SNCR denitration method for urea solutions of double concentrations

A dual-concentration, urea technology is applied in separation methods, chemical instruments and methods, and dispersed particle separation. It can solve problems such as zero, slow reduction reaction, and wide range, so as to ensure denitrification efficiency, reduce the adjustment range, The effect of increasing supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

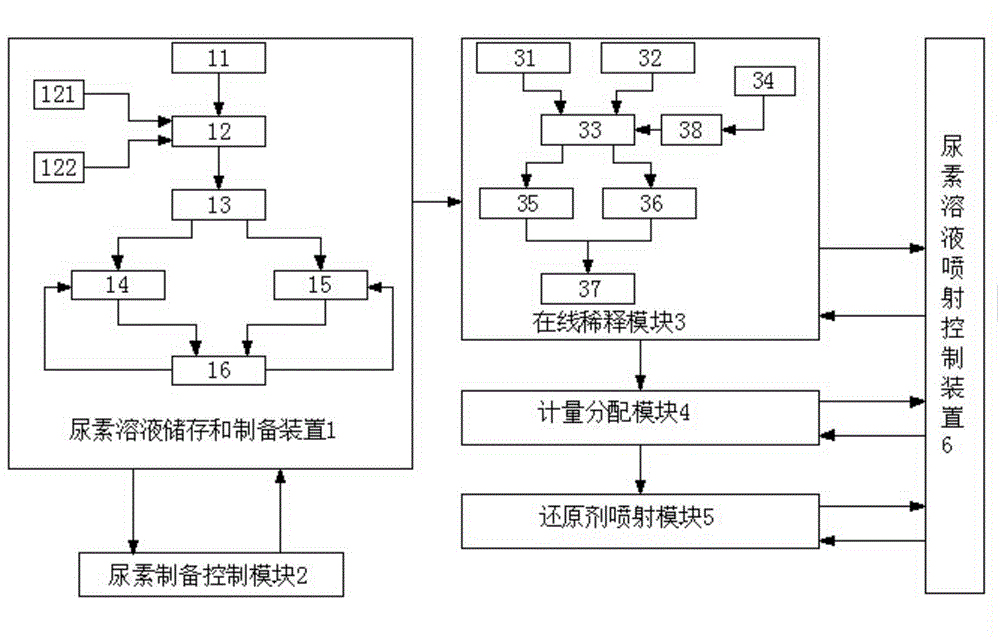

[0015] see figure 1 , a SNCR denitrification method for a dual-concentration urea solution comprising a urea solution storage and preparation device 1, a urea preparation control module 2, an online dilution module 3, a metering distribution module 4, a reductant injection module 5 and a urea solution injection control device 6, wherein , the information output end of the urea solution storage and preparation device 1 is connected to the information input end of the urea preparation control module 2, and the control end of the urea preparation control module 2 is connected to the urea solution storage and preparation device 1; the online dilution module 3. The information output terminals of the metering distribution module 4 and the reducing agent injection module 5 are respectively connected to the information input ports of the urea solution injection control device 6, and the control terminals of the urea solution injection control device 6 are respectively connected to the...

Embodiment 2

[0019] First, 30% urea solution or 50% urea solution are respectively configured in the urea dissolving tank 12, here in no particular order, as long as 30% urea solution and 50% urea solution are respectively injected into two mutually independent first urea solution storage Tank 14 and the second urea solution storage tank 15 get final product. In order to save operating time, it is better to configure 50% urea solution earlier. In the present embodiment, 30% urea solution is injected into the first urea solution storage tank 14. 50% urea solution is injected into the second urea solution storage tank 15, which is the first-stage dilution configuration, so there is a large difference between two kinds of urea solutions with different concentrations; when the urea solution is passed through the urea solution lifting device 16, the urea solution back pressure cycle Afterwards, the 30% urea solution in the first urea solution storage tank 14 is injected in the first heating tank...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com