Lifting basket for tower crane

A technology of tower cranes and side plates, applied in the direction of load hanging components, transportation and packaging, etc., can solve the problems of poor safety, inconvenient operation, no limit fixing mechanism, etc., and achieve the effect of ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to make the technical problems, technical solutions and beneficial effects to be solved by the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

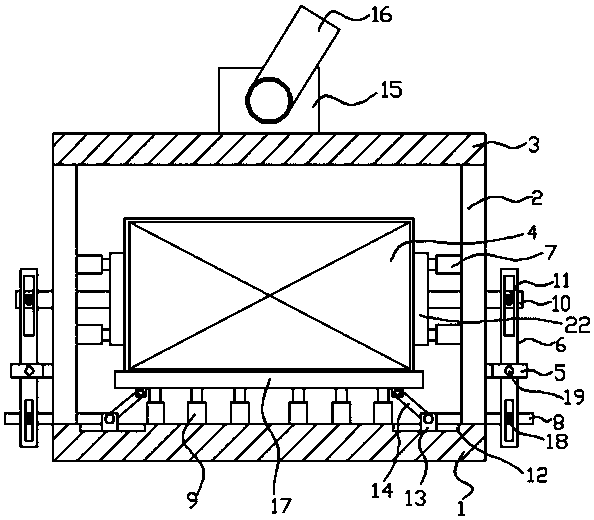

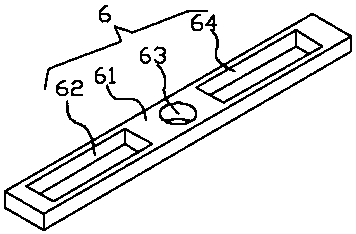

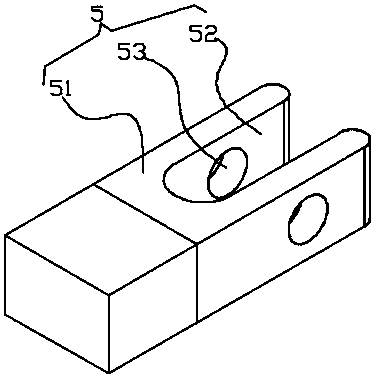

[0032] see figure 1 In one embodiment provided by the present invention, a hanging basket for a tower crane includes a bottom plate 1, a top plate 3, and at least two side plates 2 that are connected to each other and form an accommodating cavity, wherein the accommodating cavity is provided with The storage platform 17 erected on the bottom plate 1 by the elastic support member 9; at least two pressing plates 22 are also symmetrically arranged in the accommodating chamber, and when the storage platform 17 moves downwards, the transmission mechanism pushes the pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com