Patents

Literature

103results about How to "Realize compression and fixation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

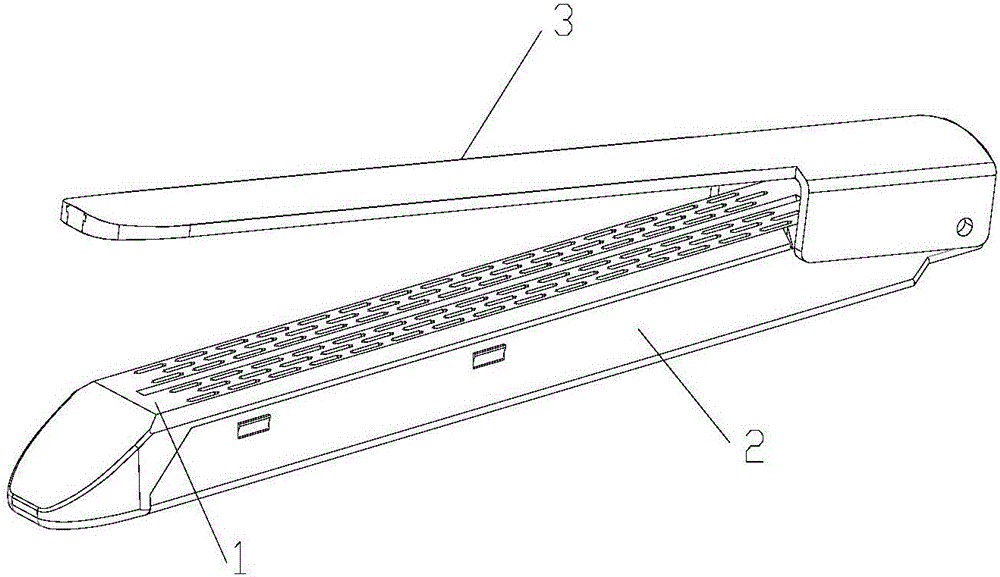

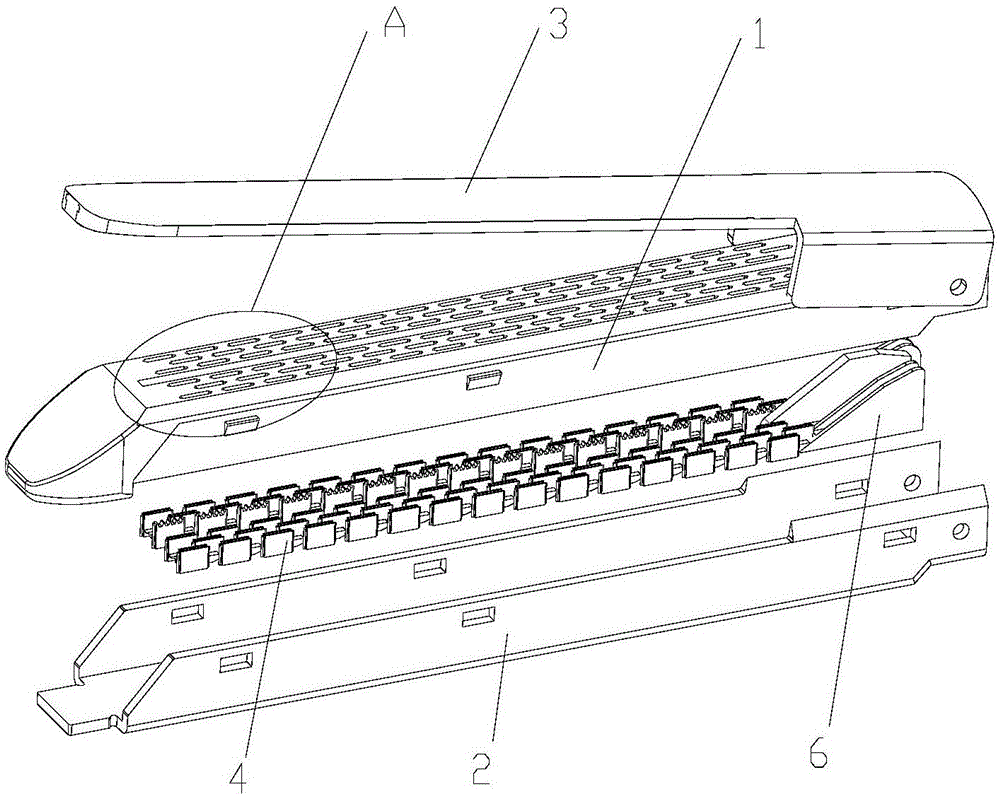

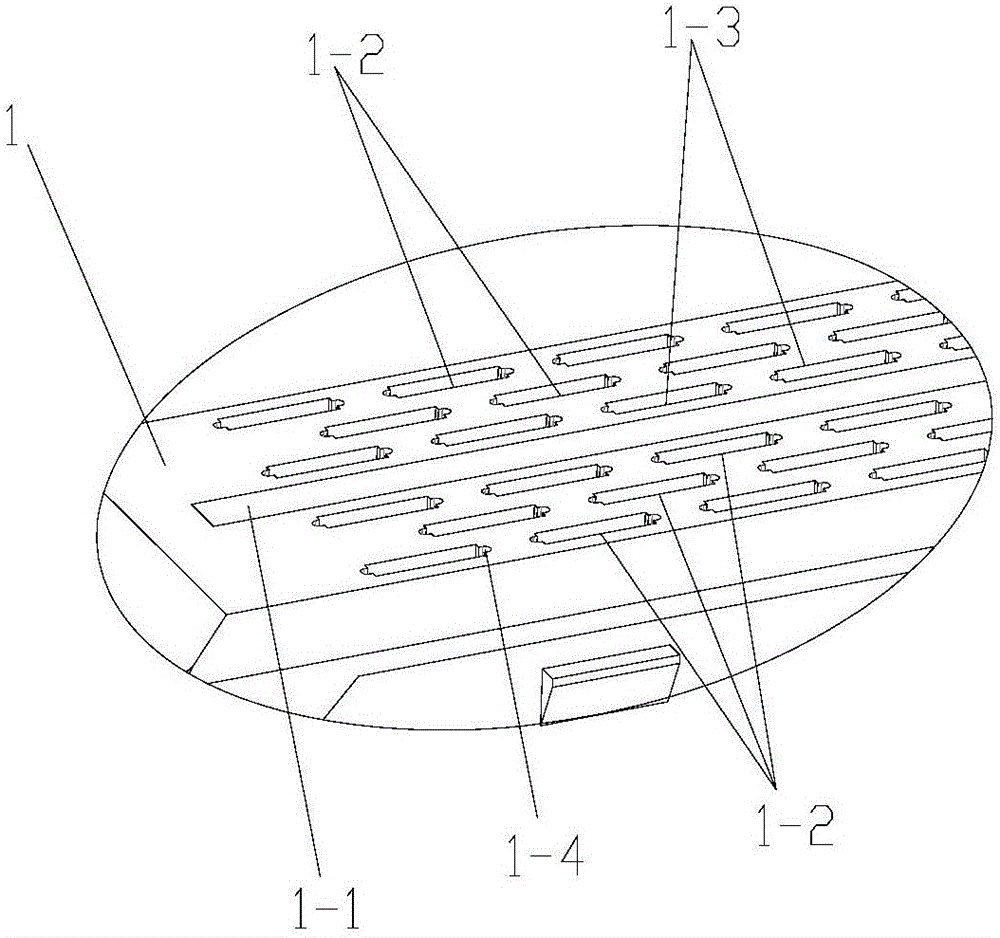

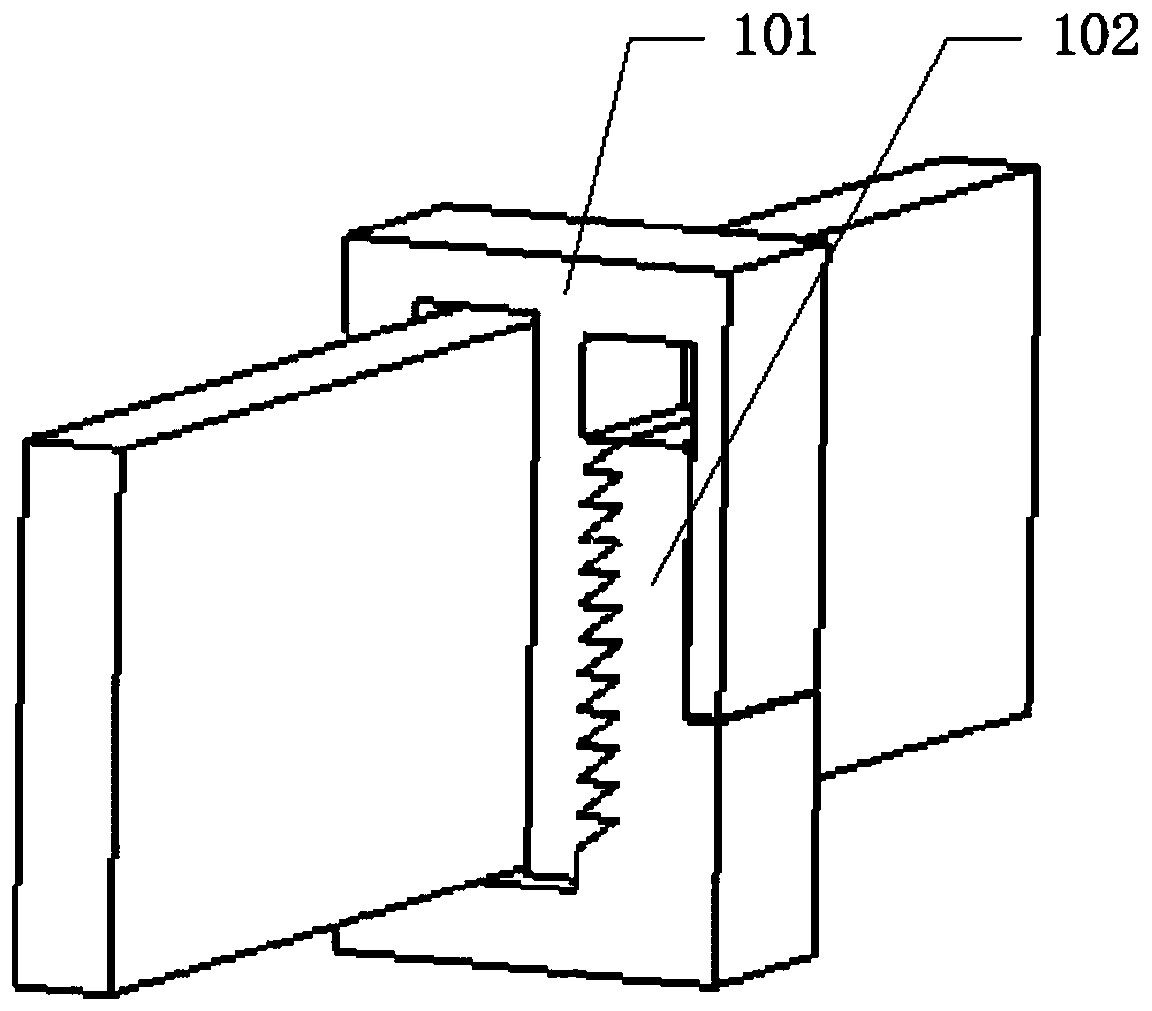

Staple cartridge assembly of disposable intracavity cutting and edge incising anastomat

ActiveCN106344091ARealize compression and fixationEnsure stabilityIncision instrumentsSurgical staplesEngineeringBlood vessel

The invention provides a staple cartridge assembly of a disposable intracavity cutting and edge incising anastomat. The staple cartridge assembly comprises a staple cartridge, a staple cartridge base and a staple butting plate, wherein the staple cartridge is arranged in the staple cartridge base, a cutting slot is formed in the middle of the staple cartridge, multiple rows of suturing staple slots are formed in two sides of the cutting slot in the staple cartridge, staple pushing piece groups corresponding to the suturing staple slots are arranged in the staple cartridge seat below the staple cartridge, tissue pressing block slots are further formed in the staple cartridge on one side of the cutting slot and are located on the staple cartridge between one row of suturing staple slots on the innermost layer and the cutting slot, tissue pressing structures are arranged on the staple pushing piece groups and / or staple butting plate corresponding to the tissue pressing block slots, and the tissue pressing structures are tissue pressing blocks at certain heights. With the adoption of the tissue pressing structures, pathological frozen sections after an operation can be made while complete tissue is reserved, the stability of the tissue during the operation can also be guaranteed, blood vessel breakage is reduced, and the operation risk is reduced.

Owner:PRECISION CHANGZHOU MEDICAL INSTR

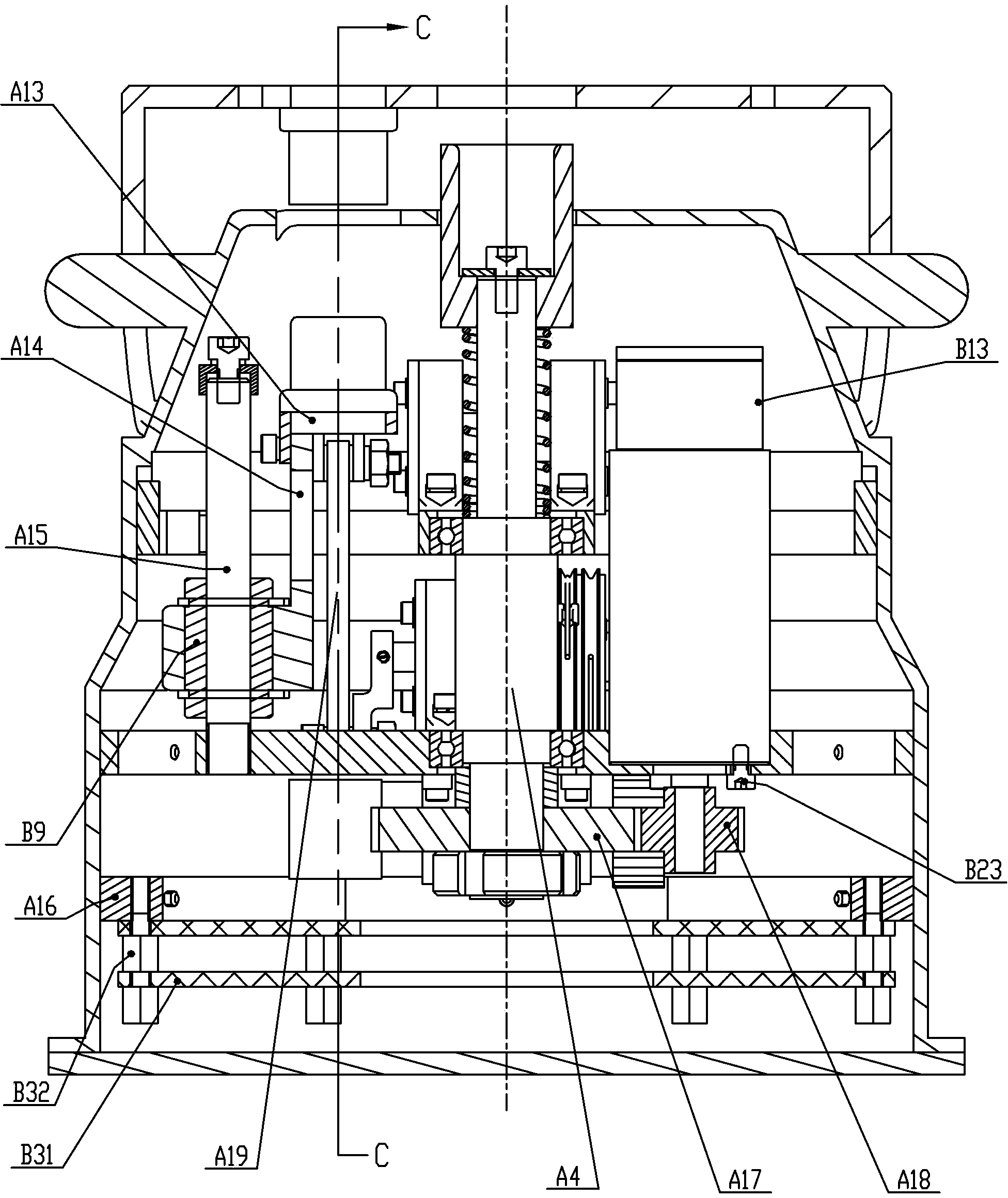

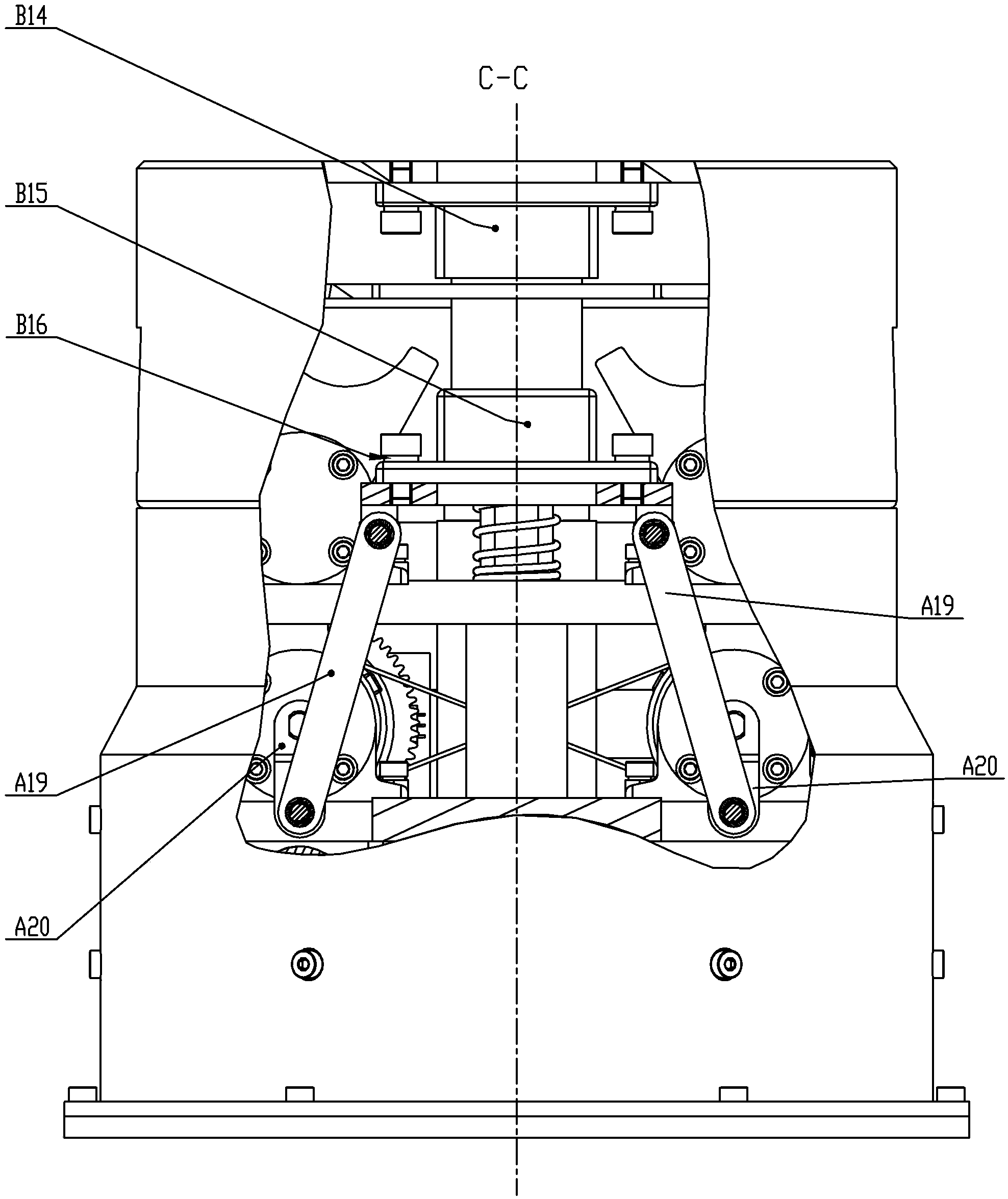

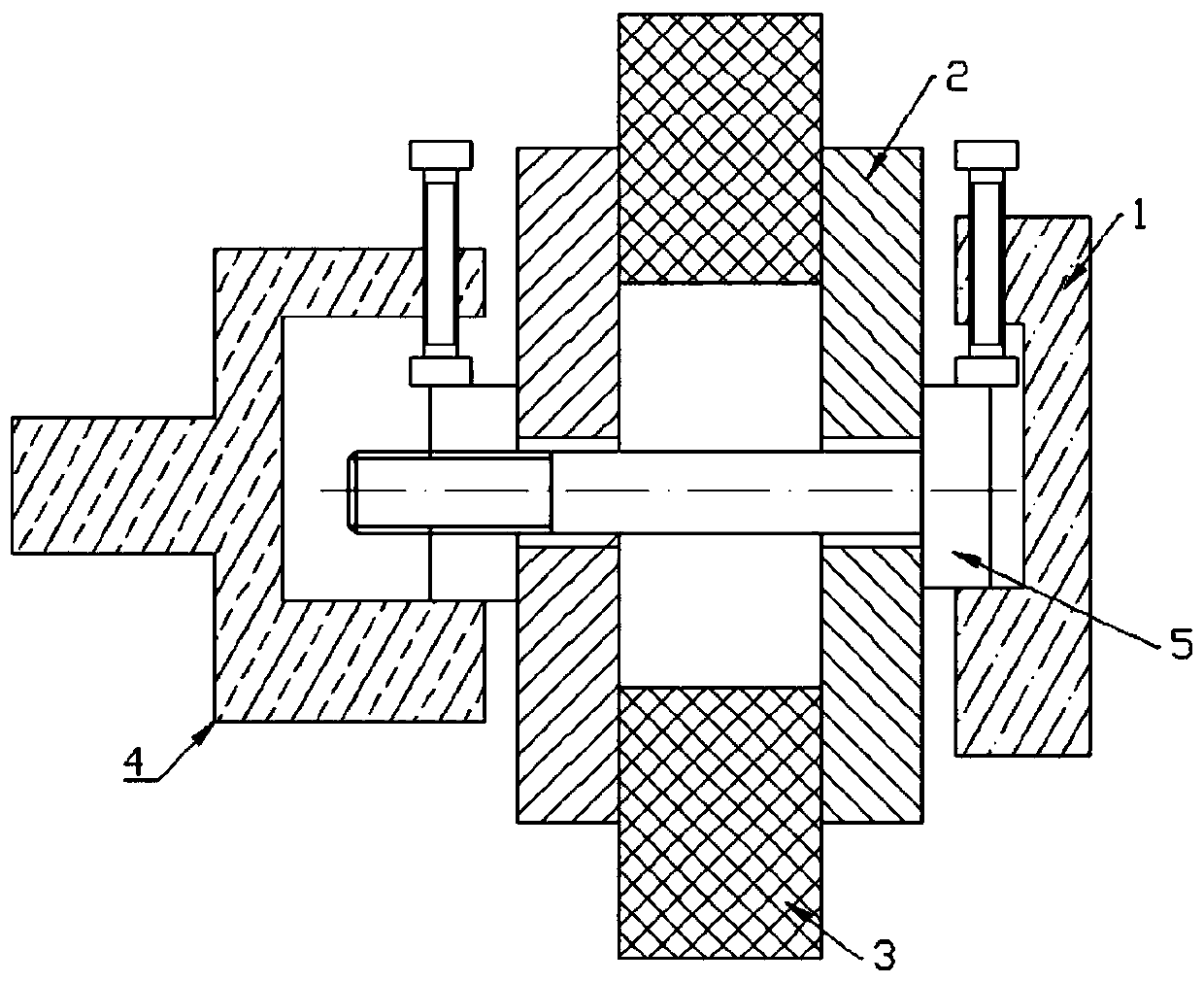

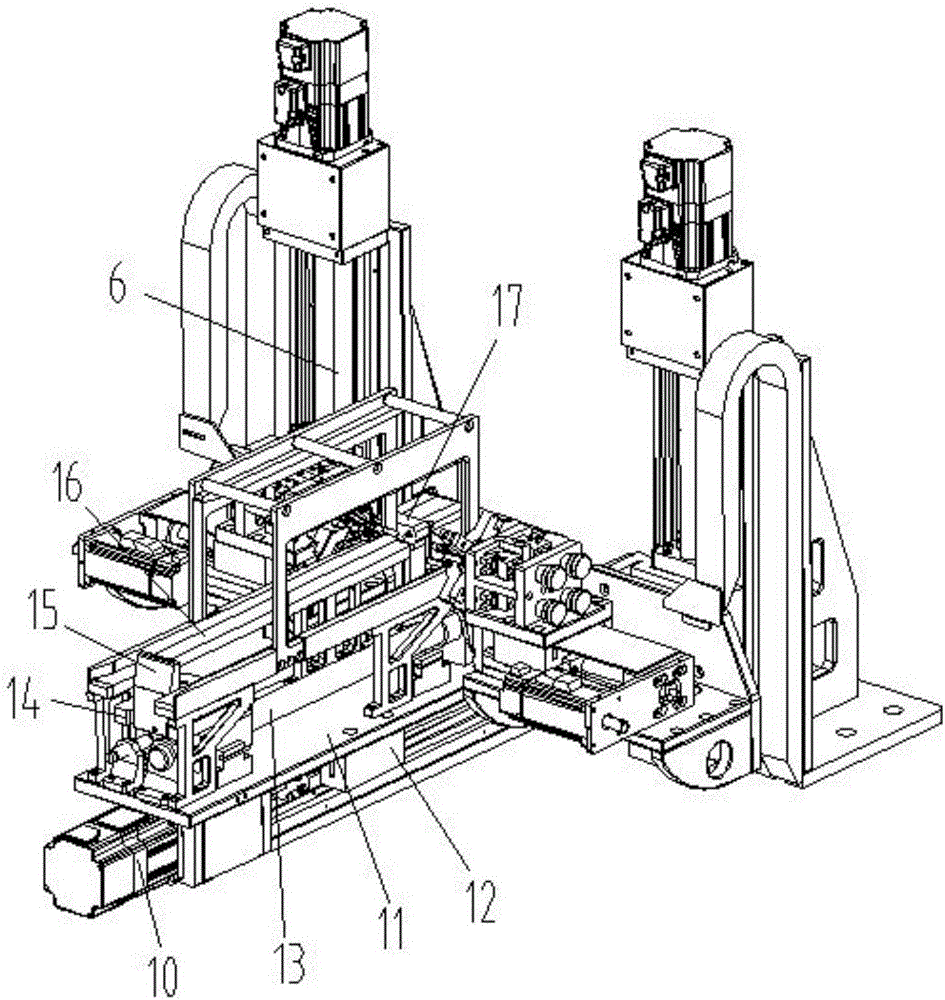

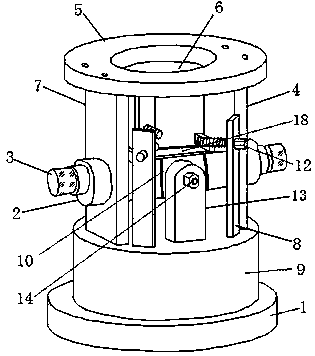

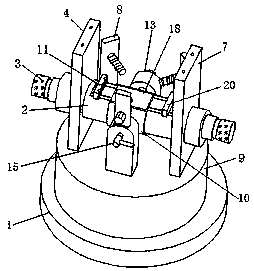

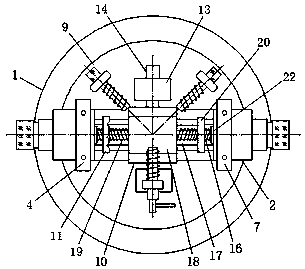

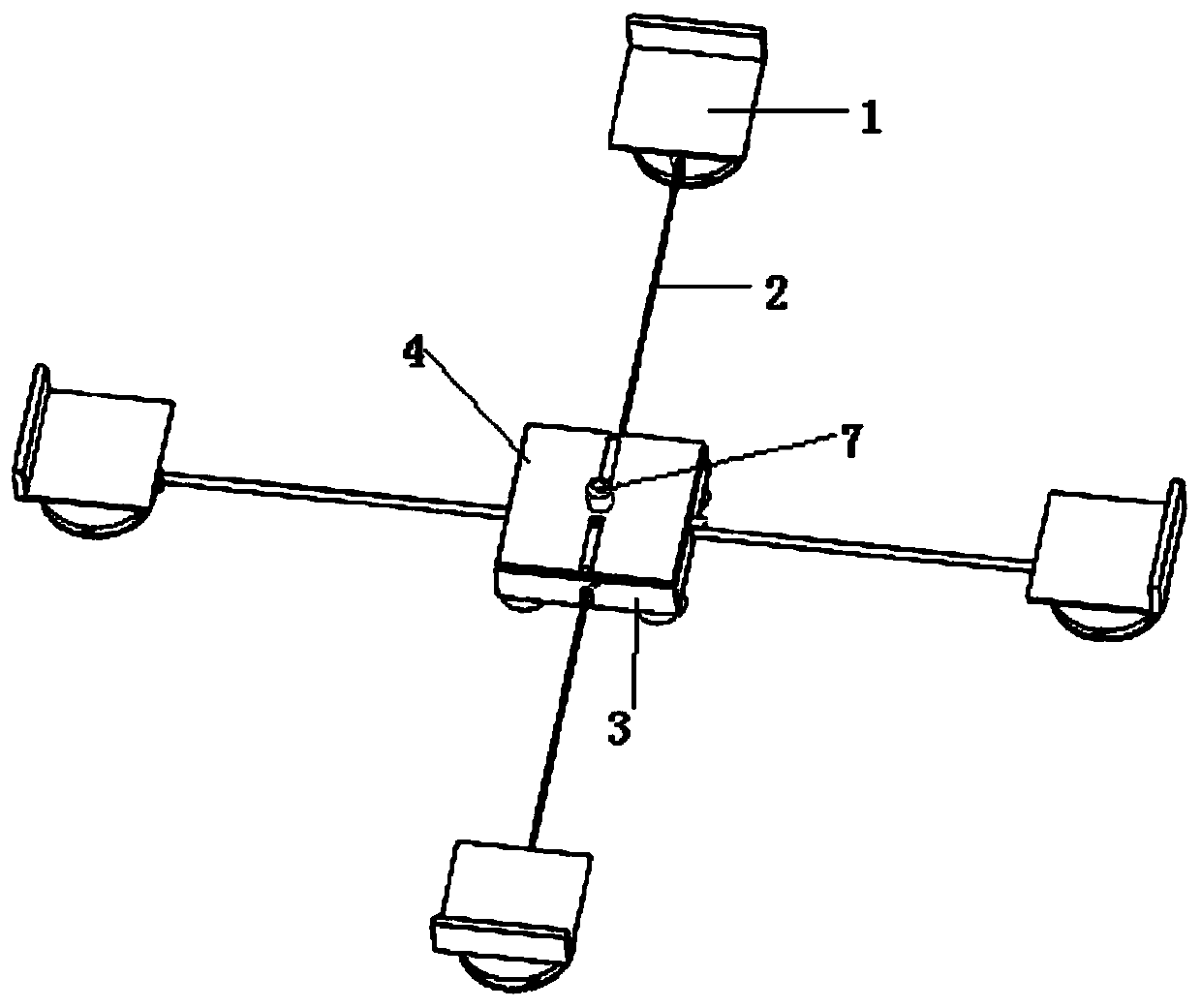

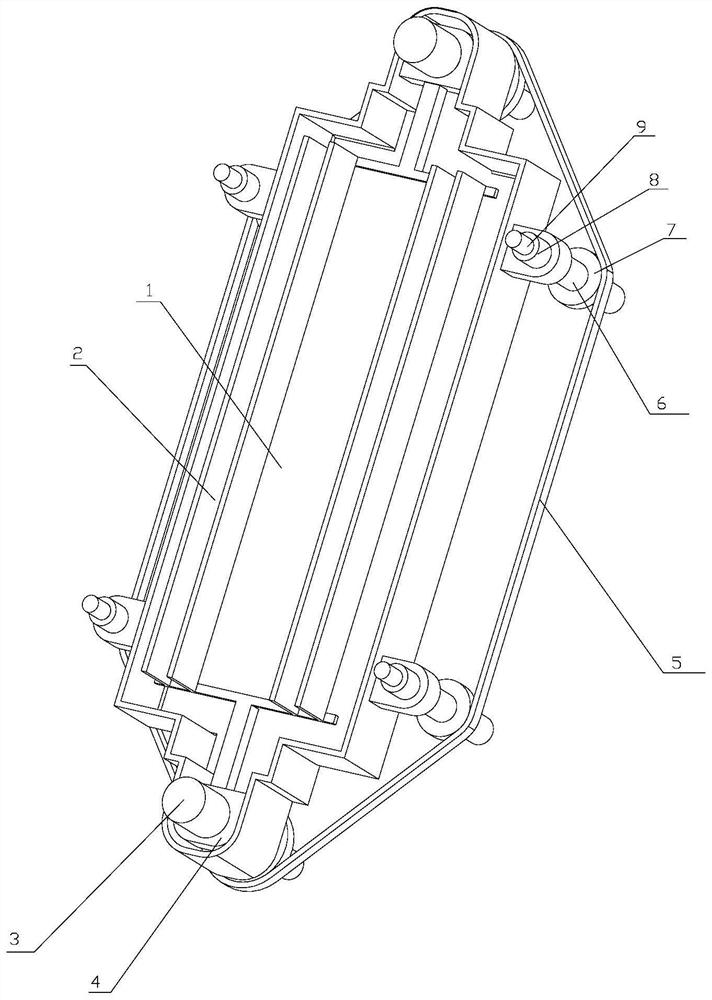

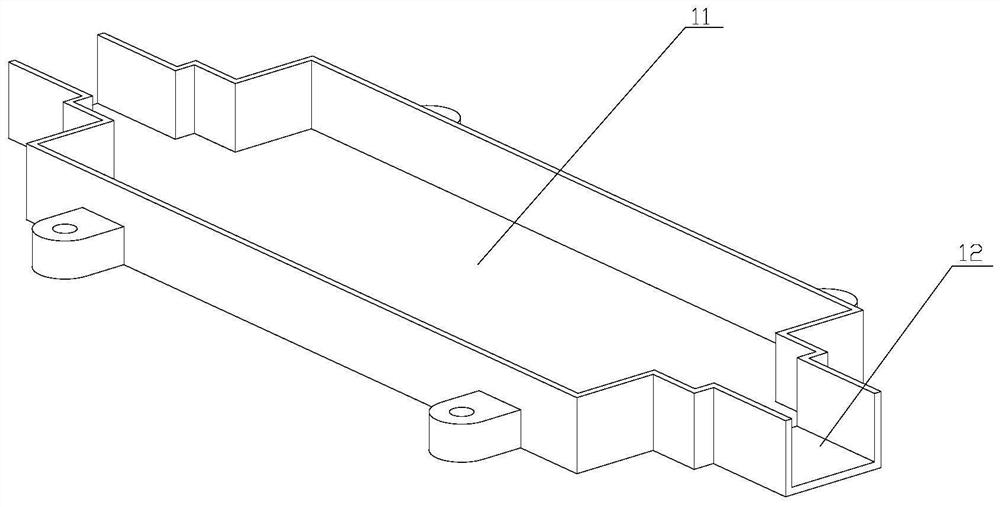

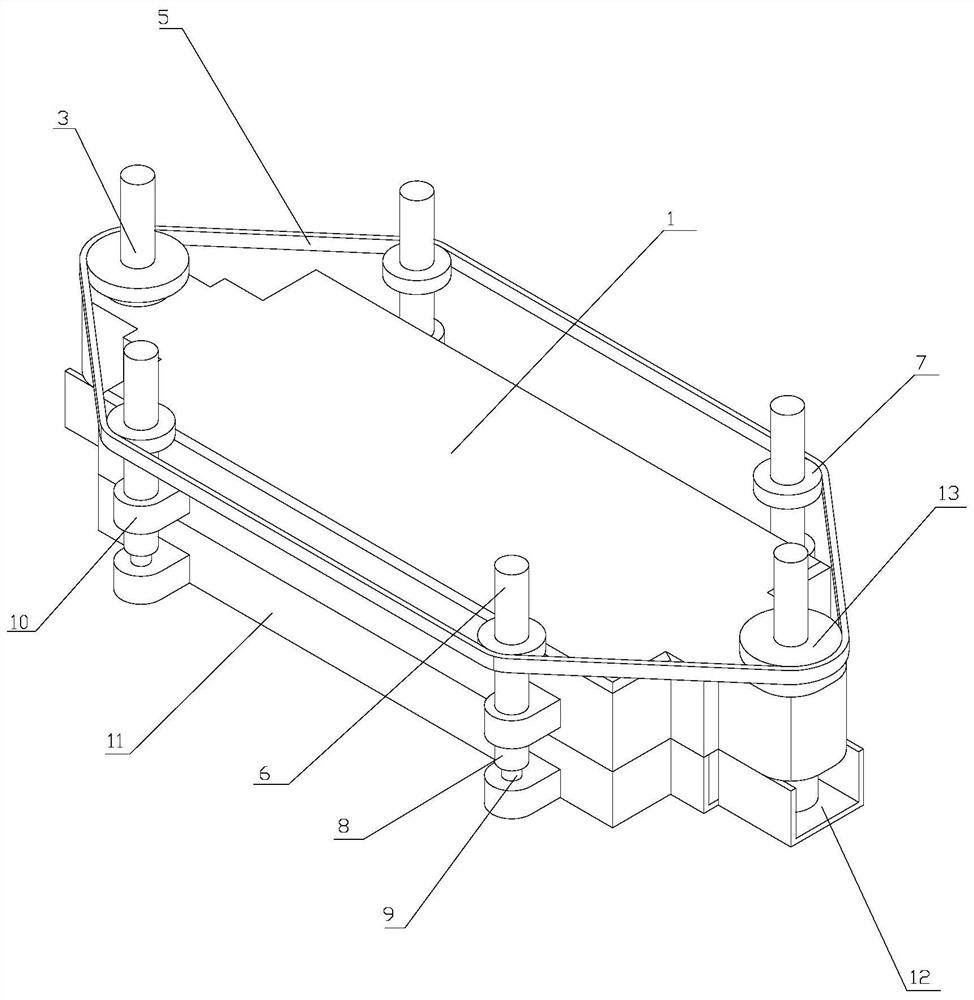

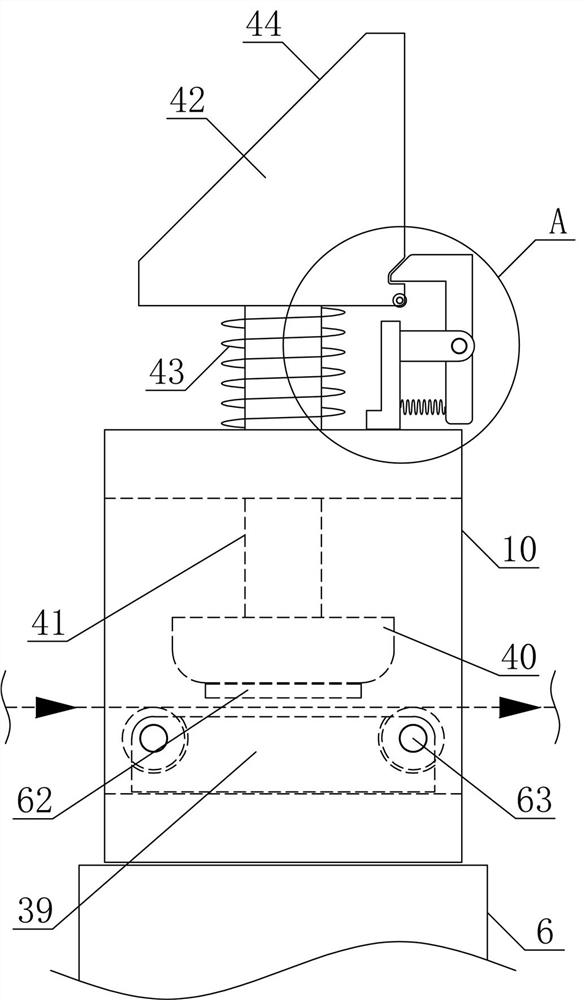

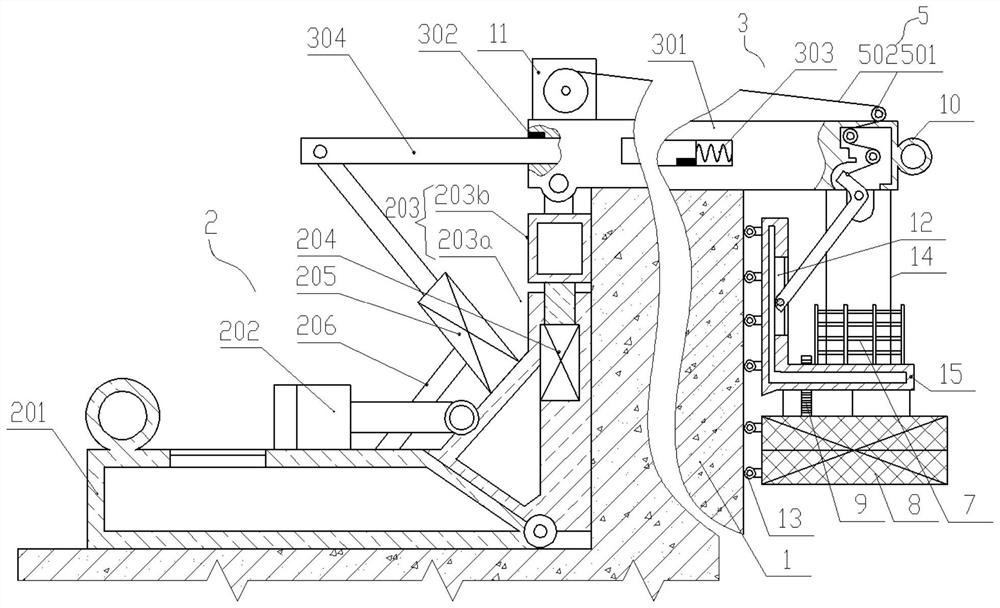

Orbit tool changer based on grooved wheel mechanism

ActiveCN103358325ALarge pose toleranceMeet the requirements for autonomous replacement of end toolsToolsManipulatorElectricityElectric power transmission

An orbit tool changer based on a grooved wheel mechanism relates to the field of in-orbit service of space robots and aims to solve the problem that the conventional orbit tool changer has a large mass and a too complex structure, so that the reliability in space operation is affected. According to the orbit tool changer, two connection ways are achieved through two sets of driving systems. As for mechanical transmission, the motor of the first set of driving system is utilized to drive gears, the gears drive a transmission shaft, and a bolt sleeve on the transmission shaft is butted with a bolt head at another end so as to serve the function. As for electric transmission, before electric connector butting, grooved wheels are driven by driver plates to realize tool end locking, that is, the second set of driving system adopts a motor to input power and adjusts time series through the grooved wheels so as to realize output of the two actions of tool end locking and electric connector butting. The orbit tool changer has higher pose tolerance capability, a compact structure, high pose tolerance and high reliability and meets the requirement of in-orbit autonomous change of end tools of the space robots.

Owner:HARBIN INST OF TECH

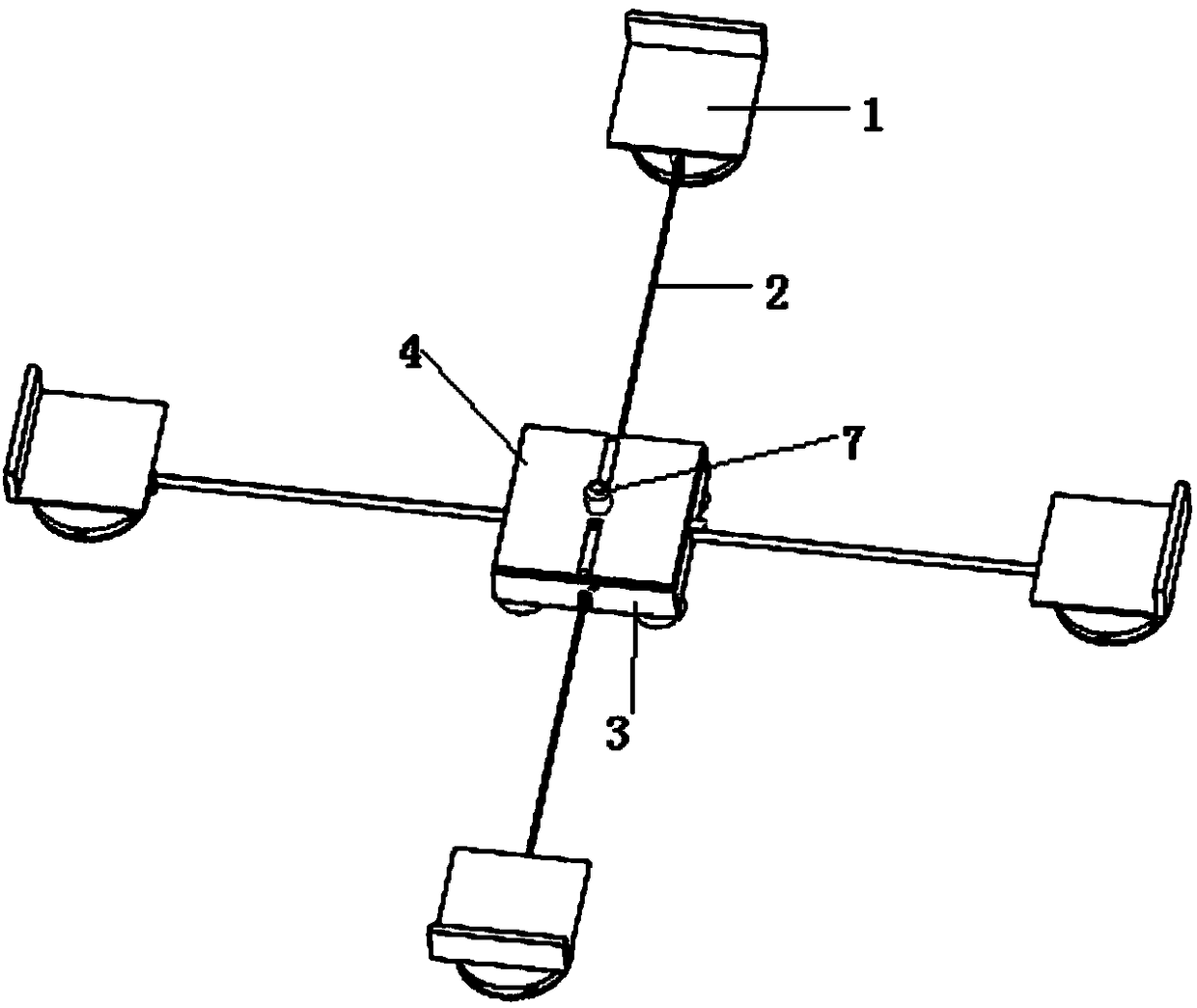

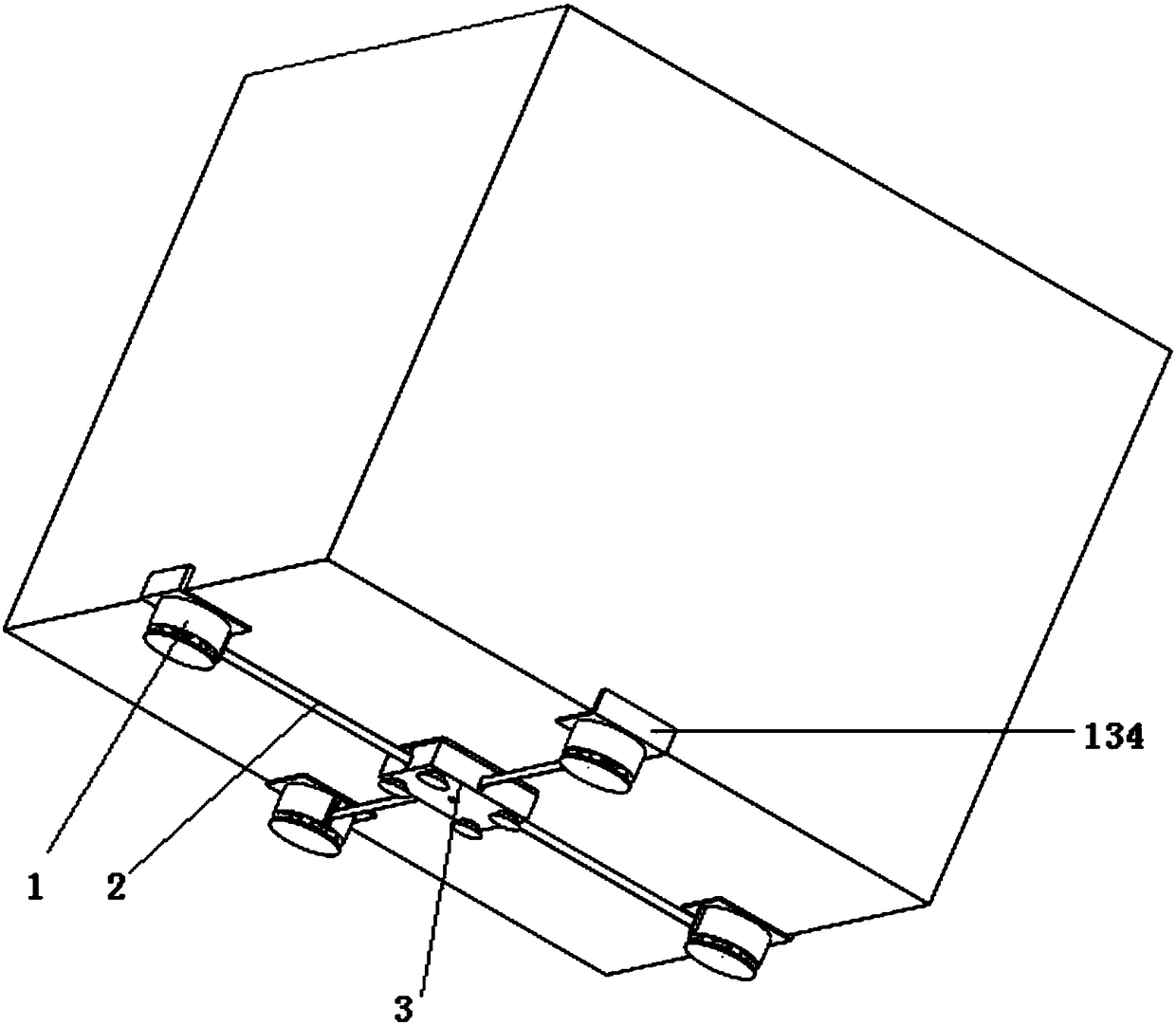

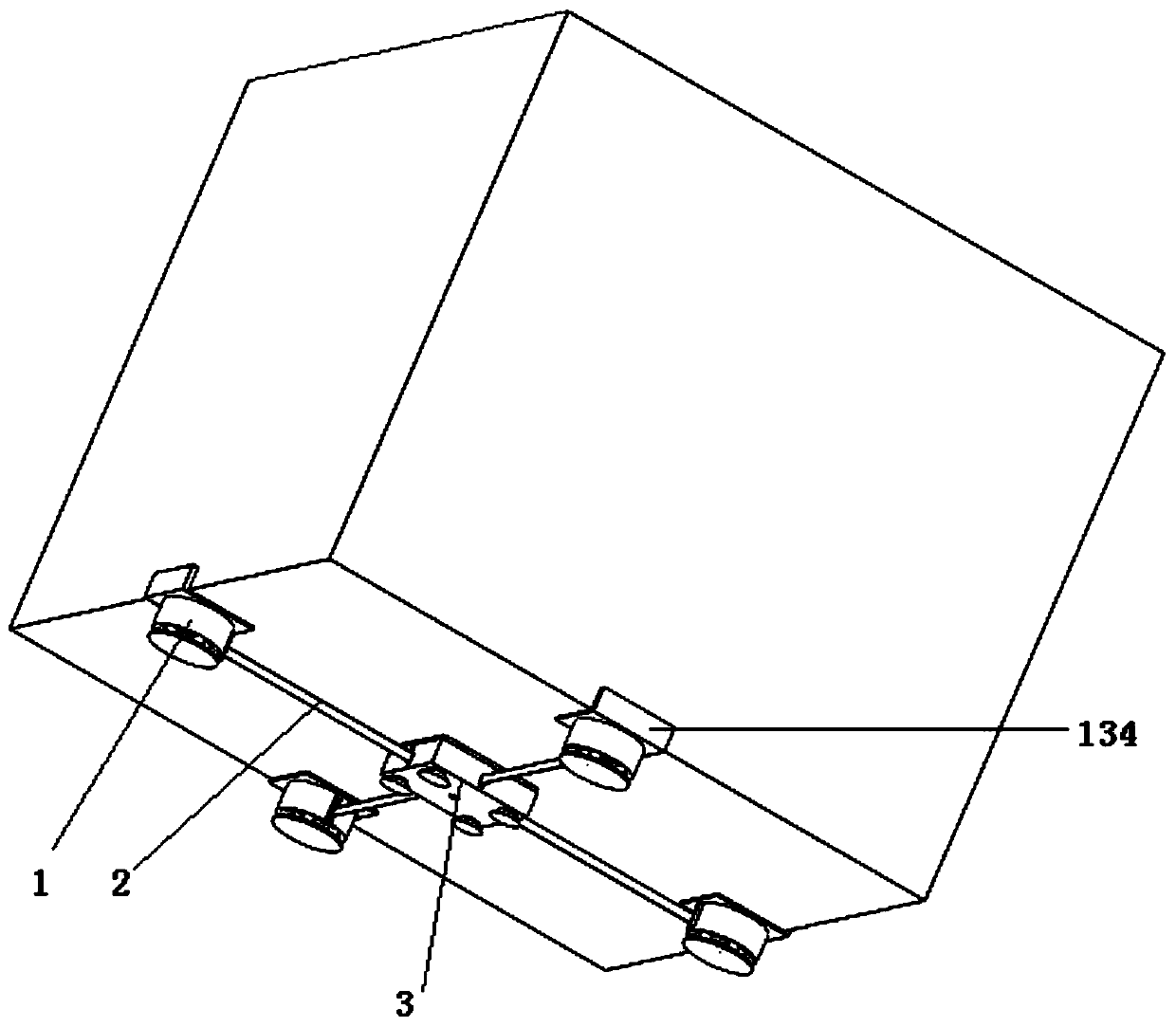

Light portable carton printer bearing protection device

The invention discloses a light portable carton printer bearing protection device. The light portable carton printer bearing protection device comprises a center fixing base and four elastic bearing bases distributed on the periphery of the center fixing base with equal angles. The elastic bearing bases and the center fixing base are connected and fixed through rubber connecting belts. The bottomface center position of a carton printer is fixed to the center fixing base, and meanwhile the four edge sides of the bottom face of the carton printer are placed on the elastic bearing bases. The light portable carton printer bearing protection device is provided with the center fixing base and the elastic bearing bases connected through the rubber connecting belts, adjustment of the stretching length of the rubber connecting belts can be achieved by controlling belt winding wheels on the center fixing base, accordingly, adjustment of the size of the bearing device is achieved, universality and convenience are achieved, and the weight is small. Meanwhile, when the light portable carton printer bearing protection device is not used, the rubber connecting belts are withdrawn through rotation of the belt winding wheels, the size of the bearing device becomes small, and carrying and transferring are convenient.

Owner:CHUZHOU CIGARETTE MATERIALS FACTORY

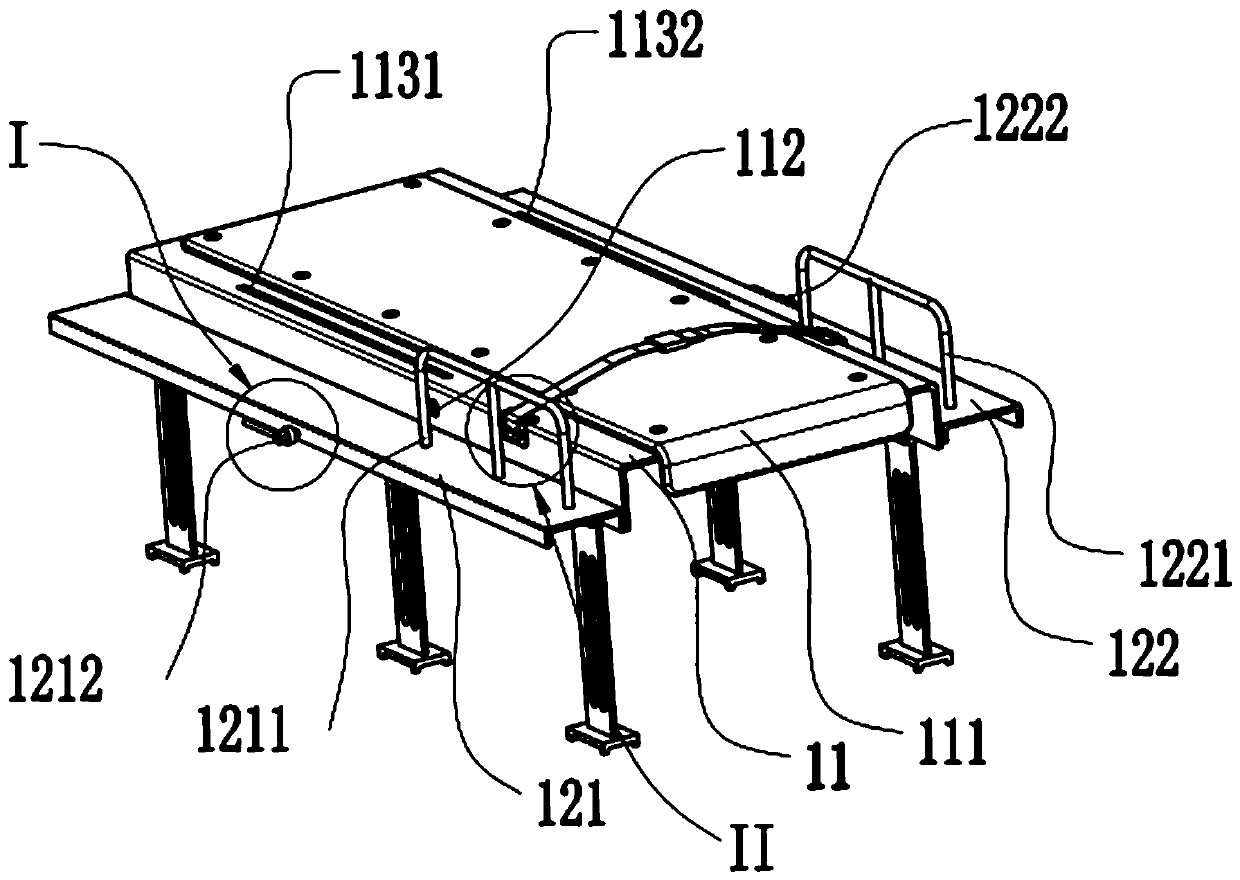

Lifting basket for tower crane

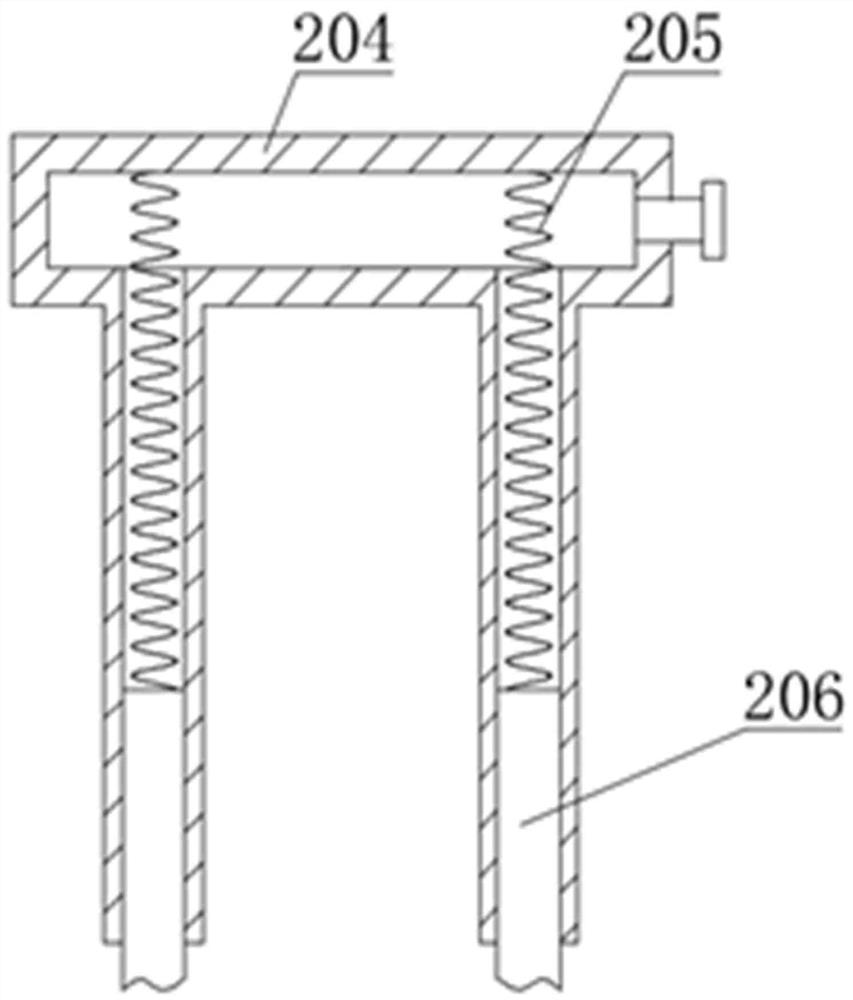

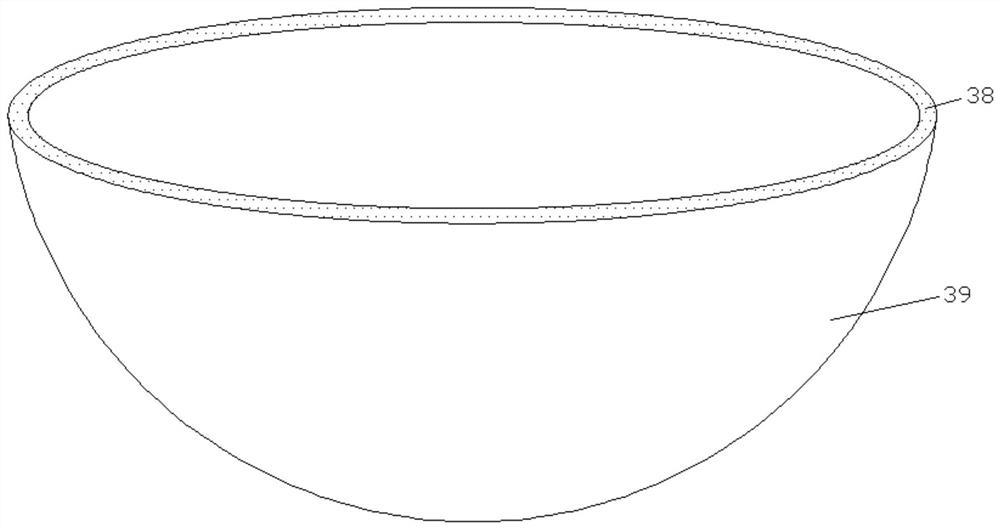

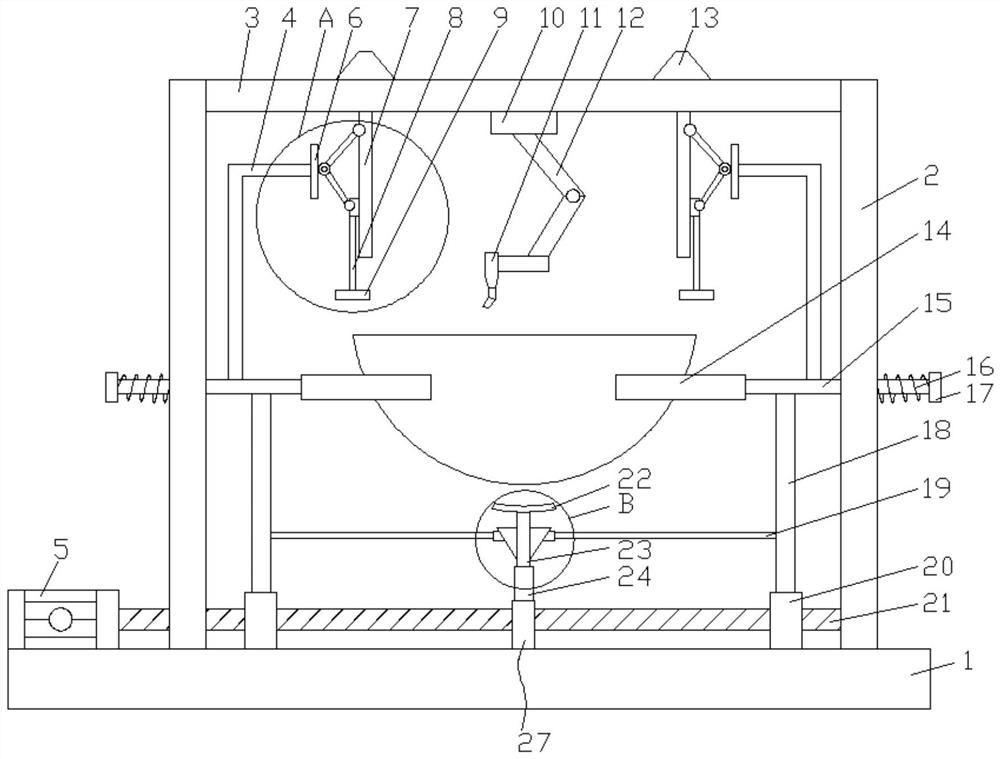

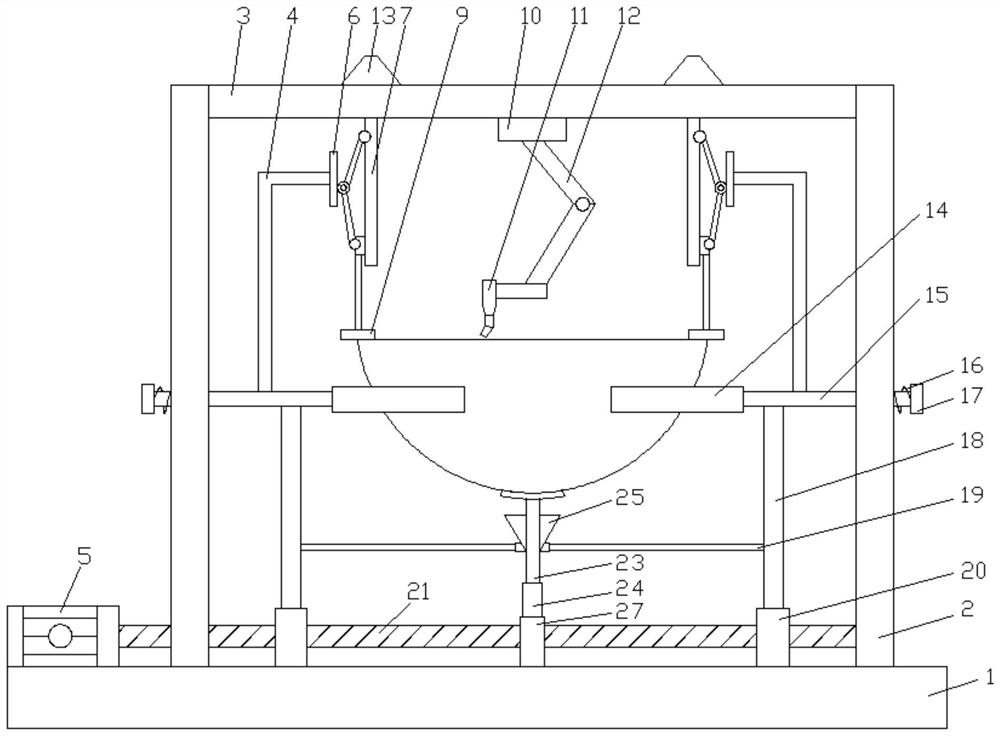

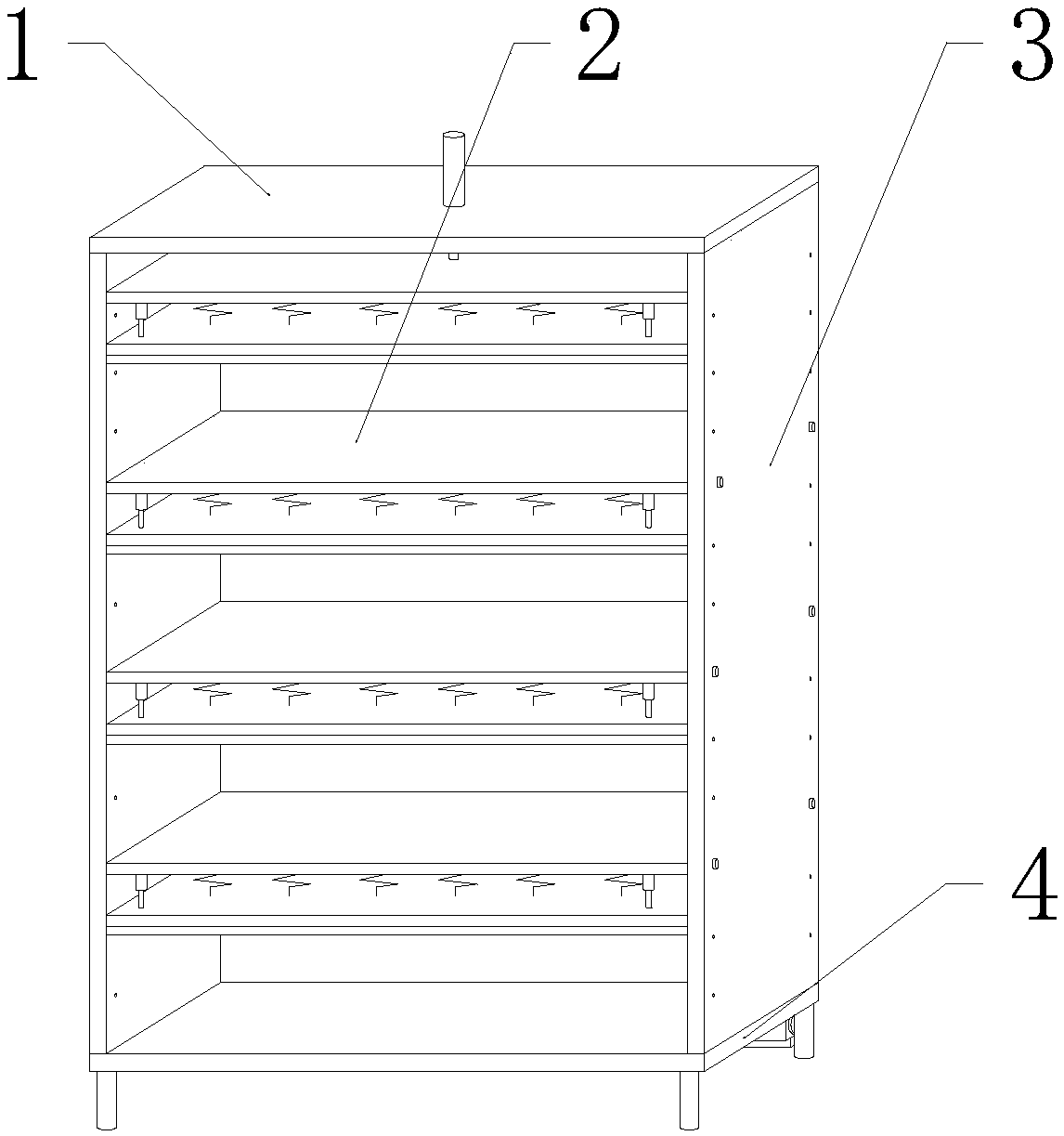

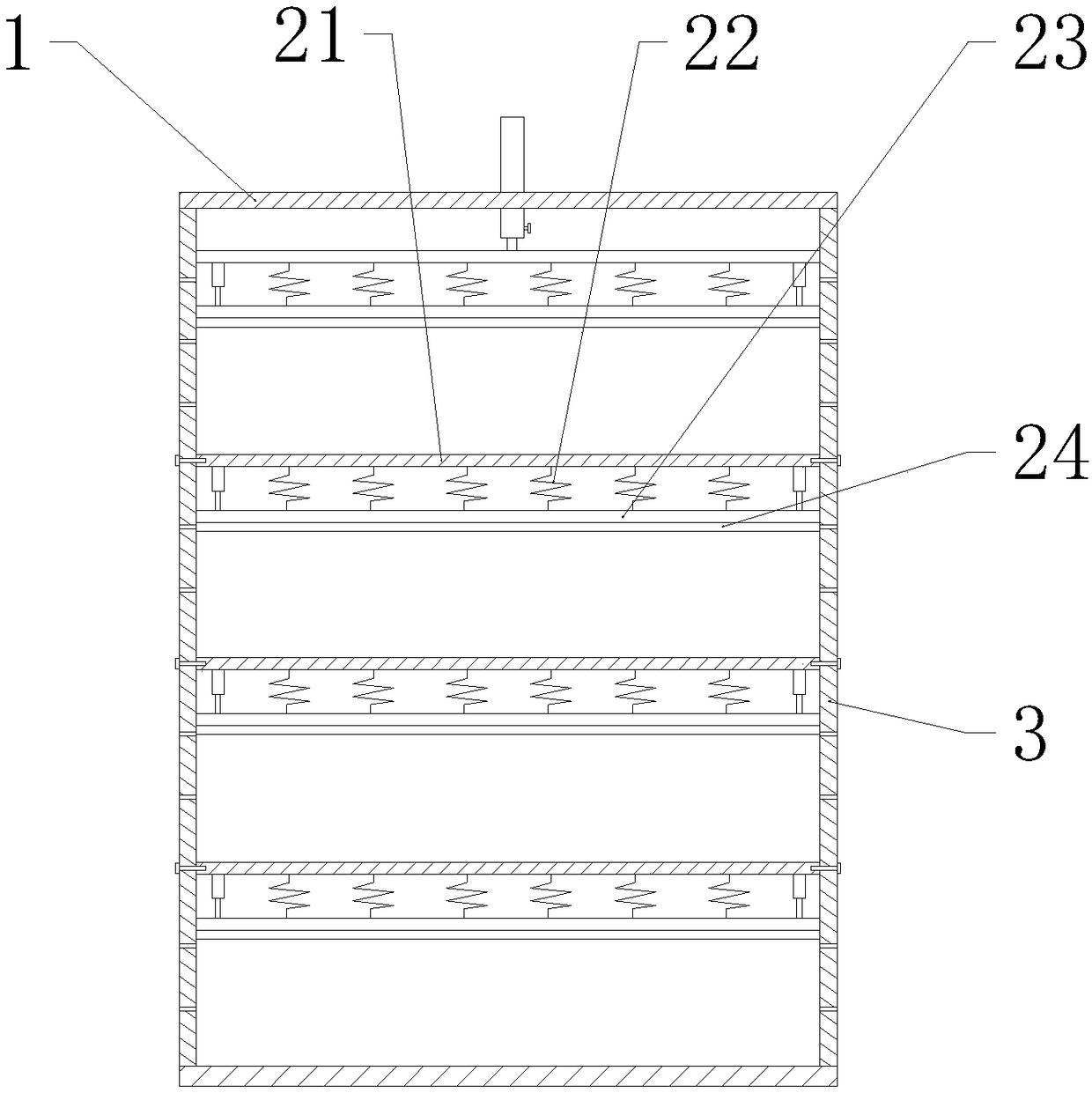

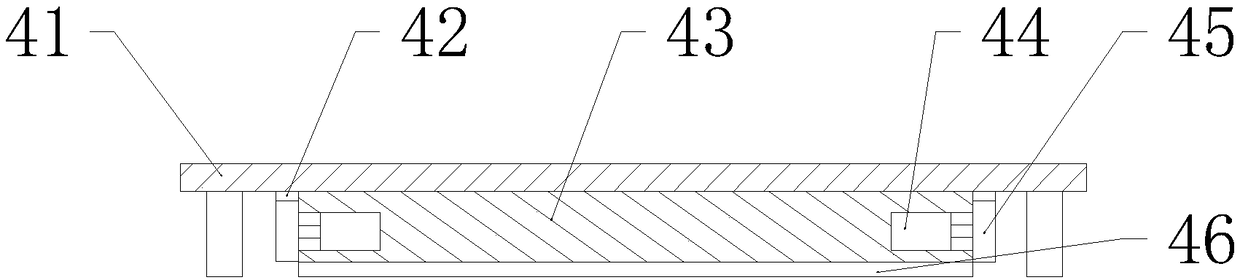

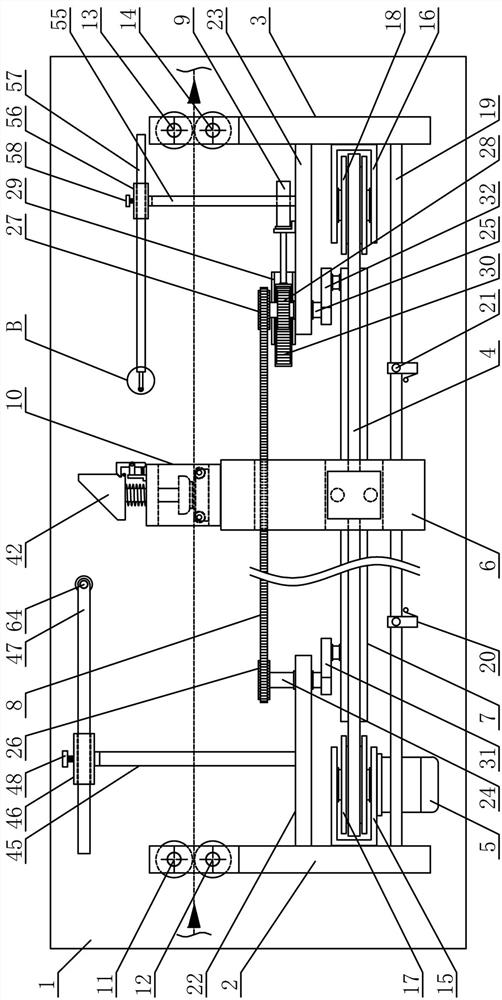

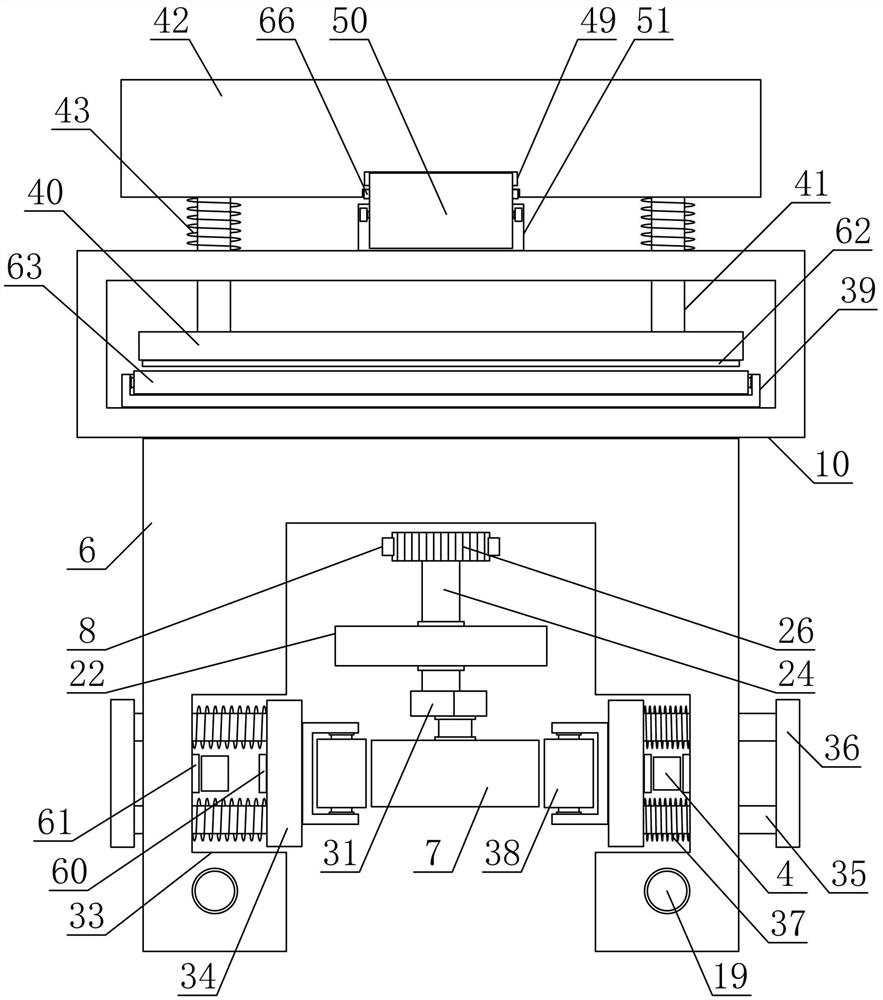

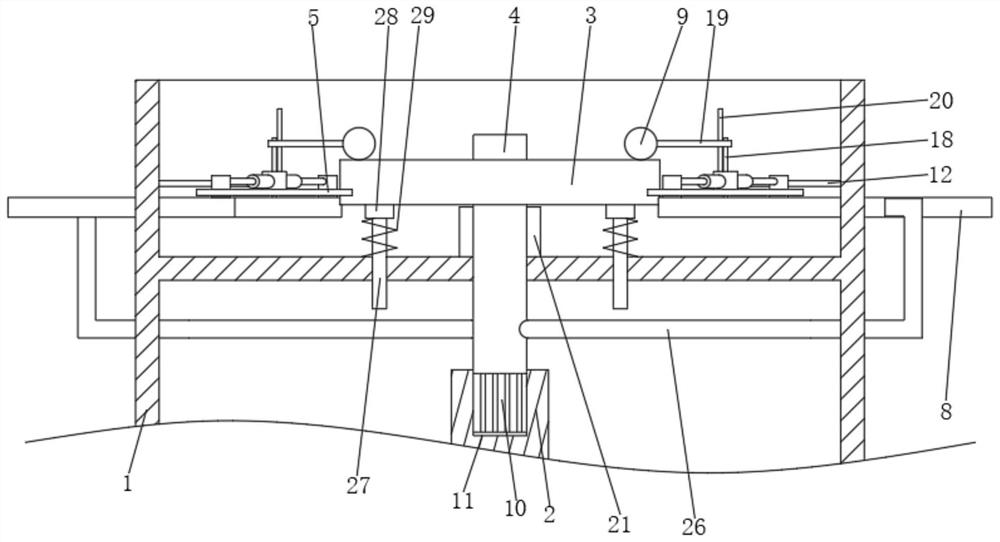

ActiveCN110104539AGuaranteed stabilityRealize compression and fixationLoad-engaging elementsEngineeringHanging basket

The invention relates to the field of crane equipment and in particular discloses a lifting basket for a tower crane. The lifting basket comprises a bottom plate, a top plate and at least two side plates connected one another to form an accommodating cavity. A storage platform arranged on the bottom plate is arranged in the accommodating cavity through an elastic supporting part; at least two compression plates are also symmetrically arranged in the accommodating cavity, and the storage platform moving downward pushes the compression plates to move to a compression material box through a transmission mechanism. According to the lifting basket for the tower crane provided by the embodiment of the invention, under the action of gravity of the material box, the storage platform moves downwardto further push the compression plate to compress and fix the material box under the joint action of the transmission mechanism, so that the stability of the material box is guaranteed. When the hanging basket swings, the material box generates a pressure to the storage platform, so that the compression plate further compresses and fixes the material box, and therefore, the stability of the material box in a using process of the hanging basket is guaranteed.

Owner:福建开辉机械工程有限公司

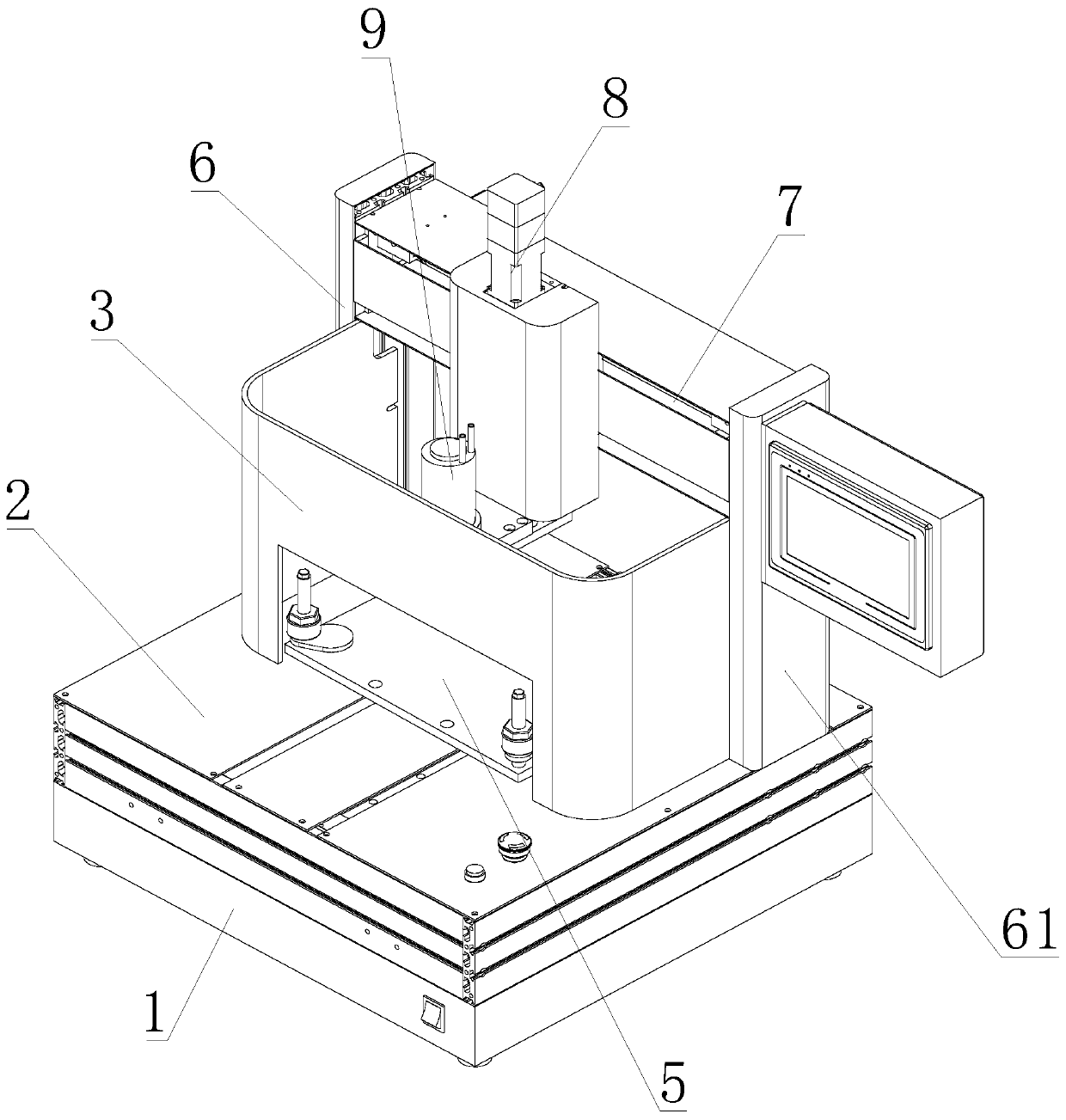

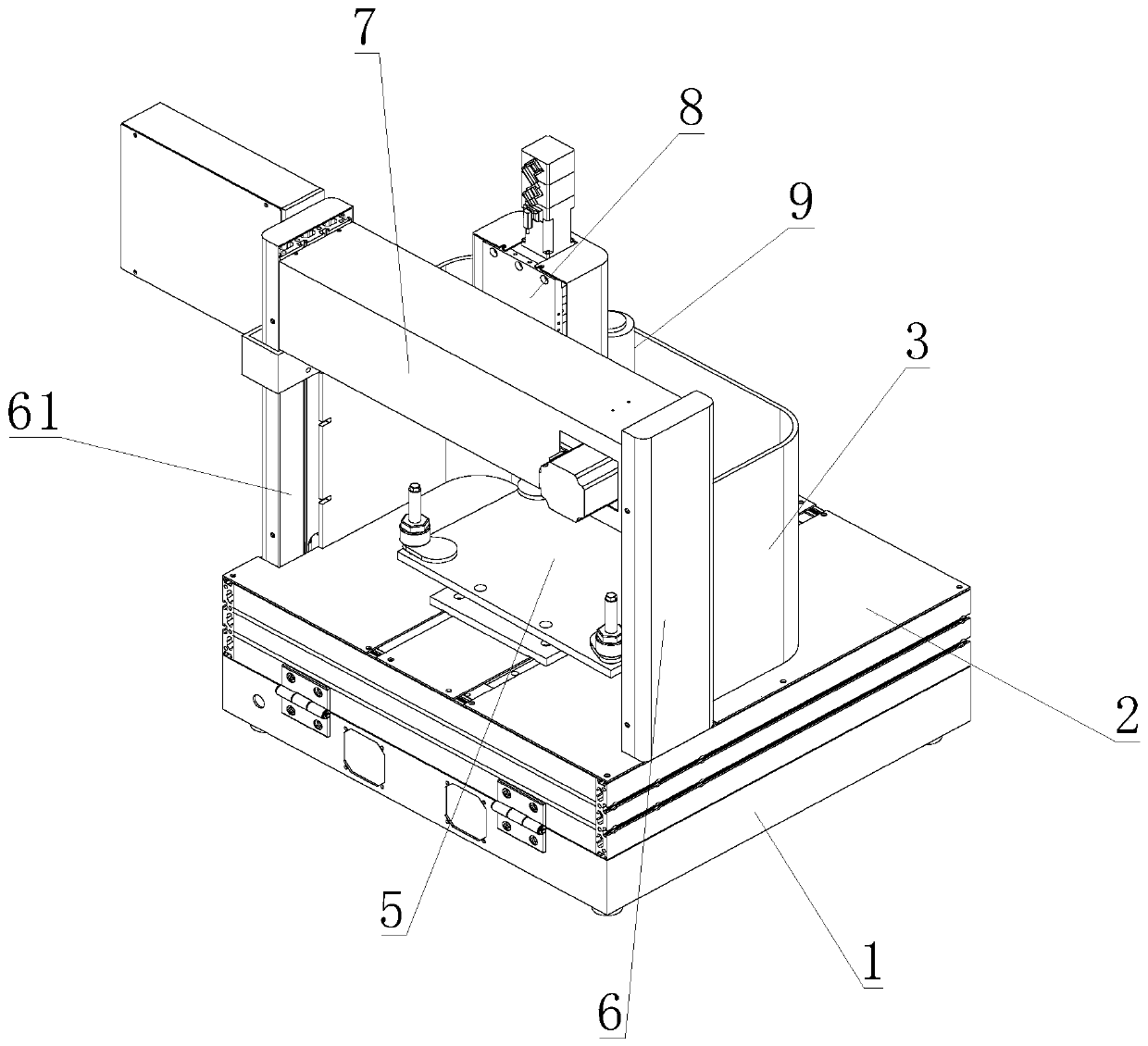

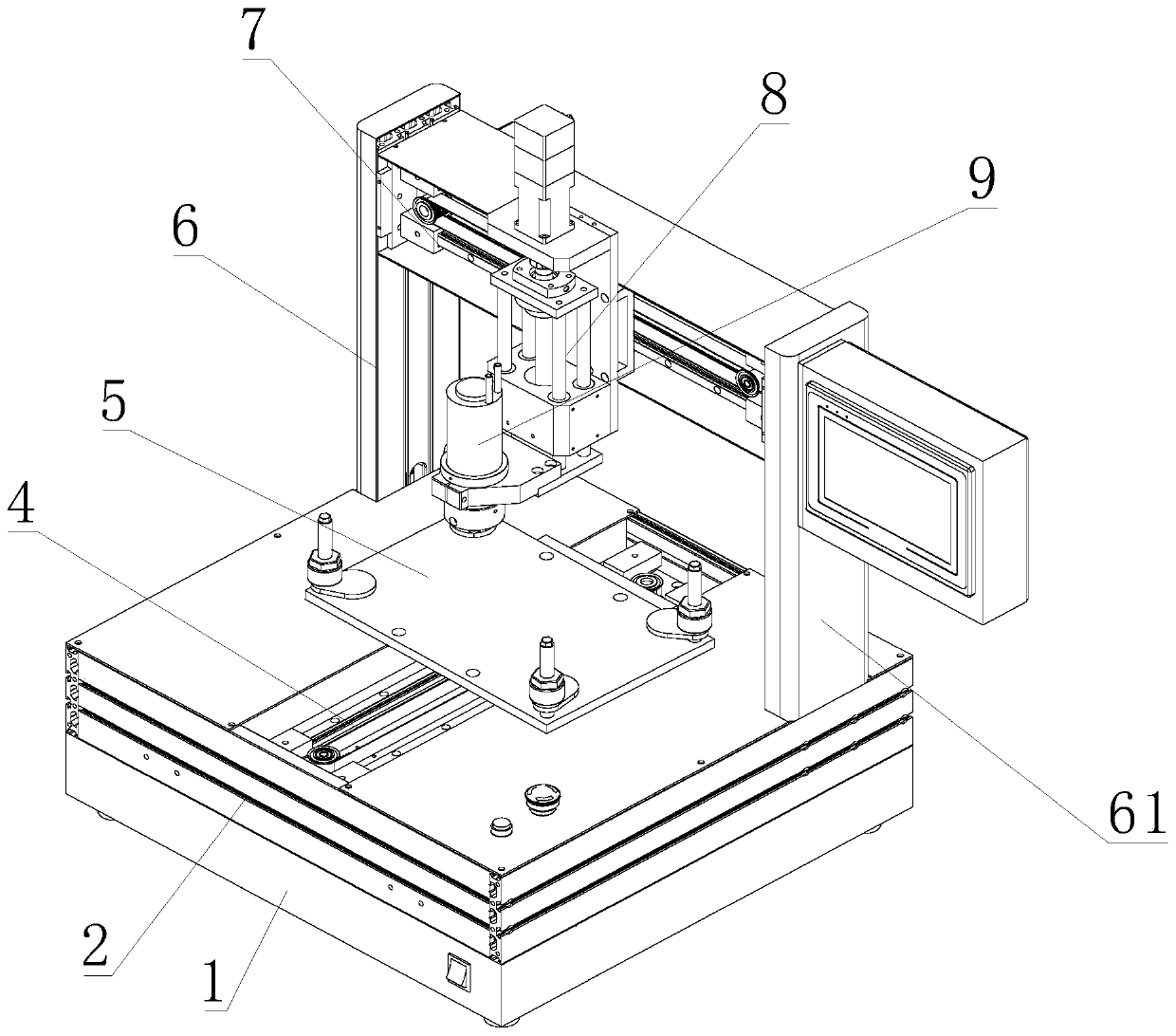

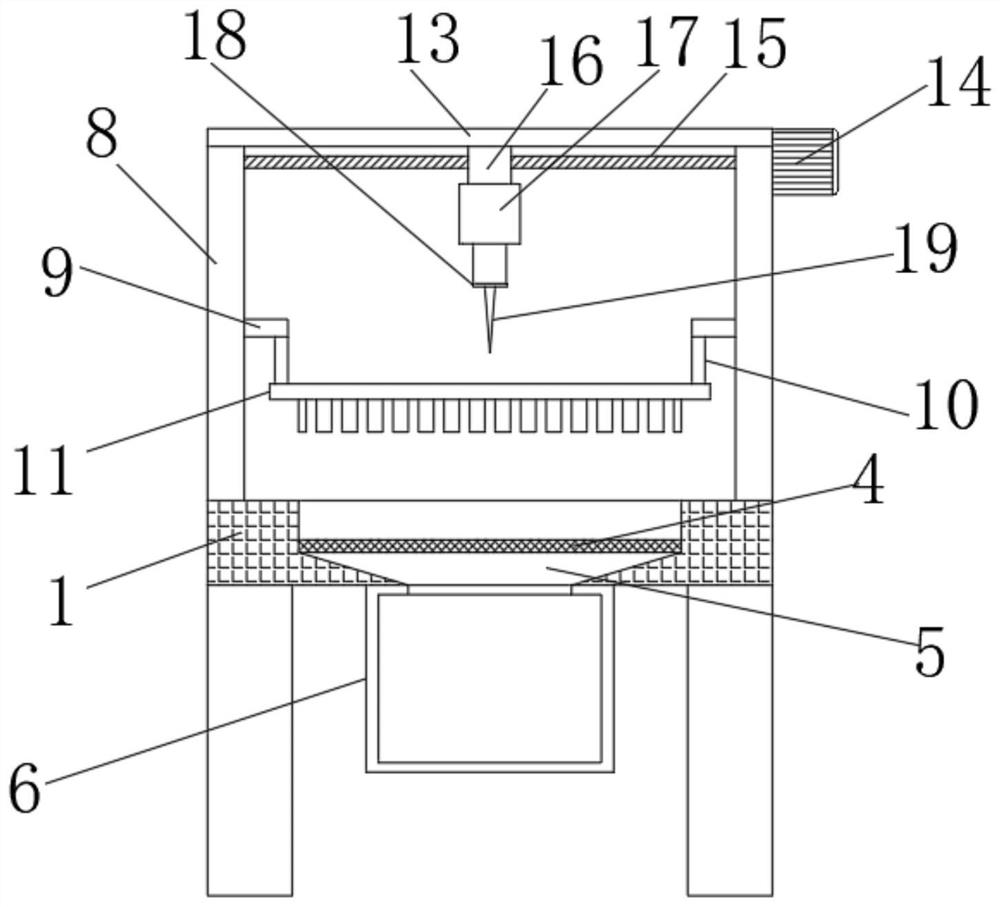

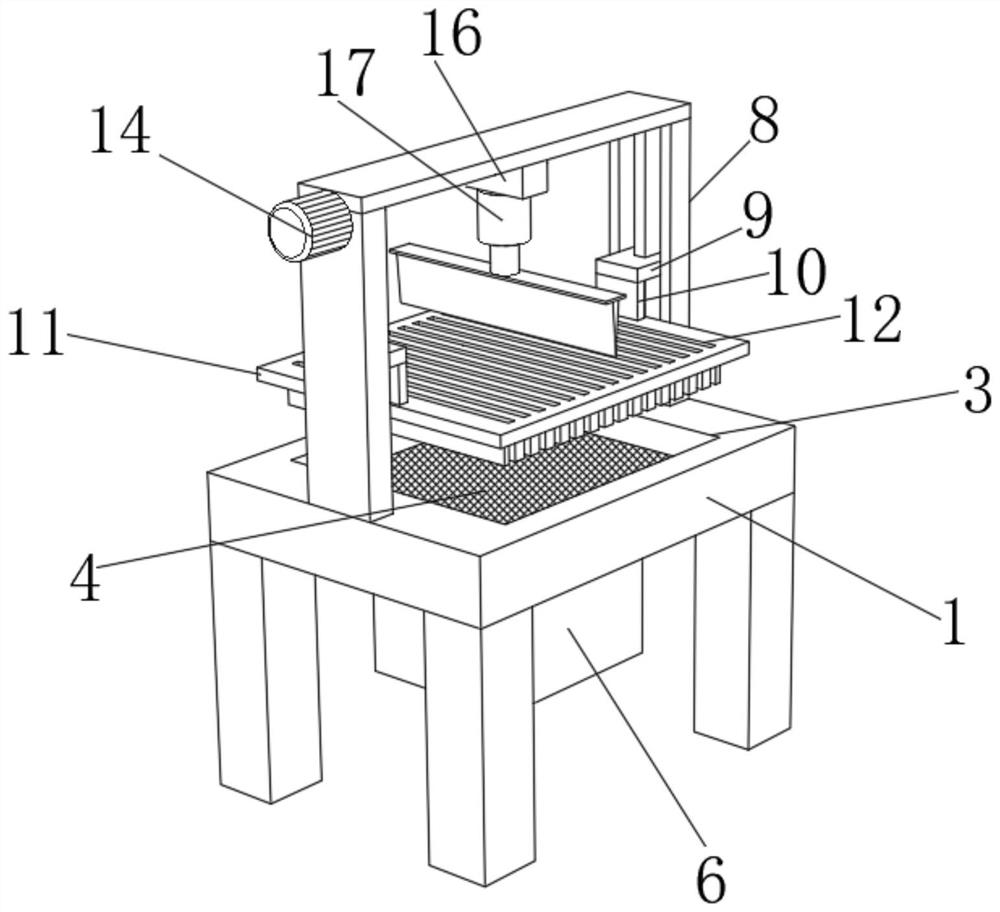

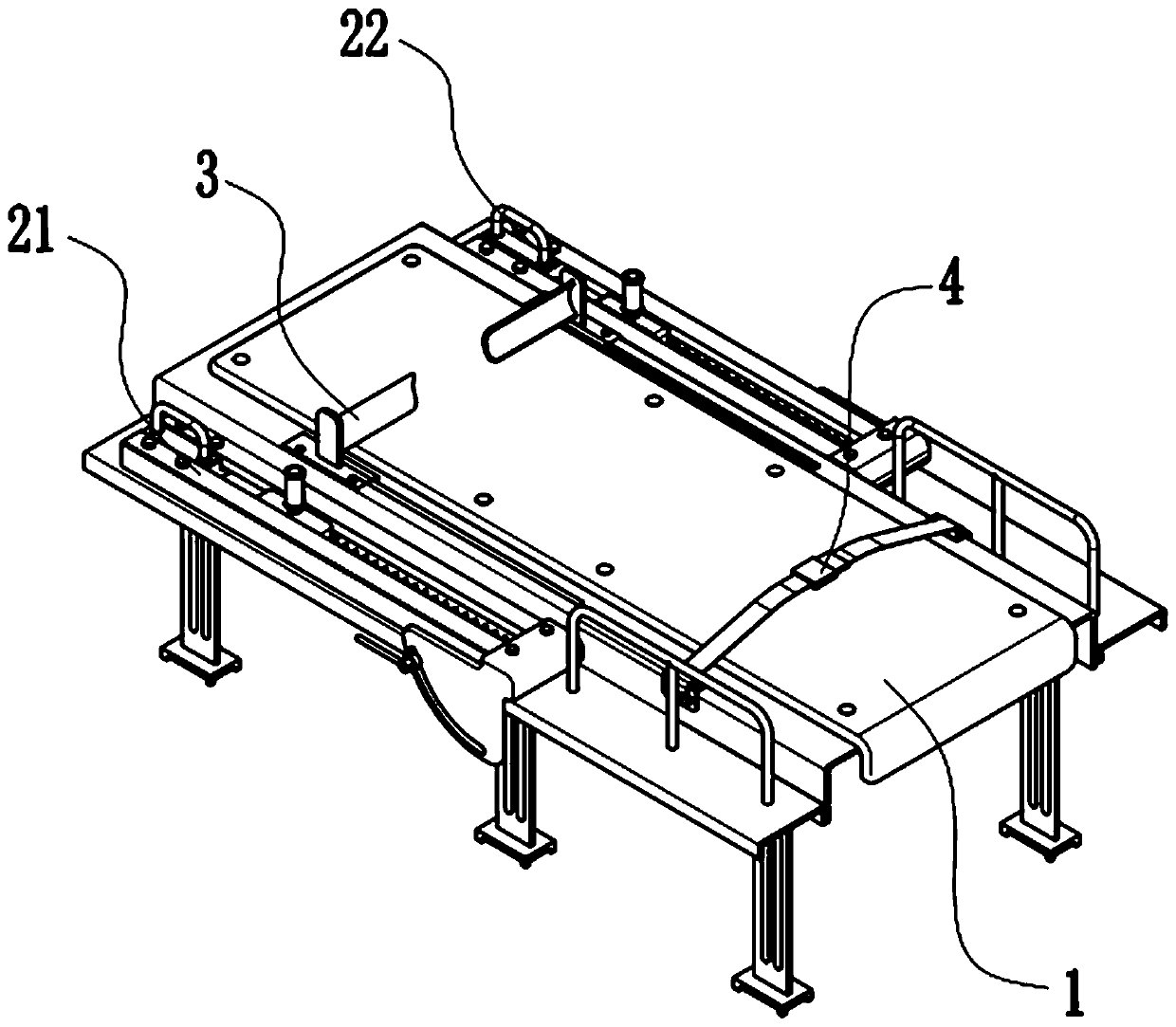

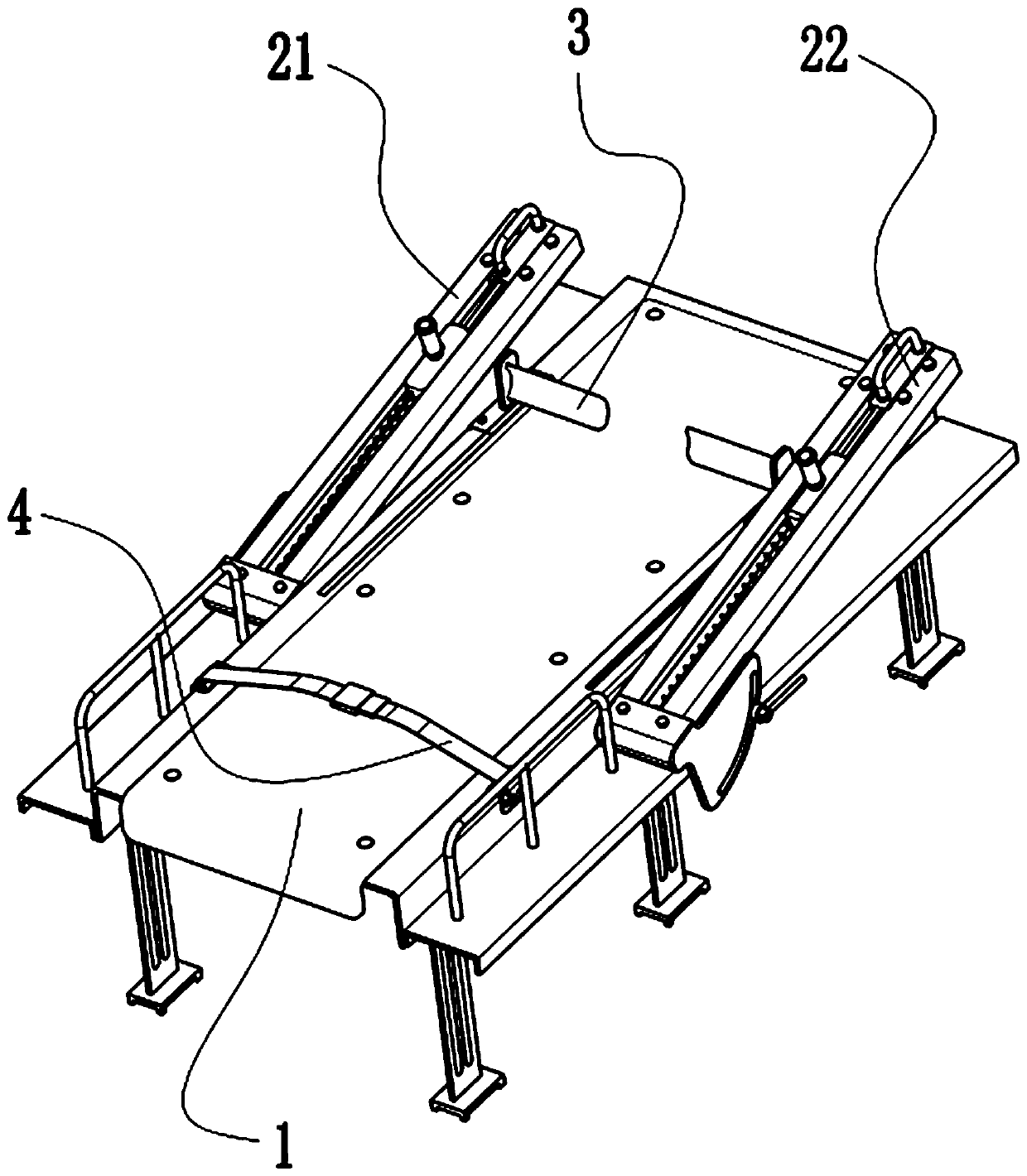

Fast cutting device for furniture plate processing and cutting method of cutting device

InactiveCN110774372AEasy to observeQuick cutProfiling/shaping machinesManufacturing engineeringBraced frame

The invention discloses a fast cutting device for furniture plate processing. The cutting device can solve the problem that most of existing furniture plate cutting is manual cutting, only one direction can be cut each time when cutting, workload is large, the cutting efficiency is low, and in the existing plate cutting process, the staff often need to take the plate manually, the fixing effect ofthe plate is low, the cutting accuracy is affected, and the staff are prone to being damaged in the cutting process. The cutting device comprises a bottom frame, an aluminum profile support frame anda Y-axis drive mechanism, the aluminum profile support frame is connected above the bottom frame, the aluminum profile support frame is internally provided with an X-axis drive mechanism, a first side support frame and a second side support frame are respectively arranged on both sides of the upper end of the aluminum profile support frame, and the Y-axis drive mechanism is connected between thefirst side support frame and the second side support frame.

Owner:安徽持家汉家居工艺品有限公司

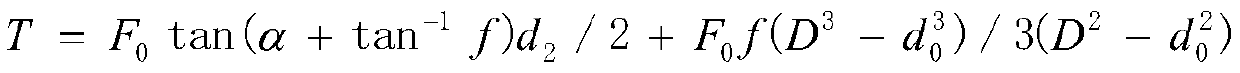

Method for improving connection reliability of composite-material-based connecting member

ActiveCN110308055ASolve the problem that the preload of the connector cannot be directly measured through the testRealize compression and fixationMaterial strength using steady torsional forcesEngineeringStrain gauge

Provided in the invention is a method for improving connection reliability of a composite-material-based connecting member. The method comprises: step one, inserting a composite-material-based connecting member that is a bolt and has a thread light column section pasted with a strain gauge into a composite-material-based connecting member connection hole; step two, fixing a bolt head of the connecting member, screwing a nut into a bolt thread, and screwing the nut tightly preliminarily; step three, screwing the nut tightly based on a torque value predetermined by the test and monitoring a strain value of the strain gauge; step four, replacing a connecting member with the same specification, repeating the operation at least five times, and recording torque values and strain values monitoredin all tests; step five, based on the test values, determining a finite element simulation model meeting the precision requirement; step six, establishing a mapping relationship model between a tightening torque and a pre-tightening force; and step seven, according to the mapping relationship model of the tightening torque and the pre-tightening force, calculating a tightening torque corresponding to the pre-tightening force that is needed to be applied in the current composite-material-based connecting member connection process and carrying out screwing based on the tightening torque to realize reliable connection.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

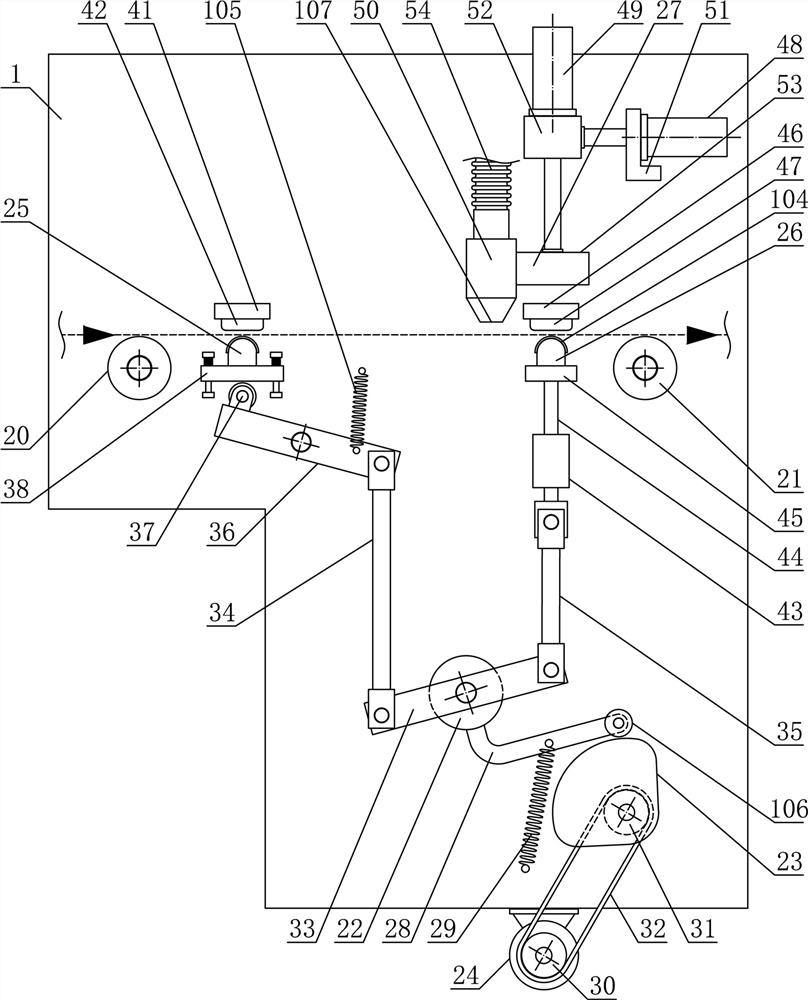

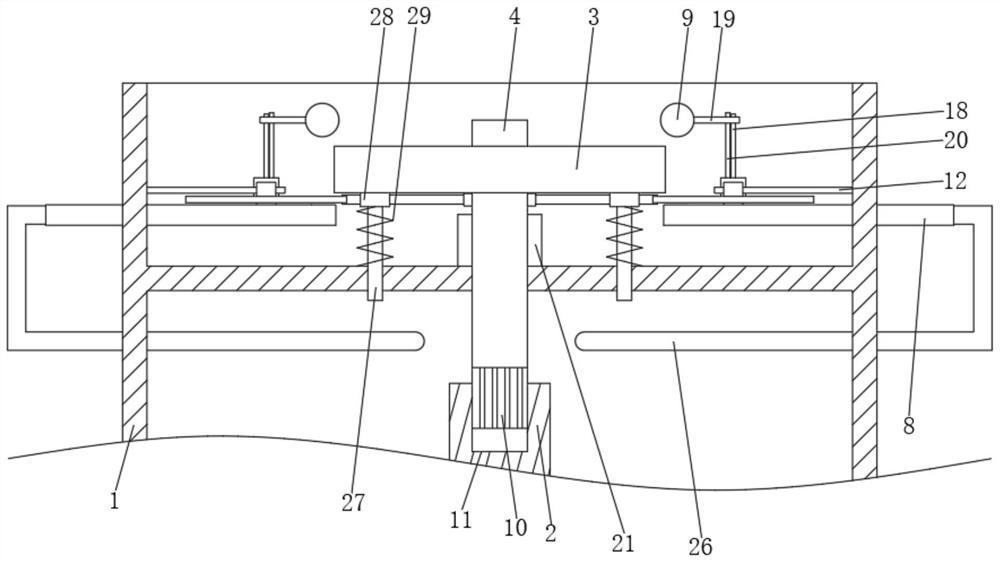

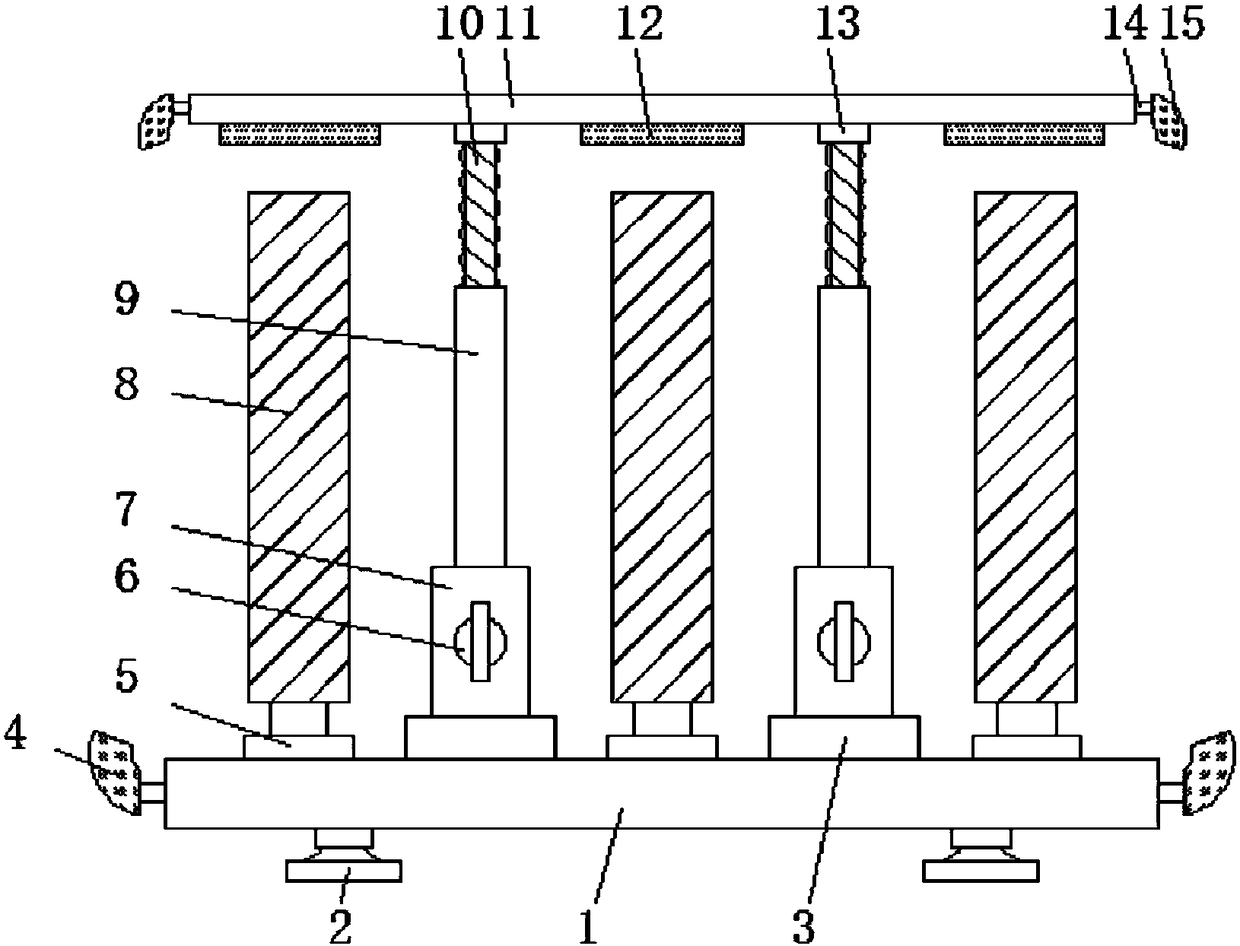

Tension detection mechanism for yarn strength

InactiveCN114047063ARealize compression and fixationEasy to installMaterial strength using tensile/compressive forcesEngineeringStructural engineering

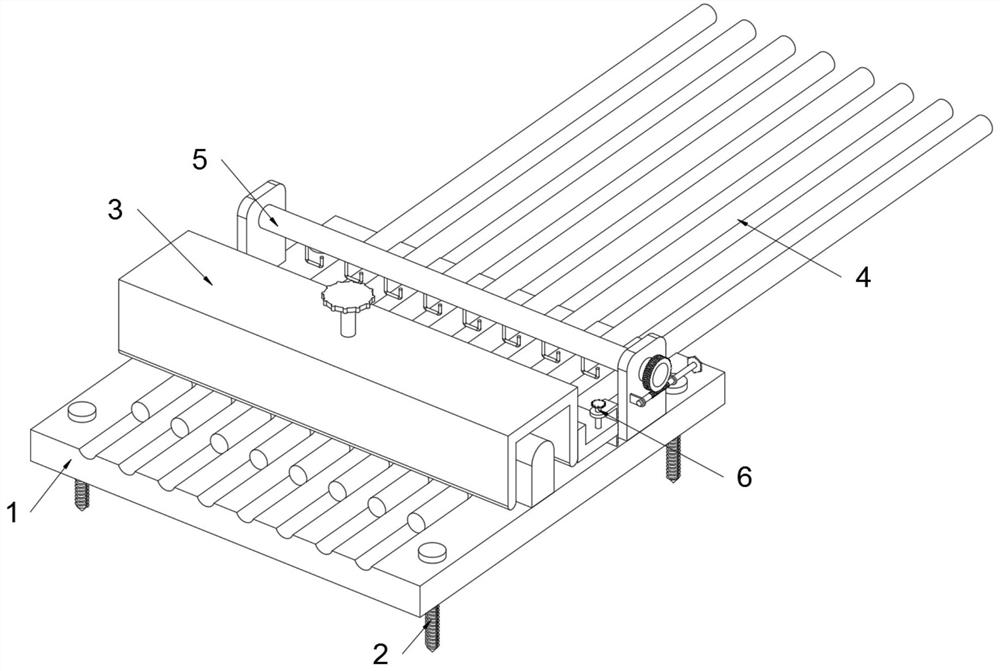

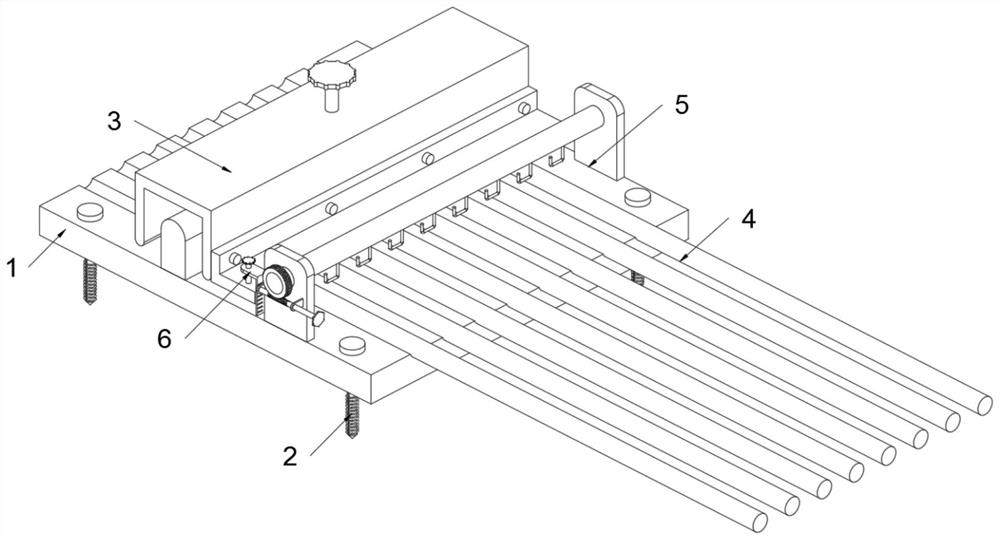

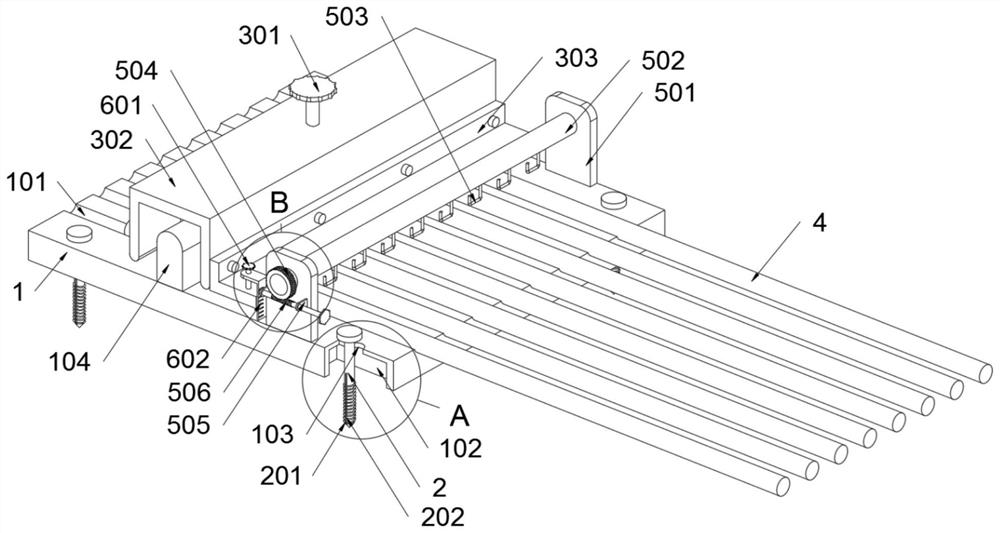

The invention discloses a tension detection mechanism for yarn strength. The mechanism comprises a base, a plurality of winding plates are fixedly mounted on the base, a sliding groove is formed in the base between adjacent winding plates, a pressing head is slidably clamped in the sliding groove, a pressure applying mechanism is mounted in the base, the pressure applying mechanism is connected with the pressing head, a tension sensor is fixedly mounted on the outer wall of one winding plate, clamping mechanisms are installed at the two ends of the tension sensor, a display screen is fixedly installed on the base, and a connecting line is installed between the display screen and the tension sensor. Yarn is wound on the multiple winding plates and sequentially penetrates through the multiple pressing heads, then the two ends of the yarn are fixedly clamped to the two ends of the tension sensor through the clamping mechanisms respectively, and the multiple pressing heads are driven by the pressure applying mechanism to synchronously move, so the multiple pressing heads evenly apply pressure to the yarn in a segmented mode till the yarn is broken; and the yarn tension strength can be detected through the tension sensor, the detection is convenient, the force application strength can be slowly applied, and the detection precision is high.

Owner:安徽汀州工程科技有限公司

Sorting system after molding of fine ceramic product

ActiveCN110524708ARealize processingAchieve recyclingGrinding carriagesGrinding drivesMetalMaterials science

The invention discloses a sorting system after the molding of a fine ceramic product. The system comprises a rapid cooling device after the fine ceramic molding, a drying device for producing the fineceramic sealed with the metal, a fine ceramic grinding device witha dust collection function, a fine ceramic polishing device, a storing, taking and placing device for producing the fine ceramic sealed with the metal and a conveying device for producing and machining the fine ceramic. Through the reasonable arrangement and cooperation of the above several processes, the finished ceramic productsare sorted, and the percent of pass of the products is increased.

Owner:湖南福易达电子科技有限公司

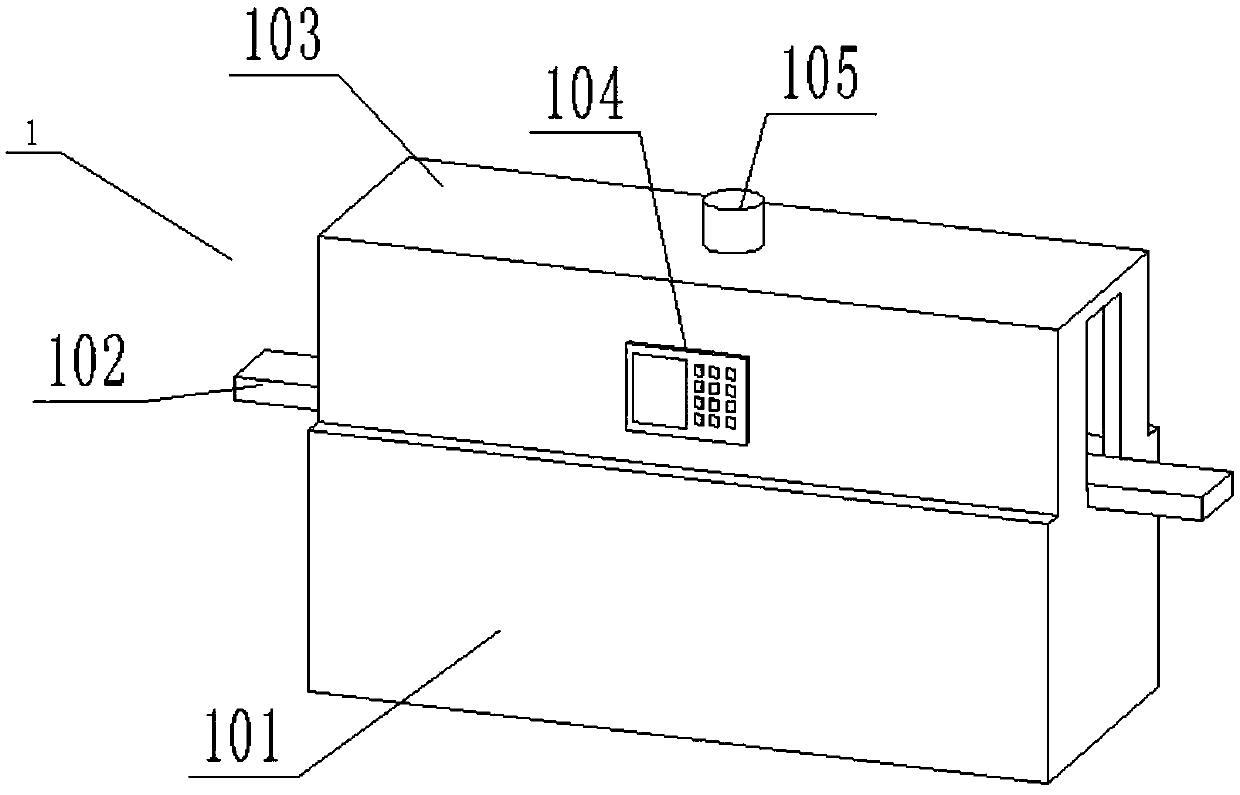

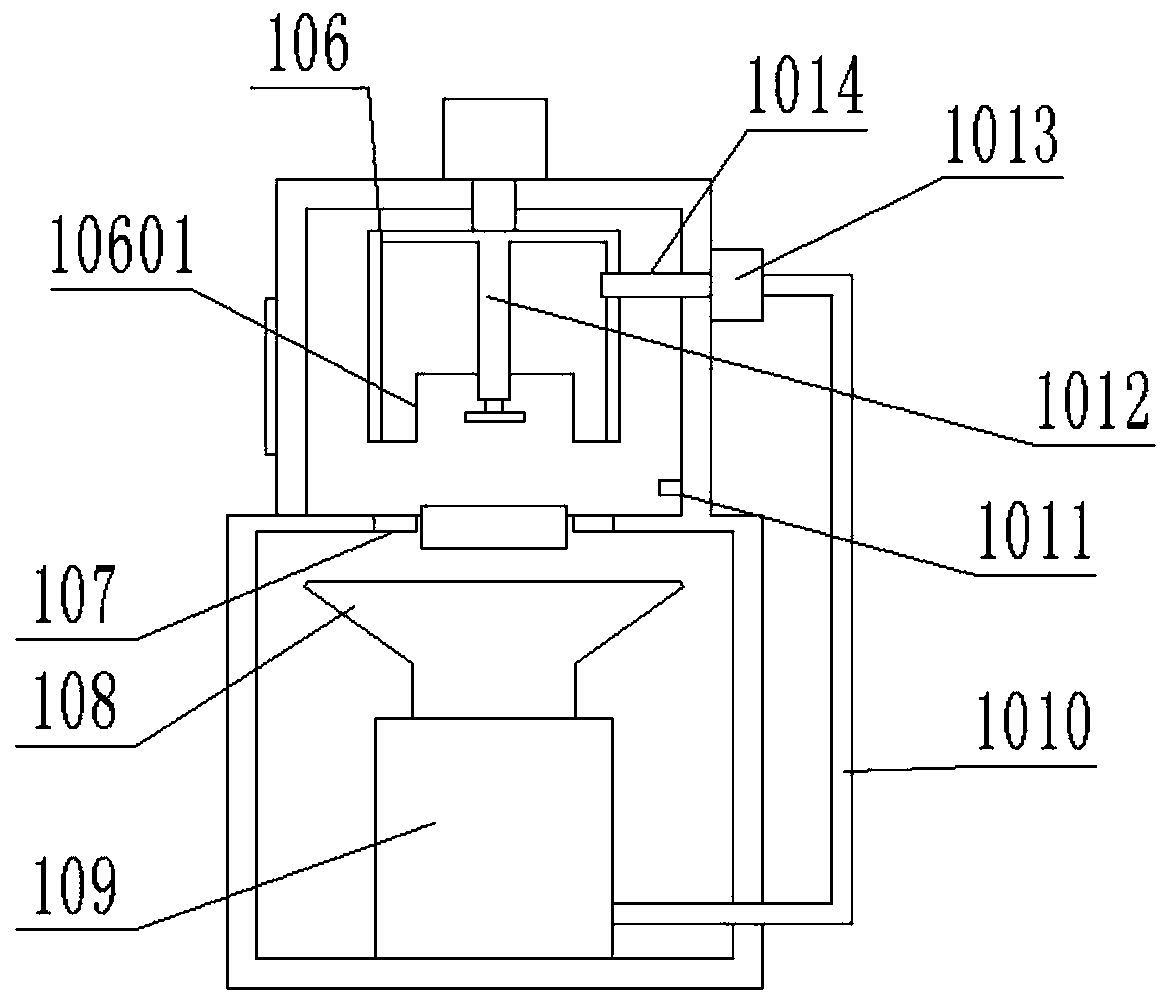

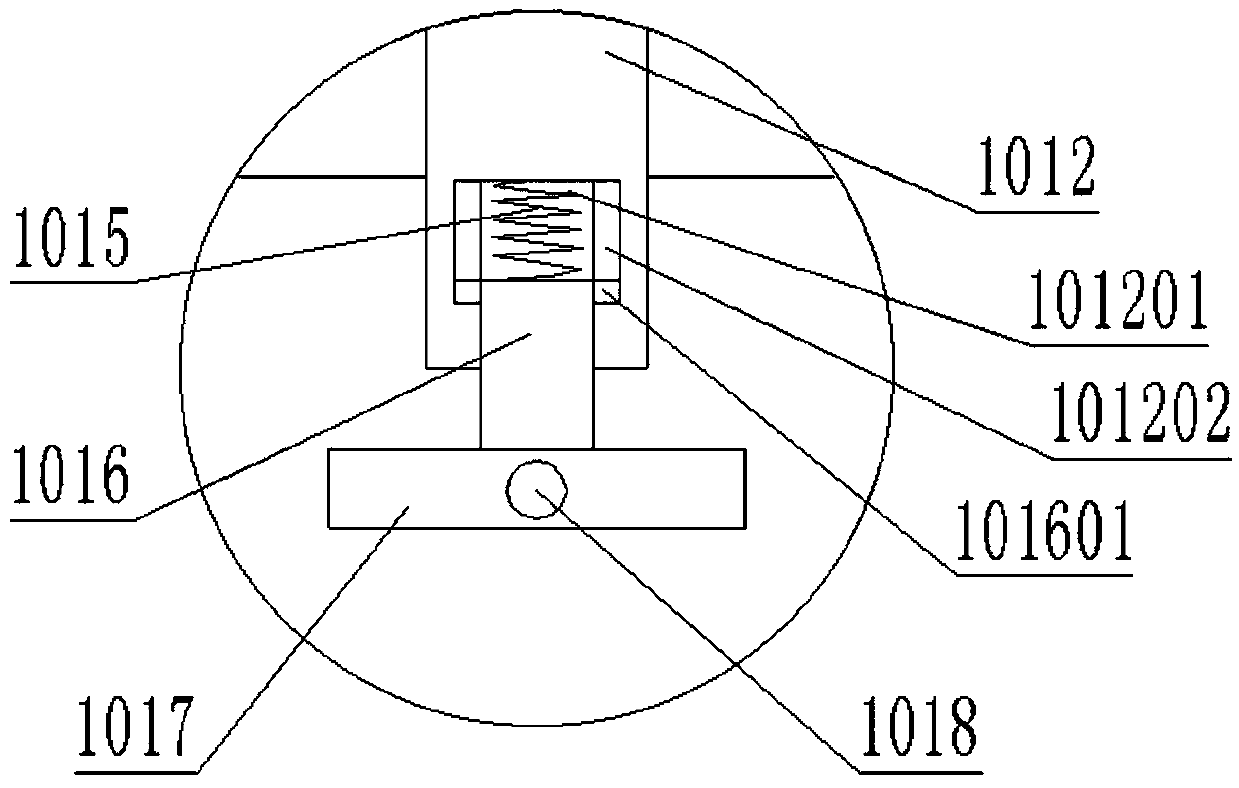

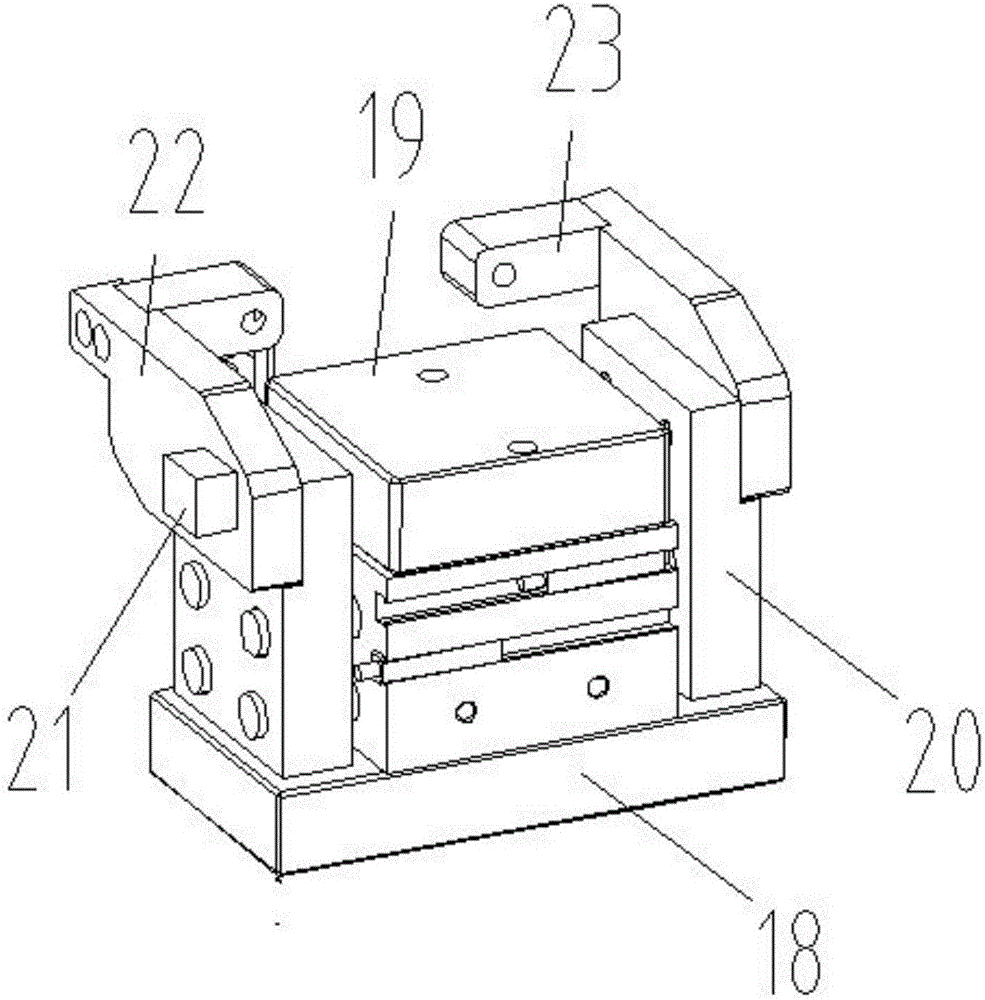

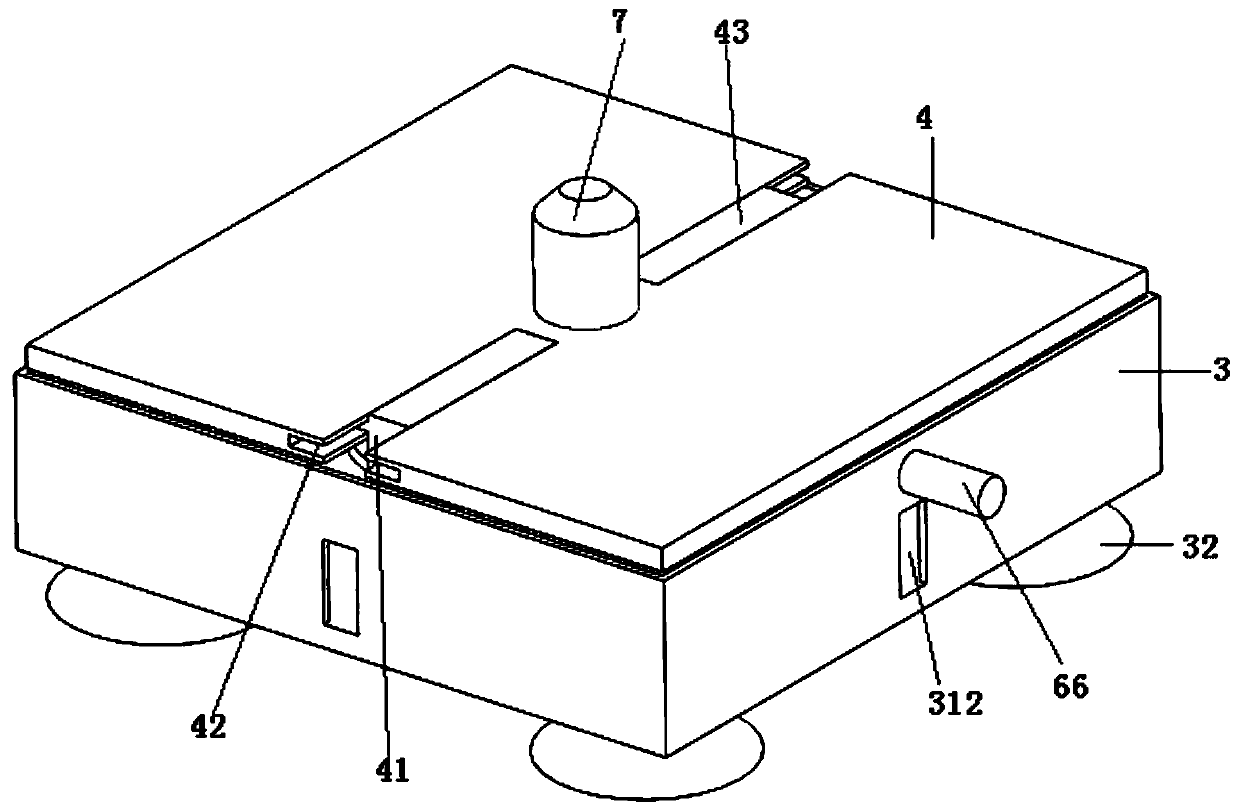

Eyeglasses lens processing device and application method thereof

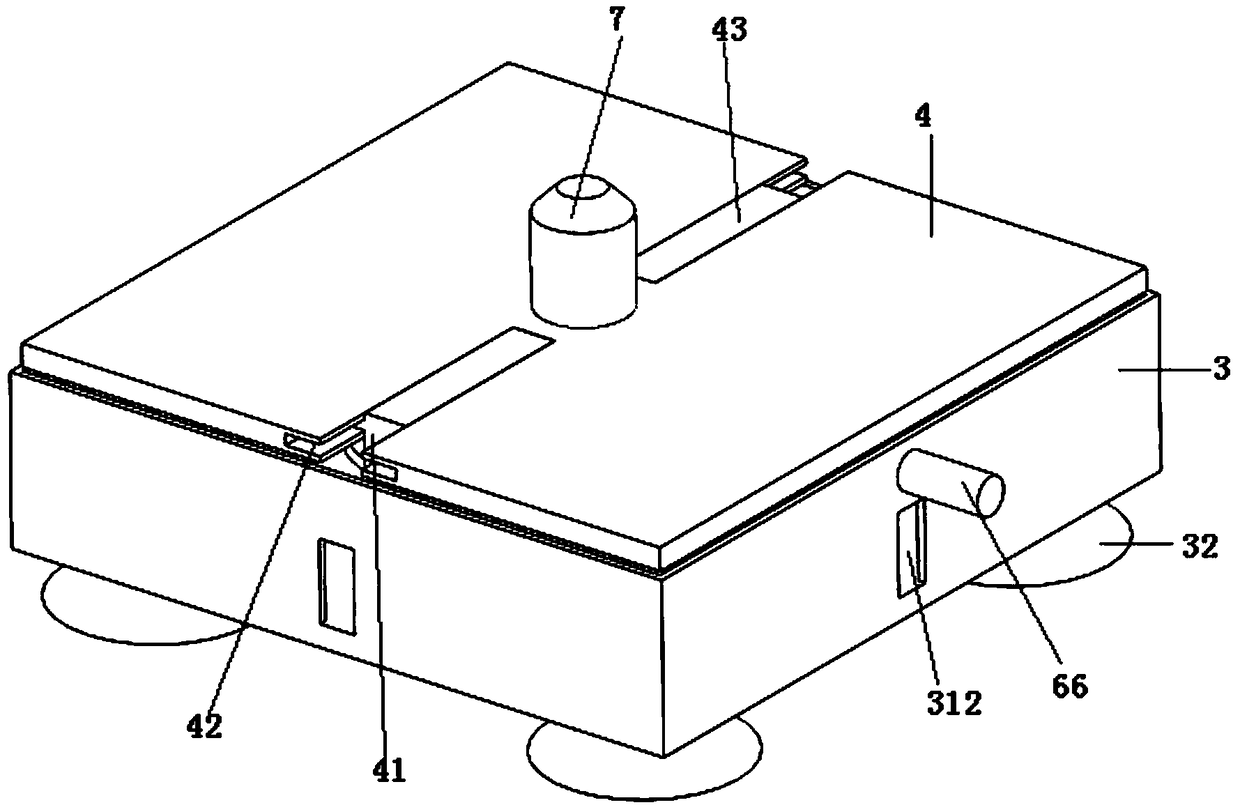

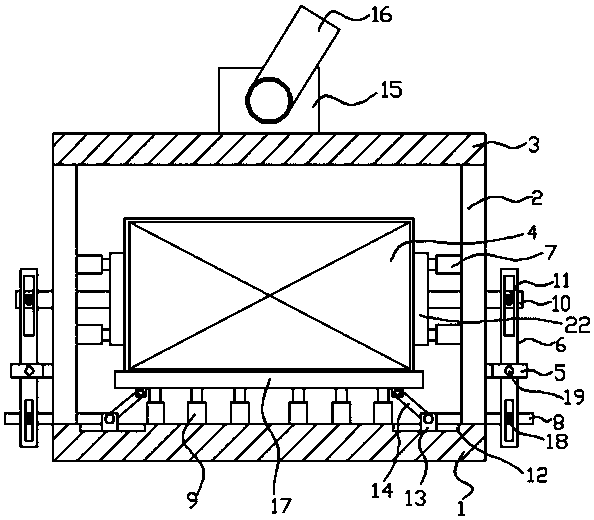

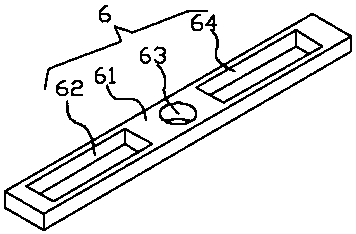

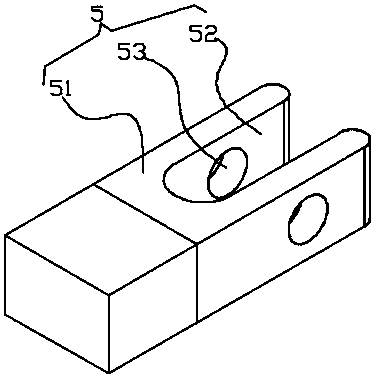

ActiveCN111347091ARealize automatic clampingRealize compression and fixationCopying process control systemsWorking accessoriesEyeglass lensesOphthalmology

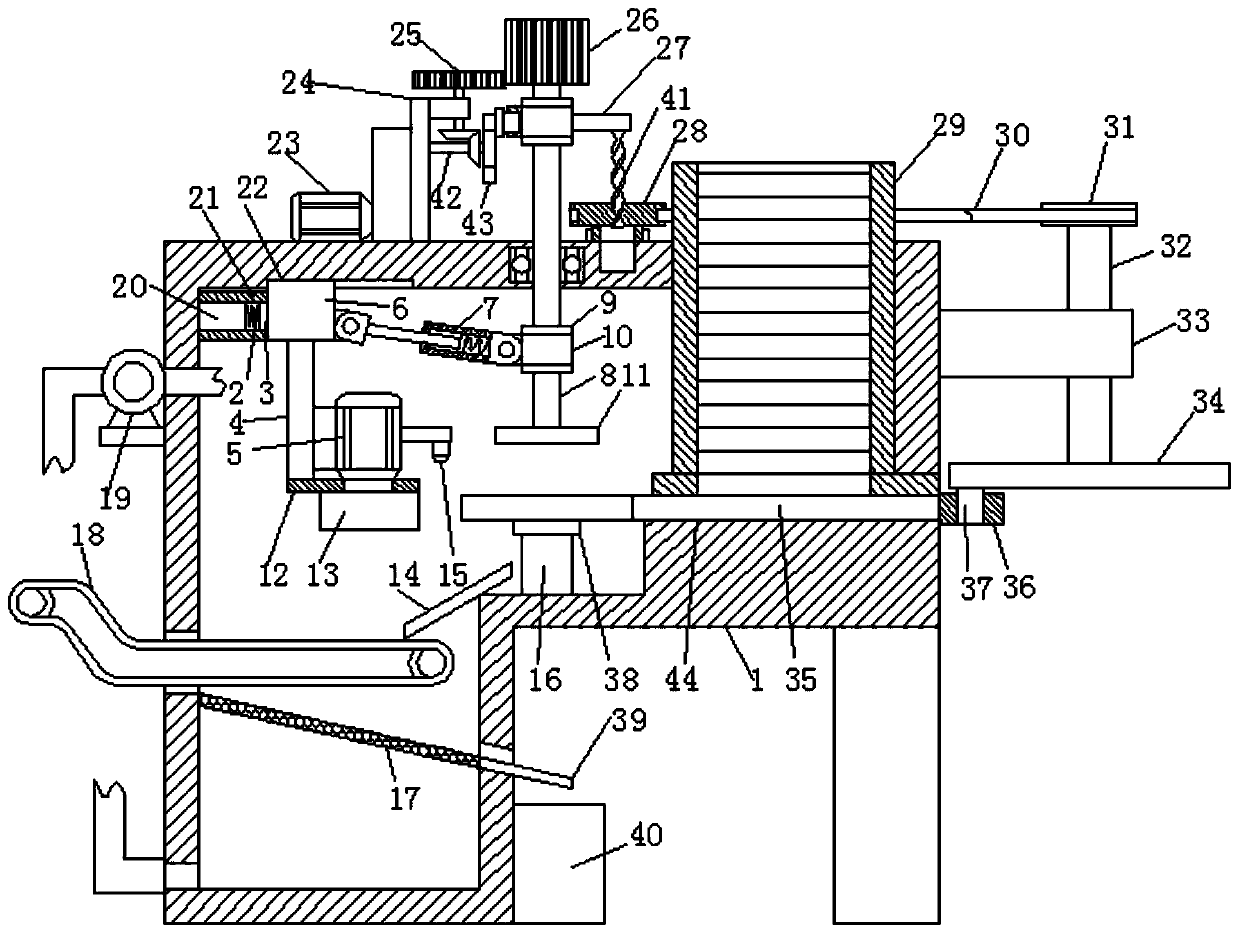

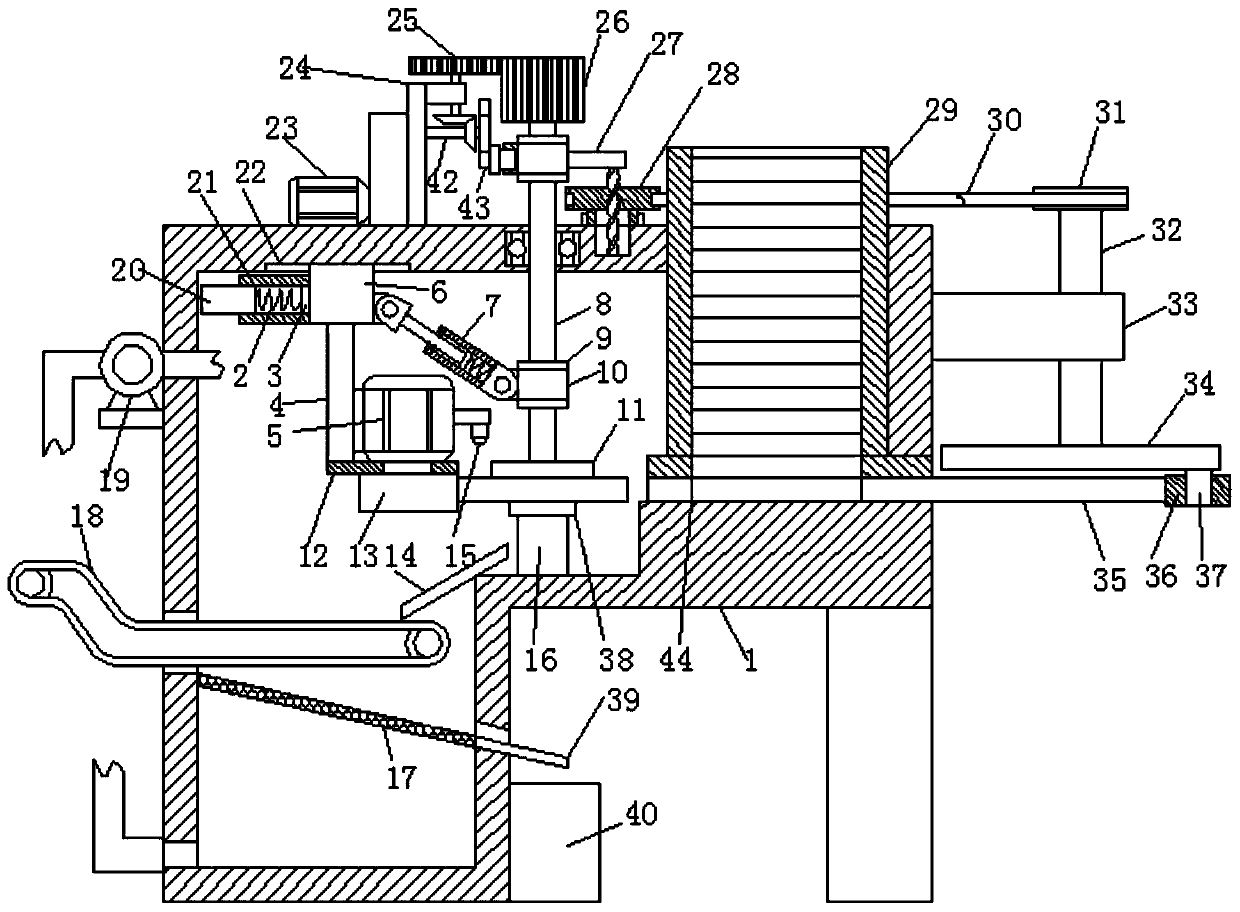

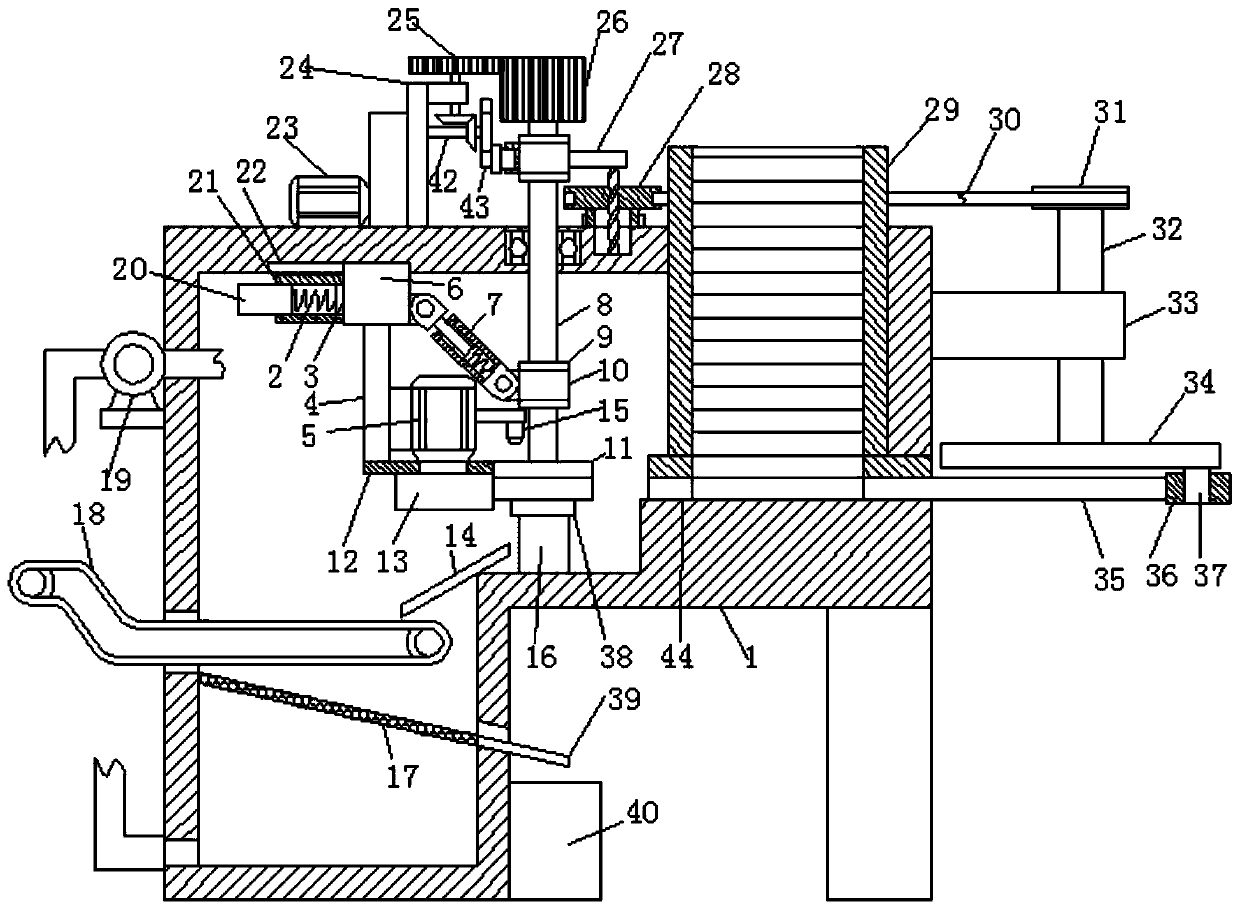

The invention relates to the field of eyeglasses processing equipment, in particular to an eyeglasses lens processing device and an application method thereof. The eyeglasses lens processing device comprises a case, wherein an edge milling mechanism for edge-milling lenses is arranged in the case; a clamping mechanism for clamping the lenses is arranged on the top part of the case; a feeding mechanism for conveying the lenses is arranged on the right side part of the case; and the clamping mechanism is in transmission connection with the feeding mechanism and the edge-milling mechanism. According to the eyeglasses lens processing device and the application method thereof, the lenses are continuously processed, the automation degree of the whole process is high, and the lenses have no needto be installed or taken down for multiple times, so that the operation is simplified, and the labor intensity is greatly reduced; and in addition, the consistency in positioning each lens is realized, and the uniformity of the processing quality is high, so that the lens processing quality is improved.

Owner:鲁德昊

A fabric cutting device

ActiveCN113684669BRealize compression and fixationReduce offsetMechanical cleaningPressure cleaningEngineeringStructural engineering

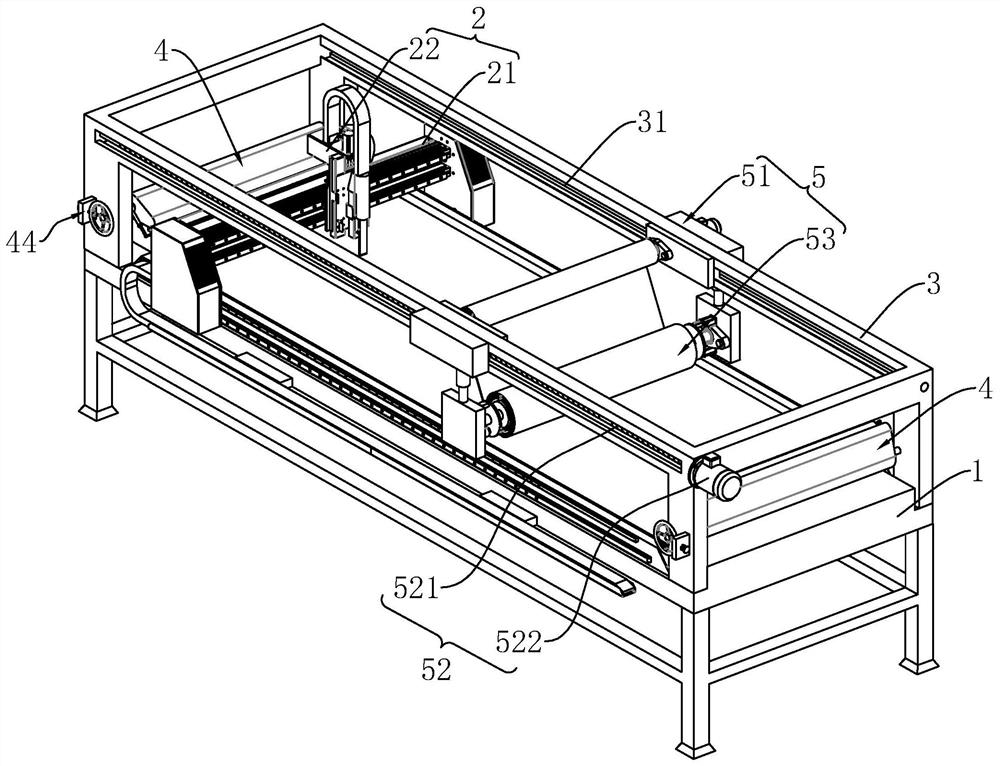

The present application relates to a cloth cutting device, comprising a cutting table for placing the cloth, a cutting mechanism arranged on the cutting table to cut the cloth, a fixing frame arranged on the cutting table, and a fixing mechanism arranged on the fixing frame to fix the cloth The fixing mechanism is provided with two groups for fixing the two sides of the cloth respectively, and each group of fixing mechanisms includes a rotating shaft rotatably connected to the fixing frame, a coaxially fixed and sleeved abutting roller on the rotating shaft, and a limiting rotating shaft. The rotating limit assembly, the rotating shaft is located above the cutting table, the abutting protrusions for pressing the fabric are protruded from the abutting rollers, so that the cross-section of the abutting rollers is cam-shaped. When the contact convex portion is rotated upward, there is a gap for the cloth to pass between the peripheral wall of the contact roller and the cutting table. The present application has the effect of reducing the potential for slippage of the cloth.

Owner:厦门海溢针纺织品有限公司

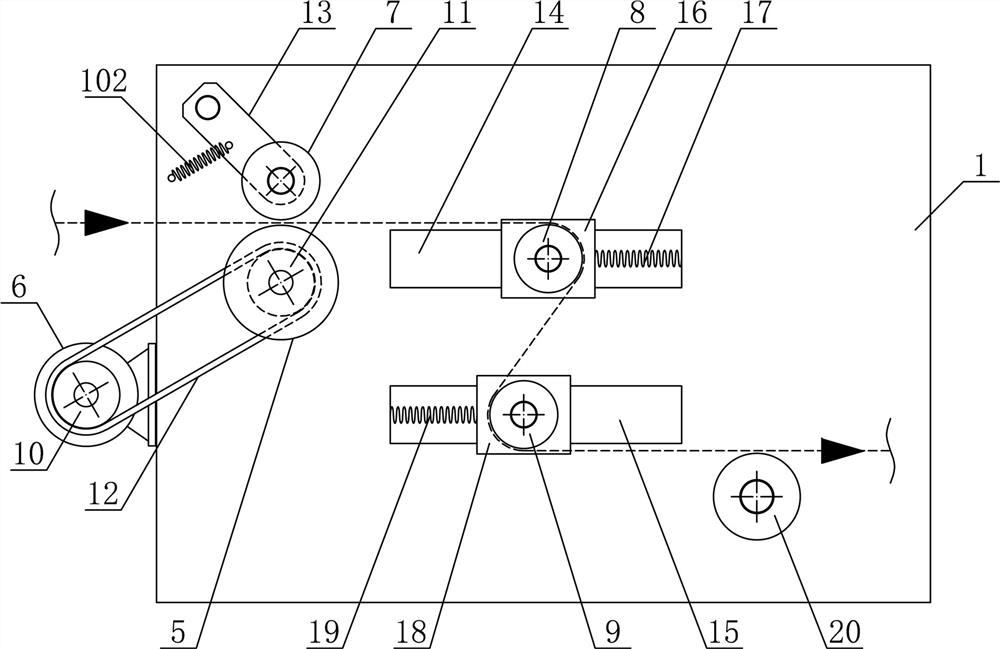

Melt-blown cloth conveying and processing device

ActiveCN111824828ASwing smoothly and convenientlySufficient and efficient suctionWebs handlingEngineeringMechanical engineering

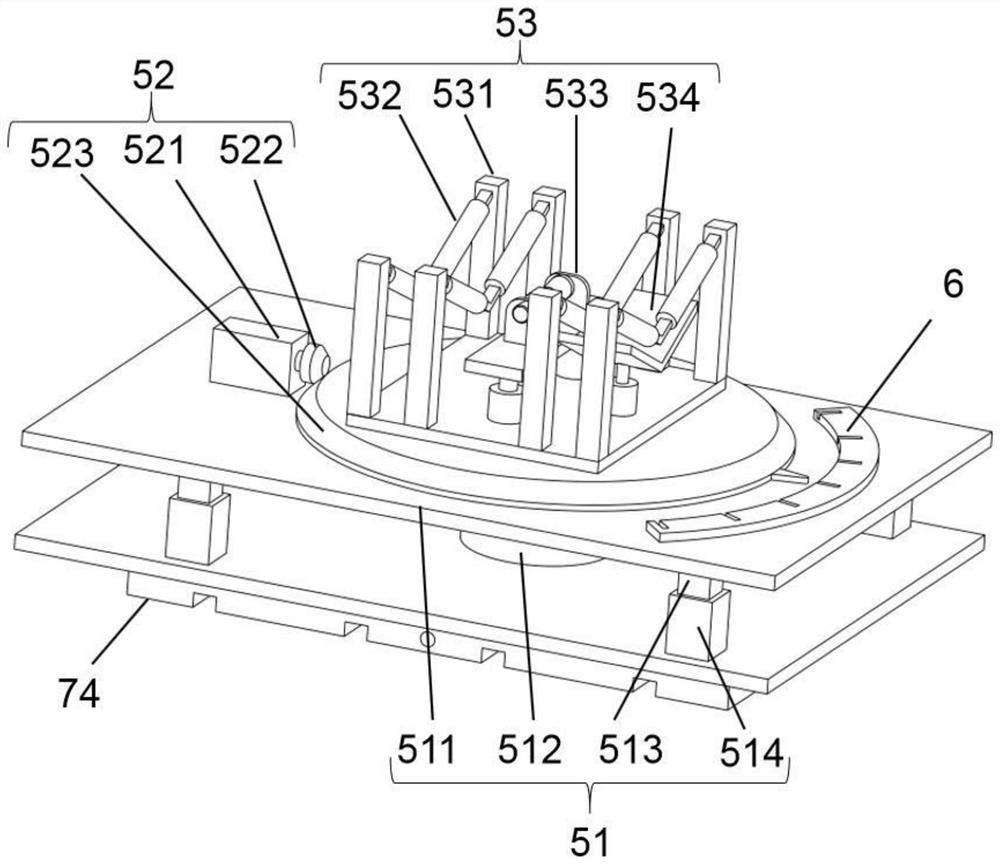

The invention discloses a melt-blown cloth conveying and processing device, and belongs to the field of melt-blown cloth production equipment. The melt-blown cloth conveying and processing device is characterized in that a cloth feeding and guiding mechanism, a cloth pressing and impurity sucking mechanism and a cloth pulling and conveying mechanism are sequentially arranged on a cloth conveying and processing support; a melt-blown cloth pressing rotary roller is arranged on the upper side of a cloth feeding and conveying rotary roller, a front positioning cloth pressing plate is arranged on the upper side of a front lifting guide plate, and a rear positioning cloth pressing plate is arranged on the upper side of a rear lifting guide plate; a reciprocating and impurity sucking mechanism isarranged on the part, on the upper sides of the front positioning cloth pressing plate and the rear positioning cloth pressing plate, of the cloth conveying and processing support; and a front clothpulling guide plate and a rear cloth pulling guide plate are arranged on the two sides of a reciprocating cloth pulling guide rod, and a disc positioning mechanism is arranged on the part, on the lower side of a cloth pulling rotating disc, of the cloth conveying and processing support in the radial direction of the cloth pulling rotating disc. The melt-blown cloth conveying and processing deviceis reasonable in structural design, melt-blown cloth can be efficiently, conveniently and sequentially pulled and conveyed in a segmented mode, the melt-blown cloth can be stably and smoothly subjected to segmented impurity sucking processing in the melt-blown cloth conveying process, the automation degree of melt-blown cloth production and processing is improved, and the requirements of production and use are met.

Owner:桐乡市中瑞环保科技有限公司

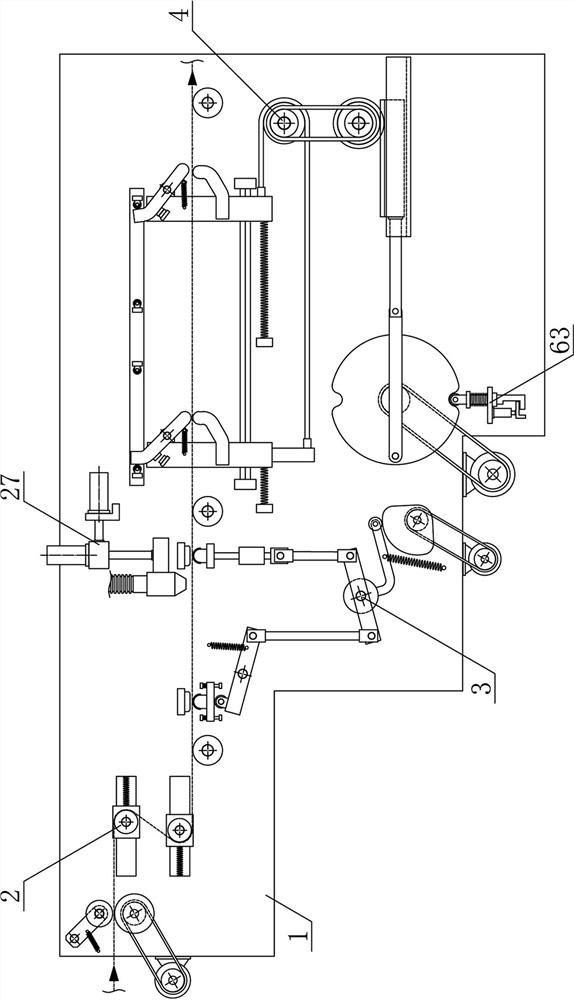

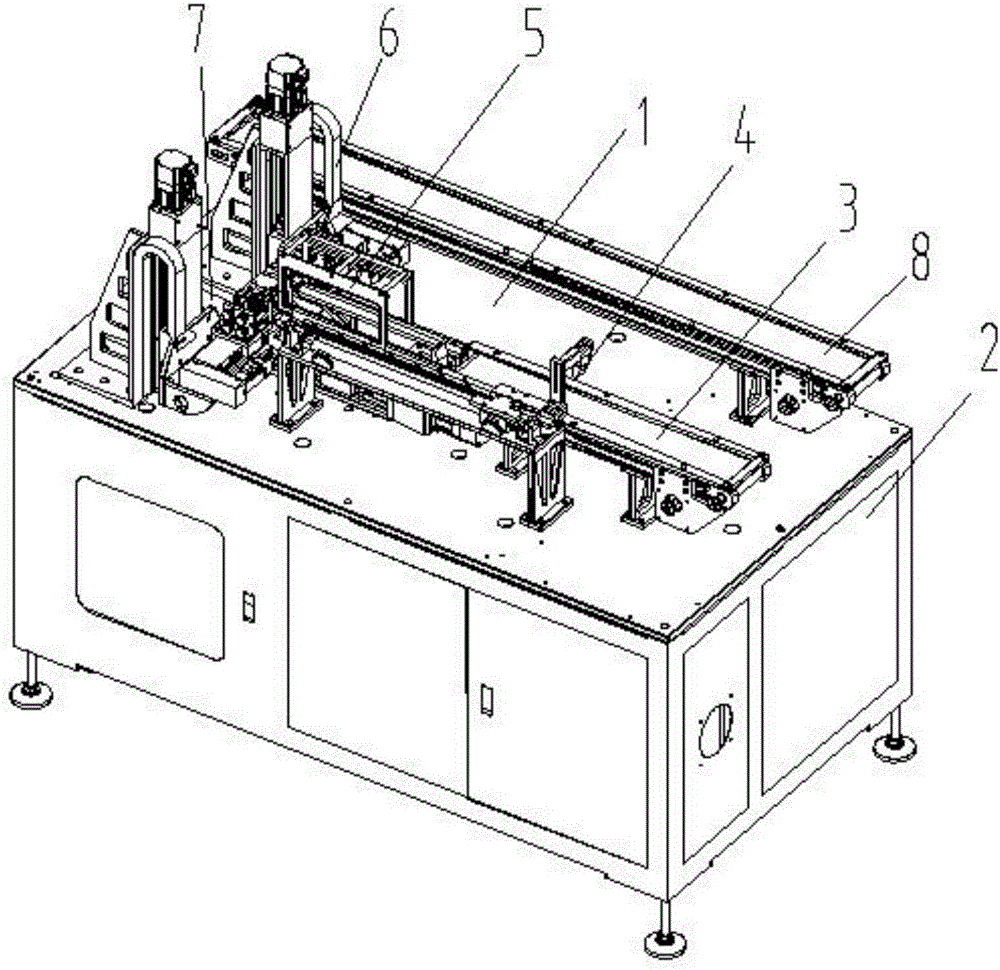

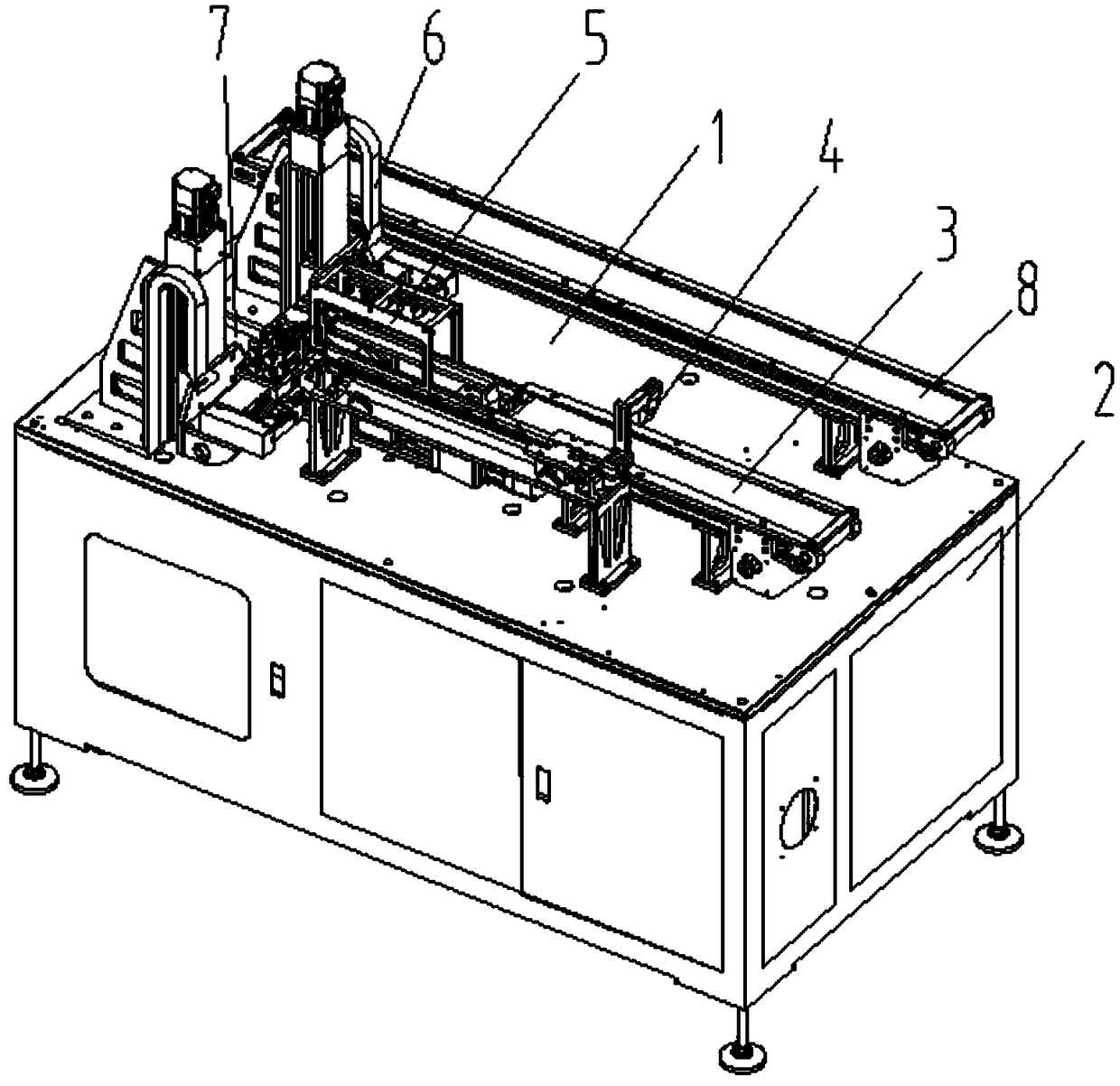

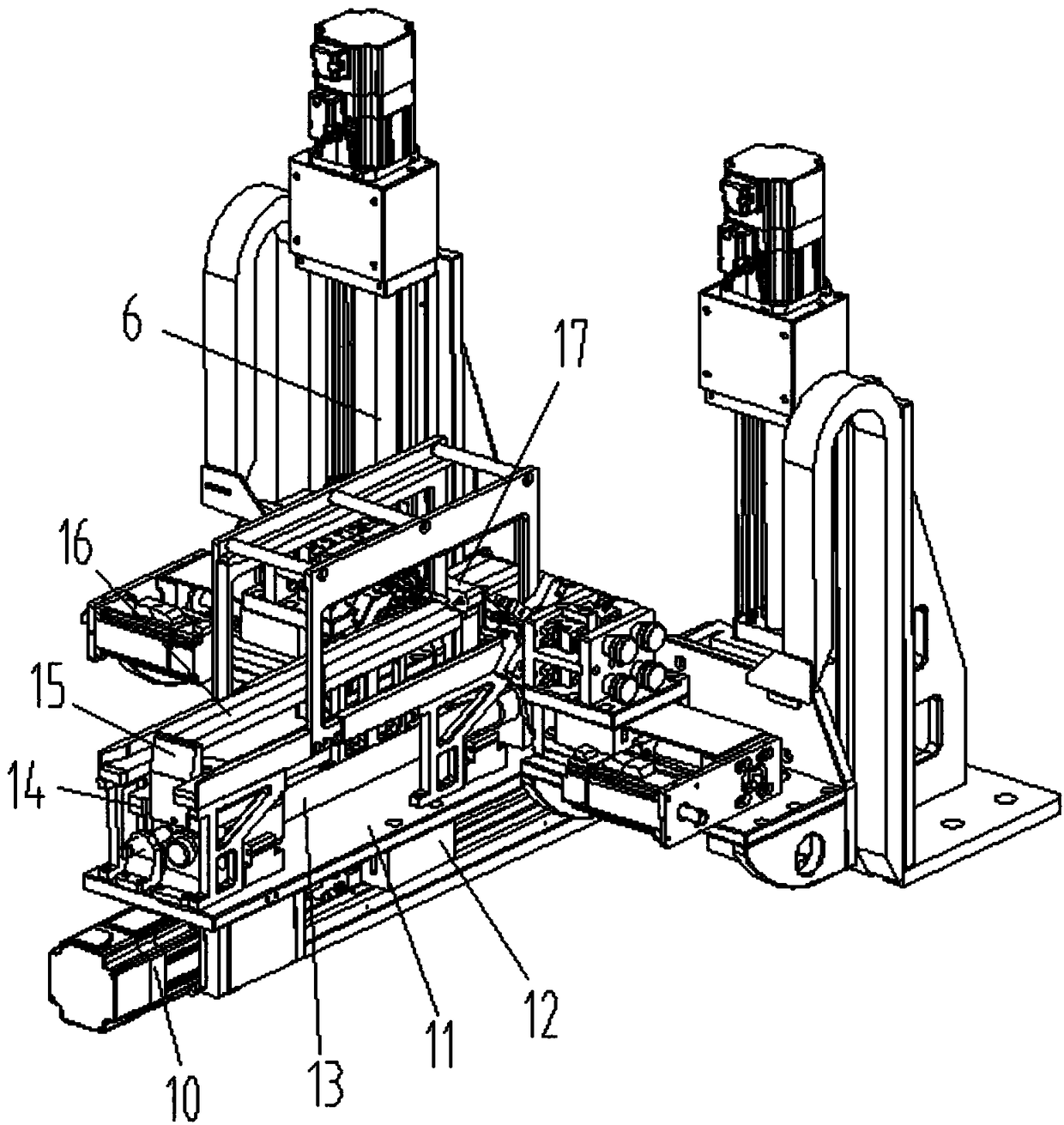

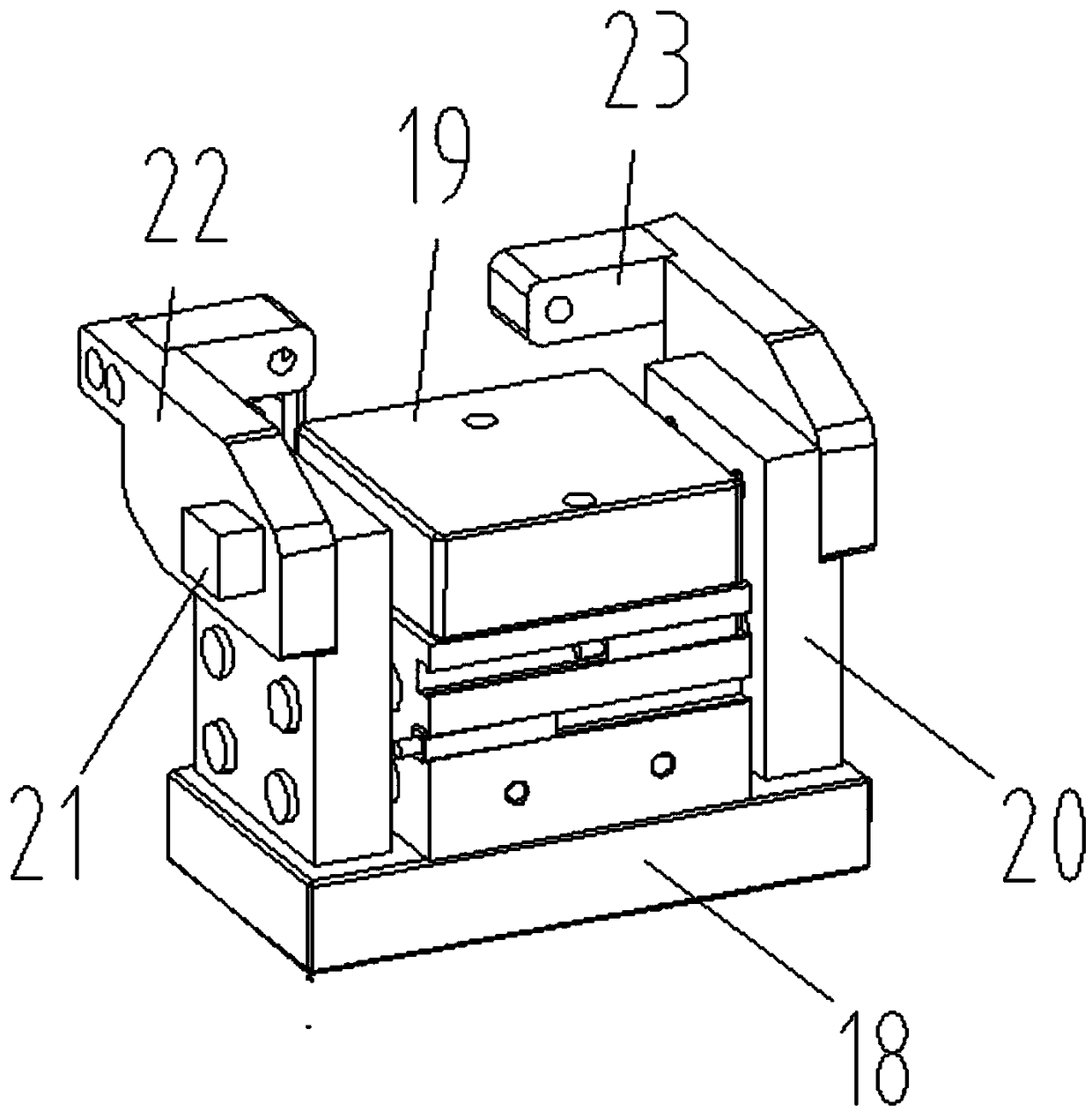

Automatic welding machine of home decoration aluminium profiles

ActiveCN106826009AVersatilePrecision weldingWelding/cutting auxillary devicesAuxillary welding devicesDistribution controlEngineering

The invention relates to an automatic welding machine of home decoration aluminium profiles. The automatic welding machine comprises a rack and a power distribution control cabinet, wherein a material carrying mechanism is arranged on the rack; the material carrying mechanism comprises a carrier feeding motor and a carrier feeding screw rod which are arranged on the rack; a carrier feeding matching block is connected on the carrier feeding screw rod in a sleeving manner; a carrier feeding seat is arranged on the carrier feeding matching block; a fixing device matched with a product is arranged on the carrier feeding seat; welding devices are arranged on the front and back sides of the fixing device; the welding devices comprise welding seats; welding lifting cylinders and welding lifting seats are arranged on the welding seats; welding movable motors and welding movable screw rods are arranged on the welding lifting seats; welding movable seats are matched on the welding movable screw rods; and welding heads are mounted on the welding movable seats. According to the automatic welding machine, the welding devices are matched on the front and back sides of the material carrying mechanism, the welding heads of the welding devices are horizontal at front and back, the welding heads are lifted and lowered through the welding lifting cylinders, accurate welding can be achieved, and the automatic welding machine has universality for the aluminium profiles of various models.

Owner:TIANCHANG JINGFA ALUMINUM IND

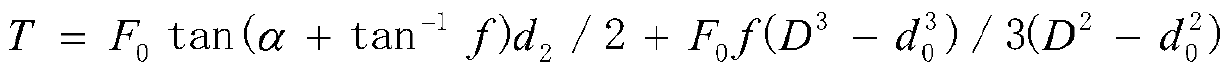

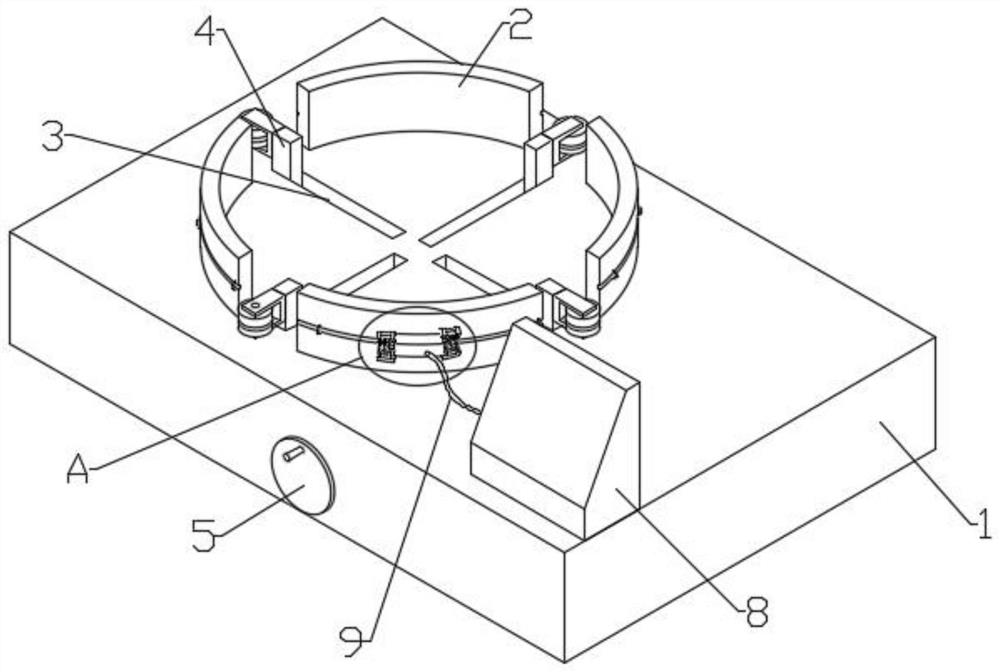

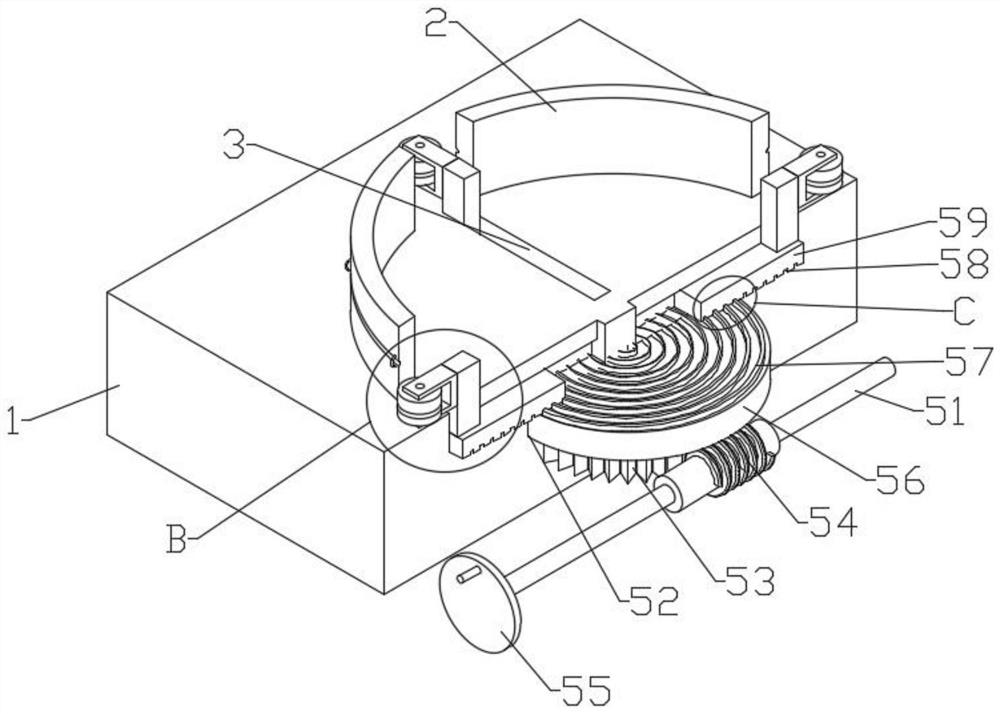

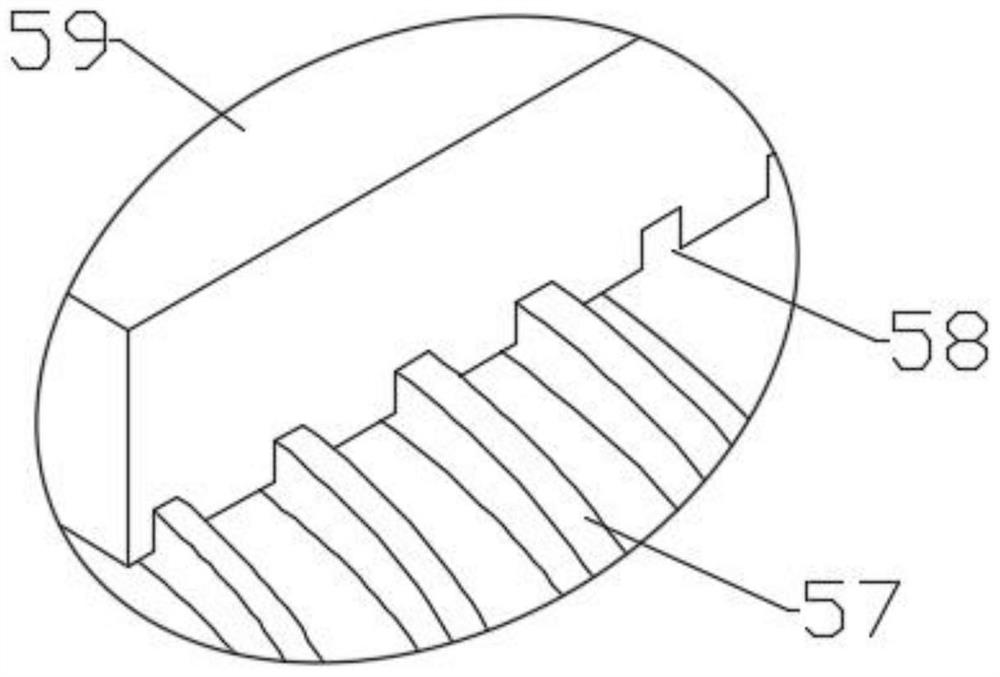

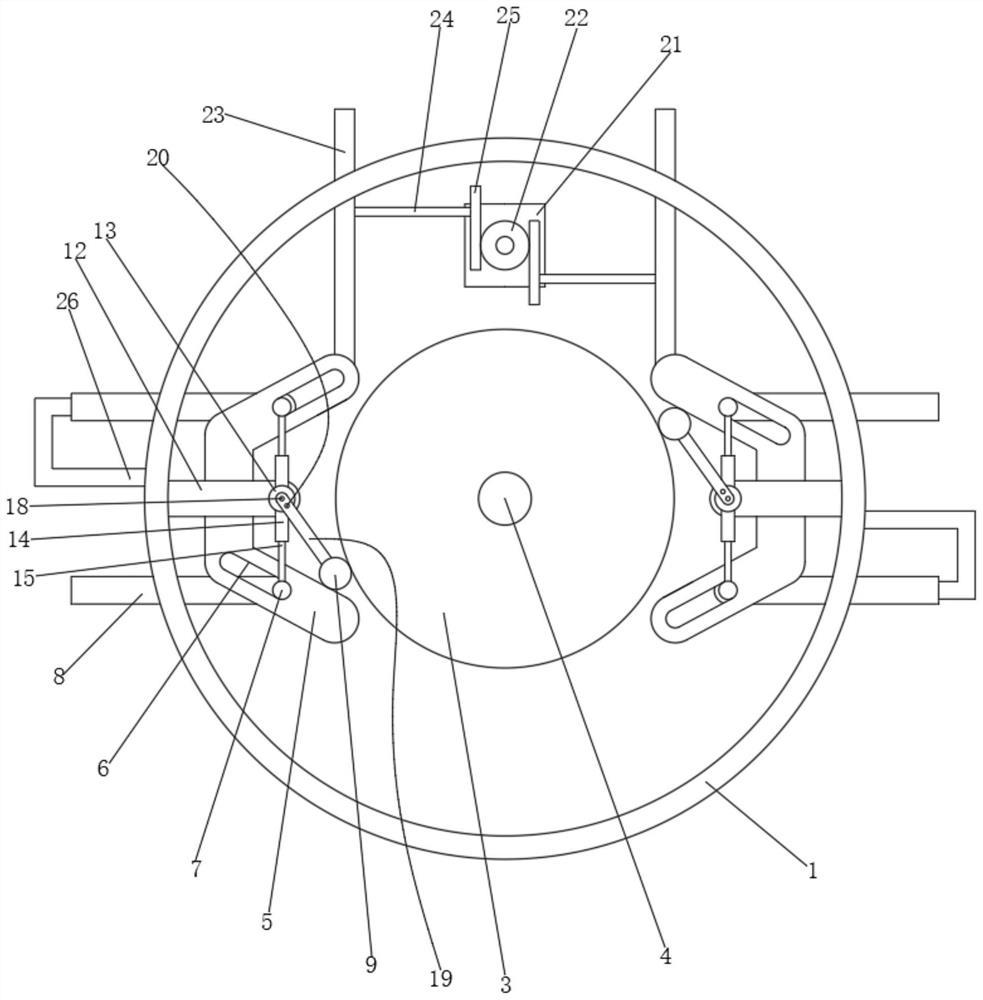

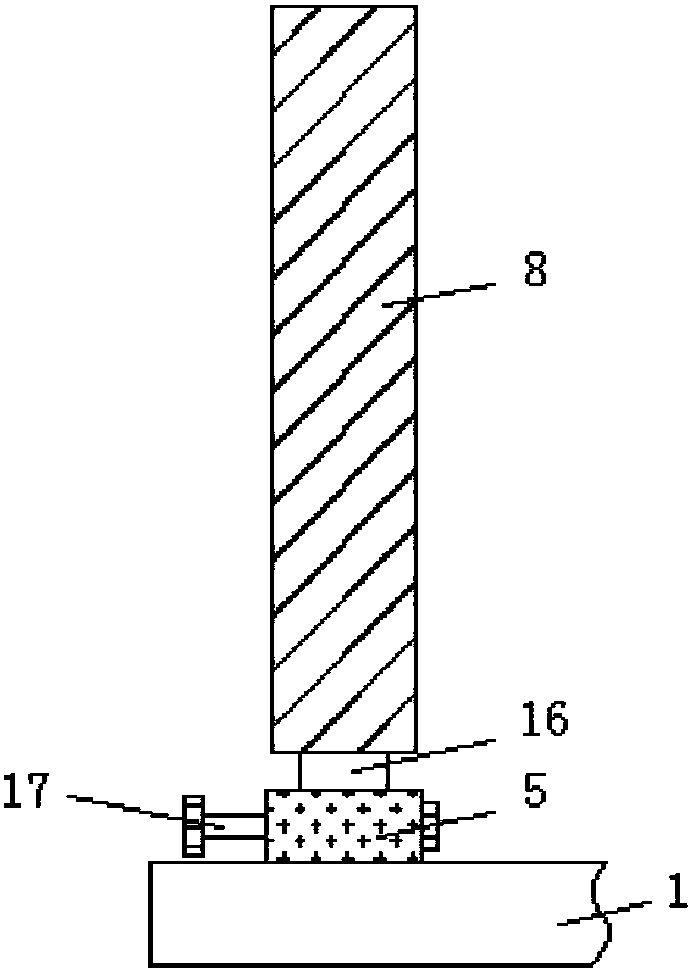

Adjustable hardness test fixture

PendingCN109540660ARealize compression and fixationSolve the phenomenon of biasInvestigating material hardnessHardnessEngineering

The invention discloses an adjustable hardness test fixture. A pedestal is arranged on a chassis, a left supporting frame and a right supporting frame are symmetrically installed on both sides of thepedestal, a positioning disk is connected to the tops of the left supporting frame and the right supporting frame, the section of a fixture seat takes the shape of a major arc, a guide groove is formed in the fixture seat, a sliding sleeve is sleeved on the periphery of the middle segment of the fixture seat, an objective table is arranged on the sliding sleeve, a tooth surface clamping block is connected to a left-handed screw, a plane clamping block is connected to a right-handed screw, and adjusting screws are installed on upright posts. By adoption of the adjustable hardness test fixture disclosed by the invention, a tested workpiece of any shape can be pressed and fixed, the operation is stable, the hardness test is met, and the phenomenon that when the hardness test is performed on an irregular tested workpiece, bias pressing is generated due to the unstable fixation, resulting in a large deviation between the measured hardness and the actual hardness, is solved. The working efficiency of inspectors can be greatly improved, the accuracy and stability of the microhardness test are ensured, and the applicability is wide.

Owner:NANCHANG HANGKONG UNIVERSITY

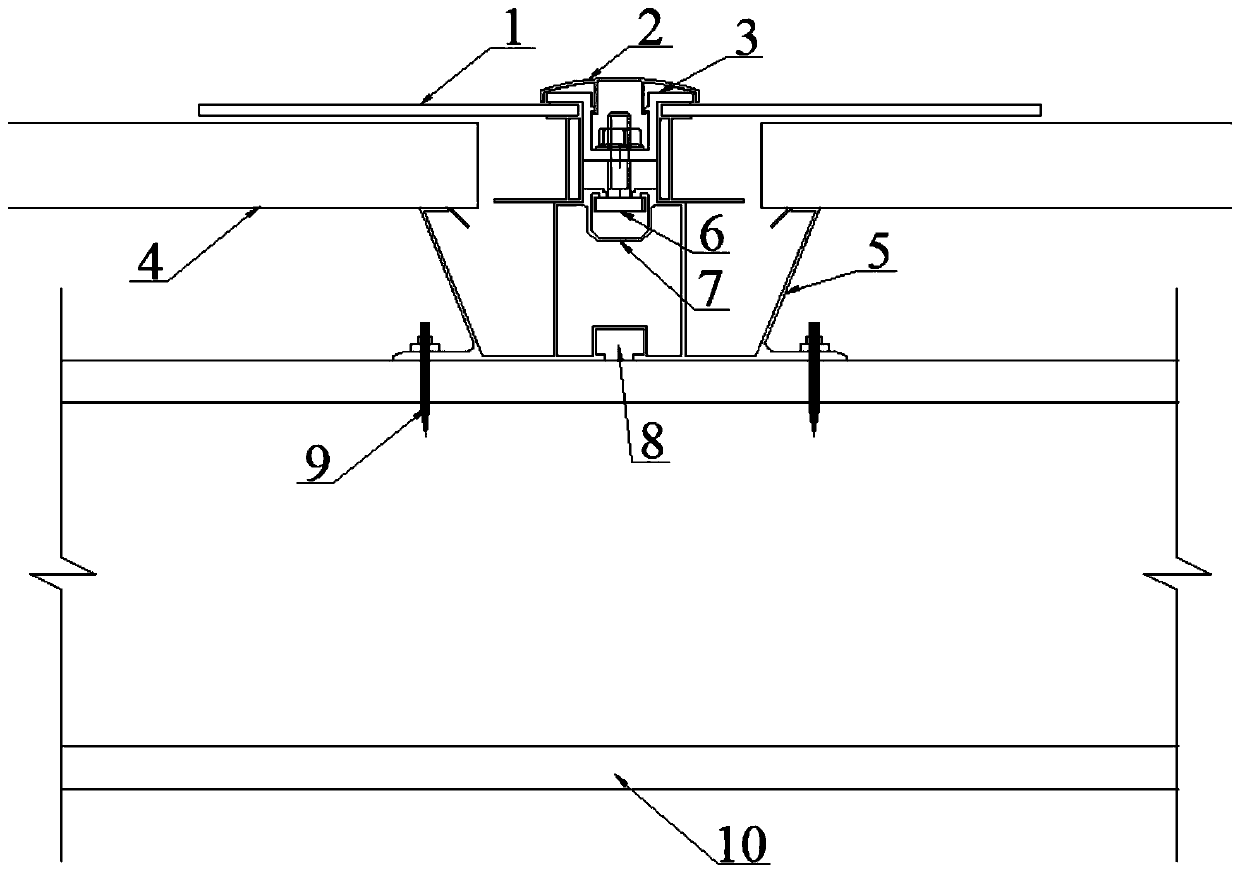

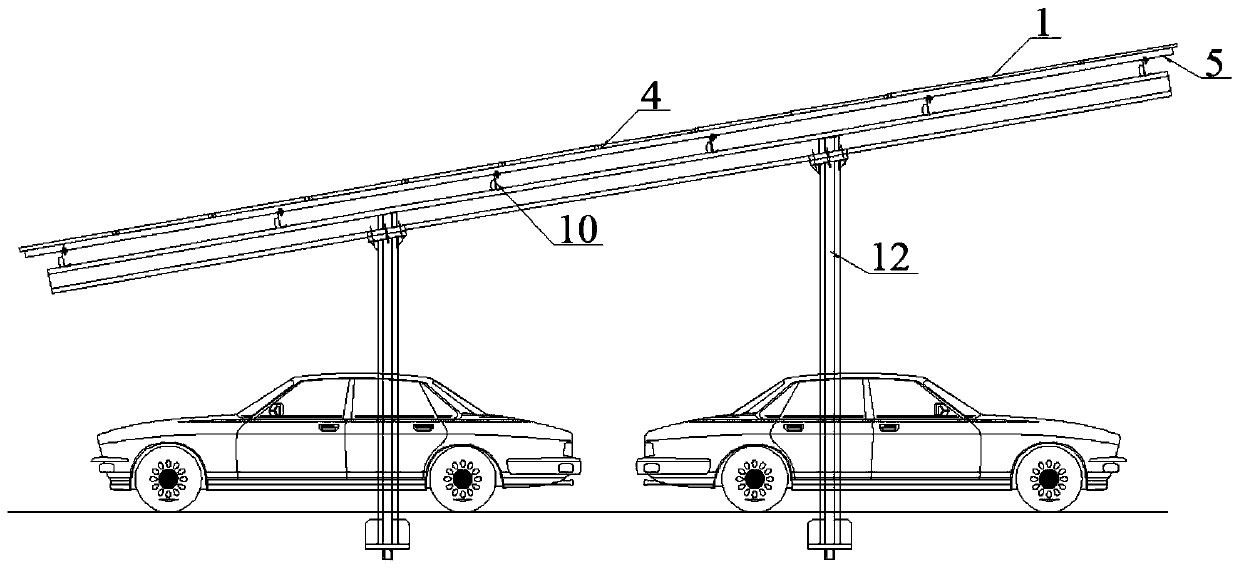

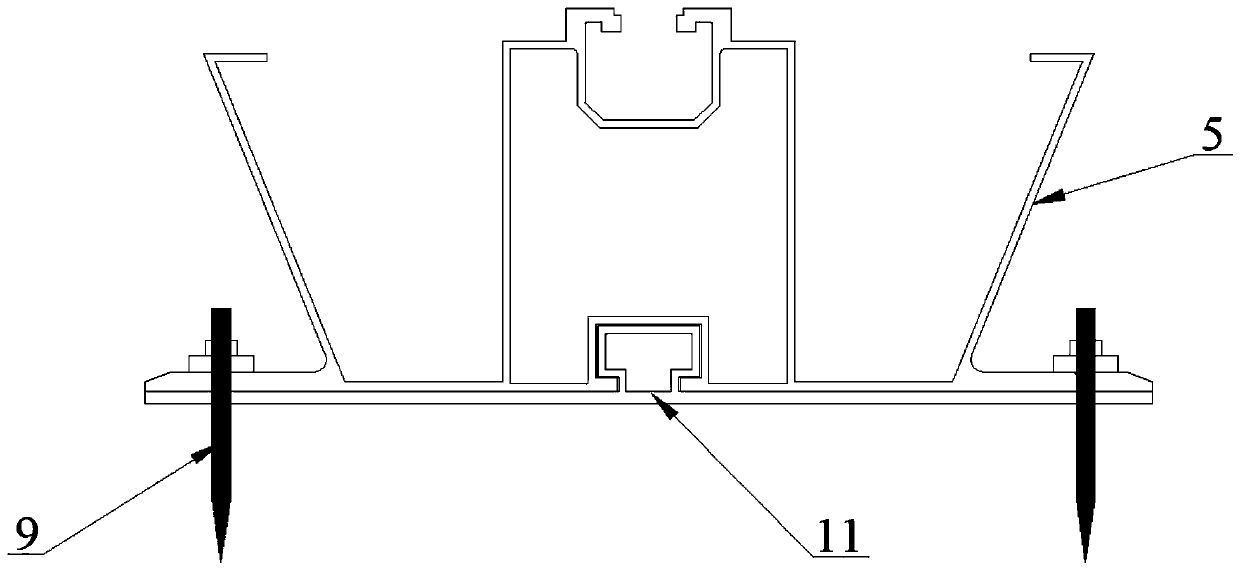

Waterproof system of photovoltaic shed assembly and waterproof photovoltaic shed

PendingCN110359740AFunctionalPrevent water leakagePhotovoltaic supportsRoof covering using slabs/sheetsArchitectural engineeringPhotovoltaics

The invention discloses a waterproof system of a photovoltaic shed assembly. The system comprises a guide rail fixed to the upper side of a steel purline, a transverse mounting groove for fixing the photovoltaic assembly and draining is formed in the upper side of the guide rail, an assembly mounting slot for accommodating an assembly fixing part is formed in the middle of the guide rail, a pressure block presses and fixes the photovoltaic assembly through the assembly fixing part, and a cover plate is arranged on the upper side o the pressure block. The invention also discloses a waterproof photovoltaic shed. The guide rail of the waterproof system of the photovoltaic shed assembly has structure fixing and waterproof and drainage functions and can form an independent cavity to avoid waterleakage of fixed points.

Owner:正泰安能数字能源(浙江)股份有限公司

Rectangular harness fixing buckle

ActiveCN110289580ARealize compression and fixationAvoid damageElectrical apparatusElectric/fluid circuitEngineeringBiomedical engineering

Owner:FJ MOTOR GRP YUDO NEW ENERGY AUTOMOBILE CO LTD

A light-weight portable carton printing machine bearing protection device

The invention discloses a load protection device for a lightweight portable carton printing machine, which comprises a central fixing seat and four elastic bearing seats equiangularly distributed around the central fixing seat, the elastic bearing seats and the central fixing seat are connected by a rubber connecting belt The connection is fixed, the center of the bottom surface of the carton printing machine is fixed on the central fixing seat, and the four sides of the bottom surface of the carton printing machine are placed on the elastic bearing seat at the same time. The invention is provided with a central fixing seat and an elastic bearing seat connected by a rubber connecting belt, and by controlling the belt winding wheel on the central fixing seat, the adjustment of the protruding length of the rubber connecting belt can be realized, thereby realizing the adjustment of the size of the bearing device, which is universal and convenient. And the weight is light, and at the same time, when not in use, the rubber connecting belt is retracted directly by rotating around the pulley, so that the volume of the carrying device is reduced, and it is easy to carry and transfer.

Owner:CHUZHOU CIGARETTE MATERIALS FACTORY

An automatic welding machine for household decoration aluminum profiles

ActiveCN106826009BVersatilePrecision weldingWelding/cutting auxillary devicesAuxillary welding devicesEngineeringWelding

Owner:TIANCHANG JINGFA ALUMINUM IND

Cutting device for sponge

PendingCN114290415ARealize compression and fixationGuaranteed flatnessDirt cleaningMetal working apparatusStructural engineeringMechanical engineering

The invention relates to the technical field of sponge production equipment, and discloses a sponge cutting device which comprises a cutting table, a cutting groove is formed in the center of the top of the cutting table, a supporting plate is arranged at the bottom of the cutting groove, and electric sliding rails are fixedly connected to the centers of the left side and the right side of the top of the cutting table. Sliding blocks are slidably connected to the sides, close to the cutting groove, of the electric sliding rails correspondingly, fixing plates are fixedly connected to the sides, away from the electric sliding rails, of the bottoms of the sliding blocks correspondingly, and the bottoms of the fixing plates are fixedly connected to the left side and the right side of the top of a guide plate correspondingly. According to the sponge cutting device, an electric sliding rail drives an extrusion plate to move downwards to extrude a sponge, the sponge is pressed and fixed, the problems that the cutting flatness is low and the cutting efficiency is low due to the fact that the sponge has elasticity are solved, and an electric telescopic rod drives a cutting knife to penetrate through a guide groove to cut the sponge; and the cutting smoothness is guaranteed through the limiting and guiding effects of the guiding grooves.

Owner:安徽太平海绵制品有限公司

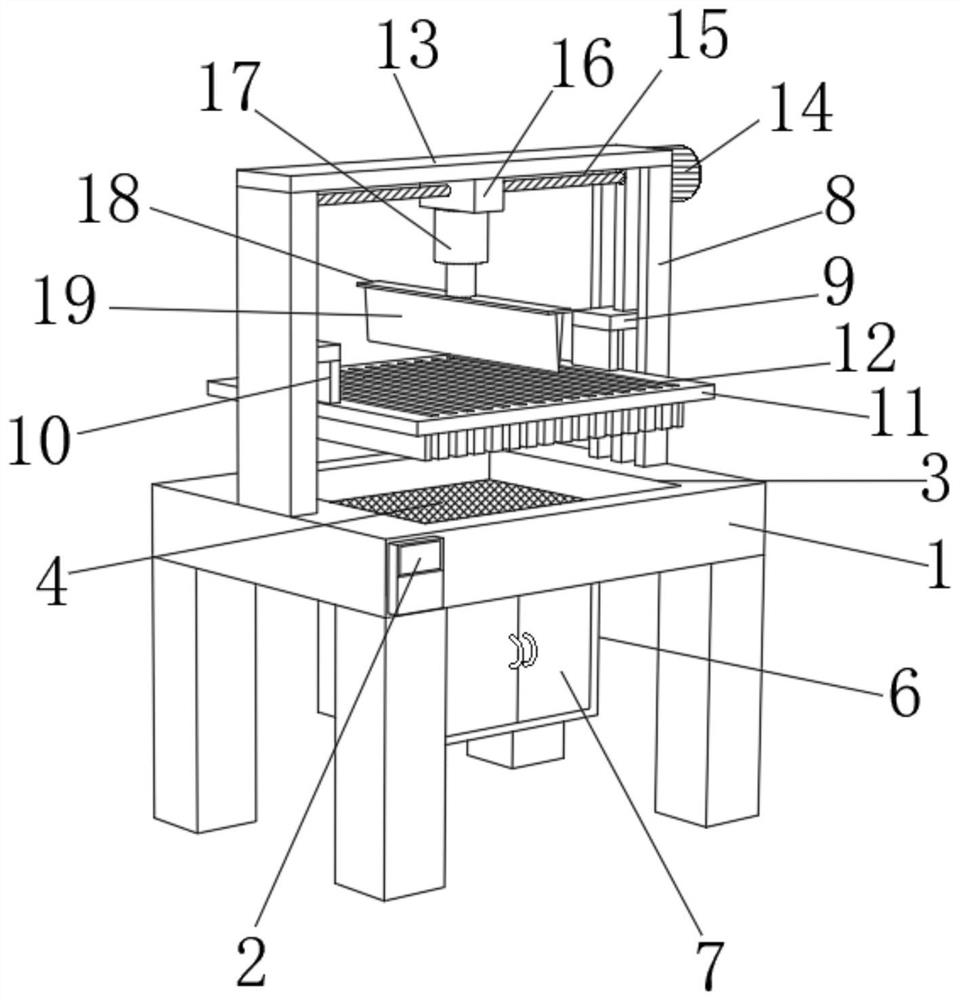

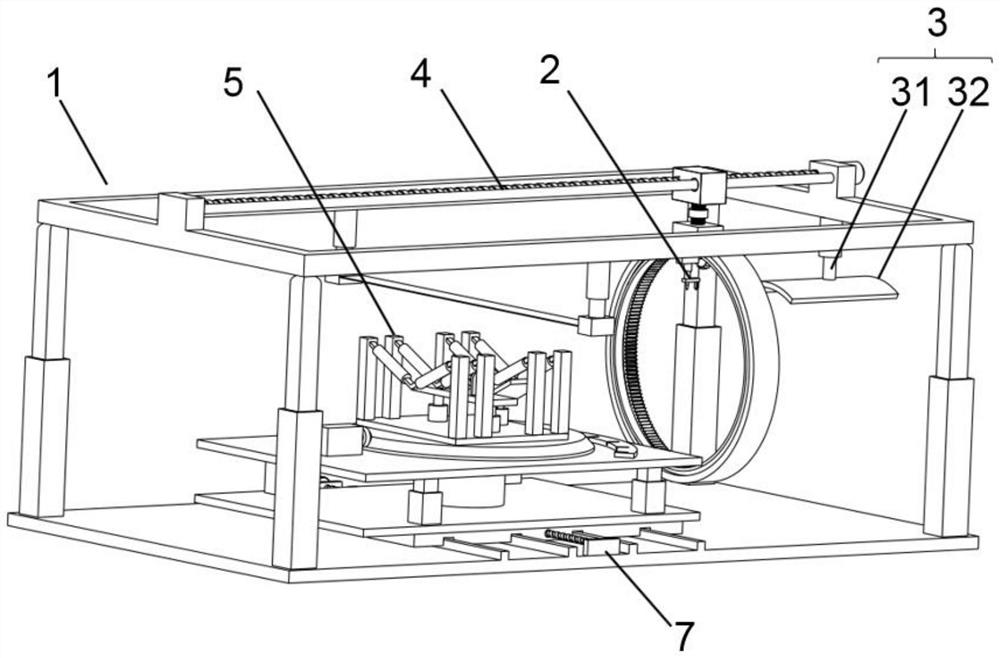

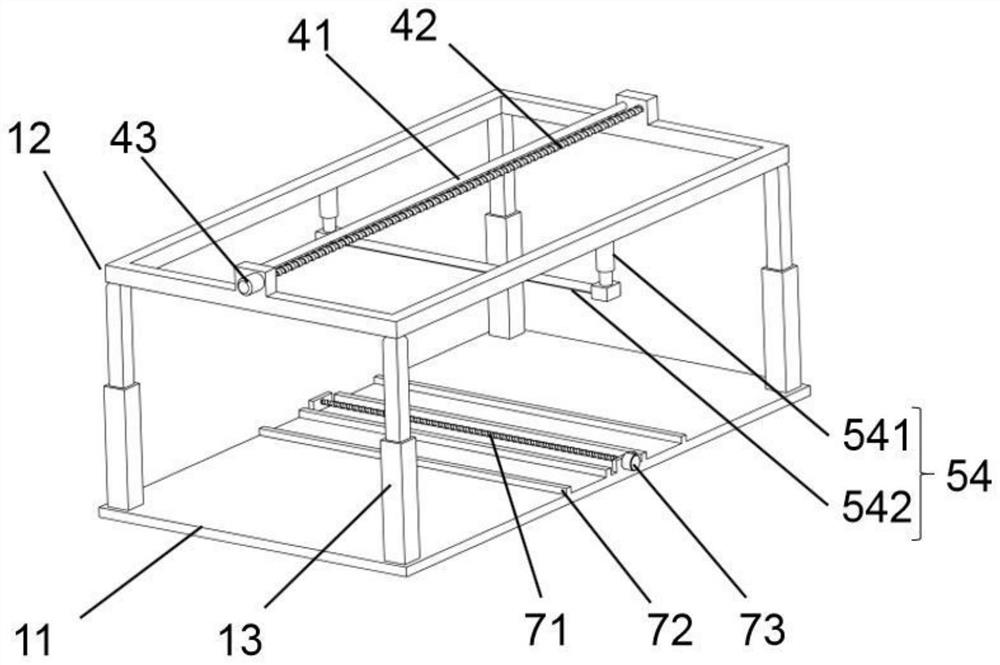

Auxiliary equipment for oil and gas long-distance pipeline construction and construction method thereof

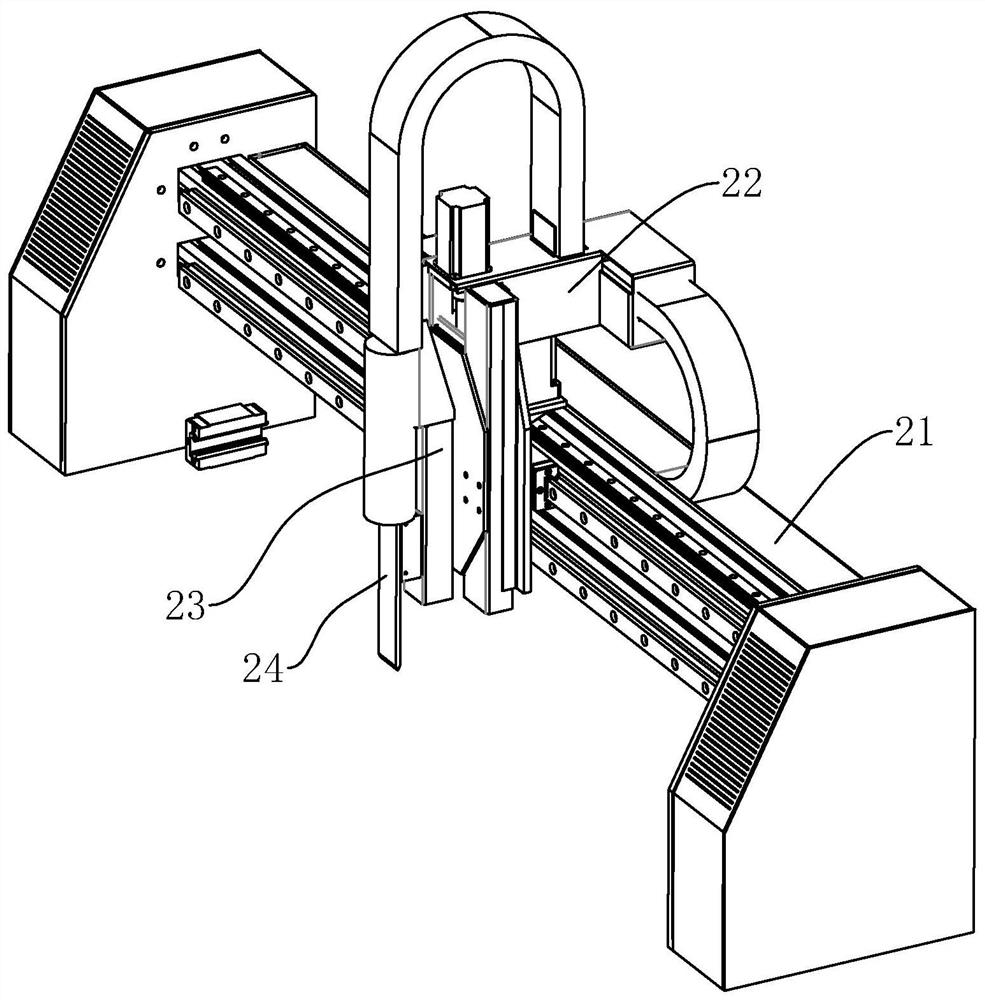

PendingCN114505626ADoes not affect alignmentHigh precisionWelding/cutting auxillary devicesAuxillary welding devicesPortal frameIndustrial engineering

The invention discloses auxiliary equipment for oil and gas long-distance pipeline construction and a construction method thereof, and belongs to the technical field of oil and gas long-distance pipeline construction.The auxiliary equipment comprises a main frame and a welding part, the main frame comprises a base and two portal frames, and a rail assembly is connected between the tops of the two portal frames; the welding part is movably mounted on the rail assembly; a pipeline feeding part and a translation assembly are arranged on the side, away from the positioning part, of the base. The pipeline feeding part comprises a lifting assembly, a rotating assembly is arranged on the lifting assembly, and a pipeline conveying assembly is arranged on the rotating assembly; a clamping assembly is arranged at the top of the pipeline conveying assembly; position adjustment of the to-be-welded pipeline in three directions can be achieved, the position of the to-be-welded pipeline is adjusted through a mechanical structure, the welding part can achieve automatic welding of the pipeline, and safety and reliability are higher.

Owner:刘展

Spool classification tightening device for intelligent manufacturing

InactiveCN112260162ARealize elastic anti-looseningImprove anti-loosening performanceElectrical apparatusFilament handlingSmart manufacturingScrew thread

Owner:阳江尚跃凯智能科技有限公司

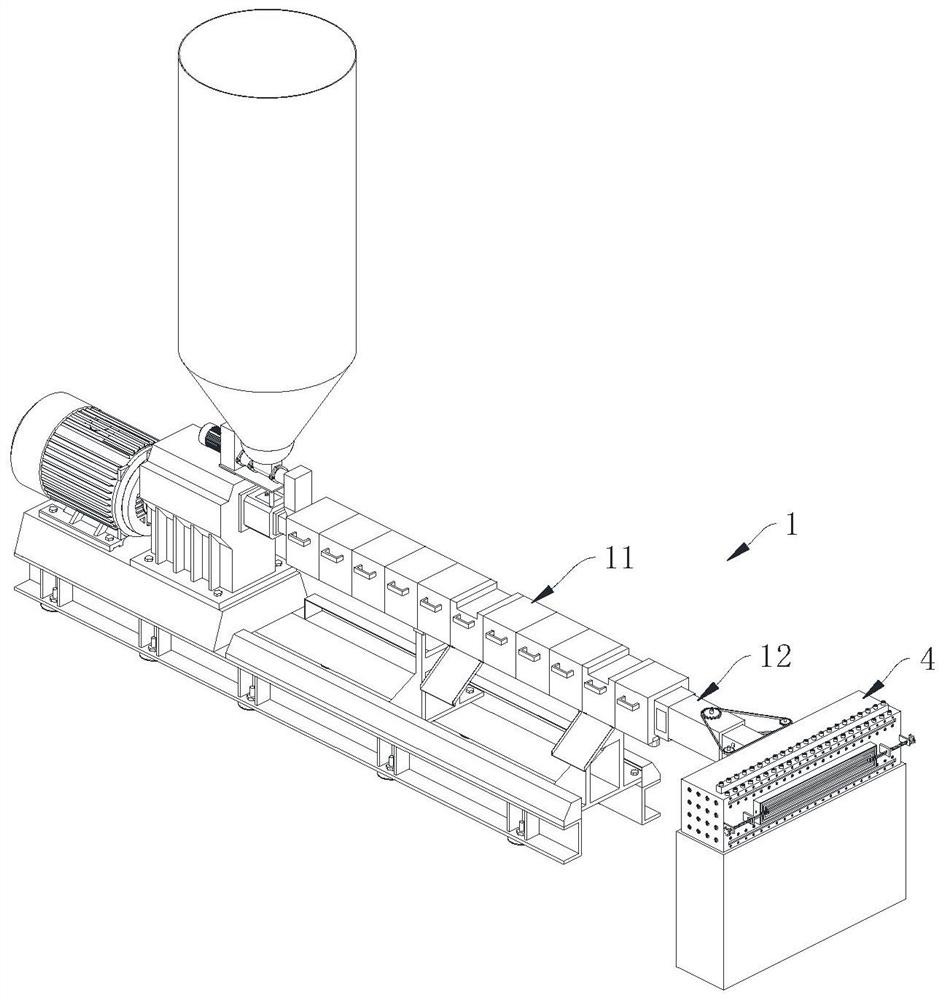

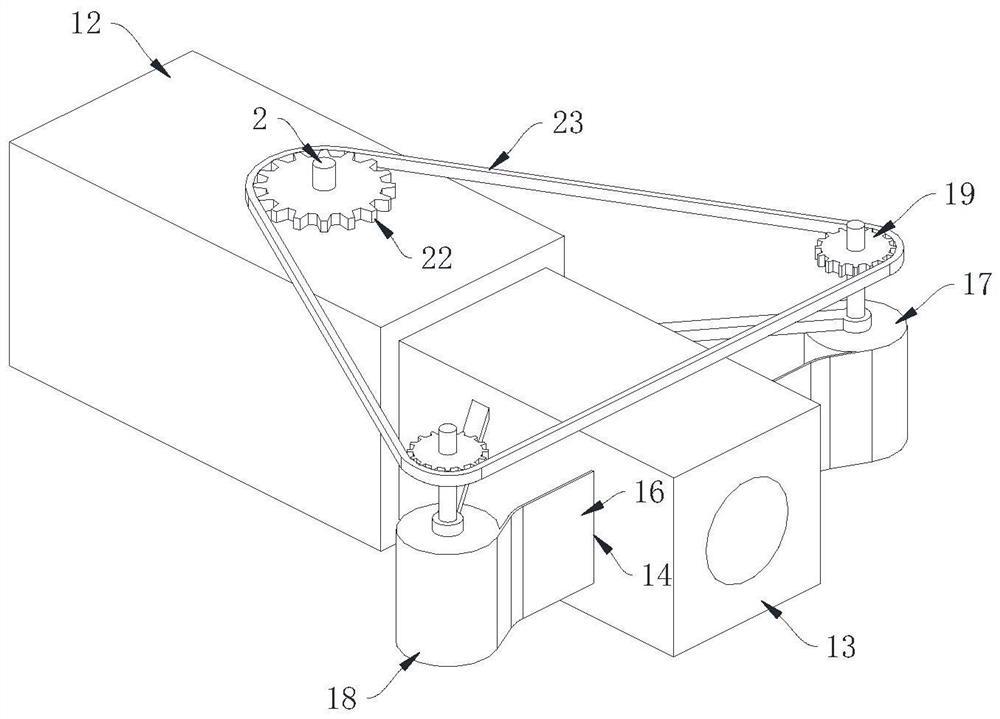

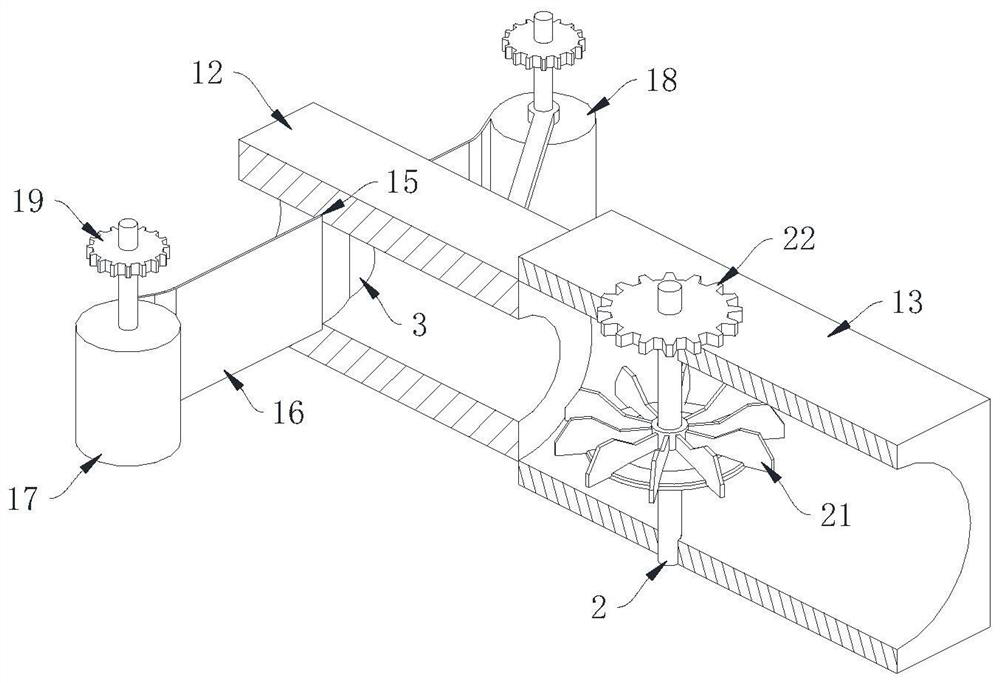

A plastic hollow board extruder

ActiveCN111531835BEasy to produceAdjust the size of the cross-sectional areaEngineeringMechanical engineering

The invention relates to the field of plastic hollow board production, and discloses an extruder for plastic hollow boards, which includes an extruder body, and a strip-shaped molding seat is connected to the outlet end of the extruder body, and the molding seat is hollow. The side of the forming seat away from the extruder body is horizontally provided with a strip-shaped discharge port; the side of the forming seat close to the discharge port is provided with a frame around the discharge port, and the frame is sequentially nested. A plurality of adjustment frames are provided, and the plurality of adjustment frames are used to cover the discharge port, and both ends of the forming seat are provided with locking parts for fixing the adjustment frames. The present invention has the following advantages and effects: by setting a detachable and conveniently disassembled adjustment frame, the rapid adjustment of the size of the cross-sectional area of the discharge port is realized, so that the above-mentioned extruder can more conveniently and quickly produce plastics with different widths and thicknesses. Hollow plate, to achieve the effect of efficient production.

Owner:荆州市骏达科技有限公司

Assembled automobile air conditioner wire harness protection shell

ActiveCN112152168ARealize compression and fixationAchieve fixationElectrical apparatusElectric/fluid circuitDrive shaftAutomobile air conditioning

Owner:安徽合博机电有限公司

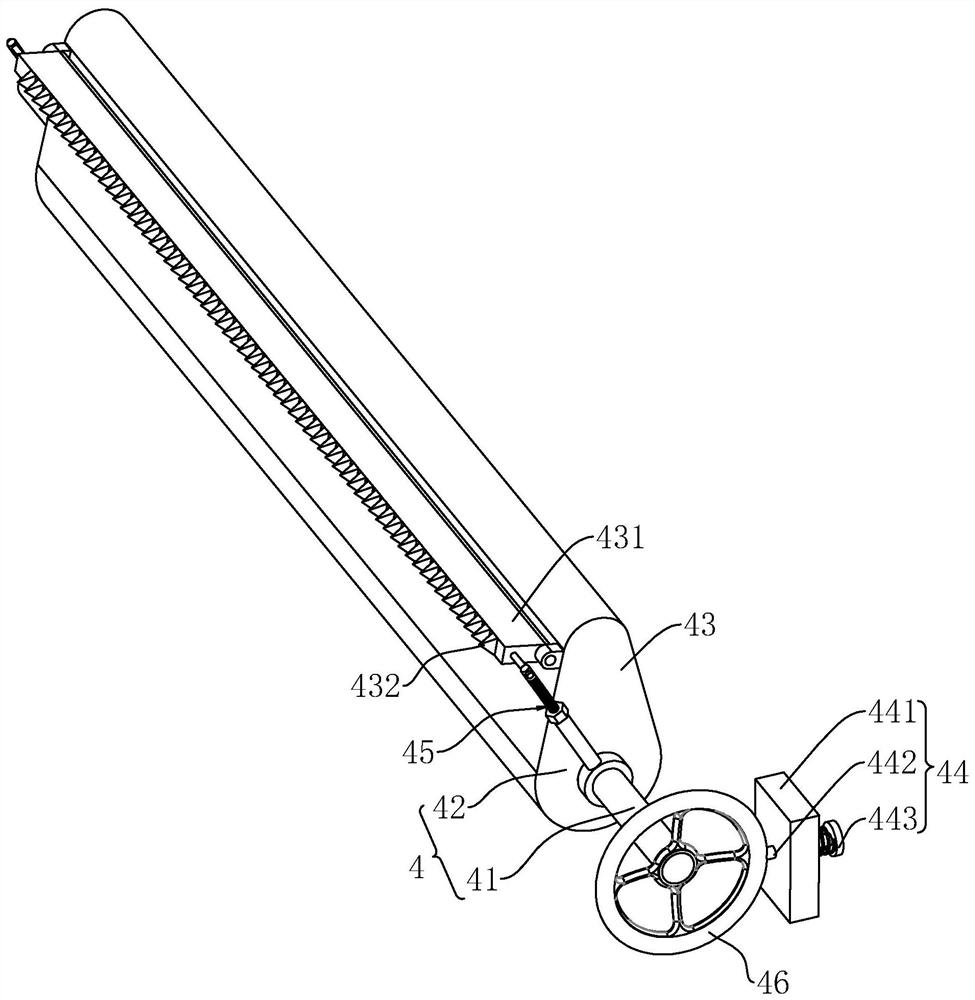

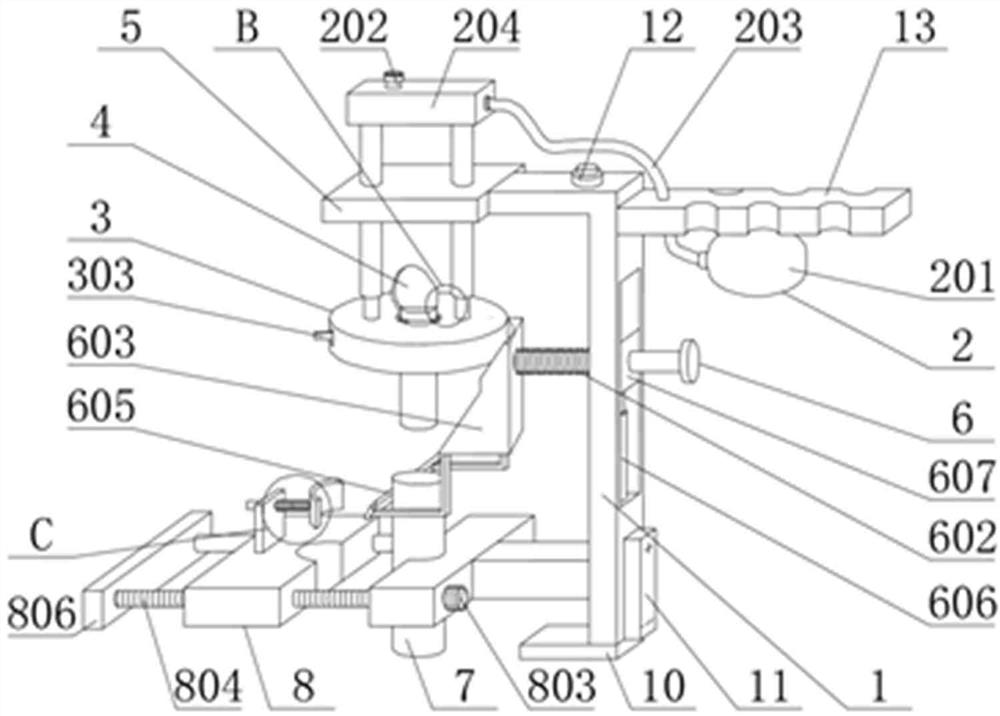

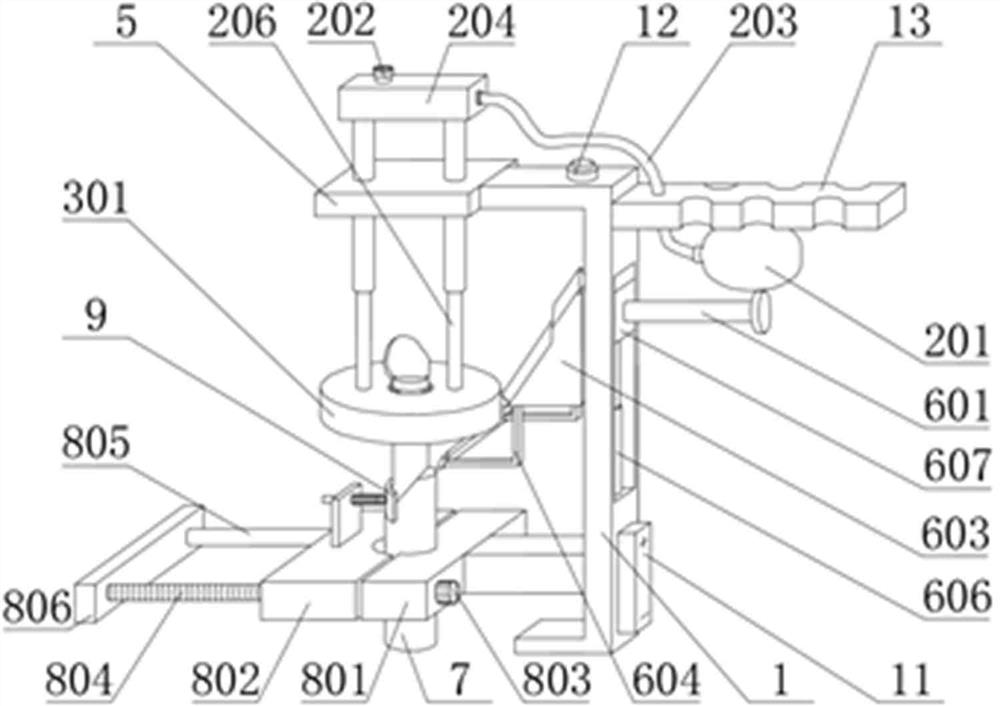

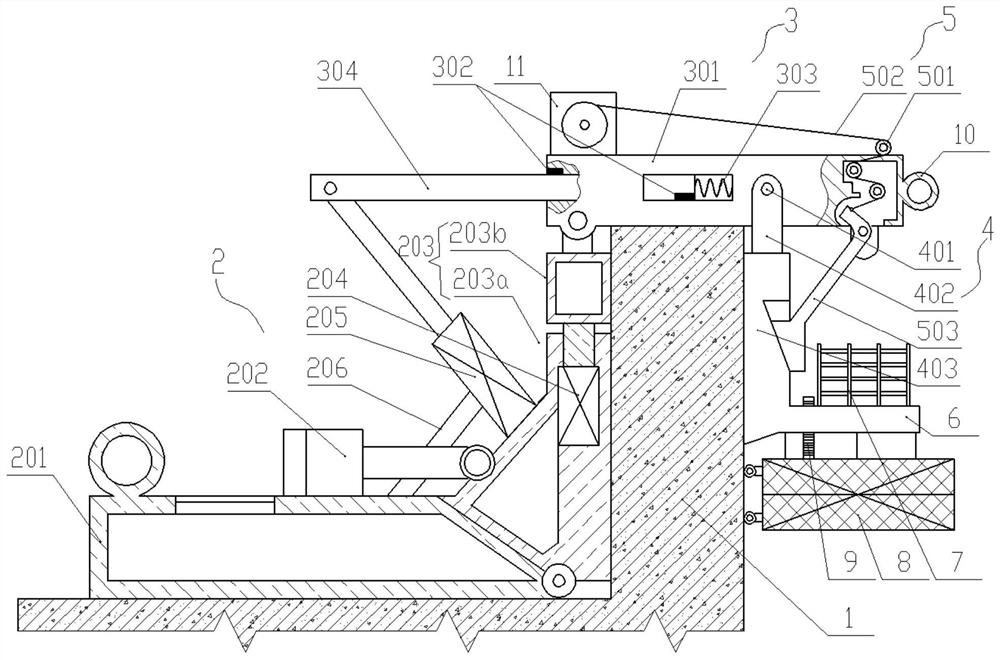

High-survival-rate automatic grafting device for watermelon growth and use method thereof

The invention relates to the technical field of watermelon grafting, in particular to a high-survival-rate automatic grafting device for watermelon growth and a use method thereof. The high-survival-rate automatic grafting device comprises a scion, a stock, a supporting frame, an operating handle fixedly arranged on the right side of the supporting frame, a bottom plate fixedly arranged on the bottom side of the supporting frame, a storage battery and a control switch; the top end of the supporting frame is fixedly connected to a fixing plate, a scion moving mechanism capable of moving downwards is arranged on the fixing plate, a scion fixing mechanism is fixedly connected to the bottom end of the scion moving mechanism, and the scion fixing mechanism comprises a fixing disc used for fixing scions. According to the high-survival-rate automatic grafting device, through integrated design, the device is convenient to take and move, convenience in use is added, functions of cutting, butt joint and the like are designed together in a mutual linkage mode, automation of grafting operation is added, cutting of scions and stocks is completed through a same cutter and a same angle, the splicing integrity during butt joint of the scions and the stocks is guaranteed, and therefore survival rate is guaranteed.

Owner:萧县火红果蔬种植农民专业合作社

Pressure vessel end socket welding tool with locking and positioning functions

ActiveCN114161061ARealize compression and fixationImprove stabilityWelding/cutting auxillary devicesAuxillary welding devicesClassical mechanicsStructural engineering

The pressure vessel end socket welding tool with the locking and positioning functions comprises a base and a supporting mechanism, the base is connected with a supporting side plate, the supporting side plate is connected with a supporting mechanism used for supporting a vessel body, the supporting mechanism comprises a guide column and a supporting plate, the guide column is connected with an abutting mechanism supported by the supporting plate, and the supporting plate is connected with the abutting mechanism. The abutting mechanism comprises supporting columns and a second push rod, the supporting columns are connected with a driving mechanism used for driving the two supporting columns to get close to each other or get away from each other, the second push rod is used for driving the supporting mechanism to ascend, the supporting mechanism comprises a supporting disc and an ejection block, and the guiding columns are connected with a pressing mechanism used for pressing the port. The pressing mechanism comprises a push plate, a pressing plate, a first inclined rod and a second inclined rod. The push plate is used for driving the pressing plate to move towards the supporting plate. The stability of the pressure vessel end socket is improved, centering is achieved, a good foundation is provided for follow-up welding, and operation is flexible and coherent.

Owner:ERZHONG GROUP ZHANJIANG HEAVY EQUIP FACTORYCO

Mold placement frame convenient to clean

PendingCN108555864AEasy to placeRealize compression and fixationCleaning using toolsWork tools storageEngineering

The invention provides a mold placement frame convenient to clean. The mold placement frame comprises a side plate, a first supporting plate, a first spring, a first pressing plate, a base plate, a rack, a supporting block, a motor, a gear and a sponge. The first supporting plate is arranged at the inner end of the side plate, the first spring is fixedly arranged at the lower end of the first supporting plate, the first pressing plate is assembled at the lower end of the first spring, the first supporting plate and the first pressing plate are connected through the first spring, due to the design, molds of different heights can be fixed, the base plate is fixedly arranged at the lower end of the side plate, the rack is fixedly arranged at the lower end of the base plate, the supporting block is assembled at the lower end of the base plate, the supporting block is arranged at the inner end of the rack, the motor is fixedly arranged inside the supporting block, the gear is installed at the outer end of the motor, the gear is assembled at the outer end of the supporting block, the gear is installed at the lower end of the rack, and the sponge is fixedly arranged at the lower end of the supporting block. Due to the design, the automatic cleaning function is achieved, and the mold placement frame is safe, stable, convenient to clean and wide in application range.

Owner:天津市友森金属结构有限公司

Segmented guiding and conveying device for aluminum material

ActiveCN112897163AReasonable structural designSmooth panning motionWebs handlingElectric machineryEngineering

The invention discloses a segmented guiding and conveying device for an aluminum material, and belongs to the field of aluminum material machining and conveying mechanical equipment. According to the guiding and conveying device, a material pulling conveying motor drives a front conveying belt wheel to rotate, a reciprocating material pulling support is horizontally arranged on a material pulling translation guide rod in a sliding mode, the output end of a pressing plate swing air cylinder is fixedly connected to the end part of a reciprocating translation toothed plate, a reciprocating translation pressing plate is horizontally arranged between the front conveying belt wheel and a rear conveying belt wheel, the end part of the lower side of a front swing connecting plate and the end part of the lower side of a rear swing connecting plate are connected to the two sides of the upper portion of the reciprocating translation pressing plate correspondingly, the two sides of a rotary conveying belt are horizontally arranged in belt pressing square grooves in the two sides of the reciprocating material pulling support correspondingly, and a translation material pressing support is horizontally and fixedly arranged on the upper side of the reciprocating material pulling support, and a material pressing lifting wedge plate is horizontally arranged on the upper side of the translation pressing support. The guiding and conveying device has the advantages that the structural design is reasonable, the aluminum material can be efficiently, accurately, stably and orderly pulled, conveyed and guided in a segmented mode, the aluminum material conveying automation degree is improved, and the production and use requirements are met.

Owner:江苏鸿锦新能源有限公司

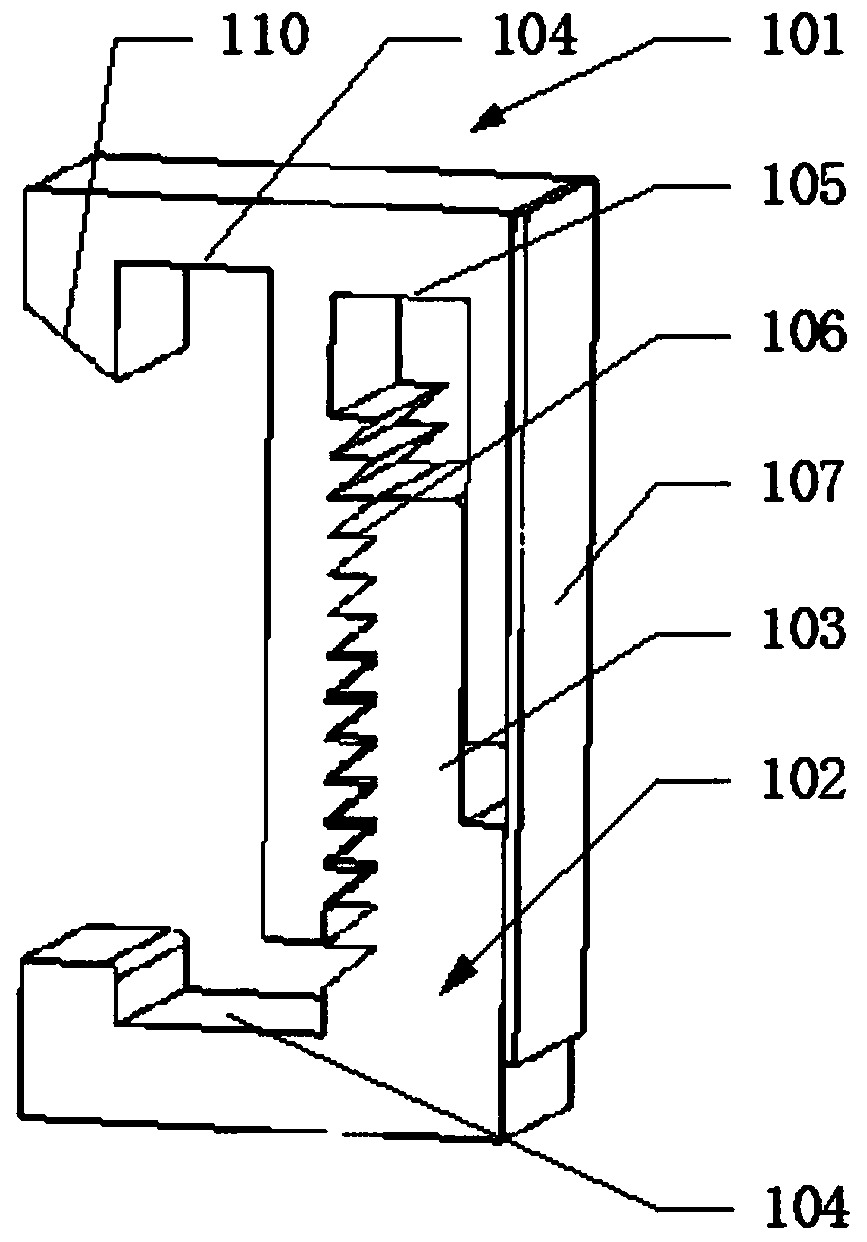

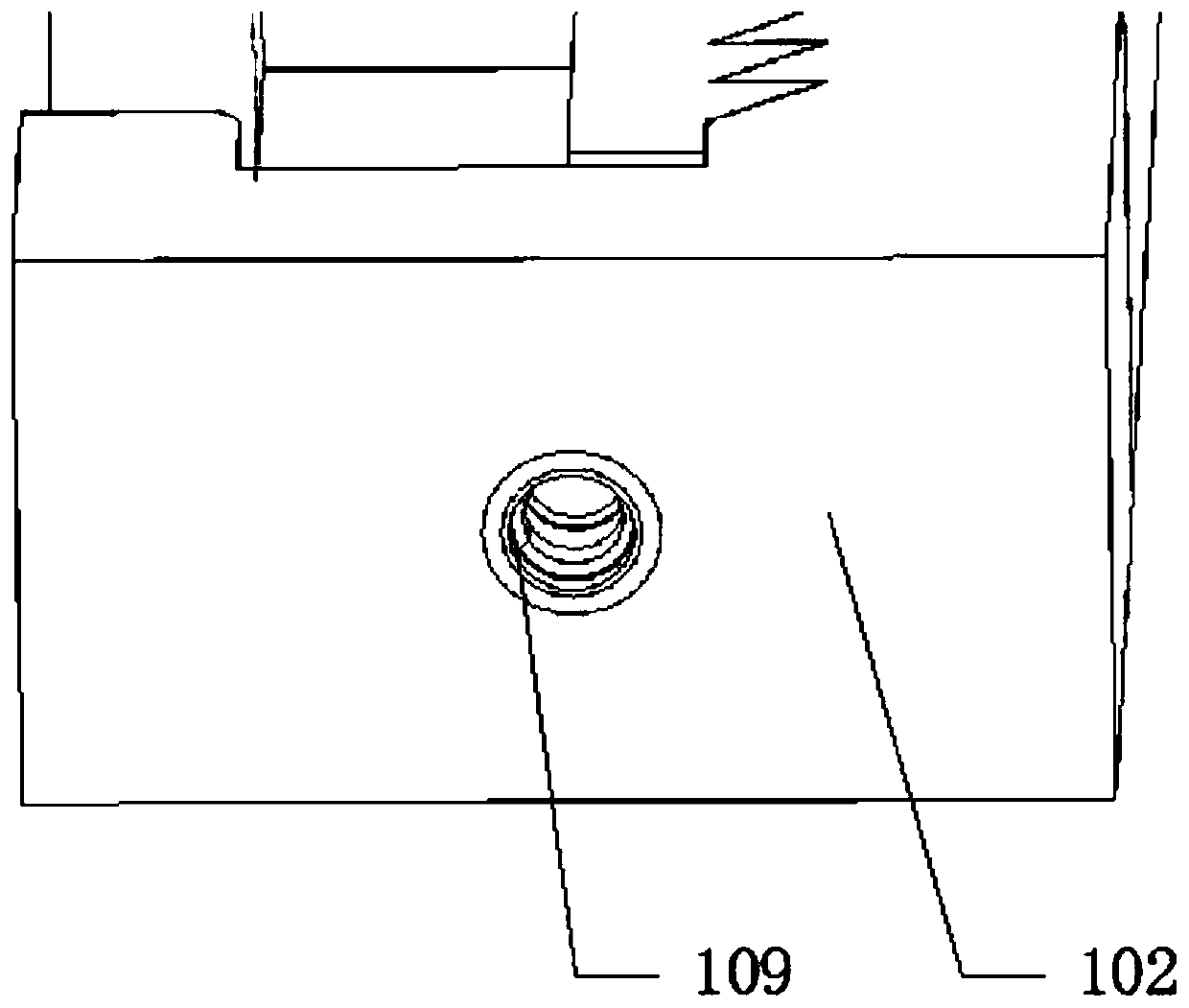

High-precision mountable and dismountable potentiometer and use method thereof

ActiveCN112071535AAchieve initial fixationRealize compression and fixationResistor mounting/supportingAdjustable resistorsStructural engineeringElectrical and Electronics engineering

The invention discloses a high-precision mountable and dismountable potentiometer. The potentiometer comprises a shell, an output shaft is mounted at the lower part in the shell, a connecting shaft ismounted in the middle of the shell of the potentiometer in a penetrating manner, two guide plates are connected to the upper part in the shell in a front-back sliding manner, and two oblique grooveswhich are symmetrically formed are formed in the surfaces of the guide plates; the guide plates are slidably connected with sliding columns through the oblique grooves, the end portions of the slidingcolumns are fixedly connected with first limiting columns, the upper portion of the shell is provided with first through holes allowing the first limiting columns to penetrate out and transversely slide, and thepotentiometer further comprises a pressing block and a transmission mechanism, and the pressing block is driven to vertically move while rotating under the action of the transmission mechanism through the movement of the two sliding columns; and the potentiometer also comprises a driving mechanism used for driving the two guide plates to move forwards and backwards. The potentiometer has the effect of conveniently mounting and dismounting the potentiometer, and solves the problem that the potentiometer is generally mounted directly through welding or bolts and is relatively complicated to dismount and mount.

Owner:迈格半导体技术(深圳)有限公司

Stainless steel mica heating coil rack

InactiveCN108406715AEasy to plug inConvenient and efficient insertion inWork tools storageWear resistantCoil spring

The invention discloses a stainless steel mica heating coil rack comprising a support baseplate, locking plates, connectors and locking bolts. The surface of the support baseplate is fixedly providedwith fixed hinge supports, and each fixed hinge support is internally provided with a pin; each fixed hinge support is fixedly provided with a fixed rod of which one end is provided with a foam tube,and the support baseplate is provided with telescopic cylinders connected to stainless steel telescopic rods; and one end of each stainless steel telescopic rod is provided with a spiral spring of which one end is provided with a dust cover, and the bottom end of the dust cover is provided with wear-resistant cushions. According to the stainless steel mica heating coil rack, the stainless steel telescopic rods on the telescopic cylinders freely extend through rotation of two height regulators, while one end of each stainless steel telescopic rod is fixed to the dust cover so that the dust cover is moved downwards, and the pressing fixation of heating coils is achieved; and meanwhile the dust cover has the function of dust prevention and blockage, and the cleanliness of stainless steel micaheating coils is ensured.

Owner:袁文林

Fast-assembly type construction platform based on bridge anti-collision wall

InactiveCN111877154ARealize compression and fixationAvoid Rollover SituationsBridge structural detailsClassical mechanicsEngineering

The invention provides a fast-assembled construction platform based on a bridge anti-collision wall, and the platform comprises an inner side positioning part and a cantilever part; the inner side positioning part comprises a first inner side sub-positioning part, a second inner side sub-positioning part and a second hydraulic rod which are hinged with one another, and the first inner side sub-positioning part is of a right-angled trapezoidal plate body structure which can be flatly placed on a bridge, and the inclined surface is arranged towards one side of the anti-collision wall; the surface of the side, facing the anti-collision wall, of the second inner side sub-positioning piece can be attached to the inner surface of the anti-collision wall; the surface of the side, facing the anti-collision wall, of the cantilever part can be attached to the top face of the anti-collision wall, a sliding shaft is installed in the cantilever part in a sliding fit mode, and one end of the slidingshaft is inserted into a sliding hole of the cantilever part from the end, facing the inner side of the bridge, of the cantilever part and connected with the bottom of the sliding hole through an elastic element, and the other end of the spring extends out of the sliding hole and is hinged with the free end of the first hydraulic rod. The platform is simple in structure, easy to manufacture and use, safe and reliable, and does not influence traffic.

Owner:孙喜军

Rehabilitation exercise device

InactiveCN107670237AImprove push-pull operationAchieve rehabilitationResilient force resistorsLocking mechanismEngineering

The invention discloses a rehabilitation exercise device. A lying board is arranged in the middle of a bearing base, the lying board is in an inverted U shape, and left and right mechanism rotation holes are correspondingly arranged on both sides of the sleeping board, and shoulder blocking mechanisms are arranged on both sides of the top board of the lying board. The shoulder stop mechanism can adjust the position along the length direction of the lying board. The rear part of the sleeping board is fixed with straps, and the bottom of the two side boards of the sleeping board is respectively fixed with the left and right bearing boards extending outward and the outside of the left and right bearing boards There are left mechanism locking unit and right mechanism locking unit with the same structure. The operating rod drives the fixed pressure ring to rotate to realize the pressing and fixing of the left mechanism locking unit to the left mechanism. There is a positioning sliding column inside the chute, and the positioning sliding The post runs through the sliding body and the sliding body can slide along the positioning sliding post. The present invention can realize the rehabilitation treatment of the upper limbs by setting the left mechanism and the right mechanism, and the shoulder retaining mechanism can be fixed at different positions to adapt to people of different heights, and has wide applicability. The invention is suitable for wide application in rehabilitation devices.

Owner:刘昊飞

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com