Automatic clothes folding equipment based on clothes processing

A clothing and equipment technology, applied in the field of automatic clothing folding equipment, can solve problems such as inability to realize clothing folding in linkage, reduce costs, and elastically prevent loosening of fixing bolts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

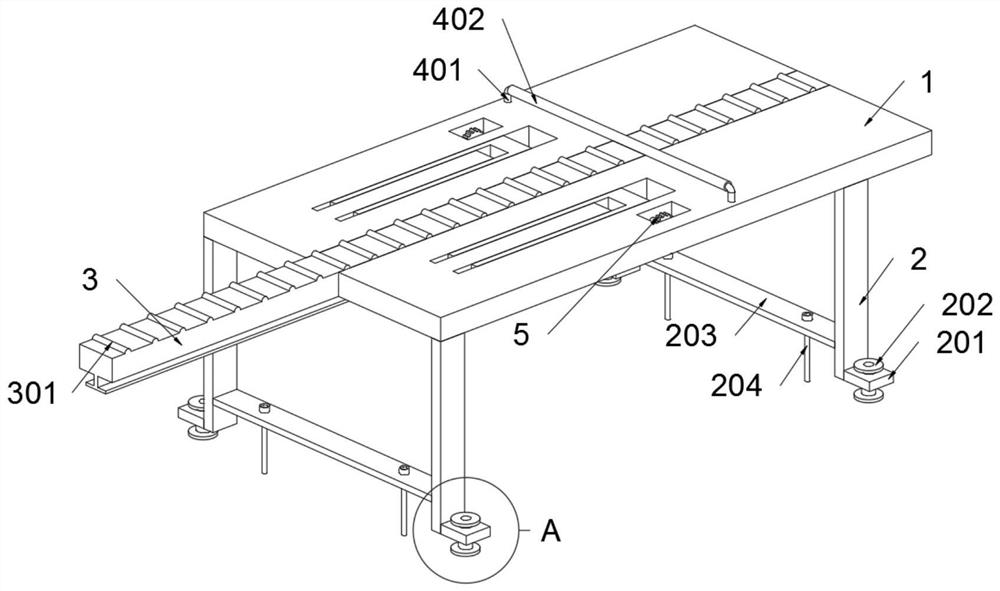

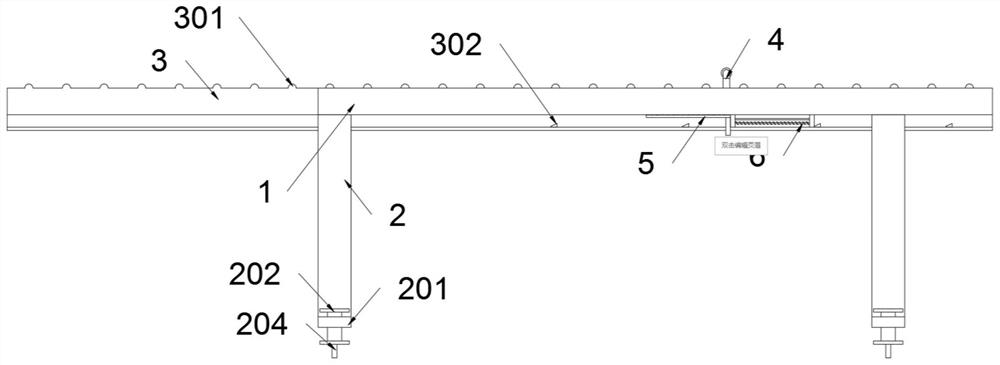

[0034] as attached figure 1 to attach Figure 8 Shown:

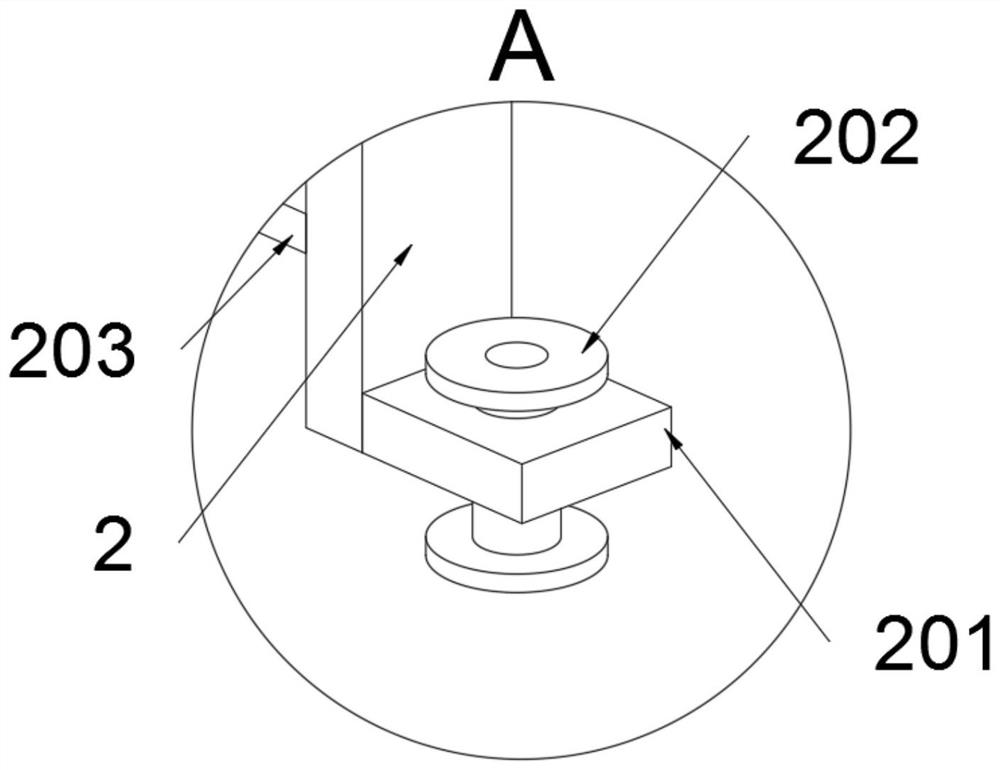

[0035] The present invention provides an automatic clothing folding equipment based on garment processing, which includes a main frame 1; four supporting legs 2 are welded on the main frame 1, and an assembly line belt 3 is slidably connected to the main frame 1, and the main frame 1 is welded with Auxiliary structure 4; bending structure 5 is installed on the main frame 1, and a driving structure 6 is also installed on the main frame 1; refer to as Figure 4 Figure 5 and Image 6, the assembly line belt 3 includes a toggle protrusion 302, and the toggle protrusion 302 is welded on the assembly line belt 3 in a rectangular array; the drive structure 6 includes an elastic block 606, and the elastic block 606 is adhered to the bottom surface of the force seat 605, and is elastic The block 606 is in contact with the toggle protrusion 302, so that the movement of the bearing seat 605 can be realized under the toggle of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com