A convenient replacement friction pair thrust bearing experimental device

A thrust bearing and experimental device technology, applied in the direction of mechanical bearing testing, etc., can solve the problems of the complex assembly process of the experimental bearing, achieve the effect of a wide range of materials, simplify the assembly process, and reduce the replacement cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

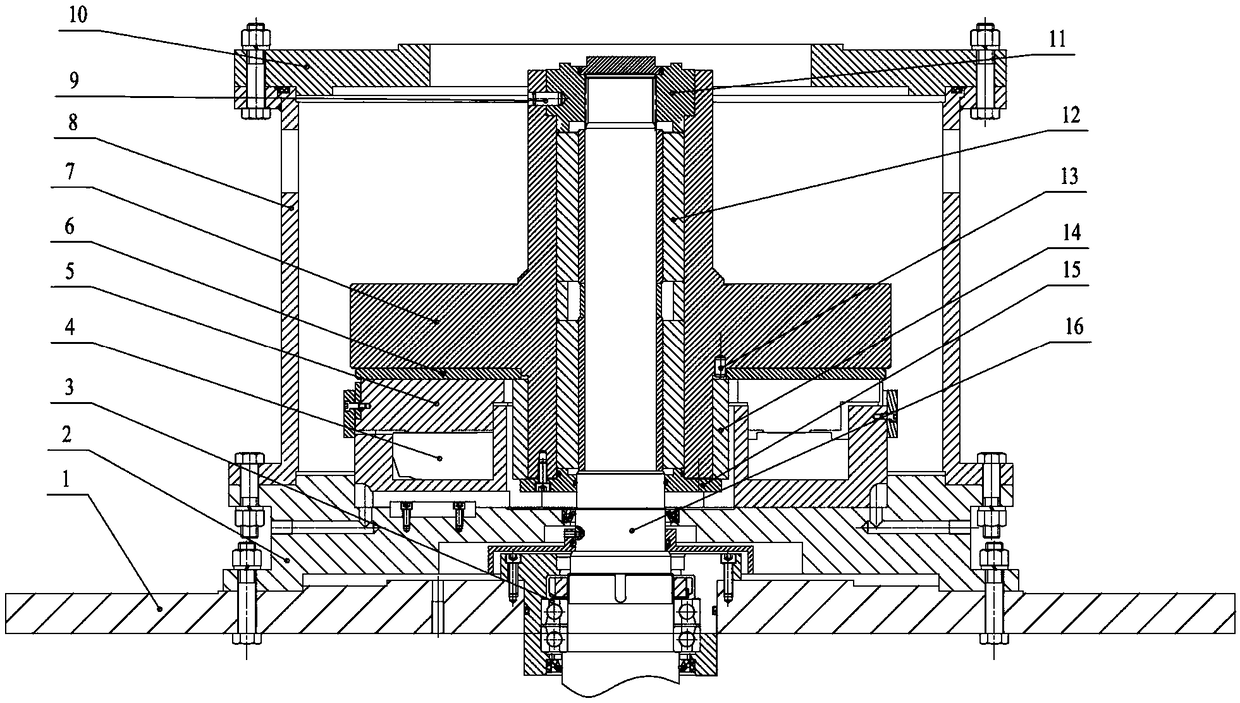

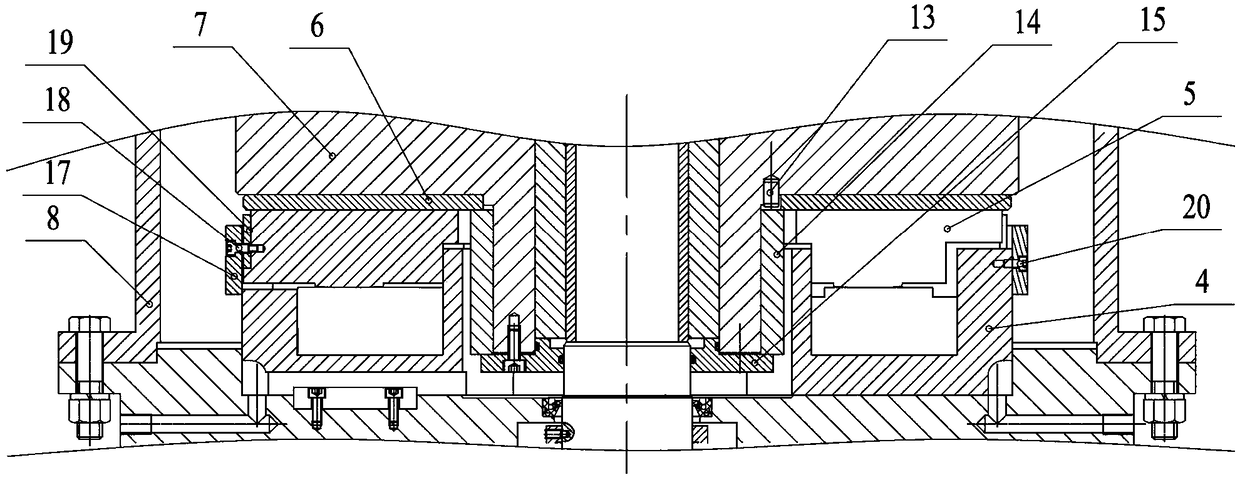

[0030] A friction pair thrust bearing experimental device that can be easily replaced, including an experimental platform base 1, an experimental cavity base 2 connected to the experimental platform base 1, an experimental cavity 8 connected to the experimental cavity base 2, the upper part of the experimental cavity 8 connected to the experimental The cavity roof 10 connects,

[0031] The bearing to be tested is composed of a bearing seat 4, an experimental thrust pad 5 and a friction disc 6, and the bearing seat 4 is installed on the base 2 of the experimental chamber.

[0032] The rotating shaft 16 of the system relies on the sealing auxiliary part 3 and the guide part 12 to realize the sealing, centering and axial displacement of the rotating shaft. The rotating shaft 16 transmits the torque to the thrust plate 7 through the spline sleeve 11 and the transmission pin 9, and the thrust plate 7 transmits the torque through the Pin 13 drives the friction pair disc 6 to rotate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com