Using method of fragment blocking device used for metal plate cutting

A technology of sheet metal parts and metal chips, applied in metal processing machinery parts, metal processing equipment, maintenance and safety accessories, etc. Reduce the difficulty of collection and manual work intensity, provide cutting efficiency, and prevent the effect of splashing around

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

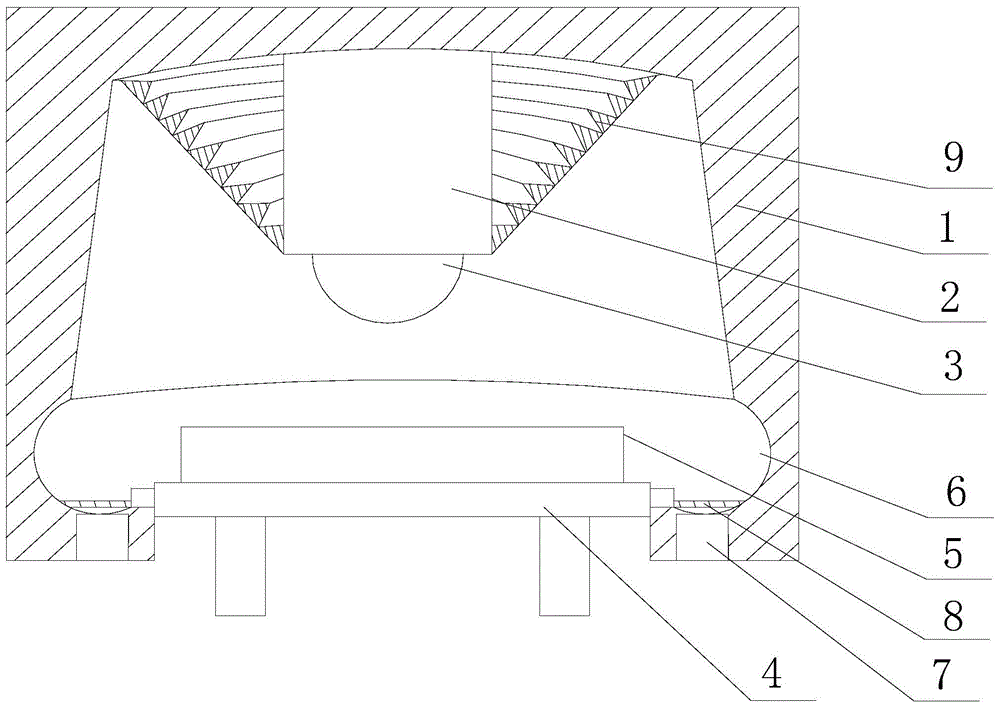

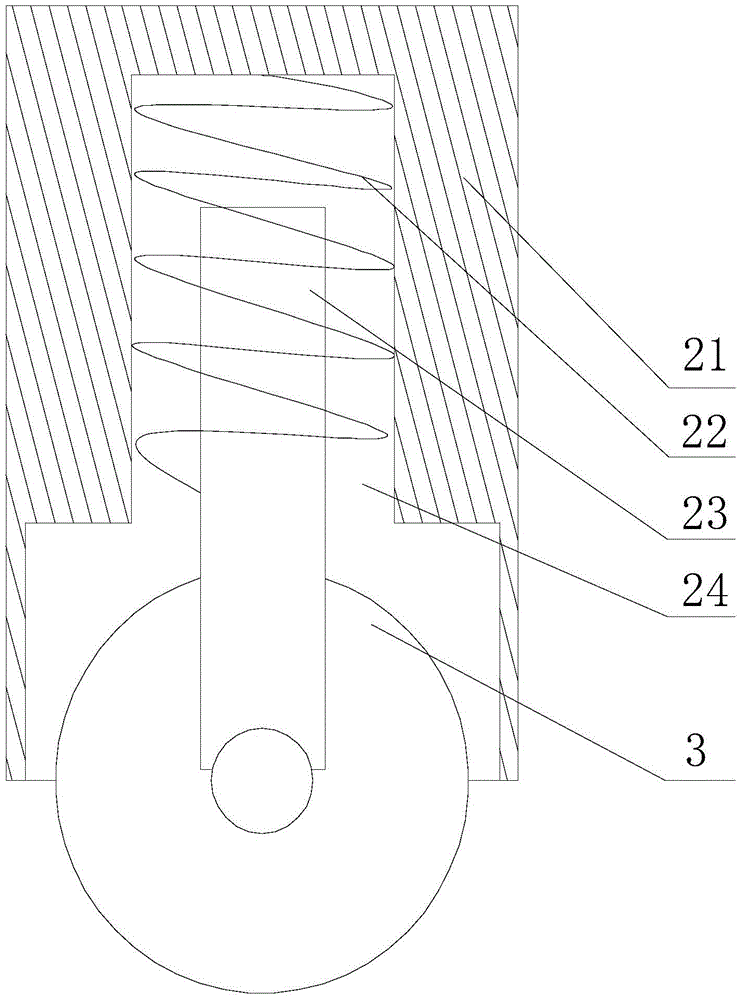

[0025] Such as figure 1 with figure 2 As shown, this embodiment includes the following steps:

[0026] A Slide the workpiece into the center of the worktable, adjust the telescopic arm so that the cutting wheel at the bottom of the telescopic arm is in contact with the upper surface of the workpiece;

[0027] B. Then close the opening of the shield, start the drive device to make the cutting wheel begin to cut the workpiece;

[0028] C. When cutting, the metal debris generated starts to slide along the inner wall of the cavity until it falls into the annular collection groove. At the same time, the metal debris generated is directly blocked by the sealing organ cover to prevent the metal debris from ejecting into the telescopic arm. In the movable parts, the stable operation of the telescopic arm is ensured. When the rotating shaft generates radial jump, the rotating shaft will transmit the applied stress to the adjusting rod. The upper end of the adjusting rod is equipped with a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com