Patents

Literature

38results about How to "Does not affect alignment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

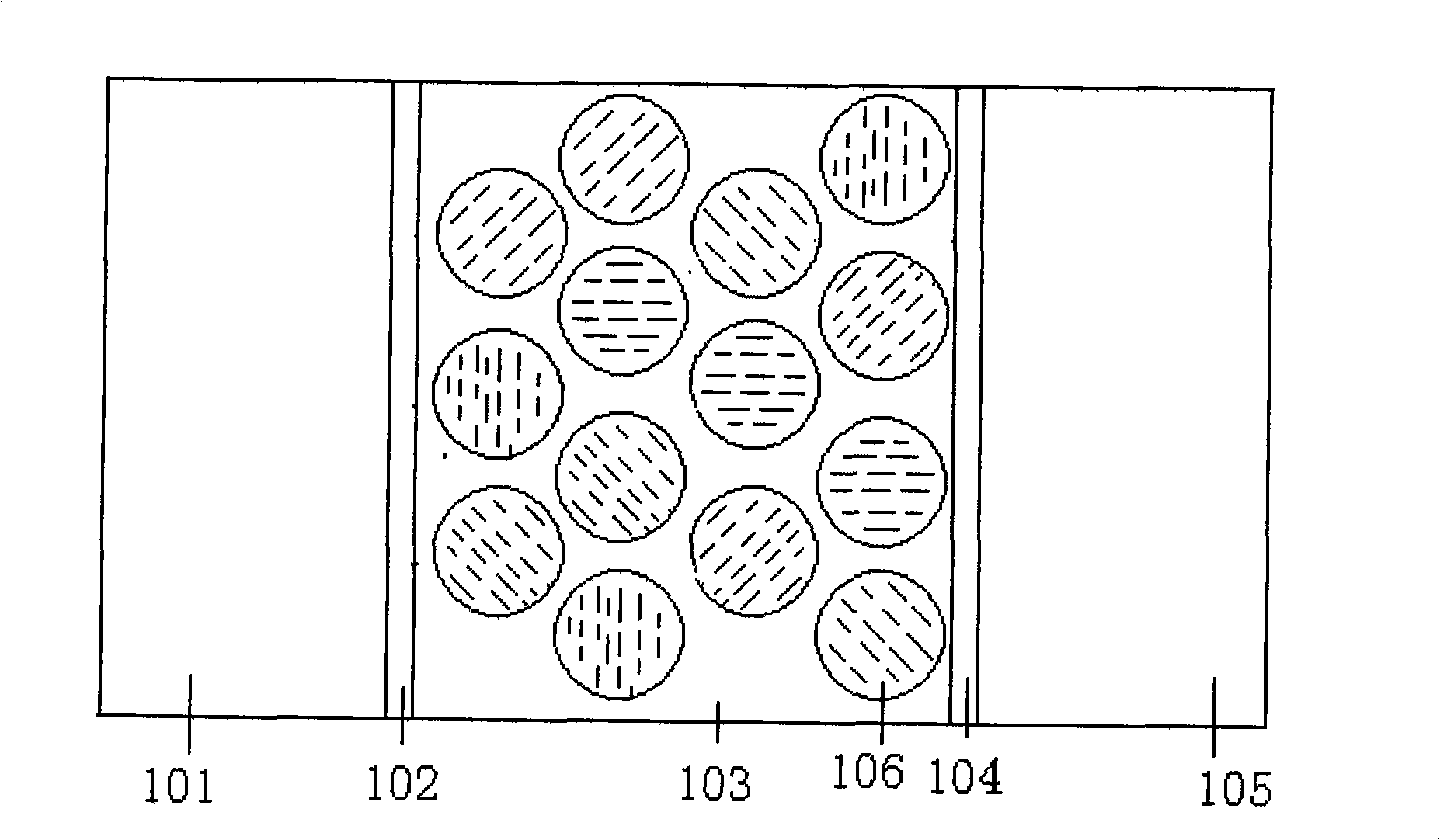

Polymer dispersed liquid crystal electronic paper and manufacturing method thereof

InactiveCN101329462AAchieve decentralizationEasy to prepareStatic indicating devicesNon-linear opticsComposite filmPolymer science

The invention relates to a polymer dispersed liquid crystal electronic paper and a manufacturing method thereof. A composite film is constituted by two transparent flexible conductive films and a polymer dispersed liquid crystal layer, wherein, electrodes are etched on the two flexible transparent conductive films. A polymer is modified polyurethane acrylate which is added by a surfactant and lecithin, and liquid crystal is dielectric switching liquid crystal material which is the mixture of 20 percent biphenyl ester and 80 percent difluoro diphenylacetylene or the product with the same series. When a low-frequency electric field is imposed on the polymer dispersed liquid crystal electronic paper, the polymer dispersed liquid crystal electronic paper is in the transparent open state, and the transparent open station is still maintained after removing the electric field; when a high-frequency electric field is imposed, the polymer dispersed liquid crystal electronic paper is in the scattering closed state, and the scattering closed state is still maintained after removing the electric field. The manufacturing method of the polymer dispersed liquid crystal electronic paper is to form the weak anchoring polymer which is packaged by a dielectric switching liquid crystal droplet structure by separating after mixing the weak anchoring polymer with the dielectric switching liquid crystal. The manufacturing method combines the natures of the weak anchoring polymer and the dielectric switching liquid crystal with the dual-frequency drive of low-frequency writing and high-frequency erasing so as to realize the stable zero-field of the polymer dispersed liquid crystal, thereby obtaining the new electronic paper technology or being applied as a new product of dimming glass.

Owner:HEBEI UNIV OF TECH

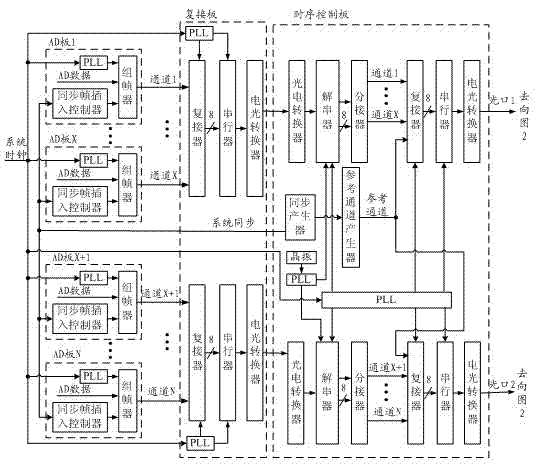

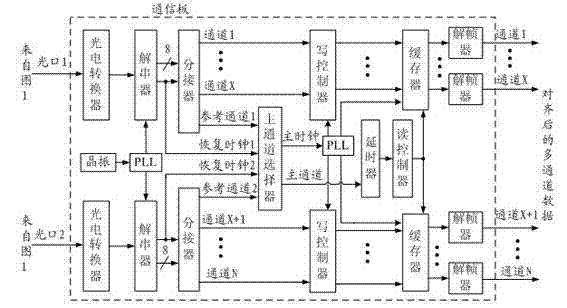

Method for aligning multichannel data based on system synchronizing and reference channel

InactiveCN102820964ADoes not affect alignmentDoes not affect data transferSynchronising arrangementComputer scienceVIT signals

The invention relates to the fields of optical fiber communication and digital communication. Particularly, the invention relates to a method for aligning multichannel data based on a system synchronizing and reference channel. The method for aligning the multichannel data based on the system synchronizing and reference channel comprises the following steps: the transmitted multichannel data are basically synchronized by arranging a ''system synchronization'' signal; then ''reference channel'' data are arranged additionally, so that a read control module for aligning channels is unrelated with the data of the working channel.

Owner:WUHAN BINHU ELECTRONICS

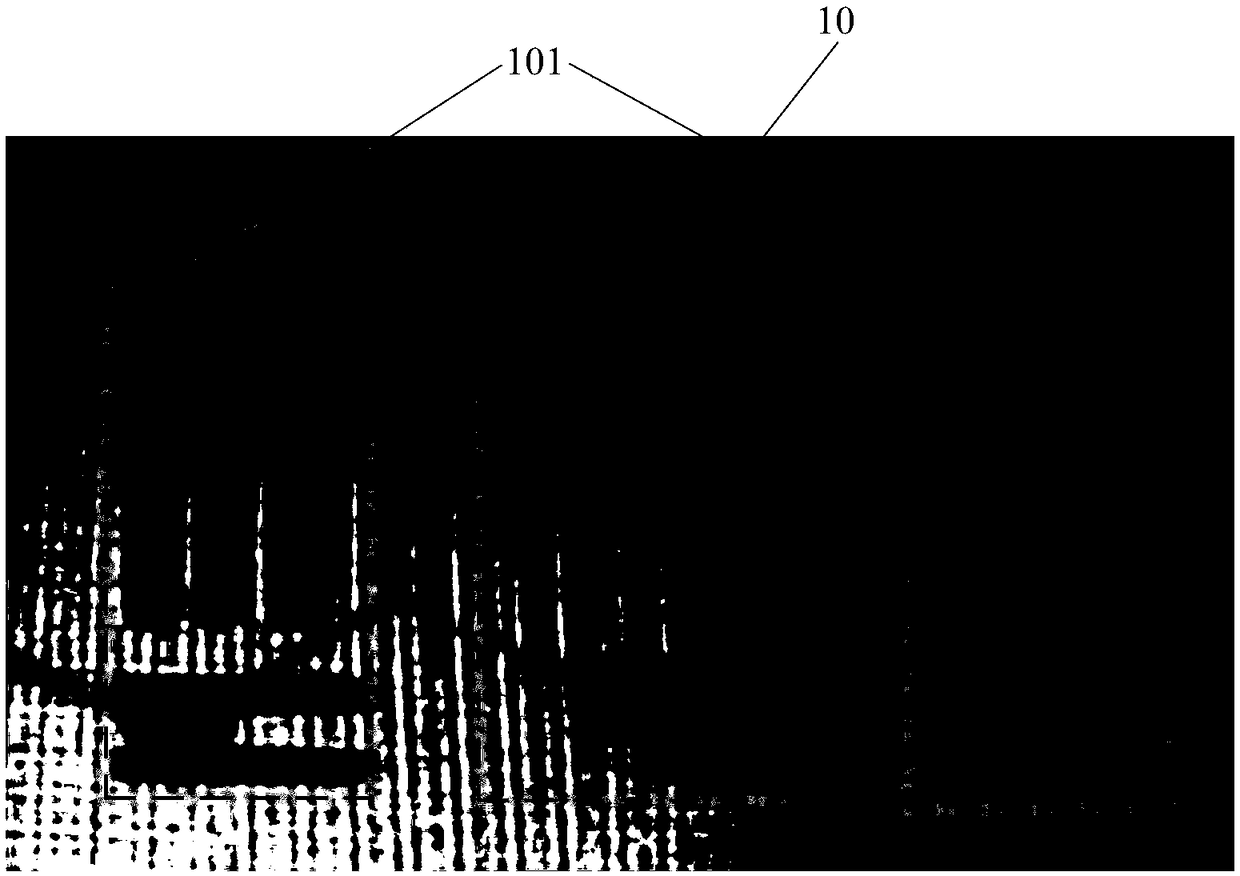

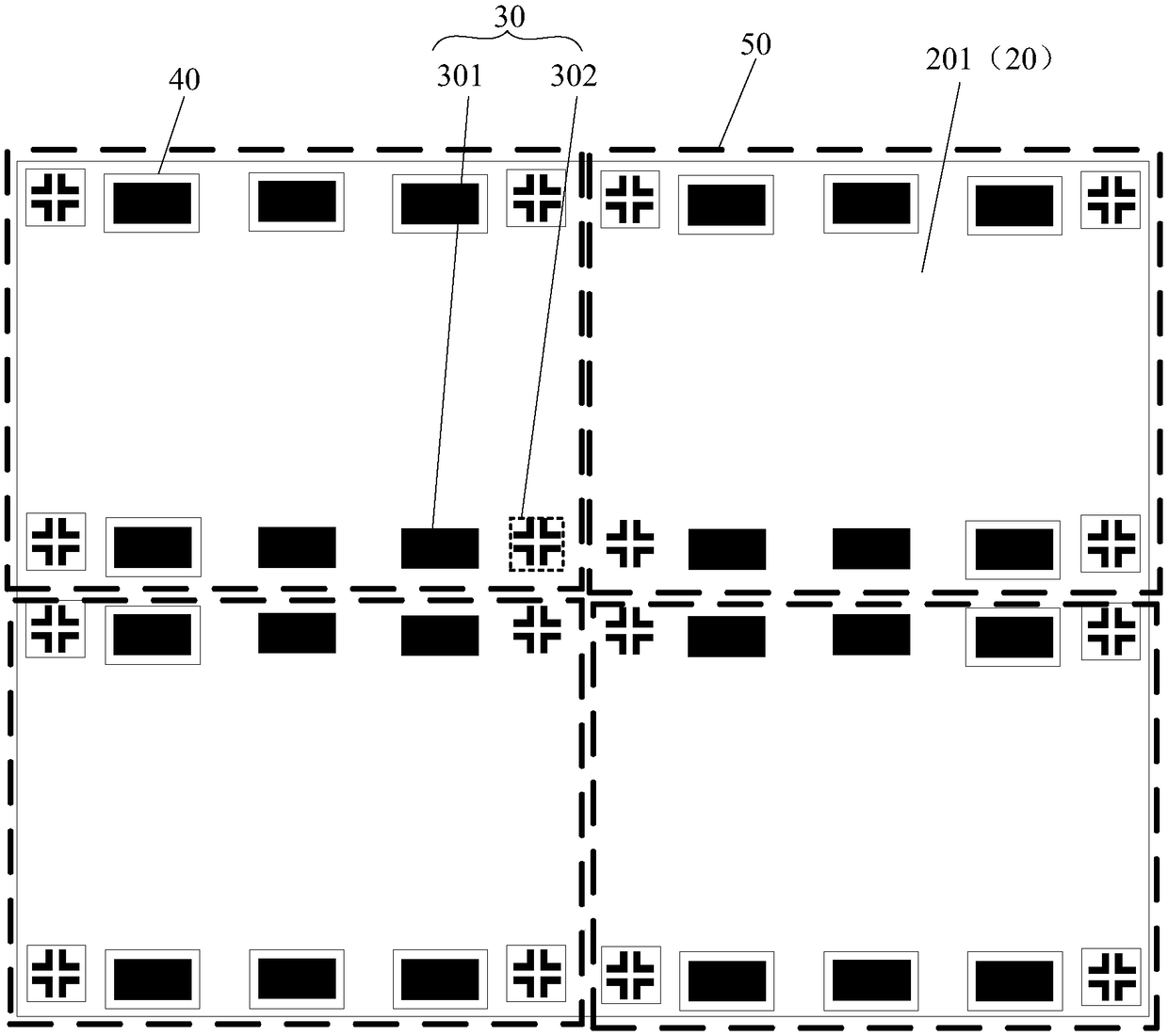

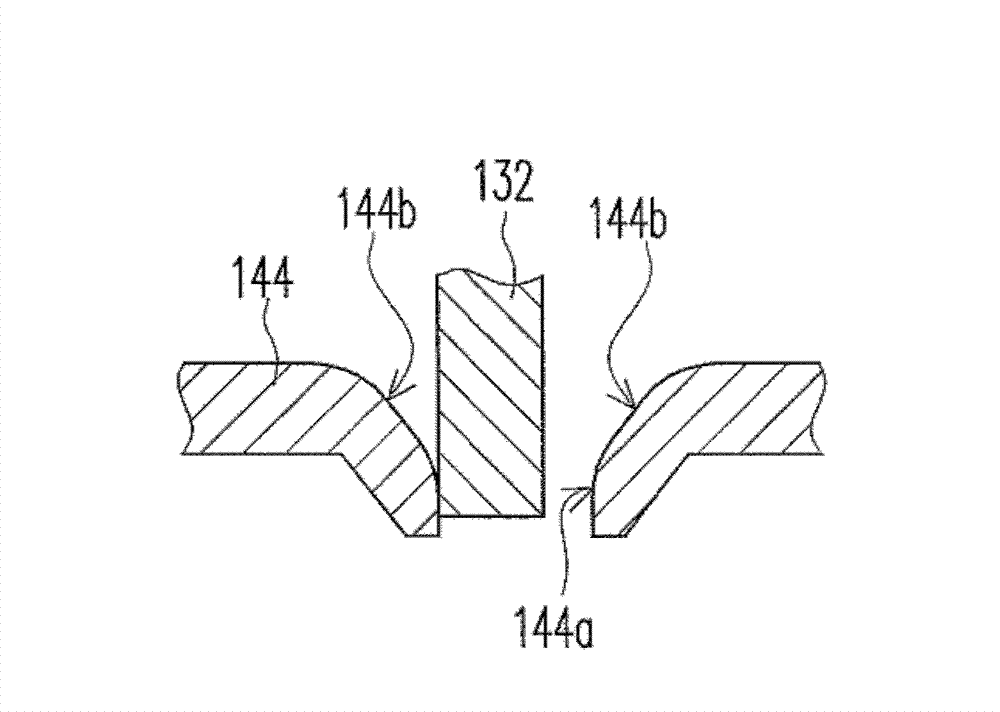

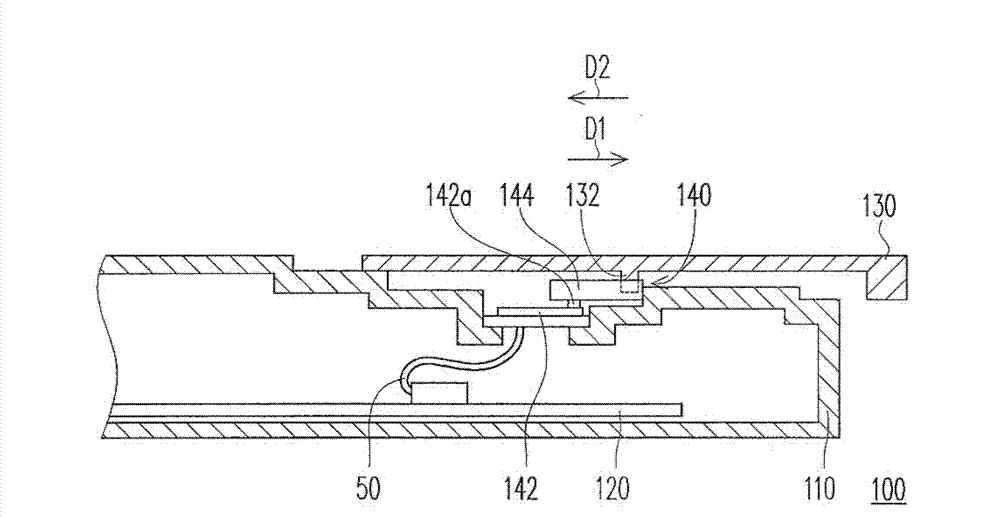

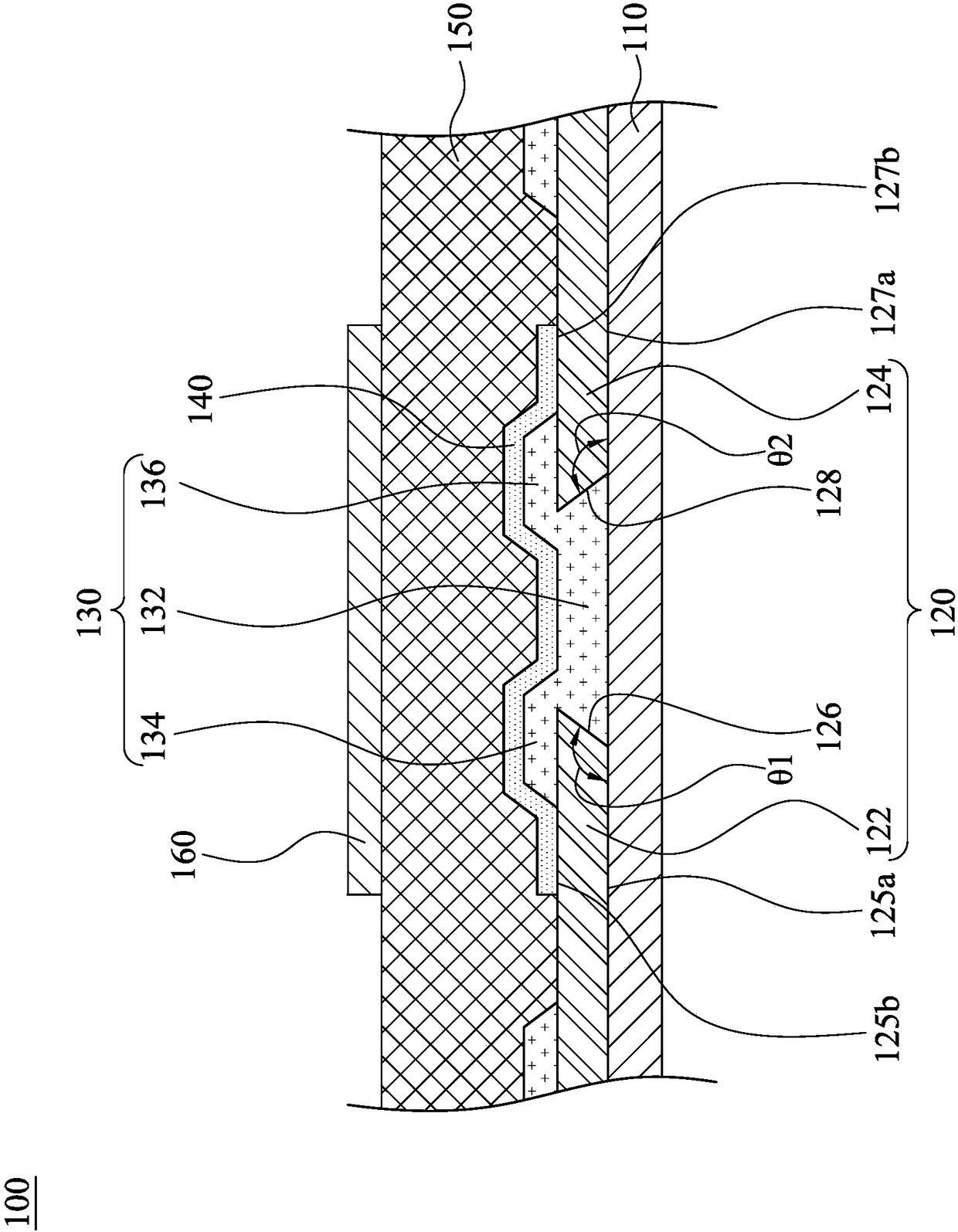

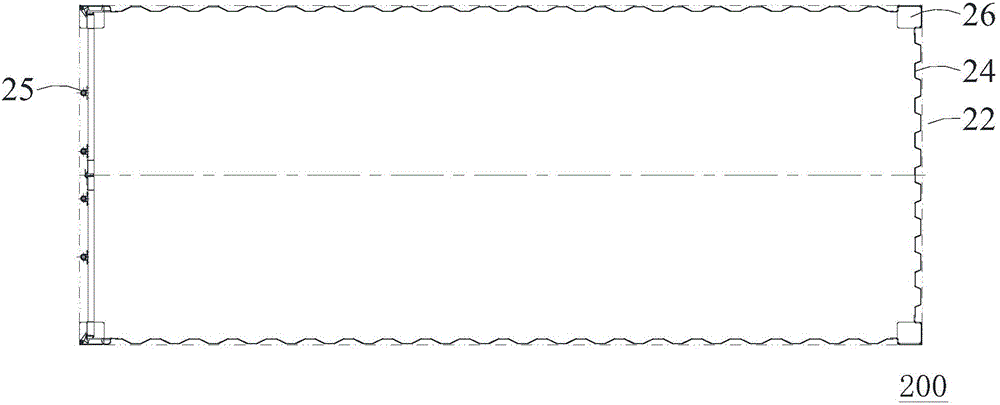

Substrate mother board for display, display panel mother board and preparation method of display panel

InactiveCN109143651AImprove production yieldDoes not affect alignmentNon-linear opticsComputer science

The embodiment of the invention provides a substrate mother board for display, a display panel mother board and a preparation method of a display panel, and relates to the technical field of display.The problem that the cleaning liquid corrodes an alignment marking pattern on the edge of the display panel mother board when the display panel mother board is cleaned can be solved. The substrate mother board for display comprises: a first alignment marking pattern arranged on a first surface of the substrate; wherein the substrate mother board for display further comprises a transparent protection pattern, wherein the protection pattern at least covers the first alignment marking pattern located on the edge of the first surface; the first alignment marking pattern comprises a first sub-alignment marking pattern and / or a second sub-alignment marking pattern, the first sub-alignment marking pattern is used for forming alignment exposure of the pattern on a second surface of the substrate,and the second sub-alignment marking pattern is used for cutting alignment; and the first surface and the second surface are two opposite surfaces of the substrate.

Owner:BOE TECH GRP CO LTD +1

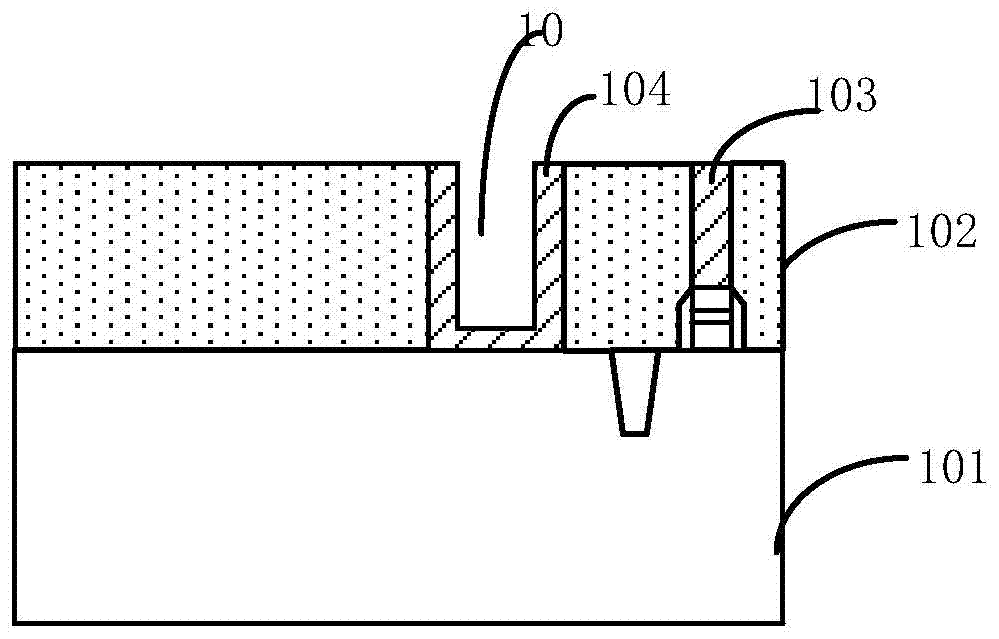

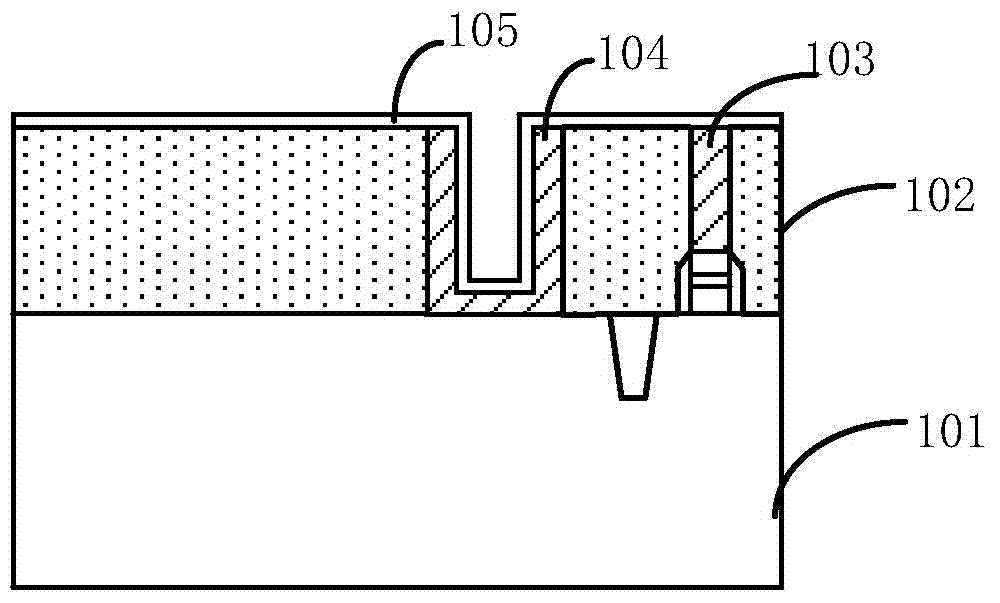

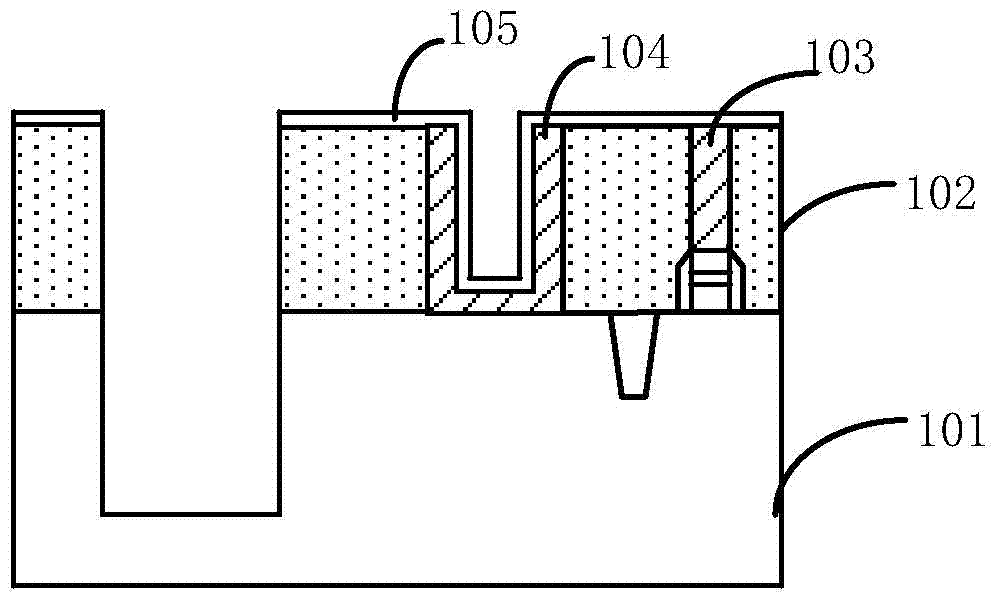

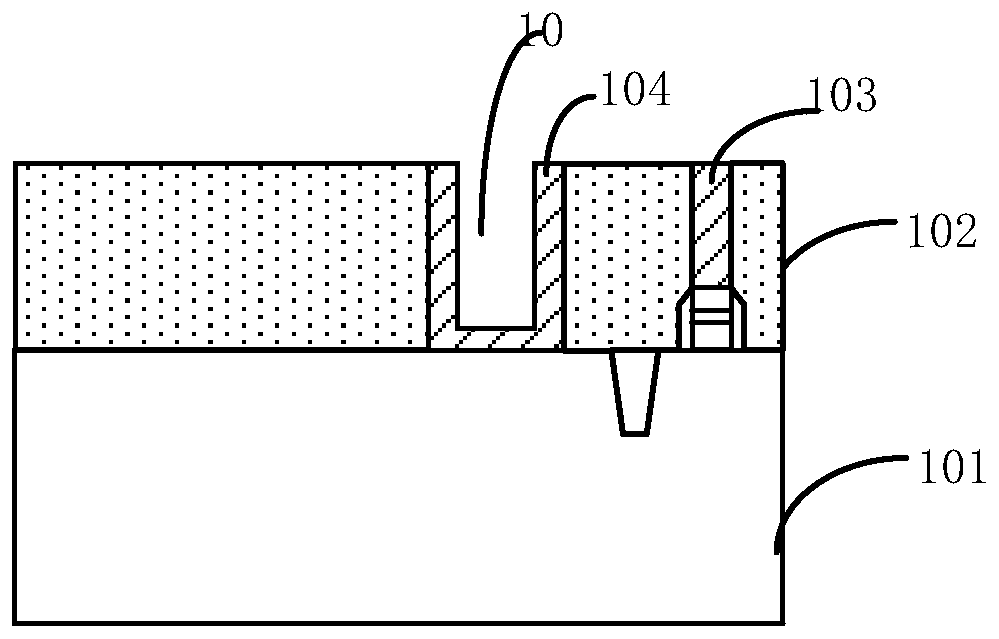

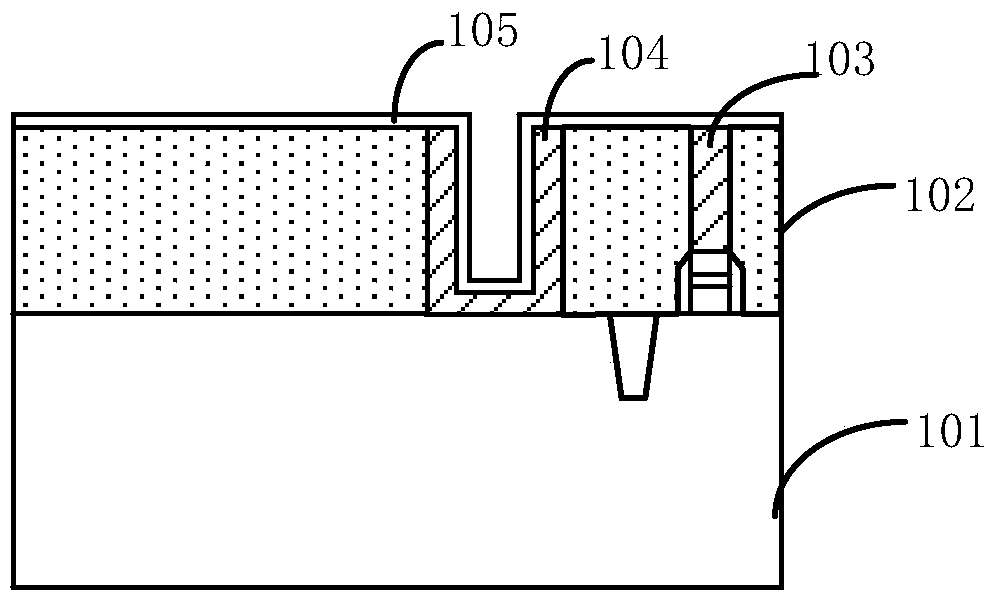

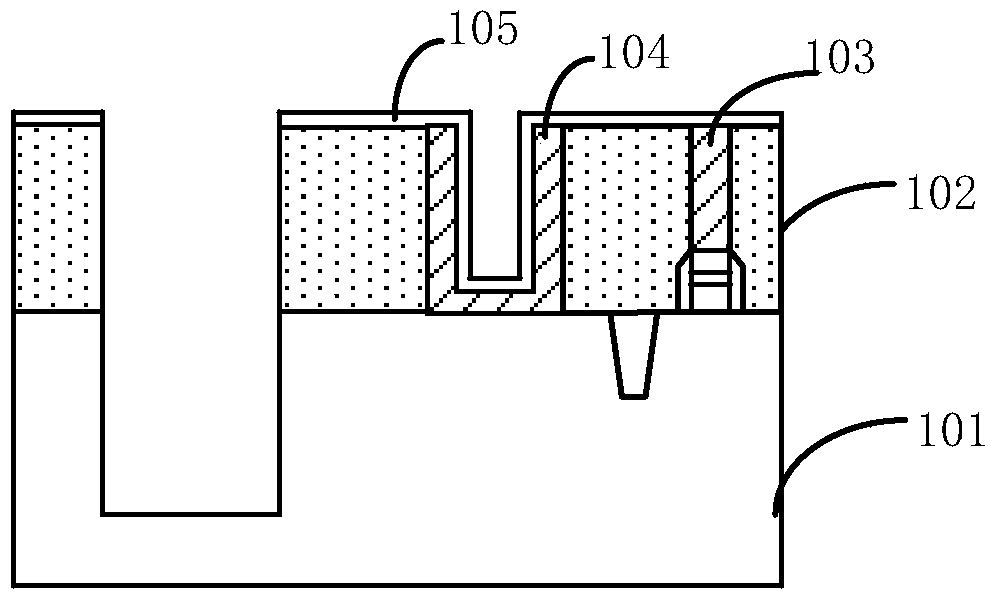

Semiconductor device and preparation method thereof

ActiveCN104752323ADoes not affect alignmentGood step coverageSemiconductor/solid-state device detailsSolid-state devicesPower semiconductor deviceProtection layer

The invention relates to a semiconductor device and a preparation method thereof. The method comprises the steps of providing a semiconductor substrate, and forming an interlayer dielectric layer on the semiconductor substrate, wherein the interlayer dielectric layer is internally provided with a contact hole and a photoetching mark hole, and the photoetching mark hole is provided with a gap; depositing a sacrificial material layer so as to completely fill the gap; forming a protection layer on the interlayer dielectric layer and the sacrificial material layer; forming a silicon through hole in the semiconductor substrate and the interlayer dielectric layer; removing the protection layer so as to expose the sacrificial material layer; and removing the sacrificial material layer so as to expose the gap. According to the invention, a-C is used to act as the protection layer of CT in the silicon through hole preparation (TSV VIA middle) process, and compared with SIN, the a-C has a better step coverage ability and can be completely removed, thereby not affecting follow-up photoetching (M1photo) alignment for a first metal layer, and effectively solving a problem of OVL measurement.

Owner:SEMICON MFG INT (SHANGHAI) CORP

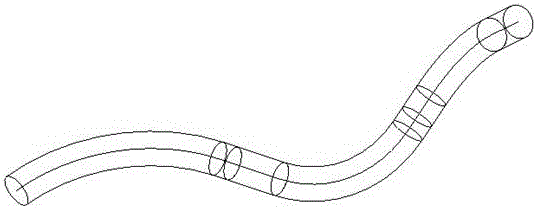

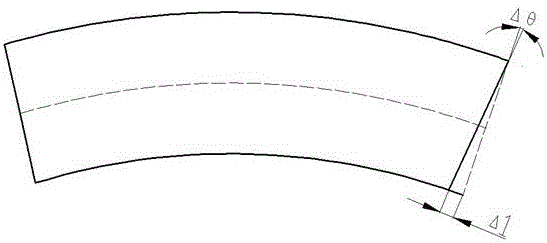

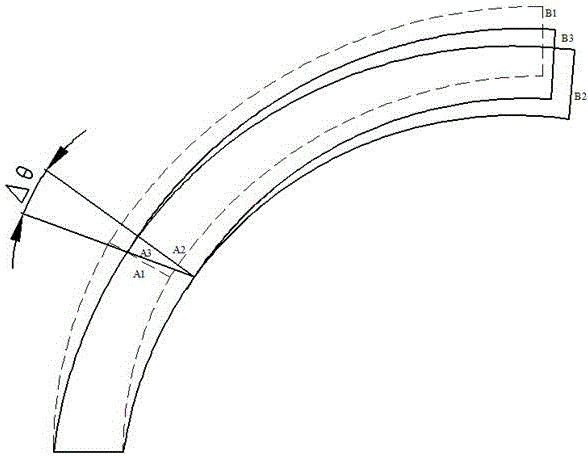

Method for controlling multi-process accumulative error of large spacial bent circular steel tubes

InactiveCN106294940AProcessing technology is less difficultReduce manufacturing costGeometric CADSpecial data processing applicationsMathematical modelEngineering

The invention discloses a method for controlling multi-process accumulative error of large spacial bent circular steel tubes. The method comprises the steps that according to the national standard, an adjustment angle delta theta is machined on the assembling plane of one bending circular steel tube, and the next section of a to-be assembled bent tube appears to rotate by the adjustment angle delta theta around the original point of a local assembly coordinate system in space; the adjustment angle delta theta rotate around a Z bar axis of the assembling plane and can rotate around an X bar axis and a Y bar axis simultaneously; the distance between adjusted three-dimensional coordinates and designed three-dimensional coordinates serves as an objective function, and an accumulative error optimized mathematical model is built by taking the requirement in the specification as the constraint condition; large spacial bent circular tube design model three-dimensional coordinate parameters are combined, two groups of parameters of design point three-dimensional coordinates and actually assembled coordinates serve as objective functions to be substituted into the spacial bent circular tube accumulative error controlling mathematical model, and the optimal solution of the adjustment angle is obtained through calculation. The method is suitable for controlling the accumulative machining error of large-span large-diameter spacial bent circular steel tubes for large exhibition halls, transportation junctions, Olympic stadiums and the like.

Owner:ZHEJIANG UNIV

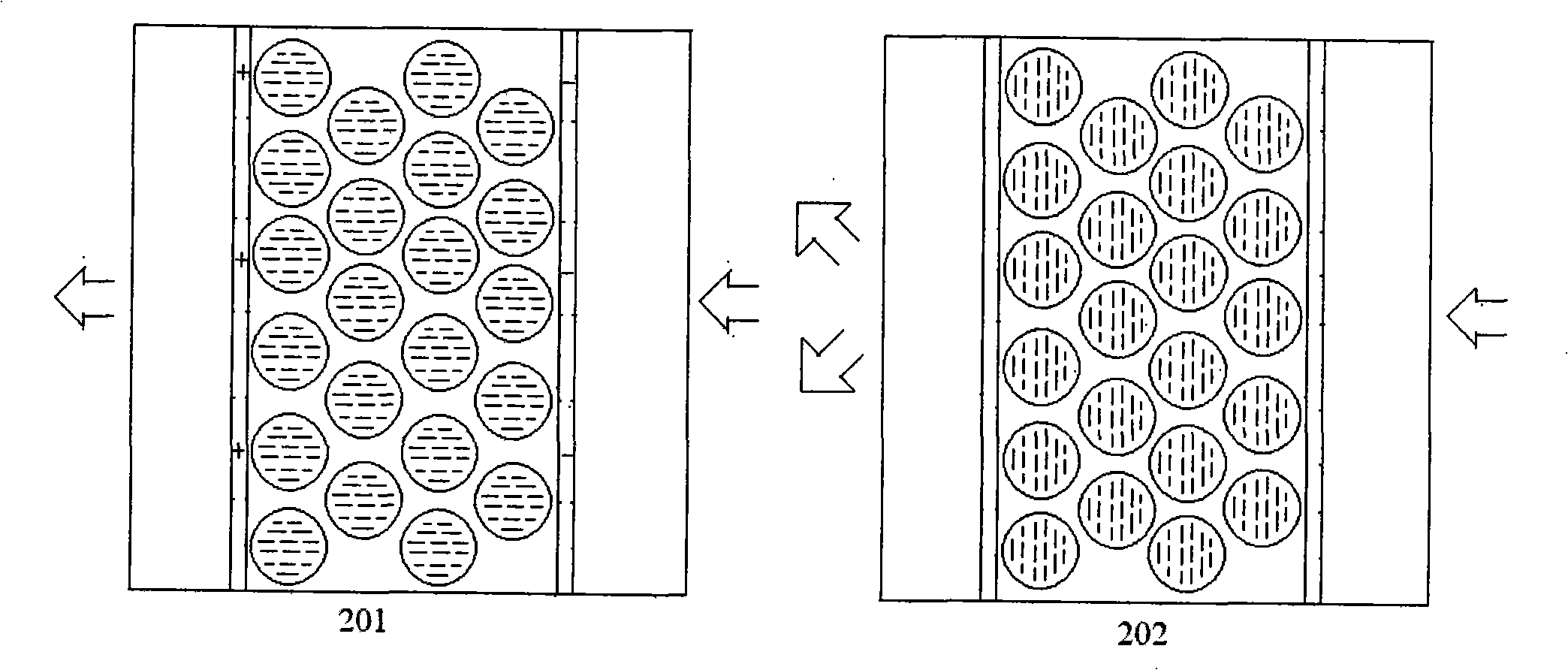

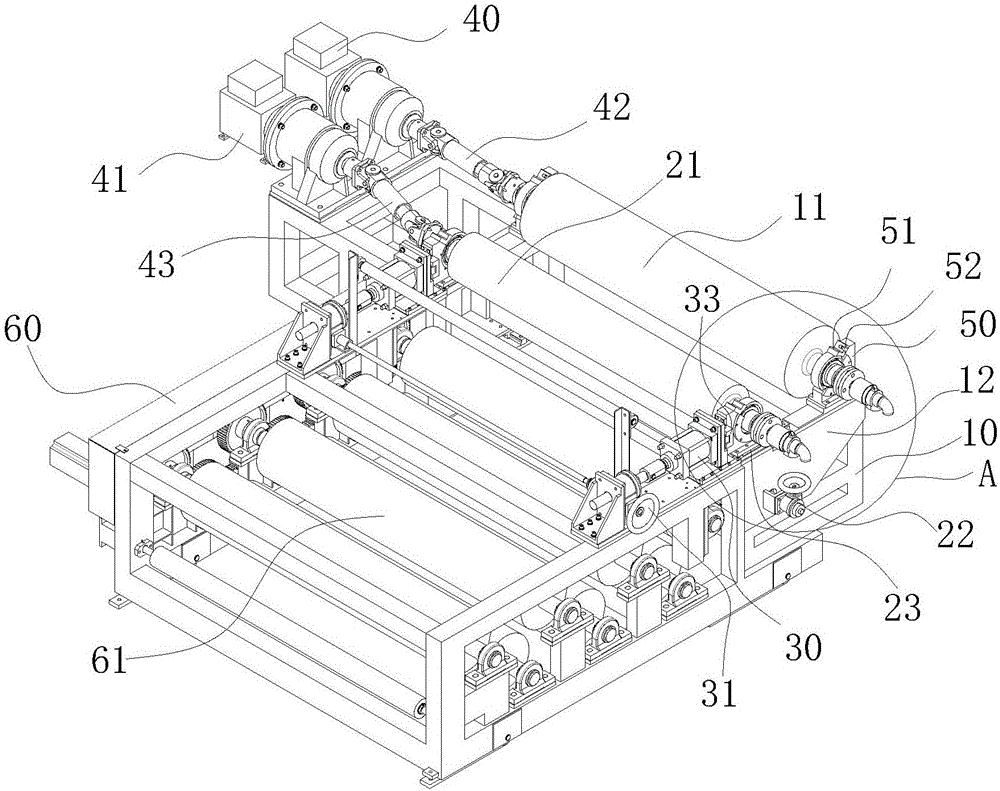

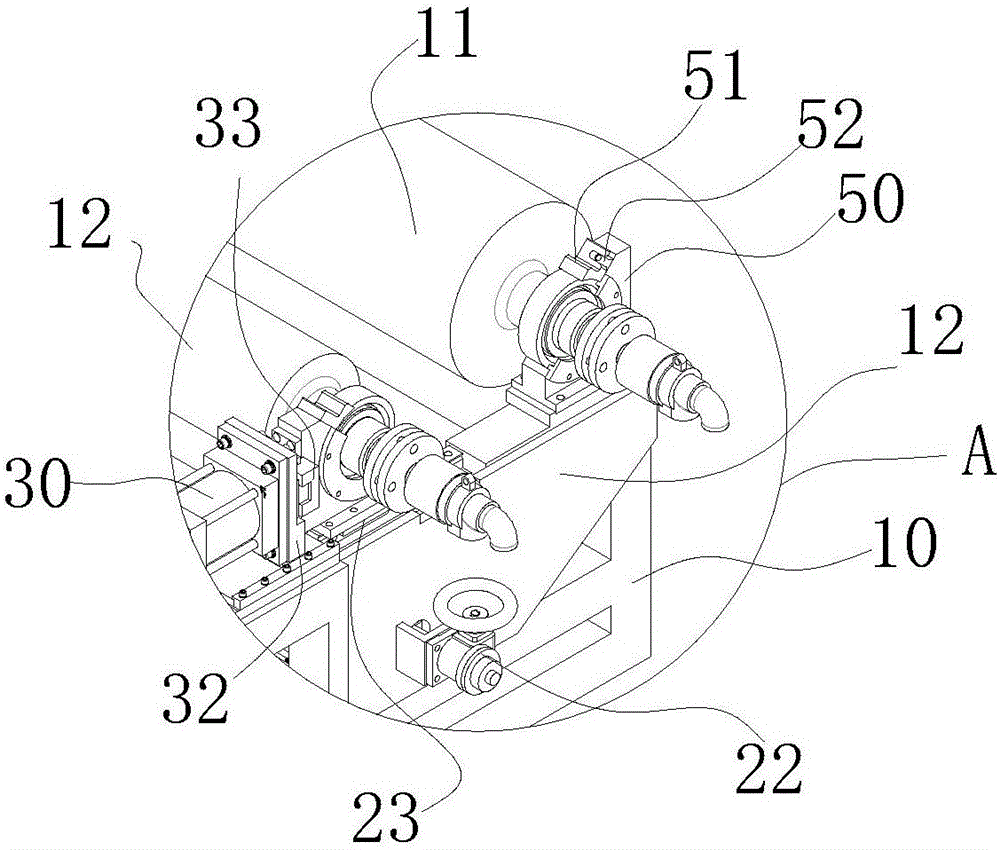

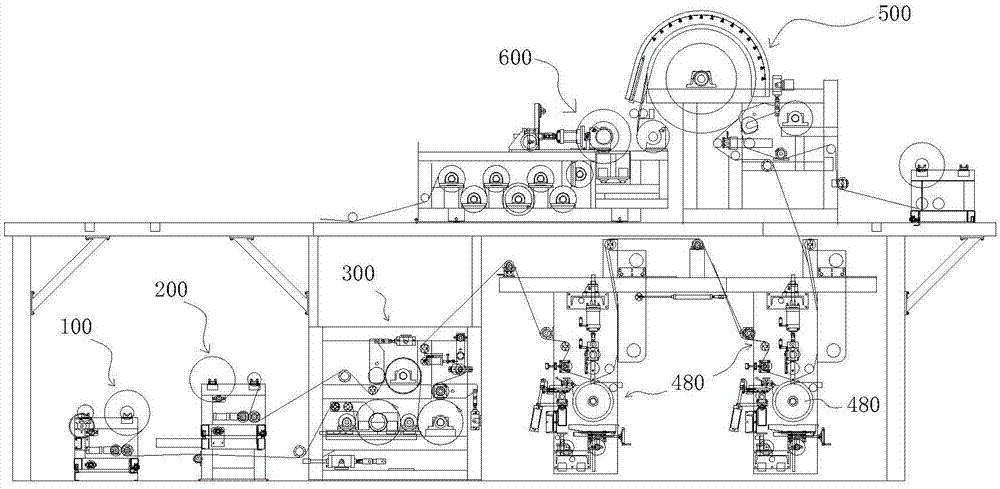

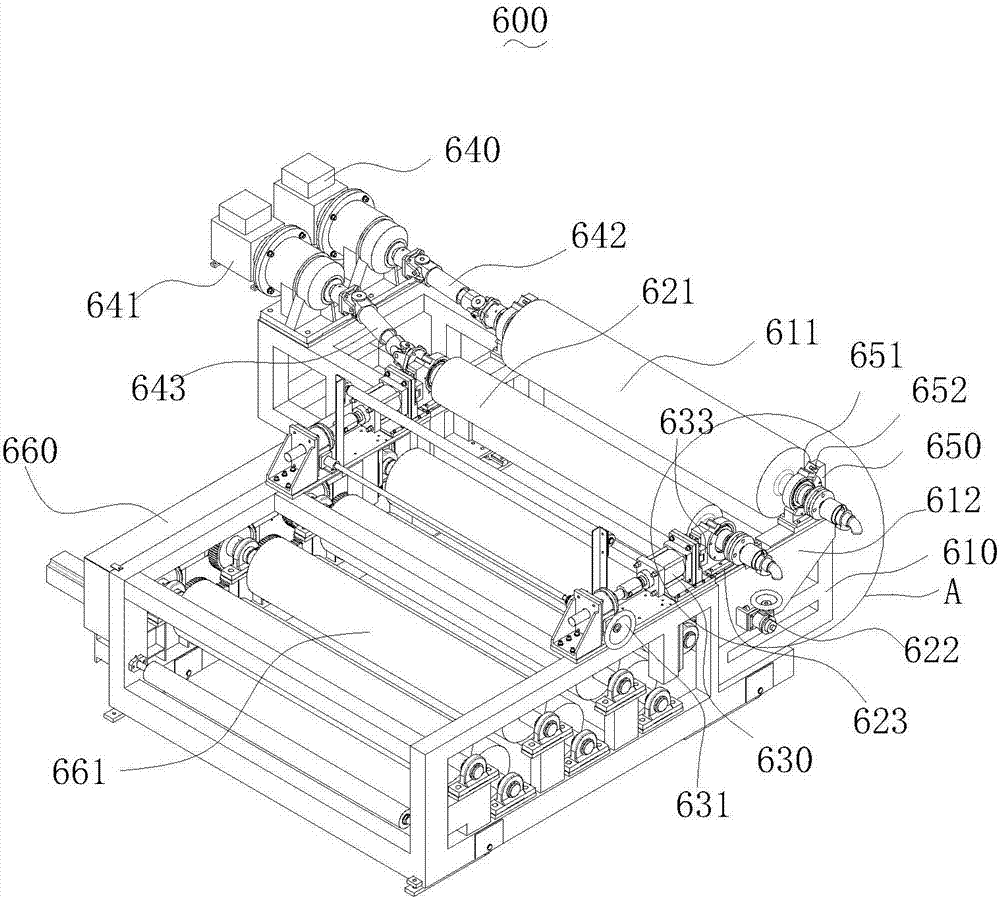

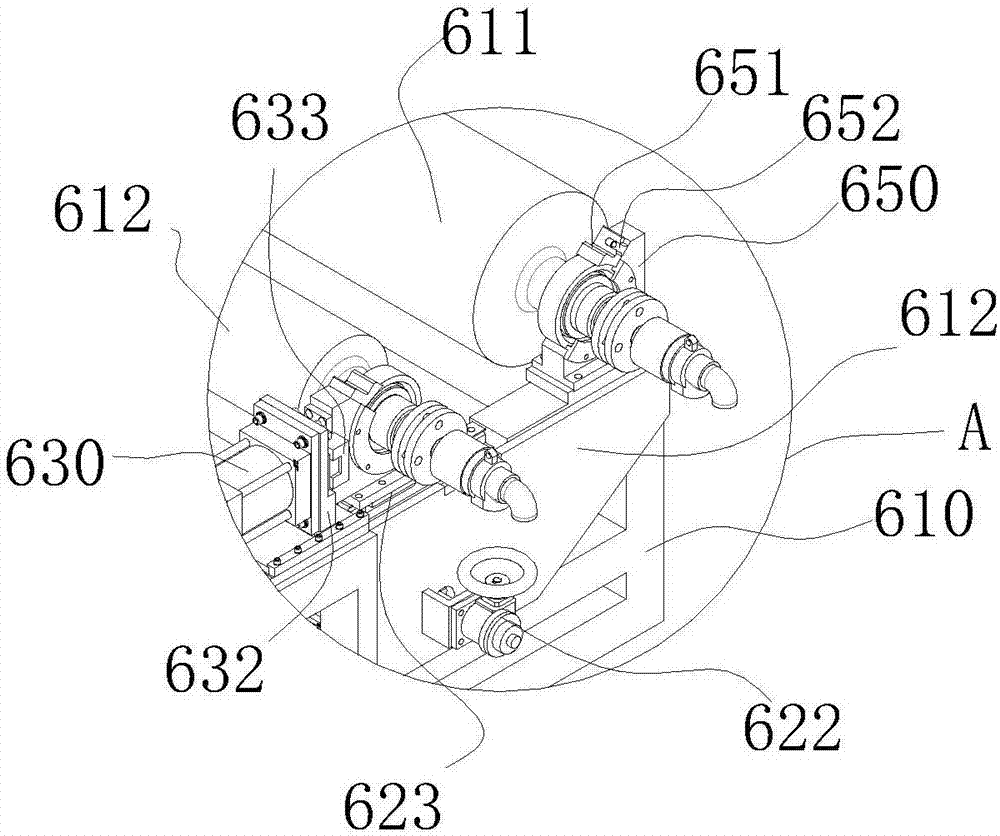

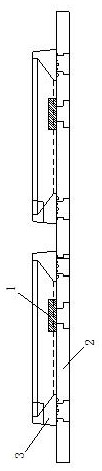

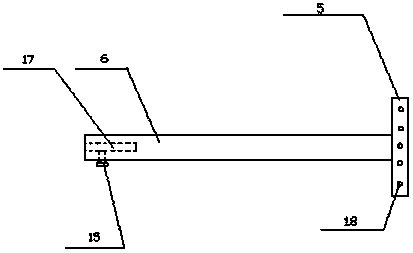

Film synchronous embossing device

The invention relates to the field of film synchronous embossing and particularly relates to a film synchronous embossing device. The device comprises a first bracket, a rubber roller arranged on the first bracket, a second bracket and an embossing roller arranged on the second bracket. The surface of the embossing roller is provided with uneven patterns the same to the film patterns. The rubber roller and the embossing roller are respectively connected to a first motor and a second motor. The first motor and the second motor respectively control a rotation direction and a rotation rate of the rubber roller and the embossing roller. The embossing roller can move relative to the rubber roller on the plane along front, rear, left and right directions. The device is free of a single driven embossing roller and a passively driven rubber roller of the conventional embossing device and drives the embossing roller and the rubber roller through the different driving devices so that the relative position of the embossing roller and a film can be adjusted at an embossing position at any time and thus the embossing patterns are corresponding to the printing patterns and the adjustment of the materials having high waste in the traditional process is avoided.

Owner:FOSHAN PUYING MACHINERY EQUIP

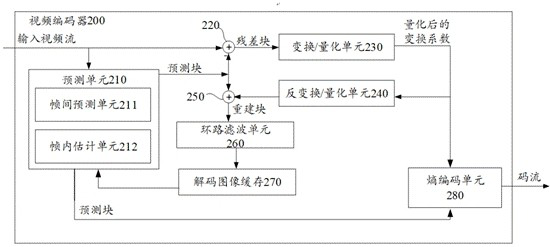

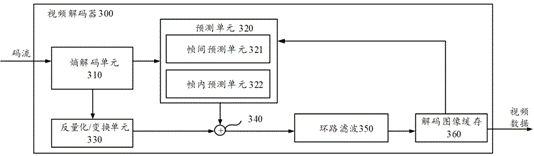

Video deblurring method and device, equipment and storage medium

ActiveCN113822824AIncrease the blur effectDoes not affect alignmentImage enhancementImage analysisPattern recognitionImage extraction

The invention provides a video deblurring method and device, equipment and a storage medium, which can be applied to various scenes such as cloud technology, artificial intelligence, smart traffic, auxiliary driving and videos. The method comprises the following steps: obtaining a current image in a video and N adjacent images of the current image; extracting first feature information of the current image under M scales and second feature information of each adjacent image in the N adjacent images under the M scales; aiming at each adjacent image in the N adjacent images, aligning the second feature information of the adjacent images under the M scales with the first feature information under the M scales; and obtaining a deblurred current image according to the second feature information of each adjacent image in the N adjacent images after alignment under the M scales. According to the invention, in a feature domain, the first feature information of the current image is aligned with the second feature information of the adjacent images, so that the video deblurring effect is improved.

Owner:TENCENT TECH (SHENZHEN) CO LTD

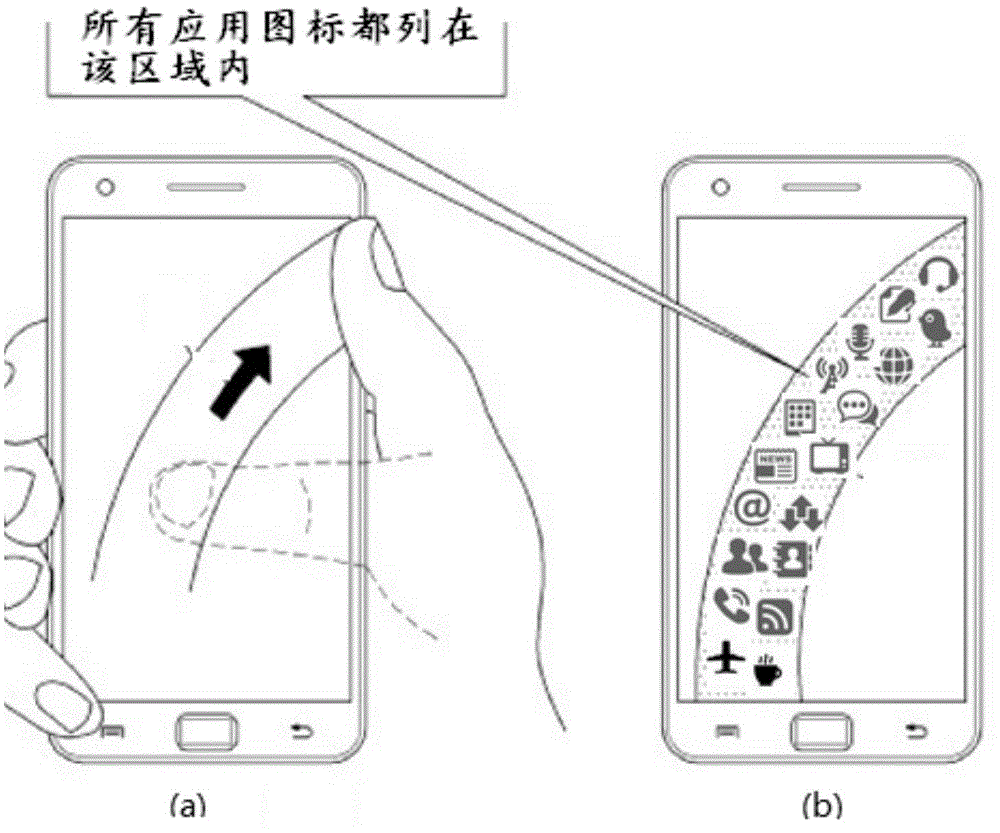

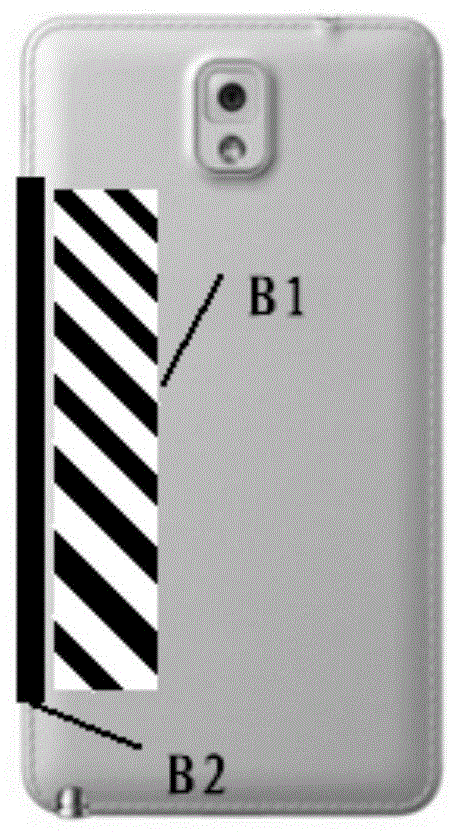

Method used for mobile equipment and mobile equipment

InactiveCN105487789AControl does not affectDoes not affect alignmentInput/output processes for data processingTouchpadMobile device

The invention is aimed at providing a method used for mobile equipment and the mobile equipment.Compared with the prior art, the method used for the mobile equipment and the mobile equipment have following beneficial effects: by arranging touch panels on the back side and / or the side surface of the mobile equipment, touch operation on the touch panel is obtained when the touch panel is triggered in order to control the mobile equipment; without affecting arrangement and sizes of mobile phone icons, control over a mobile phone by a signal hand is achieved; the mobile equipment is user-friendly; operation difficulty is reduced; and user experience is improved.

Owner:ALCATEL LUCENT SAS

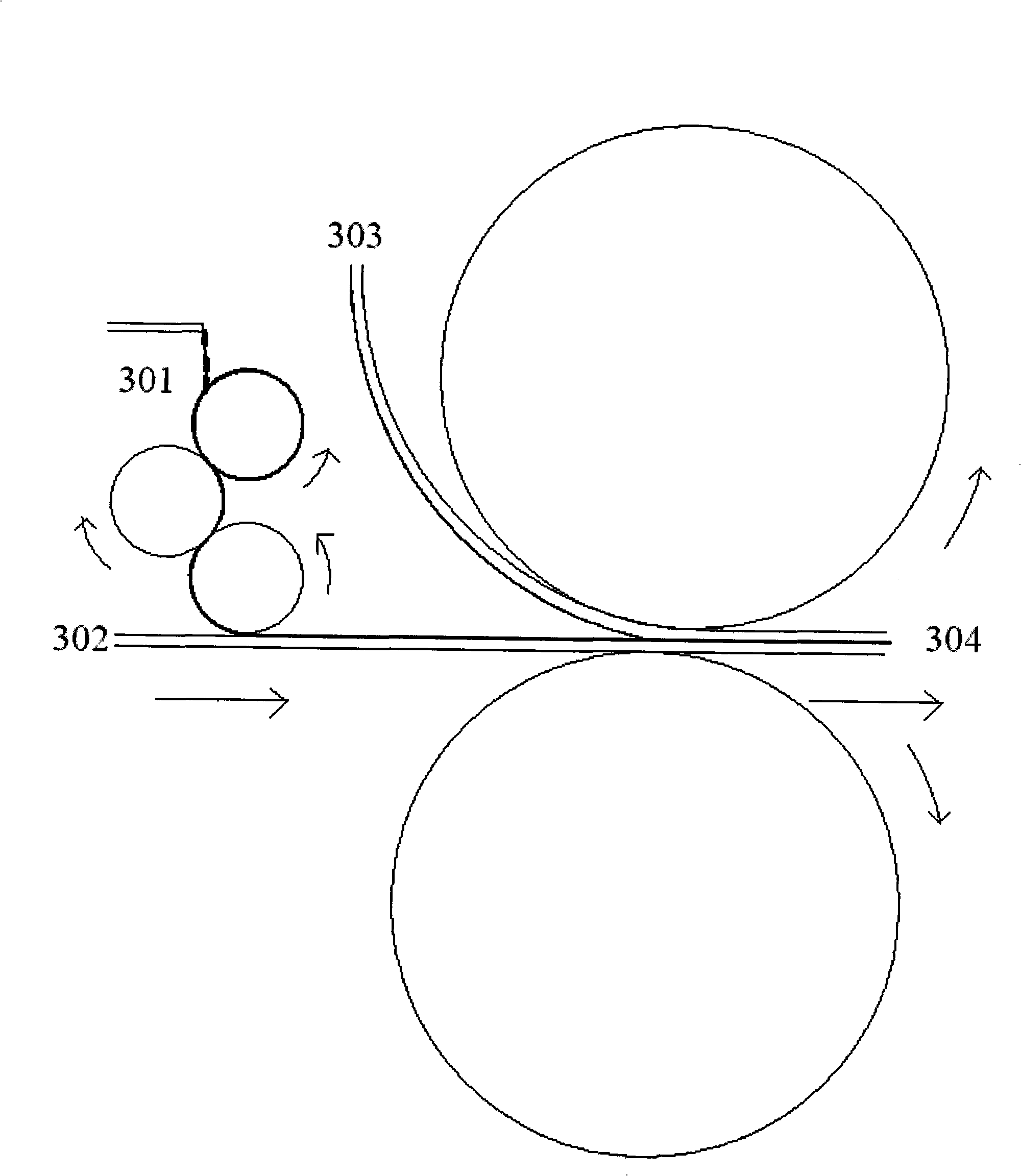

Printing machine

ActiveCN107415455AShorten the lengthAvoid deformationRotary pressesPrinting pressMechanical engineering

The invention relates to a printing machine. The printing machine comprises a printing assembly and an embossing assembly. The printing assembly comprises a plurality of printing rollers, and a film enters the embossing assembly after being printed by the printing rollers. The embossing assembly is arranged above the printing assembly. According to the printing machine, the embossing assembly is arranged over the printing rollers or above the printing rollers, so that the traditional mode of placing the embossing assembly and the printing rollers in parallel is changed, he length of the portion, between the embossing assembly and the printing rollers, of the film is shortened, the influence that the film is deformed due to tension action is reduced, a printing pattern can be accurately aligned to an embossing pattern, and the product quality is improved.

Owner:FOSHAN PUYING MACHINERY EQUIP

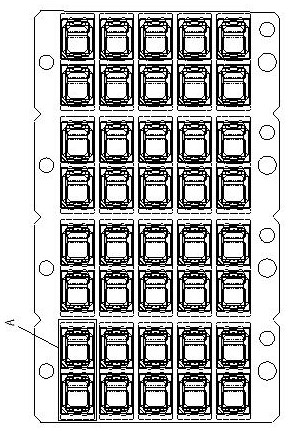

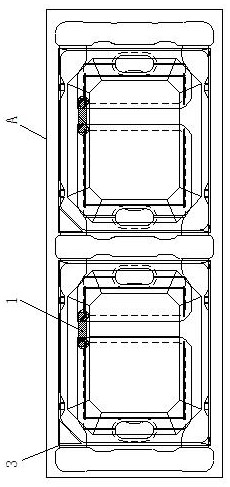

LED support processing method

PendingCN112151656ADoes not affect alignmentWill not affect light extraction efficiencySolid-state devicesSemiconductor/solid-state device manufacturingEngineeringTransient voltage suppressor

The invention discloses an LED support processing method, and relates to the technical field of LEDs. The method comprises the following steps: stamping and forming a support die bonding pad in the form of a metal material strip, after a coating is formed, enabling the support die bonding pad to enter a die bonder in the form of a material strip, fixing a transient voltage suppressor (TVS) on thesupport die bonding pad through the die bonder and soldering flux, performing eutectic welding through reflow soldering, then performing an injection molding process, and performing injection moldingon the metal material strip, so as to enable the transient voltage suppressor (TVS) to be contained in a plastic frame body to manufacture the LED support. The LED support manufactured by the invention does not influence the arrangement of light-emitting chips and the light-emitting efficiency of lamp beads, and an LED device produced based on the LED support has excellent voltage-stabilizing andpulse-resisting capabilities and a wide application prospect.

Owner:深圳市中顺半导体照明有限公司

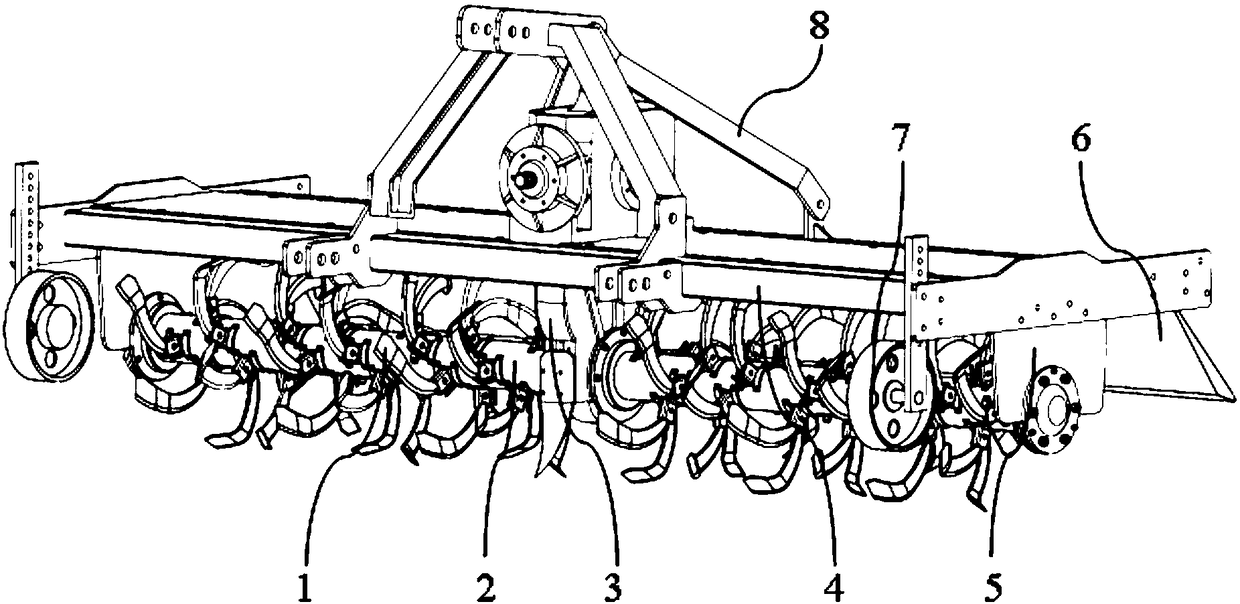

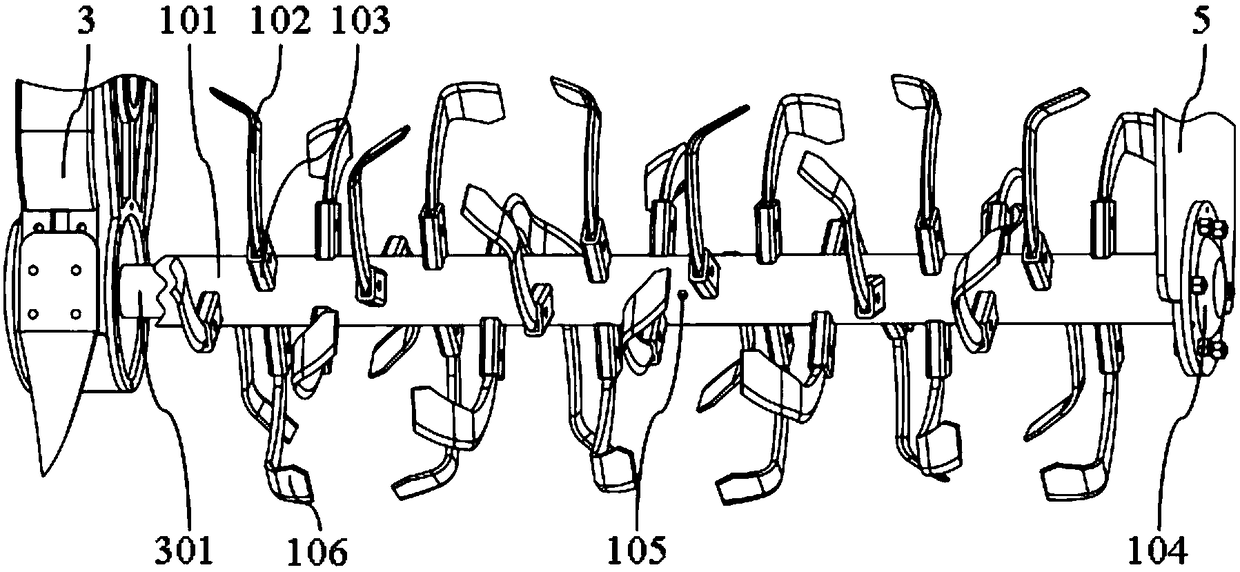

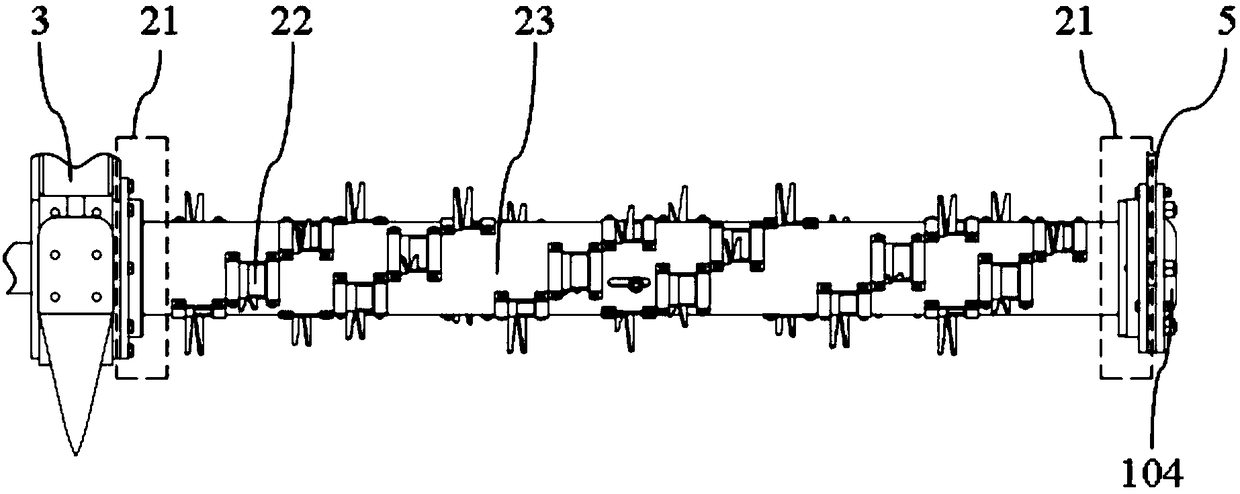

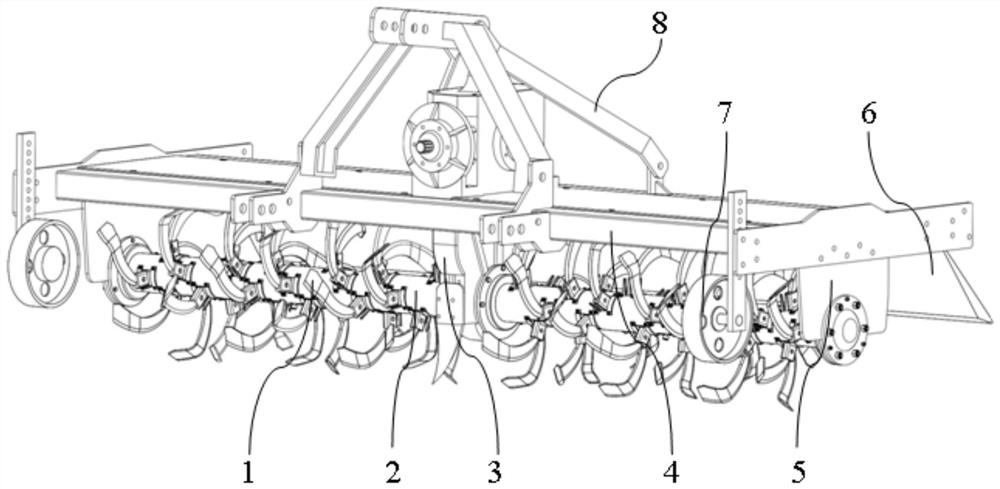

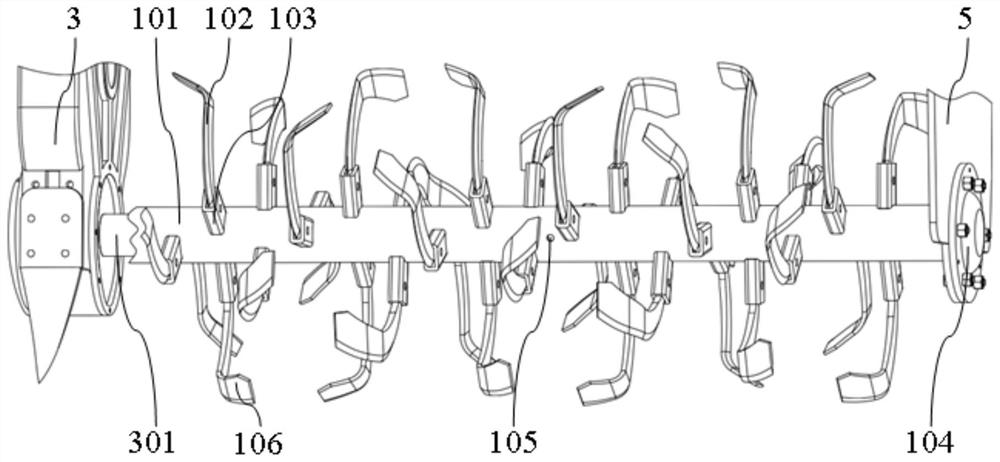

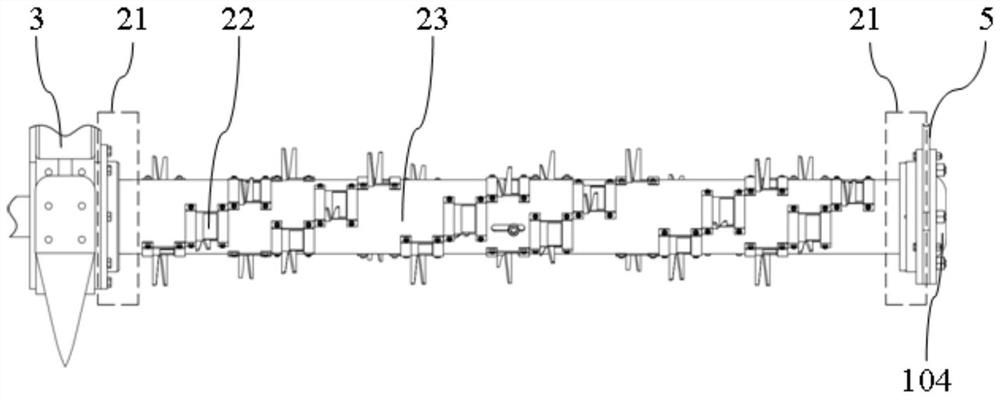

Rotary tillage knife roll vibration anti-winding and soil removing device

ActiveCN109315091AReduce soil stickinessGuarantee the quality of workAgricultural machinesTilling equipmentsEngineeringConductor Coil

The invention discloses a rotary tillage knife roll vibration anti-winding and soil removing device, knife roll assemblies which are connected with a gearbox are symmetrically arranged below a rack, and a vibration anti-winding and soil removing device is connected to the knife roll assemblies; the knife roll assemblies comprise a knife shaft which is fixedly connected with the power output shaftof the gearbox, a plurality of rotary blades are arranged on the knife shaft, fixed blades are arranged beside all the rotary blades, and axial positioning holes are further formed in the knife shaft;the vibration anti-winding and soil removing device comprises a left vibration production device and a right vibration production device, a rotation roller is connected between the two vibration production devices, the knife shaft is sleeved with the rotation roller, a plurality of vibration holes are formed in the rotation roller, the rotary blades and the fixed blades stretch out from corresponding vibration holes, moving blades which form shearing action are arranged on the outer edges of the vibration holes, straight slot holes are further formed in the rotation roller, and positioning bolts are connected between the straight slot holes and the axial positioning holes. According to the rotary tillage knife roll vibration anti-winding and soil removing device, winding can be preventedand soil adhering can be reduced under the situation that the arrangement and the shapes of the rotary blades are not affected.

Owner:HUAZHONG AGRI UNIV

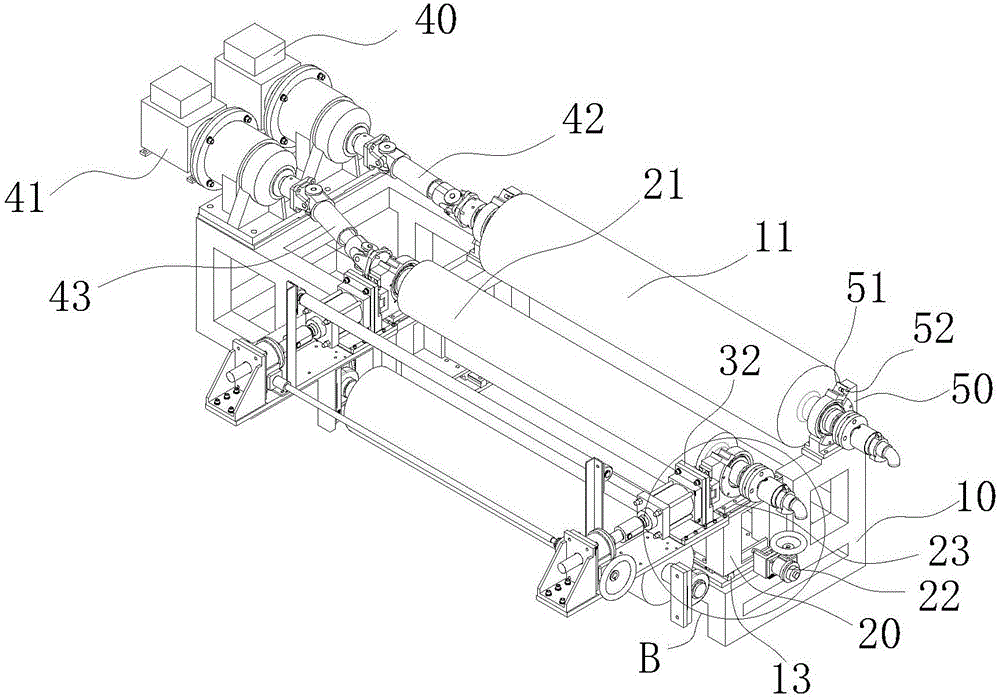

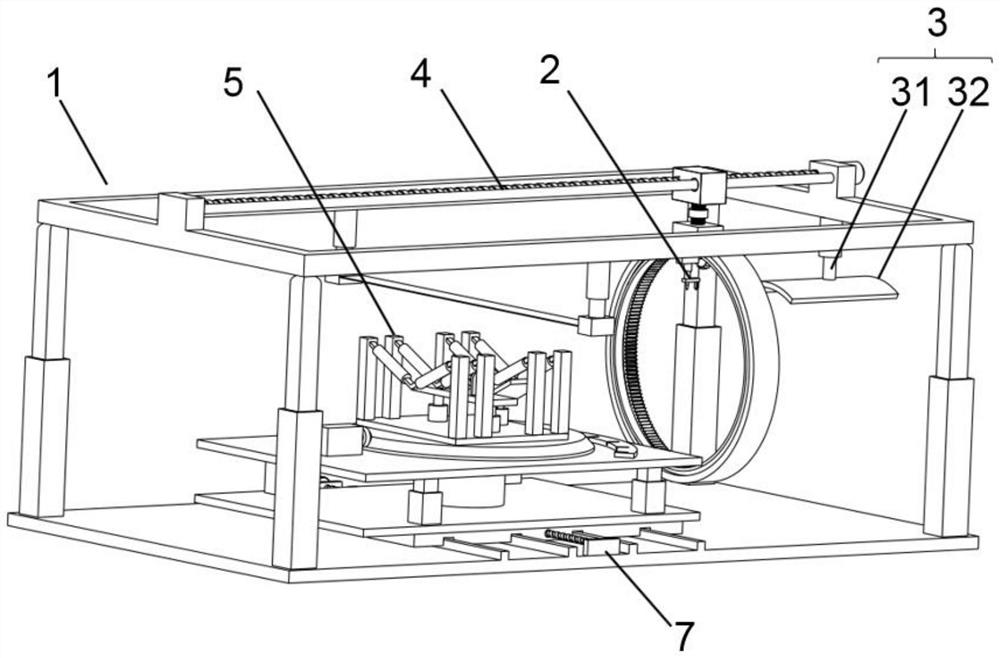

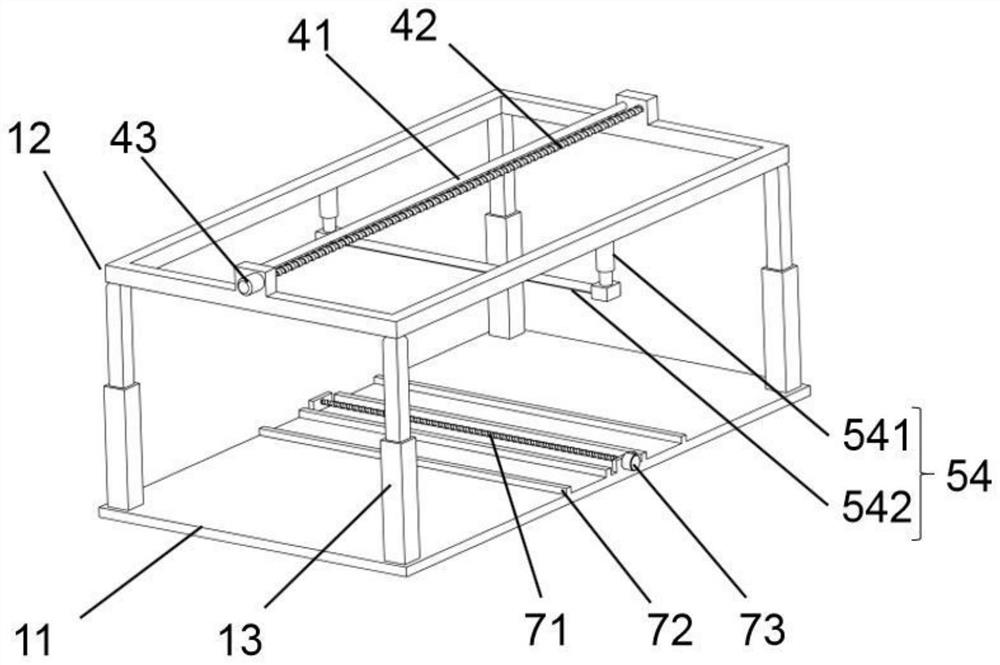

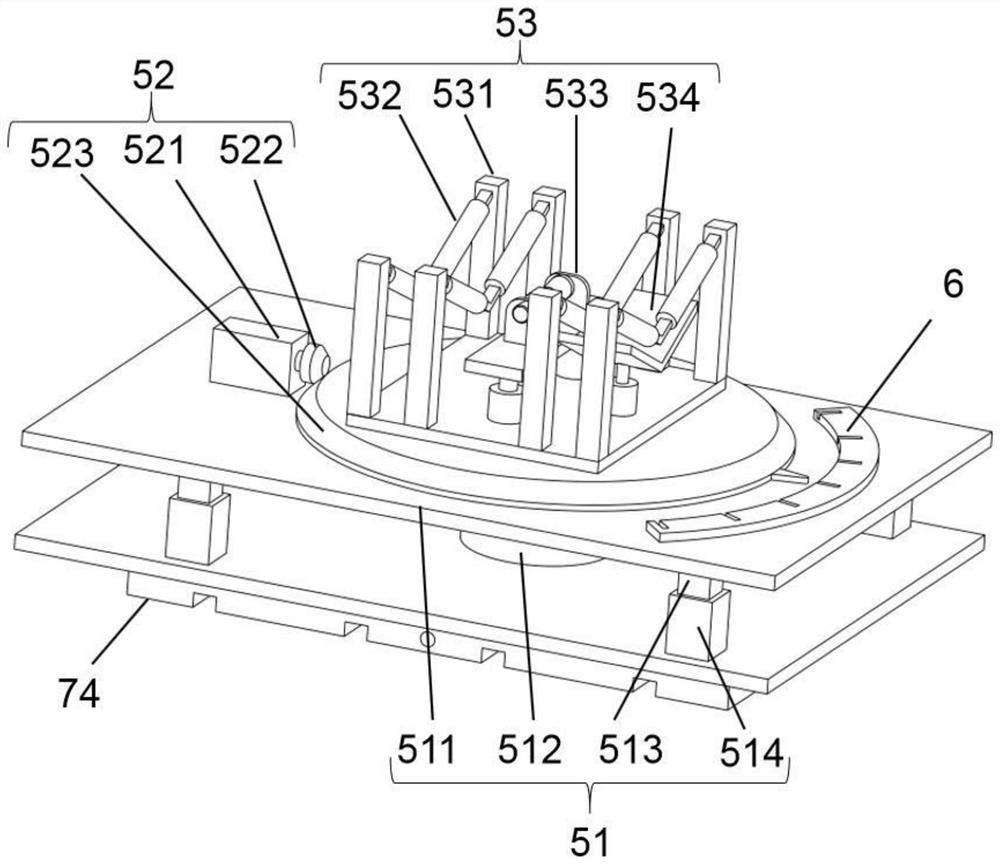

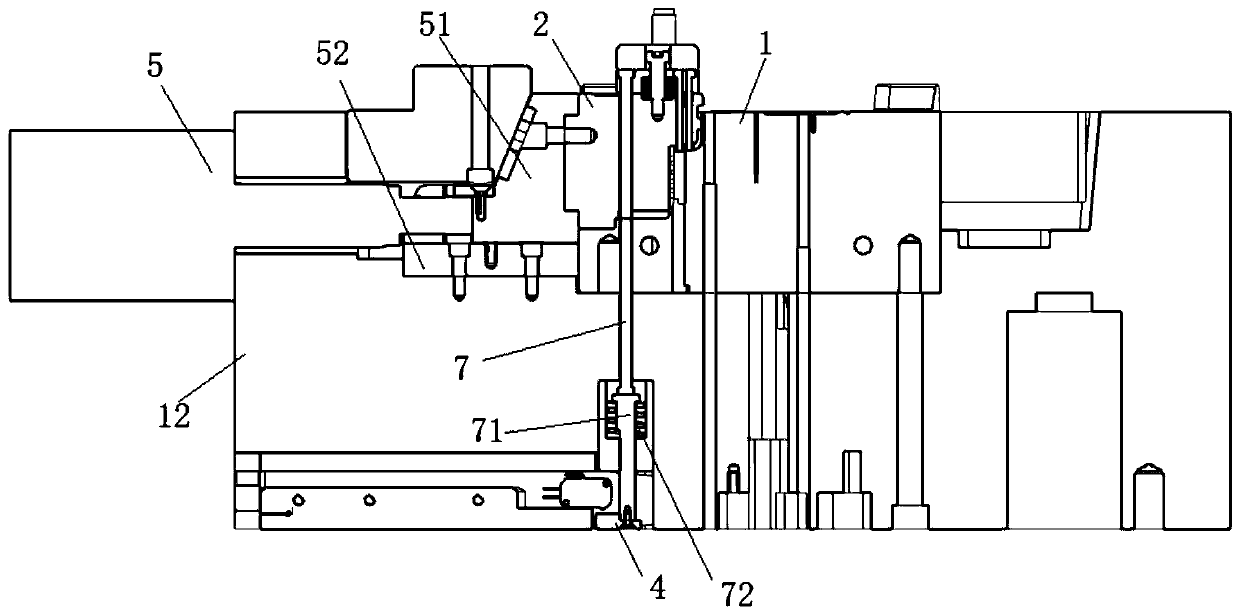

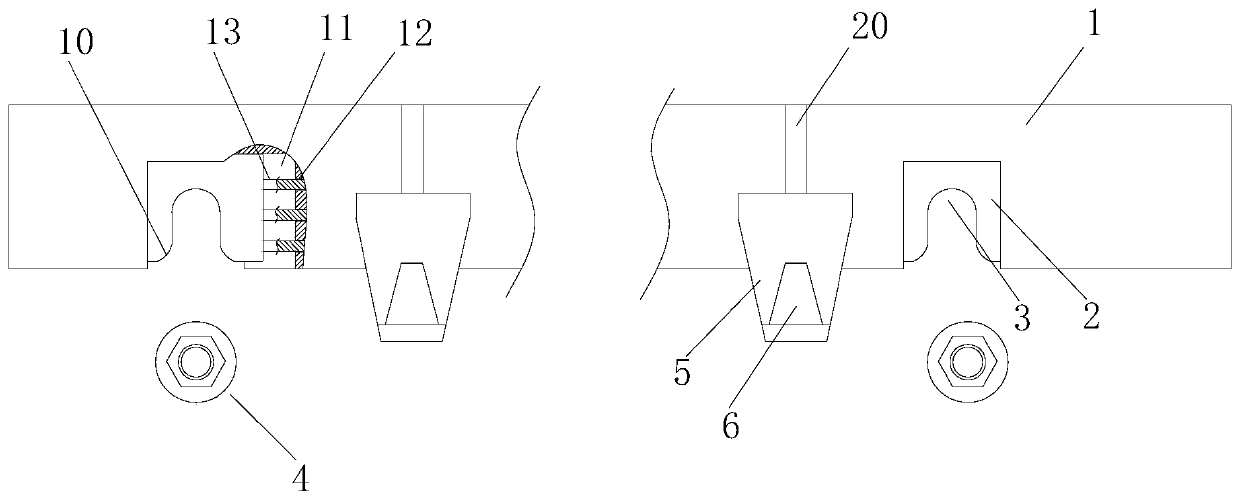

Auxiliary equipment for oil and gas long-distance pipeline construction and construction method thereof

PendingCN114505626ADoes not affect alignmentHigh precisionWelding/cutting auxillary devicesAuxillary welding devicesPortal frameIndustrial engineering

The invention discloses auxiliary equipment for oil and gas long-distance pipeline construction and a construction method thereof, and belongs to the technical field of oil and gas long-distance pipeline construction.The auxiliary equipment comprises a main frame and a welding part, the main frame comprises a base and two portal frames, and a rail assembly is connected between the tops of the two portal frames; the welding part is movably mounted on the rail assembly; a pipeline feeding part and a translation assembly are arranged on the side, away from the positioning part, of the base. The pipeline feeding part comprises a lifting assembly, a rotating assembly is arranged on the lifting assembly, and a pipeline conveying assembly is arranged on the rotating assembly; a clamping assembly is arranged at the top of the pipeline conveying assembly; position adjustment of the to-be-welded pipeline in three directions can be achieved, the position of the to-be-welded pipeline is adjusted through a mechanical structure, the welding part can achieve automatic welding of the pipeline, and safety and reliability are higher.

Owner:刘展

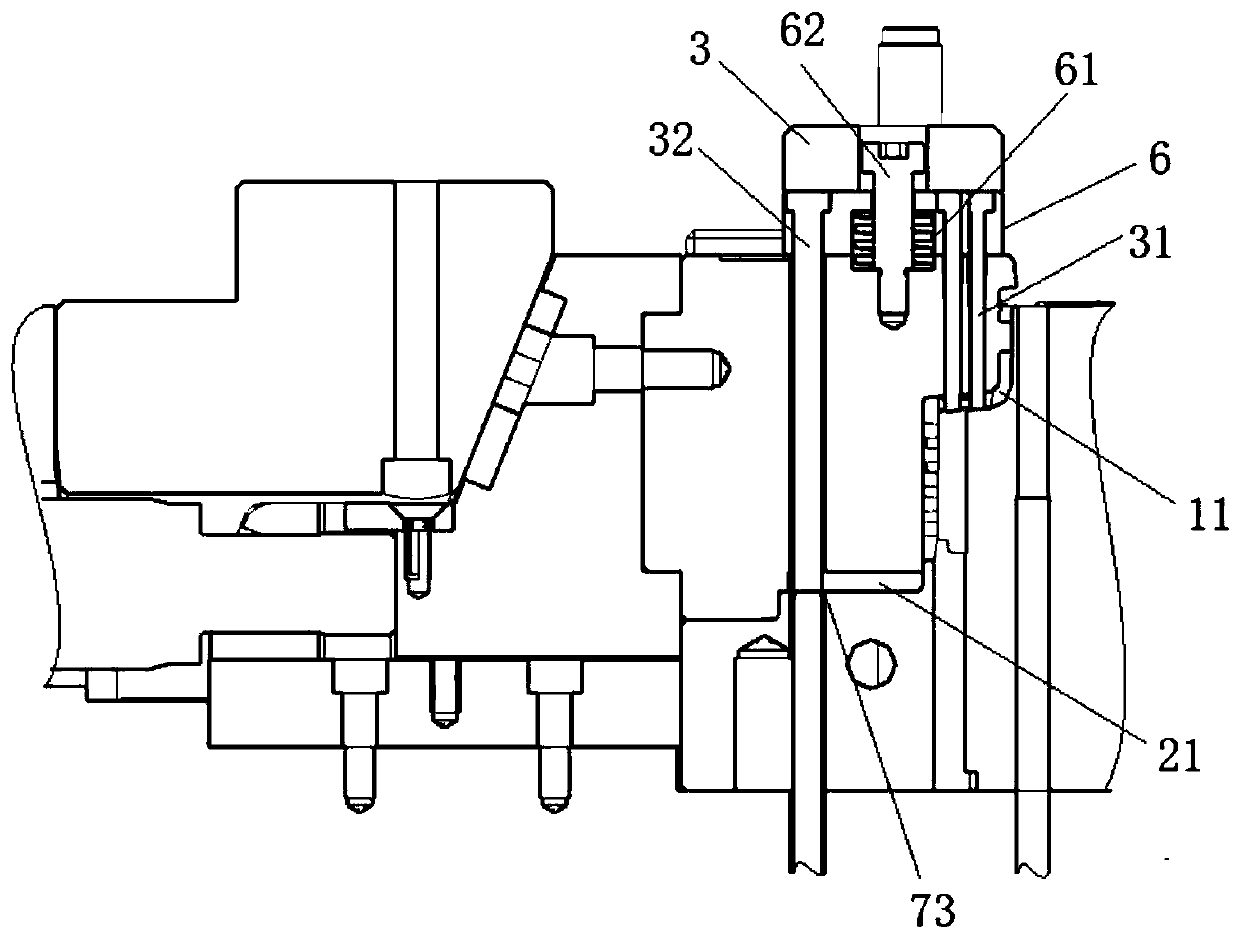

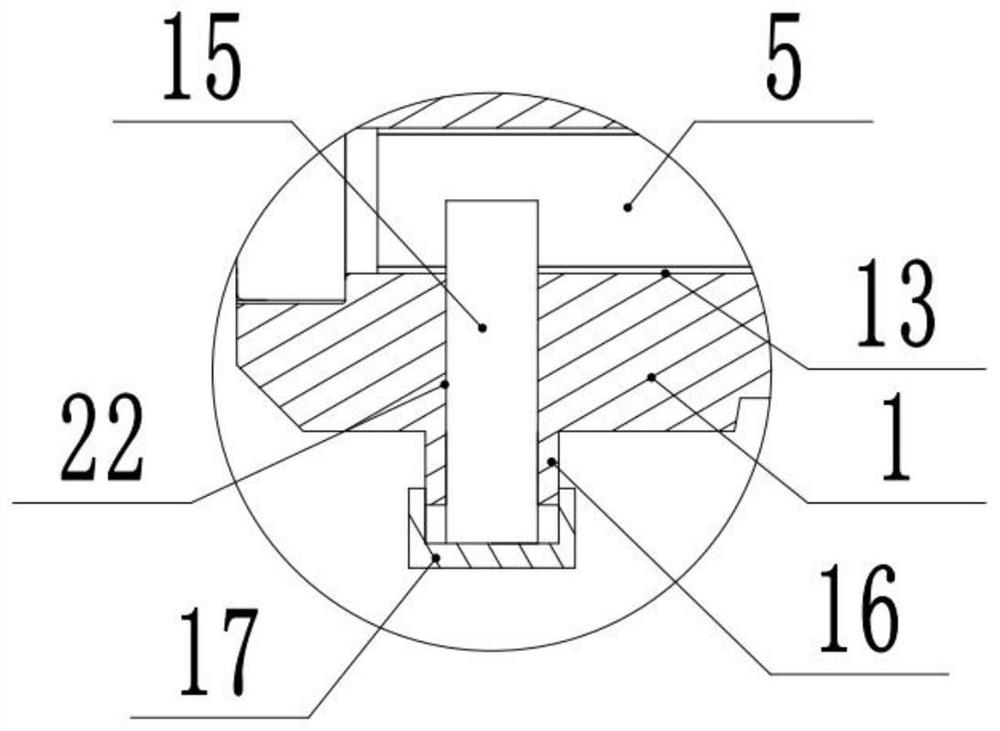

Mesh insert pin core-pulling induction die structure

PendingCN111483120APrecisely control the timing of disengagementDoes not affect alignmentEngineeringInjection molding machine

The invention discloses a mesh insert pin core-pulling induction die structure. The structure comprises a lower die core, a sliding block, an insert pin fixing plate, an insert pin, a connecting rod,a sensor and a sensing oil cylinder, wherein the sliding block and the side of the lower die core are in corresponding butt joint to form a cavity; the insert pin fixing plate is movably arranged on the top of the sliding block, the insert pin is connected to the insert pin fixing plate and penetrates through the sliding block to extend into the cavity, the connecting rod synchronously moves relative to the insert pin, the sensor corresponds to the tail end of the connecting rod, and the sensing oil cylinder is arranged on the side of the sliding block and drives the sliding block to retreat from the cavity. The sensor transmits a moving signal of the connecting rod to the sensing oil cylinder through an injection molding machine. According to the structure, the time when the sliding blockretreats is accurately controlled, and forming of a mold opening product is precisely controlled.

Owner:TAIDEXING PRECISE ELECTRON KUSN

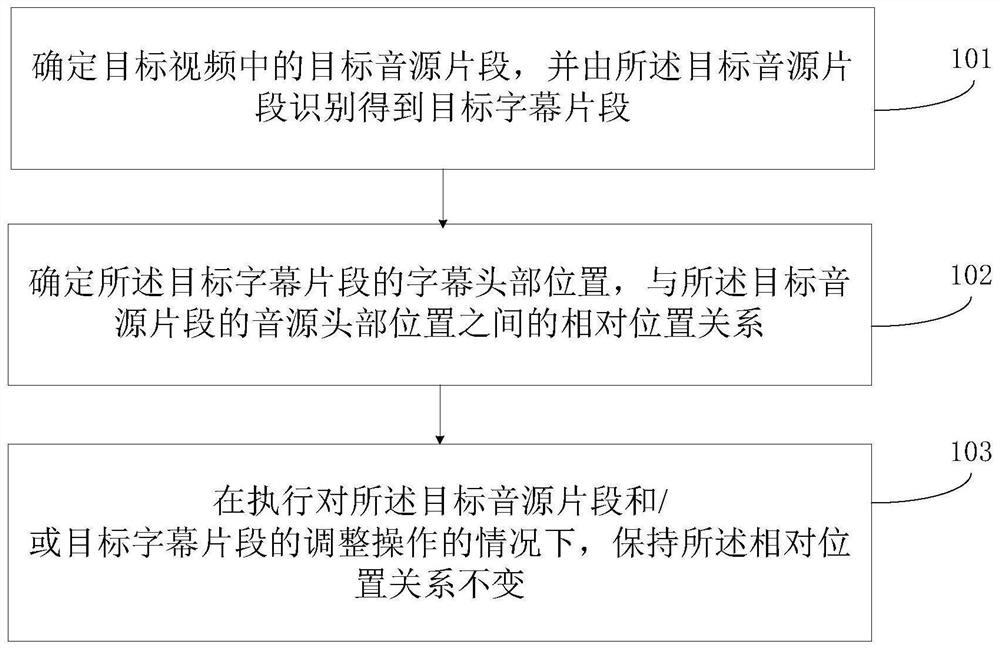

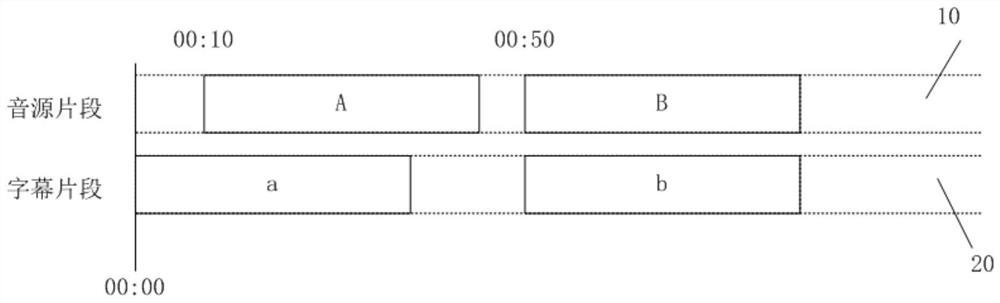

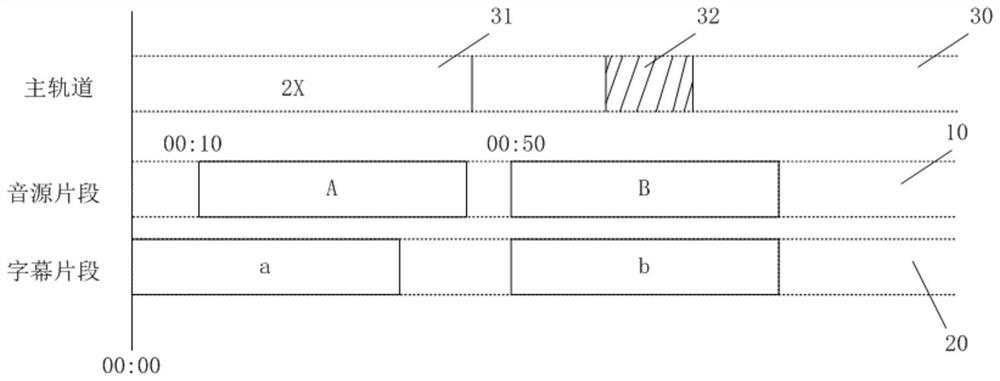

Subtitle and sound source binding method and device

ActiveCN113259776ADoes not affect alignmentReduce the chance of misalignmentElectronic editing digitised analogue information signalsCarrier indexing/addressing/timing/synchronisingSound sourcesComputer graphics (images)

The invention provides a subtitle and sound source binding method and device, an electronic device, a computer storage medium and a computer program product, and the method comprises the steps: determining a target sound source segment in a target video, and carrying out the recognition of the target sound source segment to obtain a target subtitle segment; determining a relative position relationship between the subtitle head position of the target subtitle segment and the sound source head position of the target sound source segment; and keeping the relative position relation unchanged under the condition of executing the adjustment operation on the target sound source fragment and / or the target subtitle fragment. According to the method and the device, the relative position relationship between the head positions of the target subtitle fragment and the target sound source fragment can be bound, so that the editing process of the main track is isolated from the editing process of the subtitles and the sound source, and the editing operation of the main track does not influence the alignment relationship of the subtitles and the sound source; therefore, the probability of dislocation of the sound source and the subtitles is reduced.

Owner:BEIJING DAJIA INTERNET INFORMATION TECH CO LTD

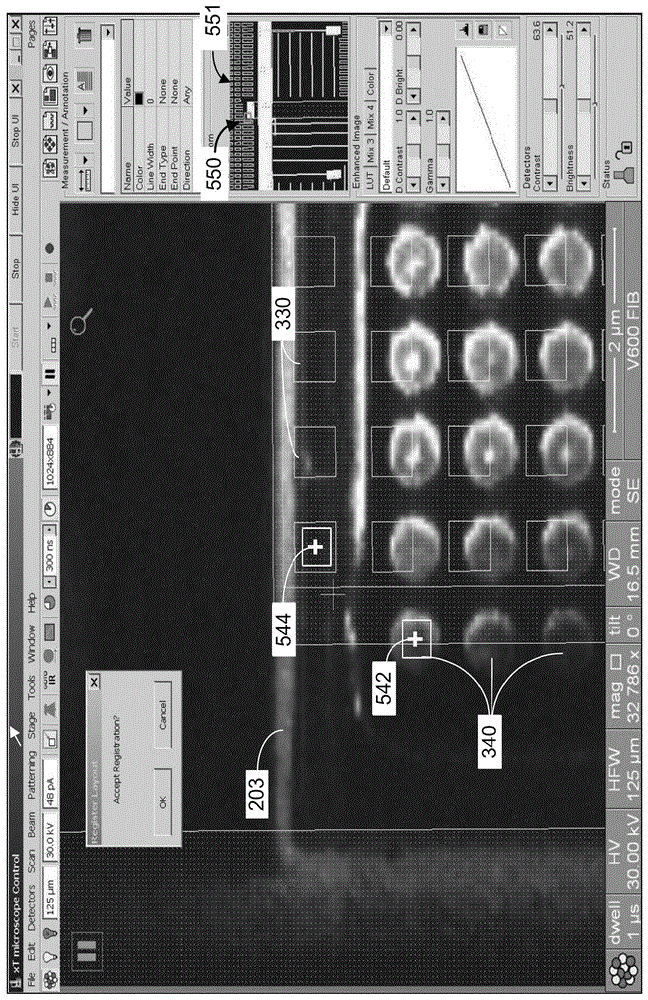

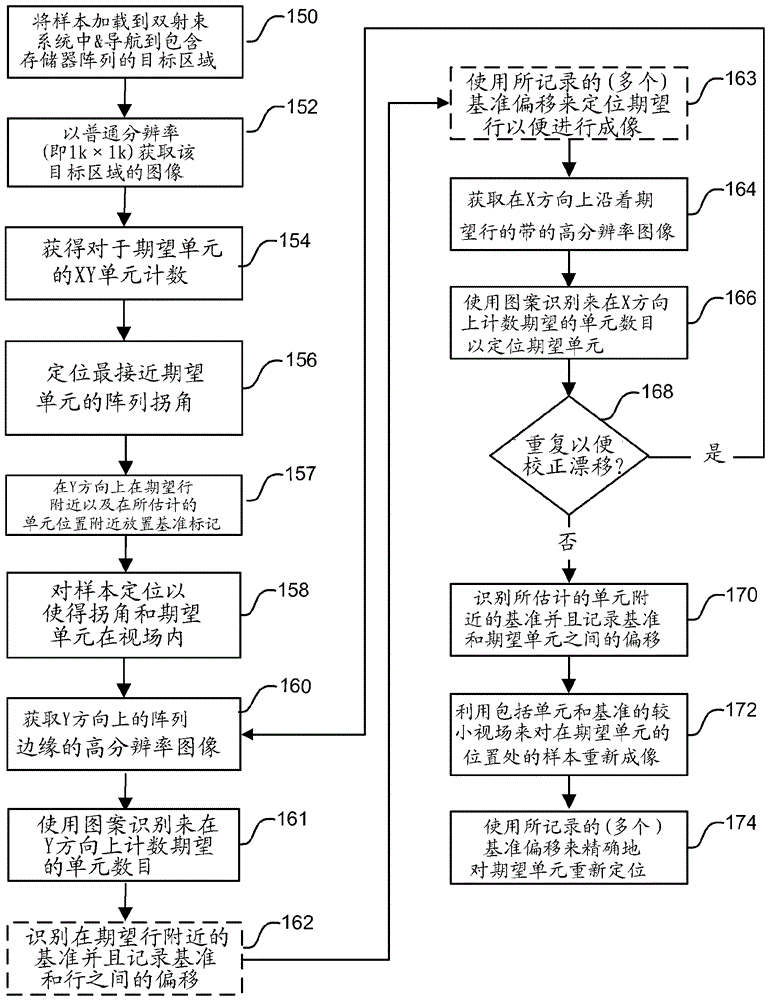

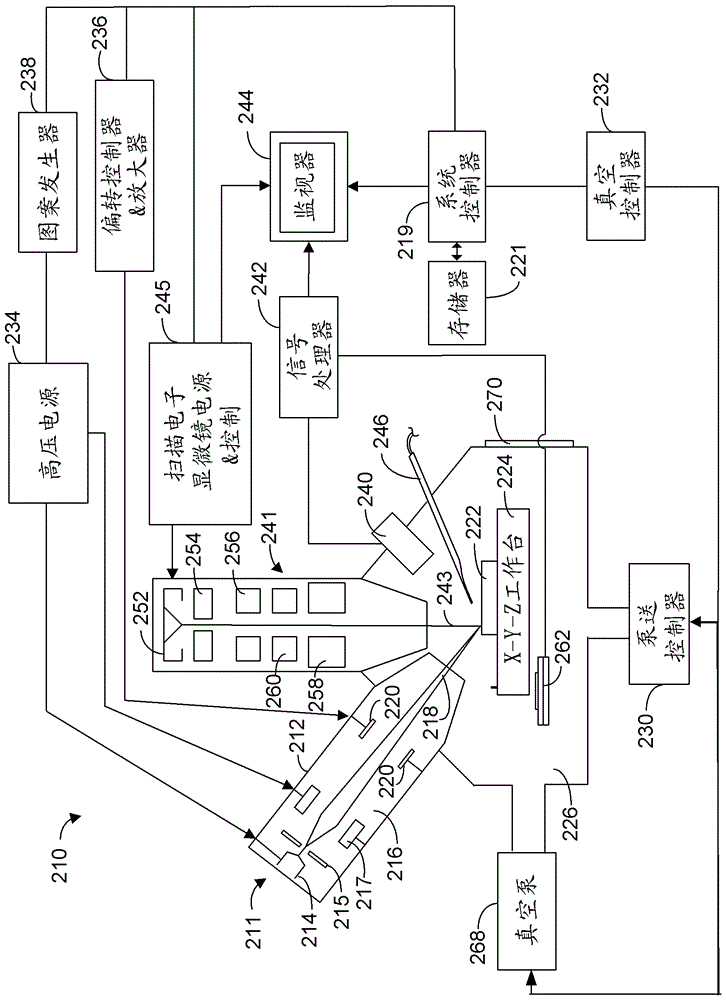

High Accuracy Beam Placement for Local Area Navigation

ActiveCN102820238BImplement navigationDoes not affect alignmentImage enhancementImage analysisComputer graphics (images)Semiconductor chip

The present invention relates to high precision beam placement for local area navigation. An improved method for high precision beam placement for local area navigation in the field of semiconductor chip fabrication is described. Preferred embodiments of the present invention can also be used to quickly navigate to an individual bit cell in a memory array or similar structure, for example, to characterize or correct a defect in that individual bit cell. Use high-resolution scanning to scan (along either the X and Y axes) a "strip" of cells on one edge of the array to locate the row containing the desired cell, followed by A similar high-speed scan in the direction of ) until the desired cell position is reached. This allows pattern recognition tools to be used to automatically "count" the cells necessary to navigate to the desired cell without spending the considerable time required to image the entire array.

Owner:FEI CO

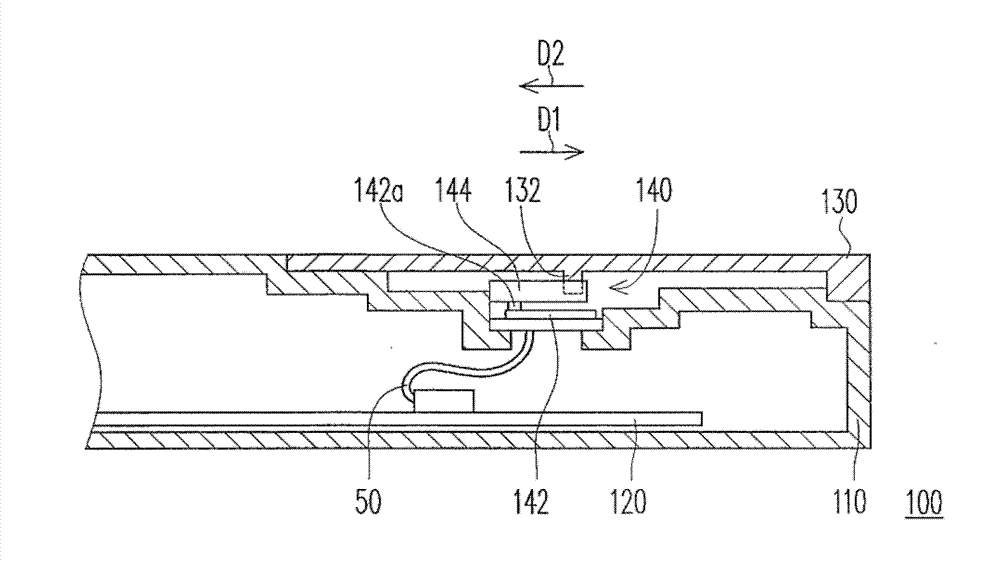

Portable electronic device and switch module

InactiveCN102740622ADoes not affect alignmentAvoid damageDigital data processing detailsCasings/cabinets/drawers detailsComputer moduleEngineering

Owner:ACER INC

Quick mounting structure for display

InactiveCN111022460ADoes not affect installationQuick installationStands/trestlesDowelsDisplay deviceStructural engineering

The invention discloses a quick mounting structure for a display. The quick mounting structure comprises a clamping head and a clamping plate. The clamping head comprises a screw. The screw is in threaded connection to an expansion bolt, a nut is in threaded connection to the tail end of the screw, a pair of sliding blocks is slidably arranged on the clamping plate, a U-shaped slot is formed in the sliding block, the U-shaped slot is in clamping fit to the screw, a pair of connecting seats is fixedly connected to the clamping plate, a clamping end is arranged on the connecting seat, and the clamping end is in clamping fit to a clamping slot in a clamping seat on a display shell. The invention provides the quick mounting structure for the display, wherein the quick mounting structure is simple in structure, few in perforated hole, rapid to mount and high in fault tolerance.

Owner:江苏艾展信息技术有限公司

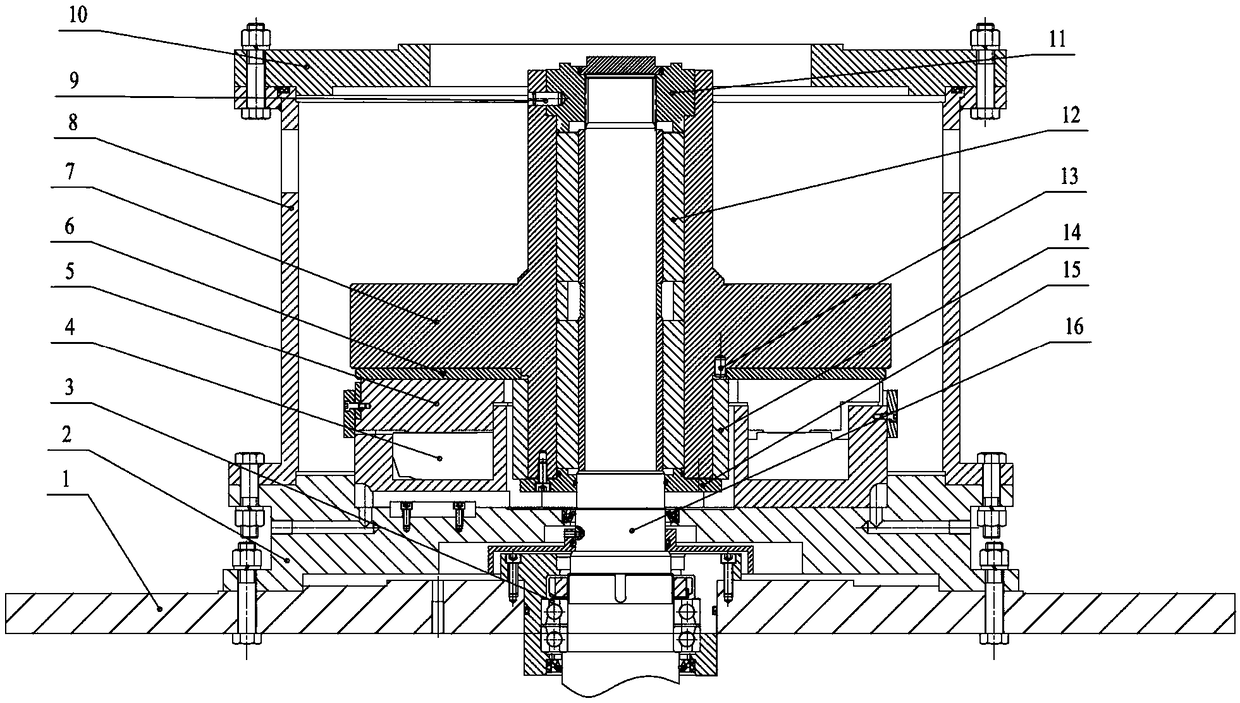

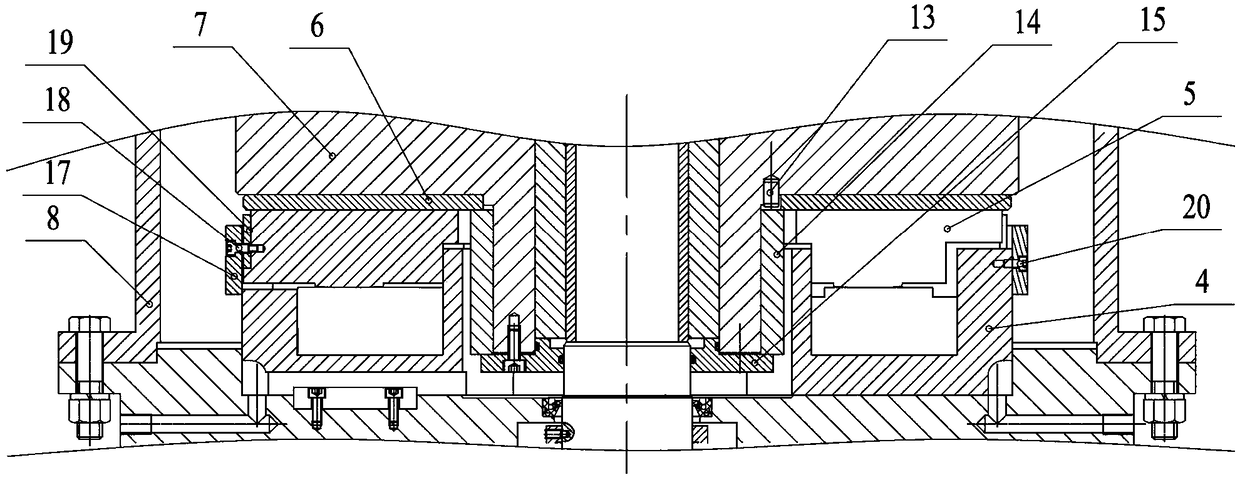

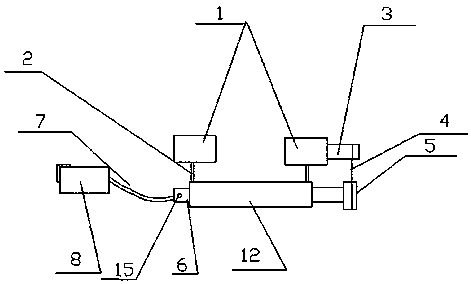

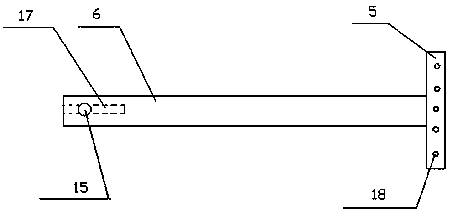

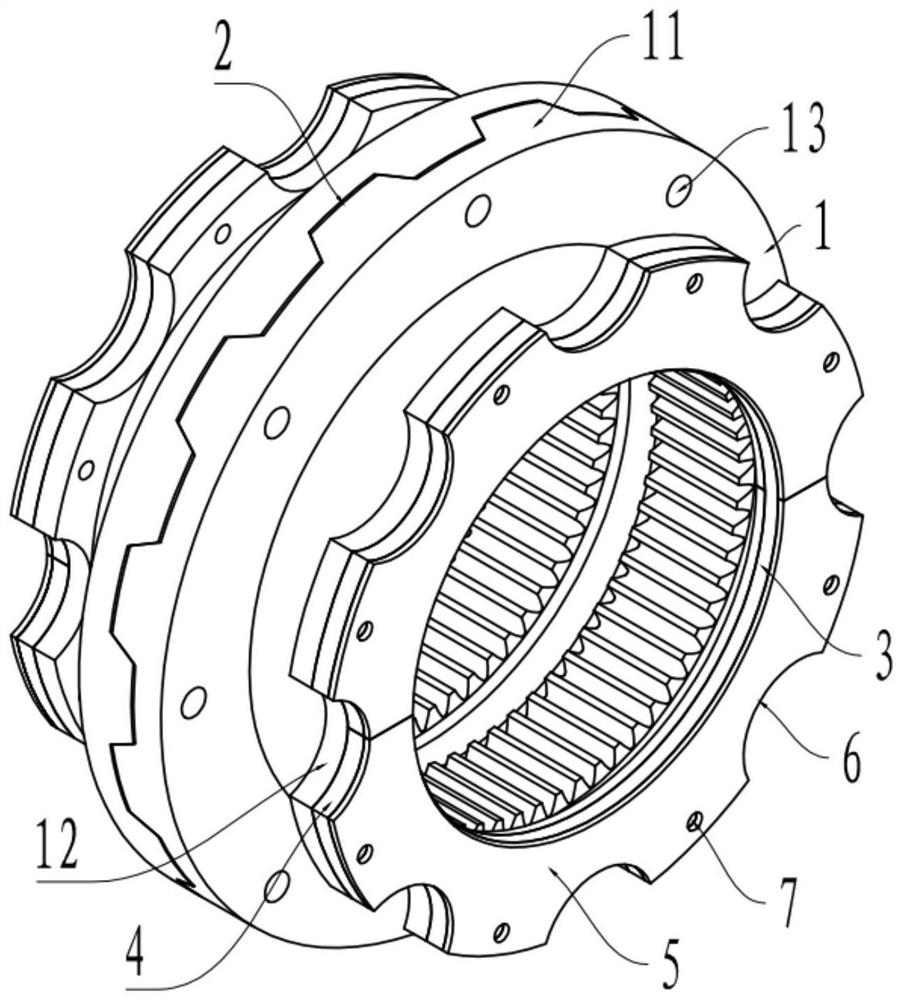

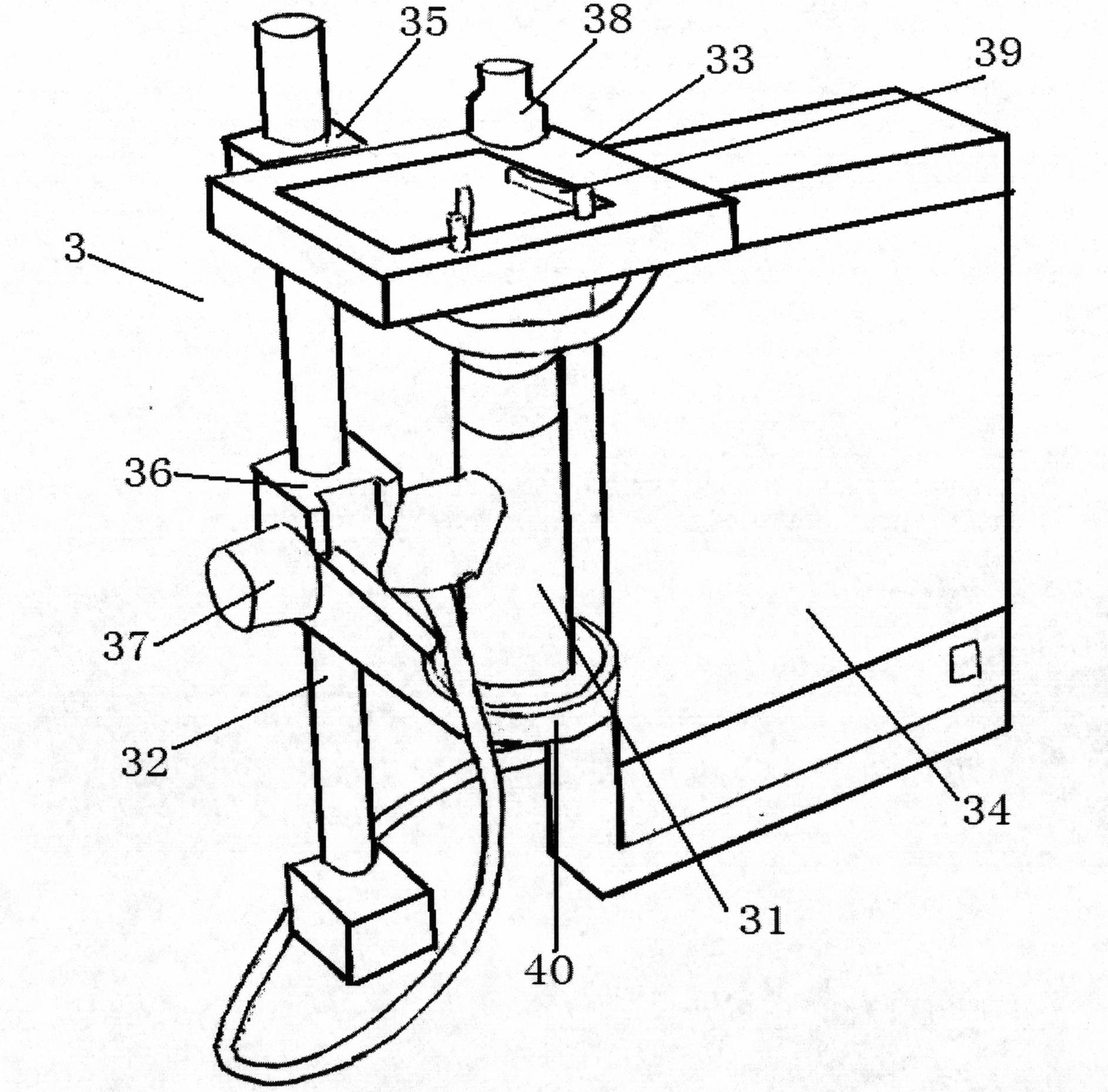

A convenient replacement friction pair thrust bearing experimental device

ActiveCN105973599BEasy to replaceAvoids the problem of replacing the entire thrust discMachine bearings testingThrust bearingTorque transmission

The invention discloses a thrust bearing experimental device capable of replacing a friction pair conveniently. The thrust bearing experimental device comprises an experimental cavity constituted by an experimental cavity base, an experimental cavity, and an experimental cavity top cover. The experimental cavity is filled with lubrication medium, and a testing bearing constituted by a bearing pedestal, an experimental thrust bearing shoe, and a friction pair disc is disposed in the experimental cavity. The bearing pedestal is disposed on the experimental cavity base, and the friction pair disc is provided with a thrust disc, and is fixedly connected with the thrust disc by a torque transmission pin. A rotating shaft passes through the experimental cavity, and is fixedly connected with the thrust disc. The thrust bearing experimental device is advantageous in that the problem that the replacement of the pairing friction pair requiring the replacement of the whole thrust disc is prevented, and the replacement cost is reduced, and at the same time, the experimental devices has a wider material application range; the radial and axial limiting of the experimental thrust bearing shoe is realized, and the assembly process is simplified; after the simple disassembly process, the experimental thrust bearing shoe can be taken out along a radial direction without disassembling the shafting, and therefore the centring performance of the whole shafting cannot be affected, and the requirement of the material pairing experiment on the frequent replacement of the experimental thrust bearing shoe is satisfied.

Owner:TSINGHUA UNIV

Mandibular second molar torque control device

The invention provides a torque controlling device of the mandibular second molar, and relates to the field of orthodontic instruments. The device comprises a mandibular first molar, first bottom plates, a bracket, a rotating part, a buccal tube, an NITI wire and a traction steel wire, wherein the mandibular first molar is attached to the side where the mandibular second molar is located; the first bottom plates are arranged on the buccal side surface of a mandibular second premolar; the bracket is attached to the lingual side surfaces of mandibular left and right first molars; the rotating part is arranged below the first bottom plates; the buccal tube is attached to the buccal side surface of the mandibular second molar; the NITI wire is arranged between the rotating part and the buccal tube; the traction steel wire is used for dragging the rotating part; the rotating part comprises a cannula which is parallel to the occlusal plane and a rotating shaft which penetrates through the cannula and can rotate in the cannula; a rotating disc is arranged at the mesial end part of the rotating shaft; a plurality of positioning parts are arranged on the rotating disc; two ends of the traction steel wire are connected with the positioning parts on the rotating disc and the mesial end parts of the first bottom plates; the distal end part of the rotating shaft is connected with the NITI wire. According to the device provided by the invention, the buccolingual torque of the mandibular second molar can be effectively adjusted.

Owner:SHANGHAI XUHUI DISTRICT DENTAL CENT

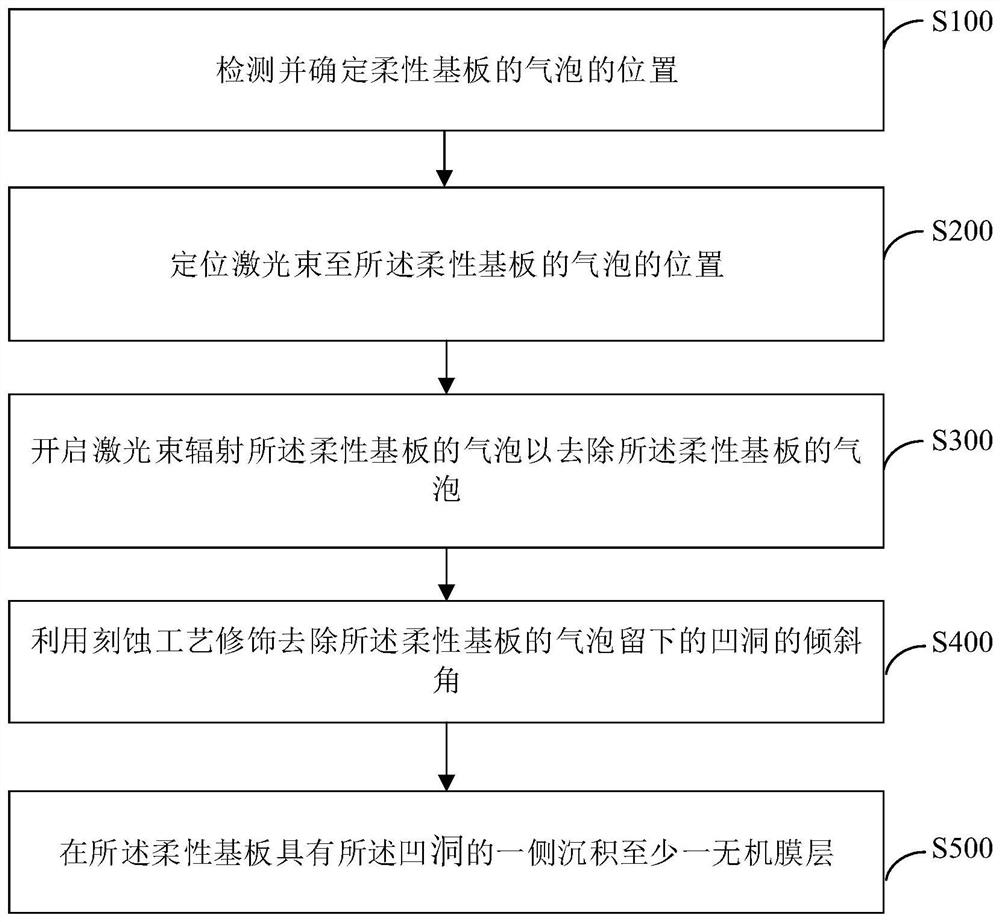

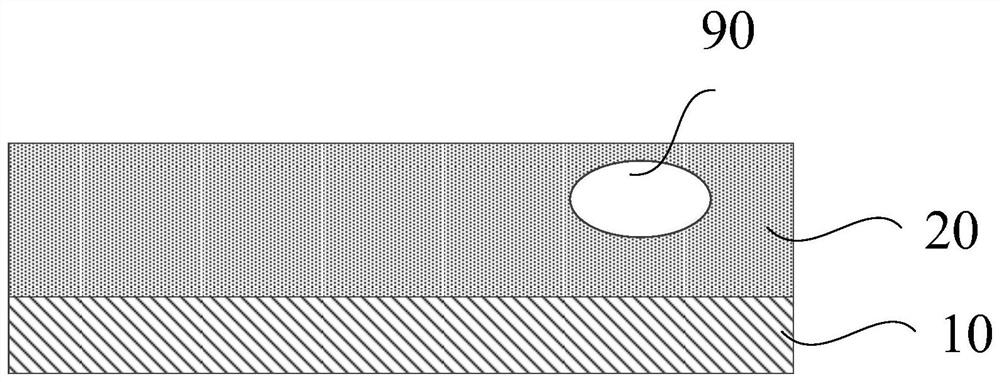

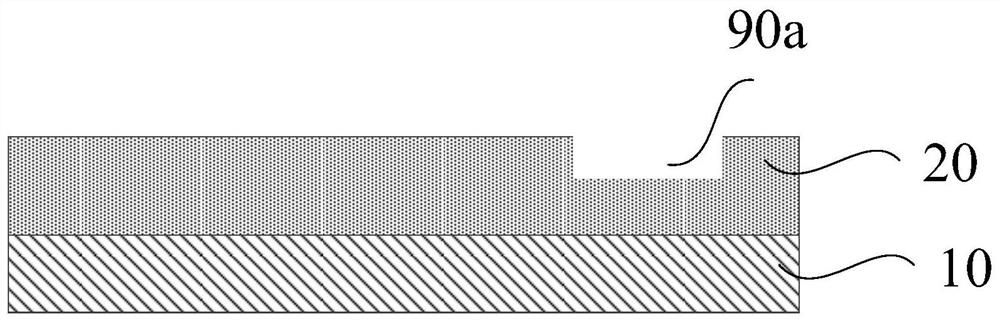

Flexible substrate bubble repairing method, flexible substrate and flexible display panel

PendingCN114335402AAvoid nudityDoes not change optical performanceSemiconductor/solid-state device testing/measurementSolid-state devicesEngineeringFlexible display

The invention provides a flexible substrate bubble repairing method, a flexible substrate and a flexible display panel. The repairing method comprises the following steps: detecting and determining the position of a bubble of the flexible substrate; positioning the laser beam to the position of the bubble of the flexible substrate; starting a laser beam to radiate the bubbles of the flexible substrate so as to remove the bubbles of the flexible substrate; modifying an inclination angle of a pit formed after the bubbles of the flexible substrate are removed by using an etching process; and depositing at least one inorganic film layer. According to the method, the bubbles are removed through the laser beams, and the inclination angle of the concave hole left by removing the bubbles is modified through the etching process, so that the repaired interface becomes gentle, the situation that the flexible substrate is exposed due to the fact that the concave hole cannot be completely covered due to the too large inclination angle of the concave hole in subsequent repair of the inorganic film layer is avoided, and meanwhile, the flexible substrate is protected. The overall optical performance of the repaired flexible substrate cannot be changed, subsequent OLED evaporation alignment cannot be affected, the yield of flexible OLED products is greatly improved, and economic losses caused by scrapping are reduced.

Owner:EVERDISPLAY OPTRONICS (SHANGHAI) CO LTD

Rotary cultivator roller vibration anti-winding and soil removal device

ActiveCN109315091BReduce tanglingReduce stickinessAgricultural machinesTilling equipmentsAgricultural engineeringStructural engineering

The invention discloses a rotary cultivator knife roller vibration anti-tangle and soil removal device. A knife roller composition connected with a gearbox is symmetrically arranged under the frame, and a vibration anti-tangle and soil removal device is connected to the knife roller composition; the knife roller composition includes and The power output shaft of the gearbox is fixedly connected to the cutter shaft. There are multiple rotary cultivating knives on the cutter shaft. There are fixed knives on the side of each rotary cultivating knife. There are also axial positioning holes on the cutter shaft; vibration prevents entanglement and soil removal The device includes two vibration generating devices on the left and right. A rotating roller is connected between the two vibration generating devices. The rotating roller is set on the knife shaft. There are multiple vibration holes on the rotating roller. The vibrating hole protrudes, and the outer edge of the vibrating hole is provided with a moving knife that forms a shearing action with the fixed knife. There is also a straight slot hole on the rotating roller, and a positioning bolt is connected between the straight slot hole and the axial positioning hole. The invention can not only effectively prevent entanglement, but also reduce soil stickiness without affecting the arrangement and shape of the rotary tiller blades.

Owner:HUAZHONG AGRI UNIV

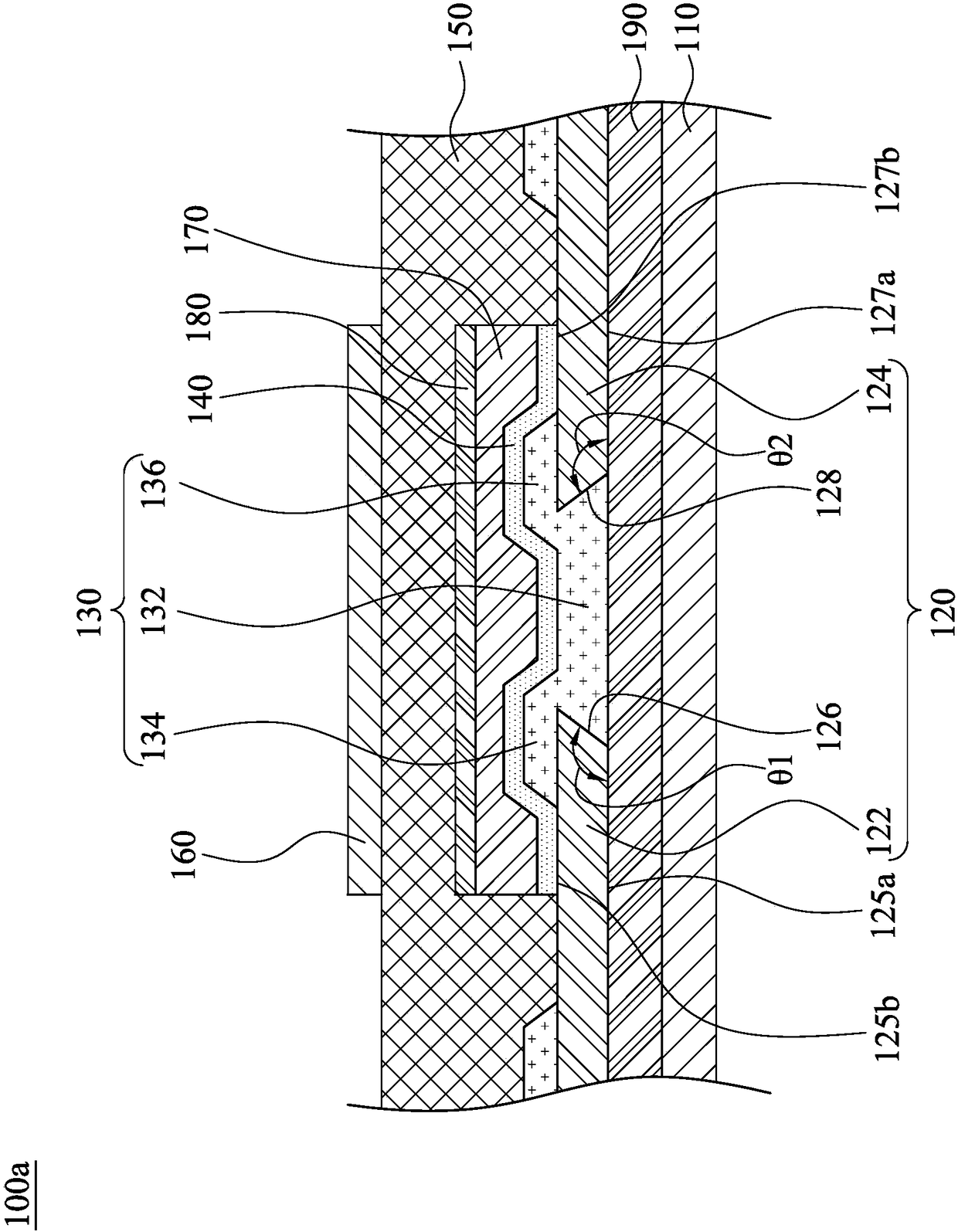

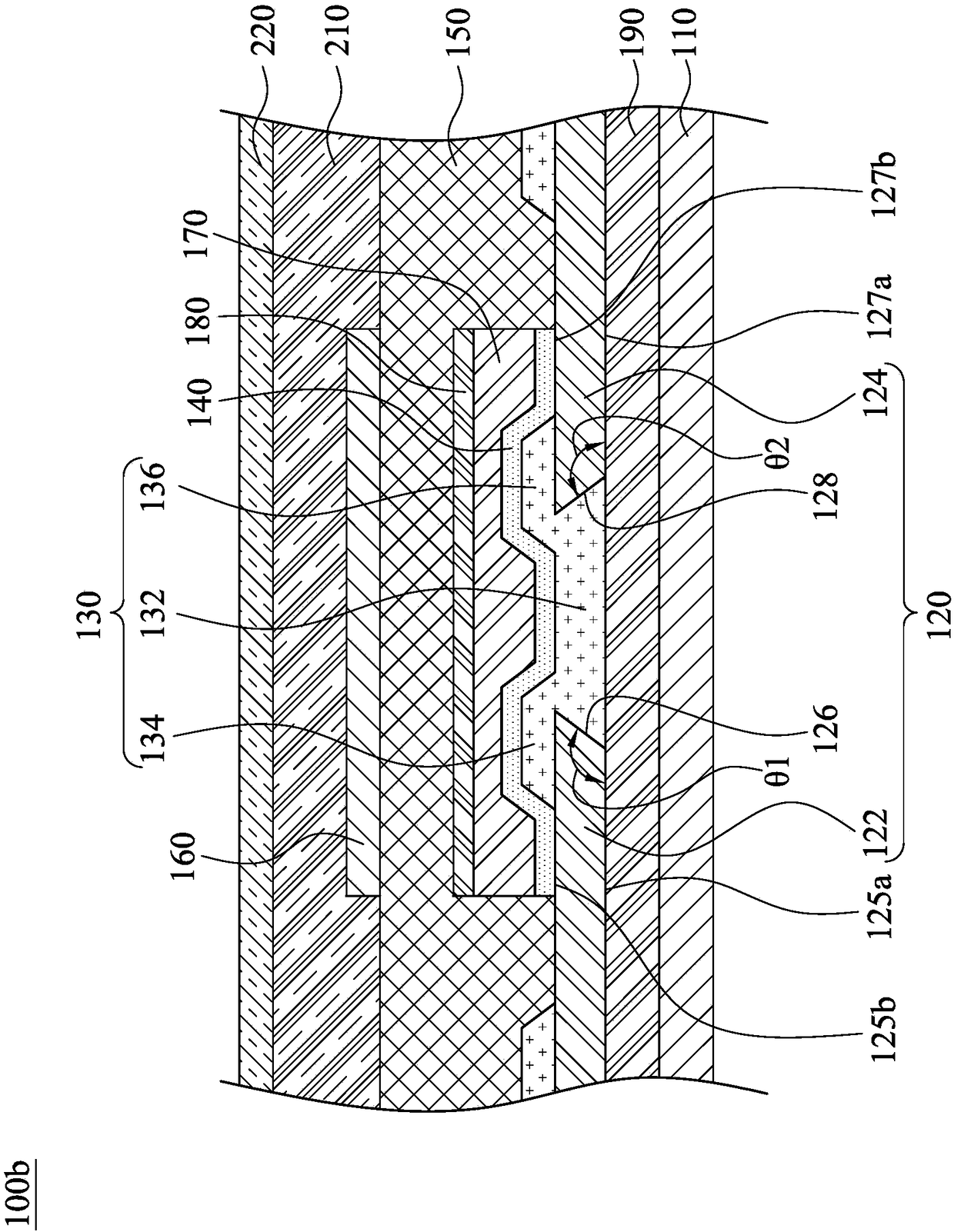

Organic thin film transistor

ActiveCN108878650AIncreasing the thicknessUniform thicknessSolid-state devicesSemiconductor/solid-state device manufacturingElectrical stabilitySemiconductor

Owner:E INK HLDG INC

A kind of semiconductor device and its preparation method

ActiveCN104752323BDoes not affect alignmentGood step coverageSemiconductor/solid-state device detailsSolid-state devicesPower semiconductor deviceLithographic artist

The present invention relates to a semiconductor device and a manufacturing method thereof, the method comprising: providing a semiconductor substrate, an interlayer dielectric layer is formed on the semiconductor substrate, a contact hole is formed in the interlayer dielectric layer, and photolithography mark holes, the photolithography mark holes have gaps; deposit a sacrificial material layer to completely fill the gaps; form a protective layer on the interlayer dielectric layer and the sacrificial material layer; Forming through-silicon holes in the bottom and the interlayer dielectric layer; removing the protection layer to expose the sacrificial material layer; removing the sacrificial material layer to expose the gap. The present invention proposes to use a-C as the protective layer of CT in the TSV VIA middle process. Compared with SIN, a-C has better step coverage ability and can be completely removed, so as not to affect the subsequent first metal Layer lithography (M1photo) alignment effectively solves the problem of OVL measurement.

Owner:SEMICON MFG INT (SHANGHAI) CORP

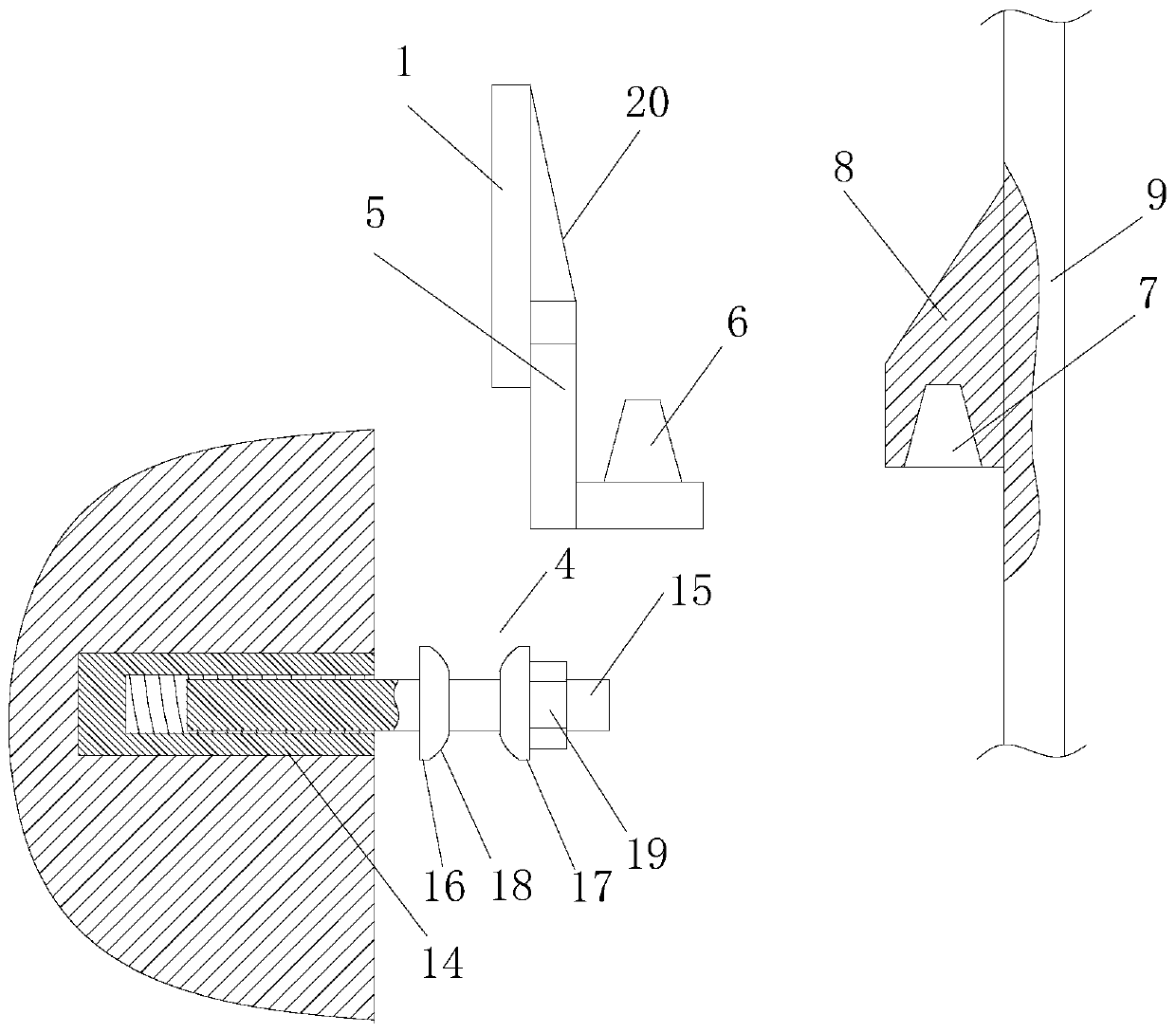

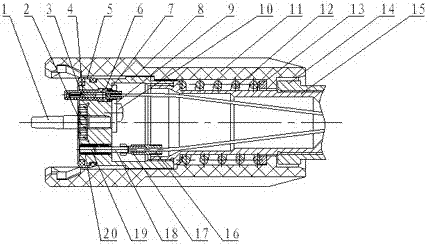

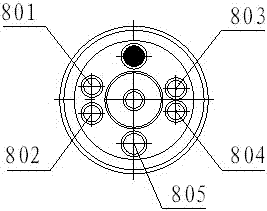

An expanded beam photoelectric composite connector

ActiveCN104730649BDoes not affect alignmentSolve the problem of wear affecting service lifeCoupling device detailsCoupling light guidesElastic componentEngineering

The invention discloses a beam-expanded type photoelectric composite connector. The connector comprises a base body. One end face of the base body is a smooth plane and provided with a guide column. The guide column is perpendicular to the smooth plane. The base body is provided with guide column holes and mounting holes for fixing an electrical contact piece and an optical collimator assembly. The electrical contact piece is arranged in the mounting holes through elastic components. A shell is arranged outside the base body. The base body is fixedly connected with the shell through a middle sleeve and a locking sleeve. According to the beam-expanded type photoelectric composite connector, the guide column, the guide column holes and the mounting holes are arranged on the end face of the base body, meanwhile, a connector optical path is aligned with a circuit, and an optical path collimator is attached through the smooth plane of the connector base body end face so that the problems that the end faces of optical contact pins of an existing photoelectric composite connector are prone to being polluted, and the service life is affected due to wear to the optical end face can be solved; electric contact pins and electric jacks are arranged in the mounting holes in a floating mode through the elastic components, and the alignment state of the optical path is not affected when the electric contact pins and the electric jacks are inserted.

Owner:CHINA ELECTRONICS TECH GRP NO 23 RES INST

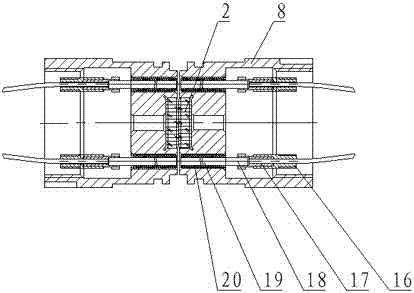

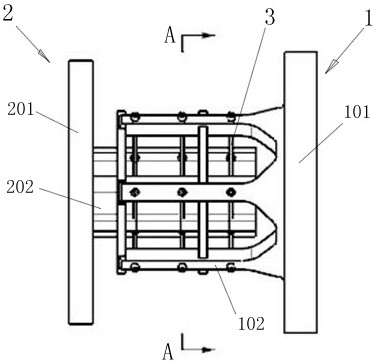

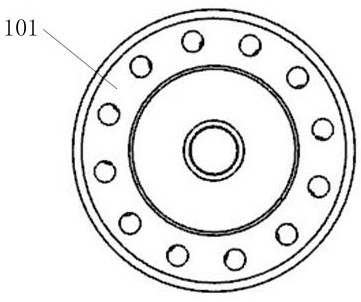

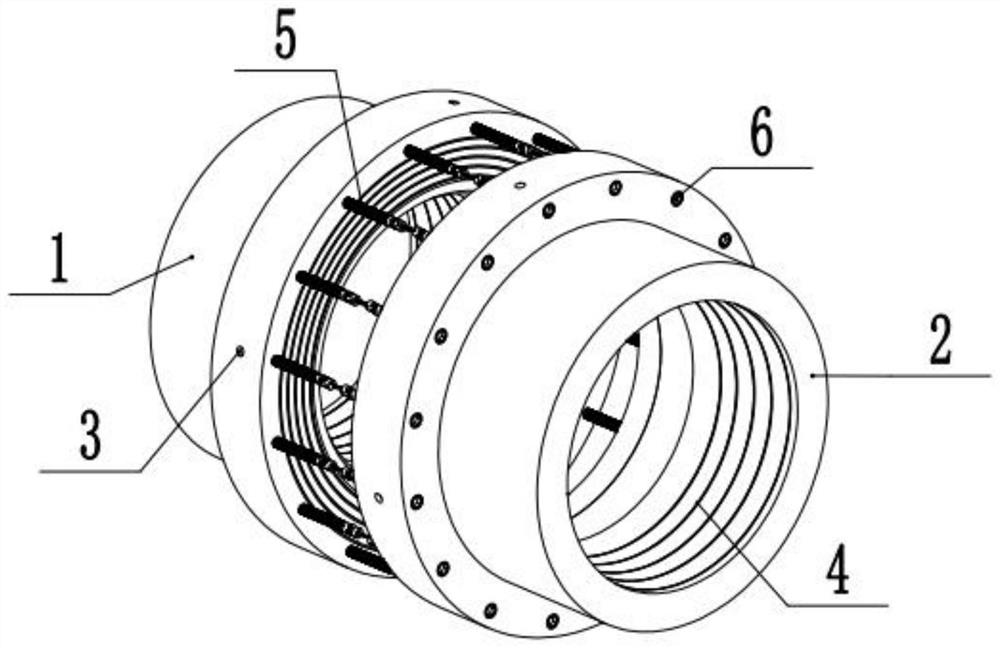

High-rotating-speed small-torque star-shaped vibration isolation coupler

PendingCN112412994AEffective torque transferReduce running noiseYielding couplingDrive shaftCoupling

The invention relates to a coupler for high-rotating-speed precision rotating machinery, in particular to a high-rotating-speed small-torque star-shaped vibration isolation coupler, which comprises adriving shaft end connector and a driven shaft end connector, and is technically characterized in that the driving shaft end connector consists of a flange plate I and a squirrel-cage-shaped shaft body connected with the flange plate I; a driven shaft end connector is composed of a flange plate II and a star-shaped shaft body connected with the flange plate II; the star-shaped shaft body is inserted into the squirrel-cage-shaped shaft body; at least one set of tension lines with ductility is connected between the star-shaped shaft body and the squirrel-cage-shaped shaft body; and each set of tension lines is composed of a plurality of tension lines symmetrically distributed in the circumferential direction of the star-shaped shaft body. The high-rotating-speed small-torque star-shaped vibration isolation coupler is compact in structure and reliable in use, solves the problem of poor vibration isolation or vibration reduction effect when an existing coupler is applied to a high-rotating-speed precision rotating machine, is beneficial to effectively reducing the influence of shaft end flutter of a driving shaft system on a driven shaft system, and is low in operation noise.

Owner:沈阳航燃科技有限公司

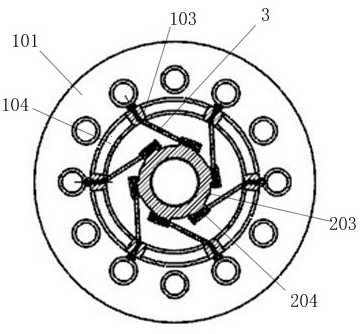

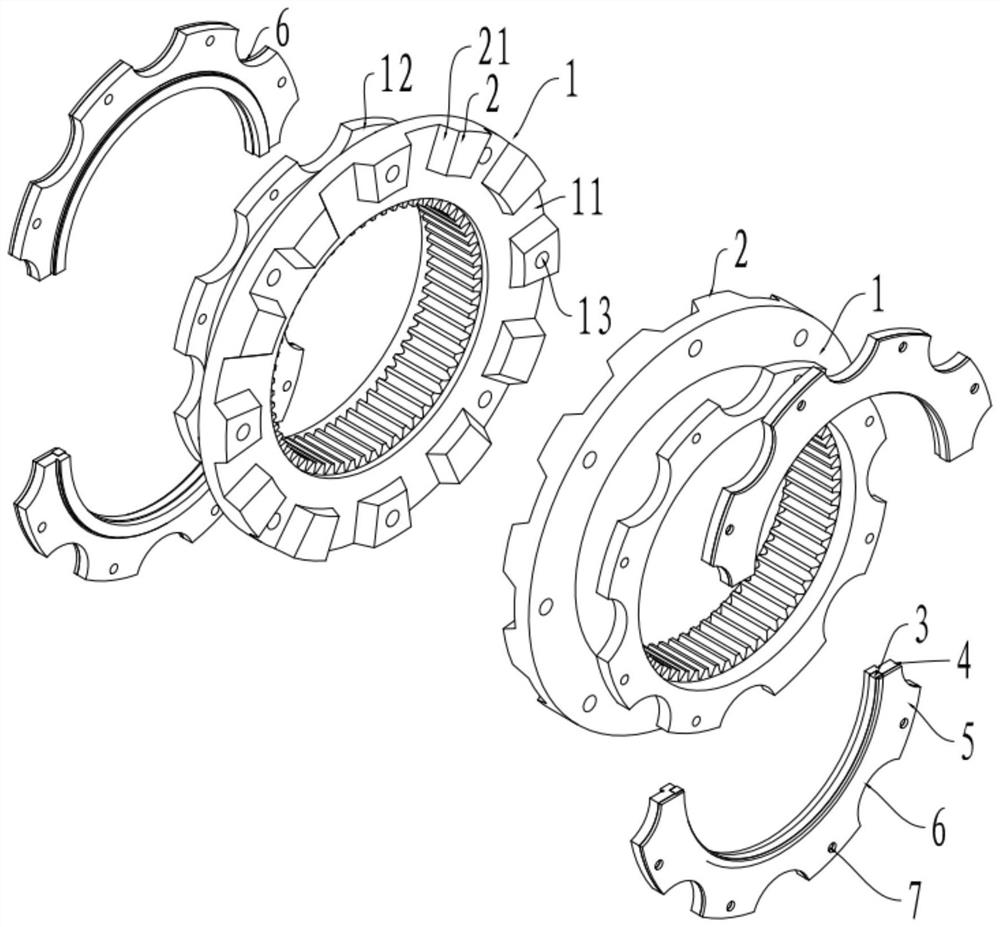

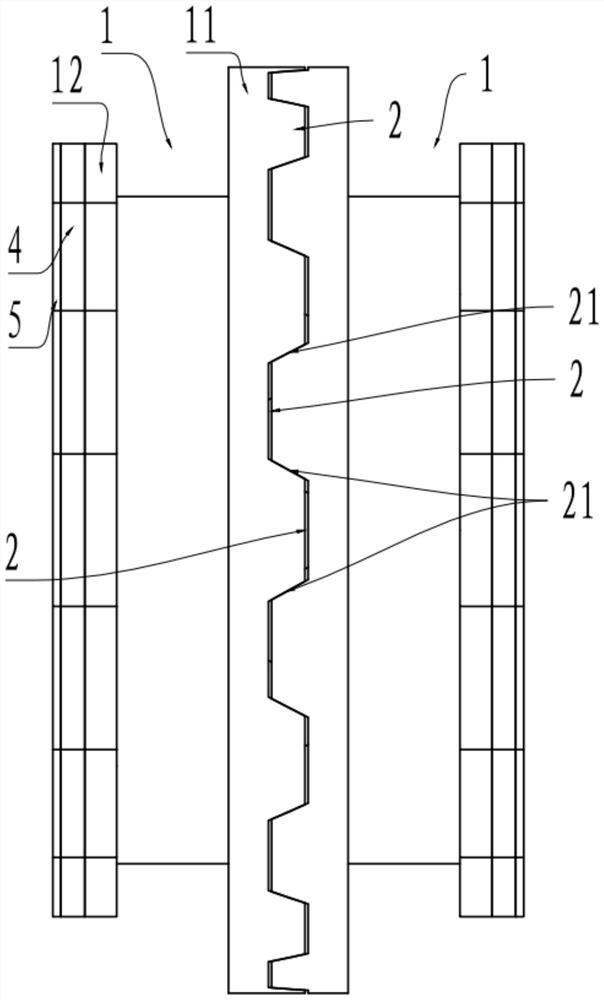

Self-hole-aligning coupler and using method thereof

PendingCN114542611AExtended service lifeConvenient to be close to each otherCouplings for rigid shaftsWind energy generationButt jointCoupling

The invention relates to the technical field of connecting parts, in particular to a self-hole-aligning coupler and a using method thereof.The self-hole-aligning coupler comprises two connecting sleeves, each connecting sleeve is provided with a plurality of protrusions evenly distributed in the circumferential direction of the connecting sleeve, each protrusion is provided with a guide face, and the guide faces on the two connecting sleeves can abut against each other; a recess for accommodating the bulge on the other connecting sleeve is formed between the adjacent bulges on the same connecting sleeve; when the coupling is used, the connecting sleeve is firstly connected with the connecting shaft; then the protrusion of one connecting sleeve is matched with the recess of the other connecting sleeve, butt joint of the two connecting sleeves is completed through sliding of the connecting sleeves along the guide faces, and finally bolts penetrate through the connecting holes to achieve fixed connection of the two connecting sleeves. The scheme is used for solving the problems of high assembly difficulty and low efficiency in the disassembly and assembly of the coupler in the prior art.

Owner:中铝西南铝板带有限公司

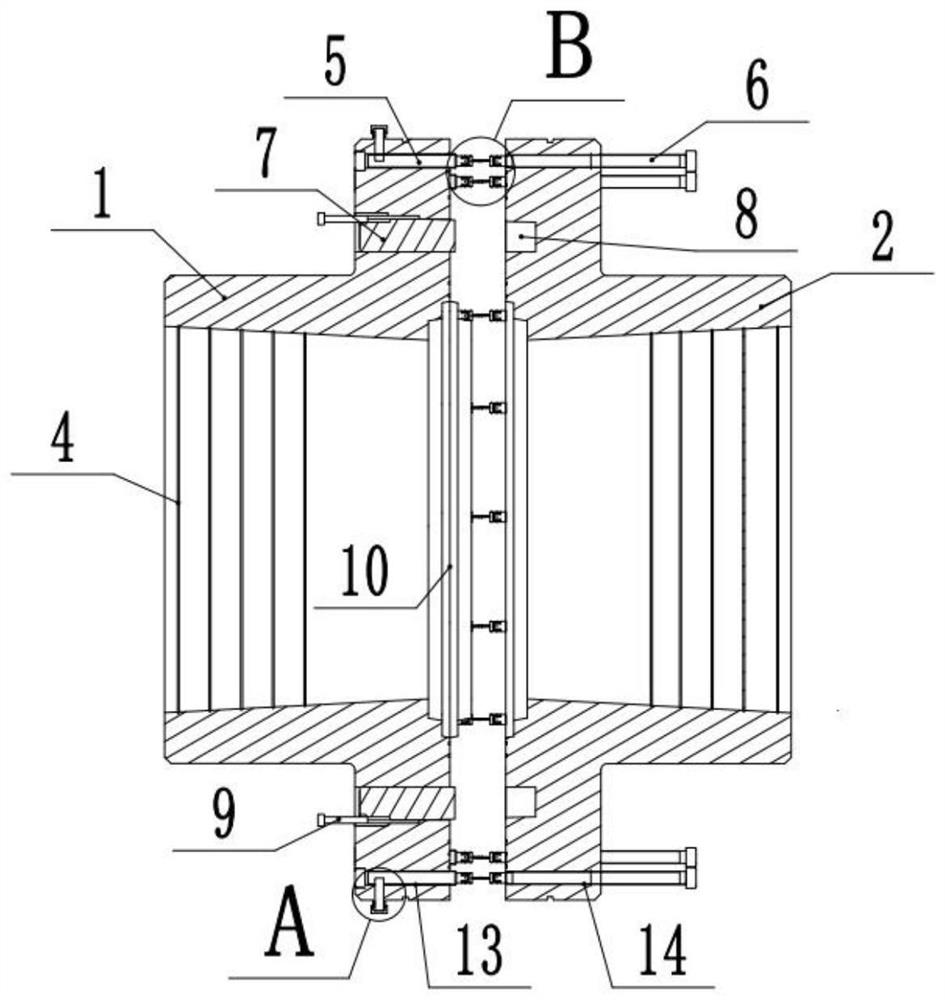

Underwater pipeline connecting device and pipeline connecting method

PendingCN114151632ASuppress stressResistance to buoyancyFlanged jointsNutsStructural engineeringMechanical engineering

The invention discloses an underwater pipeline connecting device and a pipeline connecting method.The underwater pipeline connecting device comprises a left flange, a right flange, a traction bolt, a fixing bolt and a pressing ring, the left flange and the right flange are oppositely arranged, a traction mechanism is arranged between the left flange and the right flange, and a plurality of clamping mechanisms are arranged on the traction mechanism; the left flange is further provided with a pressing waterproof mechanism. Aligning the left flange, the right flange and threaded holes and through holes in the left flange and the right flange; connecting the left flange and the right flange; a fixing bolt is clamped; and the pressing ring is pressed, so that the left flange and the right flange form a sealing seal. The device is provided with the traction mechanism, and the traction mechanism can well resist the pressure of the seabed and the buoyancy of water; simultaneous positioning of the pipeline and the threaded hole is achieved, and secondary positioning is avoided; the pressing waterproof mechanism is arranged, so that alignment between the flanges cannot be affected; and the clamping mechanism is arranged, the clamping mechanism further clamps the fixing bolt, and the fixing bolt is prevented from loosening due to seawater scouring.

Owner:INNER MONGOLIA UNIV OF TECH

Backlight module and manufacturing method thereof, display module and ring-shaped light-shielding tape

InactiveCN106200129BDoes not affect alignmentFilm/foil adhesivesNon-linear opticsLiquid-crystal displayDisplay device

The invention discloses a backlight module and a manufacturing method thereof, a displayer module and annular light shading adhesive tape and belongs to the technical field of liquid crystal display. The backlight module comprises the annular light shading adhesive tape and a backlight source. The annular light shading adhesive tape is attached to the light-out side of the backlight source, and notches are formed in at least one set of opposite corners in the four corners of the annular light shading adhesive tape in order to expose the corners, corresponding to the notches, of the backlight source. The notches are formed in at least one set of opposite corners in the four corners of the annular light shading adhesive tape in the backlight module, when the annular light shading adhesive tape and the backlight source deviate in the attachment process, the corners, corresponding to the notches, in the backlight source can be exposed, and therefore alignment of a display panel and the backlight module is not affected. The backlight module and the manufacturing method thereof, the displayer module and the annular light shading adhesive tape are used for displaying images.

Owner:BOE TECH GRP CO LTD +1

Superconducting single-photon detector and package method

Owner:NANJING UNIV

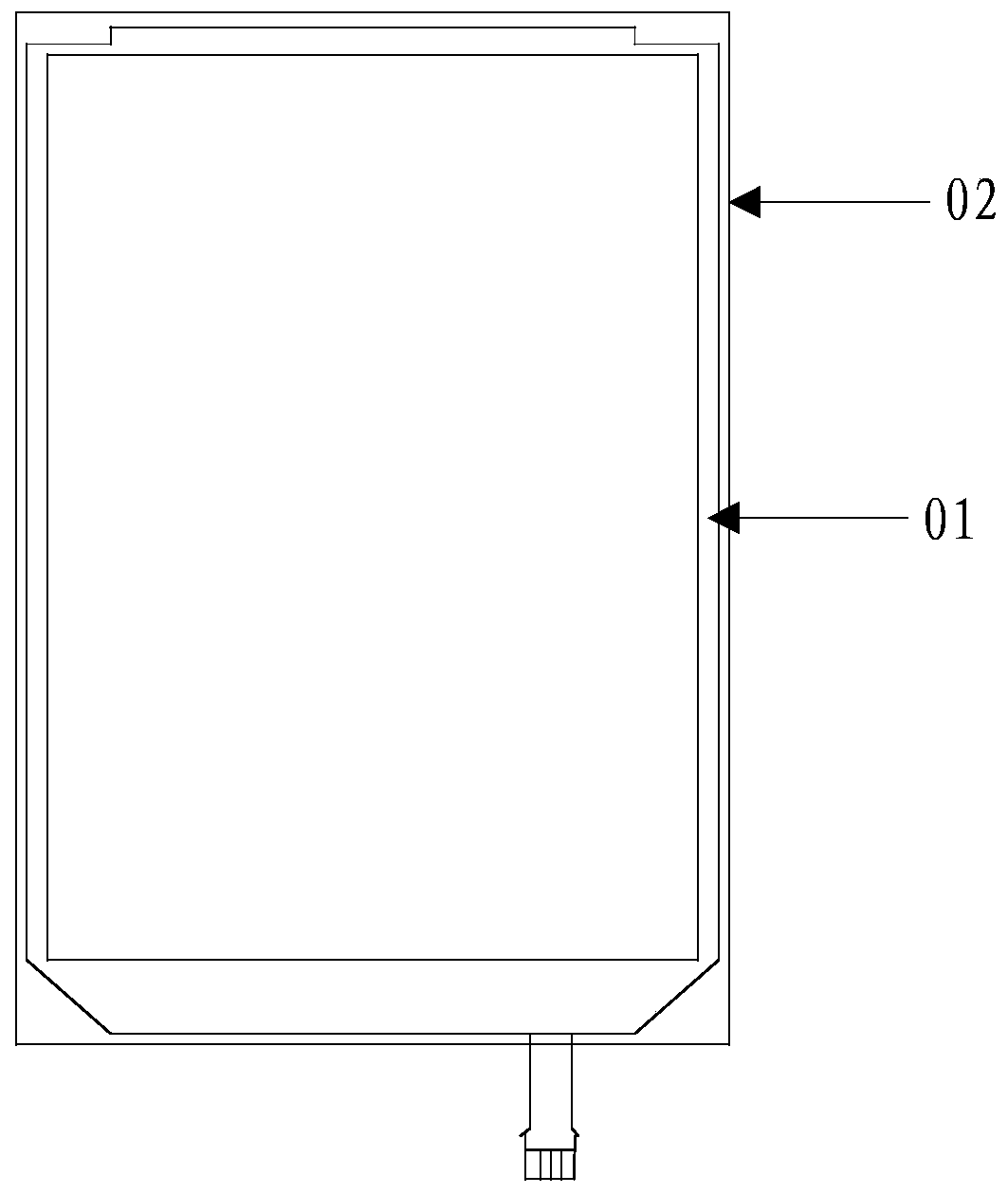

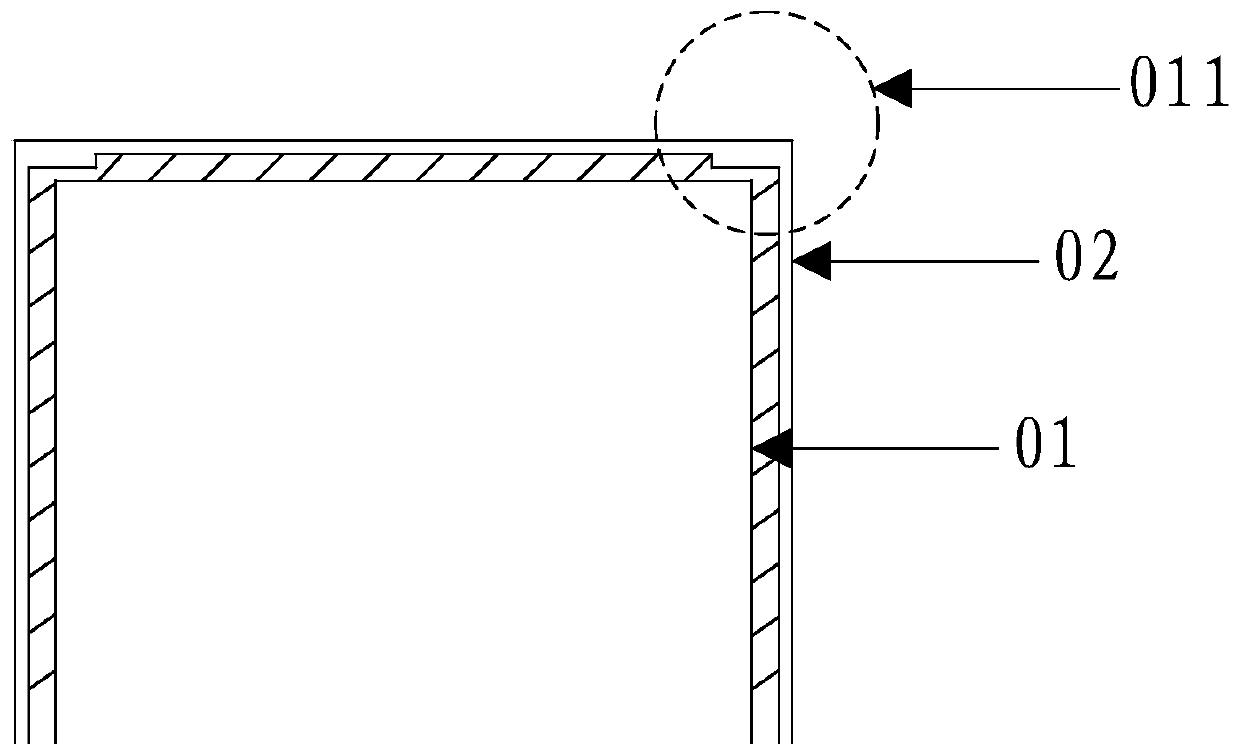

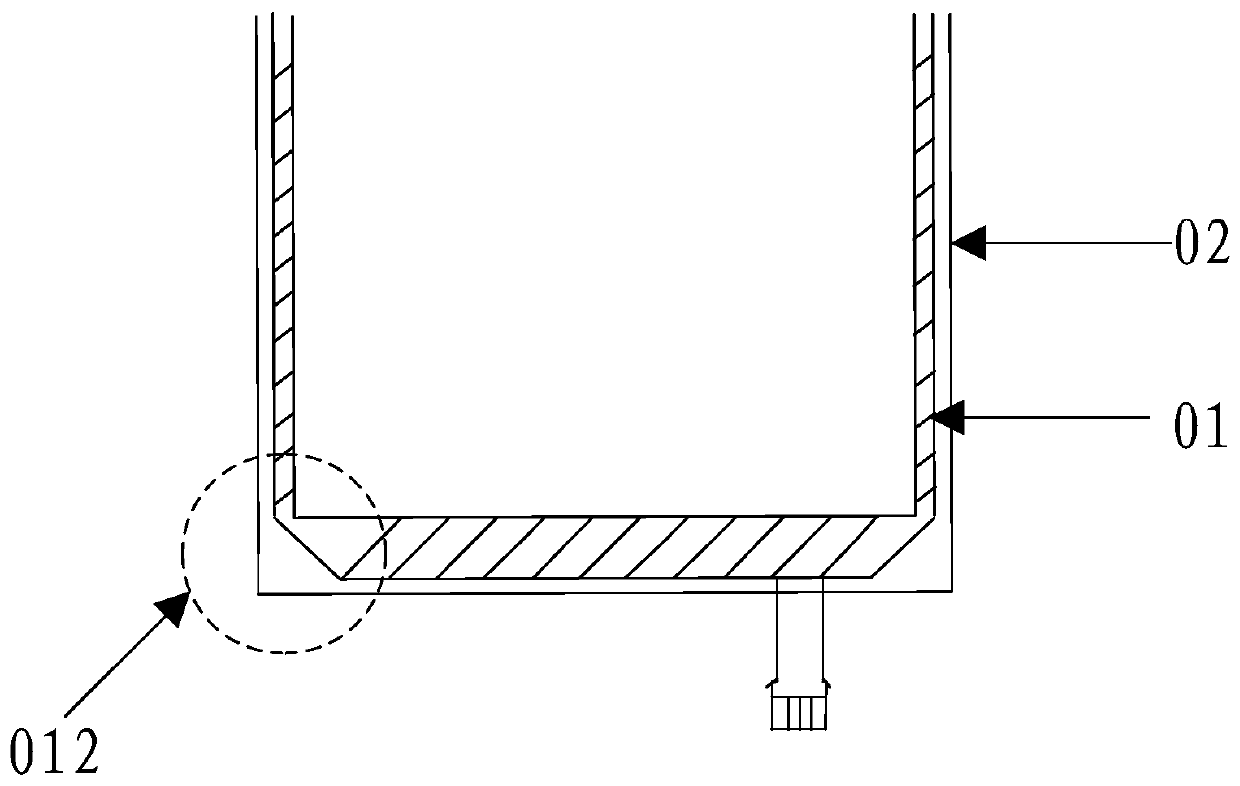

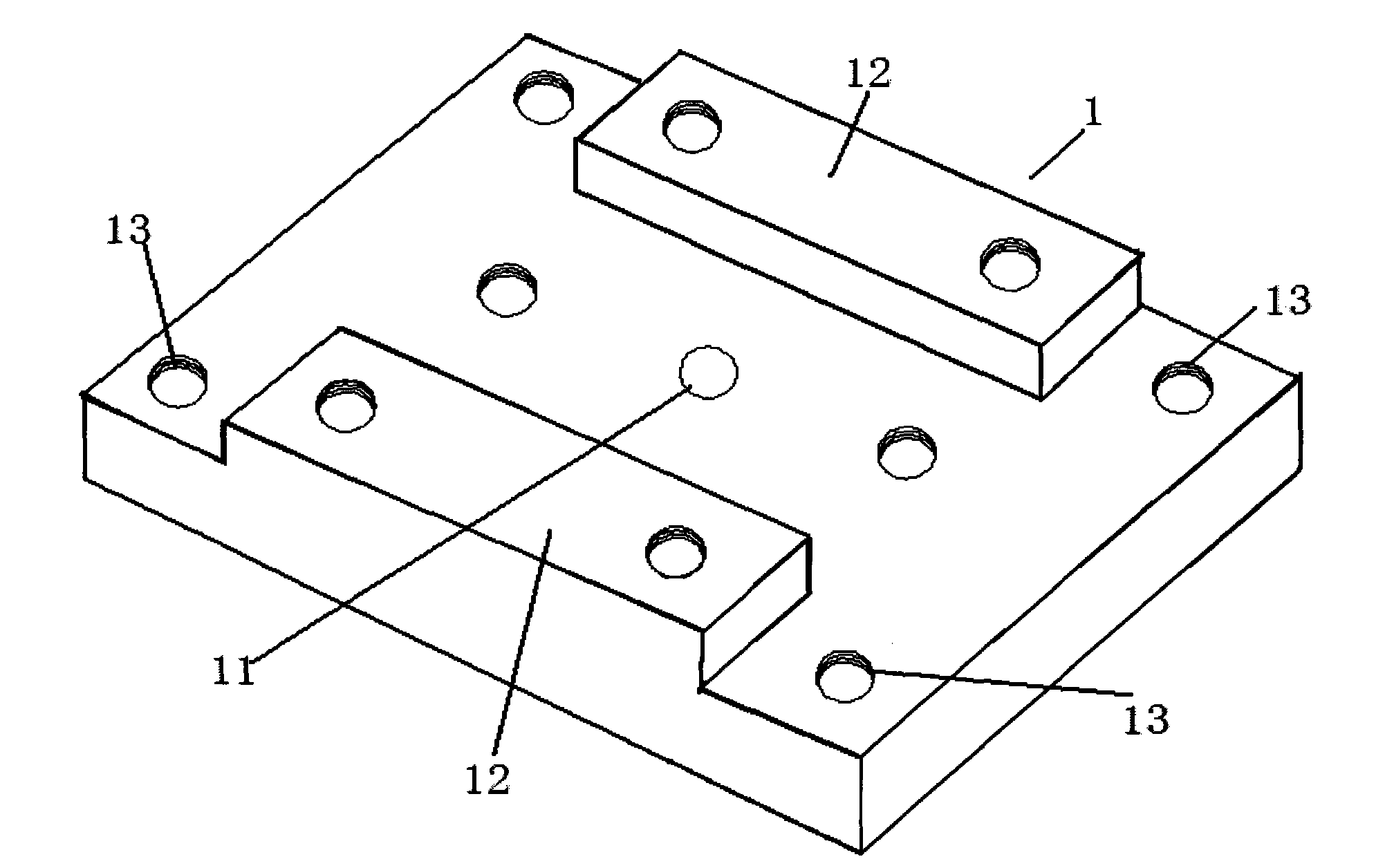

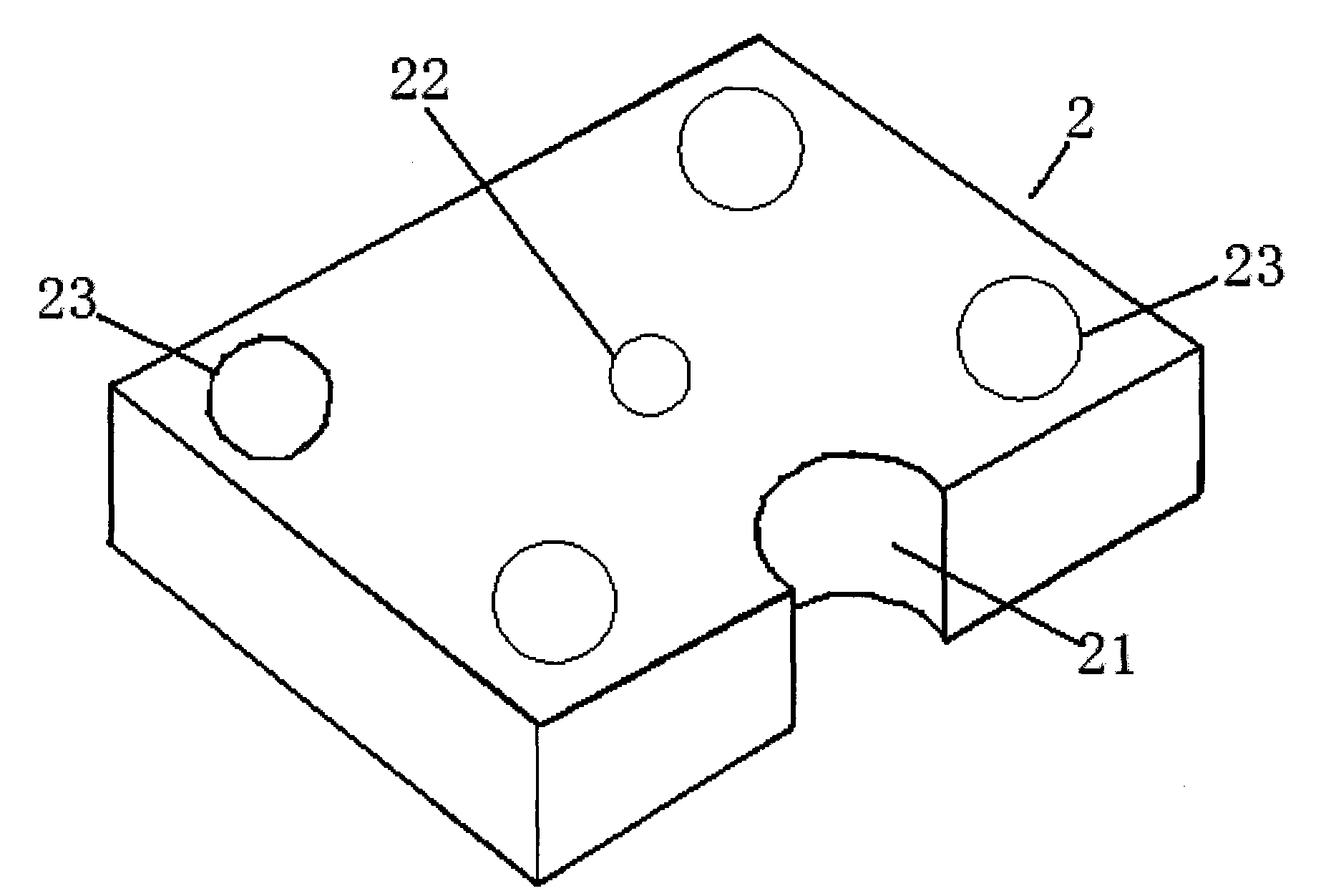

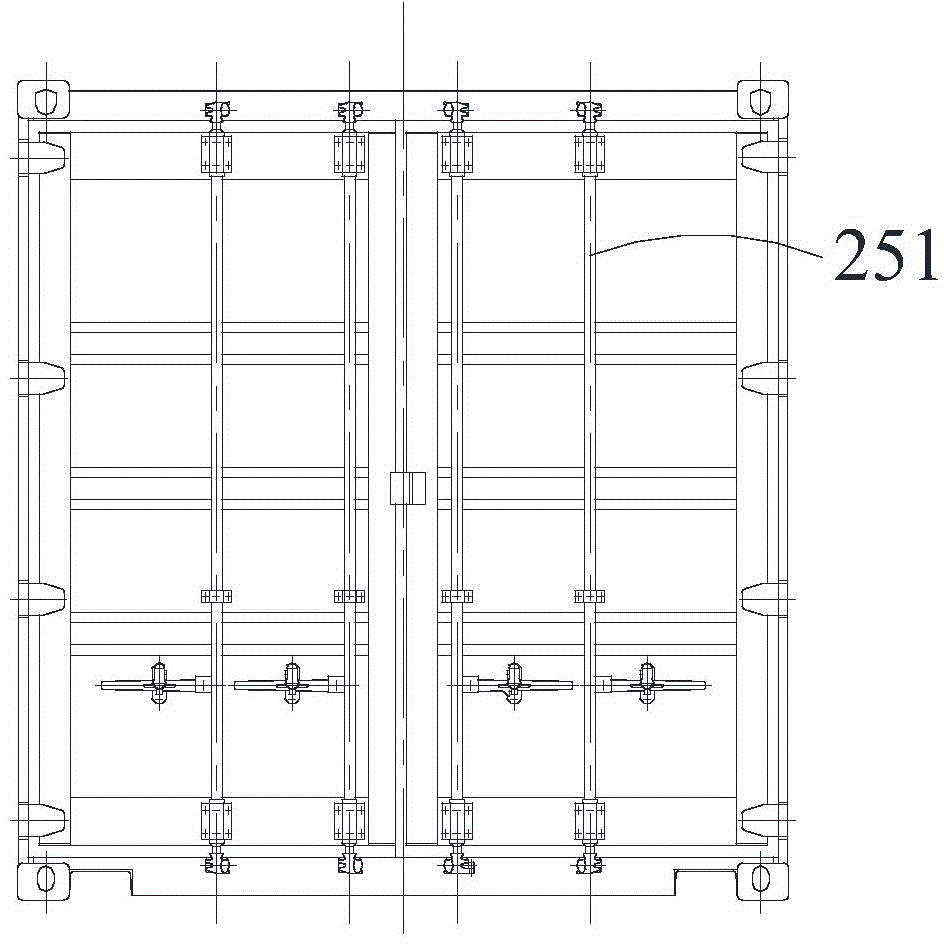

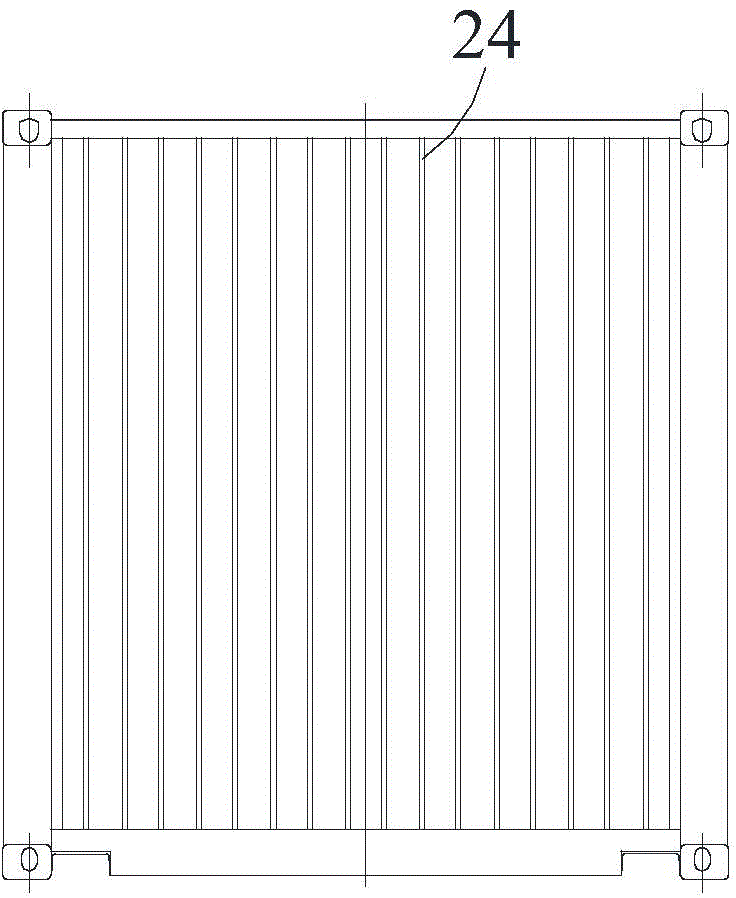

Freight container

ActiveCN104787503AIncrease the lengthTake advantage ofLarge containersEngineeringMechanical engineering

A freight container includes a container body (1) and corner fittings (2) provided at each corner of the container body. The container body (1) includes a bottom (10), a top (20), two side portions (30) and two end portions (40, 50), and at least one end portion is provided with locking devices (60) or corrugated plates (70). The locking devices (60) or corrugated plates (70) protrude beyond the outer edges of the corner fittings (2), and the position of each corner fitting and the distance therebetween accord with ISO standards. The inner length of the container is enlarged by extending outwards the rear end and / or the front end to the outer edges of the locking devices (60) or corrugated plates (70) beyond the corner fittings. The position of the corner fittings in the container and the relative distance therebetween are constant and accord with ISO standards, hence without influencing the alignment of the spreader and the corner fittings. Therefore, the inner space of the improved container is enlarged and the improved container still adapts to the existing standard products. Compared with the prior containers provided with locking bars having special structure, the present container is easy to implement and the manufacturing difficulty is small.

Owner:NANTONG CIMC SPECIAL TRANSPORTATION EQUIP MFR +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com