Axial fixing method for disc-like components mounting on axle

A technology of disc parts and journals, which is applied in the field of axial fixing of disc parts, can solve the problems of difficulty in realization and short axial dimension.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

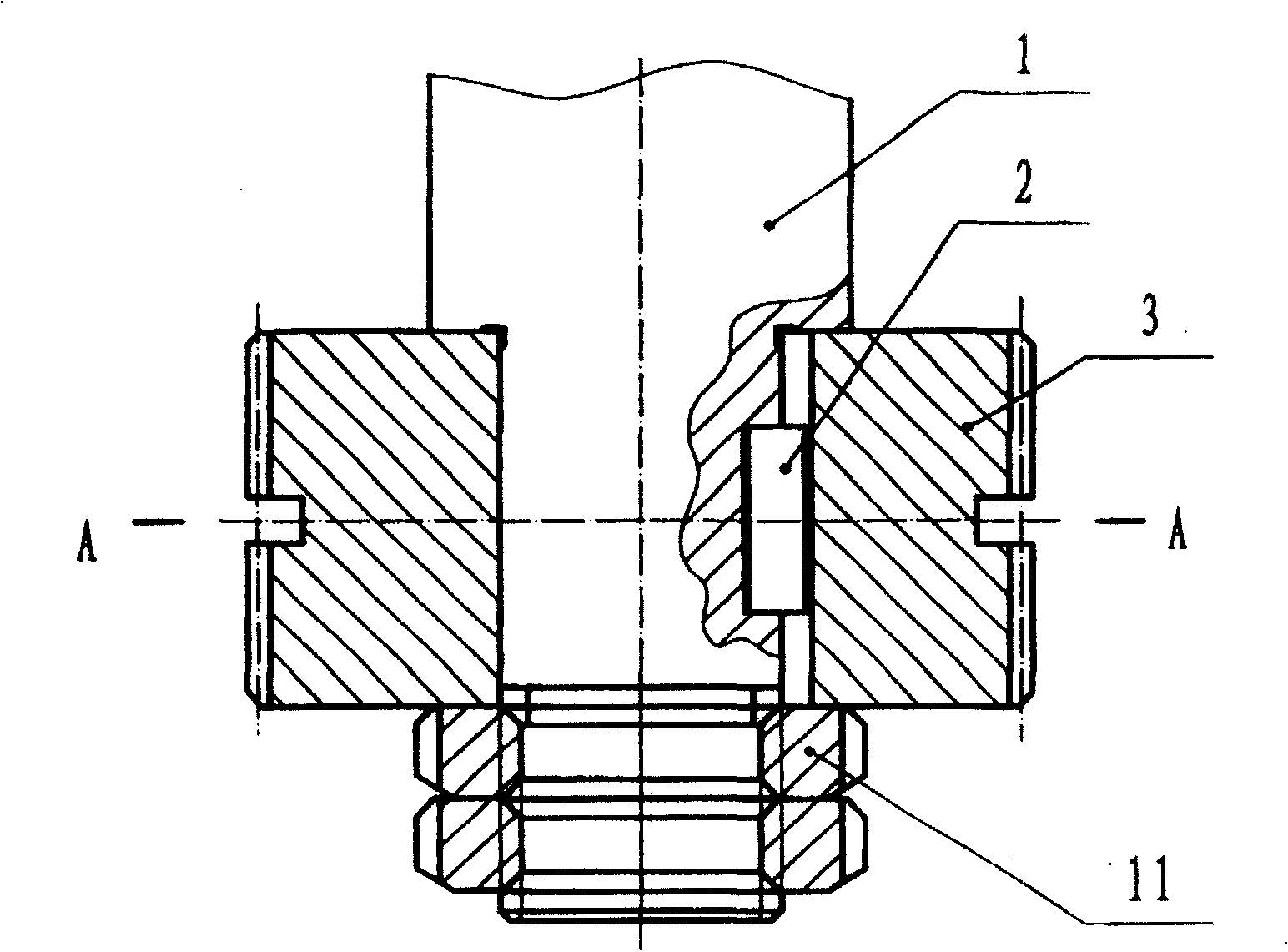

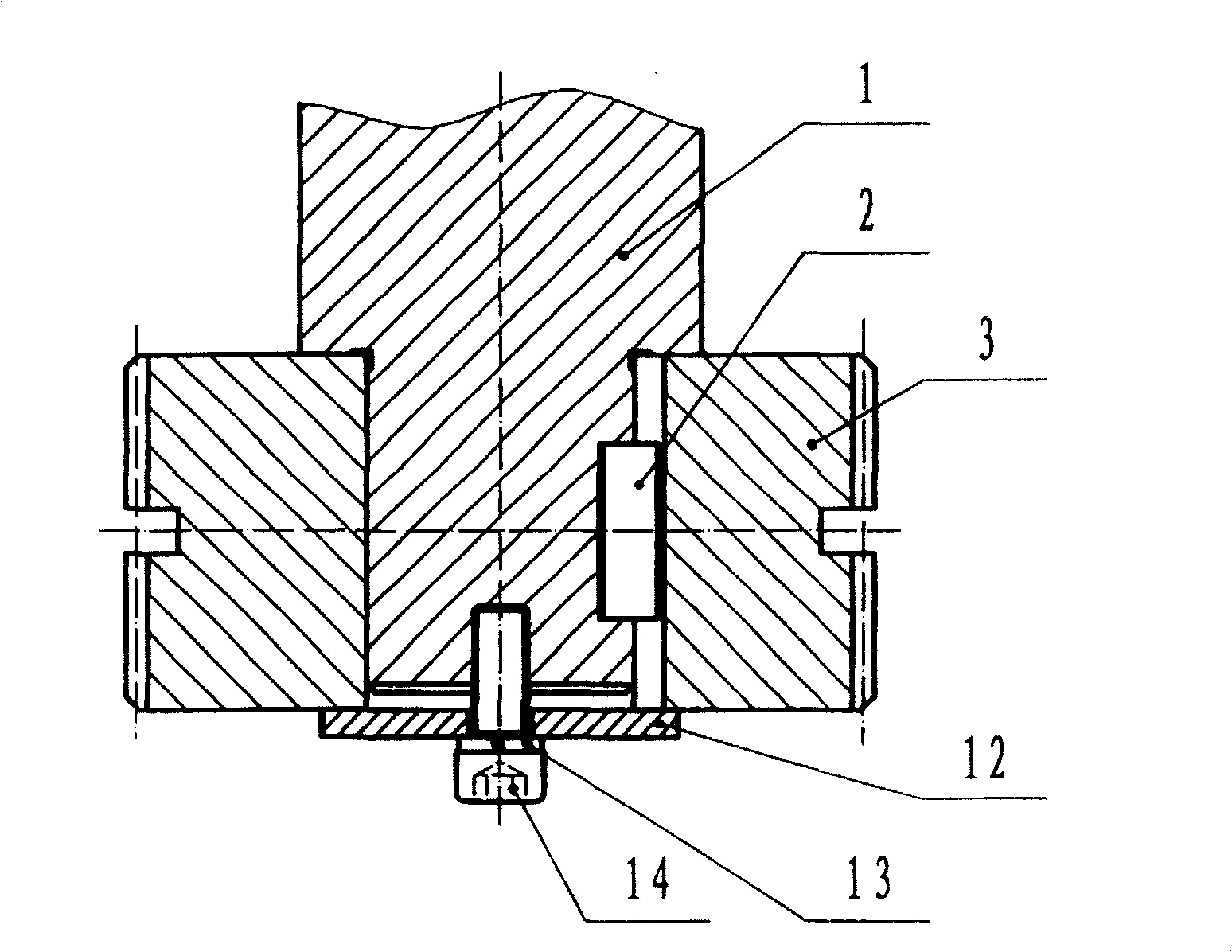

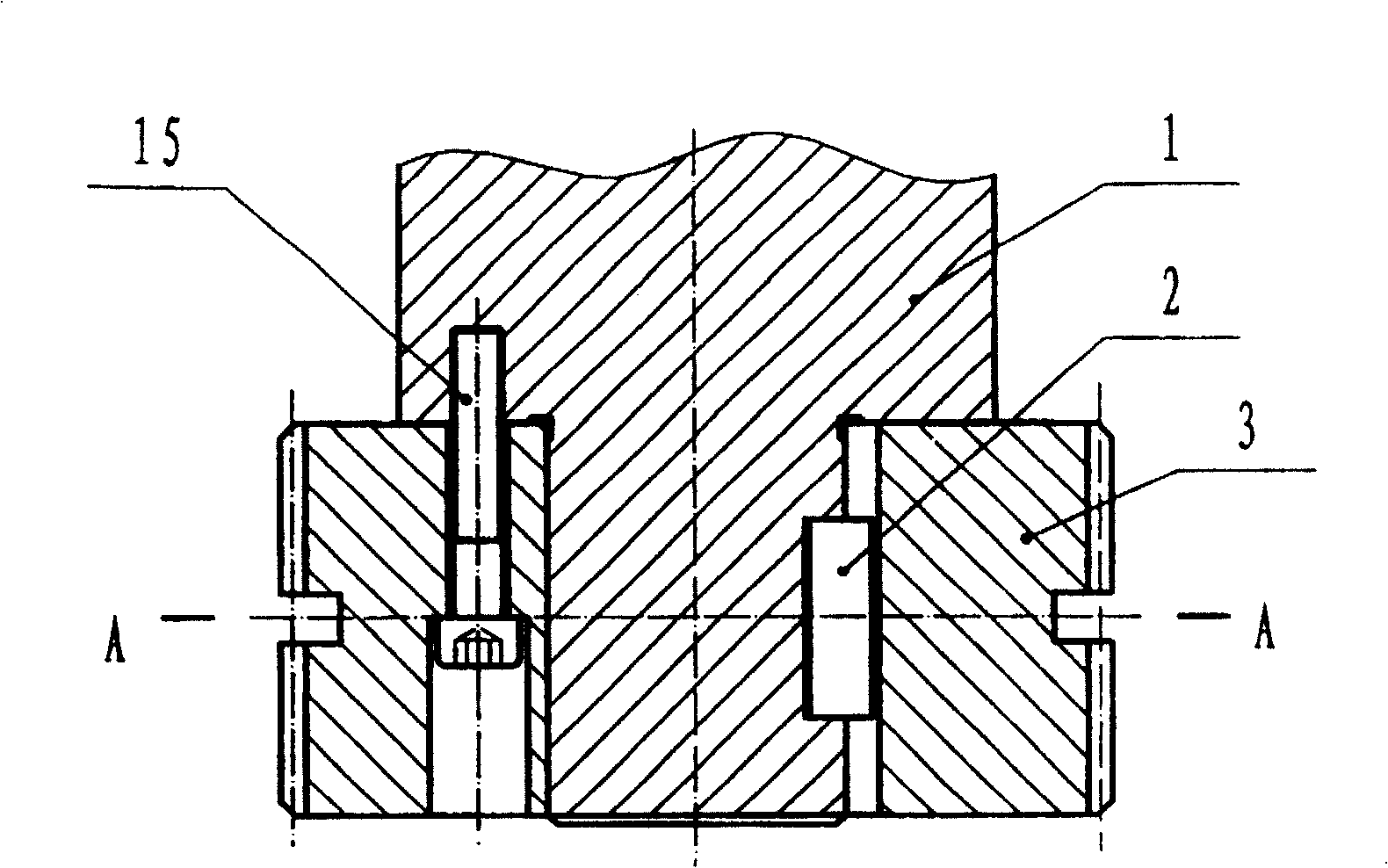

[0024] The disc part 3 is mounted on the shaft 1 through the key 2, and the end face 7 of the disc part 3 is tightly abutted on the step 8 of the shaft 1 with 3 set screws 4, and the 3 sets of screws 4 are used to lock it. . The inner hole of the disc part 3 and the journal of the shaft 1` have a clearance fit of 0 or 0.1 or 0.125mm. The distance between the circle 5 where the 3 screw holes of the disc part 3 is located and the end face 7 must be greater than that of the shaft 1. The distance from the center of the trapezoidal groove on the journal of the shaft to the step 8; the distance between the plane where the circumference 5 is located and the plane 6 where the center line of the ring groove 9 is located is 0.3mm or 0.7mm or 1mm. The size of the trapezoidal ring groove on the journal of the shaft 1 must be adapted to the set screw 4 used.

[0025] Adopt attached Figure 5 Under the premise of ensuring sufficient rigidity, the size of the disc parts 3 and the shaft 1 can be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com