Printing machine for cable markers

A cable number and number tube technology, which is applied in the field of cable number tube printing machines, can solve the problems of tens of thousands to hundreds of thousands, high cost, and low printing efficiency, achieving significant economic benefits, ensuring printing efficiency, and printing fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

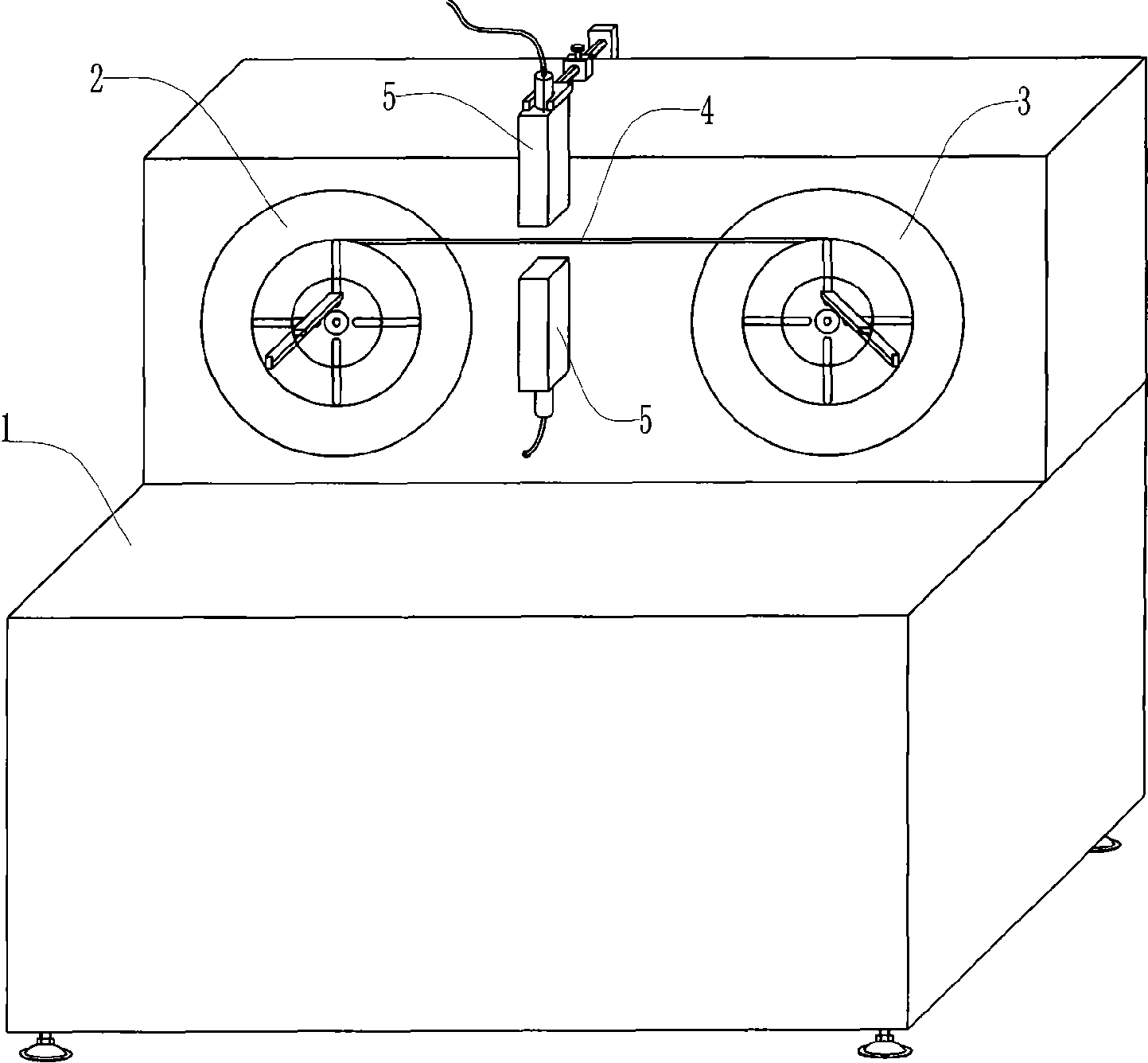

[0015] Embodiment 1, a kind of cable number tube printing machine, such as figure 1 , there is a frame 1, a feeding tray 2 and a receiving tray 3 installed on the frame, the number tube 4 is wound on the feeding tray and the receiving tray, the receiving tray 3 is driven by the receiving motor, and the receiving motor Drive the receiving tray to rotate to realize the transmission of the numbered tube 4, gradually collect the numbered tube rolled on the feeding tray 2 on the receiving tray 3, the upper and lower sides of the conveying path of the numbered tube between the receiving tray and the feeding tray The inkjet terminal 5 of two inkjet printers arranged oppositely is housed. The inkjet printer is a prior art, and has been widely used in code inkjet printing.

[0016] When the above-mentioned cable number tube printing machine is working, the number tube consumables to be printed are rolled up on the feeding tray, and one end of the number tube protrudes from the supply ...

Embodiment 2

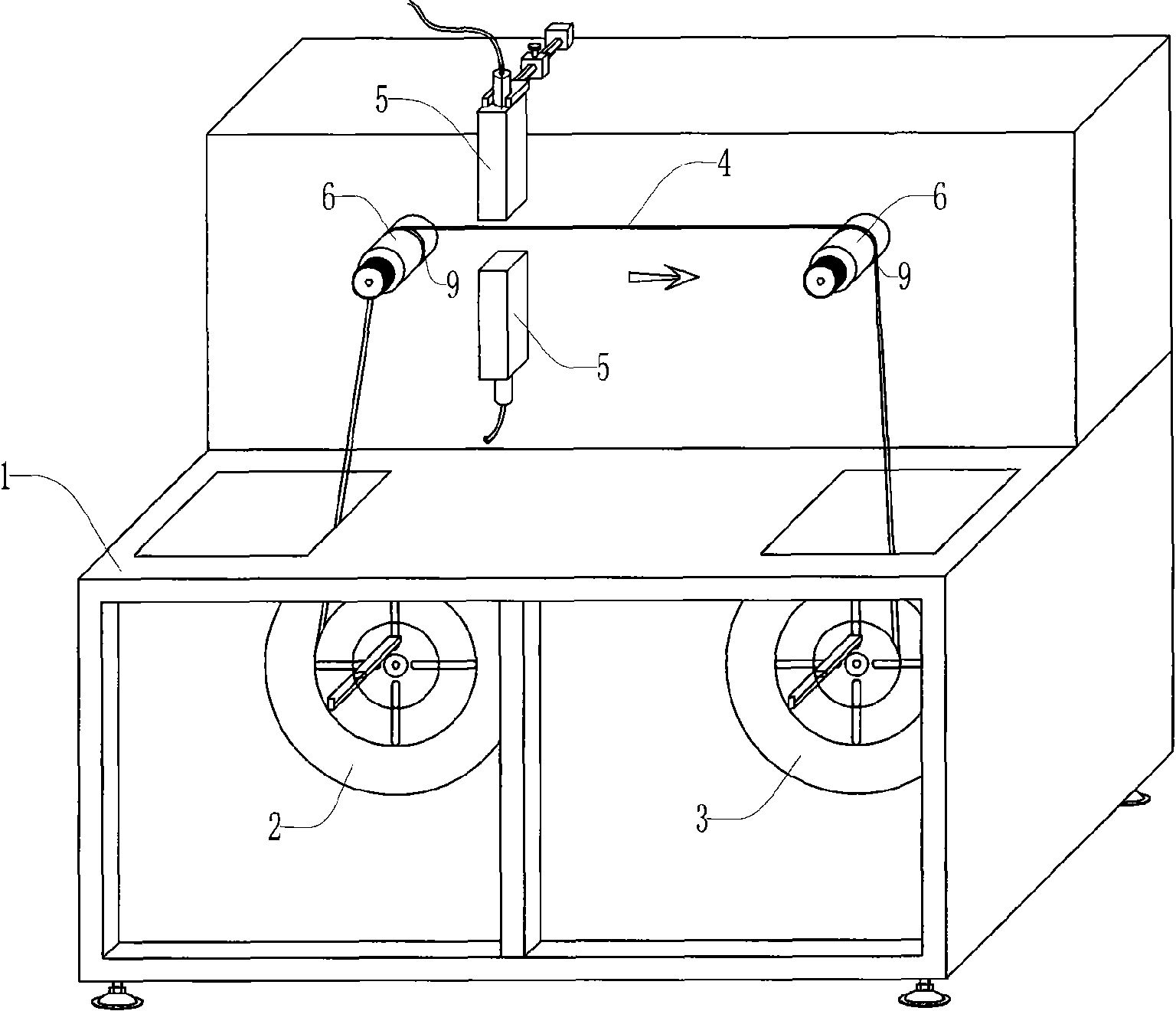

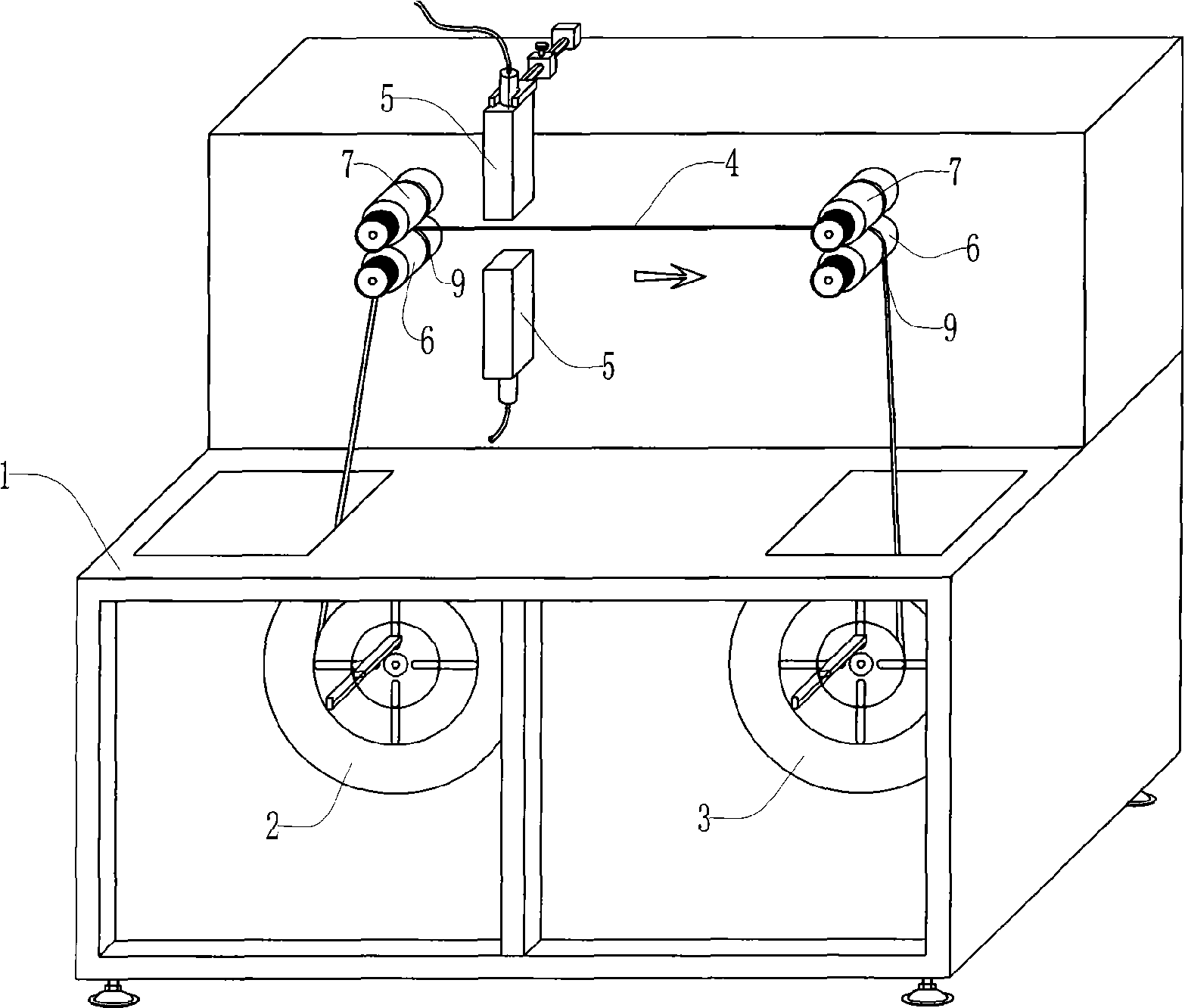

[0017] Example 2, such as figure 2 , which is different from Embodiment 1 in that two tensioning wheels 6 for tightening the numbering tubes are installed on the numbering tube conveying path between the feeding tray 2 and the receiving tray 3, and the two tensioning wheels 6 are located at At the same level, but at a different level than the feeder and receiver pans.

[0018] There are two tension pulleys on the conveying path of the number tube which are at different levels from the receiving tray and the feeding tray, which increase the tension of the number tube between the feeding tray and the receiving tray during conveying, so that the number tube It can be moderately relaxed, pulled straighter, and more favorable for number printing. The two tension pulleys 6 are located on the same horizontal plane, which can ensure that the coding section of the number tube is in a horizontal state, which can make the printing effect of the jetting dock better, and also ensure the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com