A structure based on prefabricated steel heat insulation and smoke exhaust duct plate

An anti-smoke, assembled technology, applied in the direction of pipes, rigid pipes, connecting components, etc., can solve the problems of unable to improve the sealing performance of the joint, unable to fix the bolt elastically to prevent loosening, weak sealing performance of the joint, etc. The effect of loosening performance, improving convenience, and improving sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

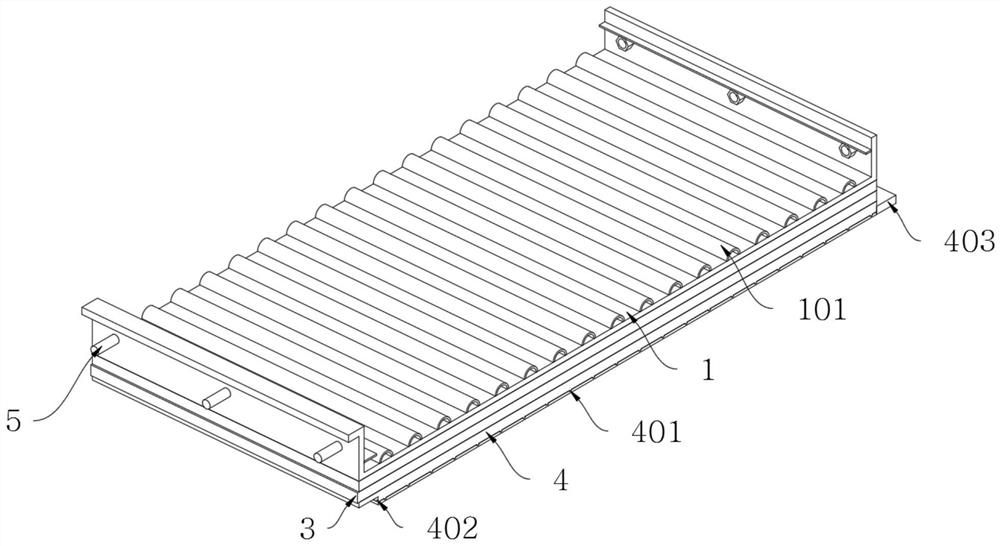

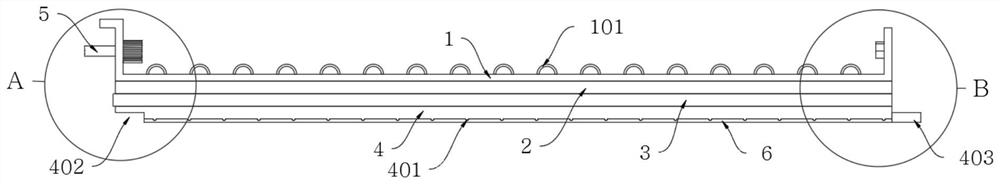

[0051] as attached figure 1 to the attached Figure 8 shown:

[0052] The present invention provides a plate structure based on an assembled steel heat-insulating, smoke-proof, and exhaust air duct, comprising an outer metal layer 1;

[0053] The outer metal layer 1 is an iron plate structure;

[0054] The outer metal layer 1 includes:

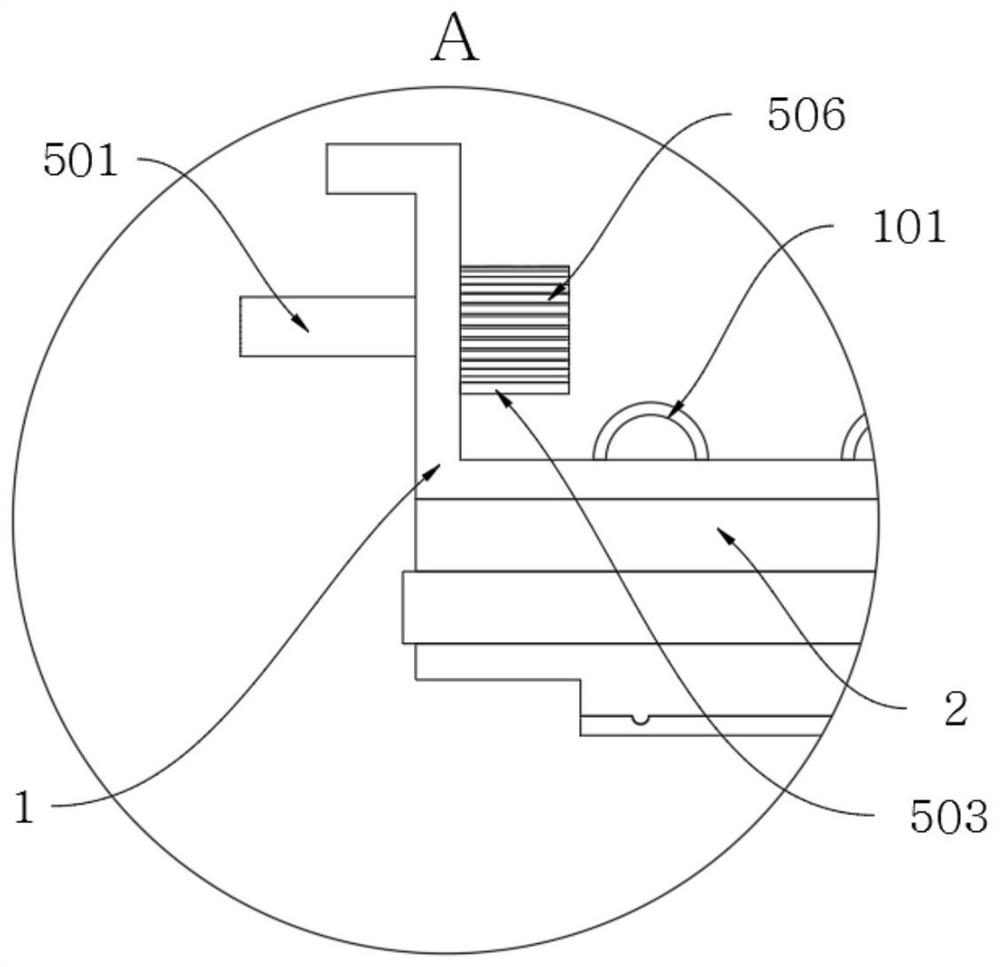

[0055] The protrusions A101 are welded on the top surface of the outer metal layer 1 in a linear array, and the protrusions A101 are semi-circular arc structures, and the protrusions A101 form the bending protection structure of the outer metal layer 1, so that the protrusions A101 The deformation protection ability of the outer metal layer 1 can be improved, and the protrusion A101 of the semi-circular arc structure can reduce the weight;

[0056] The fixing structure 5 is mounted on the outer metal layer 1 .

[0057] refer to as Figure 5 The bottom end surface of the outer metal layer 1 is provided with a gypsum layer 2, and the gypsum ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com