Workpiece clamping device of special boring machine for axle hole of machine body

A technology of clamping device and body shaft, which is applied in the field of boring machines to achieve the effect of expanding the processing range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below in conjunction with the accompanying drawings.

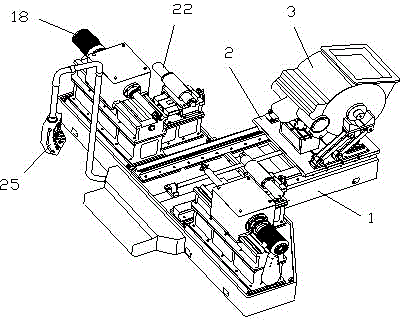

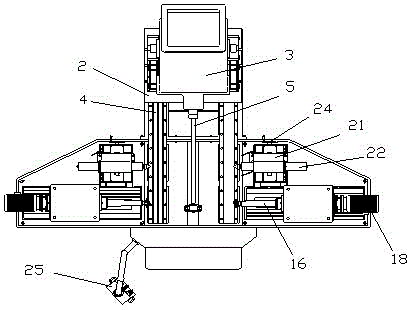

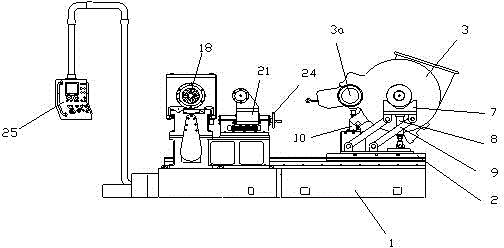

[0017] See attached picture, a Body shaft hole special boring machine , including the bed 1, the feeding table 2 arranged on the bed 1, the feeding driving mechanism for driving the movement of the feeding table 2, and the protruding parts arranged on both sides of the feeding table 2 for aligning the two sides of the workpiece 3 The workpiece supporting device for supporting, the boring tool feeding mechanism arranged on both sides of the processing area of the bed 1, and the hydraulic tip mechanism arranged on both sides of the processing area of the bed 1 for clamping and fixing the workpiece 3. The following takes the processing of the bearing bush hole of the traction motor of the locomotive as an example to illustrate.

[0018] The bed 1 is provided with two feeding rails 4 parallel to each other, the bottom of the feeding table 2 is slidably arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com