High-rotating-speed small-torque star-shaped vibration isolation coupler

A low-torque, coupling technology, used in couplings, elastic couplings, mechanical equipment, etc., can solve the problems of poor vibration isolation or vibration reduction, low operating noise, etc., to achieve long life of the main body and intuitive maintenance. , the effect of reducing operating noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

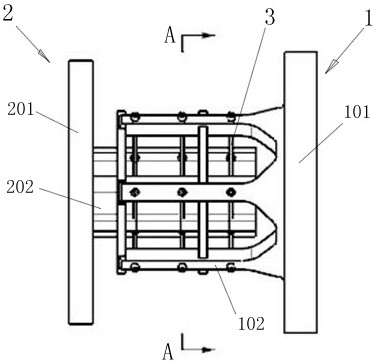

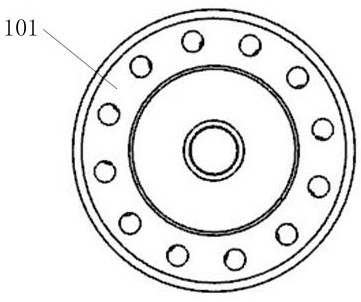

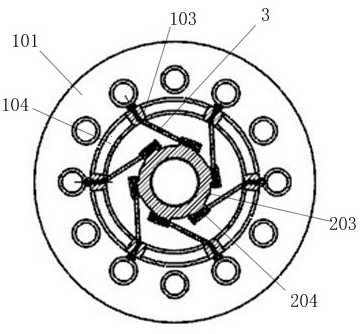

[0030] Such as Figure 1-Figure 3 As shown, the high-speed low-torque star-shaped vibration-isolation coupling includes a driving shaft end coupling body 1 and a driven shaft end coupling body 2 . Wherein, the driving shaft end coupling body 1 is composed of a flange I101 and a squirrel-cage shaft body 102 connected to the flange I101, and the driven shaft end coupling body 2 is composed of a flange II201 and a flange II 201 connected star-shaped shaft body 202, the star-shaped shaft body 202 is inserted into the squirrel-cage shaft body 102, and at least one group of tensile wires with ductility is connected between the star-shaped shaft body 202 and the squirrel-cage shaft body 102 3. Each group of tension wires 3 is composed of a plurality of tension wires distributed symmetrically along the circumference of the star-shaped shaft body 202 . In this embodiment, the tension wires 3 are divided into three groups, and each group of tension wires is distributed at intervals alo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com