Intelligent constant-speed feeding machine special for flour processing

A special intelligent feeding machine technology, applied in the field of flour processing, can solve the problem that the same amount of additives cannot be fed simultaneously, and achieve the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

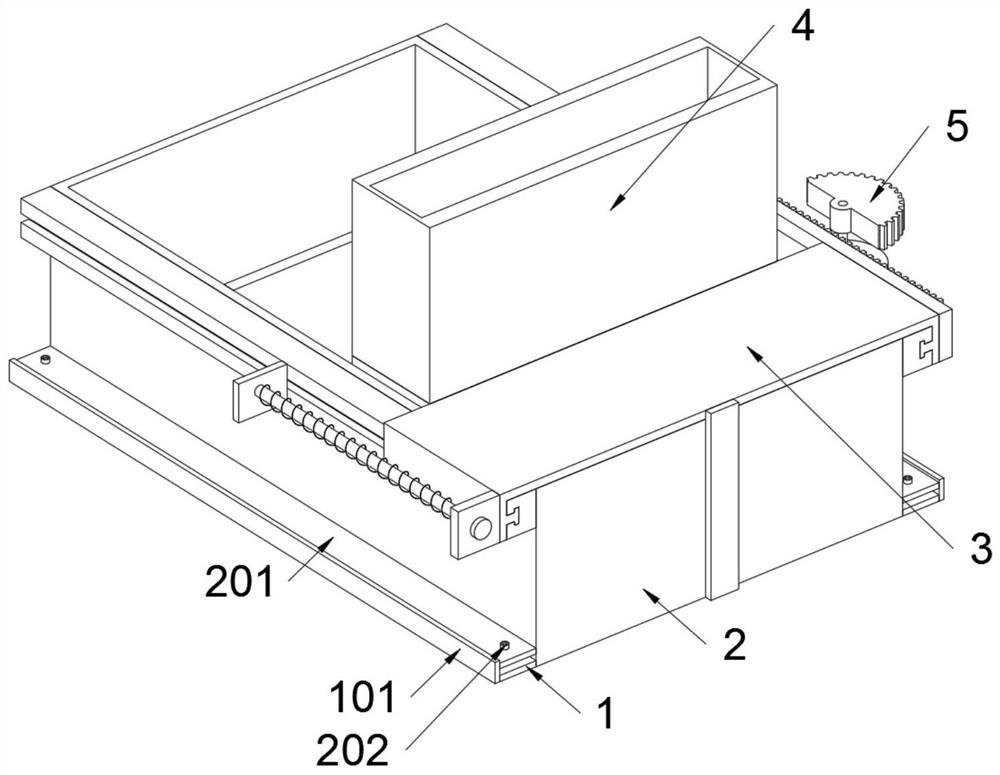

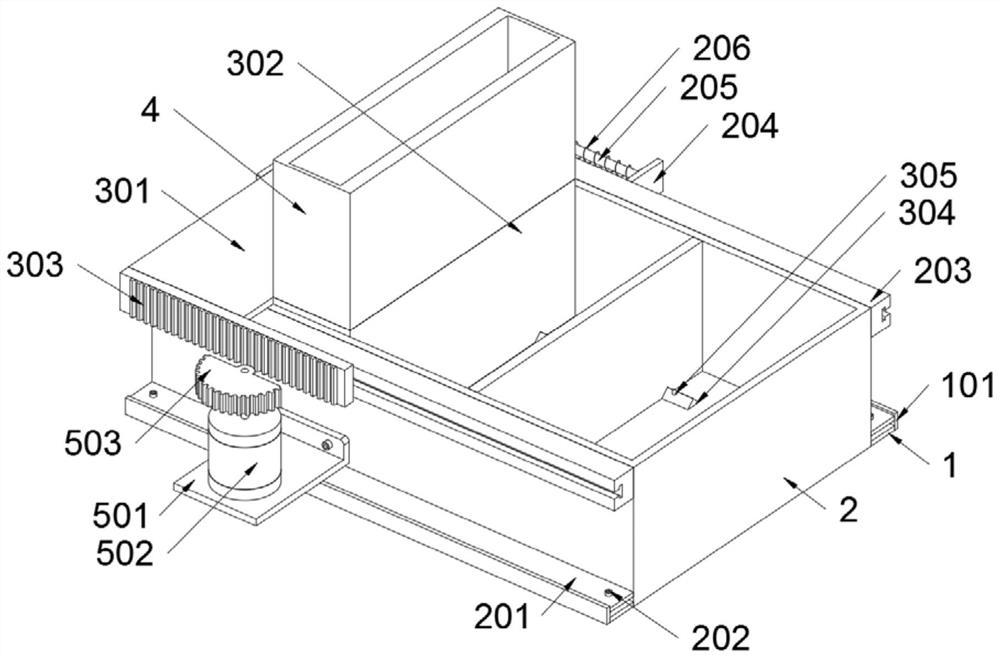

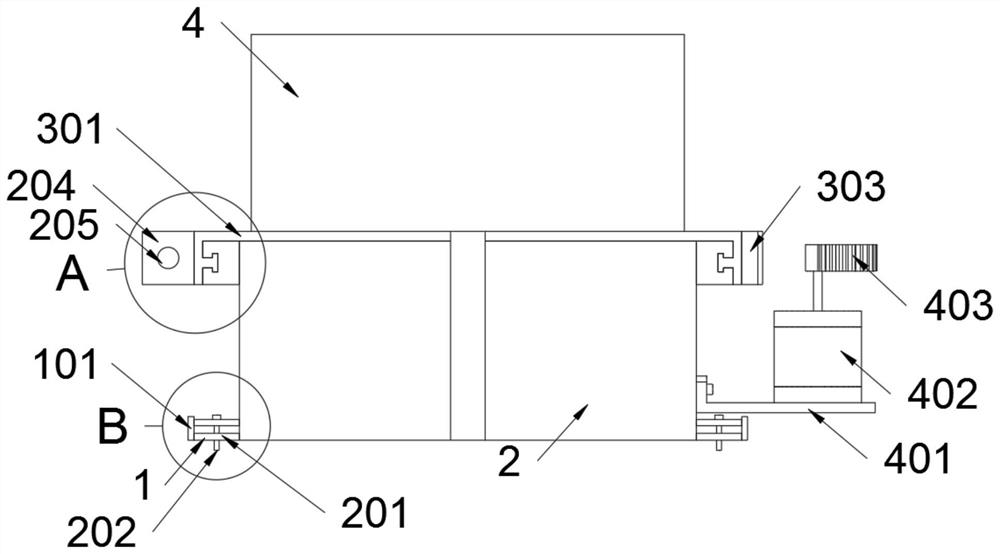

[0033] as attached figure 1 to attach Figure 7 Shown:

[0034] The invention provides an intelligent uniform-speed feeder for flour processing, which includes a fixed seat 1; a box body 2 is fixedly connected to the fixed seat 1, and a feeding structure 3 is slidably connected to the box body 2, and the feeding structure 3 is connected to the feeding The material tube B4 is in contact; the box body 2 is fixedly connected with the drive structure 5 by bolts; refer to Image 6 , the feeding structure 3 includes a feeding pipe A302, the feeding pipe A302 is welded on the connecting plate 301, and the feeding pipe A302 matches the feeding pipe B4, and the feeding pipe A302 and the feeding pipe B4 are aligned; Reference as figure 2 and Image 6, the box body 2 includes a feed hole A207, and a feed hole A207 is opened on the box body 2, and the feed hole A207 is a rectangular hole structure; the feed hole A207 matches the feed pipe A302, and when the connecting plate 301 When...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com