Self-hole-aligning coupler and using method thereof

A technology of couplings and inner holes, which is applied in the field of self-aligning couplings, can solve the problems of difficult assembly and low efficiency of couplings, reduce installation process costs, enhance reliability and compactness, and prolong service life The effect of longevity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

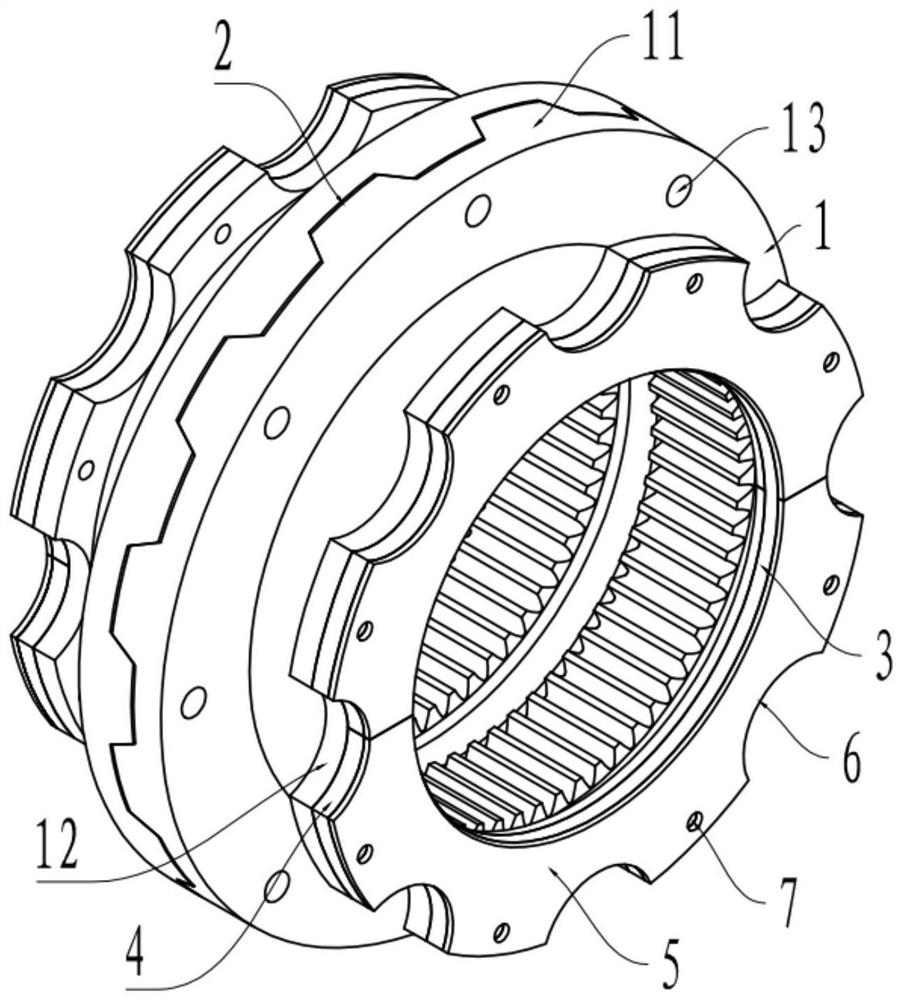

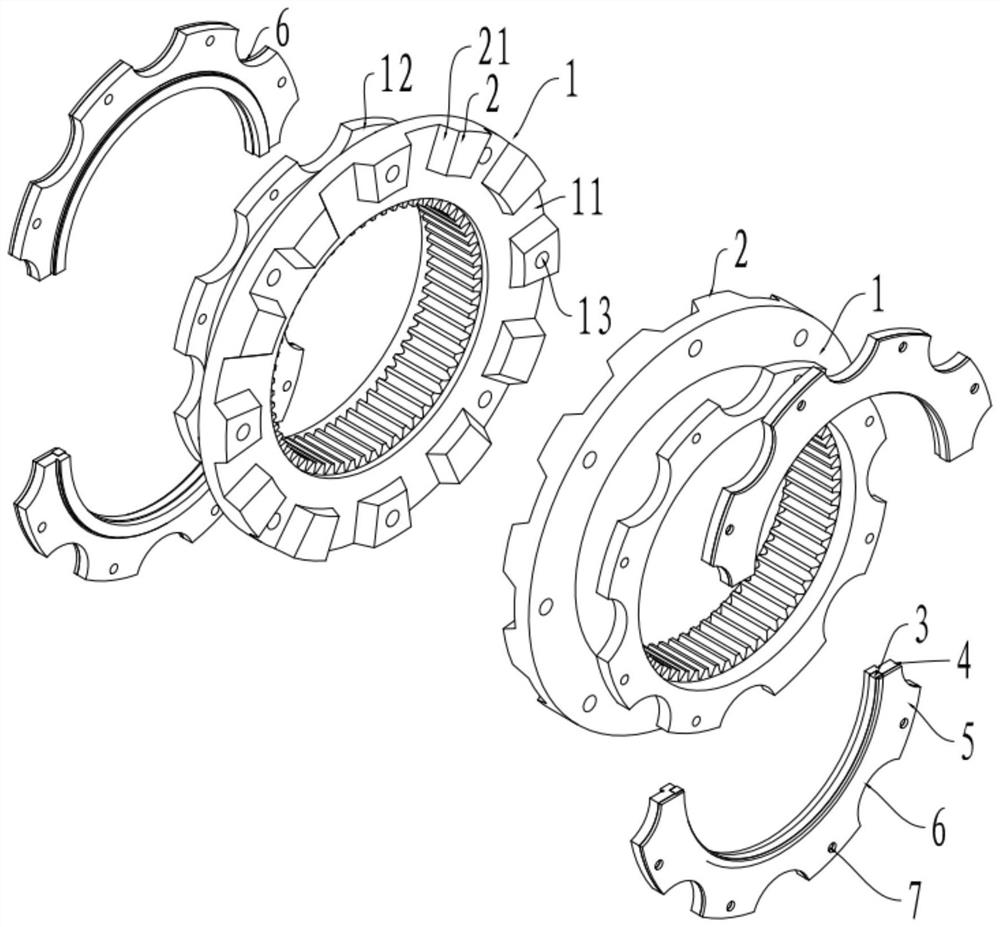

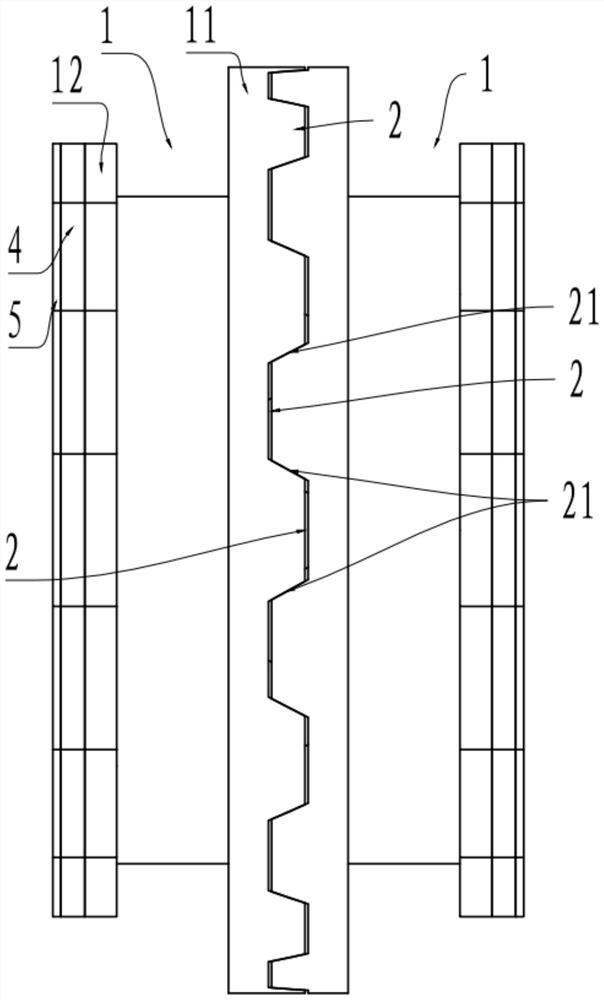

[0041] The embodiment is basically as attached Figure 1 to Figure 4 As shown, a self-aligning hole coupling includes two symmetrical connecting sleeves 1, and the inner hole of each connecting sleeve 1 is formed with mating teeth connected with the connecting shaft (the mating teeth can be in the form of splines or In the form of an inner ring gear, this embodiment adopts the form of an inner ring gear, wherein the connecting shaft has teeth meshing with the mating teeth), and the two ends of each connecting sleeve 1 are integrally formed with a flange one 11 and a flange two 12, Flange 11 is formed with a plurality of protrusions 2 uniformly distributed along the circumference of the connecting sleeve 1, and each protrusion 2 is formed with a symmetrical inclined guide surface 21, and the guide surfaces 21 on the two connecting sleeves 1 can offset each other. A depression for accommodating the protrusion 2 on the other connecting sleeve 1 is formed between adjacent protrusi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com