Spool classification tightening device for intelligent manufacturing

An intelligent manufacturing and wire tube technology, which is applied in the direction of transportation and packaging, electrical components, and delivery of filamentous materials, etc., can solve the problems of inability to achieve auxiliary fixation, inability to fix cables, and inability to achieve damage-free fixation of cables, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

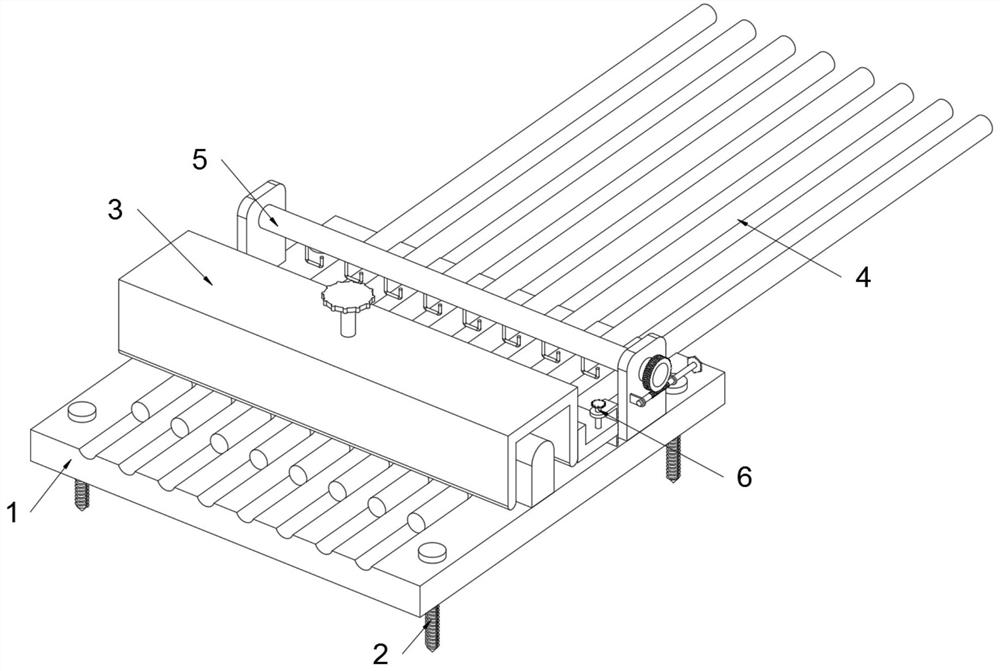

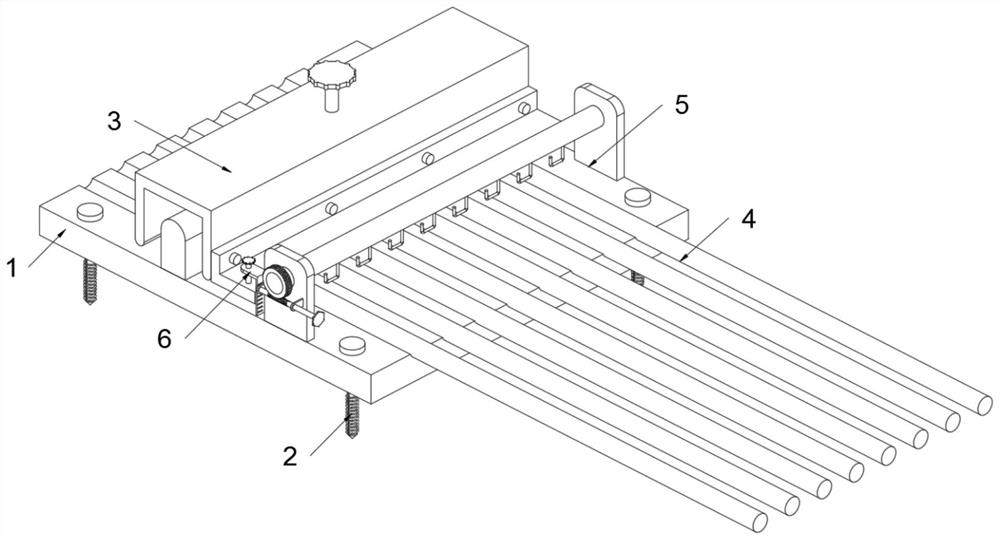

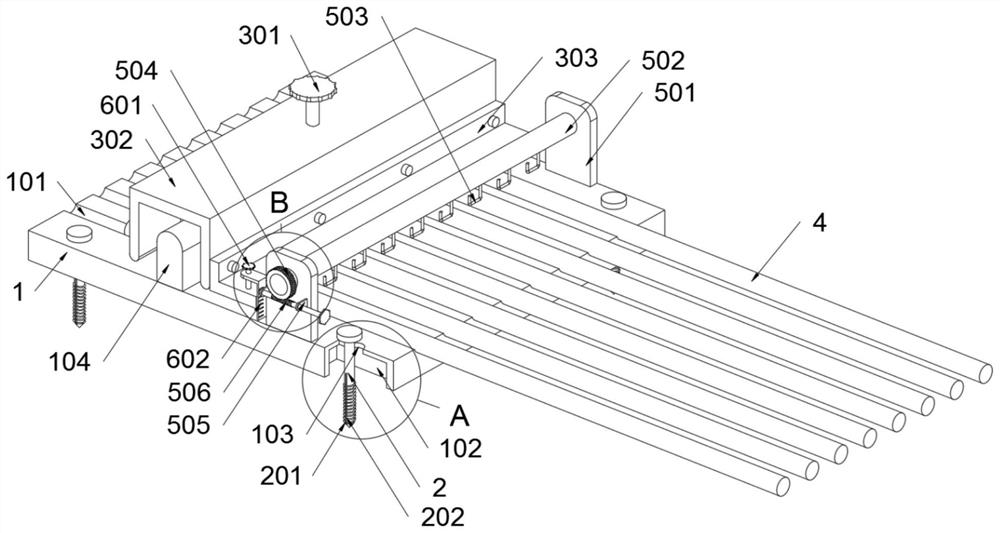

[0035] as attached figure 1 to attach Figure 8 Shown:

[0036] The invention provides a wire tube classification and tightening device for intelligent manufacturing, which includes a main body seat 1; four fixing bolts 2 are plugged into the main body seat 1, and the fixing bolts 2 are fixedly connected to the wall; There is a fixed structure 3, and eight cables 4 are fixed between the main body seat 1 and the fixed structure 3; the winding structure 5 is installed on the main body seat 1; the limit structure 6 is installed on the fixed structure 3; refer to as Figure 7 and Figure 8 , the fixed structure 3 includes a fastening bolt 301 and a fastening seat 302, the fastening bolt 301 is threadedly connected to the protrusion 104, and a fastening seat 302 is rotationally connected on the fastening bolt 301; the fastening seat 302 is a concave structure , and the bottom end of the fastening seat 302 is an arc-shaped structure, so that on the one hand, the rotation of the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com