Staple cartridge assembly of disposable intracavity cutting and edge incising anastomat

An internal cutting and stapler technology, applied in the field of medical devices, can solve problems such as inability to achieve tissue fixation, achieve the effect of reducing surgical risks, reducing blood vessel damage, and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

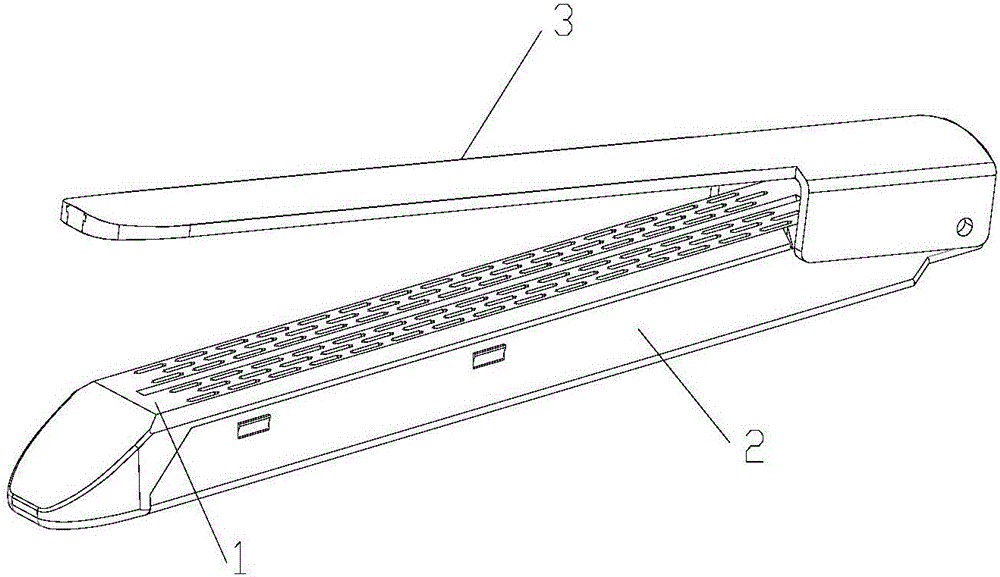

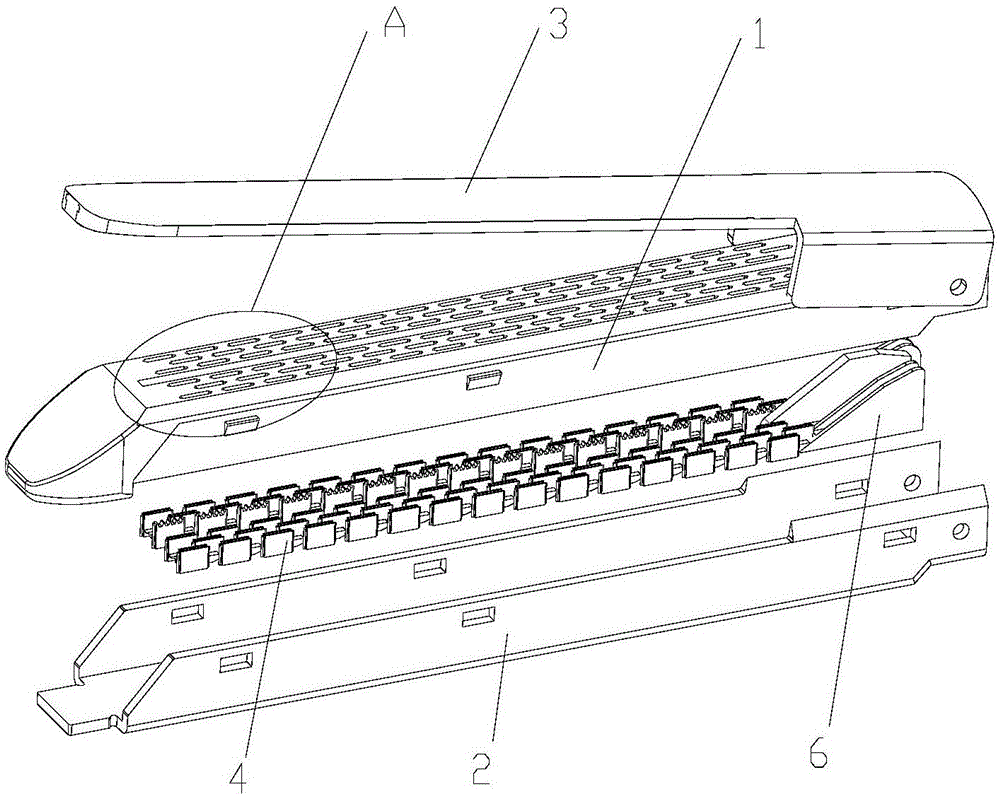

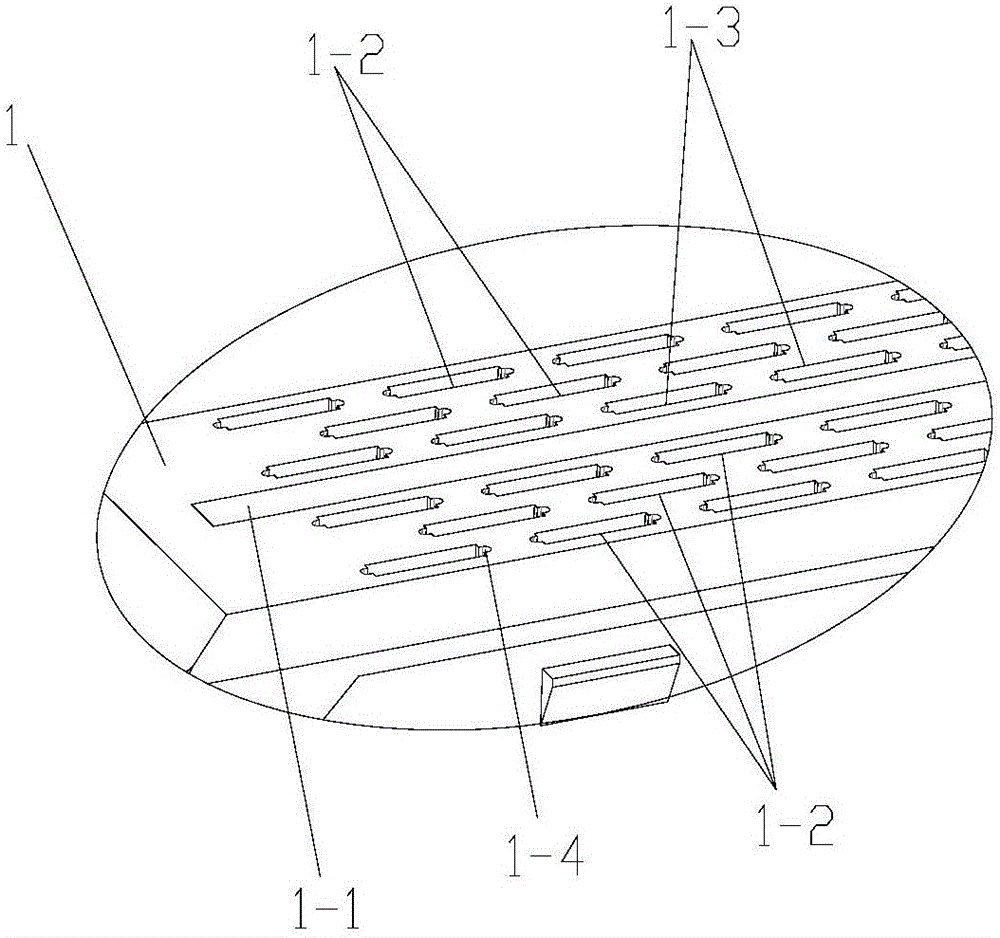

[0057] Such as Figure 1-Figure 10 As shown, a staple cartridge assembly of a disposable intracavity cutting edge stapler of the present invention includes a staple cartridge 1, a staple cartridge seat 2, a nail anvil 3 and a nail pusher set 4, and the staple cartridge 1 is set on In the staple cartridge seat 2, the nail abutment plate 3 is arranged opposite to the staple cartridge 1, the surface of the nail abutment plate 3 opposite to the staple cartridge 1 is a forming surface, and one end of the nail abutment plate 3 is rotationally connected to one end of the staple cartridge seat 2 through a rotating shaft. Through the rotation of the anvil plate 3, the opening and closing between the anvil plate 3 and the staple cartridge 1 can be realized. The middle part of the staple cartridge 1 is provided with a cutting groove 1-1, and the staple cartridge 1 on both sides of the cutting groove 1-1 There are three rows of staple grooves 1-2 on the top, and the forming surface is pro...

Embodiment 2

[0061] Such as Figure 11-Figure 12 As shown, the difference between this embodiment and Embodiment 1 is that the structure of the first tissue compression block 4-7 is different, and the top of the first tissue compression block 4-7 is provided with a first rib pattern structure, and the The extending direction of the first bar pattern structure has a certain included angle with the extending direction of the cutting groove 1-1. In this embodiment, the first bar pattern structure is a plurality of first toothed bars 4-8 arranged in parallel, and the extending direction of the first toothed bars 4-8 is mutually compatible with the extending direction of the cutting groove 1-1. Vertical, that is, the included angle is 90°. Tissue accommodation grooves are formed between two adjacent first toothed bars 4-8.

[0062] Compared with the planar structure in Embodiment 1, in this embodiment toothed bars are used to increase the contact area with the tissue and increase the blocking...

Embodiment 3

[0064] Such as Figure 13-Figure 15 As shown, the difference between the present embodiment and the second embodiment is that the setting of the tissue compression structure is different, and the tissue compression structure also includes a second strip pattern structure arranged on the forming surface of the anvil plate 3, and the first strip pattern structure The pattern structure is concavo-convexly matched with the second rib pattern structure. The second rib pattern structure is improved on the plane corresponding to the tissue pressing block groove 1-3 in the second embodiment to a second toothed bar 3-3 having a certain angle with the extending direction of the cutting groove 1-1, In order to cooperate with the first toothed strip 4-8, the second rib pattern structure in this embodiment is a plurality of second toothed strips 3-3 arranged in parallel, and the extending direction of the second toothed strip 3-3 The extension direction of the cutting groove 1-1 is perpen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com