Cutting device for sponge

A cutting device and sponge technology, applied in cleaning methods and tools, metal processing, dust removal, etc., can solve the problems of unfavorable cutting quality, low cutting flatness, and slow cutting efficiency, so as to improve the cutting effect and improve the cleaning rate , the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

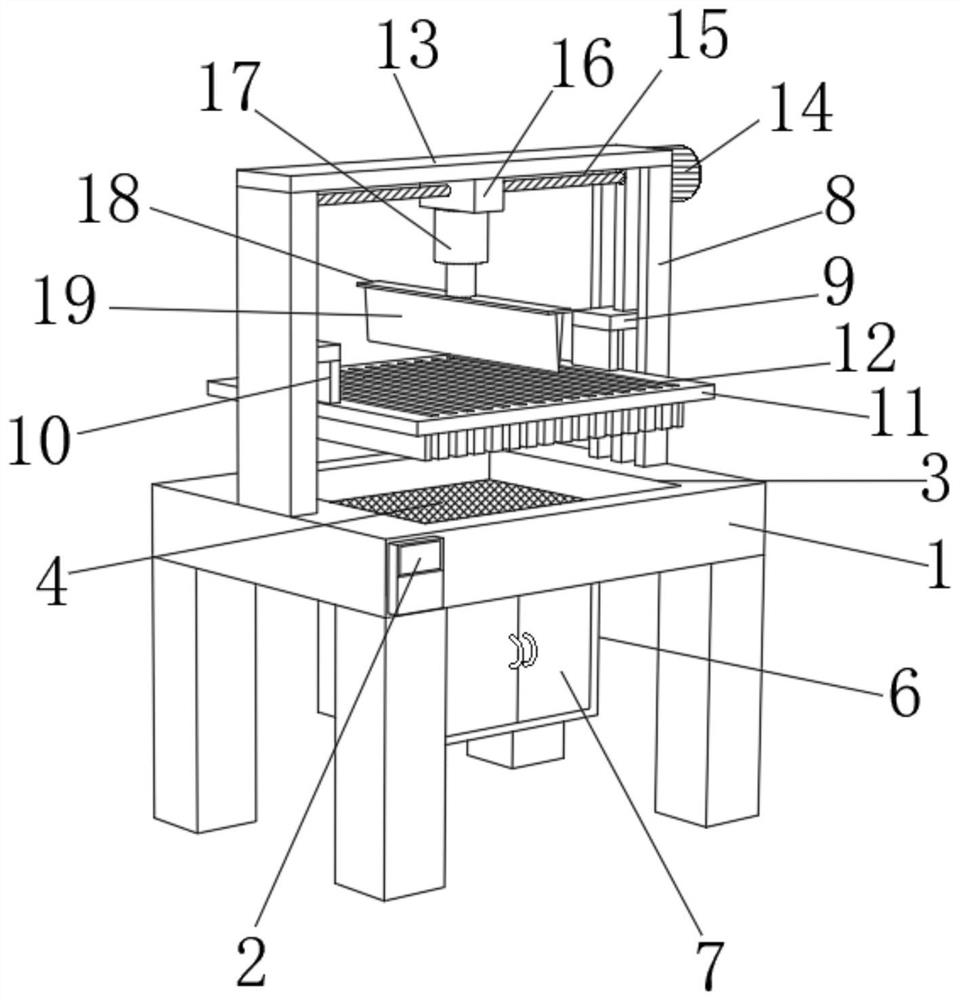

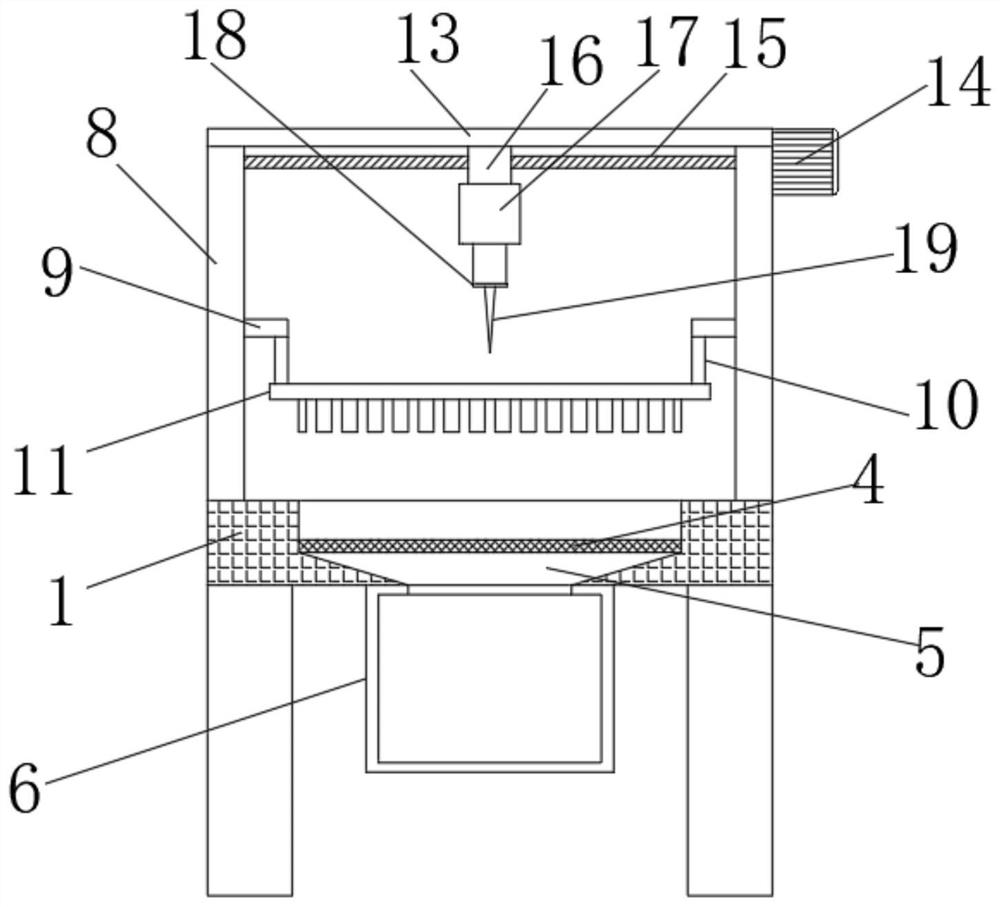

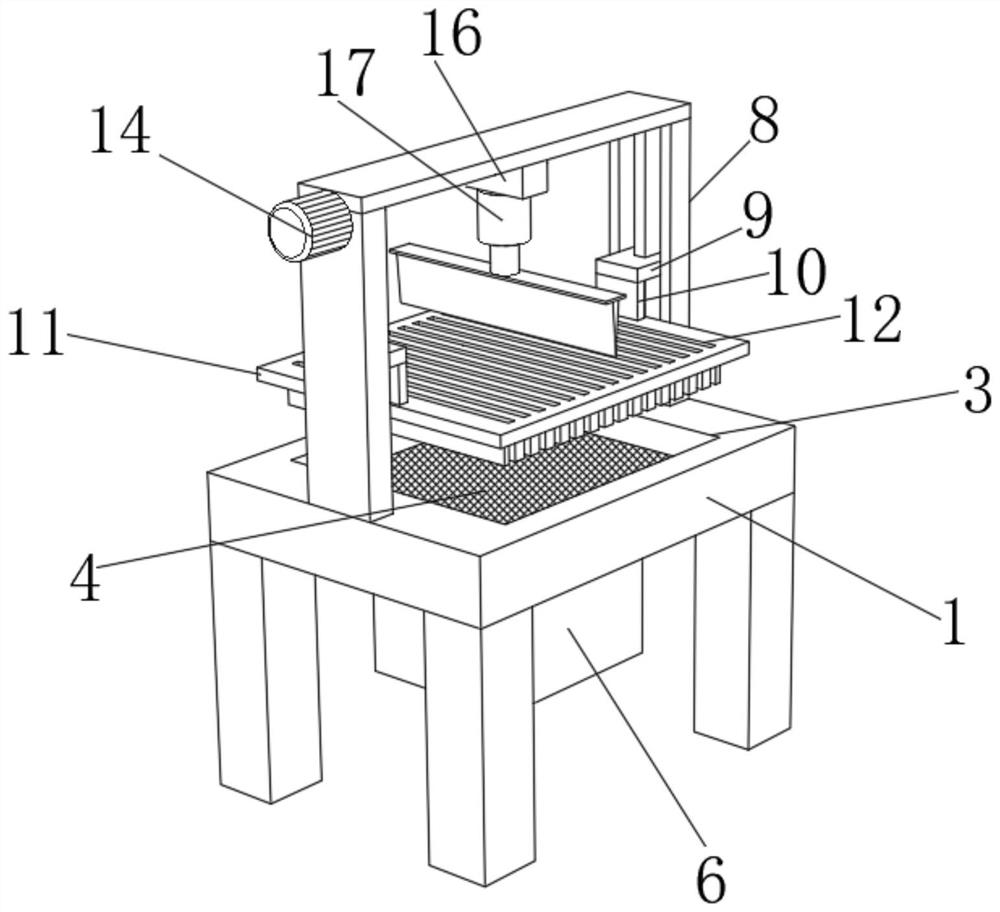

[0037] refer to Figure 1-4 , the present invention provides a cutting device for sponges, comprising a cutting table 1, a cutting groove 3 is provided at the center of the top of the cutting table 1, a support plate 4 is provided at the bottom of the cutting groove 3, and the left and right sides of the top of the cutting table 1 are The center is fixedly connected with an electric slide rail 8, and the side of the electric slide rail 8 close to the cutting groove 3 is slidably connected with a slider 9, and the side of the bottom of the slide block 9 away from the electric slide rail 8 is fixedly connected with a fixed plate 10 , the bottom of the fixed plate 10 is respectively fixedly connected to the left and right sides of the top of the guide plate 11 .

[0038] When in use, put the sponge to be cut on the support plate 4 in the cutting groove 3, start the electric slide rail 8 through the control panel 2, and the electric slide rail 8 drives the slider 9, the fixed plat...

Embodiment 2

[0041] In this embodiment, on the basis of the structural scheme disclosed in the above-mentioned embodiments, a motor 14 is fixedly connected to the top right side of the electric slide rail 8 on the right side, the driving end of the motor 14 is fixedly connected to the right end of the threaded rod 15, and The diameter is connected with a moving block 16, and the center of the bottom of the moving block 16 is fixedly connected with an electric telescopic rod 17, and the bottom of the electric telescopic rod 17 is fixedly connected with the top of the mounting plate 18, and the cutting table 1 is located inside the supporting plate 4. There is a collection tank 5, the bottom outlet of the collection tank 5 is connected to the top feed port of the dust collection box 6 through a pipe, the bottom center of the cutting table 1 is fixedly connected with the dust collection box 6, and the front side of the dust collection box 6 Two chamber doors 7 are provided.

[0042]The above ...

Embodiment 3

[0044] In this embodiment, on the basis of the structural scheme disclosed in the above-mentioned embodiments, the electric slide rail 8, the motor 14 and the electric telescopic rod 17 are all connected to the control panel 2 through signal lines, and the rear side of the control panel 2 is fixedly connected to the cutting table 1. The left end of the front side is convenient for manipulation and improves efficiency. A cutting knife 19 is arranged on the top of the mounting plate 18. The size of the cutting knife 19 is the same as that of the guide groove 12, which is convenient for the cutting knife 19 to cut the sponge and ensure the smoothness of the cutting. The top of slide rail 8 is respectively fixedly connected to the left and right ends of the bottom of the limit plate 13, the top of the moving block 16 is slidably connected to the bottom of the limit plate 13, and the left end of threaded rod 15 is connected to the right side of the electric slide rail 8 on the left s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com