Rectangular harness fixing buckle

A technology for fixing clips and rectangular wires. It is used in electrical components, circuits or fluid pipelines, transportation and packaging. It can solve the problems of damaged wire harnesses and the inability of cable ties to clamp the rectangular wire harnesses, and achieve the effect of avoiding wire harness damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to explain in detail the technical content, structural features, achieved goals and effects of the technical solution, the following will be described in detail in conjunction with specific embodiments and accompanying drawings.

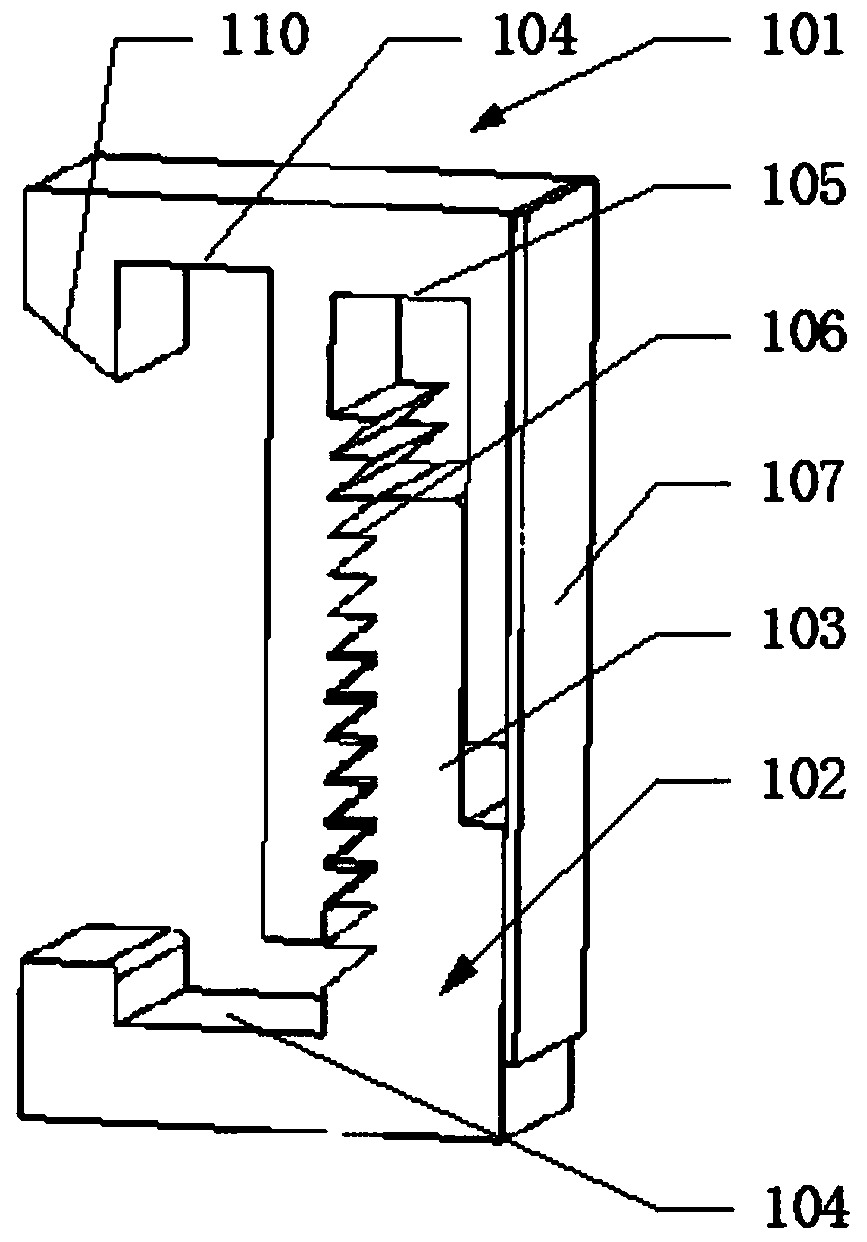

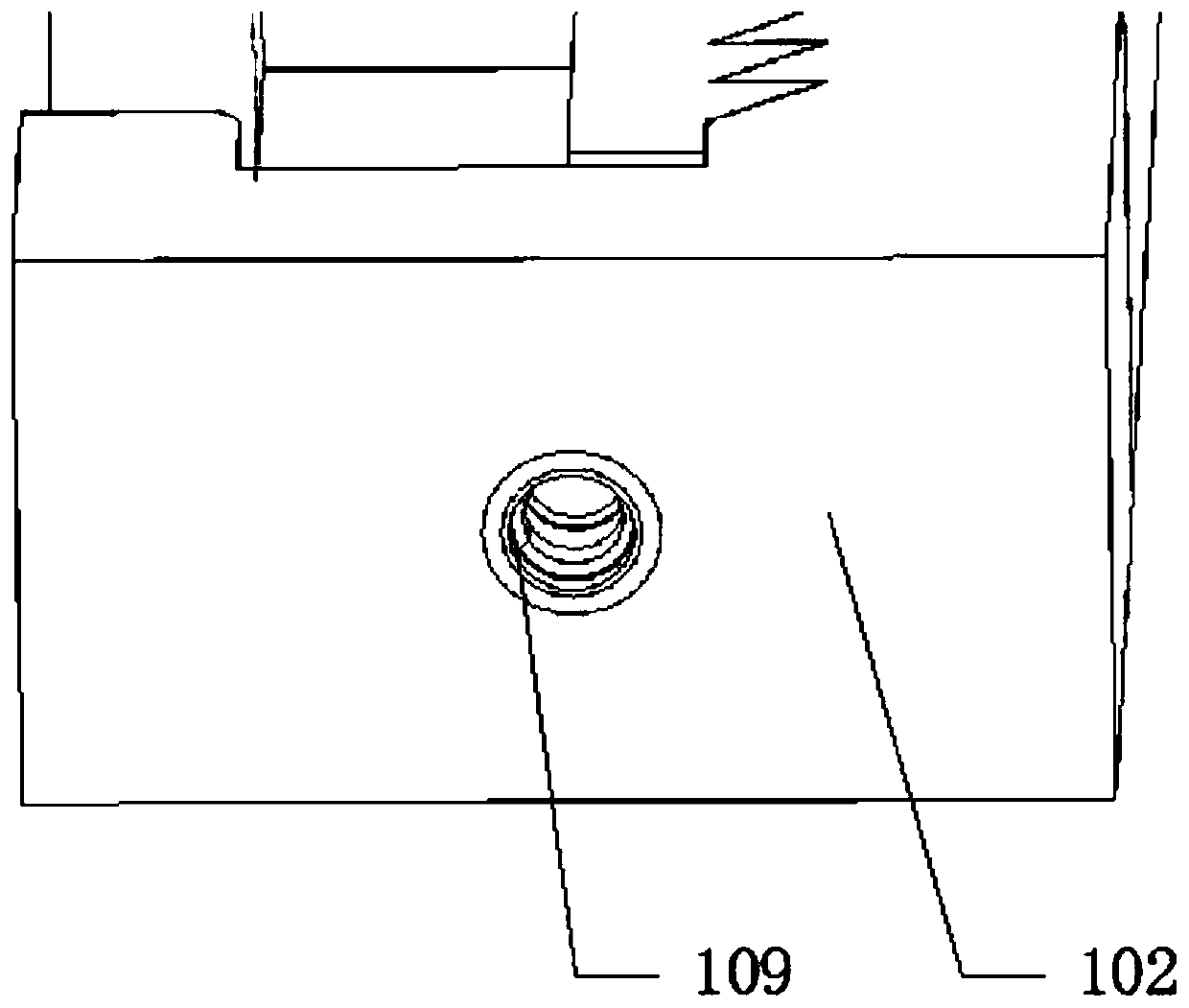

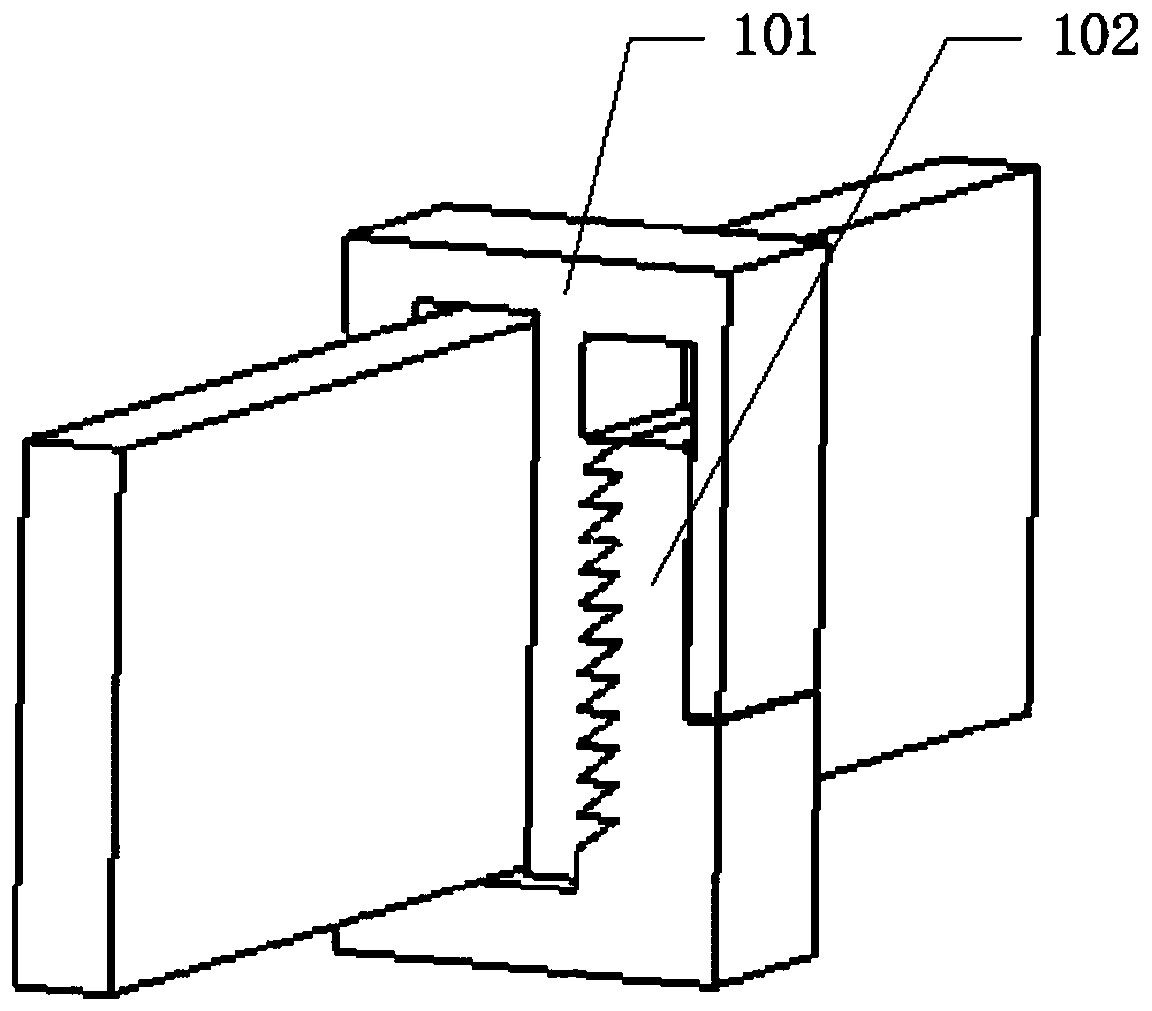

[0026] see figure 1 as well as image 3 , this embodiment discloses a rectangular wire harness fixing buckle, which includes a first clamping member 101 , a second clamping member 102 and a back adhesive plate 107 . The first clip 101 includes a clip body 103, a wire harness slot 104, a positioning slot 105, and a latch 106. The wire harness slot 104 is arranged on one side of the clip body 103. The wire harness slot 104 is a rectangular structure, and The wire harness slot runs through both sides of the clip body 103, the positioning groove 105 and the latching teeth 106 are arranged on the other side of the clip body 103, and the groove structure of the positioning groove 105 is arranged toward the length direction of the clip body...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com