Nozzle fastening system for open-end rotor spinning device

A rotor spinning, free end technology, applied in the directions of free end spinning machine, spinning machine, continuous winding spinning machine, etc., can solve the problems of blocking fixed locking, blockage, influence, etc., and achieve the effect of a simple way

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

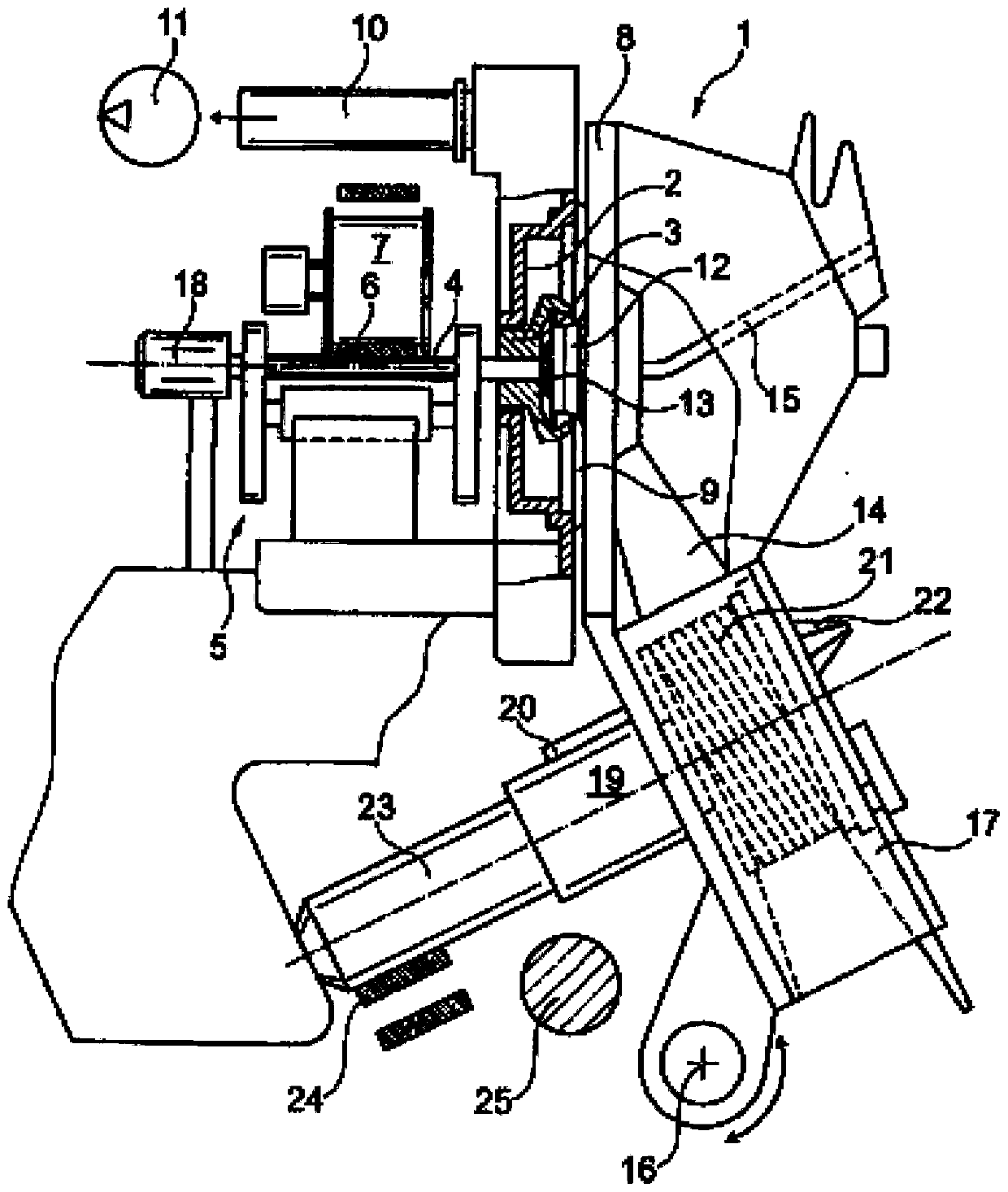

[0074] figure 1 An open-end rotor spinning device 1 is shown schematically. As is known, such open-end rotor spinning devices 1 each have a rotor housing 2 in which the spinning cup of the spinning rotor 3 rotates at a high rotational speed.

[0075] The spinning rotor 3 is supported, for example with its rotor shaft 4 , in a wedge-shaped support gap of a so-called support disc bearing system 5 , the spinning rotor 3 is frictionally driven by a tangential belt 6 which extends the length of the machine and is driven by Press roller 7 is actuated.

[0076] For example, the rotor shaft 4 is fixed axially by means of a permanent magnetic thrust bearing 18 .

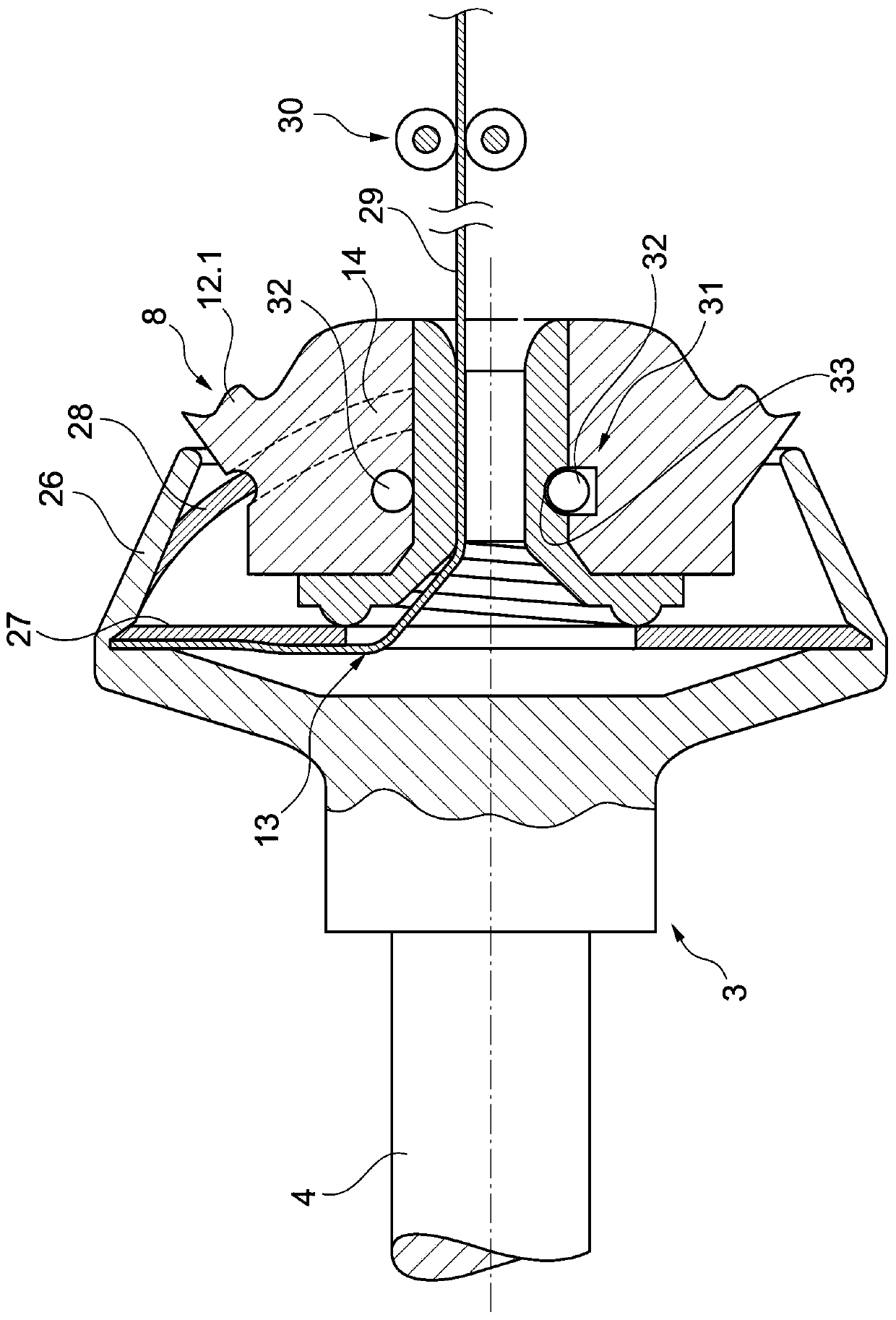

[0077] The rotor housing 2 which itself opens forward is closed during the spinning operation by a pivotally mounted cover element 8 into which a channel plate is provided which rests against the rotor by means of a circumferentially extending intermediate seal 9 Housing 2 is placed.

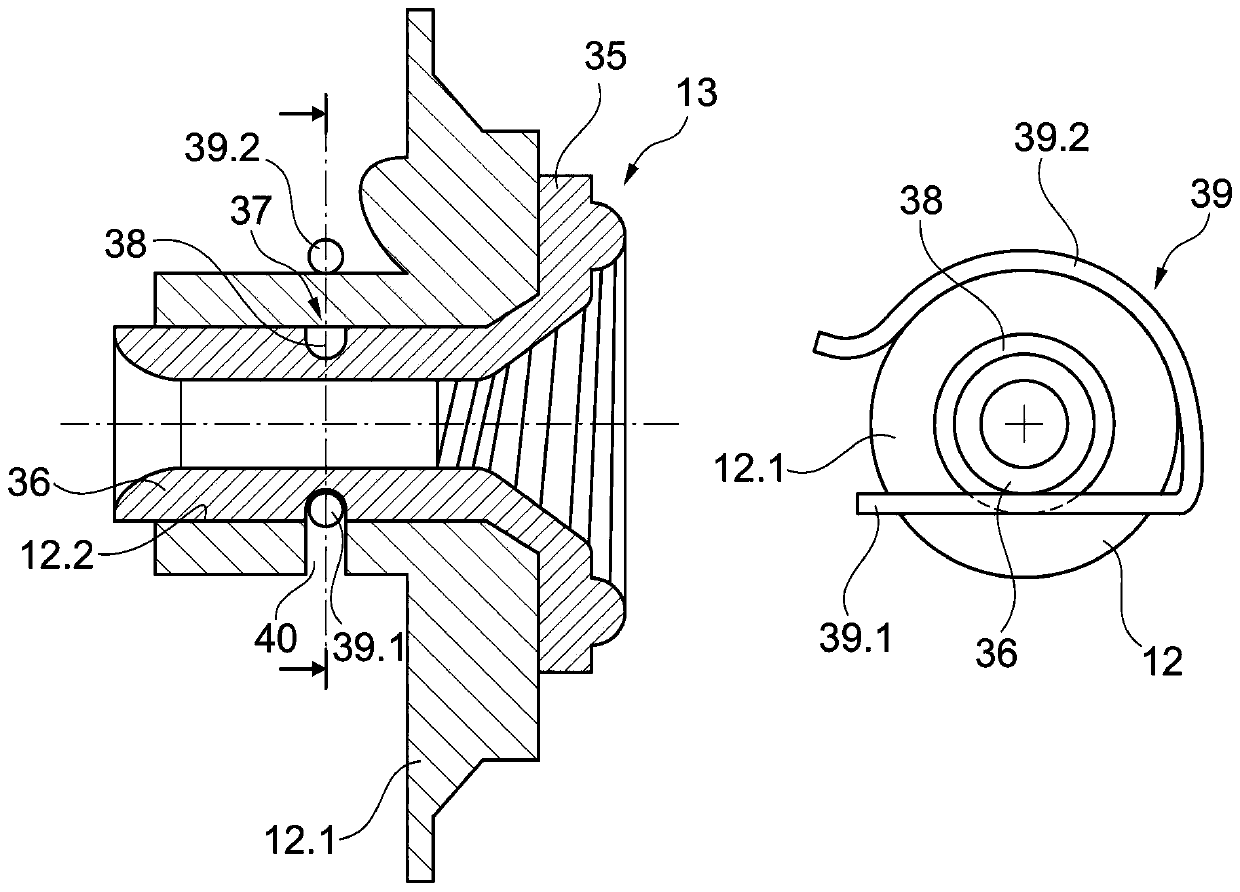

[0078] The rotor housing 2 is also c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com