LED support processing method

A technology of LED bracket and processing method, which is applied to electrical components, electric solid devices, circuits, etc., can solve the problems of occupying bracket pads, not including voltage stabilization and anti-pulse functions, affecting the arrangement of light-emitting chips, etc., and achieves broad application prospects. Excellent voltage stabilization and anti-pulse ability, simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

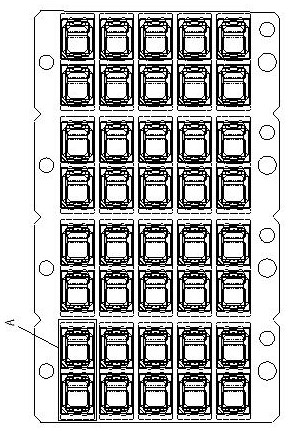

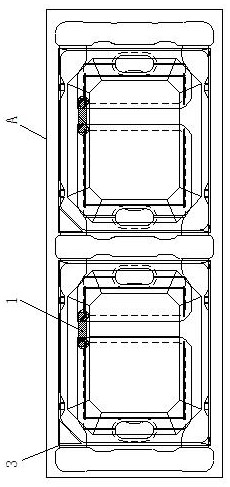

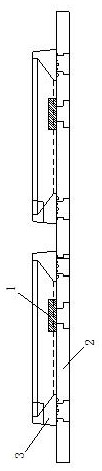

[0016] refer to Figure 1-4 , the specific implementation method adopts the following technical scheme: a LED bracket processing method, the steps are: stamping and forming the bracket crystal bonding pad in the form of a metal strip, after finishing the coating, entering the crystal bonding machine in the form of a strip, passing Solid crystal machine and flux fix the transient diode TVS on the pad of the bracket, perform eutectic welding by reflow soldering, and then perform injection molding process, inject molding on the metal strip, and include the transient diode TVS in the plastic frame , made into an LED bracket.

[0017] It is worth noting that the metal strip is formed by punching a copper material strip, and a position matching the dem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com