Mesh insert pin core-pulling induction die structure

A technology of inserting needles and mesh holes is applied in the field of core-pulling induction mold structures for mesh inserting needles. The effect of product strain and accurate mold opening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

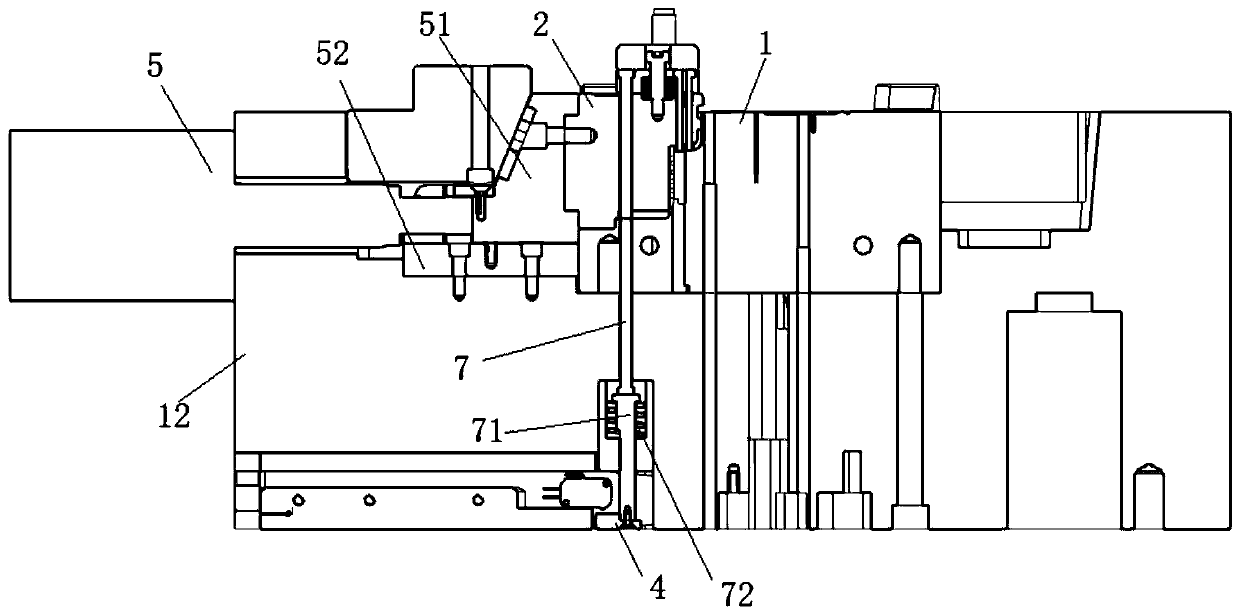

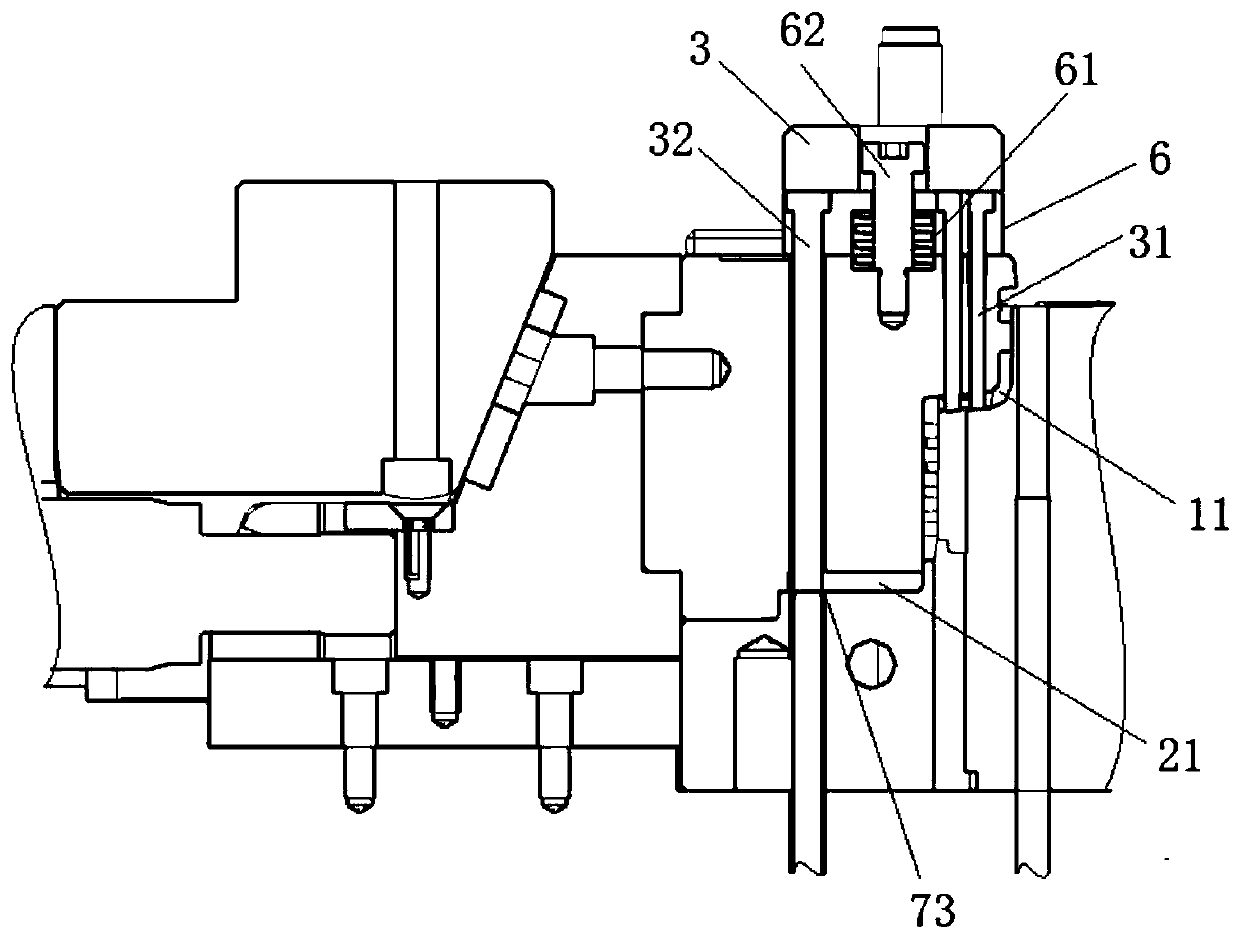

[0020] refer to Figure 1-2 As shown, this embodiment is a mesh inlaid needle core-pulling induction mold structure, including a lower mold core 1, a slider 2 that abuts against the side of the lower mold core 1 to form a cavity 11, and is movable on the slider 2. The pin fixing plate 3 on the top, the connecting pin fixing plate 3 extending through the slider 2 to the pin 31 in the cavity 11, the connecting rod 32 that moves relatively synchronously with the setting pin 31, and the sensor corresponding to the end of the connecting rod 32 4. And the induction cylinder 5 which is arranged on the side of the slider 2 and drives the slider 2 to withdraw from the cavity 11; the sensor 4 transmits the movement signal of the connecting rod 32 to the induction cylinder 5 through the injection molding machine (not shown).

[0021] The lower mold core 1 is set in the lower template 12, an arc-shaped cavity 11 is formed between the upper side of the lower mold core 1 and the slider 2, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com