High Accuracy Beam Placement for Local Area Navigation

A particle beam, charged particle beam technology, applied in the field of high-precision local area navigation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

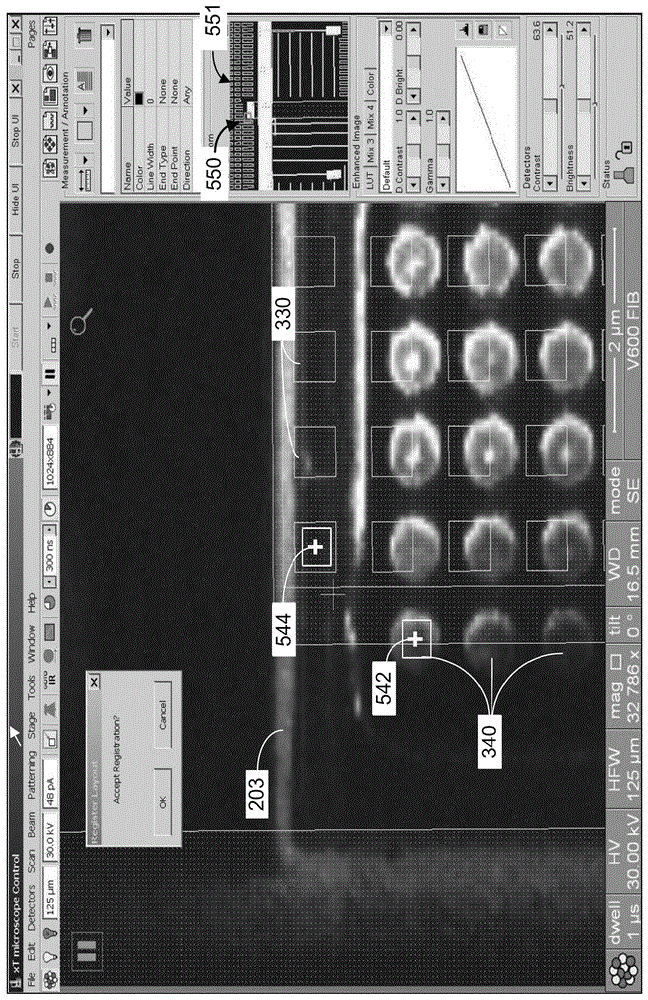

Image

Examples

Embodiment Construction

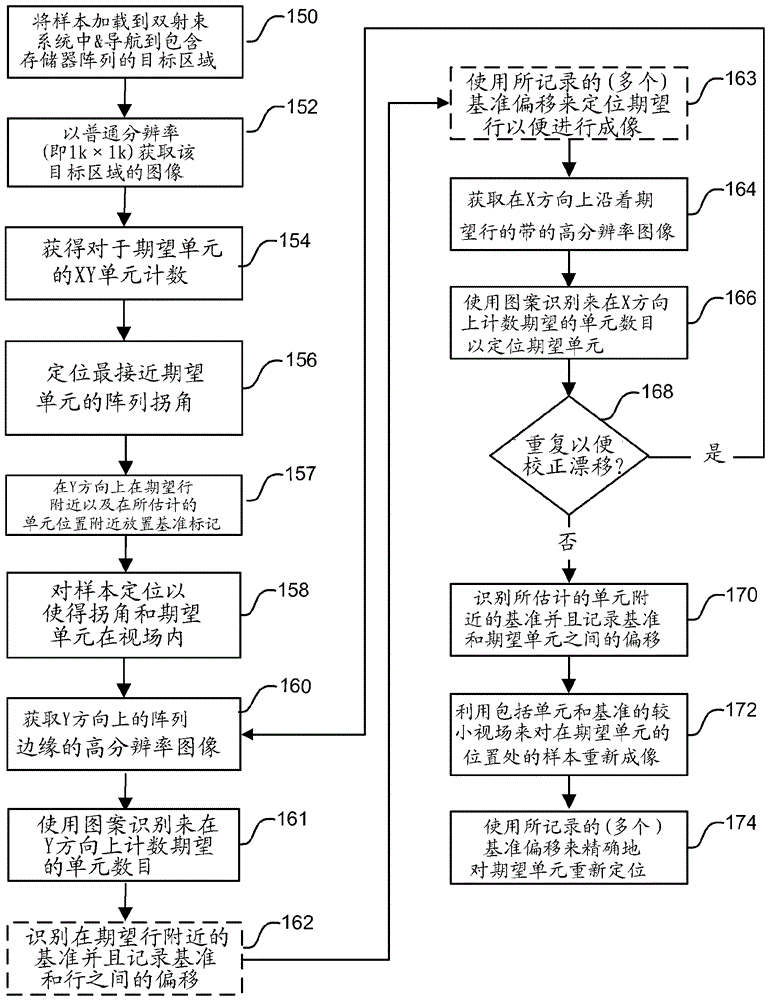

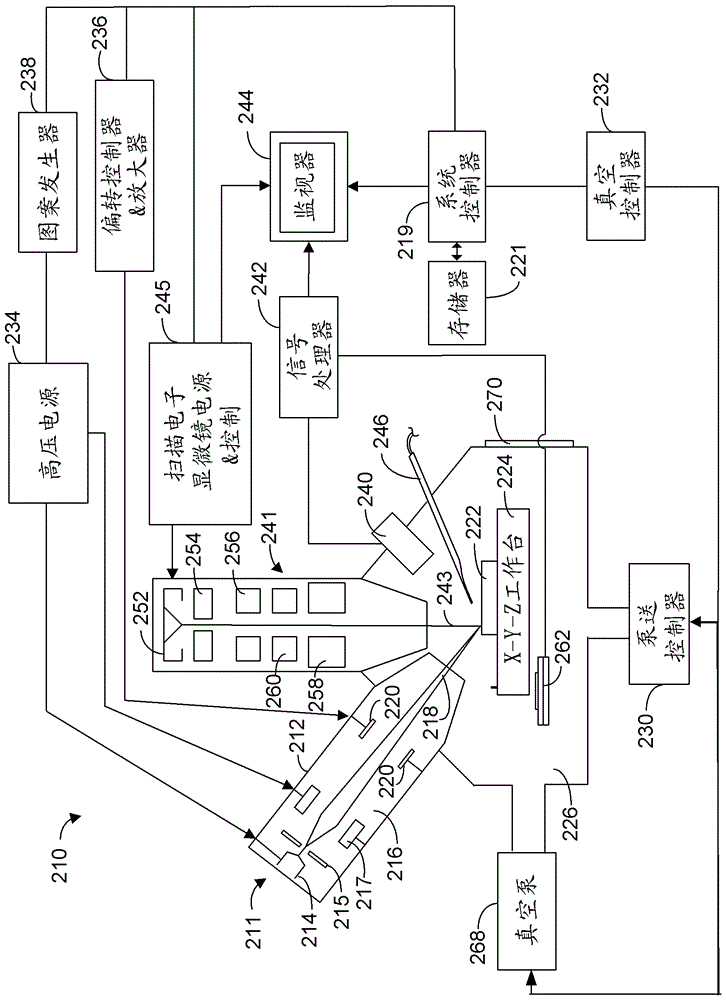

[0032] A preferred embodiment of the invention is directed to a method for high precision beam placement for local area navigation in the field of semiconductor chip manufacturing. The present invention exemplifies such a situation where it is possible to achieve a site of interest within a relatively large localized area (e.g., an area of 200 μm x 200 μm) even when the stage / navigation system is not normally capable of high-accuracy navigation. A method for high-precision navigation.

[0033]According to a preferred embodiment of the present invention, a high resolution image of a relatively large target area (a large area including the location of one or more appropriate alignment marks and features of interest) is first acquired. For example, a suitably high resolution region might be 250 μm wide, with a resolution of about 4096 pixels wide. According to a preferred embodiment, CAD polygons are used to cover the region of interest and two or three point CAD polygon re-re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com