Patents

Literature

111results about How to "Guaranteed normal cutting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

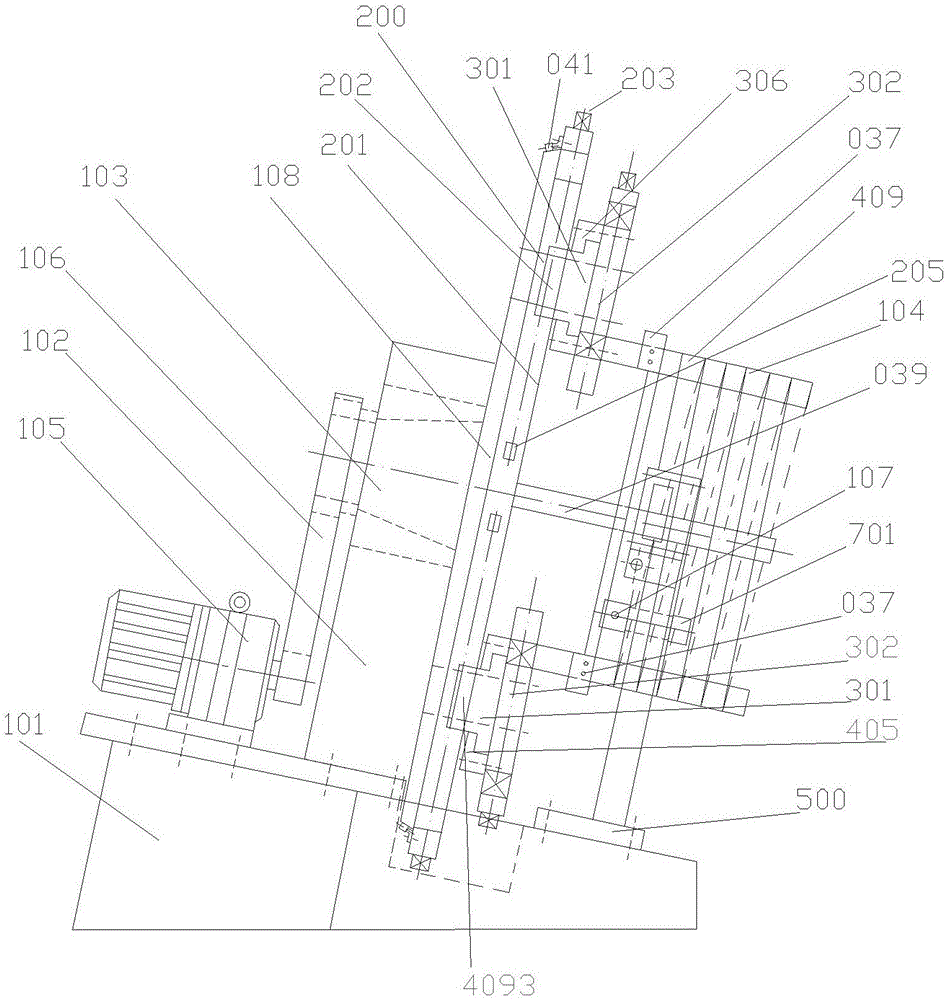

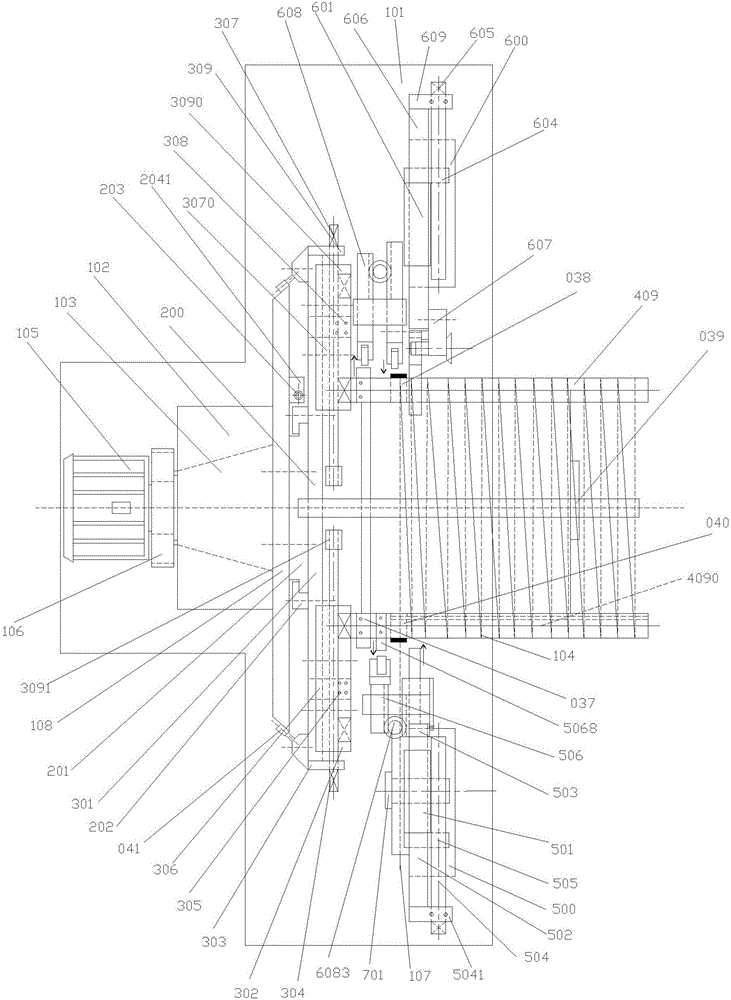

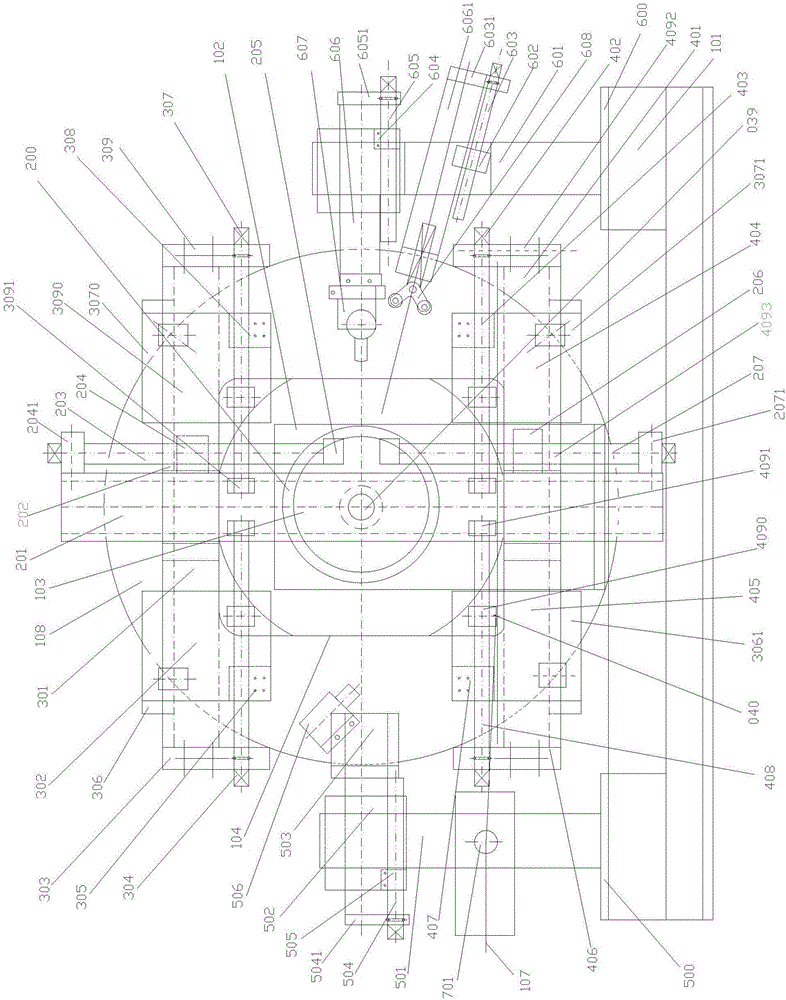

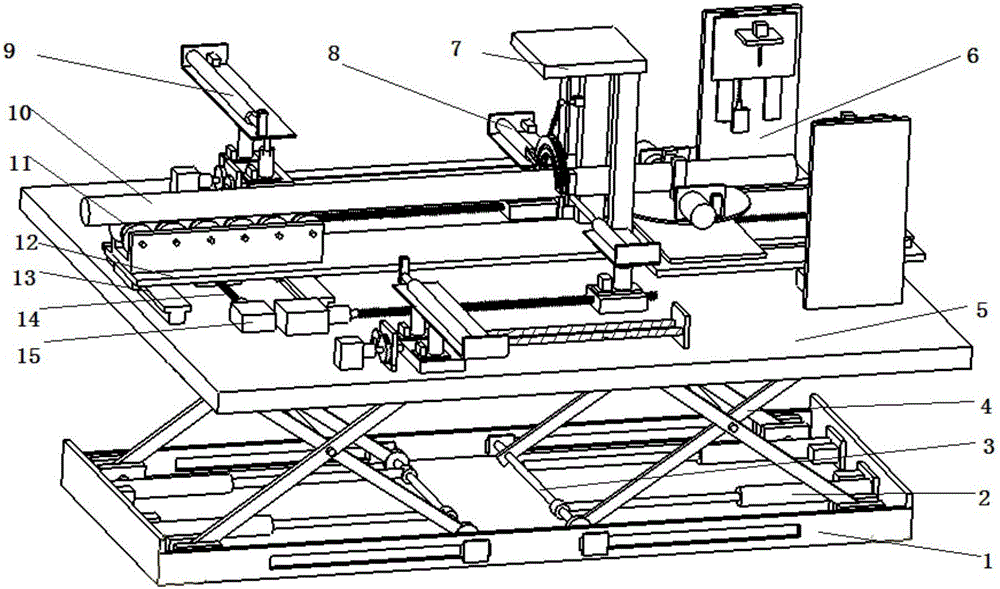

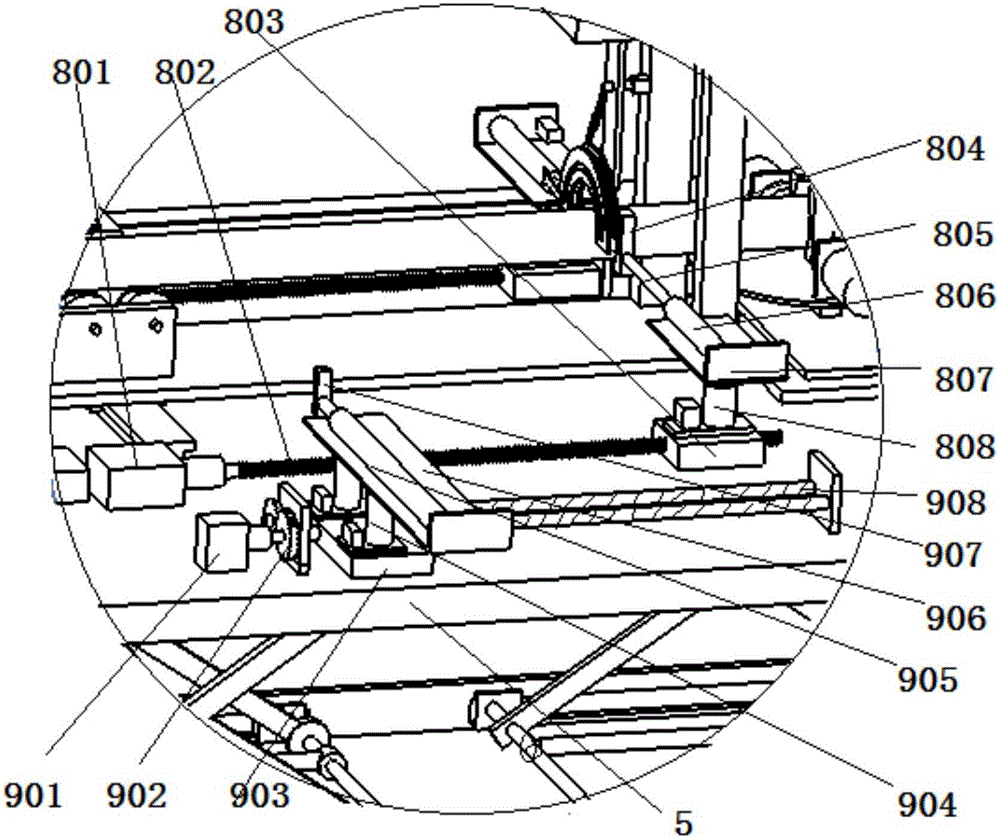

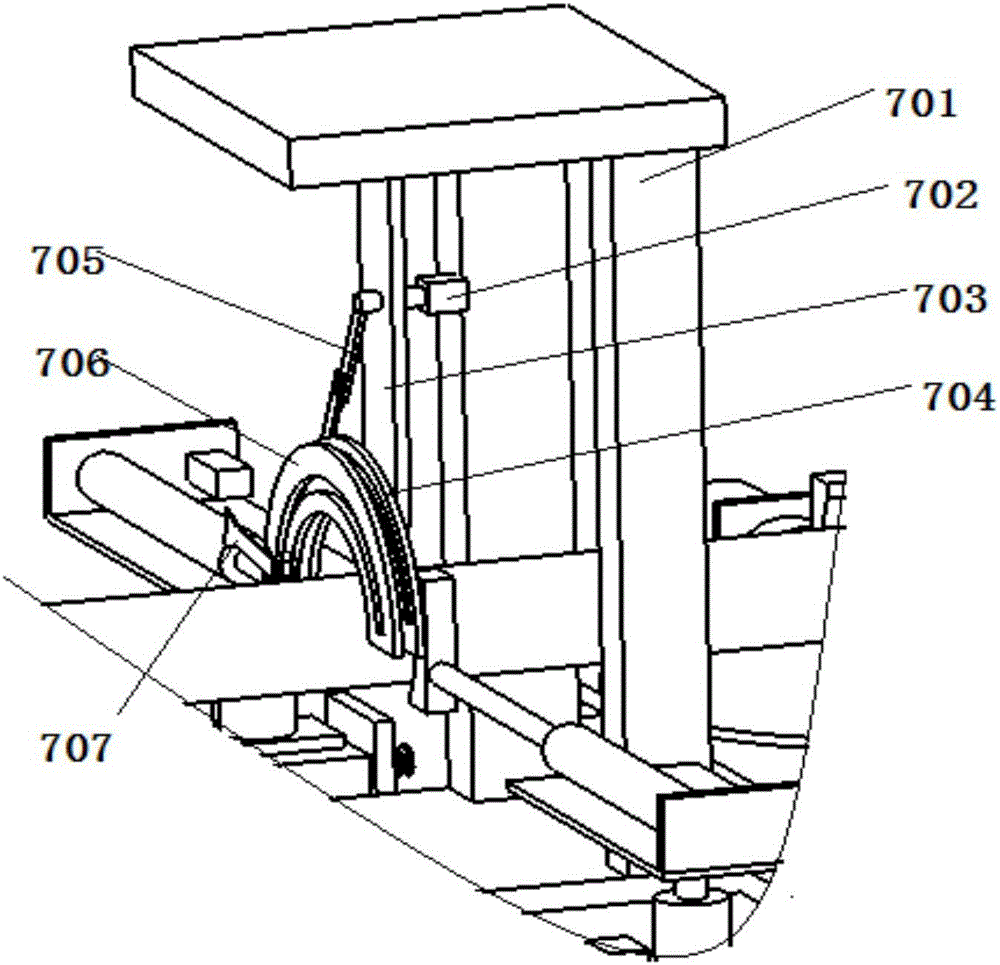

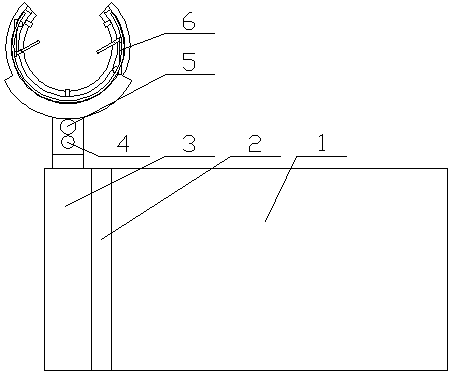

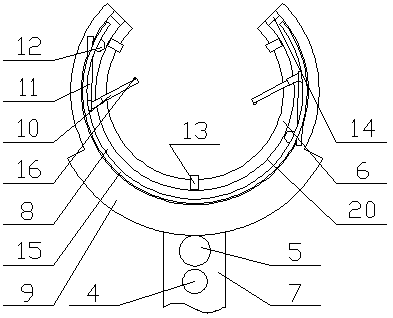

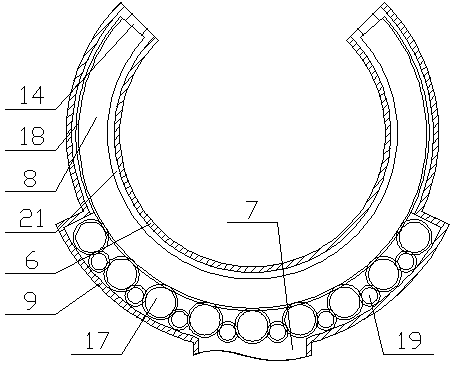

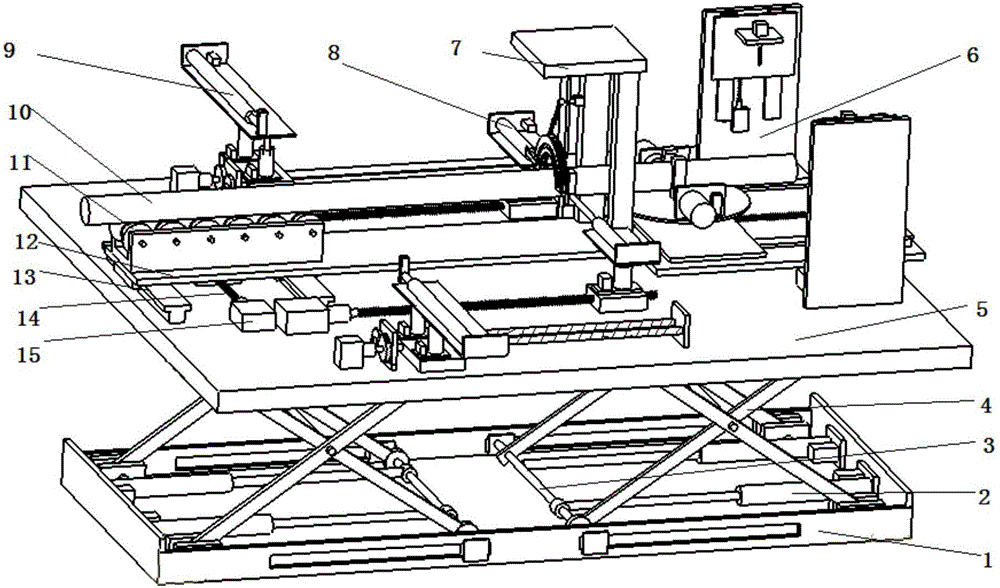

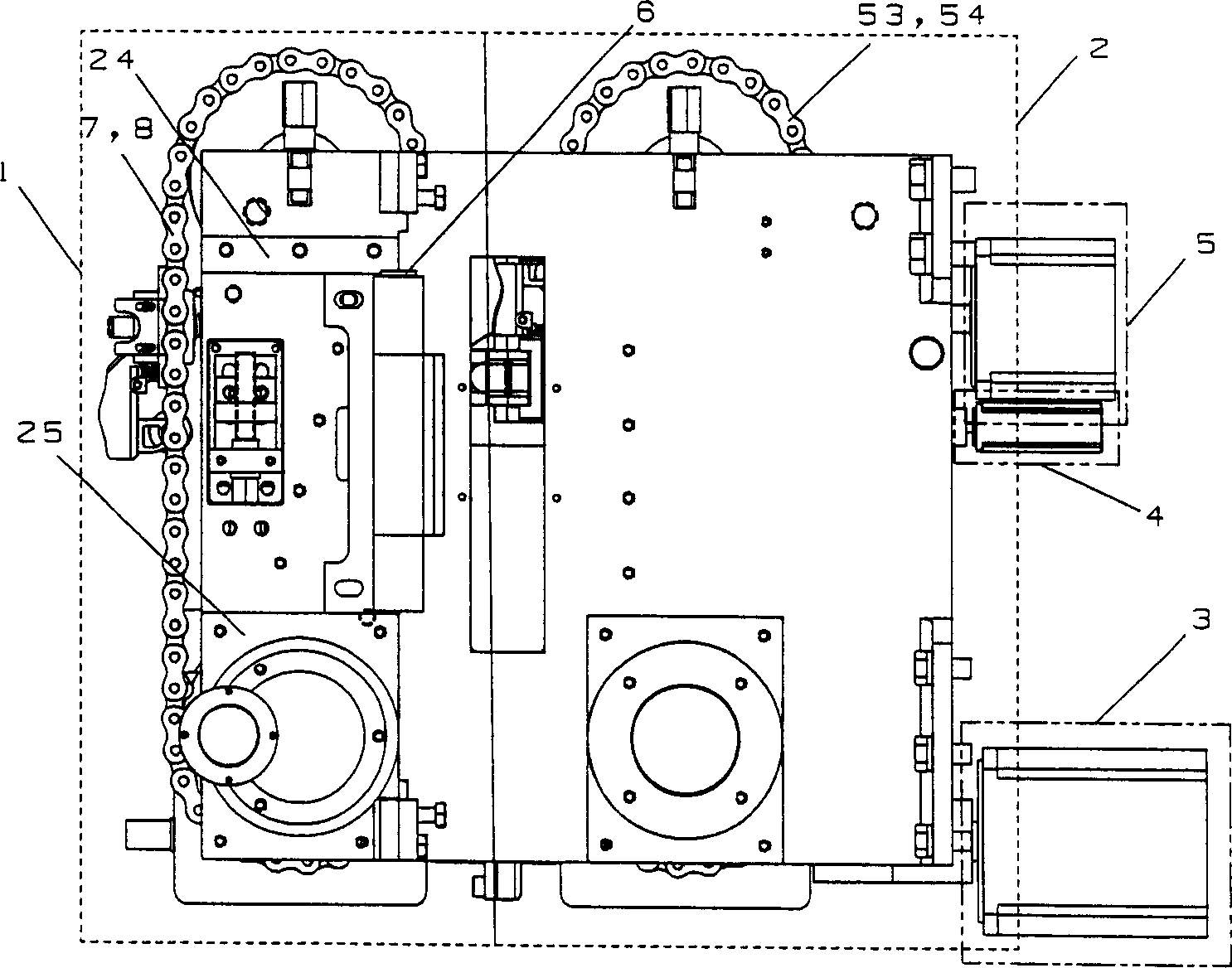

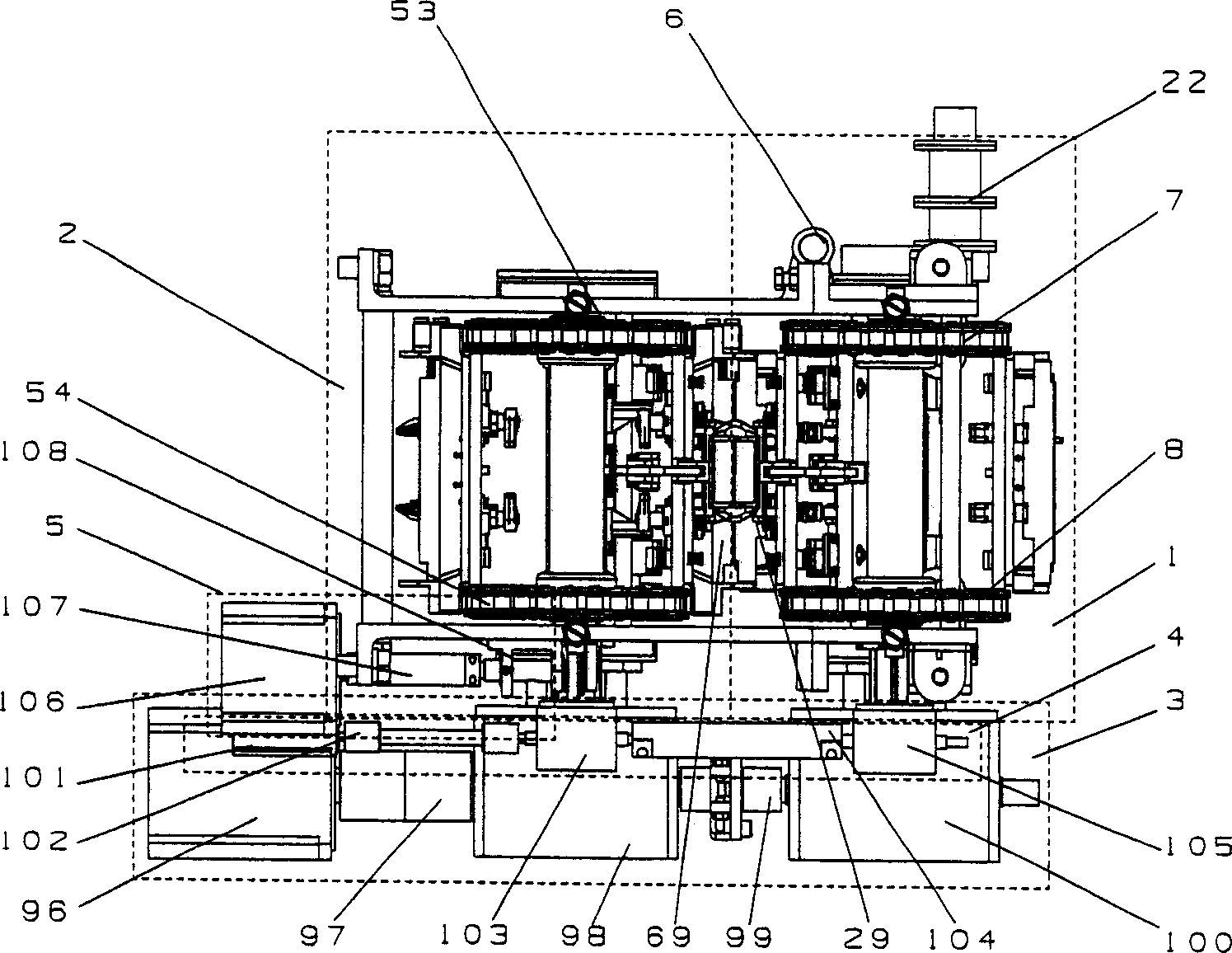

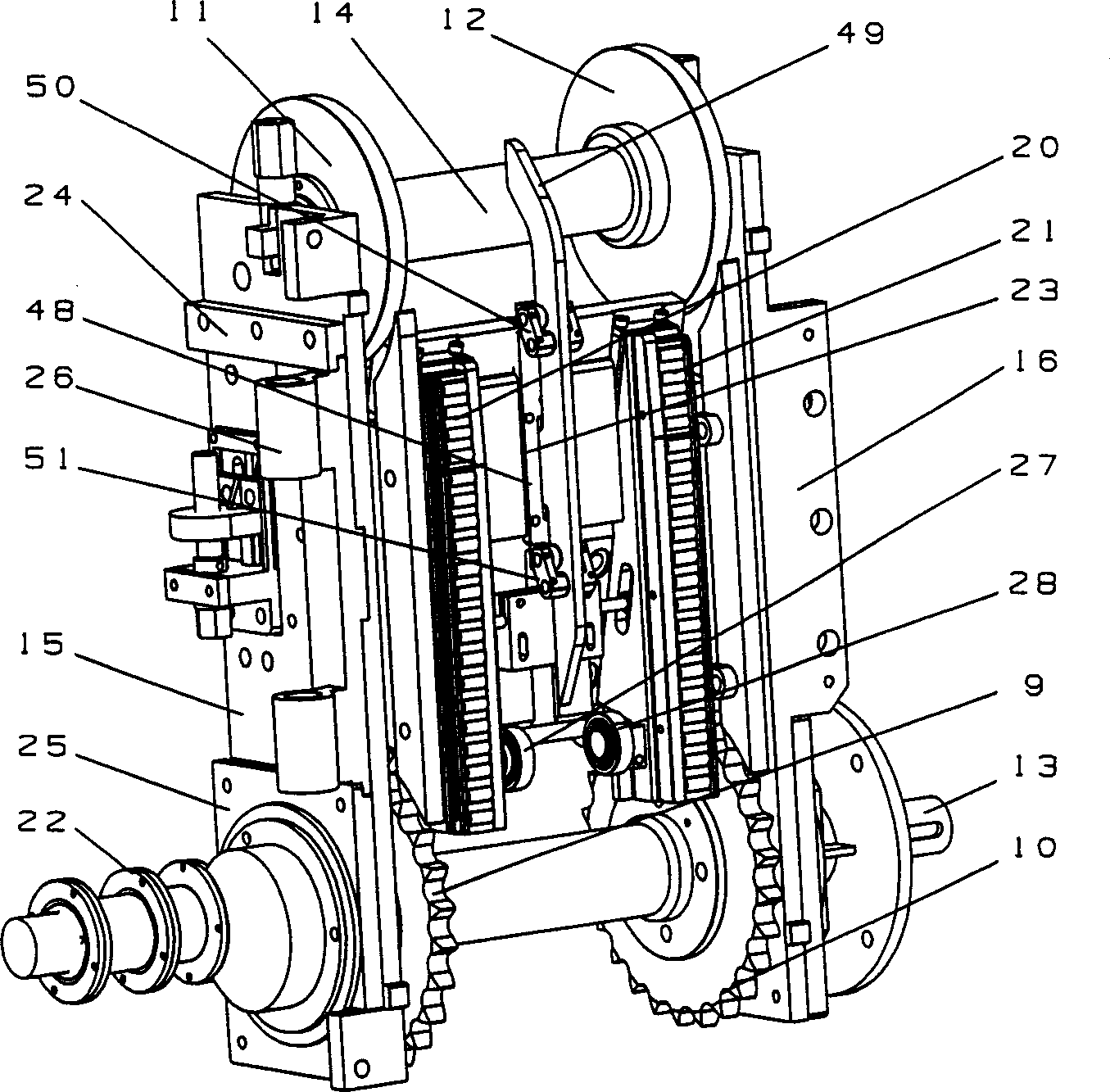

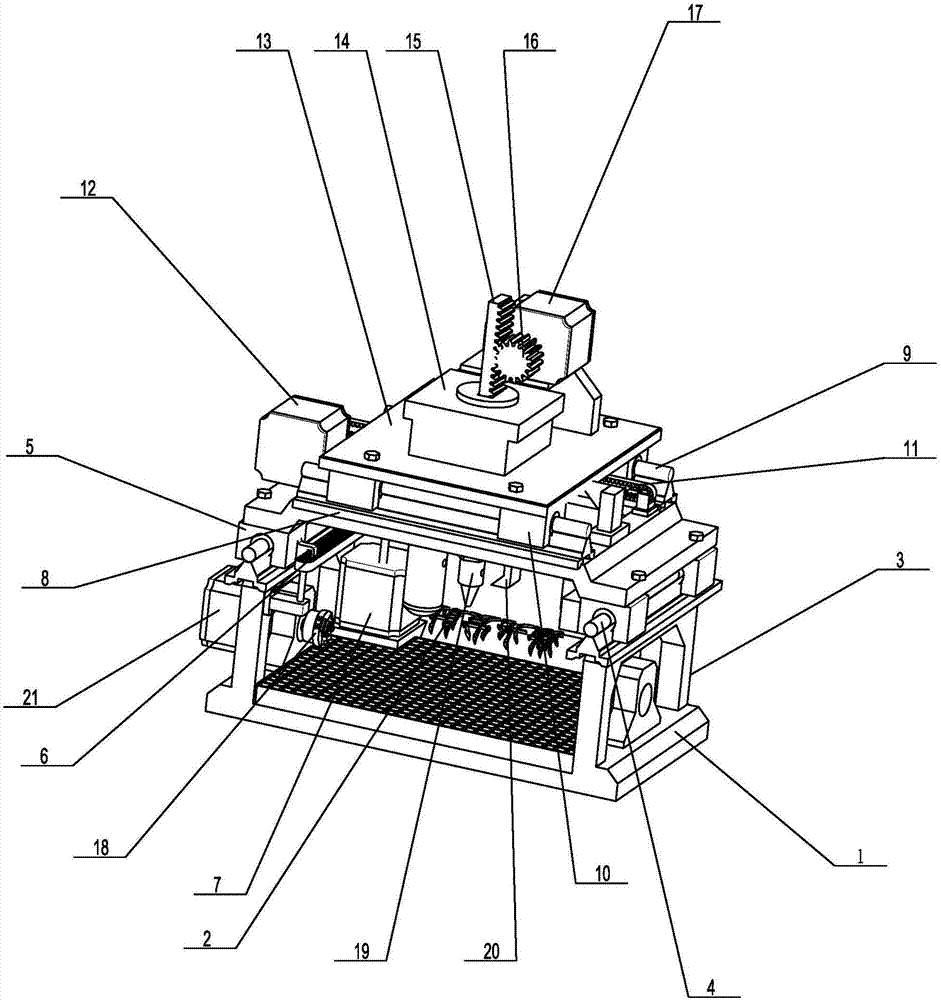

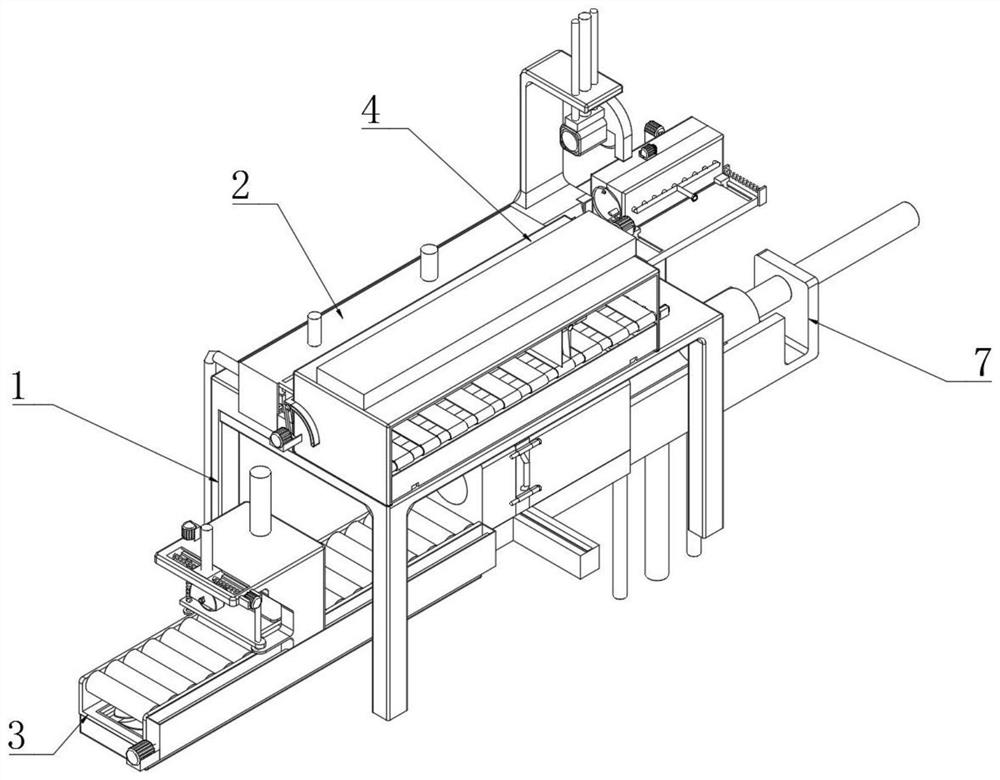

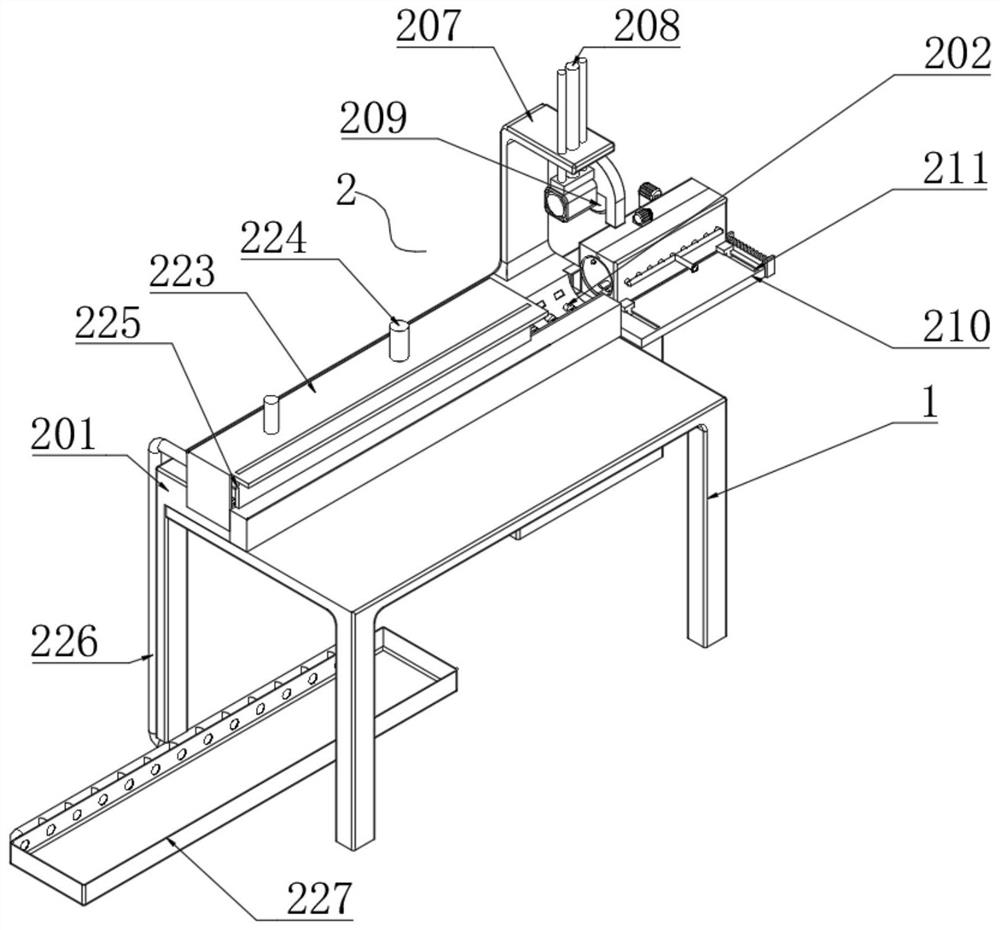

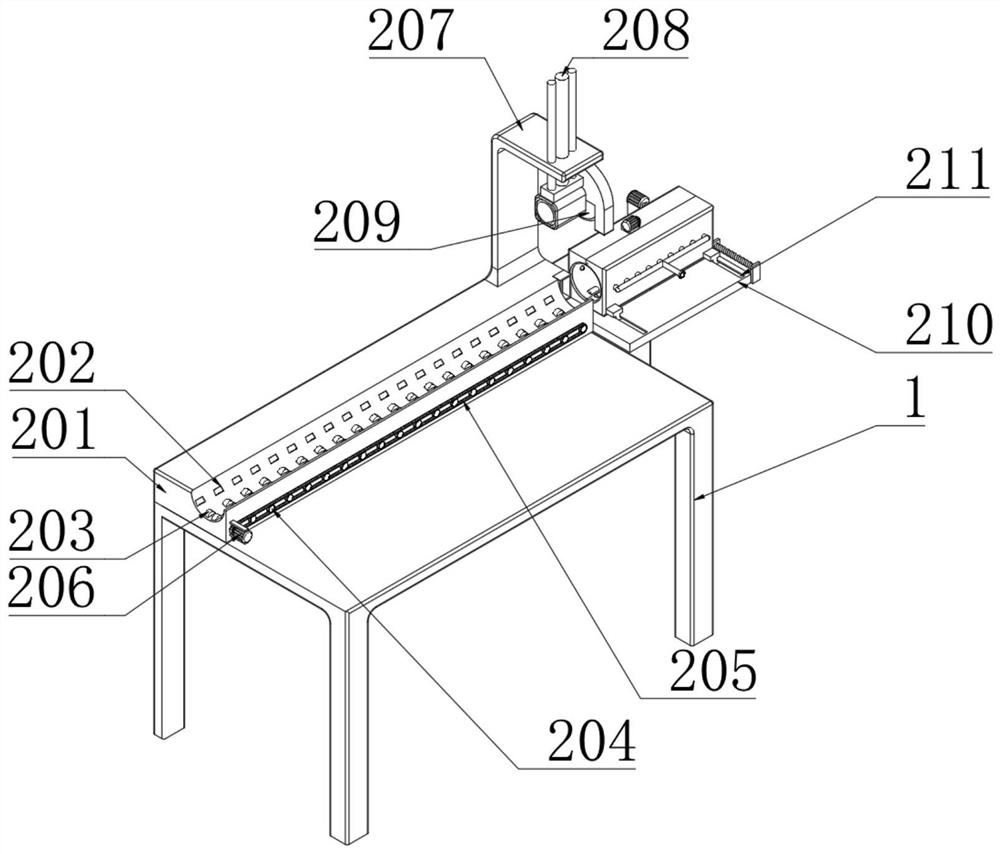

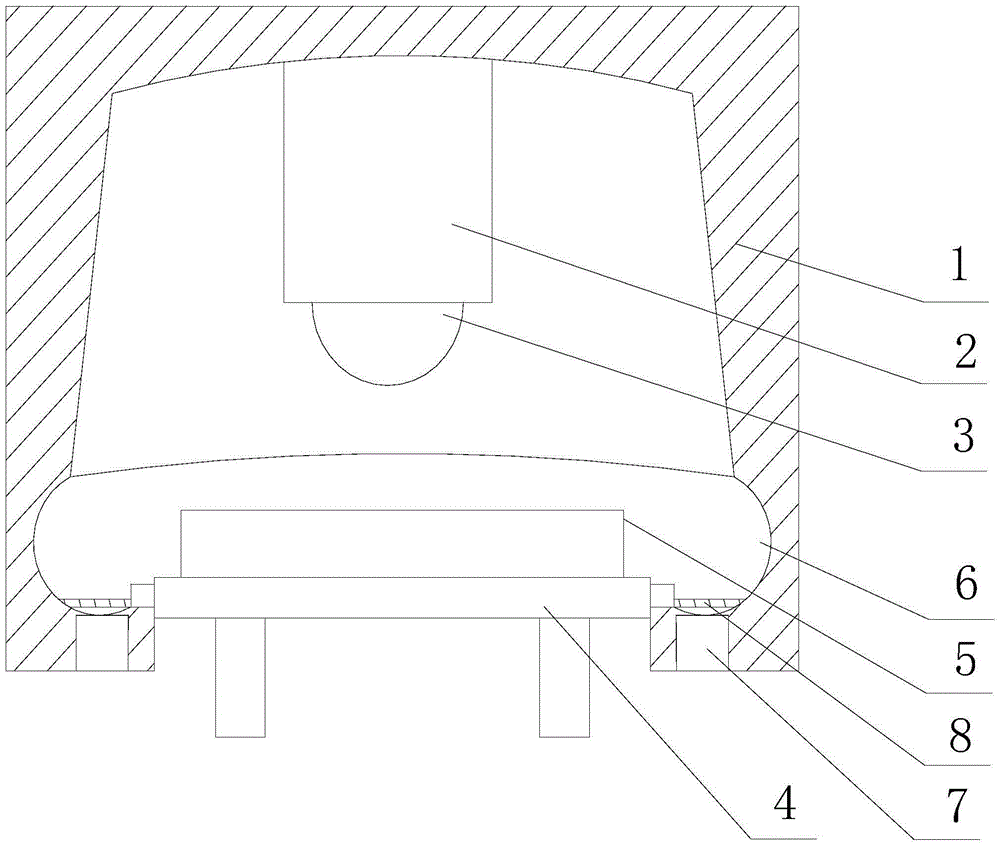

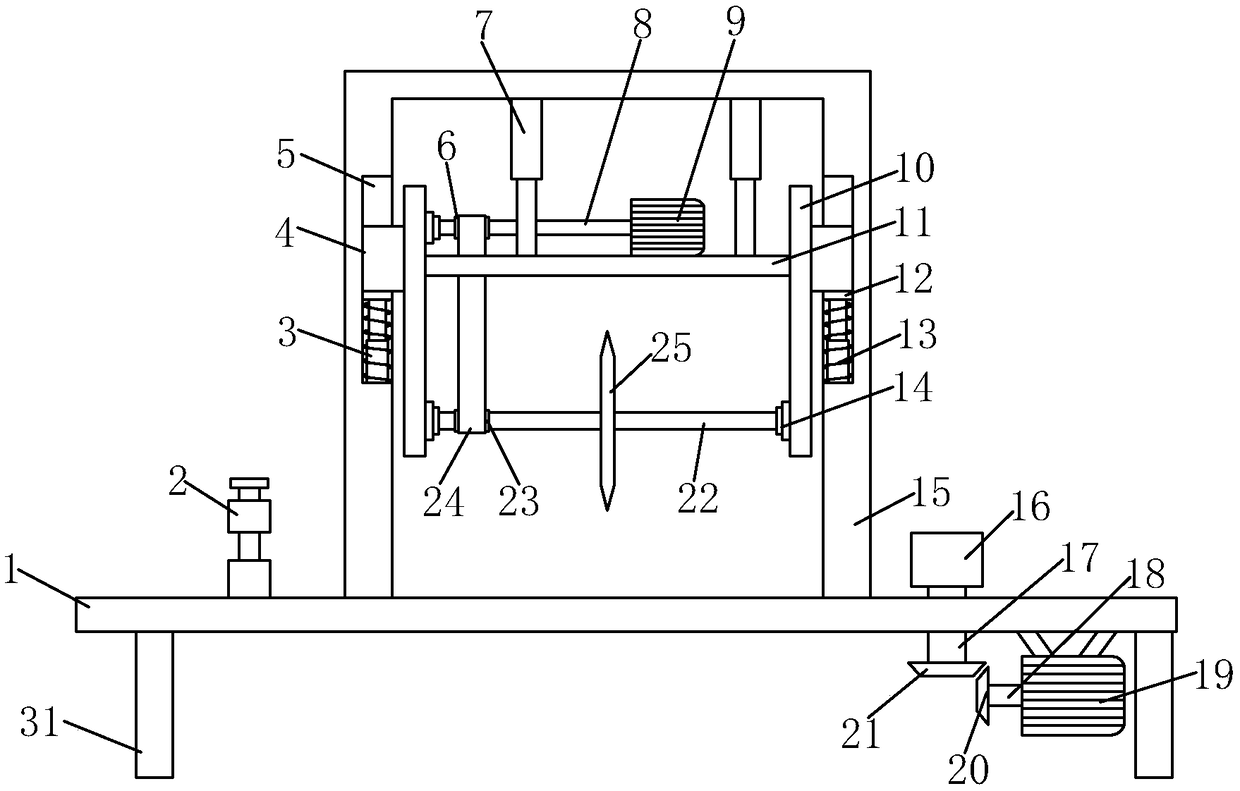

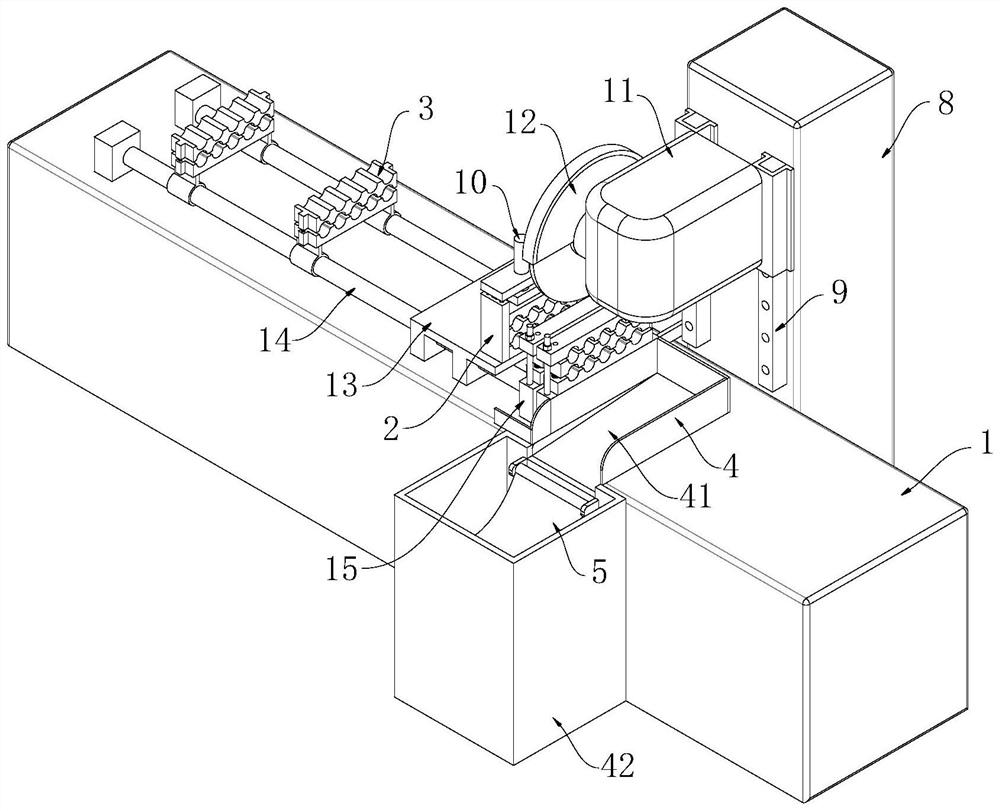

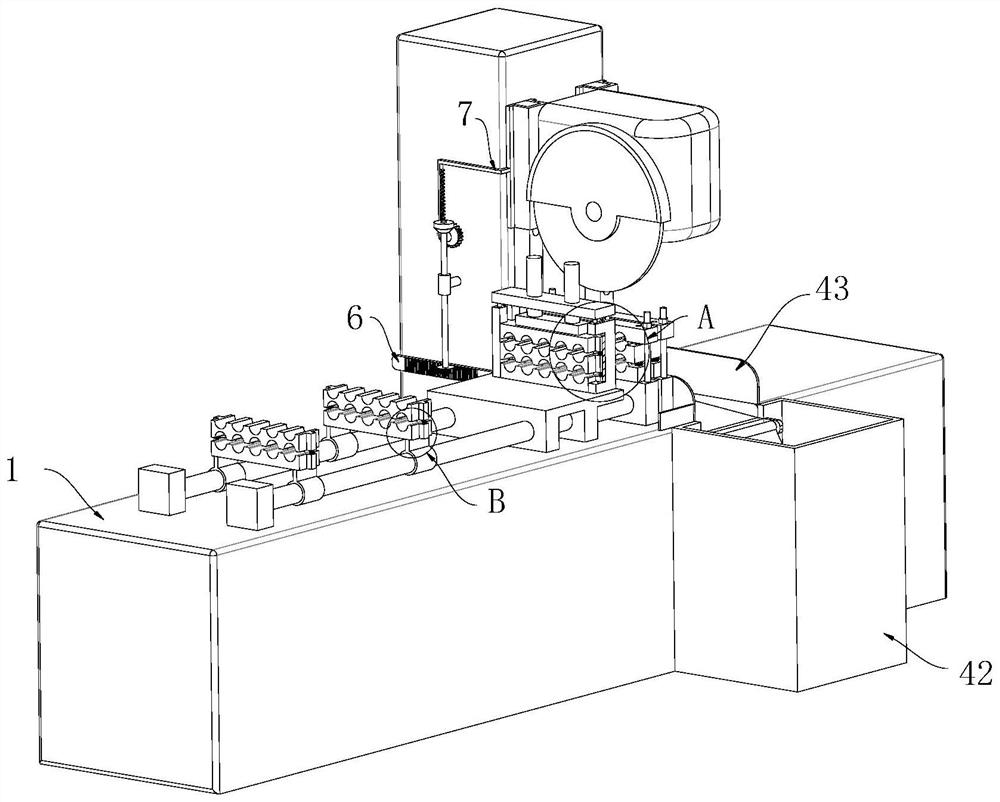

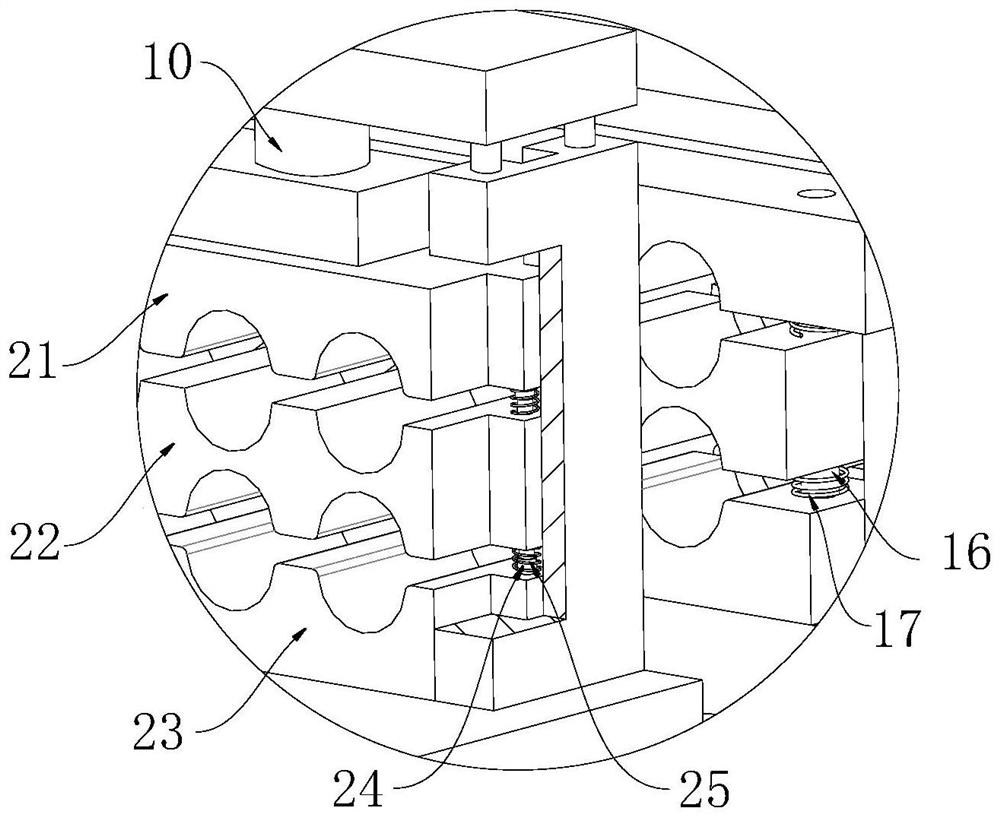

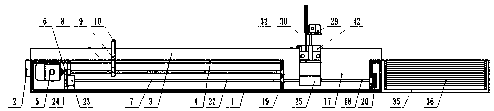

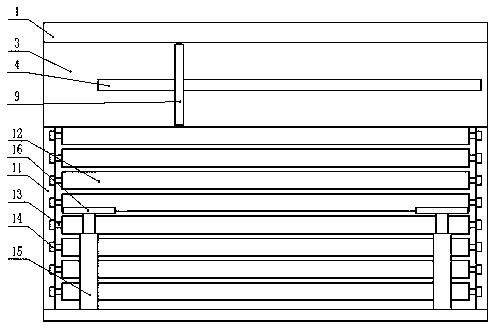

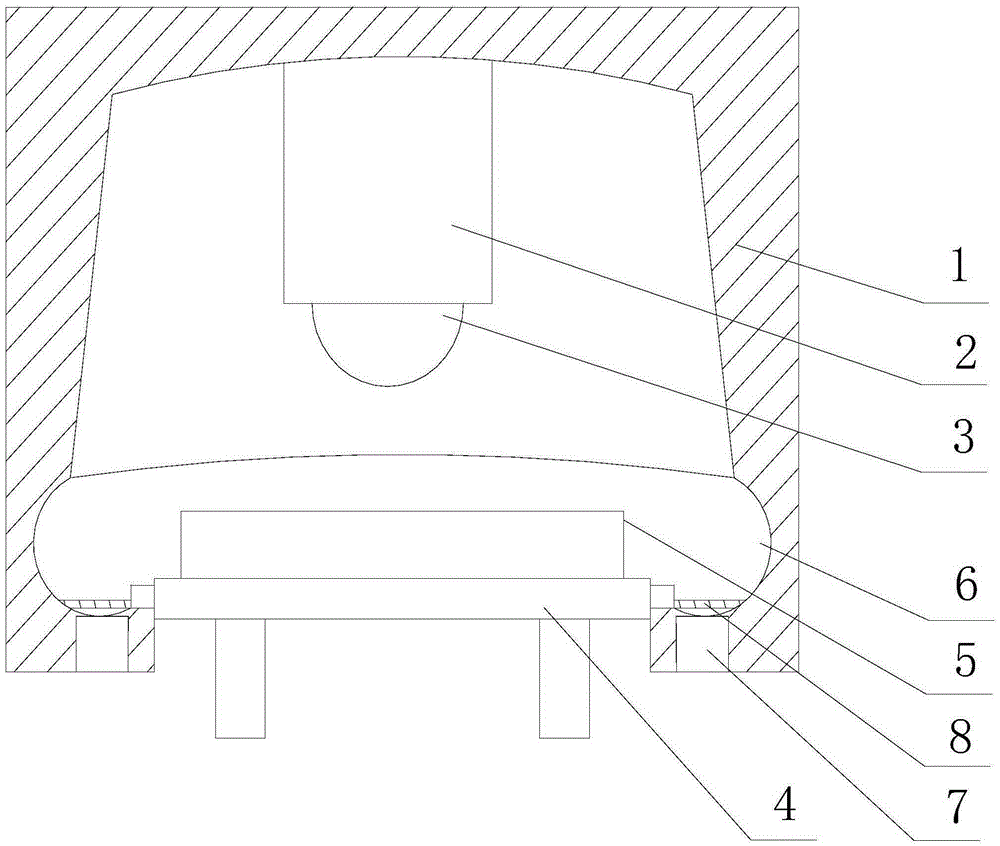

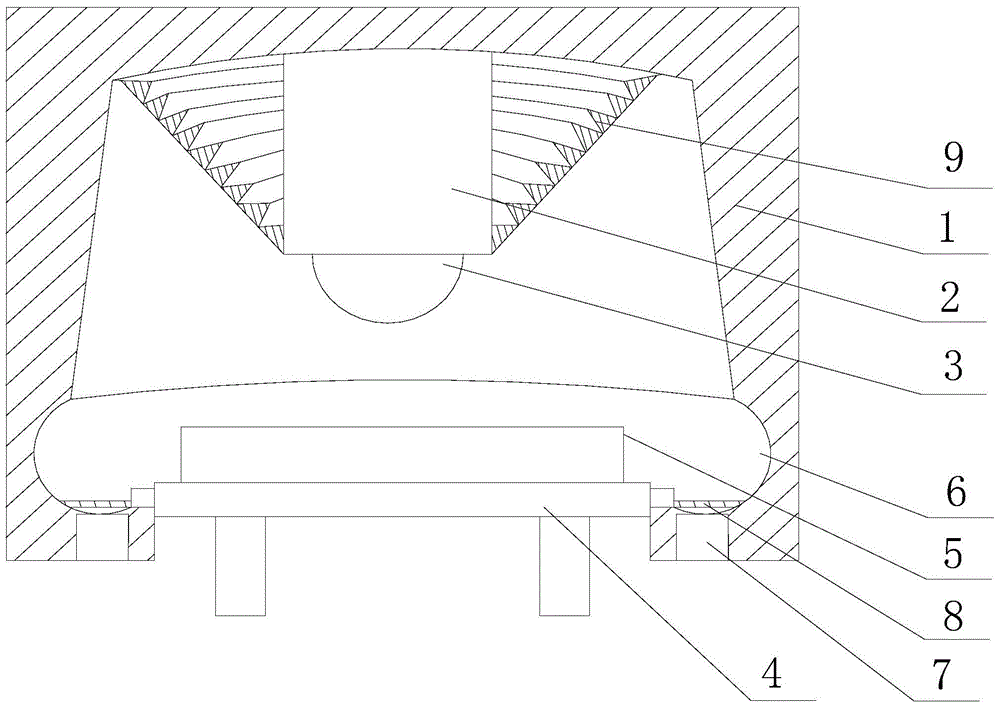

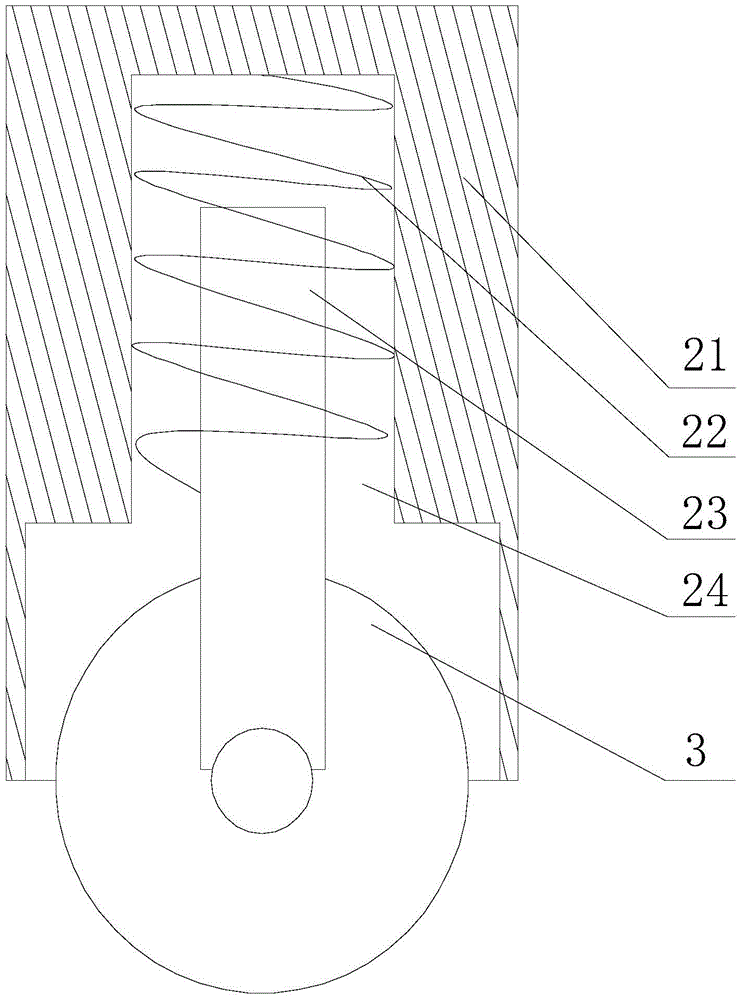

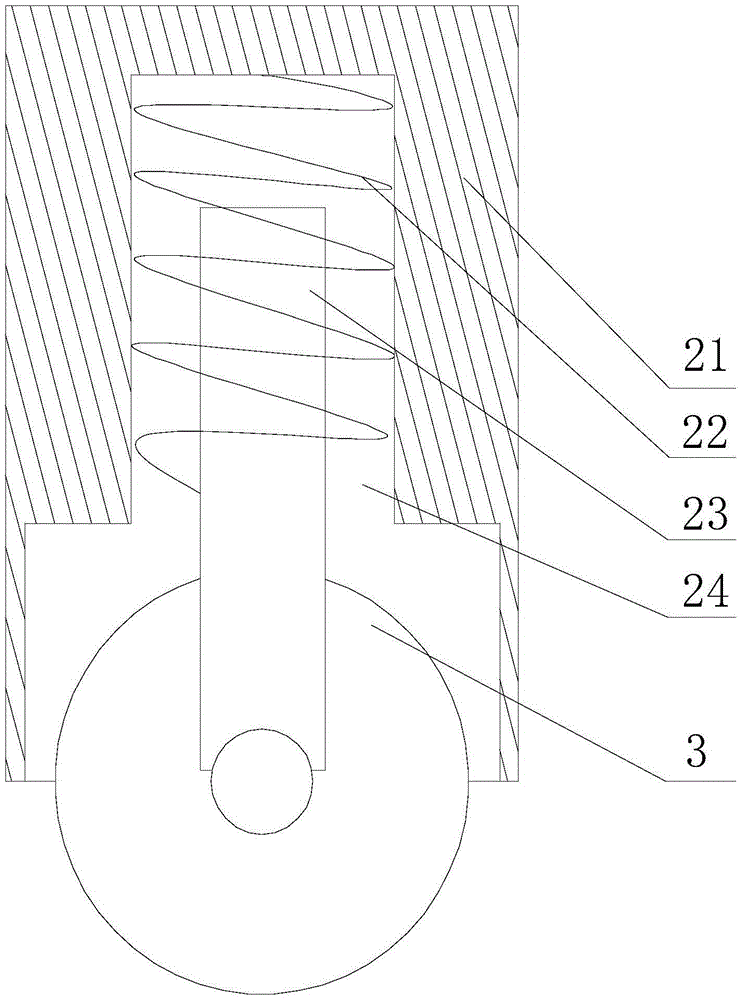

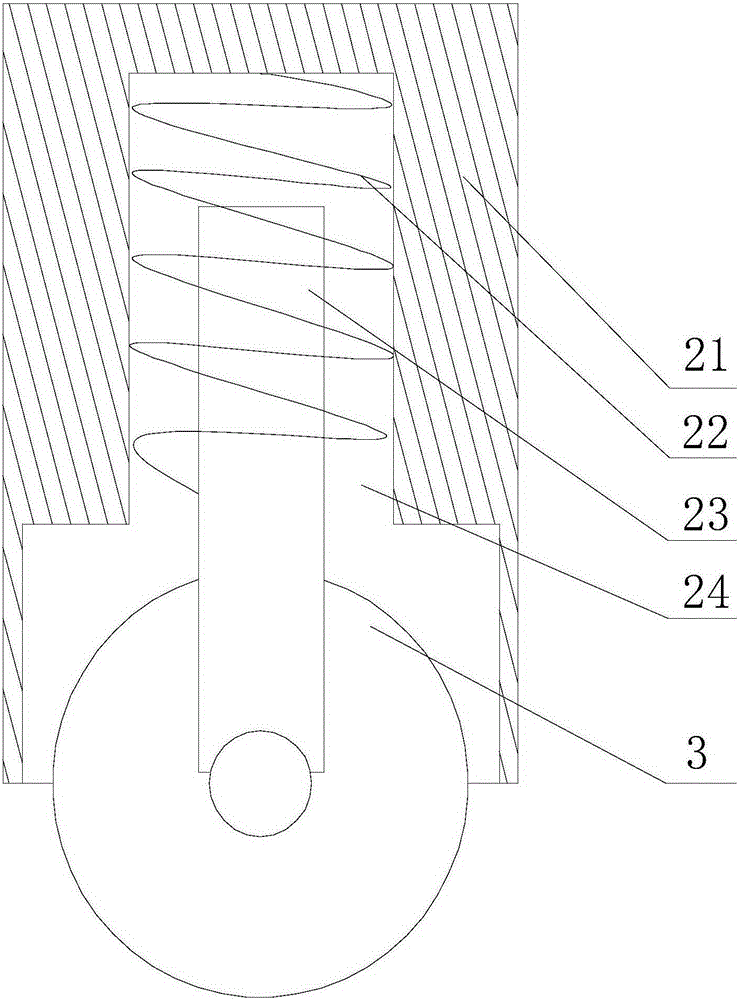

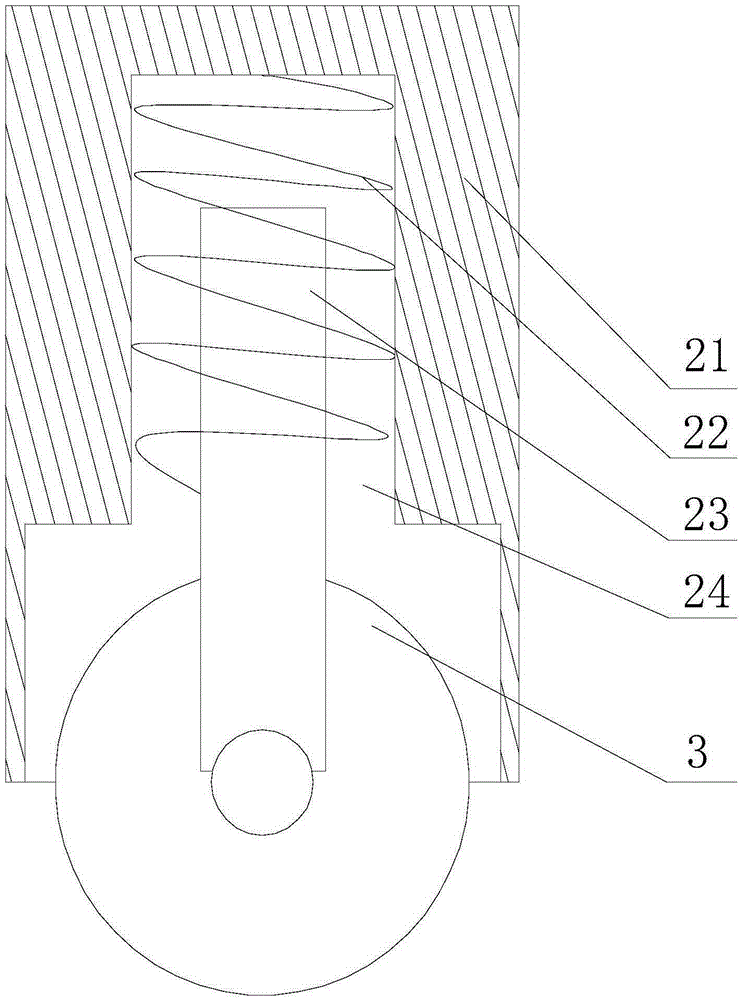

Spiral stirrup continuously and synchronously machining machine and machining method

The invention discloses a spiral stirrup continuously and synchronously machining machine and a machining method. The machining machine comprises a machine body seat, a spiral stirrup machining device and a monitoring device. The spiral stirrup machining device comprises a rotary workbench, a stirrup winding mechanism, a feeding mechanism and a cutting mechanism. The stirrup winding mechanism comprises a stirrup twining frame, a rolling type bending mechanism and a screw pitch axial feed mechanism. The monitoring device comprises a control device, a counting unit and a rotating speed measuring unit. The machining method comprises the first step of determining the number of winding shafts and the installation position, the second step of adjusting the positions of the winding shafts, the third step of feeding and positioning stirrup material, the fourth step of forming spiral stirrups and the fifth step of cutting spiral stirrups. The machining machine is simple in structure, continuous machining of spiral stirrups is achieved, and the production efficiency is high; meanwhile, the concrete constraining force of beam columns of buildings can be improved through the produced spiral stirrups, and therefore the seismic capacity of the buildings is improved. Practicality is high, and the machining machine and the machining method are low in carbon, environmentally friendly and efficient and save energy.

Owner:刘国政 +1

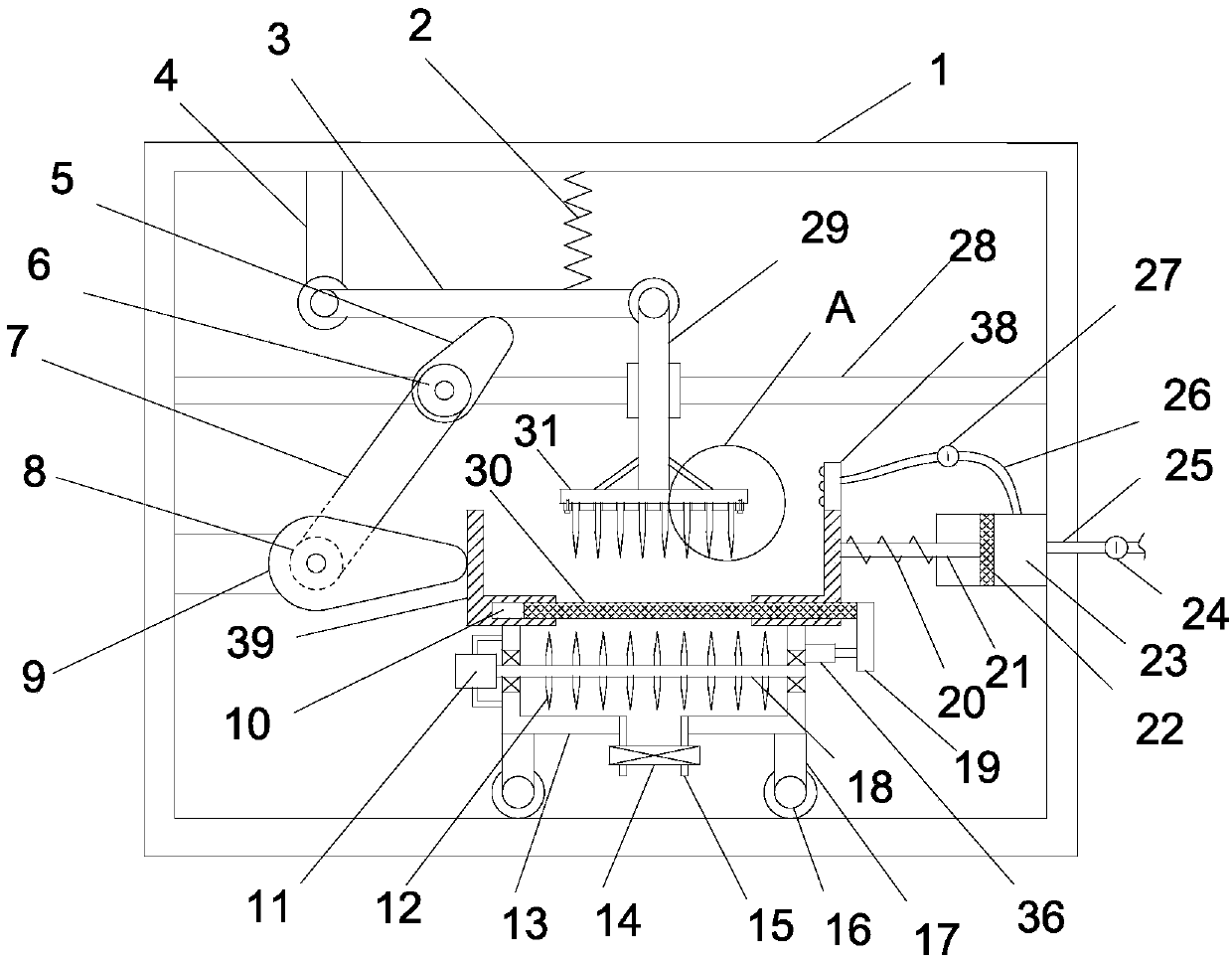

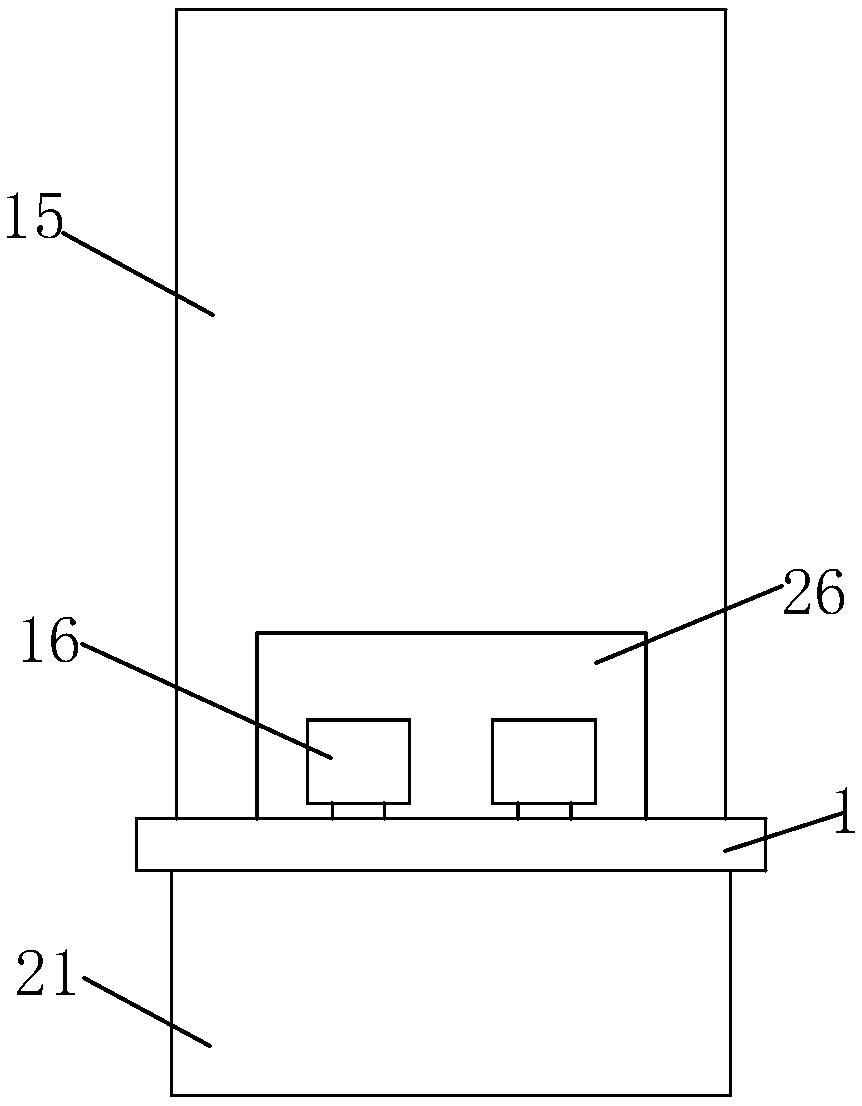

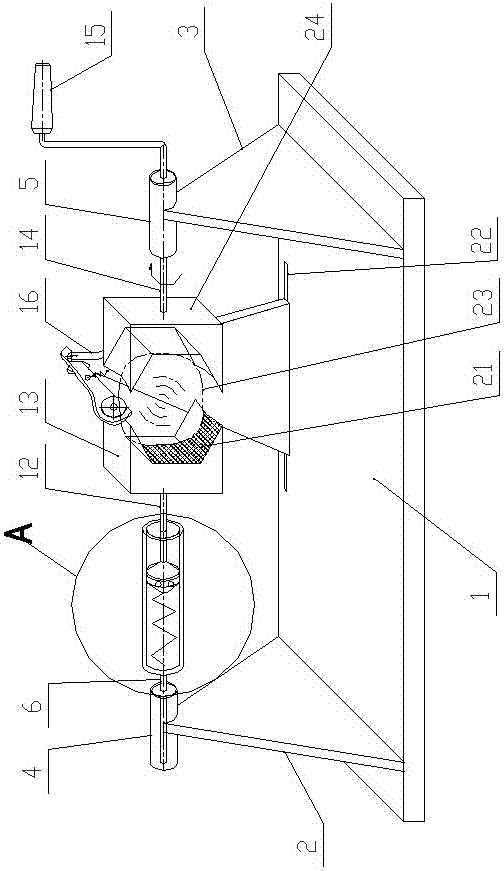

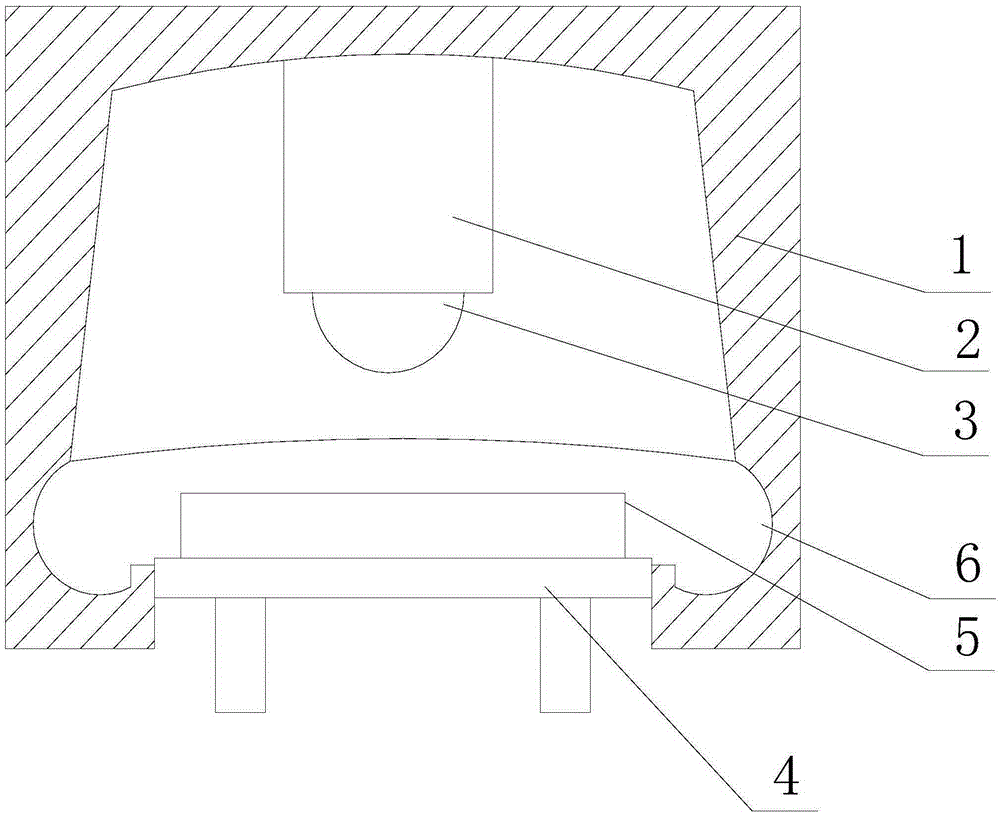

Straw crushing device for livestock breeding

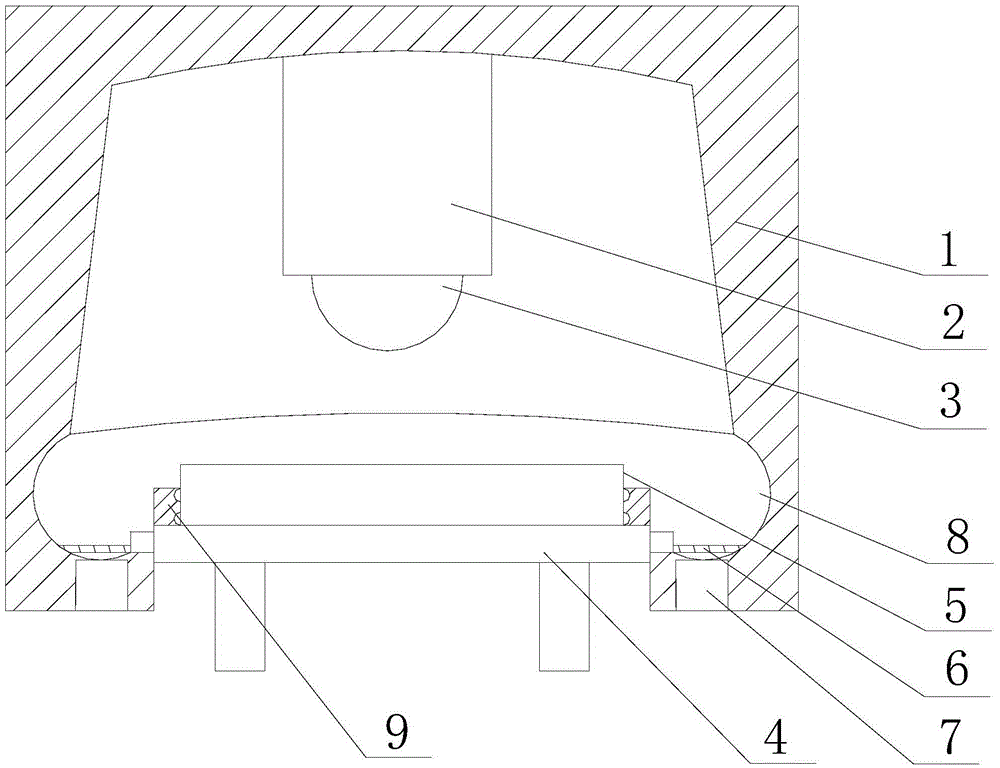

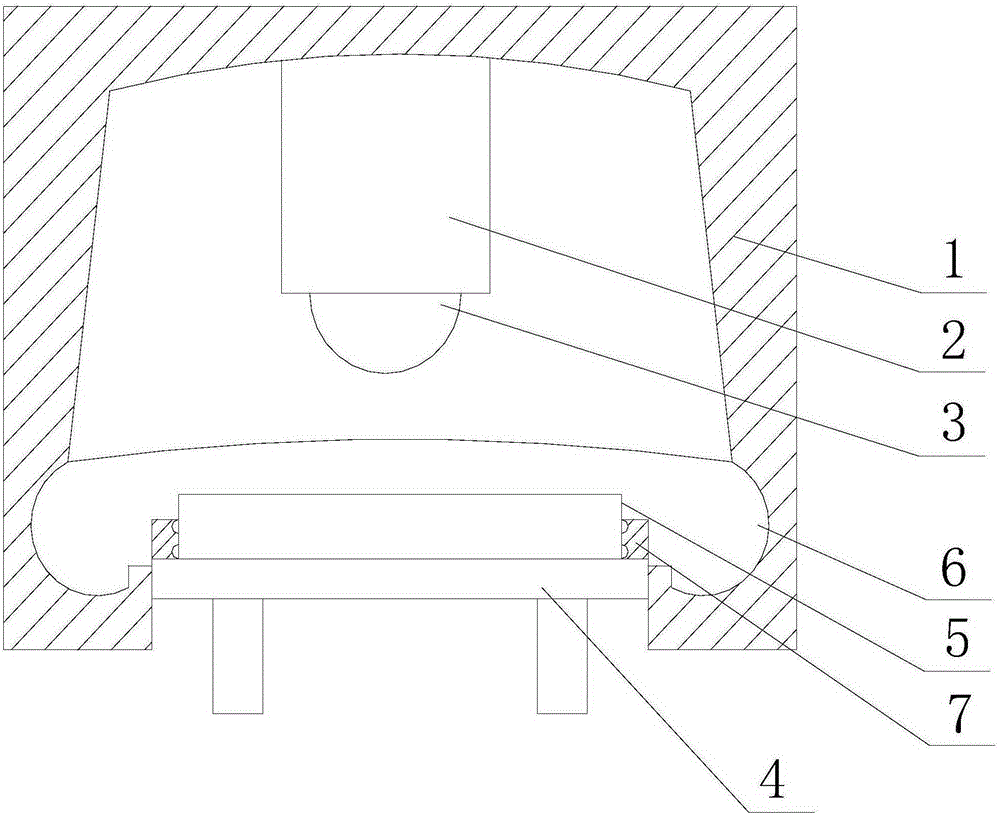

InactiveCN107624387AFully crushed and refinedGuaranteed normal cuttingShaking/oscillating/vibrating mixersUsing liquid separation agentSlagScrew thread

The invention discloses a straw crushing device for livestock breeding. The straw crushing device includes an operating room, a horizontal rod is fixedly arranged inside the operating room in a horizontal mode, a sliding rod is arranged penetratingly on the horizontal rod in a vertical sliding mode, the upper end of the sliding rod is connected with the end, away from a hanging rod, of a rotatingplate in a hinged mode, a number of cutting blades are arranged at equal spacing on the bottom of a connecting plate, locking screws are arranged on screw holes in a penetrating mode, and the lockingscrews are connected with the connecting plate in threaded fit; a number of crushing blades are arranged on the surface of a rotating shaft uniformly, and a water inlet pipe connected with an externalwater source is arranged on a water drawing sleeve. The straw crushing device for livestock breeding is ingenious in structure and convenient to operate, and a first crushing effect is achieved through straws receiving the cutting handling of the cutting blade and then receiving the rotary cutting and crushing of the crushing blades, the situation that longer straws clamp crushing blades is avoided, meanwhile the straws receive full crushing refinement, the straws sandwiched between the cutting blades or stuck on the cutting blades can be removed through the removal of a slag filter plate, and the normal cutting of the straws by the cutting blades is ensured.

Owner:GUANGZHOU SONGSUNCE INFORMATION TECH CO LTD

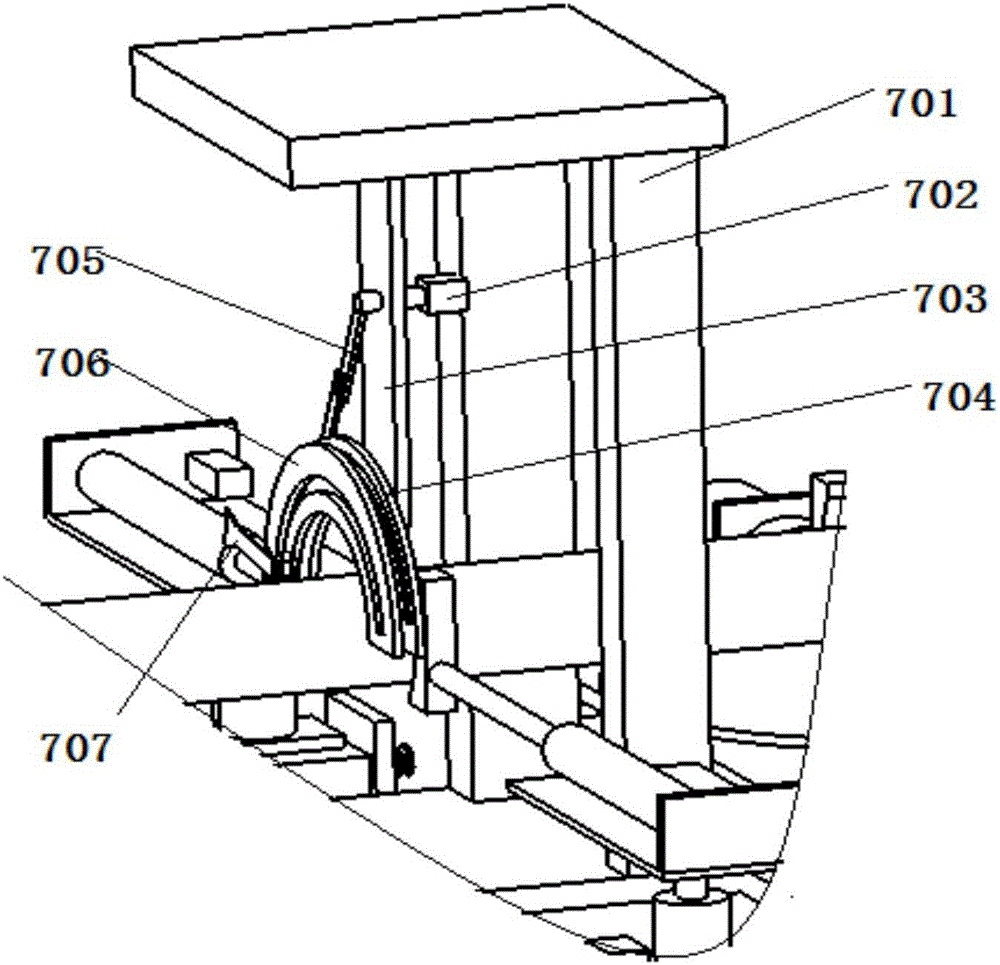

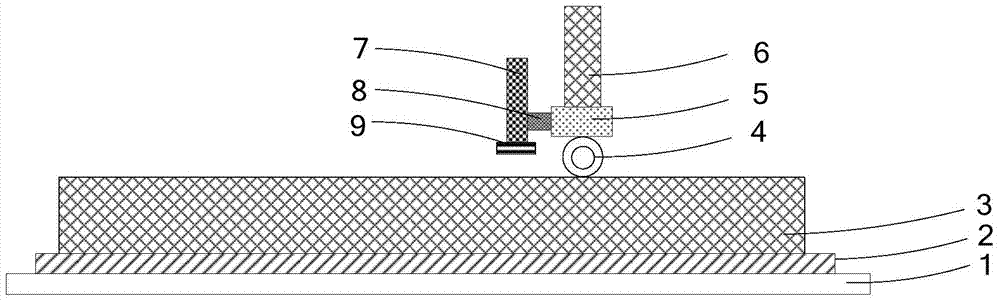

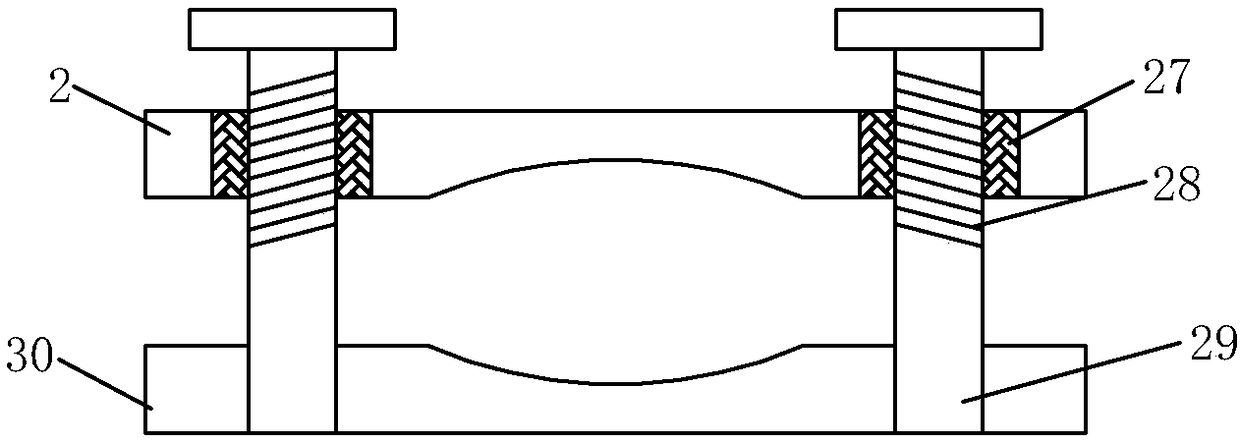

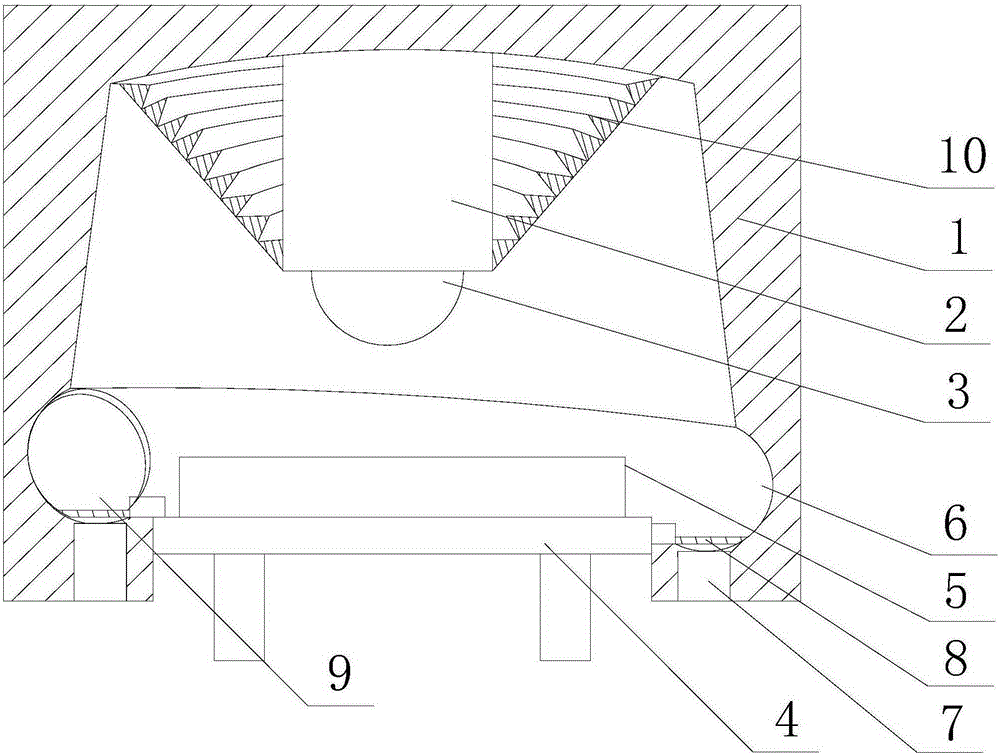

Equal-length glass tube batch production cutting device

InactiveCN106495457AReduce workloadReduce time for step-by-step processingEdge grinding machinesGlass severing apparatusBatch productionEngineering

The invention provides an equal-length glass tube batch production cutting device which comprises a base and a lift plate. A pad plate is slidably connected to the lift plate, rollers are arranged on the pad plate, a clamping mechanism is arranged on the lift plate, a cutting mechanism is further arranged on the pad plate, a milling mechanism is further arranged on the lift plate, the clamping mechanism includes a first clamping mechanism and a second clamping mechanism, the first clamping mechanism comprises a first motor and a first transmission rod, the cutting mechanism comprises a support and a cutter arranged on the support, a first arc connection plate and a second arc connection plate are arranged on the support, the milling mechanism comprises a side wall and a milling cutter slidably connected with the side wall, and a sliding plate is slidably connected to the pad plate. By using the equal-length glass tube batch production cutting device, cutting and milling of equal-length glass tubes can be completely efficiently, staff's manual operation during the entire process is omitted, potential safety hazards of staff are reduced, production efficiency is improved, and machining cost is reduced.

Owner:天津南玻节能玻璃有限公司

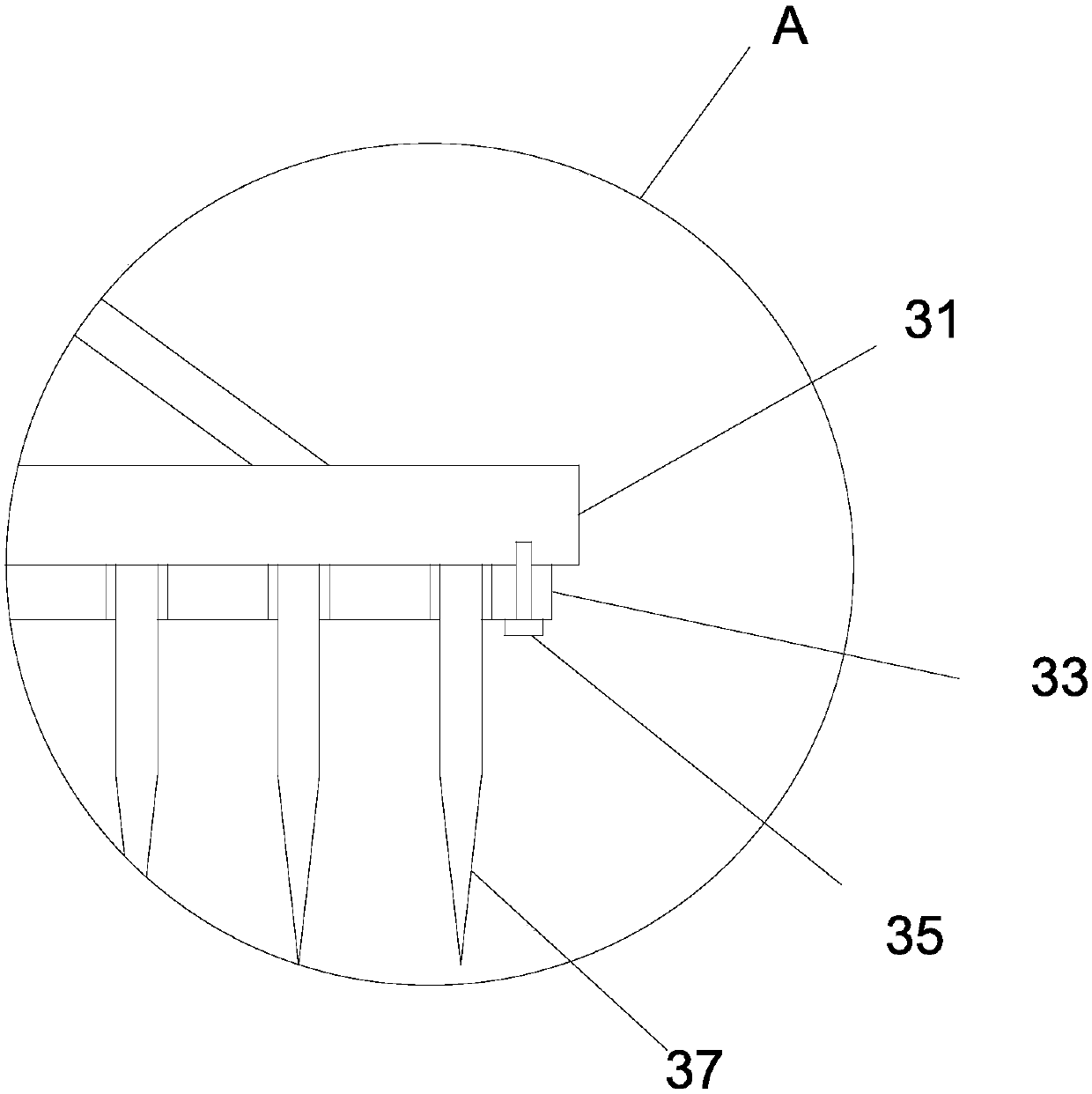

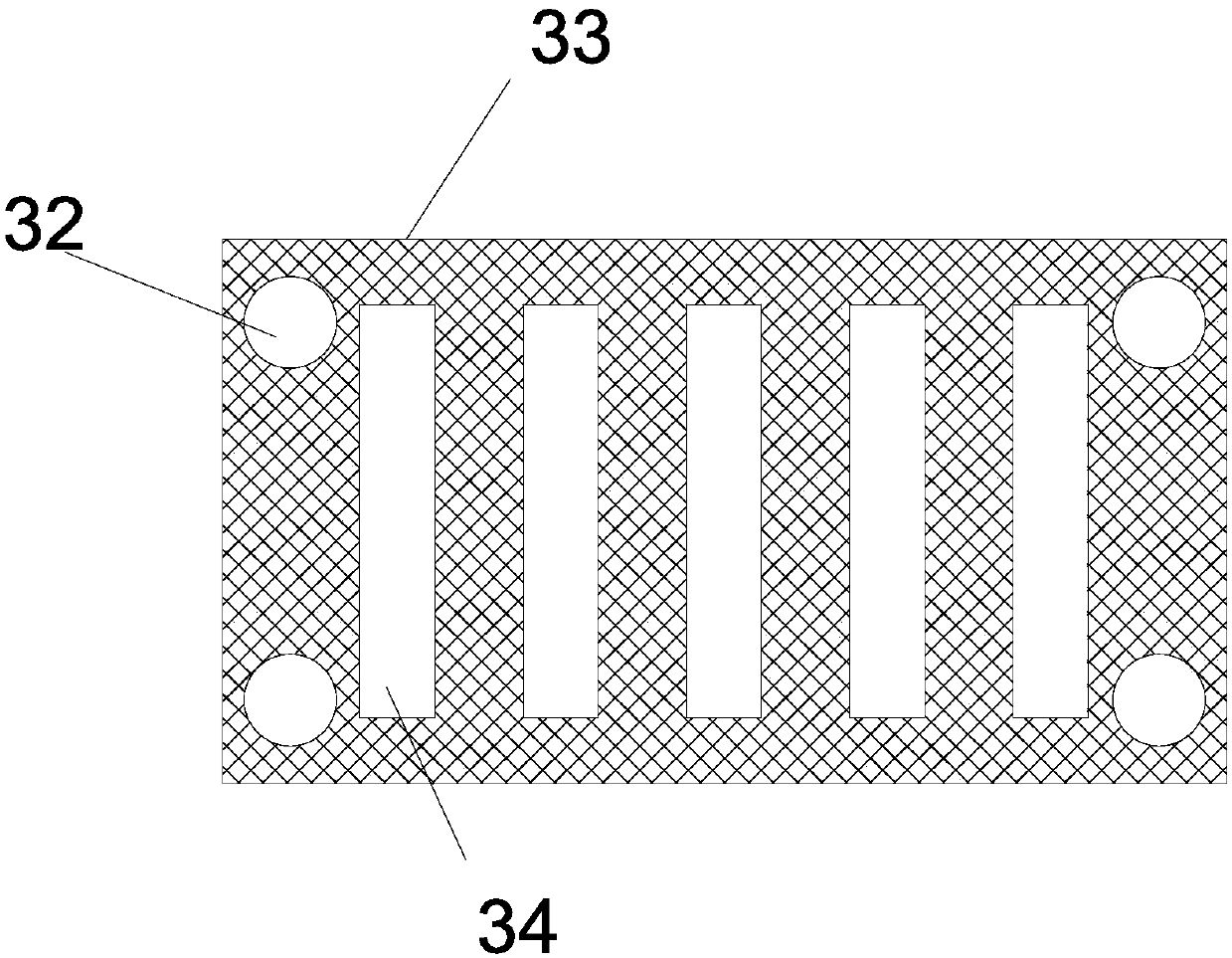

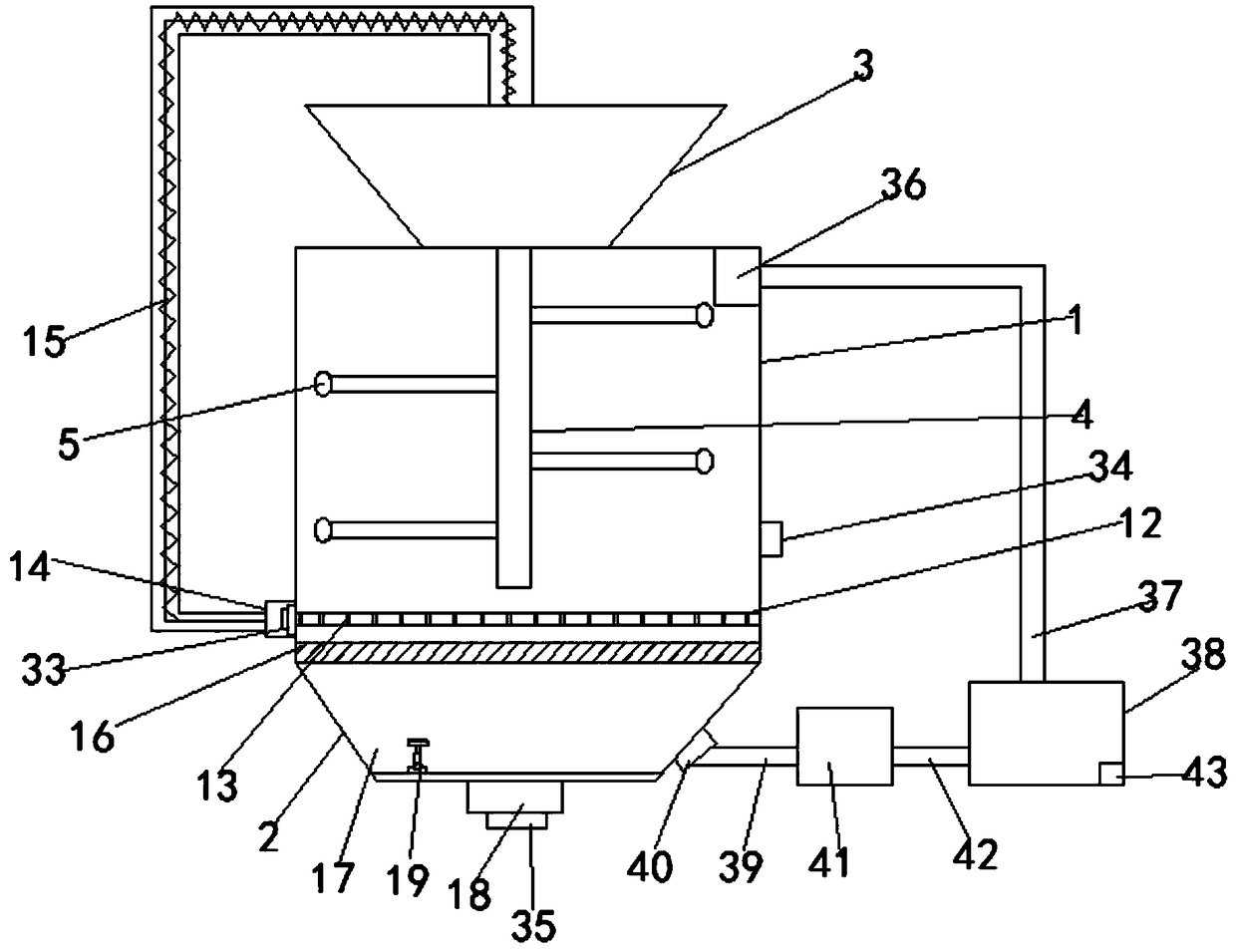

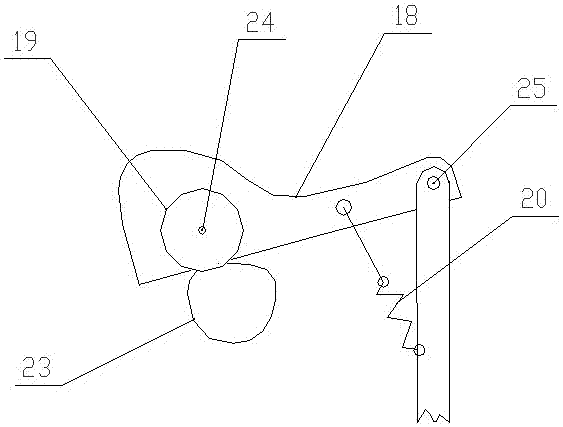

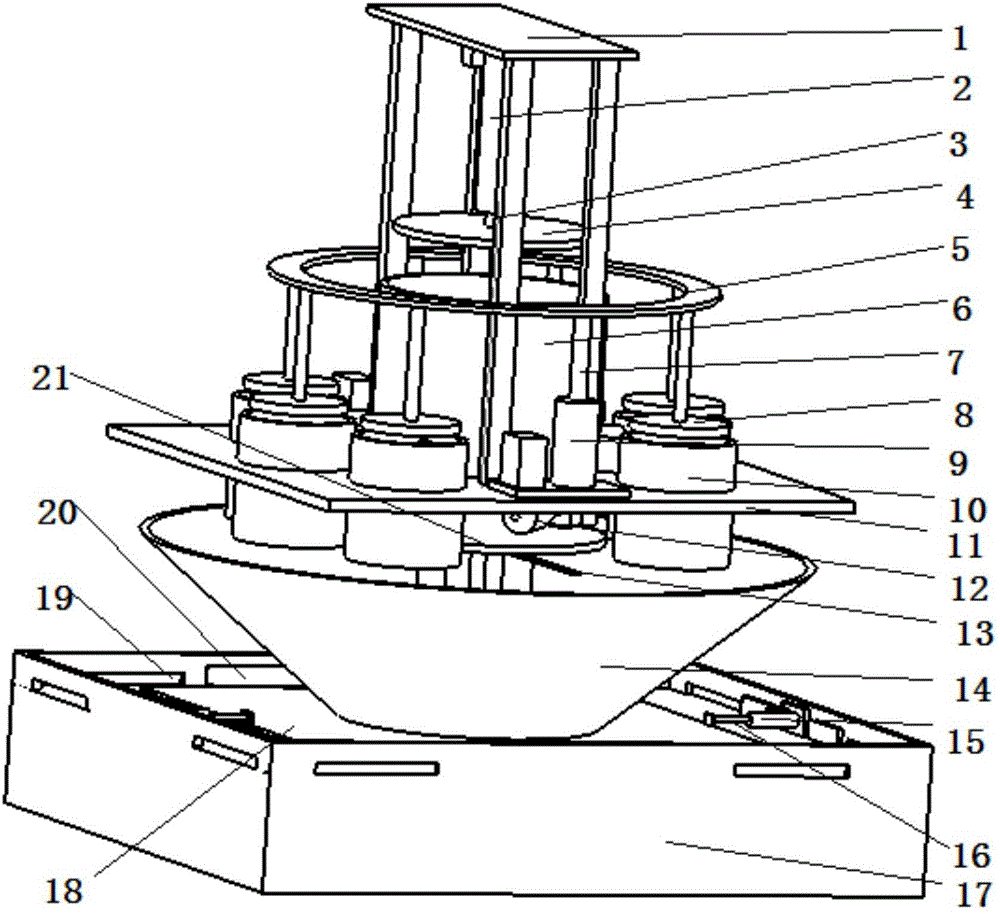

Harvester for leaves of agave sisalana

ActiveCN107926278AAchieve mechanized harvestingChanging the game for manual harvestingHarvestersEngineeringUltimate tensile strength

The invention discloses a harvester for leaves of agave sisalana. A lifting frame is movably connected up and down with the front end of a vehicle body, a piston is transversely fixed at the front endof the lifting frame, a piston rod of the piston extends towards one side of the vehicle body, and a harvesting device is fixed at the end part of the piston rod; and the harvesting device comprisesa ring sleeve, a hollow cavity is arranged in the ring sleeve, a groove opening is arranged in the middle of the top surface of the ring sleeve, an annular rod which is in slide connection along the ring sleeve is arranged in the ring sleeve, one side, far away from the piston, of the ring sleeve is provided with a gap A, the annular rod is provided with a gap B, the straight line distance of a gap with a smaller radian in the gap A and the gap B is greater than or equal to the diameter of the stem of the agave sisalana, the top, located at in the range of the groove opening, of the annular rod is inwards provided with cutting knives, and the distance between each cutting knife and the circle center of the annular rod is greater than the radius of the stem of the agave sisalana. Accordingto the above structure, the harvester for the leaves of the agave sisalana provided by the invention realizes mechanized harvesting of the leaves of the agave sisalana, thereby changing the industry rule that the agave sisalana can only be manually harvested, greatly reducing the labor intensity of harvesting of the leaves of the agave sisalana, and improving the harvesting efficiency of the leaves of the agave sisalana.

Owner:JIANGSU HIMALAYA NATURAL FIBER PROD

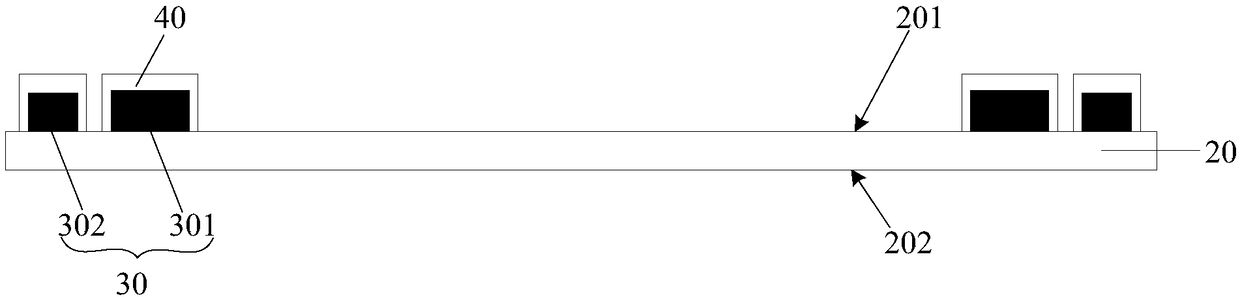

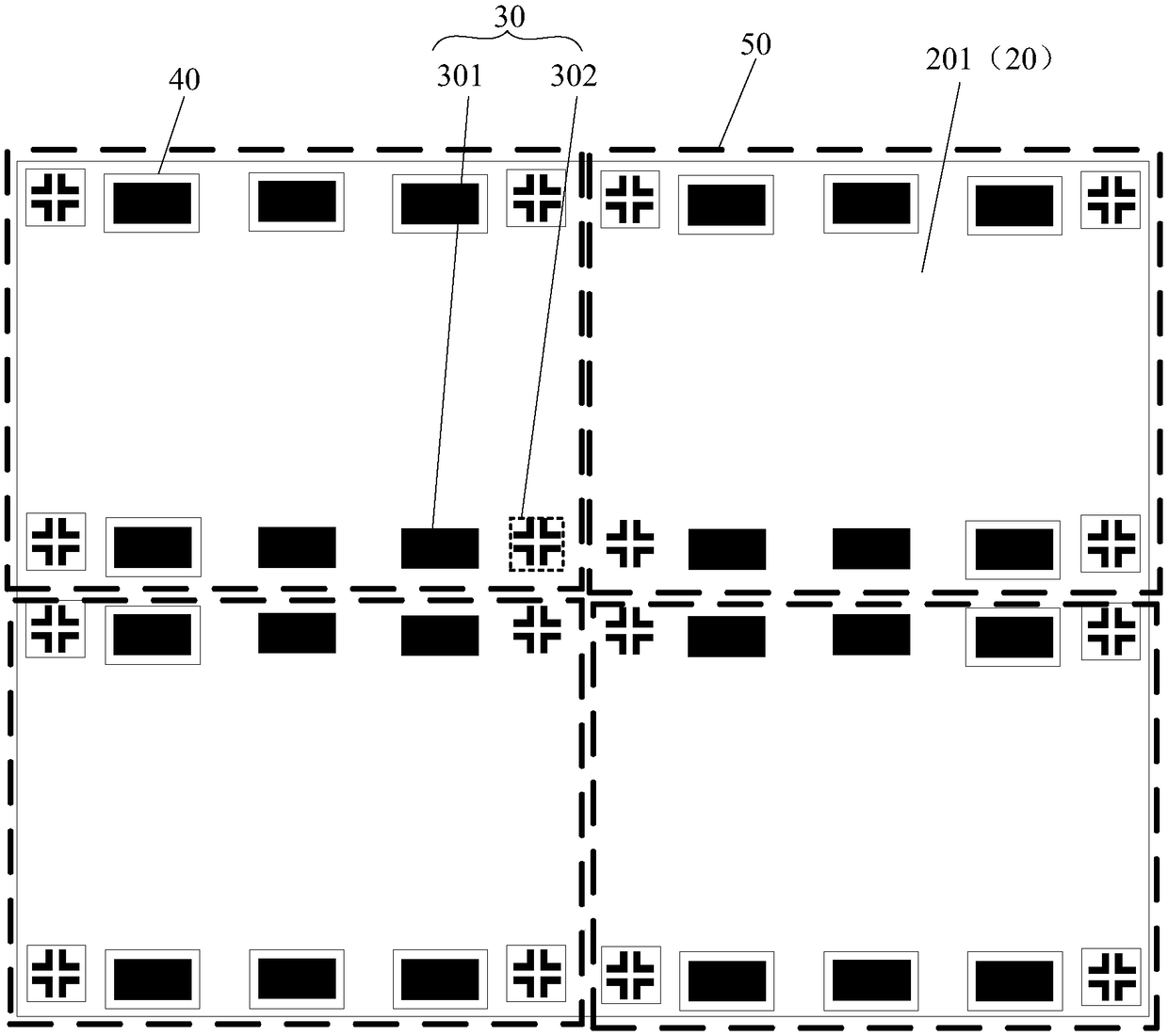

Substrate mother board for display, display panel mother board and preparation method of display panel

InactiveCN109143651AImprove production yieldDoes not affect alignmentNon-linear opticsComputer science

The embodiment of the invention provides a substrate mother board for display, a display panel mother board and a preparation method of a display panel, and relates to the technical field of display.The problem that the cleaning liquid corrodes an alignment marking pattern on the edge of the display panel mother board when the display panel mother board is cleaned can be solved. The substrate mother board for display comprises: a first alignment marking pattern arranged on a first surface of the substrate; wherein the substrate mother board for display further comprises a transparent protection pattern, wherein the protection pattern at least covers the first alignment marking pattern located on the edge of the first surface; the first alignment marking pattern comprises a first sub-alignment marking pattern and / or a second sub-alignment marking pattern, the first sub-alignment marking pattern is used for forming alignment exposure of the pattern on a second surface of the substrate,and the second sub-alignment marking pattern is used for cutting alignment; and the first surface and the second surface are two opposite surfaces of the substrate.

Owner:BOE TECH GRP CO LTD +1

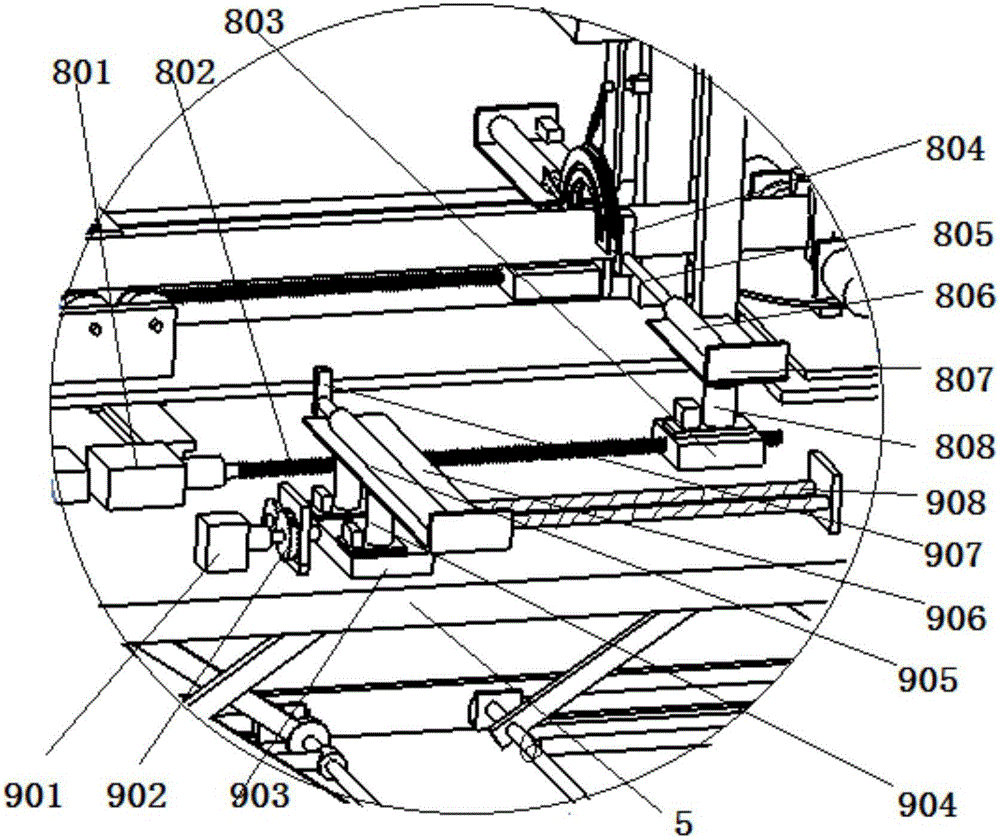

Cutting mechanism of cutting device for batch production of equal-length glass tubes

InactiveCN106396357AReduce workloadHigh precisionEdge grinding machinesGlass severing apparatusBatch productionEngineering

The invention provides a cutting mechanism of a cutting device for batch production of equal-length glass tubes. The cutting mechanism comprises a base and a lifting plate, wherein a backing plate is glidingly connected onto the lifting plate, multiple rollers in uniform single-row distribution are arranged on the backing plate, clamping mechanisms are arranged on the lifting plate, a cutting mechanism body is further arranged on the backing plate, and a milling and grinding mechanism is further arranged on the lifting plate; the cutting mechanism body comprises a support and a cutter arranged on the support, a first arc-shaped connecting plate and a second arc-shaped connecting plate are arranged on the support, a first arc-shaped groove is formed in the first arc-shaped connecting plate, a second arc-shaped groove is formed in the second arc-shaped connecting plate, and the cutter is arranged on a second slider in the second arc-shaped groove. According to the cutting mechanism of the cutting device for batch production of the equal-length glass tubes, stability of force in a cutting process is guaranteed, circumferential cutting around the glass tubes is performed, the glass tubes are prevented from cracking, notches are relatively even, and the cutting effect is better.

Owner:天津南玻节能玻璃有限公司

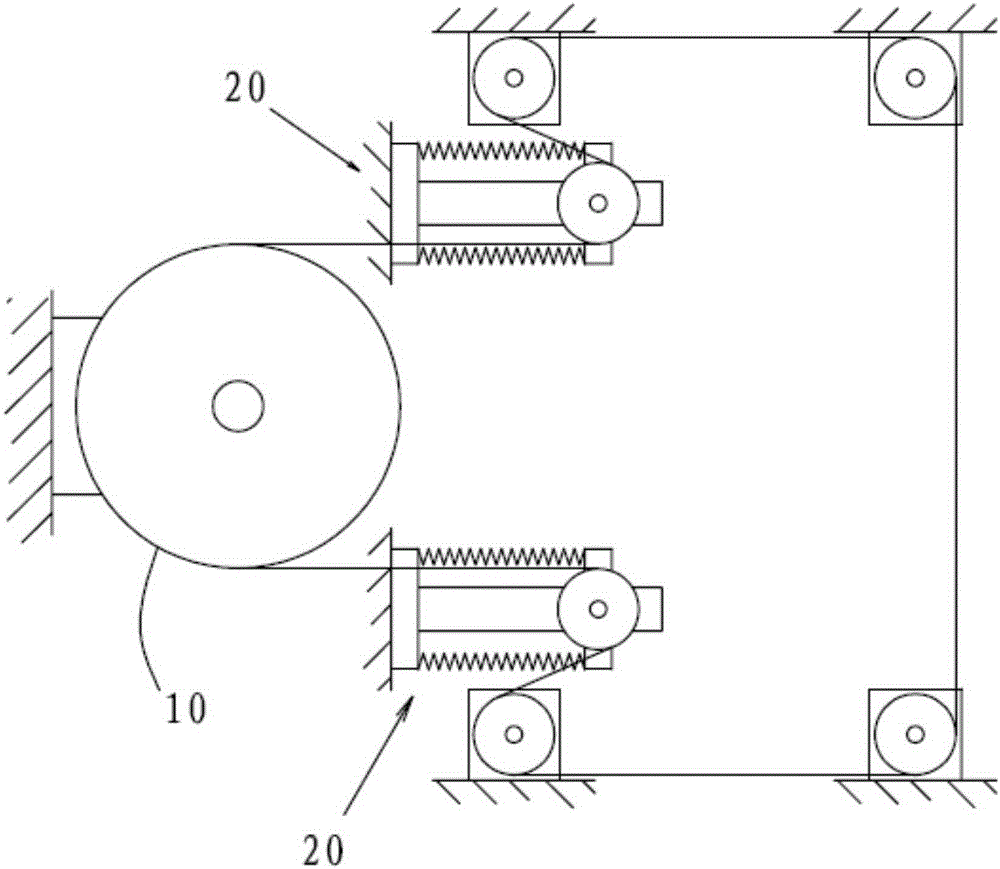

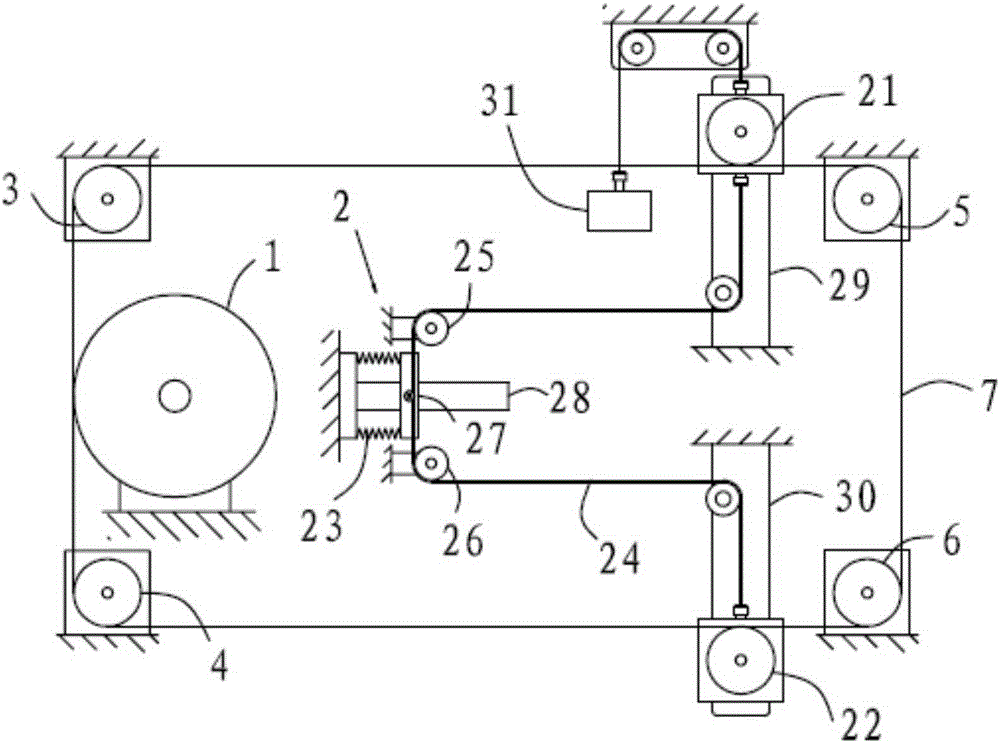

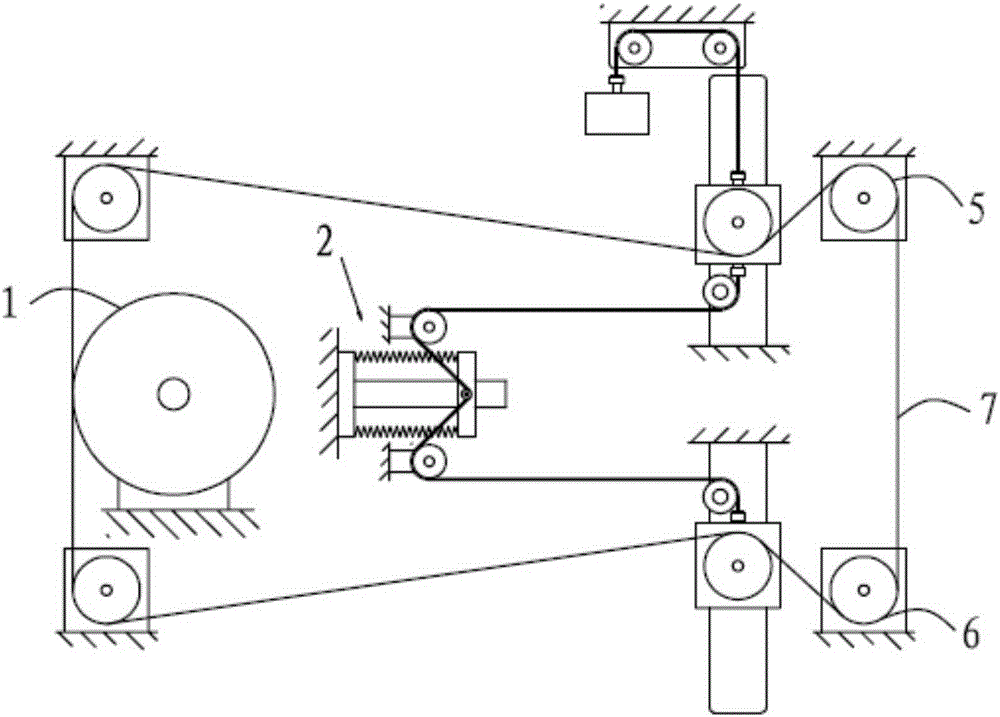

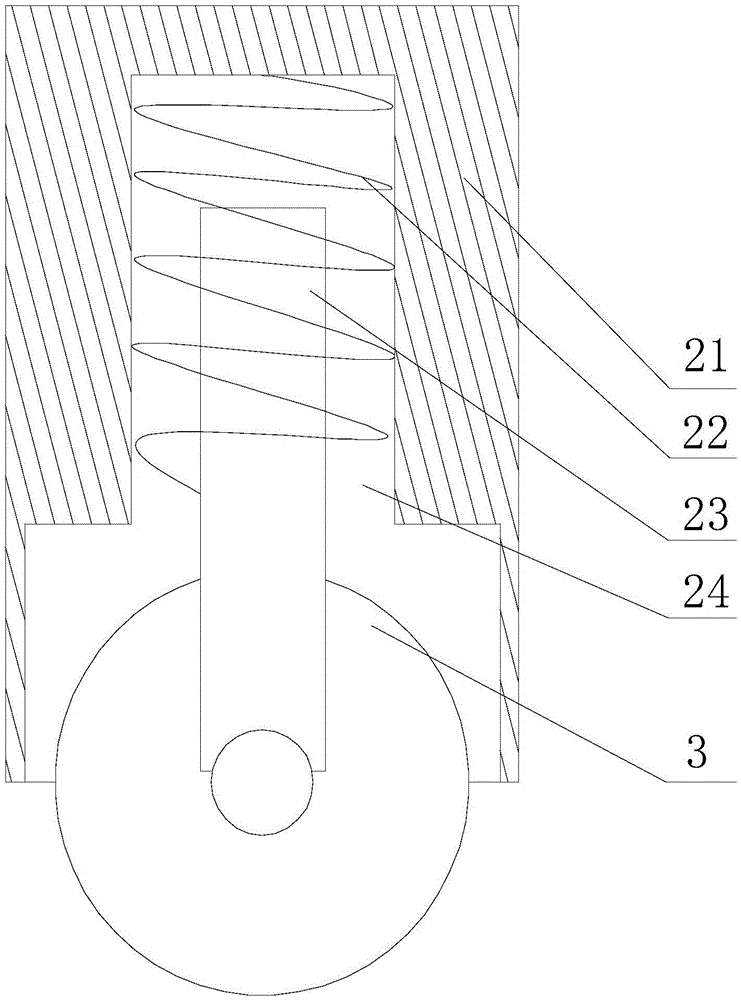

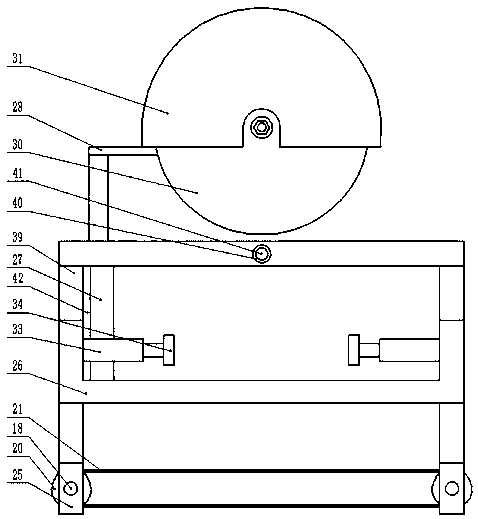

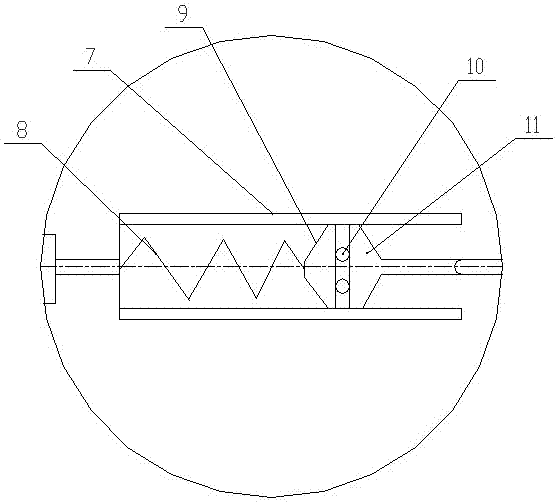

Wire tensioning mechanism for wire cutting machine tool

ActiveCN105215493AGuaranteed stabilityReduce tensionElectrical-based machining electrodesWire cuttingMachine tool

The invention discloses a wire tensioning mechanism for a wire cutting machine tool. The wire tensioning mechanism comprises a wire cylinder, a first bridge guide wheel, a second bridge guide wheel, a first working guide wheel, a second working guide wheel and a wire tensioning device; after metal wires are pulled out from the wire cylinder, the metal wires bypass the first bridge guide wheel, the first working guide wheel, the second working guide wheel and the second bridge guide wheel in sequence and then are fixed on the wire cylinder; the wire tensioning device comprises a first pressing wheel and a second pressing wheel; the first pressing wheel is positioned between the first bridge guide wheel and the first working guide wheel; the second pressing wheel is positioned between the second bridge guide wheel and the second working guide wheel; and the first pressing wheel and the second pressing wheel are matched with the metal wires. The metal wires are tensioned by tightly pressing the metal wires through the first pressing wheel and the second pressing wheel; the wire cylinder receives the upper tensile force and the lower tensile force, so that stress balance is kept and the stability of the wire cylinder is guaranteed; and the distance between the wire tensioning device and the first working guide wheel as well as the distance between the wire tensioning device and the second working guide wheel are shortened, so that the tensioning force, applied to the metal wires, of the wire tensioning device is increased and the cutting quality is guaranteed.

Owner:SUZHOU HANQI CNC EQUIP CO LTD

Induction type equipment for filling package continuously

InactiveCN1696018AEven by forceSimple structureWrapper twisting/gatheringSuccessive articlesElectrical and Electronics engineeringInduction heating

Owner:SHANGHAI JIAO TONG UNIV

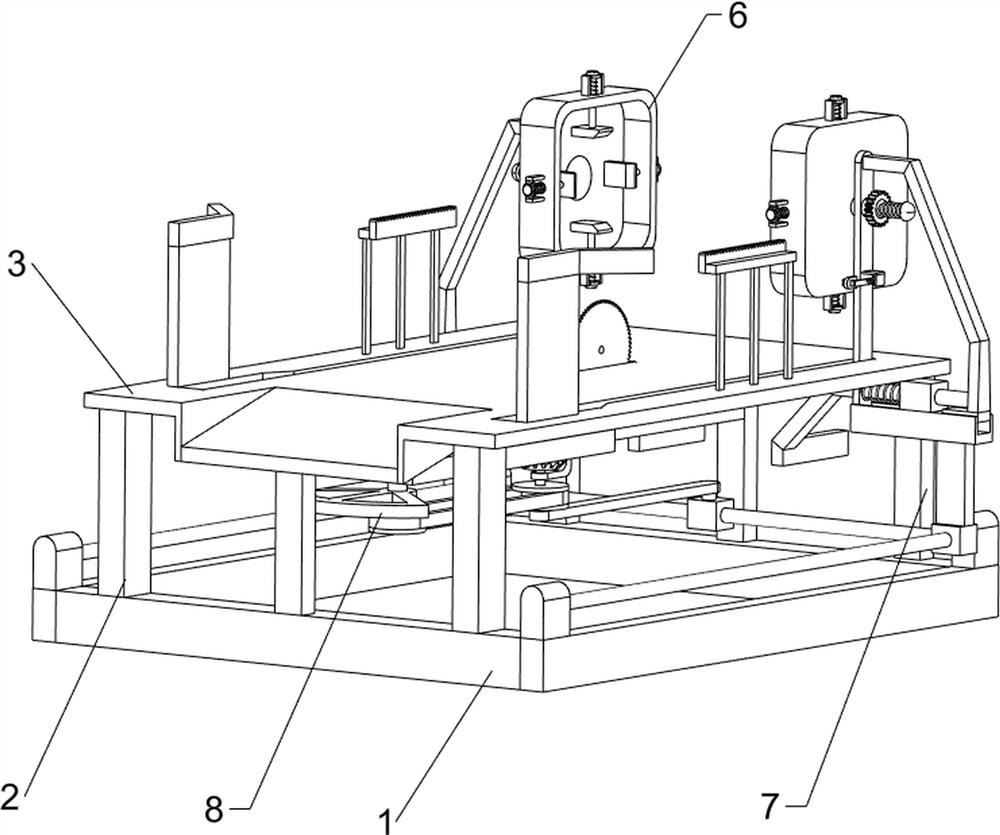

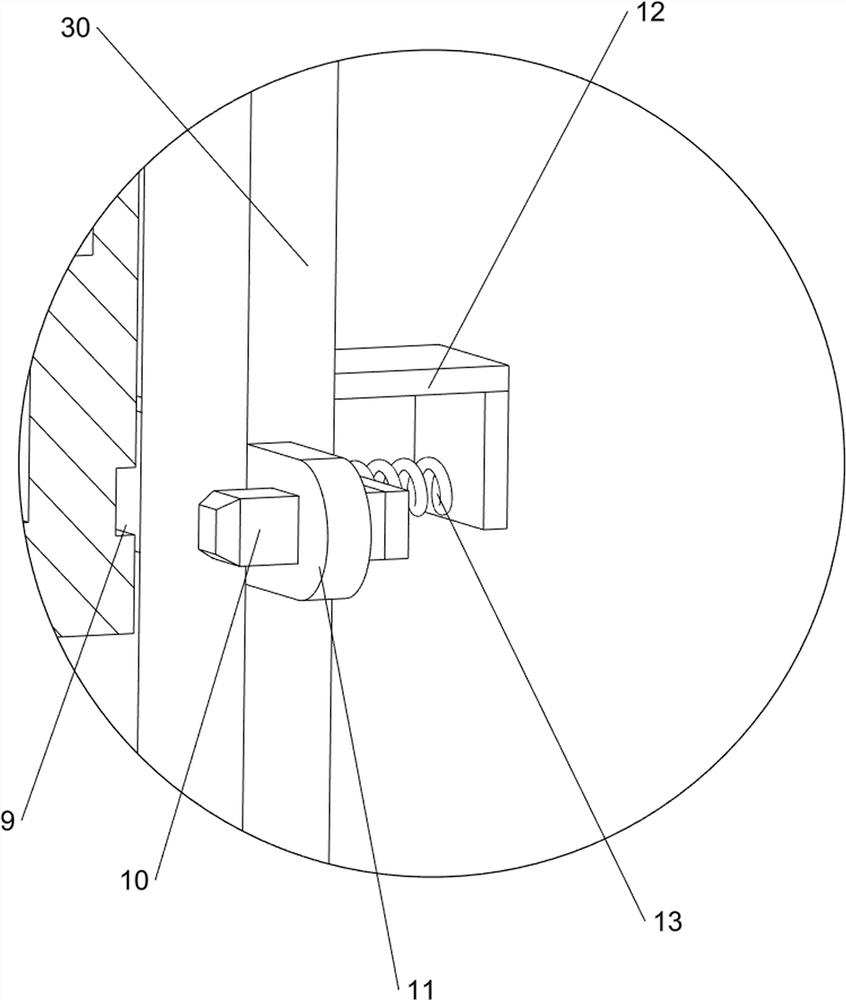

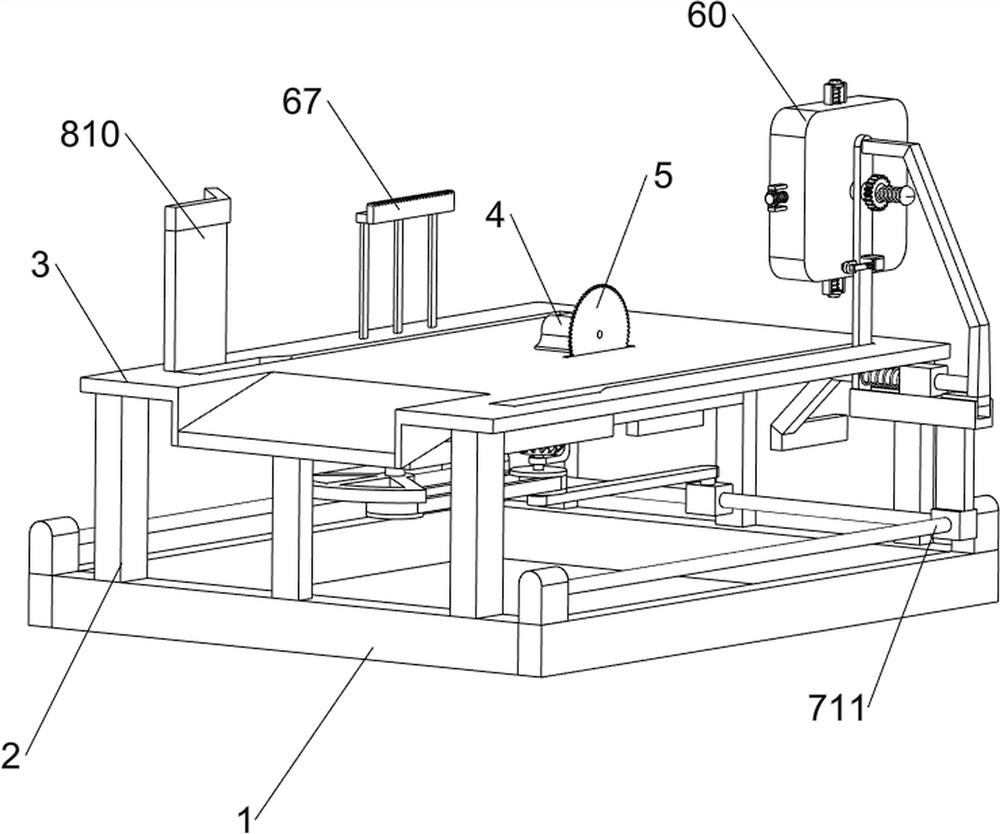

Waste plastic barrel cutting and recycling equipment

InactiveCN112454737APromote sheddingShorter contact distancePlastic recyclingMetal working apparatusElectric machineryWorkbench

The invention relates to cutting and recycling equipment, in particular to waste plastic barrel cutting and recycling equipment. According to the waste plastic barrel cutting and recycling equipment provided, a plastic barrel is automatically cut based on a machine, a cutting process does not need to be touched manually, and the plastic barrel directly slides down after cutting is completed. The waste plastic barrel cutting and recycling equipment comprises a base, a workbench, a cutting saw blade and moving guides, wherein a plurality of supports are evenly arranged at the top of the base; the workbench is connected between the tops of the supports, and a high-speed response motor is arranged at the top of the workbench; the end of an output shaft of the high-speed response motor is connected to the cutting saw blade, and the cutting saw blade is located in the workbench; and guide grooves are formed in the two sides of the top of the workbench, and the moving rods are arranged in theguide grooves in a sliding mode. By arranging a placing frame with two symmetrical sides, the plastic barrel can be clamped and fixed, so as to facilitate cutting; and by arranging the high-speed response motor, the plastic barrel can be completely cut only by rotating for one circle, and convenience and rapidness are achieved.

Owner:陈玉芹

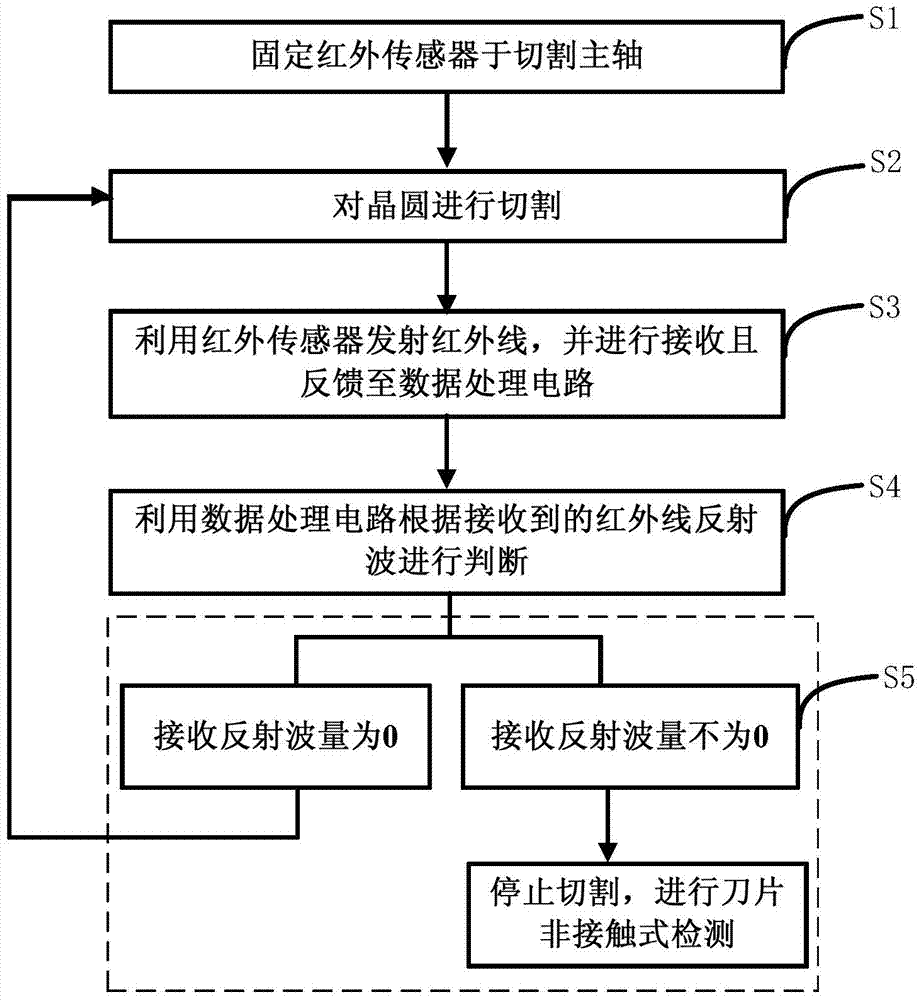

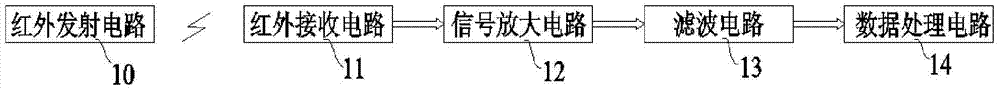

Infrared technology based wafer cutting online detecting system

InactiveCN103522434ACompact structureStrong real-time detectionWorking accessoriesEngineeringSignal amplification

The invention relates to a detecting system, particularly relates to an infrared technology based wafer cutting online detecting system and belongs to the technical field of wafer cutting detecting. According to the technical scheme, the system comprises a transmission shaft and a flange arranged at the end of the transmission shaft. An infrared sensor for detecting cutting ways is fixed on the flange. According to infrared technology based wafer cutting online detecting system, the infrared sensor is used for detecting the cutting ways of a cutting knife during cutting in real time, an infrared receiving circuit is used for receiving the wafer reflection wave amount, a signal amplification circuit and a filter circuit are used for inputting signals into a data processing circuit, and the data processing circuit is used for determining and controlling the working state of the cutting knife according to the wafer reflection wave amount. The system is compact in structure, high in detection instantaneity, capable of guaranteeing wafer normal cutting and guaranteeing the cutting knife against damage and improving the cutting stability and safe and reliable.

Owner:NAT CENT FOR ADVANCED PACKAGING

Teaching laser carving cutter

PendingCN107160043AReduce volumeEasy to carryLaser beam welding apparatusLaser transmitterPlane mirror

The invention discloses a teaching laser carving cutter. The teaching laser carving cutter comprises a base, a laser emitter arranged behind the base, and support rods arranged above four corners of the base. The teaching laser carving cutter further comprises a three-dimensional moving mechanism; a Y-axle moving mechanism comprises a Y-axle round rod, a Y-axle linear guide rail, a Y-axle synchronous belt and a Y-axle motor; an X-axle moving mechanism comprises an X-axle support plate, an X-axle round rod, an X-axle linear guide rail, an X-axle synchronous belt and an X-axle motor; a Z-axle moving mechanism comprises a Z-axle support plate, a rack bracket, a rack, a gear and a Z-axle motor; the bottom end of the rack is connected with a laser head; and a plane mirror is arranged on the laser head. The carving cutter is small in size, convenient in carrying and used for demonstration equipment in teaching, can improve the learning enthusiasm of students, facilitates direct observation of operation conditions of the equipment by the students to improve the practical ability, and is high in carving and cutting precision, excellent in machining quality, convenient in use, wide in application range and excellent in practicability.

Owner:QINZHOU UNIV

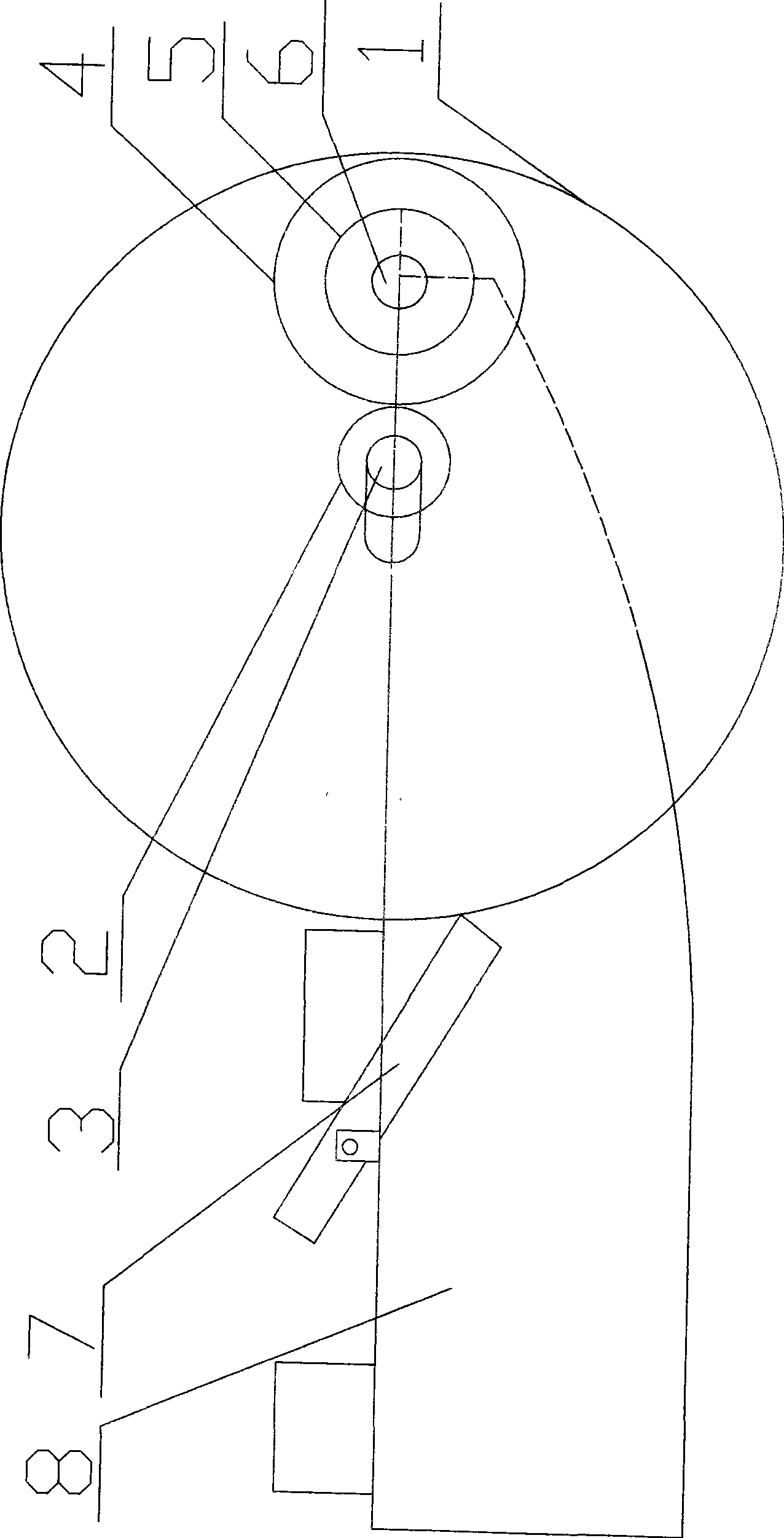

Float grass clearing device

InactiveCN101396015ASimple preparation processLow costWater cleaningHarvestersDrive shaftEngineering

A device for removing water grass comprises an external knife rest wheel (1), an external belt wheel (2), an external drive shaft (3), an internal knife rest wheel (4), an internal belt wheel (5), an internal drive shaft (6), a water grass conveyor device (7) and a boat body (8). The external belt wheel (2) is arranged on the external drive shaft (3), the internal knife rest wheel (4) and the internal belt wheel (5) are respectively arranged on the internal drive shaft (6), the external knife rest wheel (1) and the external belt wheel (2) are fixed on the boat body (8) by the external drive shaft (3), the internal knife rest wheel (4) and the internal belt wheel (5) are fixed on the boat body (8) by the internal drive shaft (6), the external belt wheel (2) and the internal belt wheel (5) are respectively connected with a power source by a transmission chain, the water grass conveyor device (7) is fixedly connected with the boat body (8), the external knife rest wheel (1) is eccentrically connected with the external drive shaft (3), and the internal knife rest wheel (4) is arranged inside the external knife rest wheel (1). With the structure, the device for removing water grass can realize second removal by applying a drawing force on water grass in the removal process.

Owner:张琳

Aluminum profile machining device

InactiveCN112828396AScientific and reasonable structureEasy to useMetal working apparatusMaintainance and safety accessoriesHydraulic cylinderMetallurgy

The invention discloses an aluminum profile machining device. The aluminum profile machining device is characterized in that an arc-shaped conveying table is welded to the top end of a fixed supporting frame, roller mounting grooves are formed in the top end of the arc-shaped conveying table, moving rollers are installed on the inner side of the roller mounting grooves, and the moving rollers are connected to transmission gears through rolling rods; an aluminum ingot cutting knife set is fixedly installed at the bottom end of a lifting hydraulic cylinder, a heating box is embedded into the top end of a fixed supporting plate, a two-way lead screw penetrates through one end of the heating box, a rotating groove is formed in the inner side of the heating box, and rotating wheels are installed on the inner side of the rotating groove; an aluminum ingot is driven to move into the heating box through the moving rollers, an external mechanical arm is not needed, and the aluminum ingot can be directly conveyed to move, so that the cut aluminum ingots are conveniently and rapidly conveyed into the heating box; and the situation that thermal stress cracks occur to the aluminum ingots due to the fact that part of the aluminum ingots are heated unevenly when the aluminum ingots are heated is avoided through circulating heat supply, and the situation that the aluminum ingots influence follow-up manufacturing is avoided.

Owner:黄嘉欣

Chipping recovering structure of cutting machine

InactiveCN106799622AGuaranteed normal cuttingPrevent splashMaintainance and safety accessoriesEngineeringBroom

The invention discloses a chipping recovering structure of a cutting machine. The chipping recovering structure comprises a working table; a shielding over is installed on the working table, an opening used for workpiece in and out is formed in the side edge of the shielding cover, and a cavity is formed in the shielding cover; an annular collecting groove is formed in the bottom of the cavity, the side edge of the colleting groove is connected with the side wall of the working table, and a telescopic arm movably penetrates through the top of the shielding cover and is installed over the working table; a cutting wheel is rotatably installed at the tail end of the telescopic arm, the suction end of a draught fan is connected with the collecting groove, and a filter screen is installed on the collecting groove; and a space is reserved between the filter screen and the bottom of the collecting groove. During cutting, produced metal chippings downwards slide in a smooth mode along the inner wall of the cavity till dropping into the annular collecting groove, after cutting is finished, the collecting groove can be cleared through simple instruments such as a broom, and meanwhile the metal chippings accumulated in the collecting groove are centrally recovered to achieve secondary using.

Owner:重庆市木越机械制造有限公司

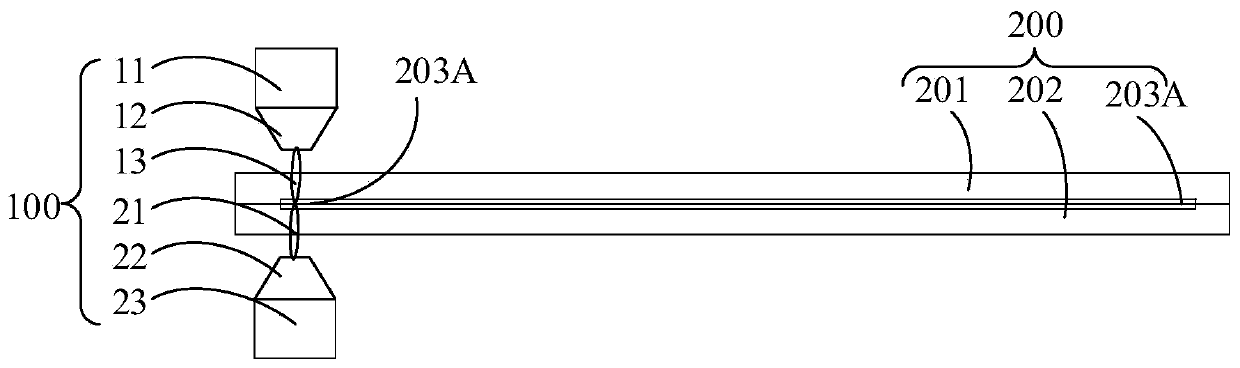

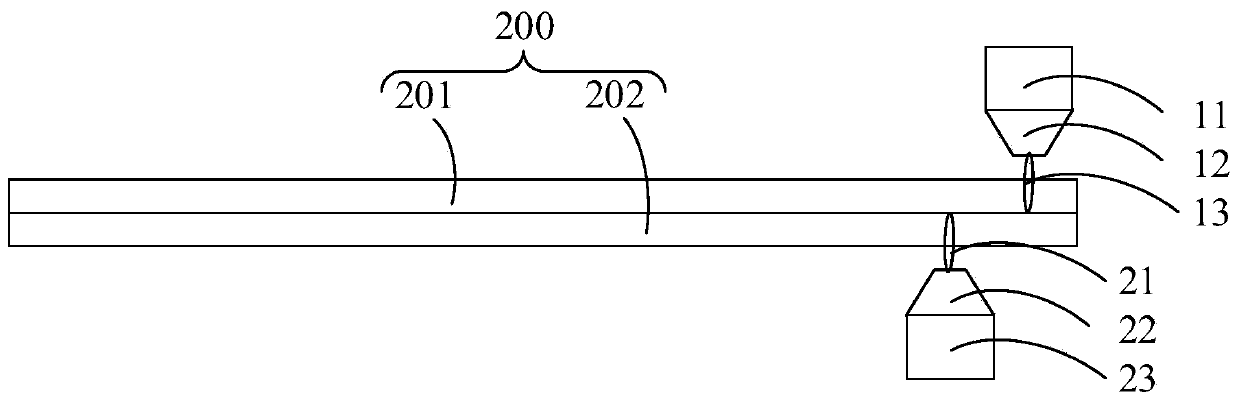

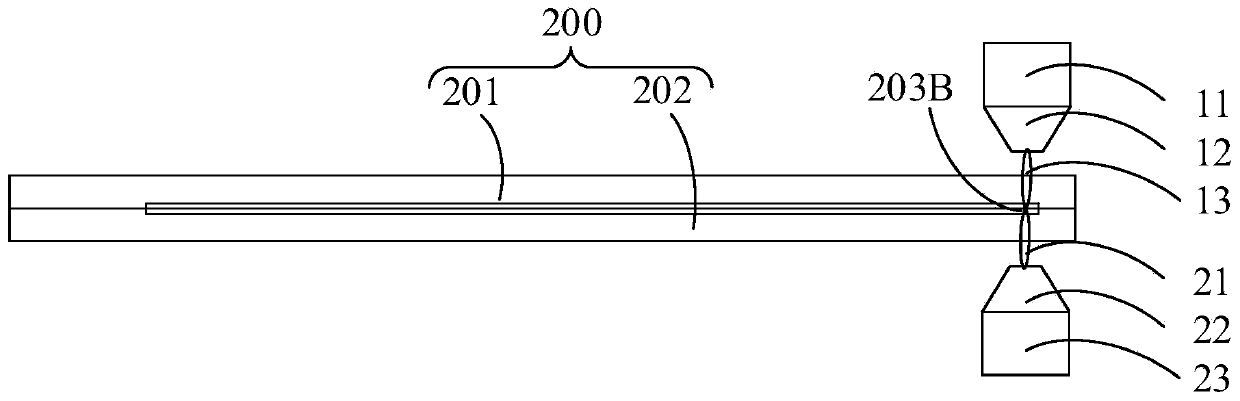

Cutting mechanism and method and display panel

ActiveCN109794984AAvoid breakingGuaranteed normal cuttingMetal working apparatusColor filmOutput device

The invention provides a cutting mechanism and method and a display panel. The cutting mechanism comprises a first output device and a second output device; the first output device drives a first cutting wheel to move along a first path to cut an array substrate of the display panel; the second output device drives a second cutting wheel to move along a second path to cut a color film substrate ofthe display panel; and in a first superposition section, the second path coincides with the first path to enable the first cutting wheel and the second cutting wheel to jointly cut sealing rubber onan edge between the array substrate and the color film substrate. The cutting mechanism and method and the display panel have the advantage that the display panel is prevented from breaking during piece split due to the fact that the sealing rubber is subjected to double-surface cutting or the sealing rubber is completely cut.

Owner:HKC CORP LTD

Steel pipe cutting device

InactiveCN109108368AGuaranteed normal cuttingGuaranteed to stopTube shearing machinesShearing machine accessoriesEngineeringAlternating current

The invention relates to the technical field of steel pipe cutting, in particular to a steel pipe cutting device. The device comprises a base. Supporting plates are fixedly mounted on the two sides ofthe lower end of the base correspondingly. A second alternating current asynchronous motor is fixedly mounted on one side of the lower end of the portion, between the supporting plates, of the base.An output shaft of the second alternating current asynchronous motor is fixedly connected with a second driving rotary shaft. A second driven rotary shaft is arranged on the second driving rotary shaft through a first transmission structure, penetrates through the base and stretches to the upper end of the base. A guide wheel is fixedly mounted on the portion, located at the upper end of the base,of the second driven rotary shaft. A cutting frame is fixedly mounted in the position, adjacent to the guide wheel, of the base. Moving plates are arranged in the cutting frame through sliding structures correspondingly. According to the steel pipe cutting device, the second alternating current asynchronous motor is utilized firstly for driving the guide wheel to achieve a guide effect on a to-be-cut steel pipe, the cutting efficiency can be greatly improved, meanwhile, electric telescopic rods drive a fixing plate to move up and down, and it can be guaranteed that a cutting disc starts and stops cutting the steel pipe.

Owner:温州市宇田钢管有限公司

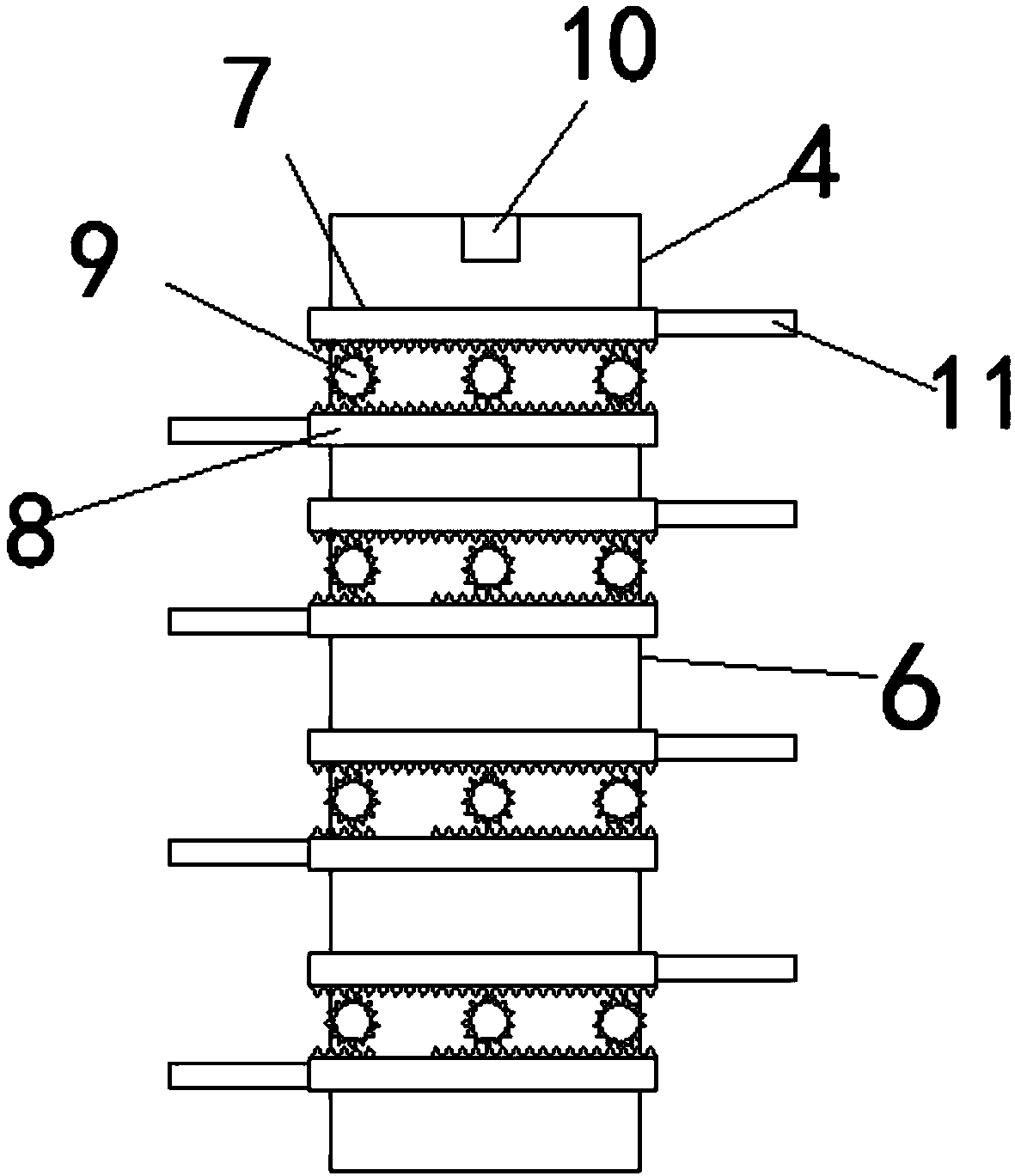

High-efficient Chinese medicine grinding machine

InactiveCN108355785AGuaranteed normal cuttingGuaranteed GrindingHollow article cleaningElectrostatic cleaningEngineeringMechanical engineering

The invention discloses a high-efficient Chinese medicine grinding machine. The high-efficient Chinese medicine grinding machine comprises a grinding chamber and a collecting chamber, wherein the collecting chamber is positioned at the bottom end of the grinding chamber, and a feed inlet is formed in the middle part of the top end of the grinding chamber; a fixed shaft is arranged at the top end of the grinding chamber, and a plurality of groups of cutting devices are arranged on the fixed shaft; the cutting devices comprise first gears, second gears and third gears, wherein the fixed shaft issleeved with the first gears and the second gears, and the third gears matched with the first gears and the second gears are arranged on the middle parts of the first gears and the second gears; a first motor is arranged in the fixed shaft, and a rotating shaft of the first motor is rotatably connected with the third gears; and cutters are symmetrically arranged on both sides of the first gears and the second gears, a conveying belt is arranged at the bottom end of the grinding chamber, and a plurality of filtering holes are uniformly formed in the conveying belt. The high-efficient Chinese medicine grinding machine has the beneficial effects that Chinese medicinal materials are cut and grinded in the grinding chamber from various directions, so that the grinding accuracy can be greatly ensured, and a dust collecting plate and a cleaning brush can thoroughly clean and collect the residual Chinese medicinal materials in a storage box and simultaneously reduce residual impurities.

Owner:钱进

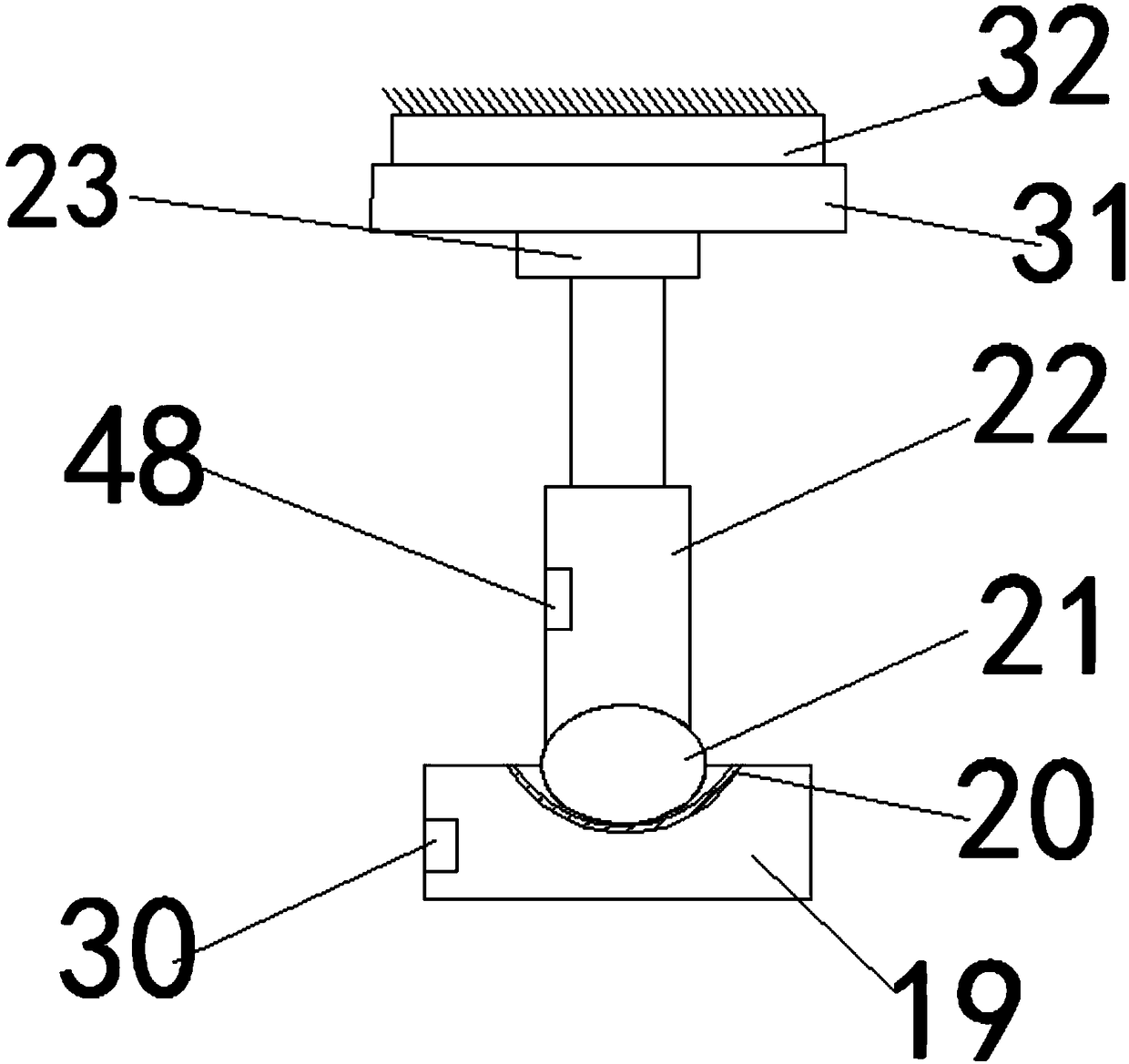

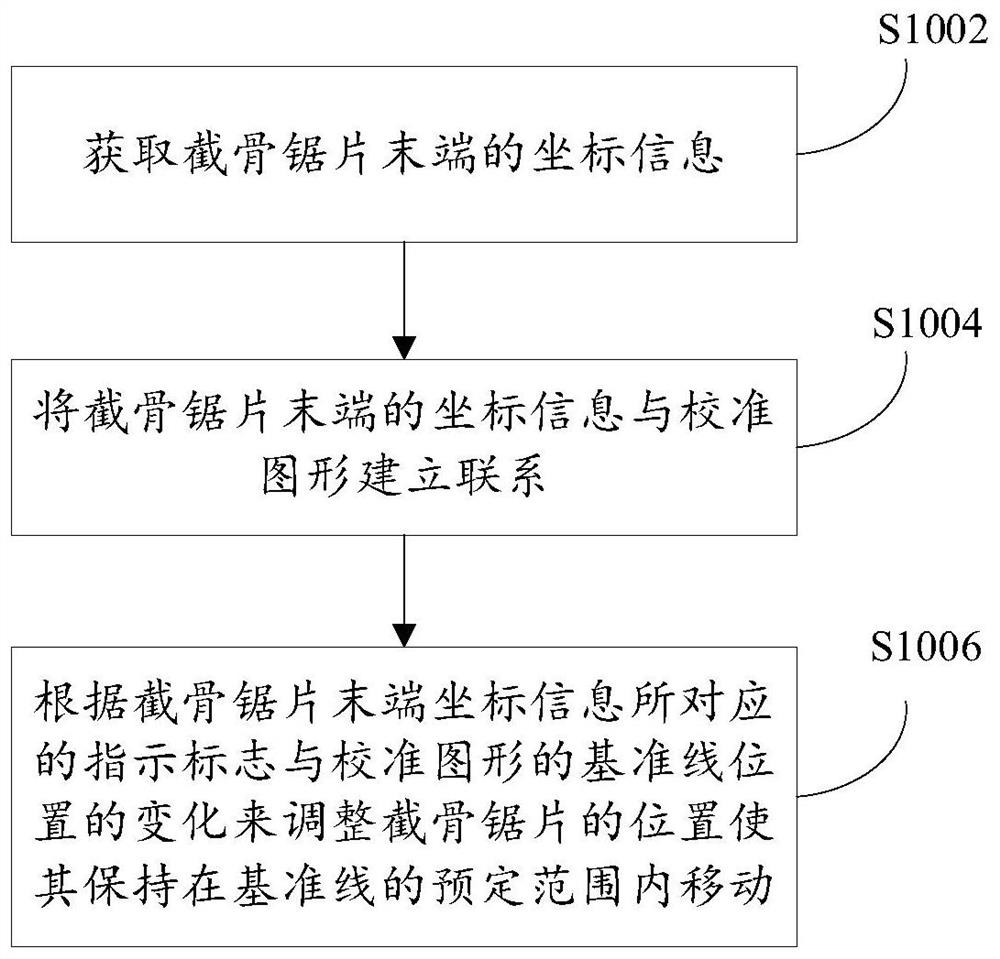

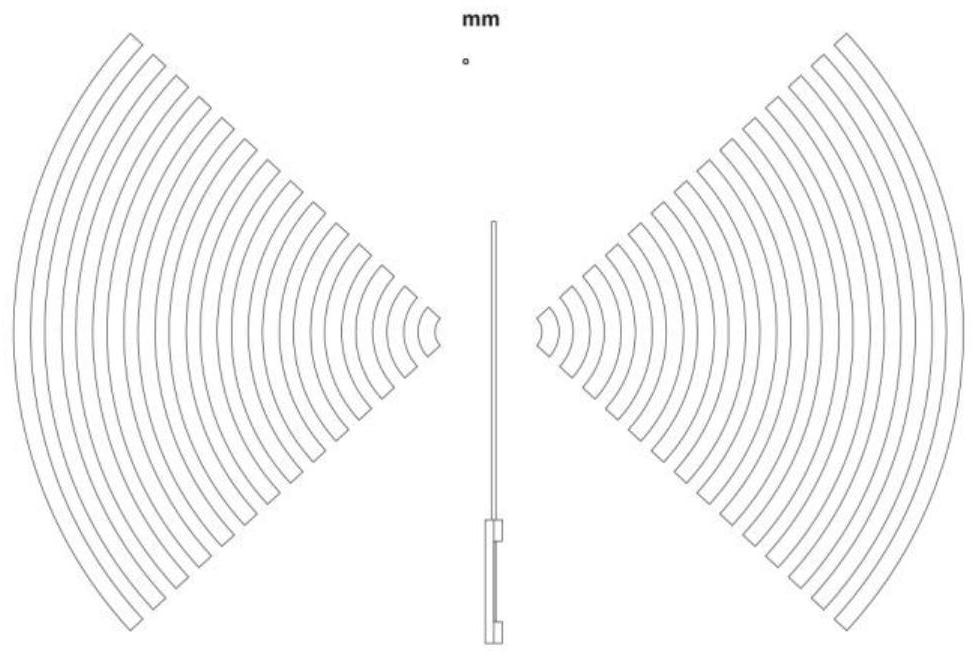

Osteotomy saw blade shaking preventing method and system

PendingCN111772727AGuaranteed normal cuttingGuaranteed accuracySurgical sawsStructural engineeringOsteotomy

The invention discloses a saw blade shaking preventing method and device, a storage medium and a processor. The method comprises the steps of obtaining coordinate information of the end of a saw blade; enabling the coordinate information of the end of the saw blade to relate with creation of calibration patterns, wherein the calibration patterns are patterns with reference lines, under the condition that the end of the saw blade is overlapped with a target cutting surface, the coordinate information of the end of the saw blade is indicated at the position of the reference line of the calibration patterns by an instructive mark corresponding to the inner part of a screen, and the instructive marks feeds back the coordinate information of the end of the saw blade in the calibration patterns;and according to the instructive mark corresponding to the coordinate information of the end of the saw blade, and the position changes of the reference lines of the calibration patterns, adjusting the position of the saw blade to enable the saw blade to be maintained to move in the preset range of the reference line. According to the saw blade shaking preventing method and device, the technicalproblem that in the prior art, through cooperation with characteristics of a mechanical arm, the saw blade is difficult for real-time guaranteeing of the precision of cutting positions, can be solved.

Owner:BEIJING HURWA ROBOT MEDICAL TECH CO LTD

Automatic machining equipment for high-performance stainless steel seamless steel pipe

PendingCN114535696AStable stateReduce deformationMetal sawing devicesMetal sawing accessoriesPipeMachining

The high-performance stainless steel seamless steel pipe automatic machining equipment comprises a working platform, a driving device is arranged on one side of the working platform, an electric sliding block for driving a steel pipe to be pushed is arranged on one side of the working platform, and a sliding rod allowing the electric sliding block to slide is arranged in the electric sliding block; and a cutting platform used for cutting the steel pipe is arranged on one side of the working platform, and anti-extrusion assemblies used for preventing the steel pipe from being excessively extruded in the cutting process are arranged on one side of the electric sliding block and one side of the cutting platform correspondingly. According to the steel pipe cutting device, it is guaranteed that steel pipes are kept in a stable state in the conveying, extruding and cutting processes, the steel pipe deformation phenomenon caused by excessive extruding is reduced, meanwhile, in the cutting process, the transmission assembly is used for providing power for the cleaning assembly, chippings accumulated in gaps of the cutting platform are effectively cleaned, and normal cutting of the steel pipes is guaranteed.

Owner:浙江永业钢管有限公司

Continuous automatic cutting device of profile steel for building

ActiveCN110238457AEasy to pushReduce cutting timeFeeding apparatusMetal working apparatusElectromagnetic clutchEngineering

The invention discloses a continuous automatic cutting device of profile steel for building. The continuous automatic cutting device of the profile steel for building comprises a cutting base, wherein a profile steel storage device is arranged on one side of the cutting base, a controller is arranged on the cutting base, an automatic profile steel pushing device is arranged on one side above the cutting base, and a reciprocating cutting device is arranged on the other side of the cutting base. The T-shaped baffle plate is driven by a variable-frequency and variable-speed motor to move, so that the profile steel is pushed to move at a high speed; when a cutting position moves below a cutting blade, the rotating speed of the variable-frequency and variable-speed motor is adjusted, and a reciprocating screw starts to rotate under the action of an electromagnetic clutch, so that a U-shaped reciprocating platform can move synchronously along with the movement of the profile steel, and the cutting blade can cut the profile steel in the moving process, thus saving the cutting time.

Owner:湖北华信建设工程有限公司

Manual Chestnut Sheller

InactiveCN105455157BAutomatically adjust the clamping distanceGuaranteed normal cuttingHuskingHullingHigh volume manufacturingEngineering

Owner:HUANGHE S & T COLLEGE

Debris blocking structure of cutting machine tool

InactiveCN106799640APrevent splashing aroundAvoid processing environmental pollutionMaintainance and safety accessoriesBroomEngineering

The invention discloses a debris blocking structure of a cutting machine tool. The debris blocking structure of the cutting machine tool comprises a worktable; a blocking cover is installed on the worktable, an opening for workpiece entering and existing is formed in the side edge of the blocking cover, an cavity is formed in the blocking cover, an annular collecting groove is formed in the bottom of the cavity, and the side edge of the collecting groove is connected with the side wall of the worktable; a telescopic arm movably penetrates through the top of the blocking cover and is installed above the worktable, and a cutting wheel is rotatably installed at the tail end of the telescopic arm; the air suction end of the draught fan is connected with the collecting groove; and a filtering net is installed on the collecting groove, and a gap is reserved between the filtering net and the bottom of the collection groove. During cutting, generated debris slides downwards along the inner wall of the metal debris till falling into the annular collecting groove; after cutting is completed, the collecting groove can be cleaned through simple tools such as a broom, meanwhile, the metal debris accumulated in the collection groove can be centrally recycled, and consequently secondary utilization can be achieved.

Owner:重庆市木越机械制造有限公司

Using method of fragment blocking device used for metal plate cutting

InactiveCN106799623AGuaranteed normal cuttingPrevent splashMaintainance and safety accessoriesEngineeringBroom

The invention discloses a using method of a fragment blocking device used for metal plate cutting. The using method comprises the following steps that a workpiece is pushed to a working table in a sliding manner, and a cutting wheel is in contact with the upper surface of the workpiece; the opening of a shielding cover is sealed, and the cutting wheel is started to cut the workpiece; during cutting, generated metal fragments start to slide down along the inner wall of a cavity and finally fall into a collecting groove, and the generated metal fragments are directly blocked by a sealing organ cover to prevent the metal fragments from catapulting into the movable part of a telescopic arm; when a rotary shaft makes diameter run-out, a spring is stressed with upward force to have compressive deformation, and within short time, the spring generates elastic force in the opposite direction to offset applied stress; the fine fragments falling at the bottom of the collecting groove are absorbed by the air suction end of a draught fan and are transmitted out of the shielding cover; the rest metal fragments are isolated on a filter screen; and after cutting, a broom and the like can be manually adopted to recycle the metal fragments with larger diameters in the collecting groove.

Owner:重庆市木越机械制造有限公司

Particle-forming disk pelleting machine

InactiveCN106378059ANot easy to stickImprove molding rateDrying solid materials with heatGranulation by material expressionHydraulic cylinderInfrared lamp

The invention provides a particle-forming disk pelleting machine. The particle-forming disk pelleting machine comprises a base, a pelleting device and a spheroidizing device, wherein the pelleting device is rotationally connected with the base; the base is also provided with a high energy accumulation infrared lamp; the pelleting device comprises a main material pressing barrel and a side material pressing barrel; the main material pressing barrel and the side material pressing barrel are communicated through a pipeline; a main material pressing mechanism is arranged above the main material pressing barrel; a side material pressing disk is arranged above the side material pressing barrel; multiple small holes which are uniformly distributed are formed in the bottom part of the side material pressing barrel; a cutter is also arranged at the bottom part of a first support; the spheroidizing device comprises a spheroidizing plate and a material retaining plate; first hydraulic cylinders are arranged at two symmetric sides of the spheroidizing plate. According to the particle-forming disk pelleting machine provided by the invention, the granulation rate of a water quality improver is increased through a simple device, the processing cost is reduced, the processing efficiency is increased to the same degree, and the benefit is increased.

Owner:TIANJIN RONG LEE BIOTECH DEV CO LTD

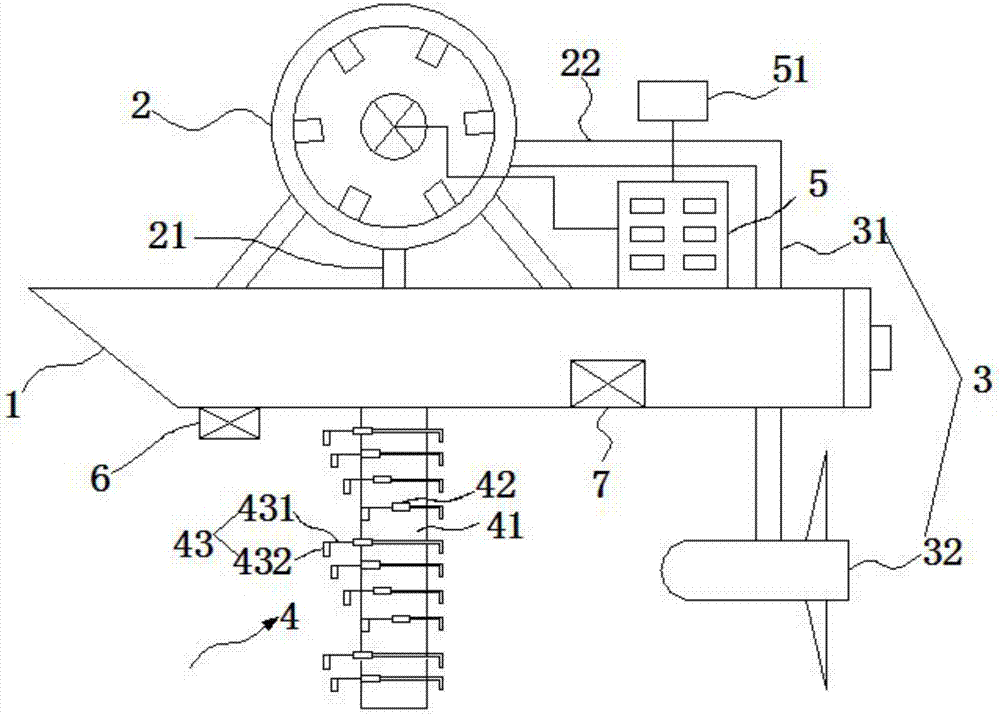

Submerged plant harvesting device

InactiveCN107018747AFlexible moving processSolve power problemsHarvestersRenewable energy machinesUnderwaterRadar

The invention discloses a submerged plant harvesting device. The submerged plant harvesting device comprises floating body equipment, the floating body equipment is provided with a solar power device, the solar power device comprises a rotating shaft and an output shaft, a propelling device is arranged on one side of the floating body equipment and comprises a propeller component and a drive component, a harvesting device is arranged at the lower part of the floating body equipment and comprises a cutting shaft, a plurality of knife holders are distributed spirally on the cutting shaft, a cutting knife is mounted on the knife holder, the floating body equipment is further provided with a controller, a radar detecting device is arranged at the bottom of the floating body equipment and located on the opposite position of the propelling device, and a warning device is arranged in the floating body equipment. The submerged plant harvesting device is reliable in structure, intelligent to control, and flexible to move, all the root part of the submerged plant is harvested, the submerged plant grows normally, the excellent underwater submerged plant landscape is built, meanwhile, the labor intensity of a staff is reduced, and the labor cost is reduced.

Owner:巢湖市银环航标有限公司

Sweep collecting structure of machine tool machining

InactiveCN106799633AGuaranteed normal cuttingPrevent splashMaintainance and safety accessoriesEngineeringBlock match

The invention discloses a sweep collecting structure of machine tool machining. The sweep collecting structure comprises a worktable; a shielding cover is mounted on the worktable; an opening allowing a workpiece to enter and go out is formed in the side of the shielding cover; a cavity is formed in the shielding cover; an annular collecting groove is formed in the bottom of the cavity; and the side of the collecting groove is connected with the side wall of the worktable. A telescopic arm movably penetrates through the top of the shielding cover, and a cutting wheel is rotatably arranged at the tail end of the telescopic arm. A filter screen is mounted on the collecting groove, and a gap is reserved between the filter screen and the bottom of the collecting groove. The collecting groove is arranged obliquely in the circumferential direction of the bottom of the cavity, a sliding block matched with the collecting groove is slidably arranged at the end, in the high position, of the filter screen, and traction ropes are connected on the two sides of the sliding block correspondingly. At the time of cutting, produced metal sweeps start to slide downward along the inner wall of the cavity until falling into the annular collecting groove, and after cutting is finished, the collecting groove can be cleaned by simple tools such as a broom. Meanwhile, the metal sweeps accumulated in the collecting groove are intensively recycled to achieve secondary utilization.

Owner:重庆市木越机械制造有限公司

A special holder for cartilage trimming

InactiveCN102283691AImprove clamping stabilityIncrease success rateSurgical forcepsOperational stabilityEar nose throat

The invention relates to a clamp holder for trimming cartilage, which is used for trimming the cartilage during ear-nose-throat department surgery. The clamp holder consists of a handle and disc-like contact surfaces, wherein the handle is connected with the disc-like contact surfaces through a rotating shaft, and comprises holding parts and a reed; the holding parts are used for adjusting the space between the disc-like contact surfaces through the rotating shaft; and the disc-like contact surfaces are contacted with the cartilage to be trimmed through a lower pallet and an upper cover plate. By the clamp holder, the problem of low operation stability in the prior art is solved. A surgeon can trim the cartilage at various angles, so that the clamp holder is easy and convenient to operateand saves time.

Owner:FOURTH MILITARY MEDICAL UNIVERSITY

Chipping-blocking mechanism used for metal plate machining

InactiveCN106799644AGuaranteed normal cuttingPrevent splashMaintainance and safety accessoriesEngineeringBroom

The invention discloses a chipping-blocking mechanism used for metal plate machining. The chipping-blocking mechanism comprises a working table; a shielding cover is installed on the working table, an opening is formed in the side edge of the shielding cover, and a cavity is formed in the shielding cover; a collecting groove is formed at the bottom of the cavity, the side edge of the collecting groove is connected with the side wall of the working table, and a cutting wheel is rotatably installed at the tail end of a telescopic arm; the suction end of a draught fan is connected with a collecting groove, a filter screen is installed on the collecting groove, and a space is reserved between the filter screen and the bottom of the collecting groove; and limiting blocks are installed at the two ends of the working table, sunken portions can be formed in the opposite side walls of the two limiting blocks in the direction away from the center of the working table, and rubber protrusions are installed in the middles of the sunken portions. During cutting, produced metal chippings star downwards sliding in a smooth mode along the inner wall of the cavity till dropping into the annular collecting groove, and after cutting is finished, the collecting groove can be cleared through simple instruments such as a broom; and meanwhile, the metal chippings accumulated in the collecting groove are centrally recovered to achieve secondary using.

Owner:重庆市木越机械制造有限公司

Using method of cutting machine tool capable of achieving recovering of metal chippings

InactiveCN106799636AGuaranteed normal cuttingPrevent splashMaintainance and safety accessoriesBroomMachine tool

The invention discloses a using method of a cutting machine tool capable of achieving recovering of metal chippings. The using method comprises the following steps that a workpiece is slidably pushed into a clamping area composed of two oppositely-arranged limiting blocks on a working table directly, and a cutting wheel makes contact with the upper surface of the workpiece; then an opening of a shield cover is closed, and the cutting wheel starts cutting the workpiece; during cutting, the produced metal chippings downwards slide in a smooth mode along the inner wall of a cavity till dropping into an annular collecting groove, and when vibration is generated during workpiece cutting, a protrusion makes contact with the side wall of the workpiece all the time; through self-deformation or deformation recovering, vibration generated by the workpiece is eliminated, when a rotary shaft generates radial run-out, a spring is subjected to upward force, and compressive deformation occurs; elastic force in opposite direction is generated by the spring in a short time to be counteracted with imposed stress; and after cutting is finished, the collecting groove can be cleared through a broom and the like to achieve secondary using.

Owner:重庆市木越机械制造有限公司

Waste recovery device used after metal piece cutting

InactiveCN106799637AGuaranteed normal cuttingPrevent splashMaintainance and safety accessoriesBroomMetal

The invention discloses a waste recovery device used after metal piece cutting. The waste recovery device comprises a workbench. A shielding cover is mounted on the workbench. An opening allowing moving-in and moving-out of workpieces is formed in the side edge of the shielding cover. A cavity is formed in the shielding cover. An annular collection tank is arranged at the bottom of the cavity. The side edge of the collection tank is connected with the side wall of the workbench. A telescopic arm movably penetrates the top of the shielding cover and is arranged over the workbench. A cutting wheel is rotationally arranged at the tail end of the telescopic arm. A circular-truncated-cone-shaped sealed organ cover is arranged on the inner wall of the top end of the shielding cover. The movable end of the sealed organ cover is connected with the outer circumferential wall of the telescopic arm. By the adoption of the waste recovery device, metal chippings generated during cutting start to slide downwards along the inner wall of the cavity and do not stop sliding until the chippings fall into the annular collection tank; and after cutting is completed, the collection tank can be cleaned with simple tools such as a broom, meanwhile the metal chippings accumulated in the collection tank are recovered in a concentrated manner, and secondary utilization is achieved.

Owner:重庆市木越机械制造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com