Adjustable hardness test fixture

A hardness test and fixture technology, applied in the direction of testing material hardness, measuring device, strength characteristics, etc., can solve the problems of unstable fixation, large deviation between measured hardness and actual hardness, bias voltage, etc., to ensure accuracy and stability, High clamping force and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

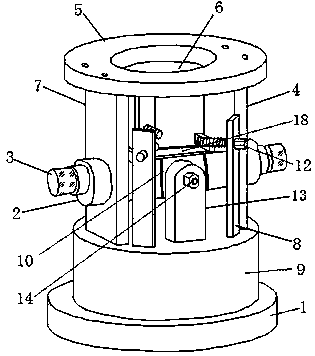

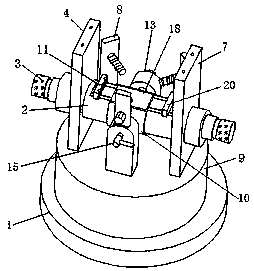

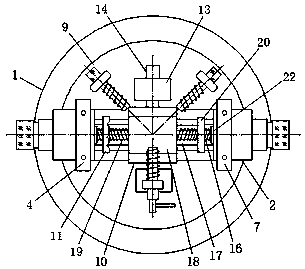

[0020] Embodiment: The present invention provides the following preferred implementation cases: the adjustable hardness test fixture adopts a chassis 1 made of high-strength steel, and its bottom surface is equipped with a cylindrical structure with a diameter of about 8mm. The feet are connected to the hardness equipment platform. A pedestal 9 is arranged on the chassis 1. The pedestal 9 is a cylindrical structure with a diameter of 70 mm and a height of 26 mm. The left support frame 4 and the right support frame 7 are symmetrically installed on both sides of the pedestal 9. The left support frame 4 and the right support frame The height of the frame 7 is 60mm, used to support the positioning plate 5 and the installation fixture seat 2 (such as figure 1 shown). The through holes of the left support frame 4 and the right support frame 7 have the same diameter and the same axis. The through hole is a circular hole, and the through hole is in clearance fit with the two ends of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com