Segmented guiding and conveying device for aluminum material

A technology of aluminum materials and guide rods, which is applied in the directions of coiling strips, transportation and packaging, thin material processing, etc., can solve the problems of unable to pull aluminum materials, complex structure, and large error in the length of aluminum material segmental transmission, etc. Achieve the effect of smooth and smooth translational movement and reasonable structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to further describe the present invention, the specific implementation of an aluminum segmental conveying device will be further described below in conjunction with the accompanying drawings. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

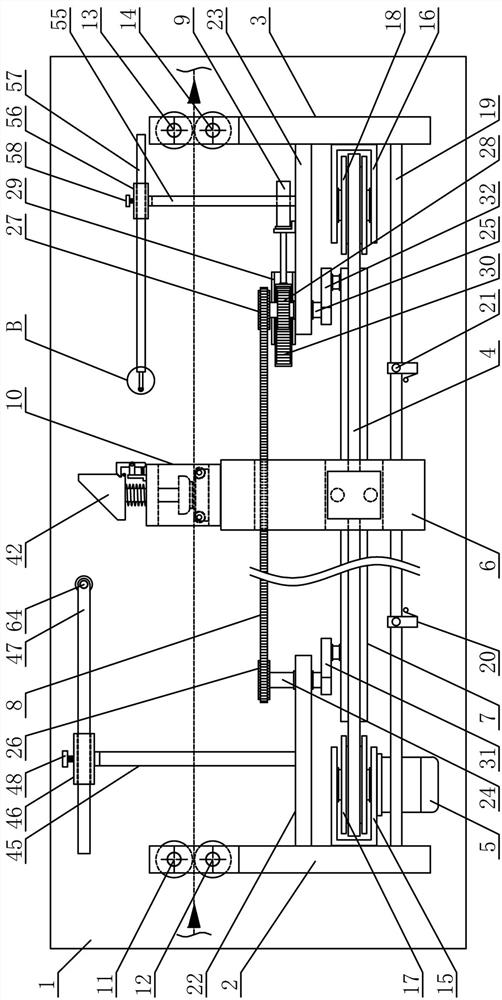

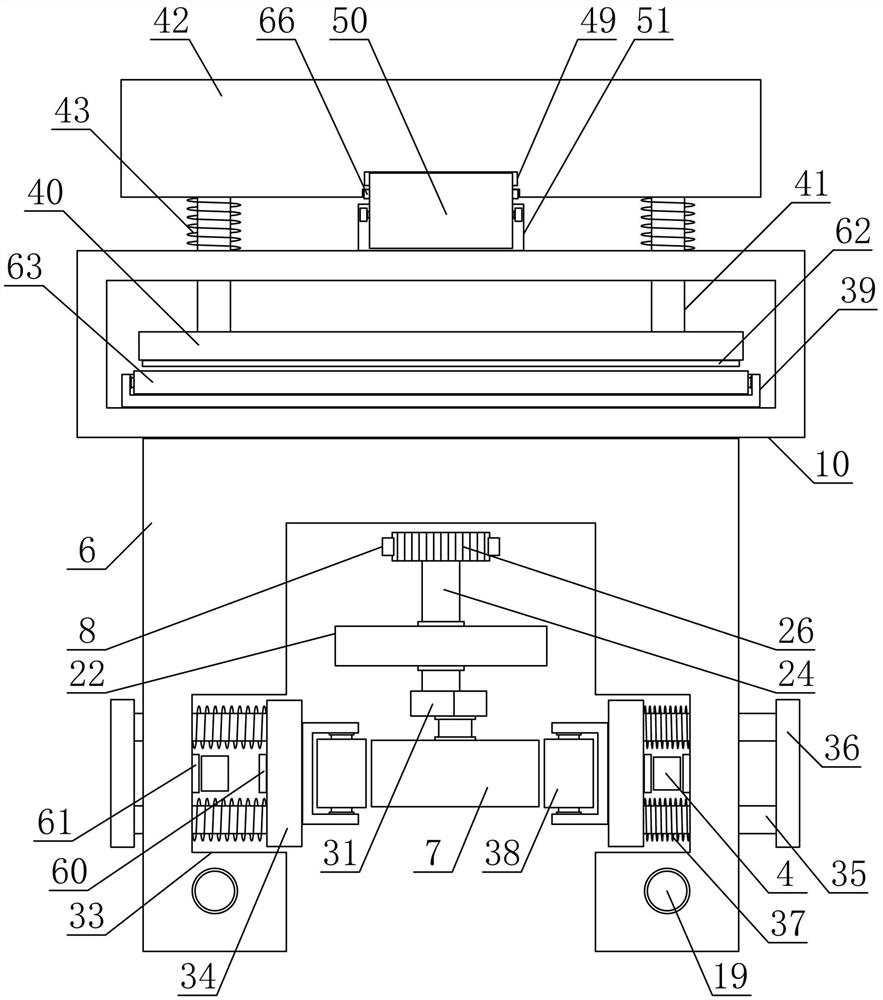

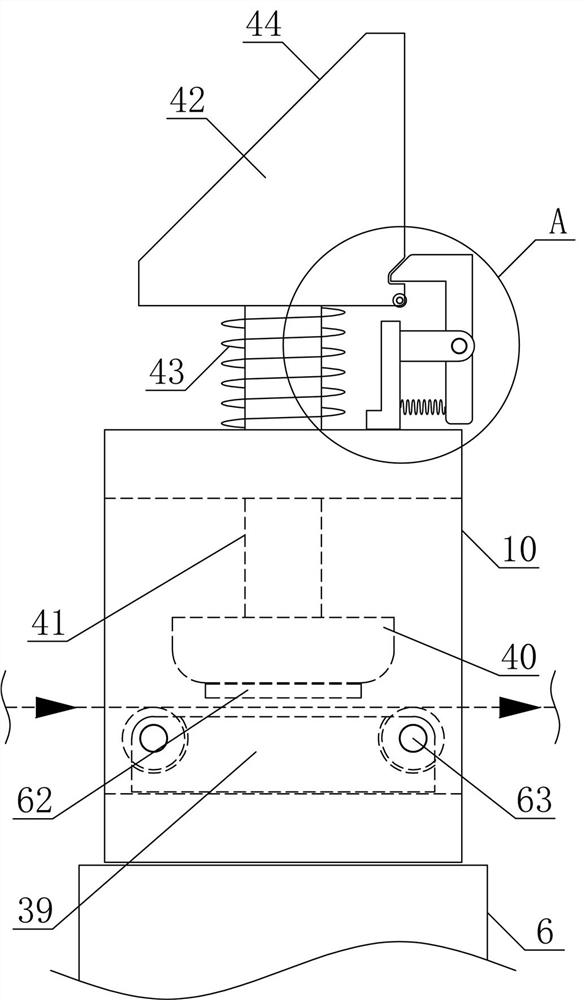

[0018] Such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 5As shown, an aluminum material segmental guide device of the present invention includes an aluminum material transmission bracket 1, a front material guide bracket 2, a rear material guide bracket 3, a rotating transmission belt 4, a material pulling transmission motor 5, a reciprocating material pulling bracket 6, Reciprocating translation pressing plate 7, pressing plate swing chain 8, pressing plate swinging cylinder 9 and translation pressing material support 10, the aluminum material transmission support 1 is vertically fixed in sequence along the horizontal dir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com