Drive motor and bead grinding machine disc lifting mechanism

A technology for driving motors and lifting mechanisms, applied in the direction of grinding drive devices, electromechanical devices, electrical components, etc., can solve problems such as poor working stability, waste of space resources, and increased costs, and achieve easy installation and disassembly, and firm axial fixation , the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

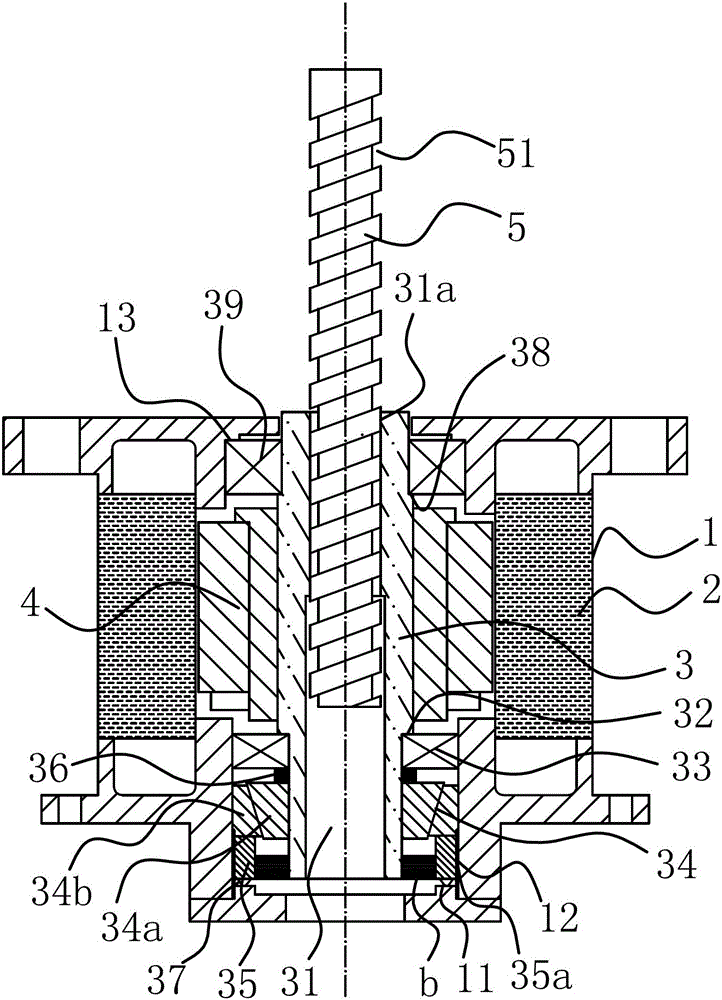

[0028] like figure 1 As shown, the driving motor includes a housing 1, a stator 2 and a rotor shaft 3 pierced in the stator 2 are arranged in the housing 1, and a rotor 4 is fixed on the rotor shaft 3, and the rotor shaft 3 and the housing The body 1 is axially positioned and connected in a circumferential direction. An axially positioned rolling structure is provided between the rotor shaft 3 and the housing 1. A channel 31 for the drive rod 5 to enter is provided at the axial center of the rotor shaft 3. The channel 31 is provided with a connection structure that can be connected with the driving rod 5 and can drive the driving rod 5 to move axially in the channel 31 when the rotor shaft 3 rotates. Obviously, the design of the drive motor in this embodiment is more reasonable, can greatly save space, makes the overall structure compact, and the relative connection method is very simple, easy to install and disassemble, virtually improves work efficiency, and conforms to the ...

Embodiment 2

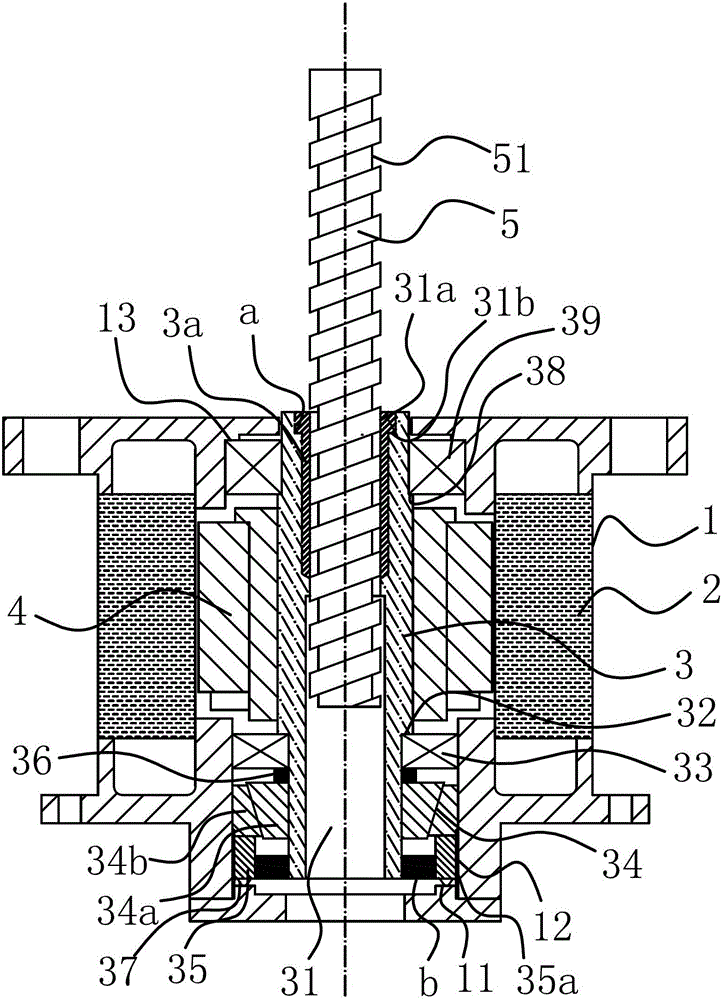

[0035] like figure 2 , 4 As shown, the structure and principle of this embodiment are basically the same as that of Embodiment 1, the difference is that the connection structure includes a screw sleeve 3a fixed in the passage 31 and having an internal thread 31a and a screw sleeve 3a arranged on the drive rod 5 The external thread 51, the internal thread 31a is threadedly connected with the external thread 51, the optimization scheme, the outer side of the screw sleeve 3a here is provided with an annular shoulder a, and an annular step 31b is provided at the end of the passage 31, and the screw sleeve The inner end of 3a is inserted into the channel 31 and the annular shoulder a is fixed on the annular step 31b.

Embodiment 3

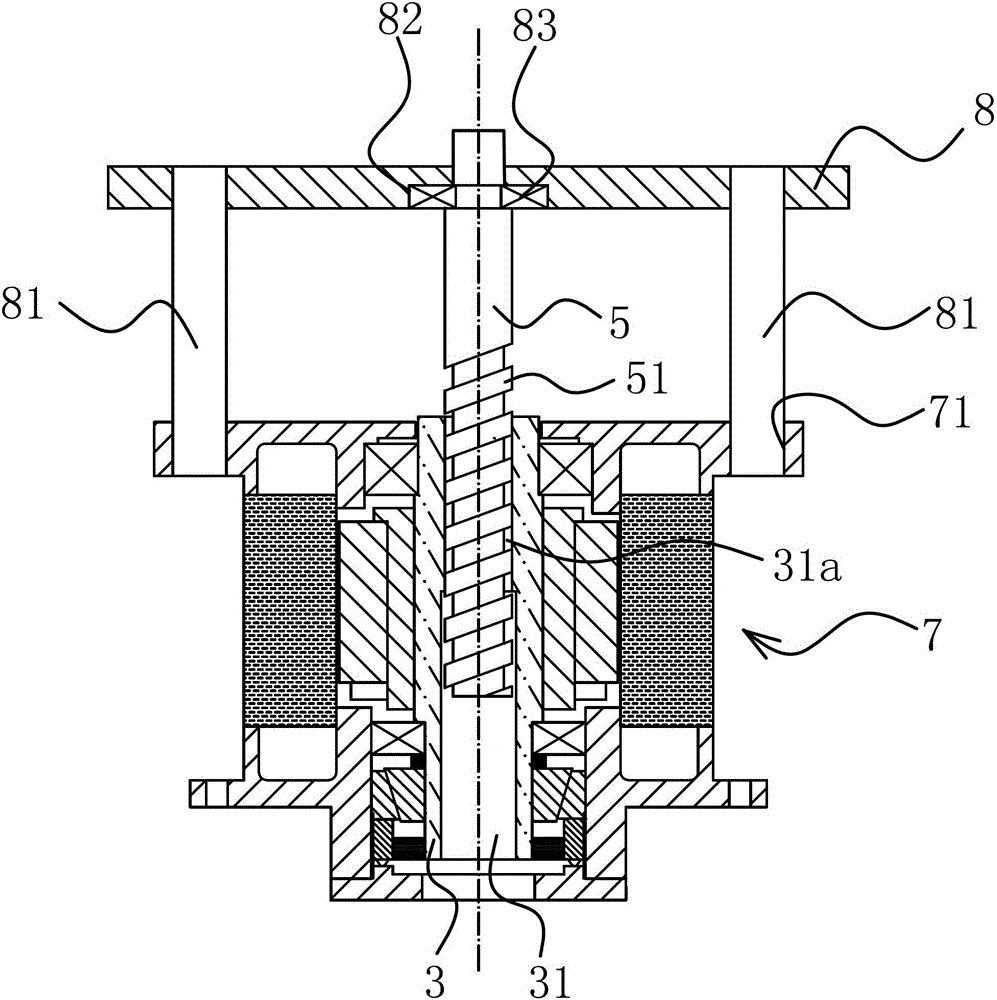

[0037] like Figure 5 As shown, the structure and principle of the present embodiment are basically the same as those of the first embodiment, except that one end of the channel 31 is closed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com