Punching device suitable for polyester filament fabric and application method thereof

A punching device and technology of polyester filaments, applied in the field of textile processing, can solve the problems of no linkage between feeding and punching operations, poor punching effect, low punching efficiency, etc., to achieve easy maintenance and repair, improve efficiency and structure. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the content of the present invention more clearly understood, the present invention will be further described in detail below based on the specific embodiments and in conjunction with the accompanying drawings.

[0034] Many textiles require perforation during production. The traditional textile punching process requires manual operation, not only the punching efficiency is low, but also the punching effect is poor. The existing textile punching equipment has a high degree of automation and can realize automatic feeding and punching. However, the feeding mechanism and the punching mechanism need their own power sources, the production cost is high, and there is no linkage between the feeding and punching operations.

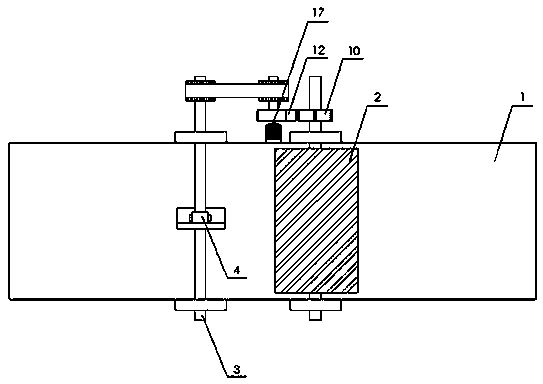

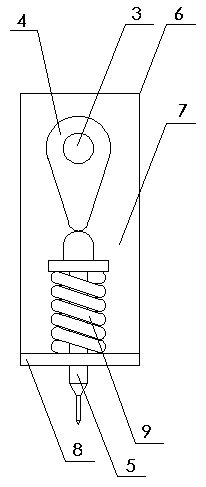

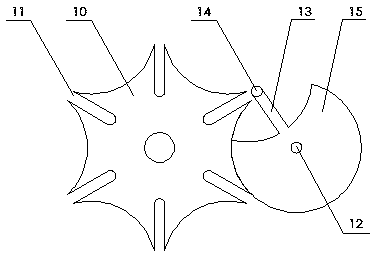

[0035] see Figure 1 ~ Figure 3 , in view of this, first embodiment of the present invention provides a kind of punching device that is suitable for polyester filament fabric, the main body of this device comprises workbench 1, feeding me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com