Denitration device for flue gas from cement kiln and use method of denitration device

A flue gas and denitrification technology, applied in separation methods, chemical instruments and methods, dispersed particle separation, etc., can solve the problems of decreased denitration efficiency, failure to meet emission standards, and high operating costs, reducing the risk of poisoning and deactivation, The effect of reducing the denitration operating cost and improving the catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0042] It should be noted that the structures, proportions, sizes, etc. shown in the drawings attached to this specification are only used to match the content disclosed in the specification, for those who are familiar with this technology to understand and read, and are not used to limit the implementation of the present invention Any modification of structure, change of proportional relationship or adjustment of size shall fall within the range covered by the technical content disclosed in the present invention without affecting the effect and purpose of the present invention. within range.

[0043] At the same time, terms such as "upper", "lower", "left", "right", "middle" and "one" quoted in this specification are only for the convenience of description and are not used to limit this specification. The practicable scope of the invention and the change or adjustment of its relative relationship shall also be regarded as the practicable scope of the present invention without...

Embodiment 1

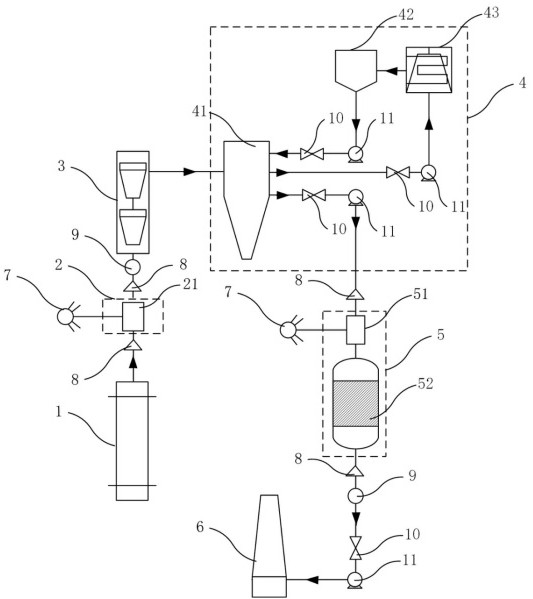

[0045] combined with figure 1 , This implementation provides a cement pit flue gas denitrification device, including a pit tail flue 1, an SNCR denitrification reaction unit 2, a preheater 3, a low-temperature dust removal unit 4, and an SCR denitrification reaction unit 5 connected sequentially along the flue gas direction and chimney 6, the SNCR denitration reaction unit 2 includes a first mixer 21; the SCR denitration reaction unit 5 includes a second mixer 51 and an SCR reactor 52 connected in sequence along the flue gas trend; Ammonia gas is injected into the first mixer 21 and the second mixer 51 ; the low-temperature dust removal unit 4 includes a low-temperature dust collector 42 .

[0046] In the above technical scheme, the combination of SNCR denitrification technology and SCR denitrification technology greatly reduces the denitrification operation cost. At the flue gas outlet near the pit tail flue 1, the SNCR denitrification reaction unit 2 is used for primary den...

Embodiment 2

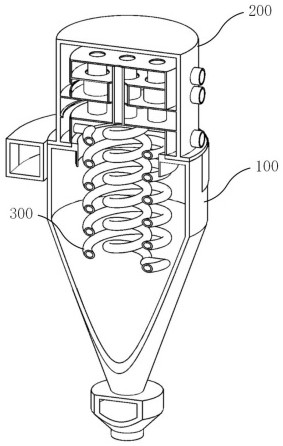

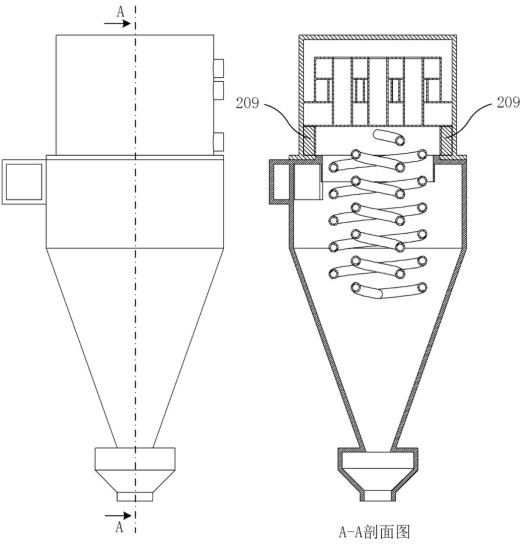

[0054] combined with Figure 2-5 , this embodiment provides a heat exchange device 41 used in Embodiment 1, the heat exchange device 41 sequentially includes a first heat exchange part 100 and a second heat exchange part 200 from bottom to top, the first heat exchange The high-temperature flue gas flowing out from the preheater 3 is passed into the part 100, the low-temperature flue gas flowing out from the low-temperature dust collector 42 is passed into the second heat exchange part 200, and the double-helix heat pipe 300 is fixed on the second Below the heat exchange part 200 and extending into the first heat exchange part 100 , the double helical heat pipe 300 includes a connected outer helical pipe 301 and an inner helical pipe 302 , and low-temperature flue gas flows through the double helical heat pipe 300 Then flow out to the second mixer 51.

[0055] In the above technical solution, the double-helix heat pipe 300 can prolong the residence time of the low-temperature ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com