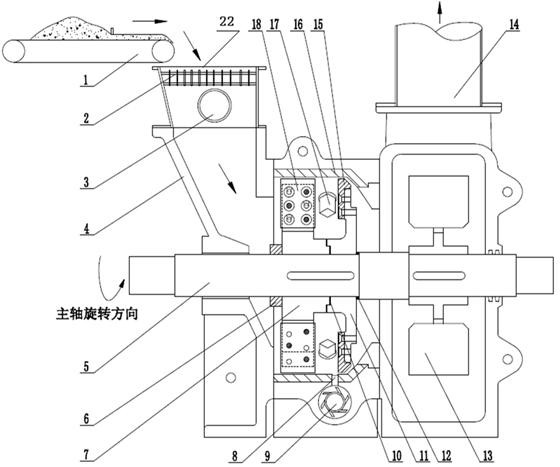

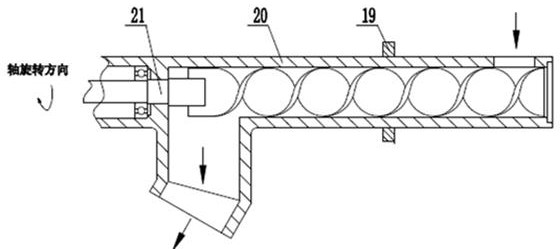

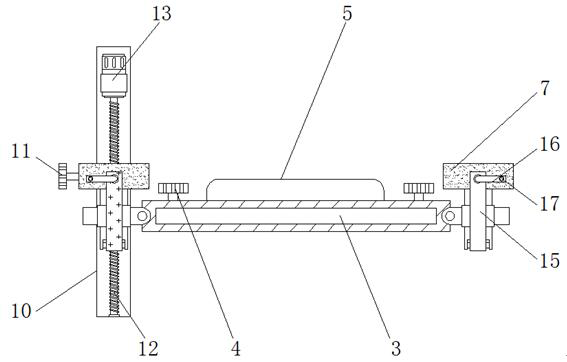

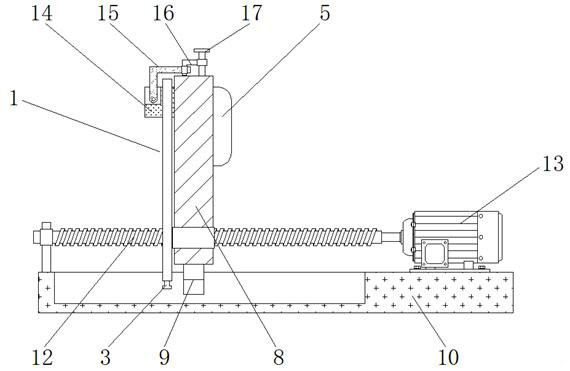

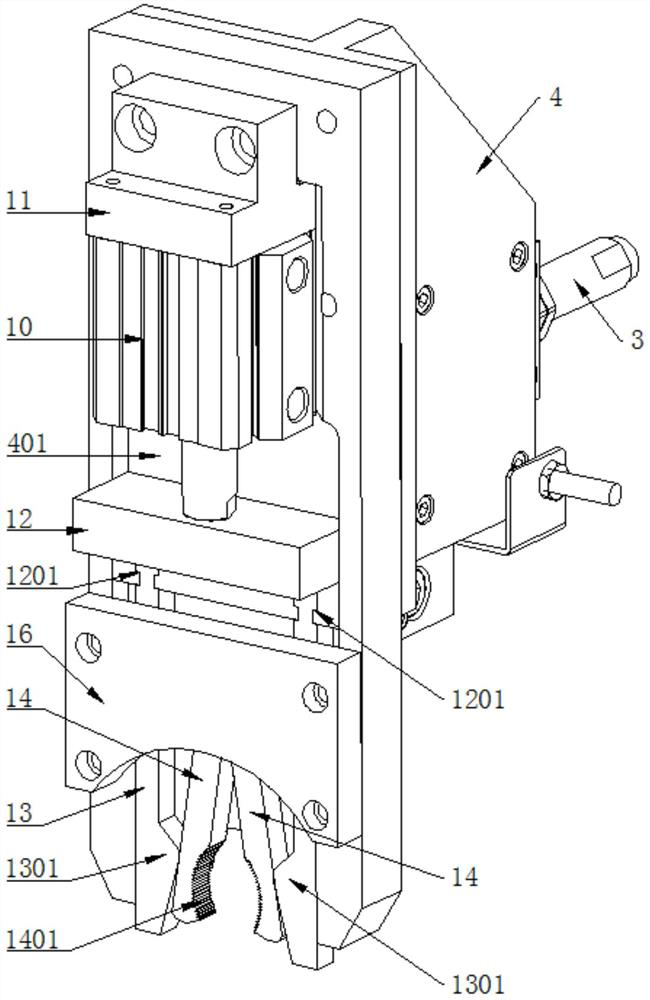

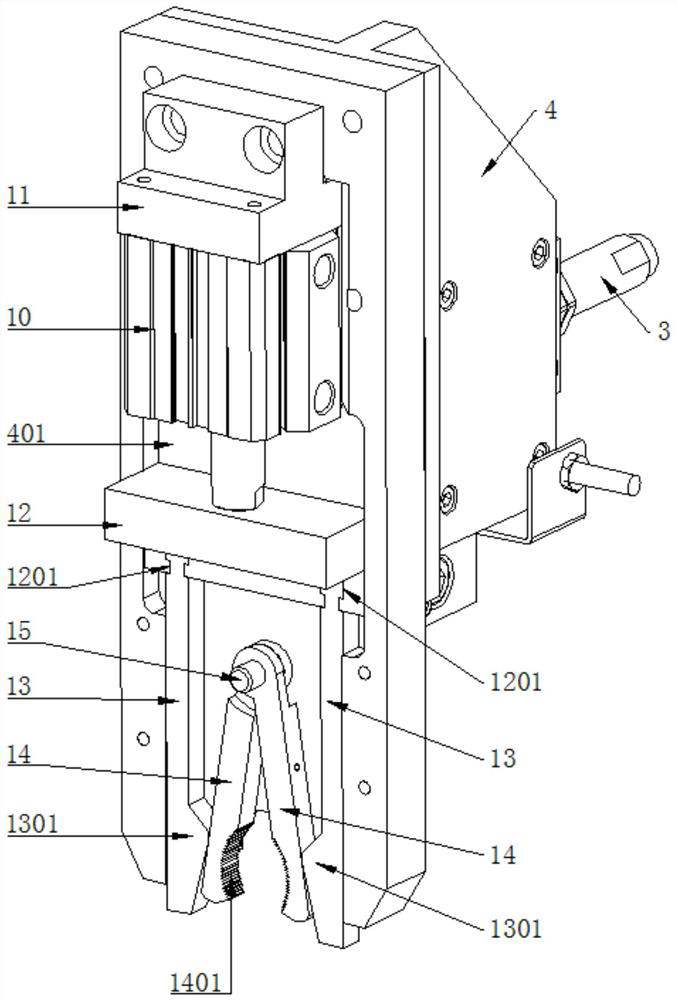

Loosening device for lathe machining

PendingCN112643383AReduce labor intensityReduce the difficulty of looseningMetal working apparatusStructural engineeringMachining

The invention discloses a loosening device for lathe machining, which comprises a mounting plate, an elastic buffer part, a movable frame, a telescopic part, push-pull blocks, clamping jaws and an elastic part; the elastic buffer part is arranged at one end of the mounting plate; the movable frame is arranged at the end, away from the elastic buffer part, of the mounting plate, and the movable frame is in sliding connection with the mounting plate; the movable frame slides in the direction close to or away from the elastic buffer part and is matched with the elastic buffer part; a telescopic piece is arranged at the end, away from the elastic buffer part, of the movable frame; the two push-pull blocks arranged side by side are arranged at the lower end of the telescopic piece, and the two clamping jaws are arranged between the two push-pull blocks; the upper ends of the two clamping jaws are both rotatably connected with the movable frame; the elastic part used for separating the two clamping jaws are arranged at the upper ends of the two clamping jaws; and protruding parts are arranged on the sides, close to the clamping jaws, of the push-pull blocks, and the protruding parts are matched with the clamping jaws. The loosening device of the invention can replace manpower to conduct material loosening operation, the material loosening difficulty is reduced, and the material loosening efficiency and the discharging efficiency are improved.

Owner:JINAN FIRST MACHINE TOOL GROUP

Atomizing nozzle

The invention relates to an atomizing nozzle. The atomizing nozzle comprises a gas-liquid mixing cavity. One end of the gas-liquid mixing cavity is provided with a liquid inlet, the other end of the gas-liquid mixing cavity is provided with an injection outlet, and the axis of the injection outlet and the axis of the liquid inlet are staggered. A channel of the gas-liquid mixing cavity is arranged in a front-back staggered mode. According to the atomizing nozzle, the axis of the injection outlet and the axis of the liquid inlet are arranged in a staggered mode, therefore, motion of conveying mediums is changed from rectilinear motion to bending motion in the moving process, and the conveying mediums can collide with the gas-liquid mixing cavity in the moving process, so that the atomizing effect is improved; meanwhile, the channel of the gas-liquid mixing cavity is arranged in the front-back staggered mode, motion of the conveying mediums is further changed into bending motion, the probability that the conveying mediums collide with the gas-liquid mixing cavity is increased, and thus the atomizing effect is further improved.

Owner:YANGZHOU YEYUN METALLURGICAL EQUIP FACTORY

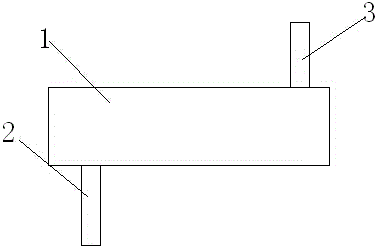

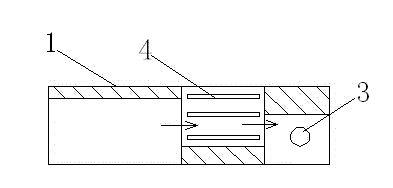

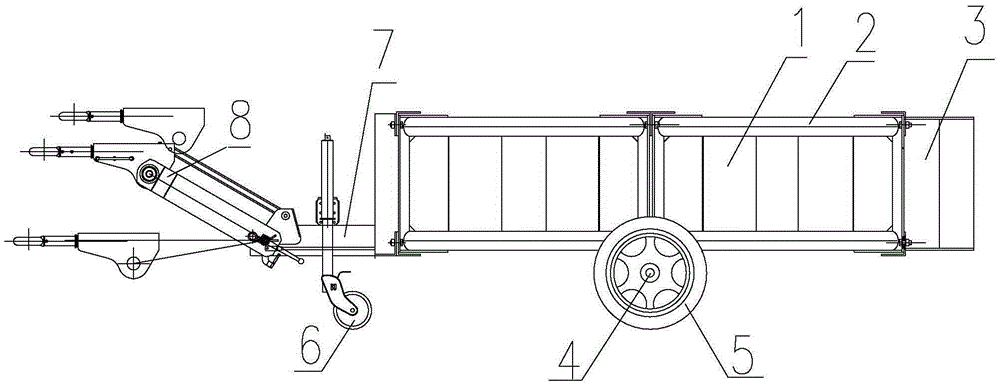

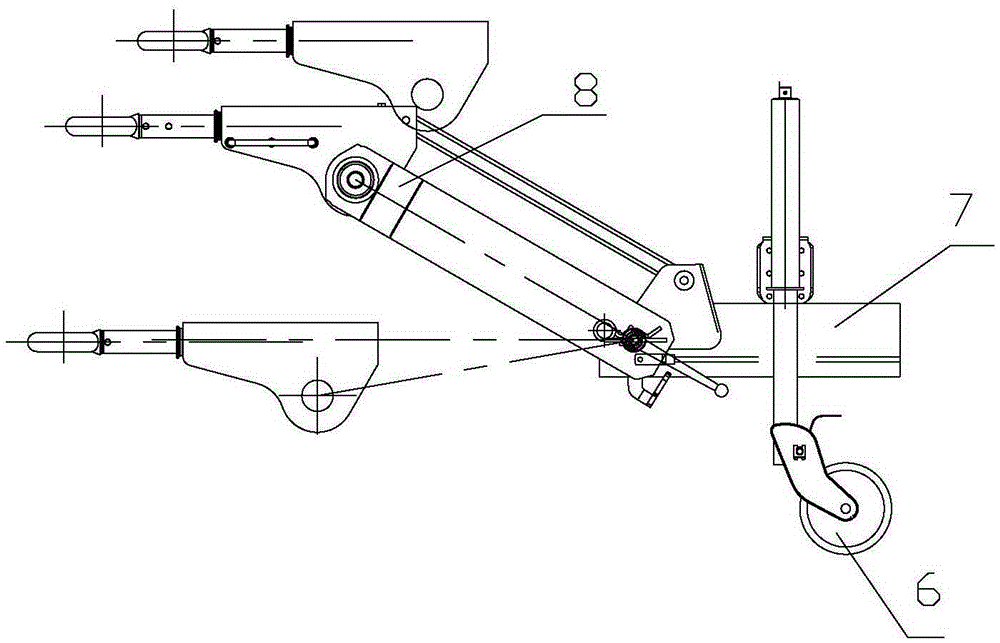

General security collision buffering device for automobiles

InactiveCN105398297AFlexible steeringGood flexibilityTowing devicesRoadway safety arrangementsVehicle frameAluminum honeycomb

The invention discloses a general security collision buffering device for automobiles. The general security collision buffering device comprises a plurality of aluminum honeycomb core plates (1), a plurality of collar frameworks (2), a traction connecting bracket and a frame, wherein the collar frameworks (2) are sequentially connected to form a multistage collar framework; two aluminum honeycomb core plates (1) are arranged in each collar framework (2), a gap is formed between the two aluminum honeycomb core plates (1) at intervals, the traction connecting bracket is mounted at the front ends of the collar frameworks (2), and the traction connecting bracket comprises two traction arms (8) which are arranged in parallel and respectively and movably connected to a stringer (7) at the bottom of the frame. According to the general security collision buffering device disclosed by the invention, adjustment and locking can be performed according to the height of a tractor, the application scope is wide, and a rubber torsion lever achieves a roller damping effect, so that the tractor can flexibly steer but is not heavy.

Owner:NANJING JINCHANGJIANG TRANSPORTATION EQUIP

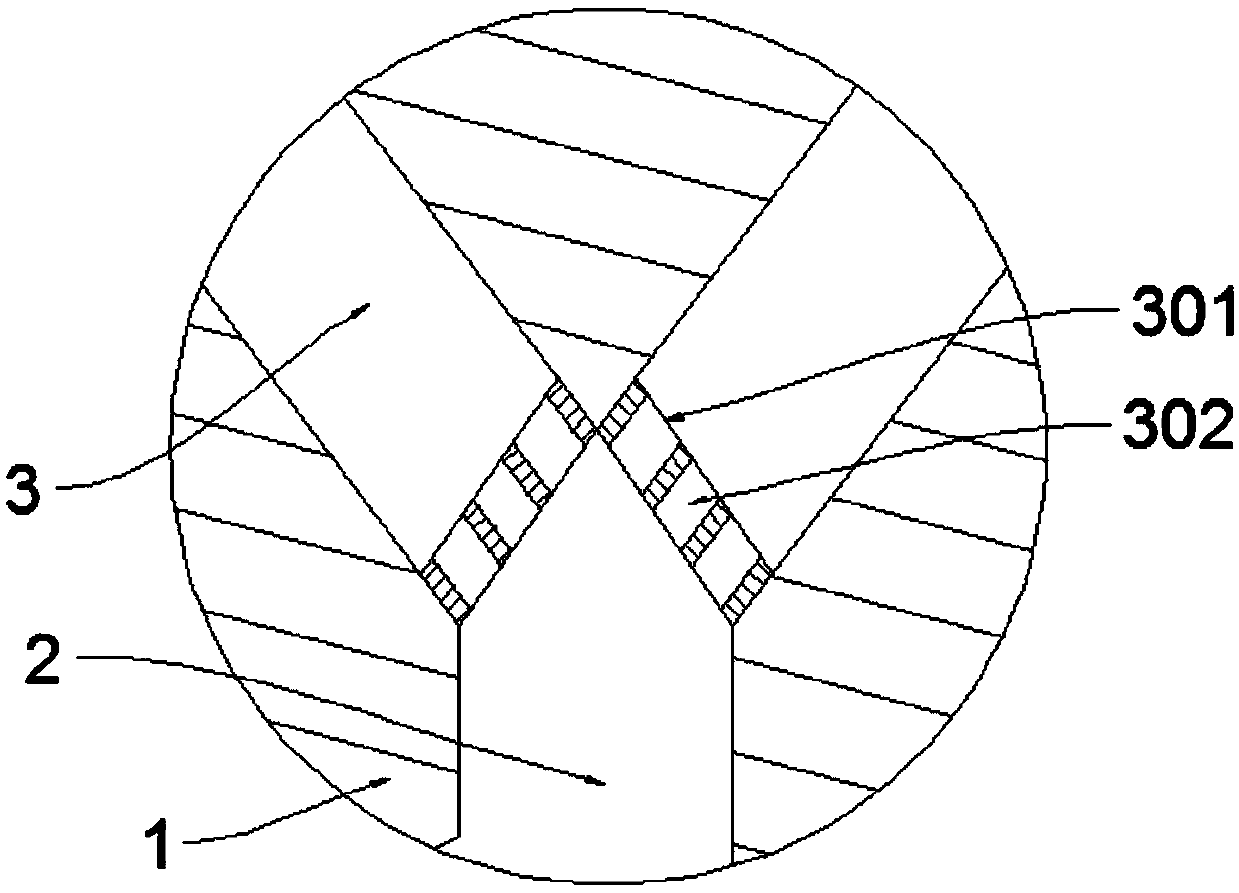

A Coal Chemical Wastewater Treatment System

ActiveCN108996639BImprove dissolution efficiencyImprove purification efficiencyWater/sewage treatment by flocculation/precipitationSpray nozzleProcess engineering

The invention belongs to the technical field of waste water treatment, and specifically relates to a coal chemical waste water treatment system, which includes a treatment box and a medicine box; it also includes a No. 1 stirring unit, a No. 2 stirring unit, and a drug nozzle; The flocculant is dissolved into the waste water at low speed; the No. 2 stirring unit is used for dissolving the flocculant into the waste water at high speed; the medicine nozzle is used for spraying the flocculant into the treatment tank. In the low-speed stirring, the No. 1 stirring unit and the No. 2 stirring unit are complementary to stir, on the one hand, the collision area between the flocculant and the impurities in the waste water is increased, thereby accelerating the dissolution efficiency of the flocculant and waste water, thereby improving the purification of waste water Efficiency; on the other hand, the flocculant is sprayed into the treatment tank reasonably according to the needs, so that the flocculant and the wastewater are dissolved, avoiding the waste of the flocculant, thereby improving the utilization rate of resources.

Owner:孙斌

Denitration device for flue gas from cement kiln and use method of denitration device

ActiveCN113908678AGuaranteed denitrification efficiencyReduce denitrification operating costsDispersed particle separationThermodynamicsNitrogen oxides

The invention relates to the technical field of treatment of nitric oxide in flue gas from industrial kilns, in particular to a denitration device for flue gas from a cement kiln and a use method of the denitration device. The denitration device comprises a kiln tail flue, an SNCR denitration reaction unit, a preheater, a low-temperature dust removal unit, an SCR denitration reaction unit and a chimney which are sequentially connected along a flue gas flowing direction, wherein the SNCR denitration reaction unit comprises a first mixer; the SCR denitration reaction unit comprises a second mixer and an SCR reactor which are sequentially connected along the flue gas flowing direction; an ammonia gas source sprays ammonia gas into the first mixer and the second mixer respectively; and the low-temperature dust removal unit comprises a low-temperature dust remover. According to the denitration device for the flue gas from the cement kiln provided by the invention, denitration operation cost is reduced on the basis of ensuring denitration efficiency.

Owner:山东东源新材料科技有限公司

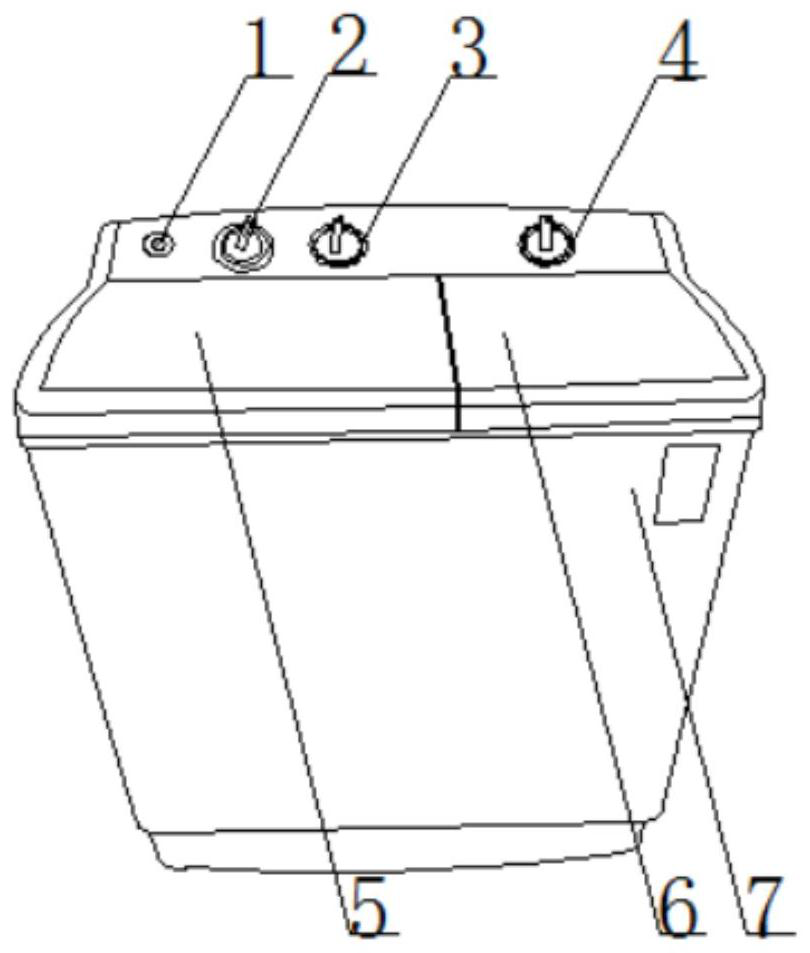

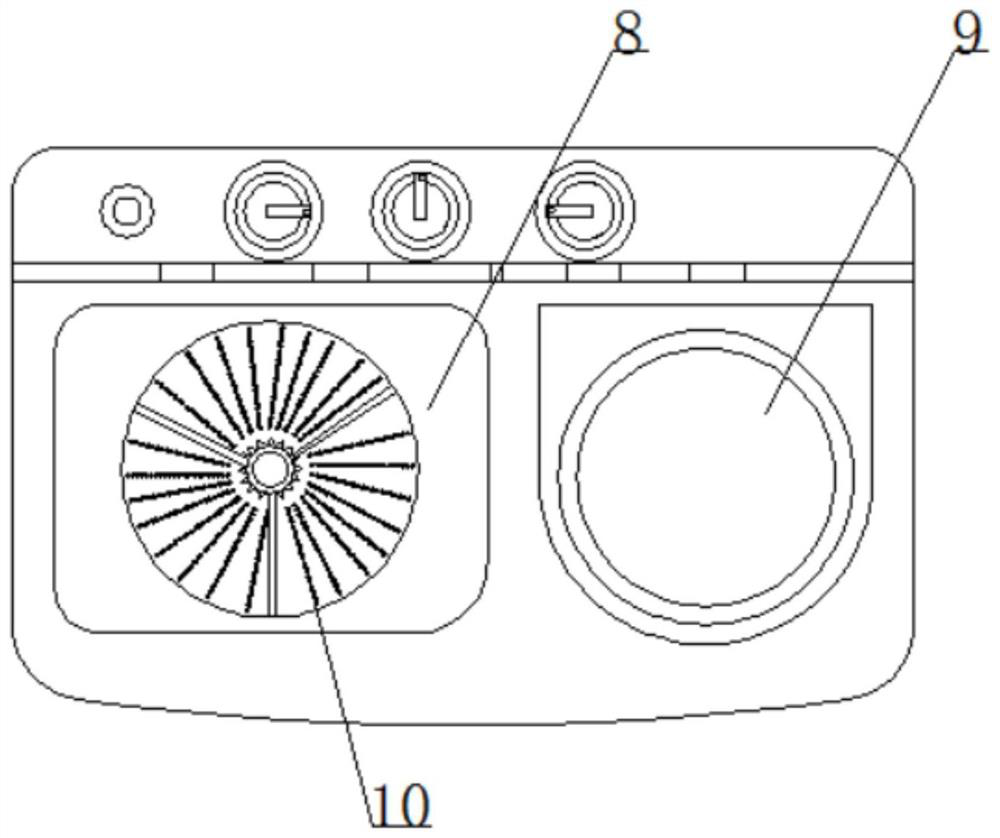

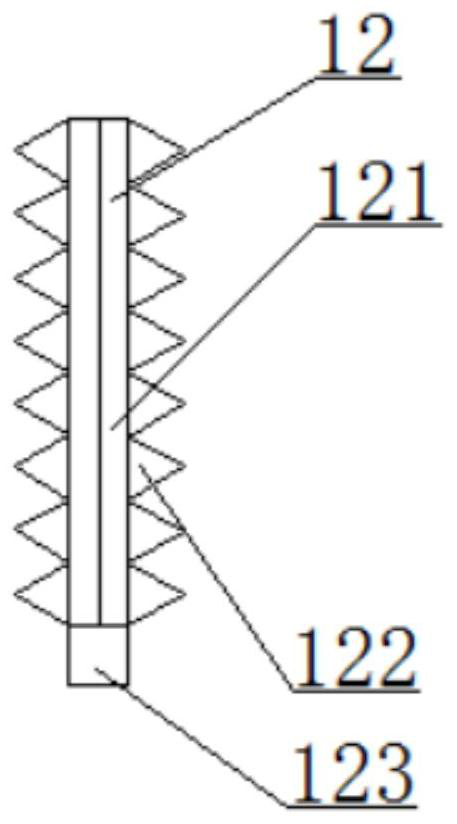

Anti-winding device for twin-tub washing machine

InactiveCN112011966AIncrease the collision areaAvoid intertwiningOther washing machinesWashing machine with receptaclesLaundry washing machineEngineering

The invention discloses an anti-winding device for a twin-tub washing machine. The device comprises a machine body and a washing cover plate, the upper end of the machine body is connected with a washing cover plate through a clamping hook; a dehydration cover plate is arranged at the right end of the washing cover plate; a water inlet is formed in the upper end of the washing cover plate; a washing timer is arranged at the right end of the water inlet; a drainage switch is arranged at the right end of the washing timer; a dehydration timer is arranged at the upper end of the dehydration coverplate; the upper end of the machine body is connected with a washing timer, a drainage switch and a dehydration timer in a sleeved way; an anti-winding shaft comprises a rotating shaft, a brush and abase; the outer surface of the rotating shaft is sleeved with the brush, and the lower portion of the rotating shaft is fixedly connected with the base through welding, so that the collision area ofclothes and the washing machine is increased, the clothes are cleaned more deeply due to the brush, the clothes cannot be wound around the rotating shaft due to rotation of the rotating shaft, and theclothes can be prevented from being wound around one another.

Owner:杭州双螺旋科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com