Slave cylinder with individual pistons, actuating device, and clutch system

A control device and a single-piston technology, applied in clutches, fluid-driven clutches, mechanical-driven clutches, etc., can solve the problems of complex composition and manufacturing cost, and achieve the effect of simple manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

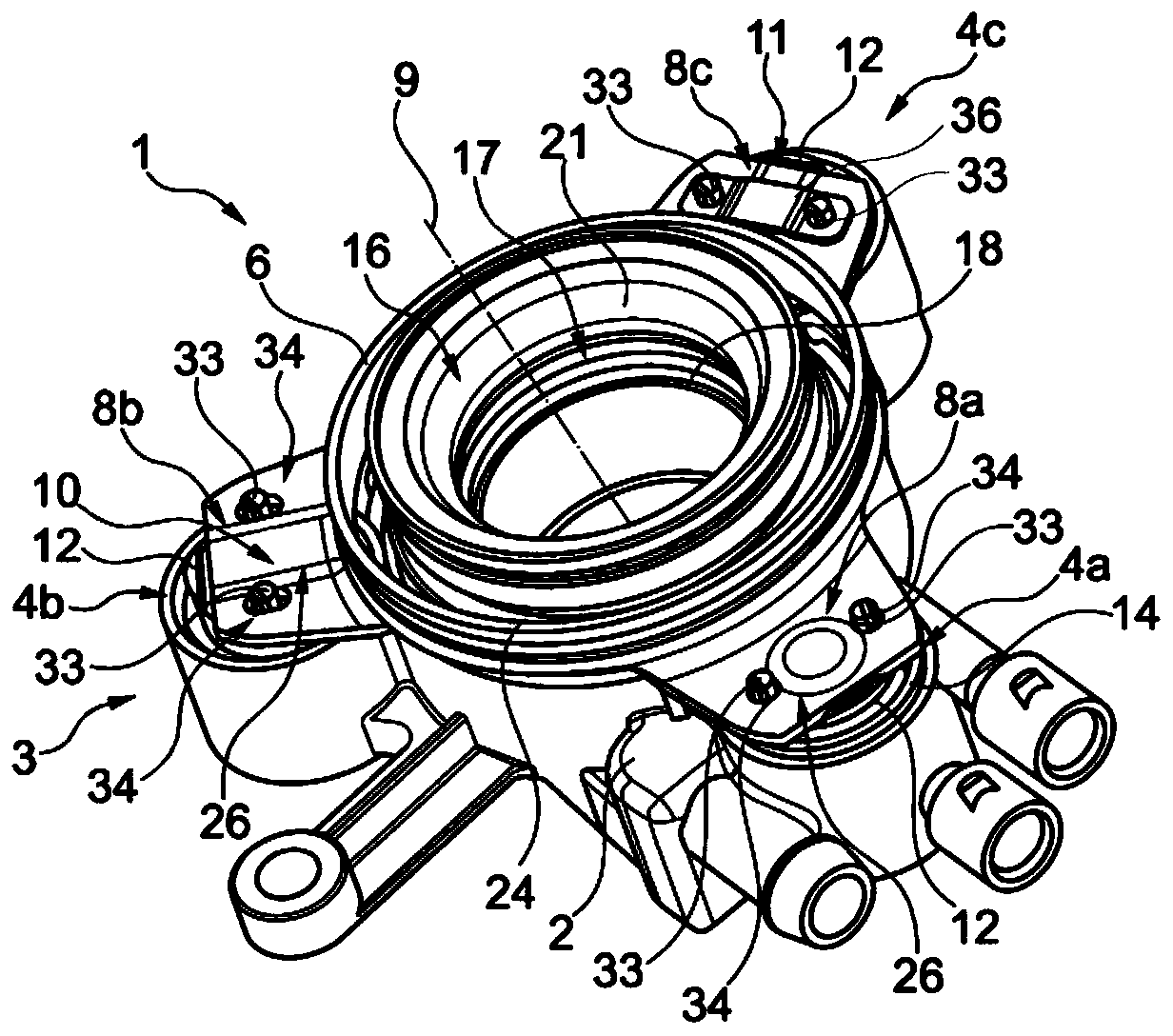

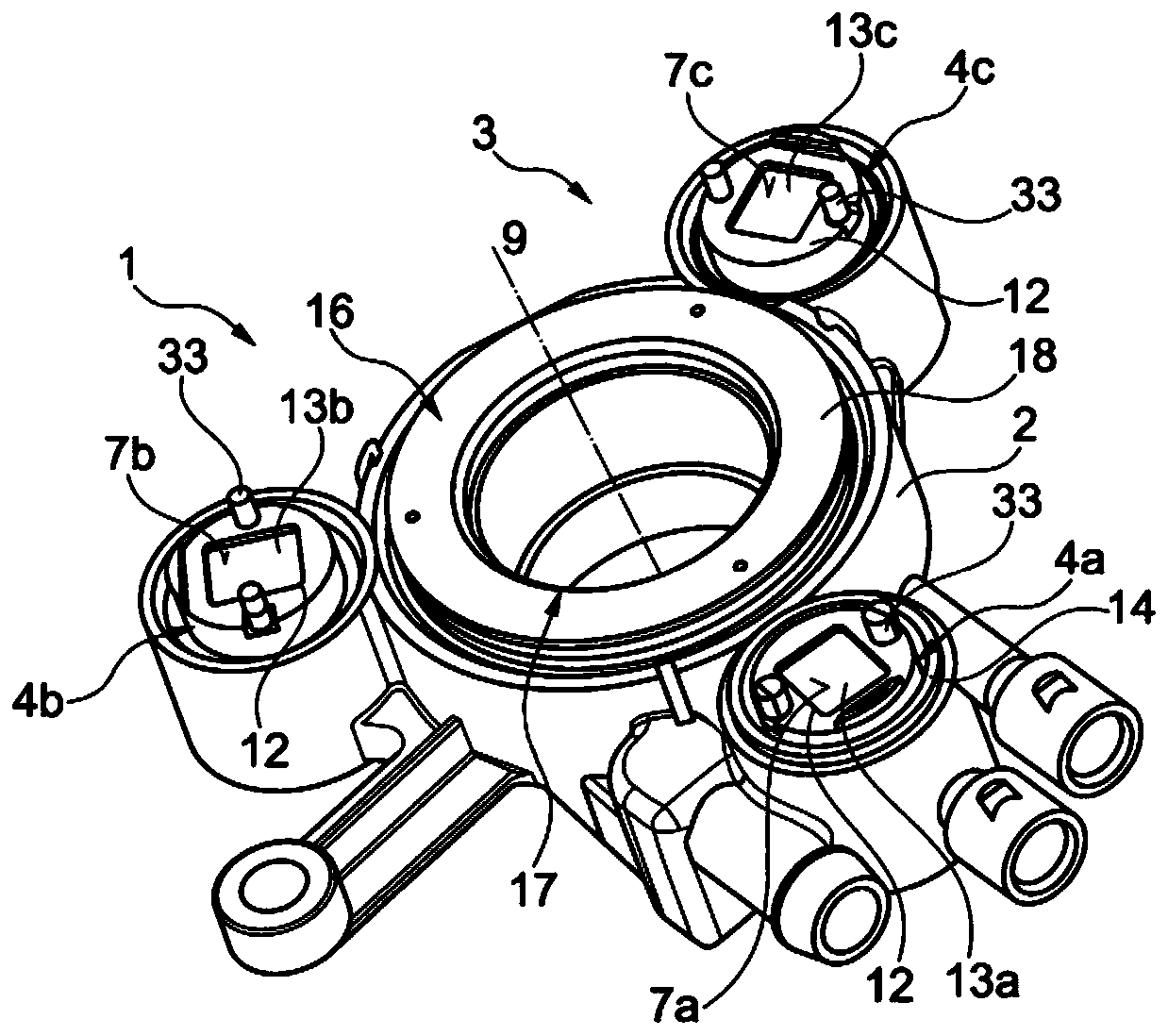

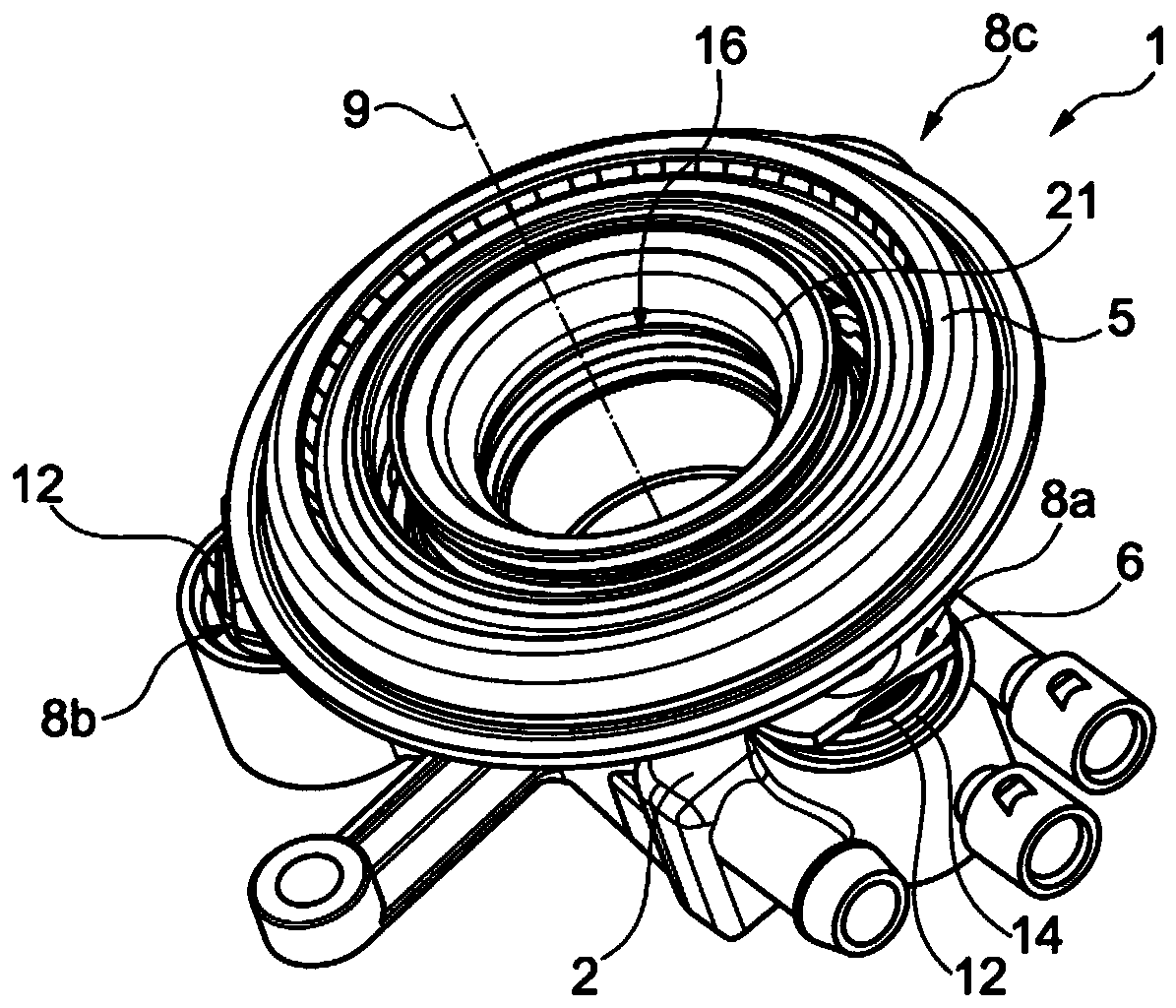

[0055] exist figure 1 shows a secondary cylinder 1 according to the invention according to a preferred embodiment. In particular, the connection between the (first) piston unit 3 of the auxiliary cylinder 1 and the carrier element 6 can be seen in the figure, which is described in detail below. The auxiliary cylinder 1 is designed as a hydraulic auxiliary cylinder 1 . The secondary cylinder 1 is realized in particular as a multi-separator. The secondary cylinder 1 therefore has, in addition to the (first) piston unit 3 , a further (second) piston unit 16 , wherein each piston unit 3 , 16 serves to actuate a separate clutch. The auxiliary cylinder 1 is thus realized in a typical manner for actuating several clutches or for actuating several partial clutches of a double or triple clutch. During operation, auxiliary cylinder 1 is typically a component of a clutch actuation system of the drive train of the motor vehicle, which is not further illustrated here for the sake of cla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com