Silica gel 3D printer based on Core XY structure and printing method thereof

A 3D printer and silica gel technology, applied in the direction of 3D object support structure, coating device, processing platform/substrate, etc., can solve the problems of printing deviation and low printing accuracy, achieve high printing accuracy, automatically correct printing deviation, improve The effect of technical effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

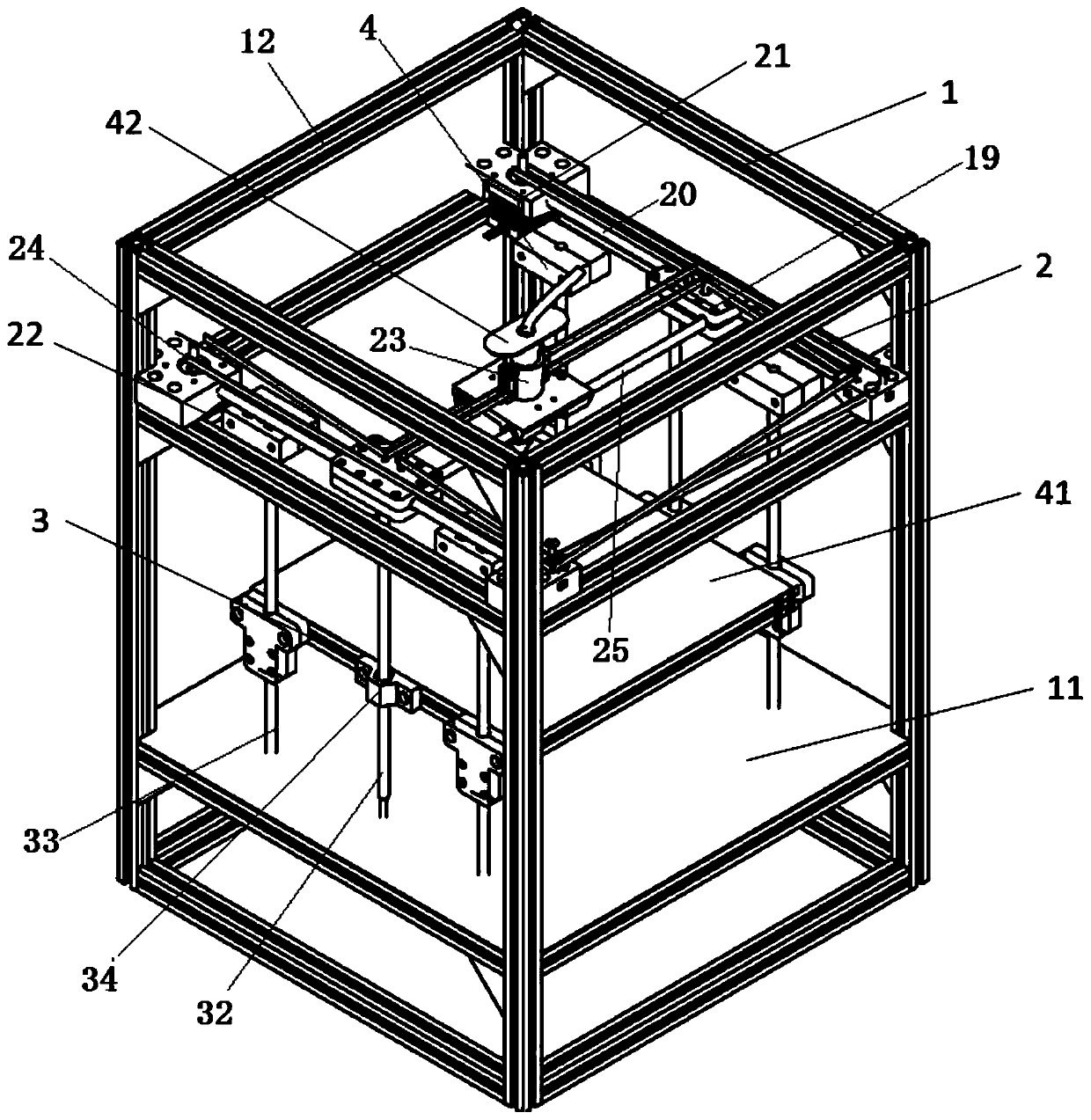

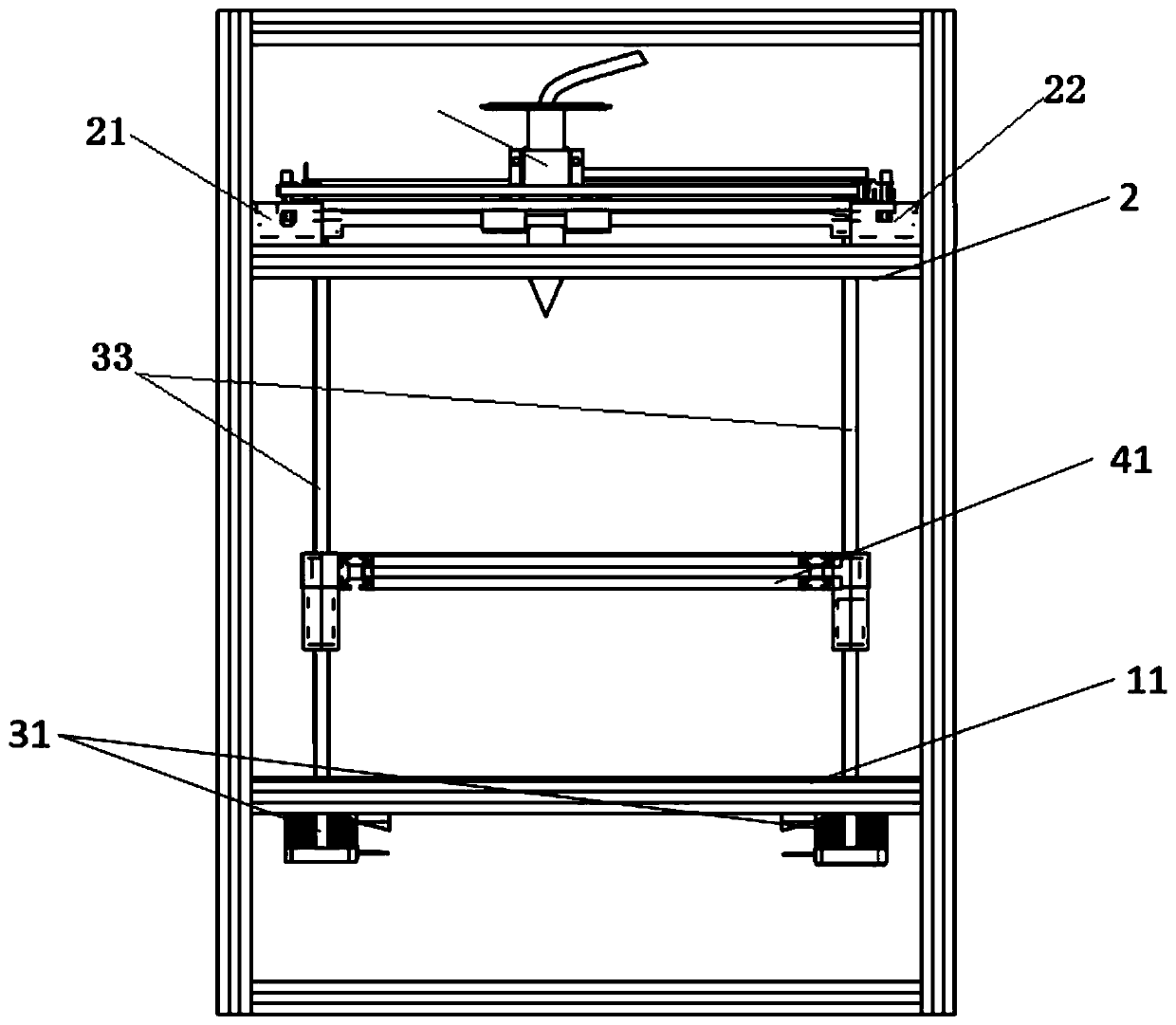

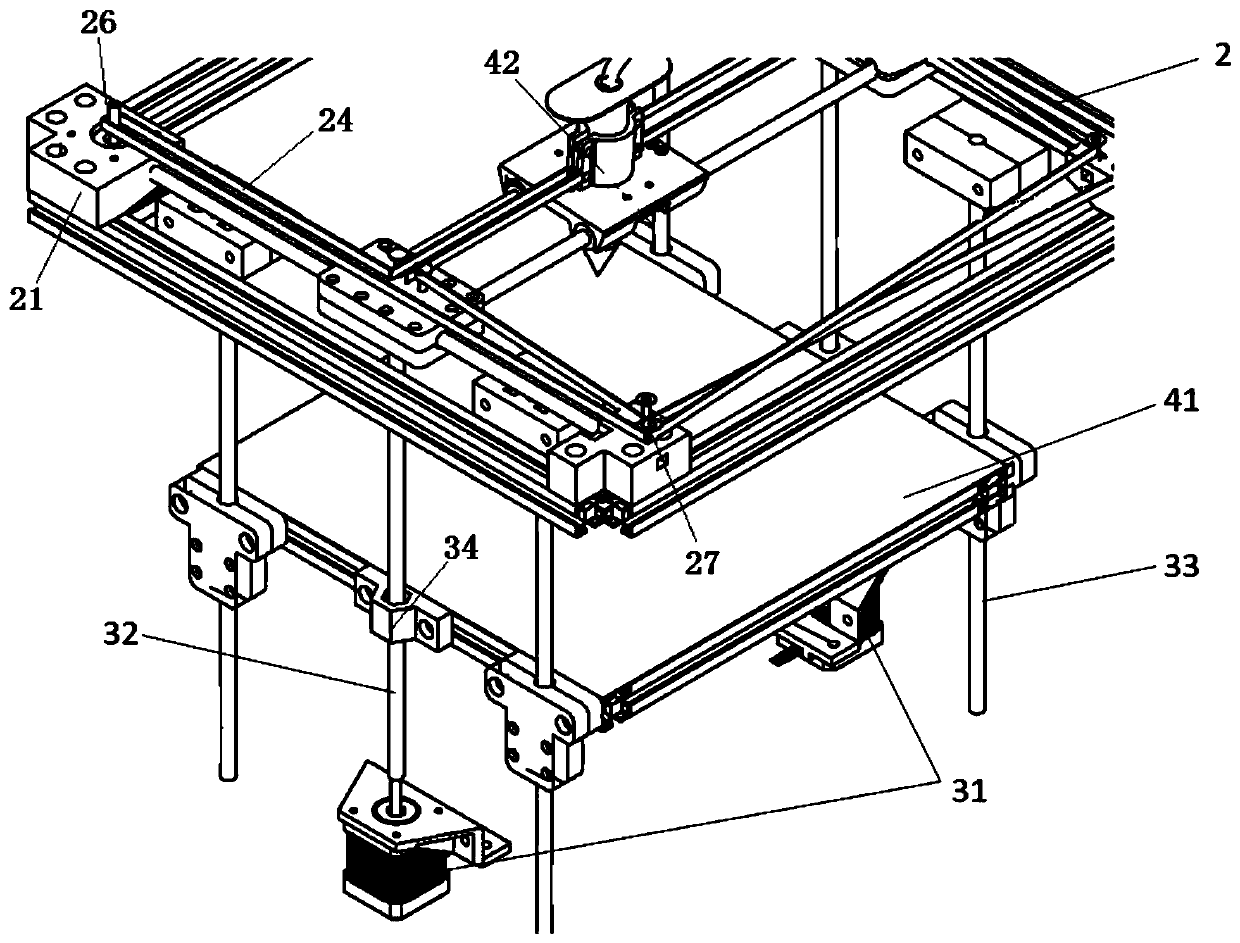

[0076] see Figure 1-4, this embodiment provides a silicone 3D printer based on the Core XY structure. The silicone 3D printer adopts the Core XY structure to realize plane two-dimensional movement, and uses liquid silicone as a raw material for printing. Silicone can be a neutral curing sealant, this type of silicone can be quickly cured on a printing surface of various materials at room temperature. The silicone 3D printer can be an improved printer for an existing 3D printer, or an independently produced printer. Among them, the silicone 3D printer includes a frame 1, a printing module 4, a horizontal plane electric module 2, a vertical axis electric module 3, a horizontal trajectory positioning module, a vertical axis trajectory positioning module, a running trajectory generation module and a master control module.

[0077] The frame 1 can be a frame structure, and in this embodiment consists of two parts, one part is a frame 12 and the other part is a bottom plate 11 . ...

Embodiment 2

[0096] This embodiment provides a silica gel 3D printer based on the Core XY structure. On the basis of Embodiment 1, the printer adds an air pressure control device, and can also add one of a temperature control device, a humidity control device, and an ultraviolet lamp. In this embodiment, the silica gel is one of heat-curing silica gel, moisture-curing silica gel, and UV-curing silica gel. When the silica gel is heat-cured silica gel, the printer is equipped with a temperature control device; when the silica gel is moisture-cured silica gel, the printer is equipped with a humidity control device; when the silica gel is UV silica gel, the printer is equipped with an ultraviolet lamp. Next, these additional devices will be described.

[0097] The air pressure control device includes a pressure sensor and an electronic pressure regulating valve. The pressure sensor is used to detect the air pressure in the dispensing syringe 42 . The electronic pressure regulating valve is u...

Embodiment 3

[0105] This embodiment provides a method for 3D printing of silica gel based on the Core XY structure, which is applied to the 3D silica gel printer based on the Core XY structure of Embodiment 1 or Embodiment 2. The silica gel 3D printing method can be stored through a U disk, a computer storage unit, etc., and can be applied to 3D printing equipment. Wherein, the silica gel 3D printing method includes the following steps.

[0106] Step 1, detect the moving distance 1 of the needle head of the dispensing syringe (42) in the length direction of the frame (1), the moving distance 2 in the width direction of the frame (1), and convert the moving distance 1 into The movement vector 1 in the three-dimensional rectangular coordinate system converts the moving distance two into the movement vector two in the three-dimensional rectangular coordinate system. The moving distance in this step can be detected by various distance sensors, and the moving vector is added with a sign to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com