Continuous automatic cutting device of profile steel for building

An automatic cutting device, cutting device technology, applied in the direction of positioning device, feeding device, clamping, etc., can solve the problem of wasting time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

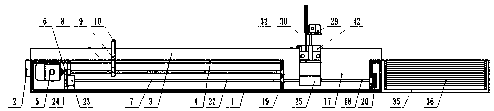

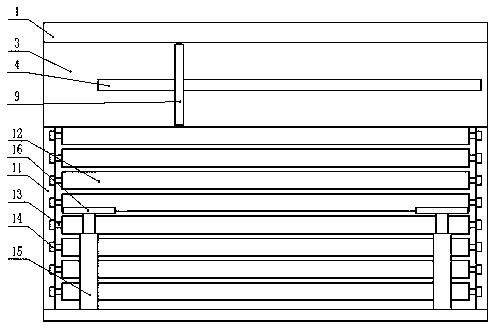

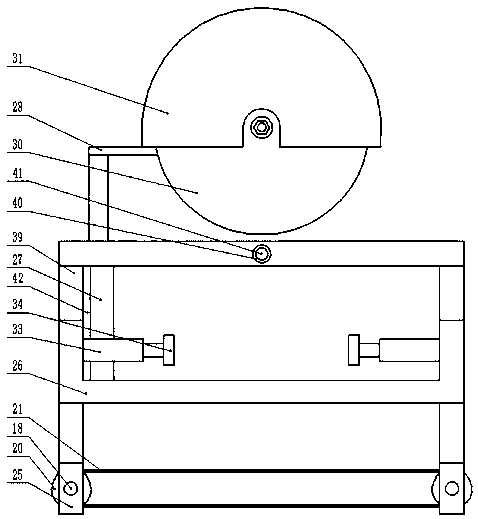

[0025] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-4 As shown, in this implementation:

[0026] In this device, the device is powered by connecting with an external power supply, and the external power supply is connected to the controller 2, the frequency conversion speed regulating motor 5, the electric telescopic rod 15, the electromagnetic clutch 23, the hydraulic cylinder 27, the cutting motor 29 and the fixed electric telescopic rod 33. The type of controller 2 is PLC controller of FX1N-40MT-001 type. The control signal output end of controller 2 is respectively connected with frequency conversion speed regulating motor 5, electric telescopic rod 15, electromagnetic clutch 23, hydraulic The oil cylinder 27, the cutting motor 29 are electrically connected with the fixed electric telescopic rod 33, and the signal receiving end of the controller 2 is electrically connected with the signal sending end of the di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com