A fabric cutting device

A cutting device and cloth technology, which is applied in the cutting of textile materials, mechanical cleaning, textiles and papermaking, etc., can solve the problems of inability to fix the cloth, reduce the precision and beauty of the cutting, and the slippage of the cloth, so as to improve the cleanliness, improve the Accuracy and aesthetics, ensuring the effect of sticky hair effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Attached to the following Figure 1-6 This application will be described in further detail.

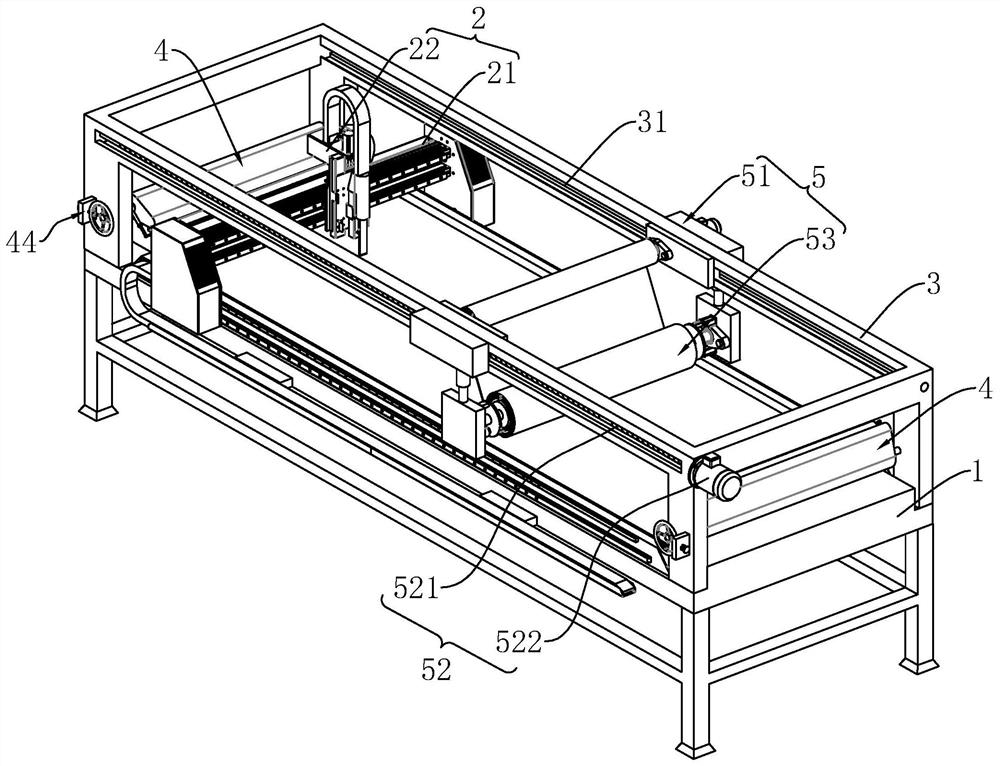

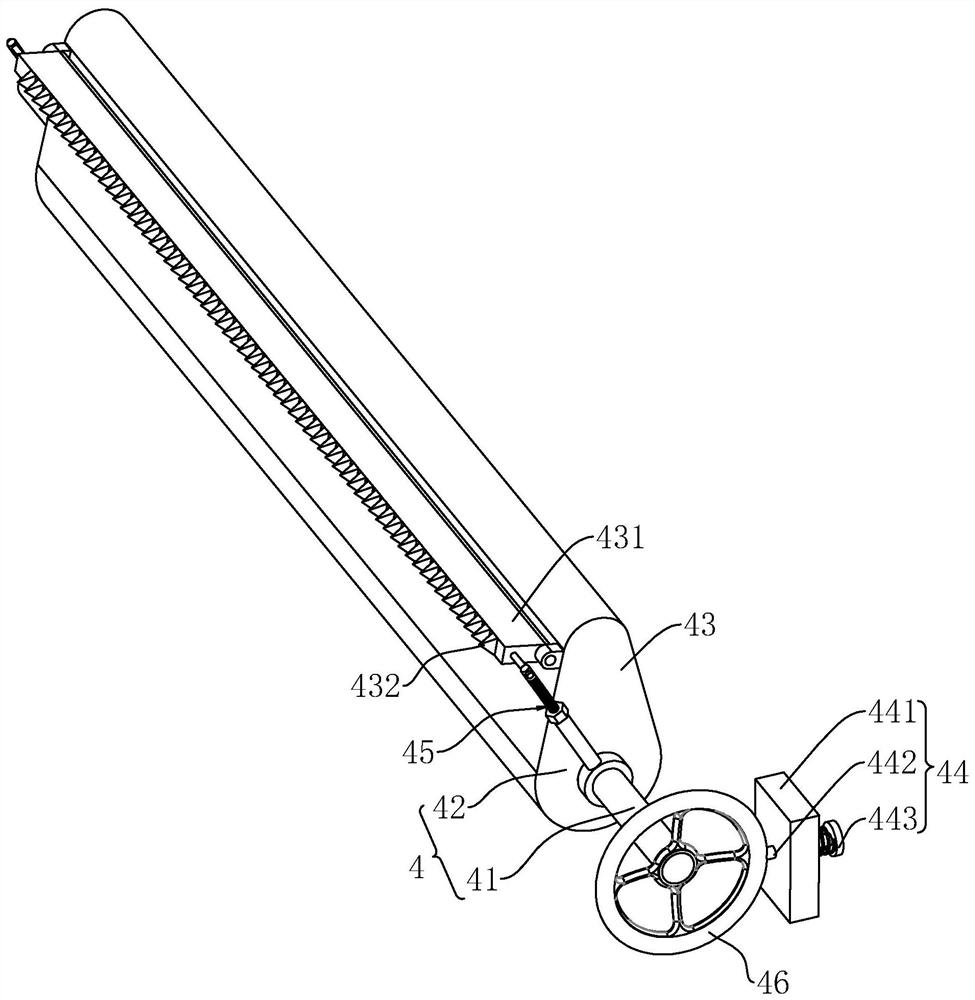

[0039] The embodiment of the present application discloses a cloth cutting device, refer to figure 1 , including a cutting table 1 for placing fabrics, a cutting mechanism 2 arranged on the cutting table 1 to cut the fabric, a fixing frame 3 arranged on the cutting table 1 and a fixing mechanism 4 arranged on the fixing frame 3 to fix the fabric, The fixing mechanism 4 is provided with two groups and is located on both sides of the cutting mechanism 2 respectively for fixing both sides of the cloth.

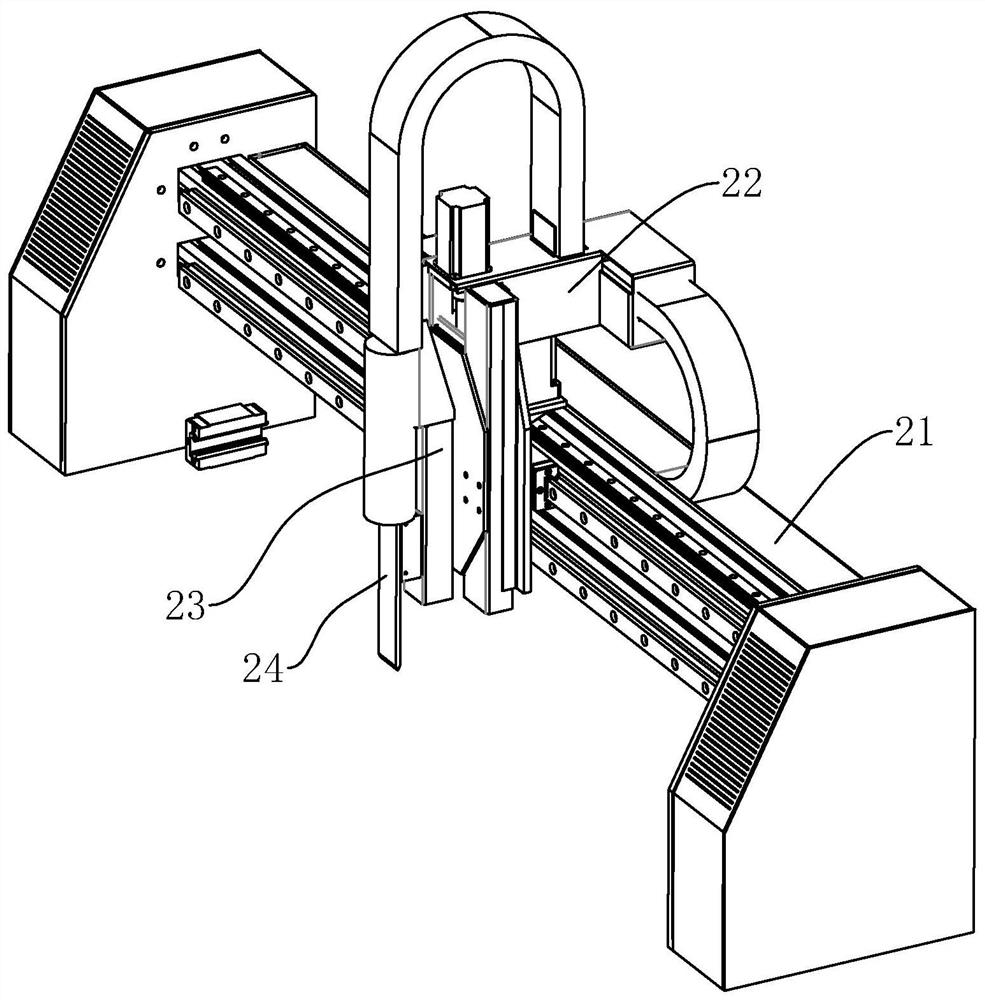

[0040] refer to figure 1 , figure 2 The cutting mechanism 2 comprises a cutting cross frame 21 slidably connected to the cutting table 1 along the length direction of the cutting table 1, a cutting longitudinal slide 22 slidingly connected to the cutting cross frame 21 along the width direction of the cutting table 1, and a vertical sliding seat 22. The cutting knife 24 seat ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com