Brush heads with wedge and spring handle interface for electric toothbrushes

An electric toothbrush and brush head technology, which can be used in household appliances, dentistry, brushes, etc., can solve problems such as the reduction in the range of movement of the brush, poor clinical efficacy, and reduced torque transmission efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

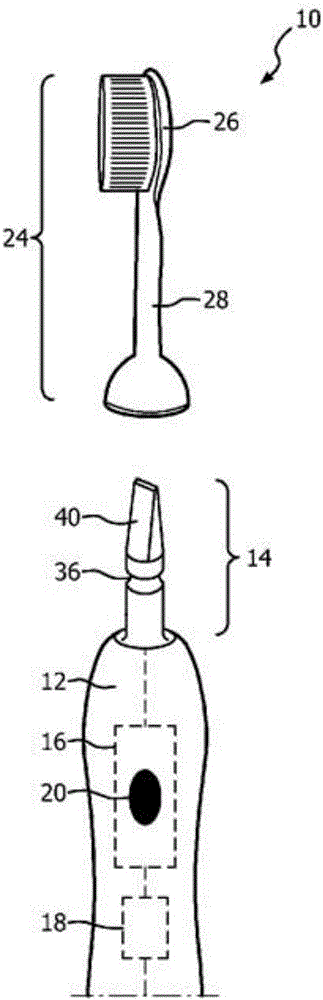

[0011] figure 1 An electric toothbrush is shown generally at 10 . It includes a handle portion 12 having a drive shaft 14 extending from the top of the handle. The drive shaft 14 is part of a drive assembly 16 in the handle that is powered by a battery 18, which is typically rechargeable. An on / off switch 20 controls the operation of the toothbrush. The drive assembly 16 can take various forms. In one embodiment, the drive assembly is an electromagnetic motor vibrating the drive shaft at a frequency in the range of 200-300 Hz, preferably about 260 Hz, through a selected angle, eg in the range of 5-20°, preferably about 11°. These specifications generally provide effective cleaning. However, it should be understood that other drive means may be used.

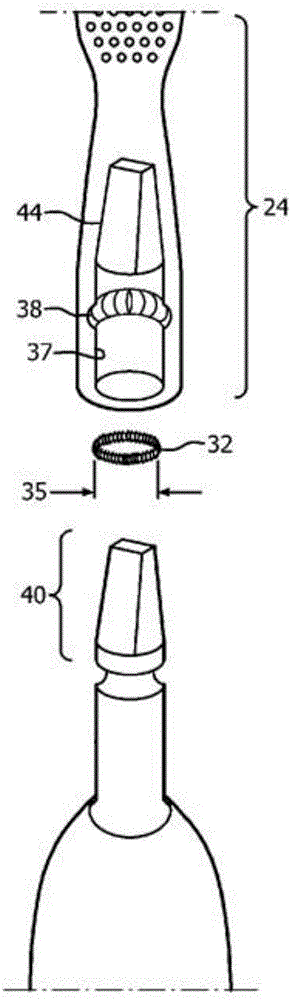

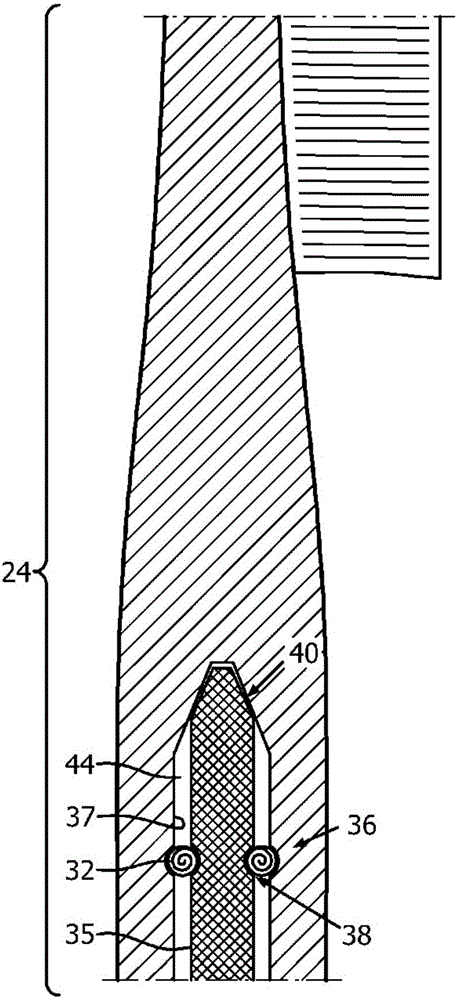

[0012] Toothbrush 10 also includes a head assembly 24 . The brush head assembly 24 includes a conventional brush member 26 for contacting and cleaning teeth, and an elongated neck 28 . The bristle member 26 is mounted at t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com