Patents

Literature

48results about How to "Enough room to move" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Micro-accelerometer and preparation method thereof

InactiveCN101634662ALow acceleration measurement sensitivity limitLarge measurement dynamic rangeTelevision system detailsAcceleration measurement using interia forcesAccelerometerEngineering

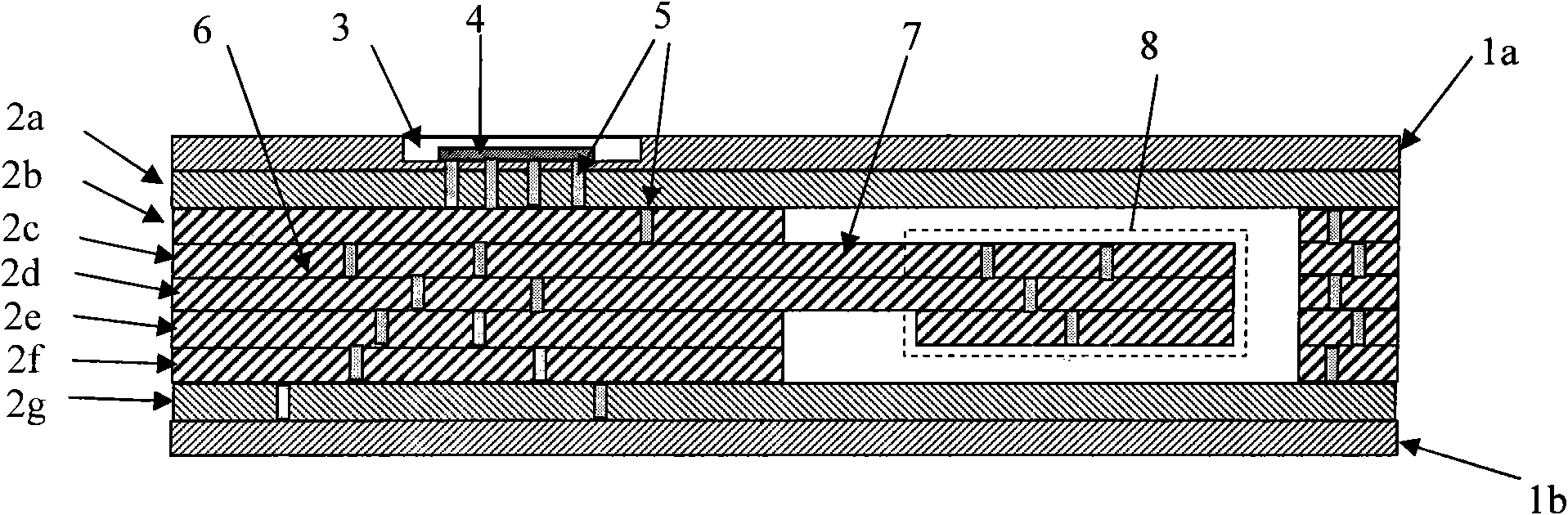

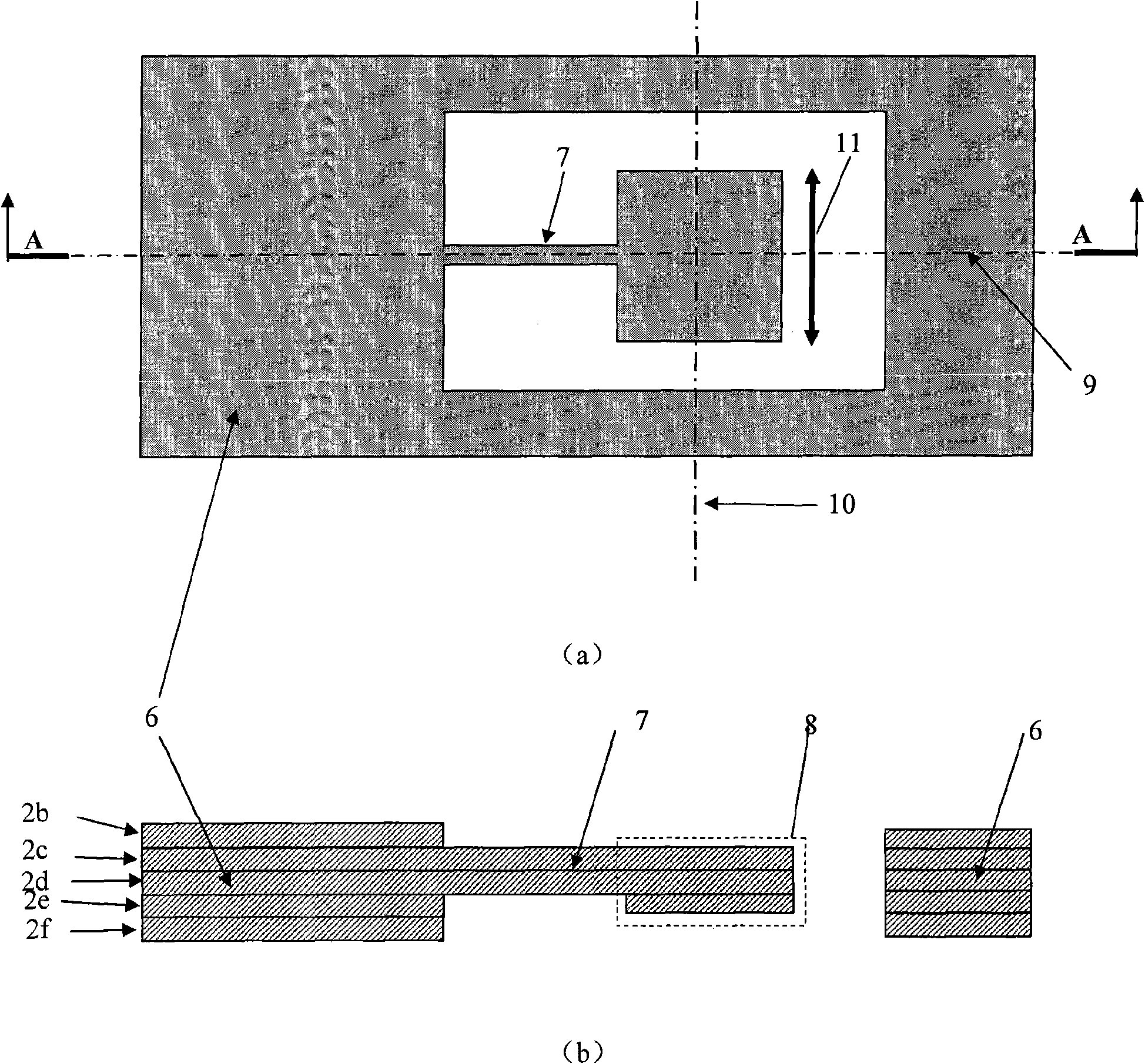

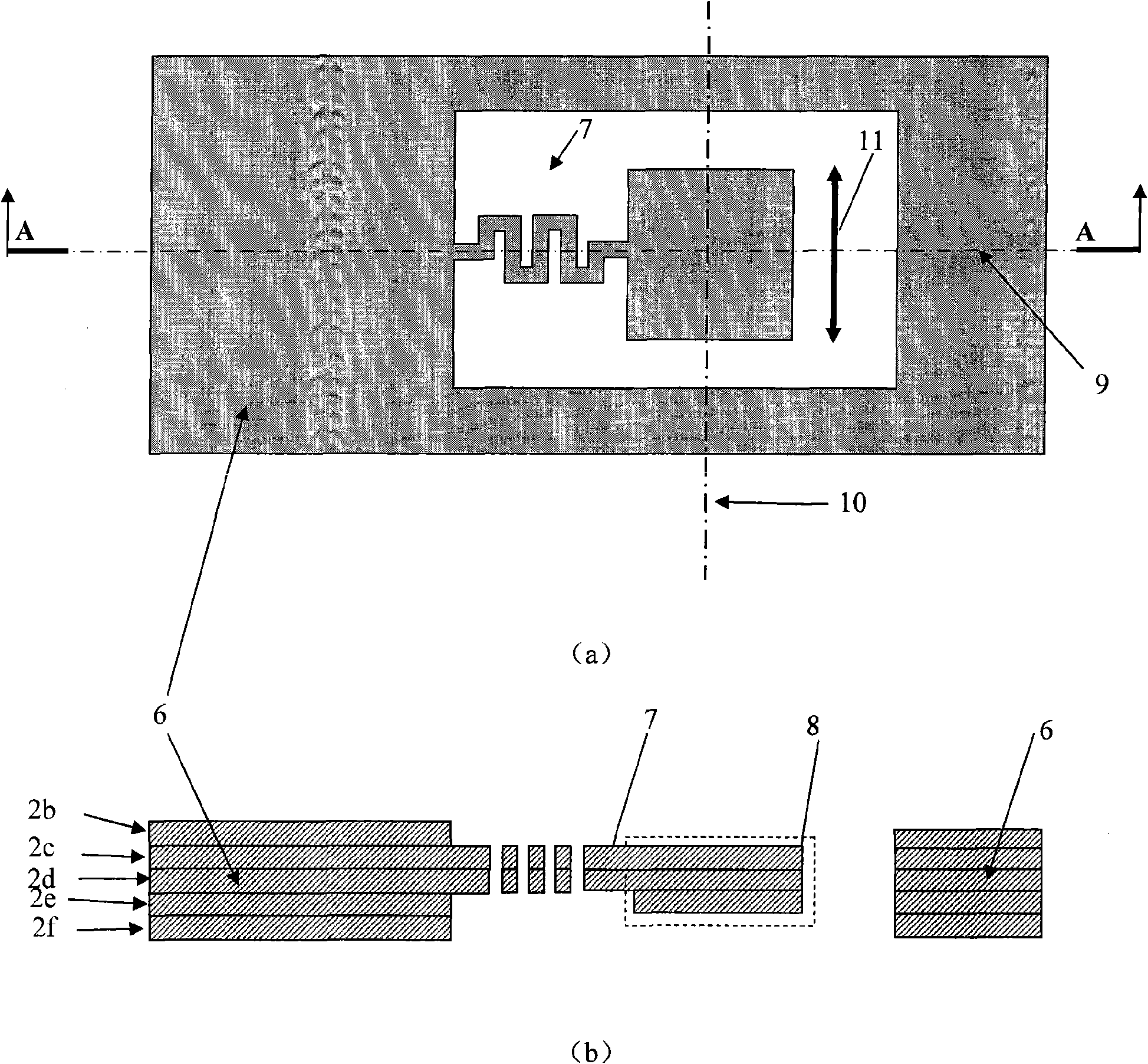

The invention discloses a micro-accelerometer and a preparation method thereof, belonging to the technical field of processing micro inertia devices. The micro-accelerometer is arranged on a package substrate which is formed by stacking an upper surface plate, a lower surface plate and a plurality of middle substrates, wherein a signal detection circuit of the micro-accelerometer is attached on the upper surface plate; a sensitive element of the micro-accelerometer is embedded in the middle substrates, i.e. the middle substrates with cavities form a frame of the sensitive element; a flexible hanger and a sensitive mass block of the sensitive element are arranged in the cavities, and one end of the flexible hanger is connected with the sensitive element, while the other end is fixed on the frame; metal electrodes are respectively sputtered on the sensitive mass block and the surface of the frame corresponding to the sensitive mass block so as to form a flat plate sensitive capacitor, or a metal piezoresistive thick-film pattern is deposited at a connecting part of the flexible hanger and the inner side surface of the frame so as to form a metal piezoresistive strain gauge. The micro-accelerometer has high sensitivity and high-temperature resistance and can be fused into a whole with a system level package substrate, thus the micro-accelerometer has low processing difficulty and cost.

Owner:PEKING UNIV

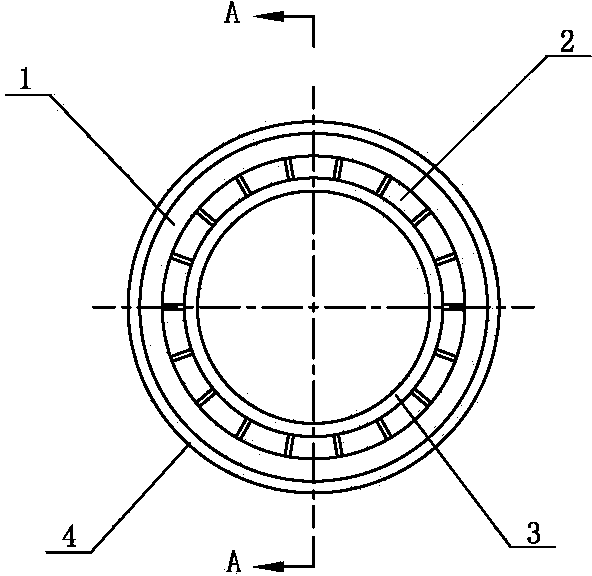

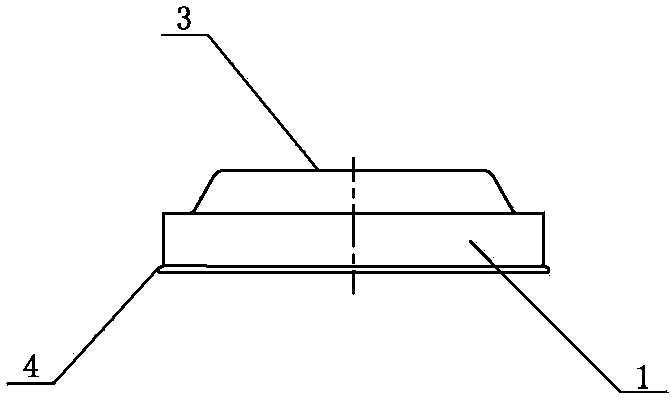

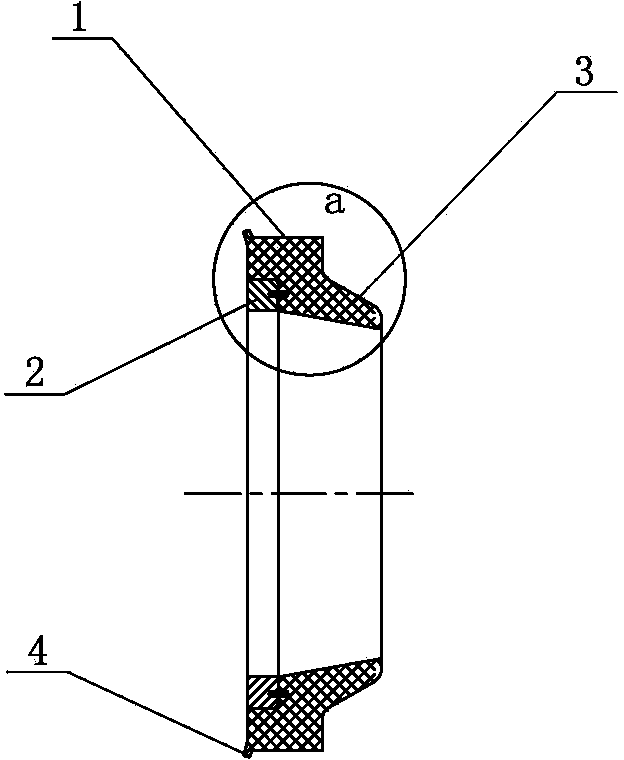

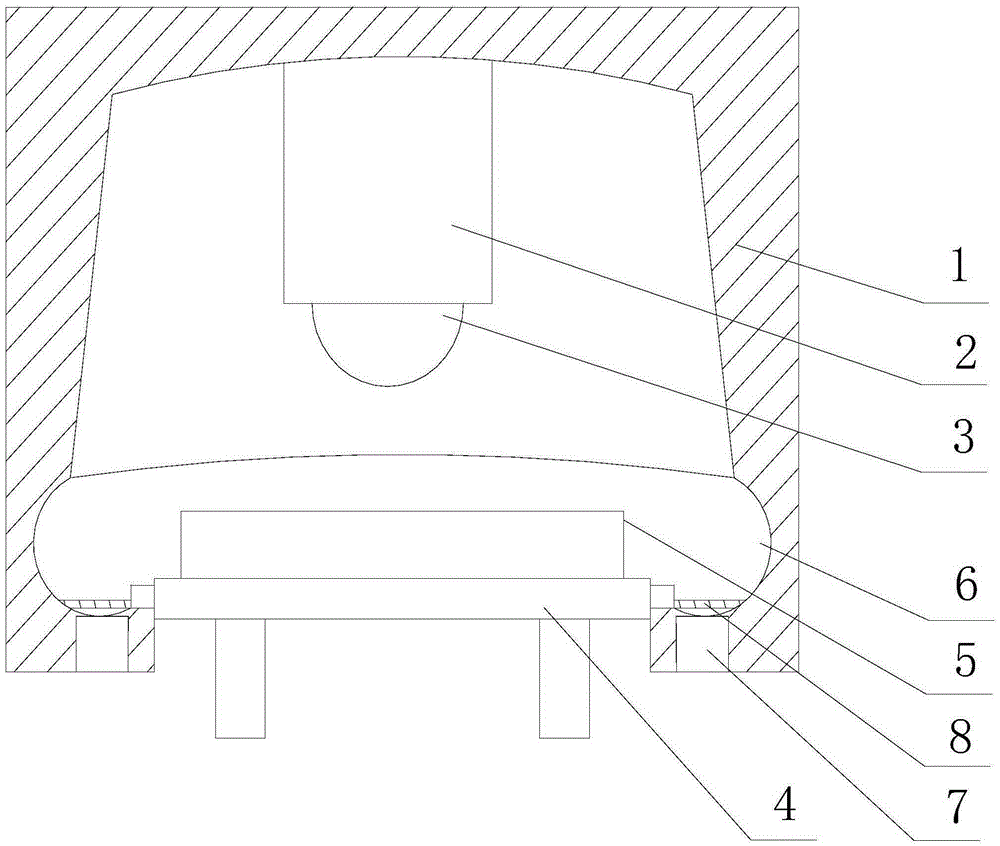

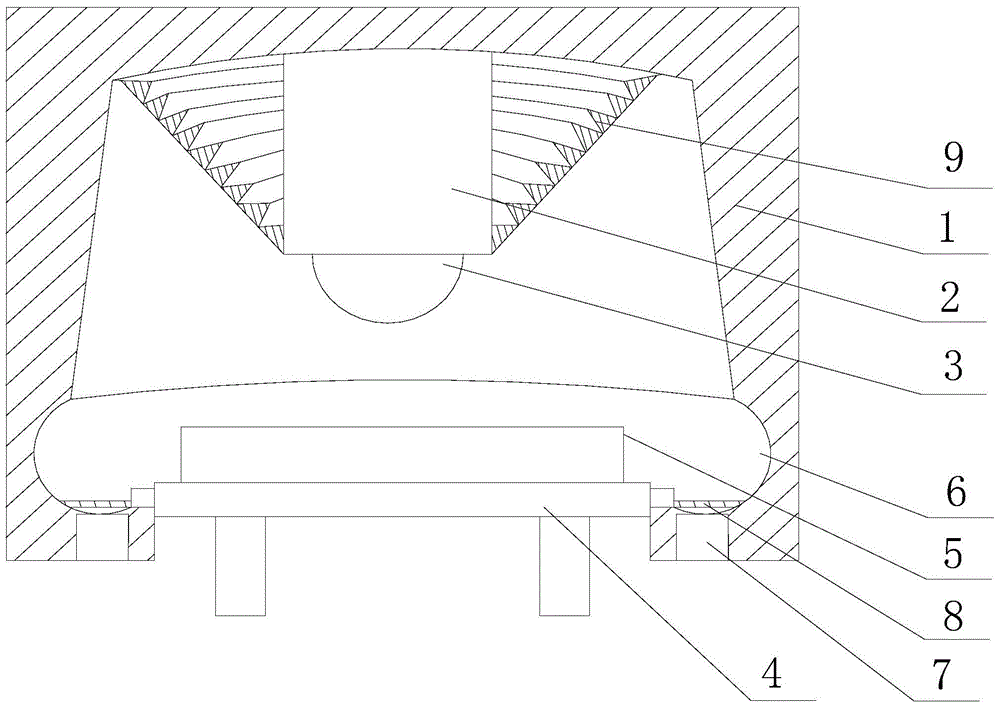

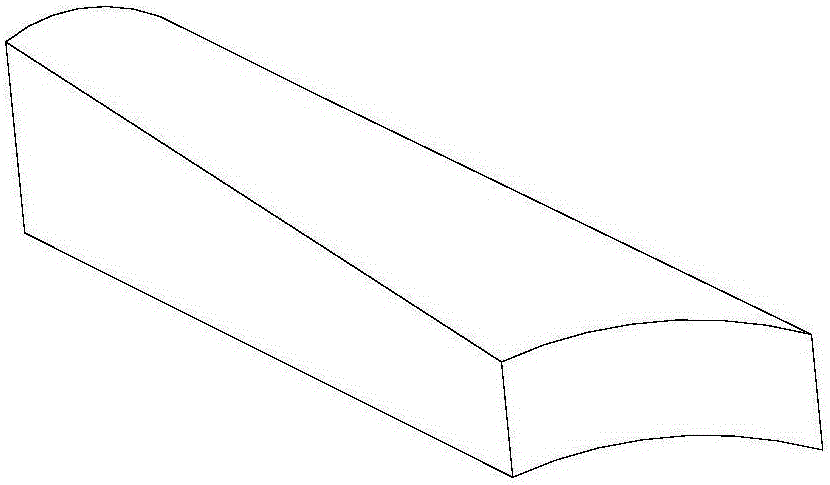

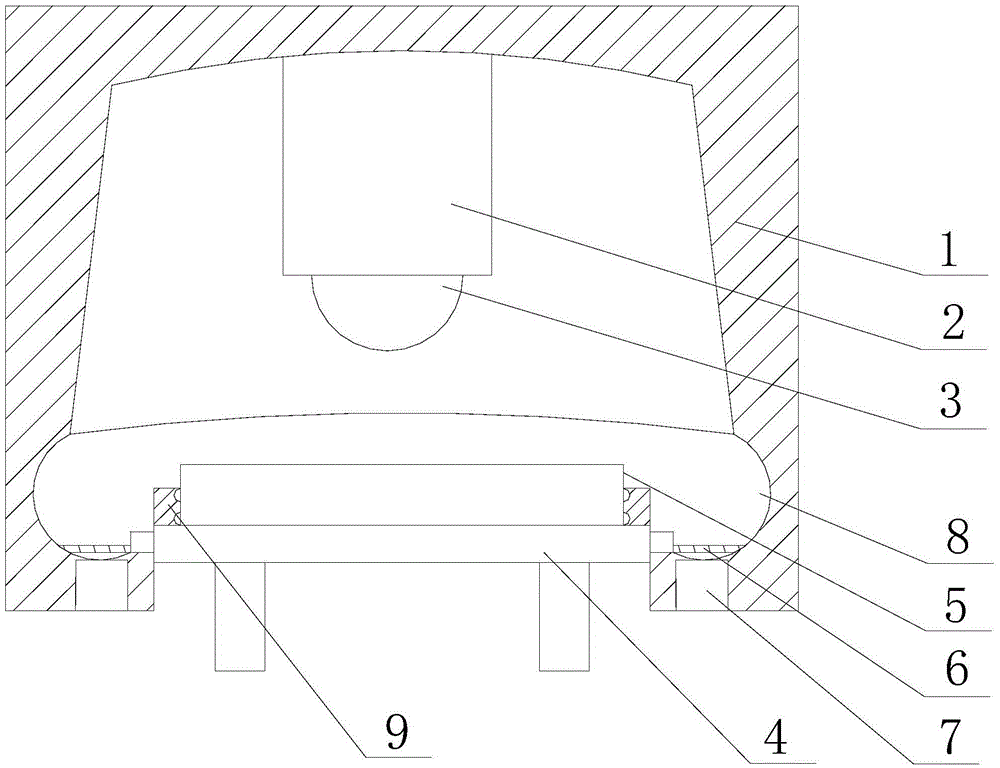

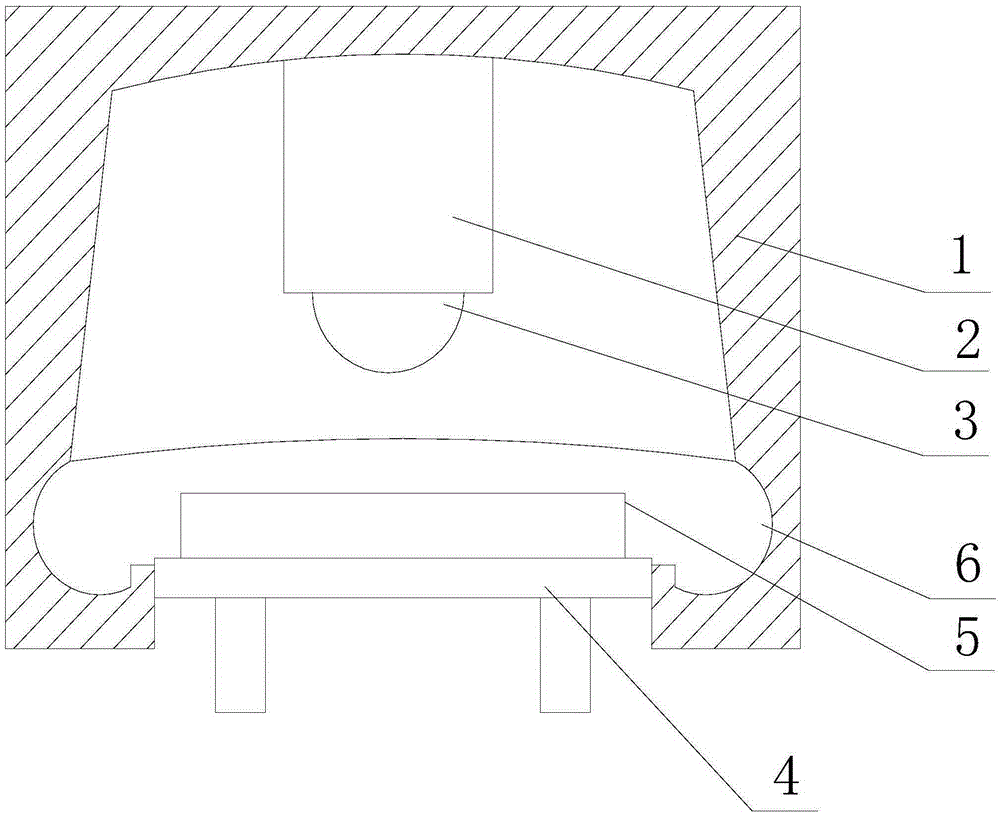

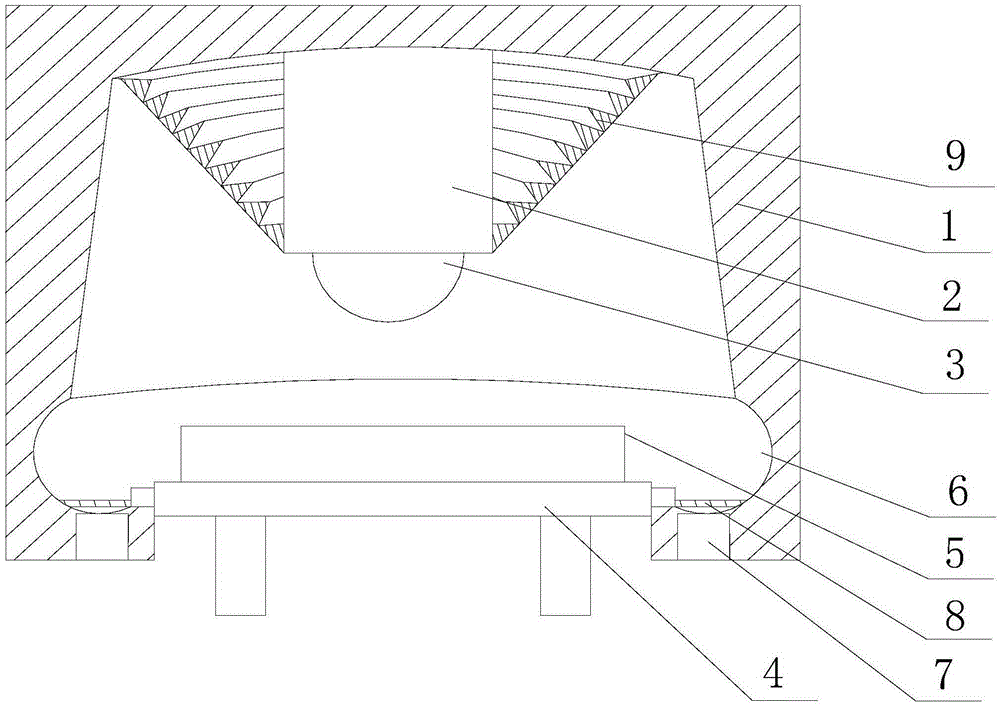

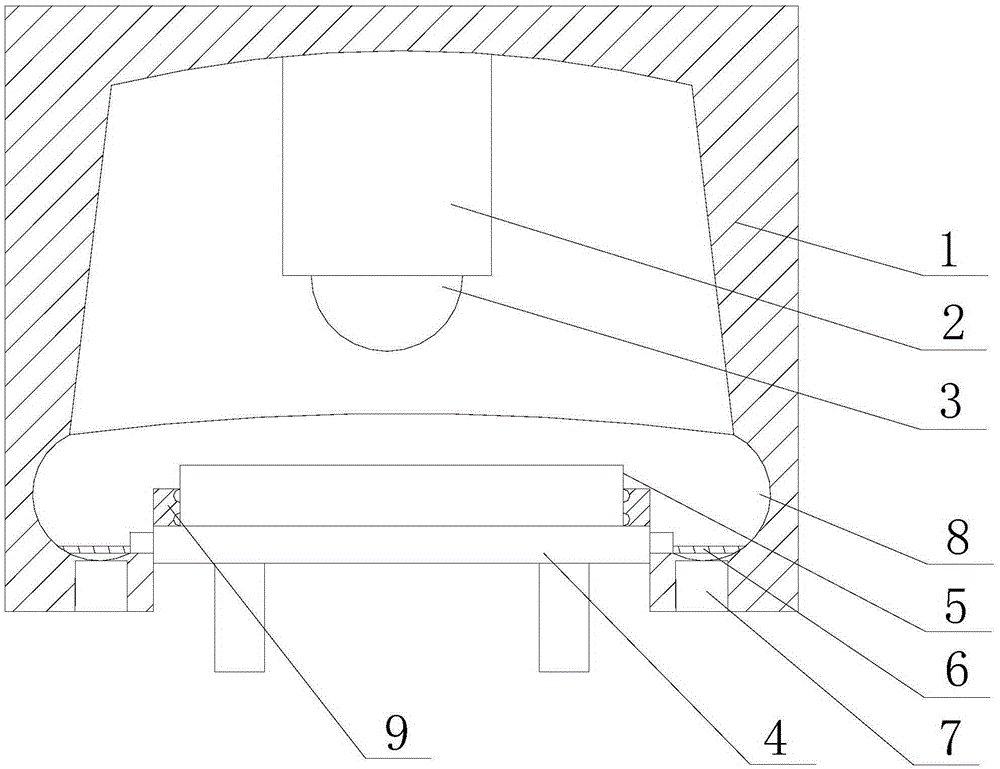

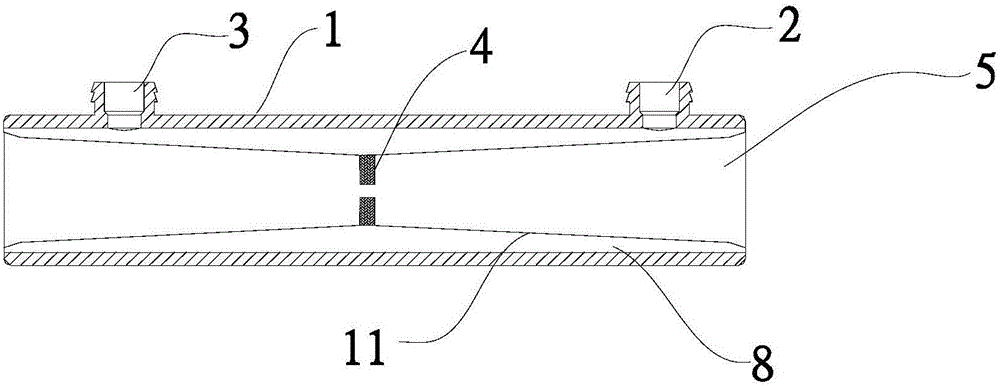

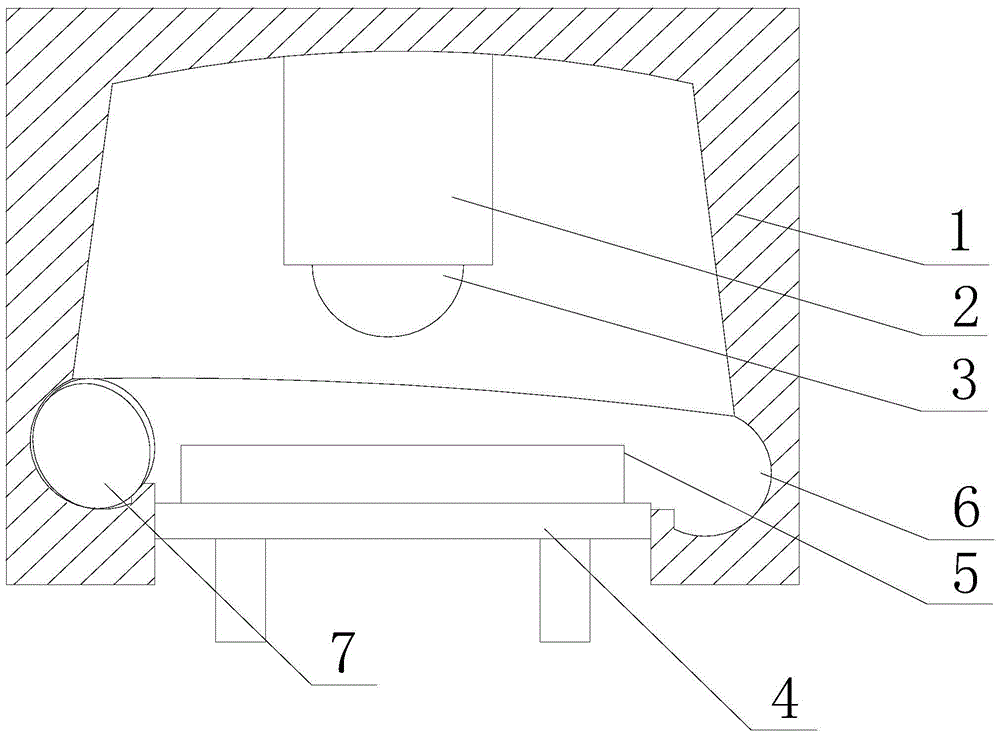

Steel tube end seal ring and sealing device

The invention discloses a steel tube end seal ring and a sealing device, and belongs to the technical field of sealing equipment. The steel tube end seal ring comprises a seal ring body and a supporting block arranged in an annular groove, and a steel tube seal peripheral edge and an end face seal peripheral edge are arranged on the end face of the seal ring body; an arc-shaped supporting groove is formed in the end face of one side of the seal ring body; a convex ring provided with a through groove is arranged on the outer circumferential face of the seal ring body. The sealing device comprises a sealing head and a locating sleeve which are mutually matched, and the steel tube end seal ring is arranged in the sealing device. A supporting ring of the locating sleeve is arranged in a supporting groove of the sealing head in a jacking mode and a gap is reserved. The steel tube end seal ring and the sealing device have the advantages that the pre-sealing link is omitted, the efficiency is improved, and cost is saved; the problem that the seal ring droops is solved, so that a pressure testing head can be designed smaller, and therefore a high-pressure test can be conducted on steel tubes with the diameter phi being larger than six hundred and thirty millimeters; the gap between the supporting groove and the supporting ring guarantees the effect that the seal ring body can be moved in place during pressure exertion, and after pressure is removed, the seal ring body can recover the original shape.

Owner:QINGDAO ZHONGRUITAI MESNAC TECH CO LTD

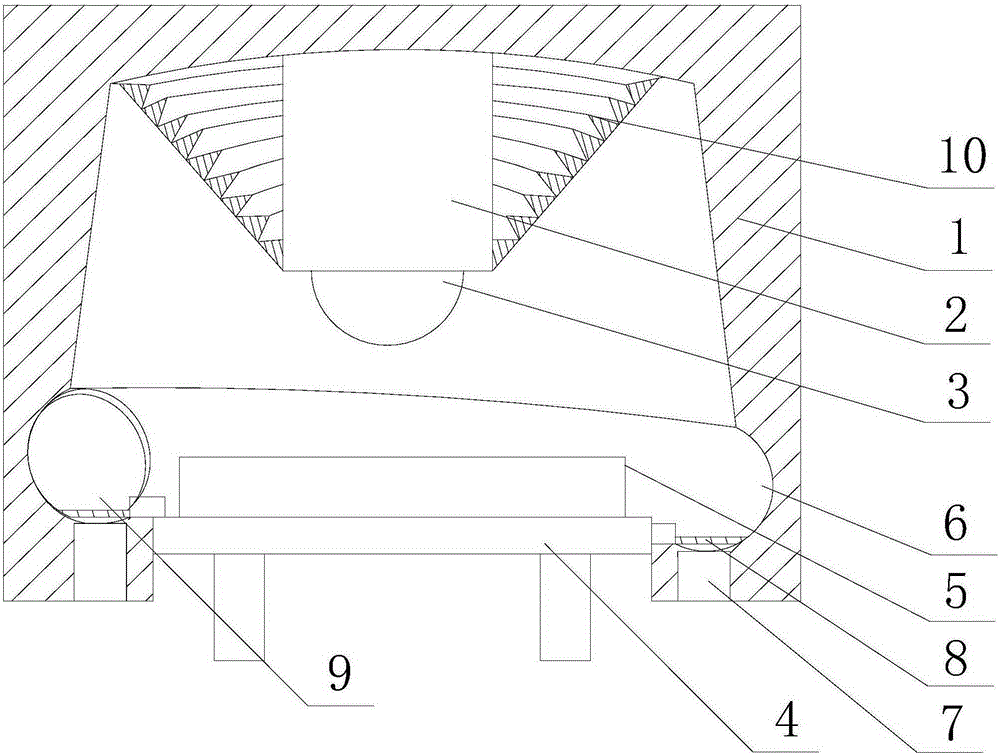

Chipping recovering structure of cutting machine

InactiveCN106799622AGuaranteed normal cuttingPrevent splashMaintainance and safety accessoriesEngineeringBroom

The invention discloses a chipping recovering structure of a cutting machine. The chipping recovering structure comprises a working table; a shielding over is installed on the working table, an opening used for workpiece in and out is formed in the side edge of the shielding cover, and a cavity is formed in the shielding cover; an annular collecting groove is formed in the bottom of the cavity, the side edge of the colleting groove is connected with the side wall of the working table, and a telescopic arm movably penetrates through the top of the shielding cover and is installed over the working table; a cutting wheel is rotatably installed at the tail end of the telescopic arm, the suction end of a draught fan is connected with the collecting groove, and a filter screen is installed on the collecting groove; and a space is reserved between the filter screen and the bottom of the collecting groove. During cutting, produced metal chippings downwards slide in a smooth mode along the inner wall of the cavity till dropping into the annular collecting groove, after cutting is finished, the collecting groove can be cleared through simple instruments such as a broom, and meanwhile the metal chippings accumulated in the collecting groove are centrally recovered to achieve secondary using.

Owner:重庆市木越机械制造有限公司

Broiler chicken breeding feed and broiler chicken breeding method

InactiveCN105942003AImprove disease resistanceImprove cleanlinessFood processingAnimal feeding stuffAnimal scienceFree range

The invention discloses a broiler chicken breeding feed and a broiler chicken breeding method. The broiler chicken breeding feed is prepared from corn, soybean meal, peanut meal, bran, mountain meal, table salt, calcium hydrophosphate, vitamin complex, Chinese herbal medicine materials, pennisetum hydridum, probiotics and the like according to the growth characteristics of broiler chickens, so that not only can growth and health requirements of the chickens be ensured, but also diseases of the broiler chickens during the growth process can be effectively prevented and controlled, and the disease resistance of the broiler chickens is improved, so that the feed can replace hormone, antibiotics and the like extensively used in the breeding industry at the present time, and the safety of broiler chicken products is improved; the feed is especially applicable to serving as a breeding feed for broiler chickens with ages in days of 121-190 during the free-ranging stages in orchards or forest lands; and the obtained product has the characteristics of thin skin, less fat, tender and smooth flesh, and heavy fragrance of chicken flavor.

Owner:湛江市山雨生态农牧有限公司

Continuous measuring moisture content meter by underground low-frequency dielectric method

ActiveCN101532384ASmall form factorGuaranteed accuracyBorehole/well accessoriesContinuous measurementDielectric

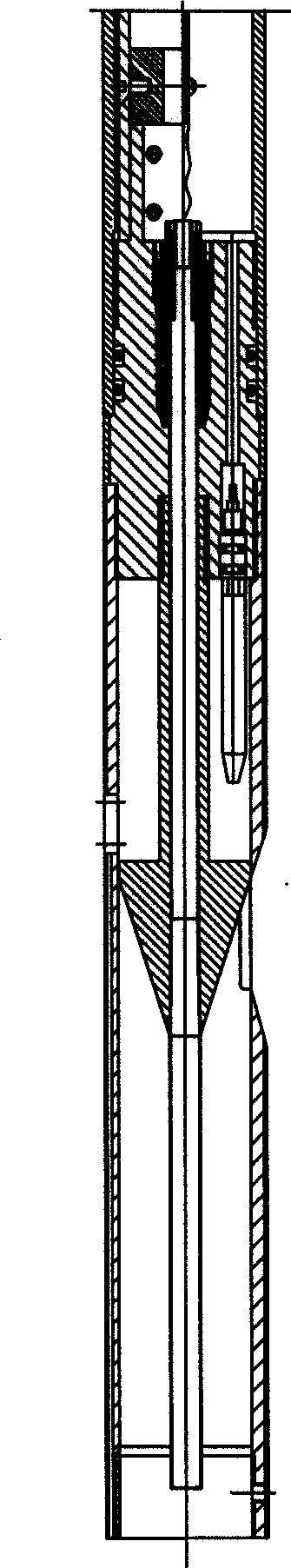

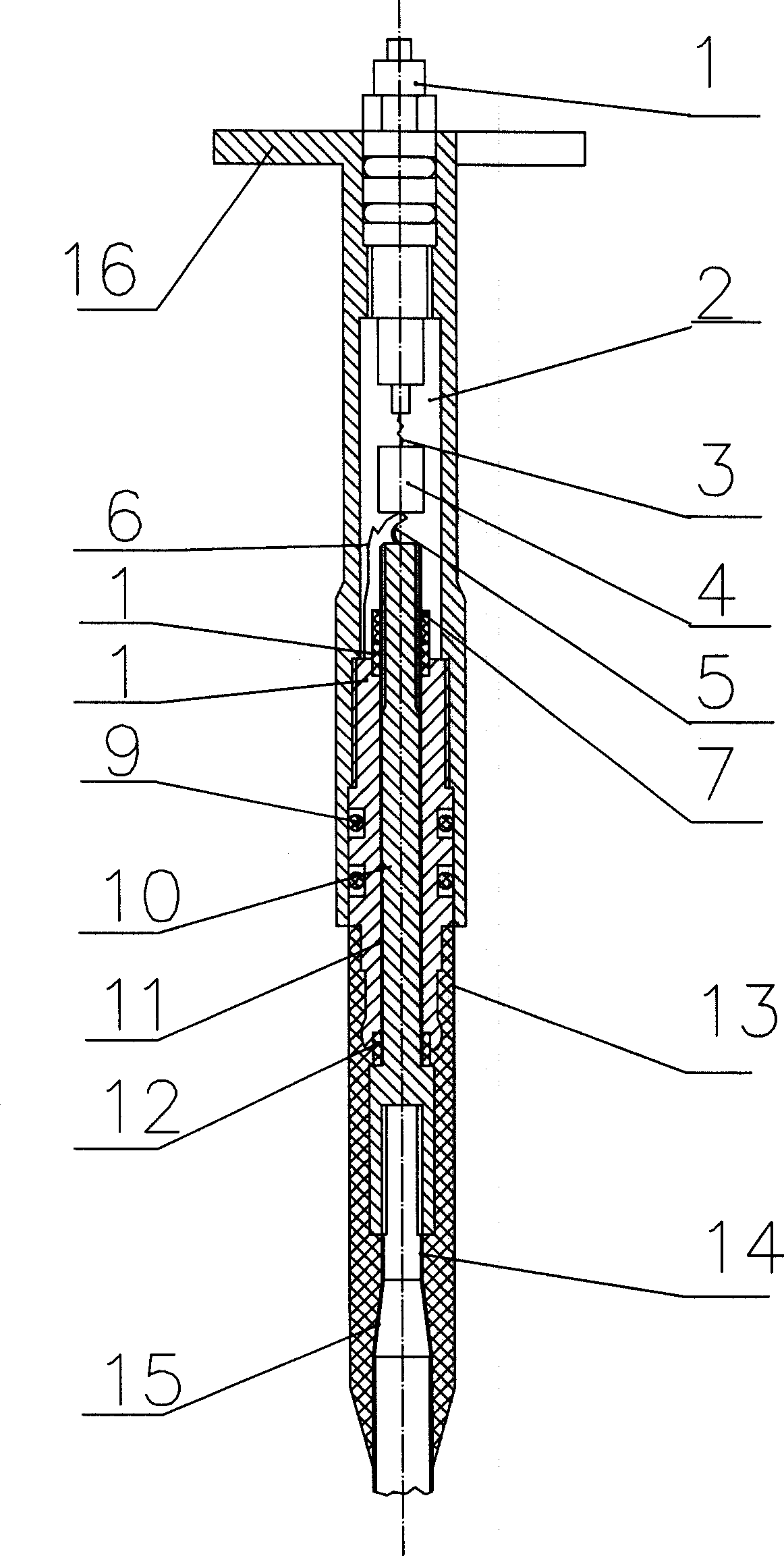

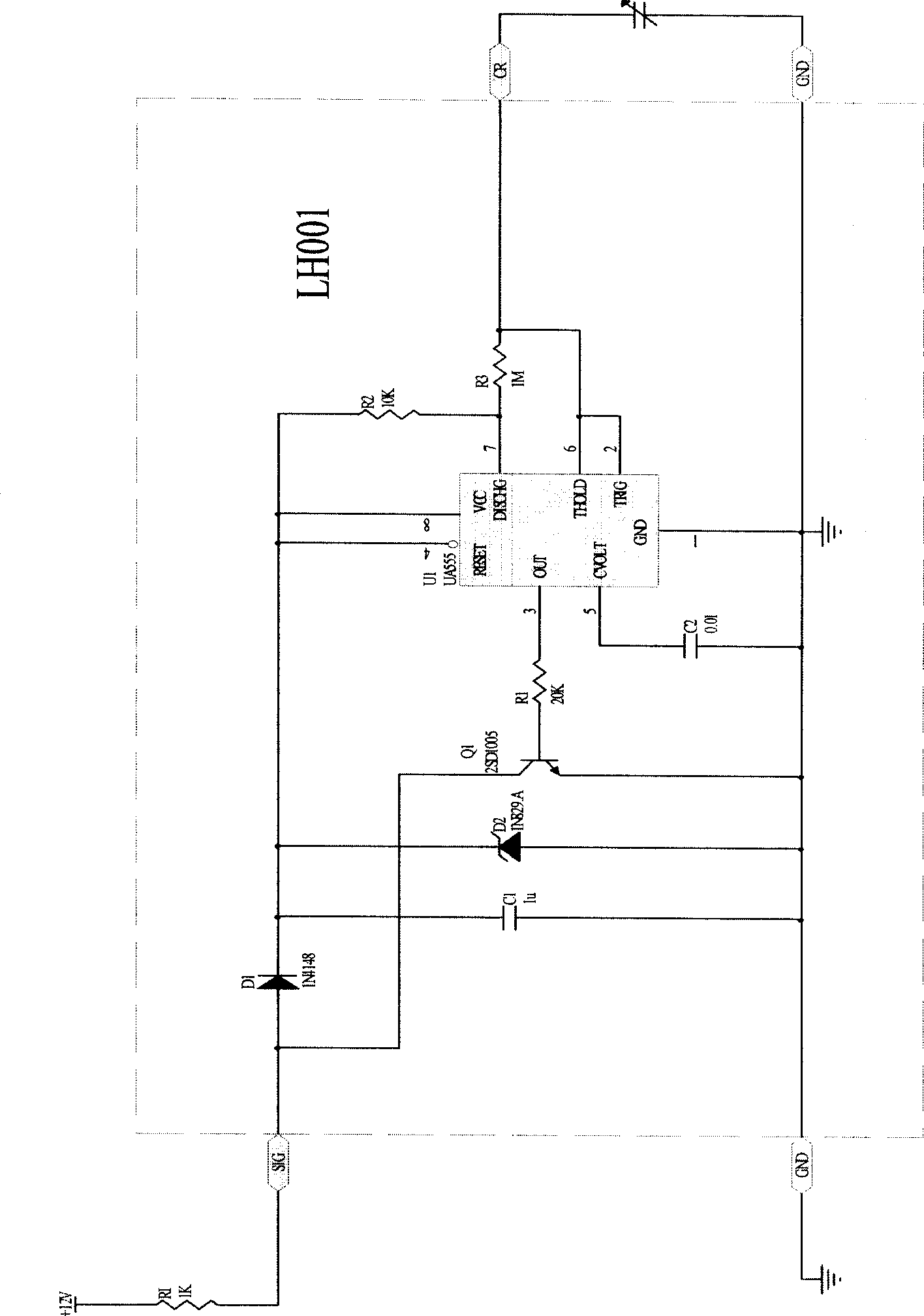

The invention relates to a continuous measuring moisture content meter by an underground low-frequency dielectric method, and mainly solves the problem that the prior moisture content meter cannot be used with a current collector to finish continuous measurement of moisture content of an underground thin layer and a thin sandwich oil layer of chemical oil displacement and fracturing oil displacement. The moisture content meter is characterized in that a connector post (1) is fixed at the upper end of a mounting arm (16), and the lower end of the mounting arm (16) is connected with a metal seal cover (8) and a rubber seal cover (13) in turn; a measuring electrode (14) of which surface is provided with an electrode insulating bush (15) is fixed in the rubber seal cover (13), the upper section of the measuring electrode (14) is connected with a sealed core (10) of which outside diameter is provided with an insulating bush (11), the upper section of the sealed core (10) is matched with an inner hole of the metal seal cover (8), the top end of the sealed core (10) passes through an electrode lead (5) and is connected with an integrated measuring circuit module (4) and a signal output line (3) in turn, and the signal output line (3) is connected with the connector post (1). The continuous measuring moisture content meter can be arranged at any position of a logging instrument, and the resolution of extra-high moisture content of over 95 percent can reach 1 percent.

Owner:DAQING OILFIELD CO LTD +1

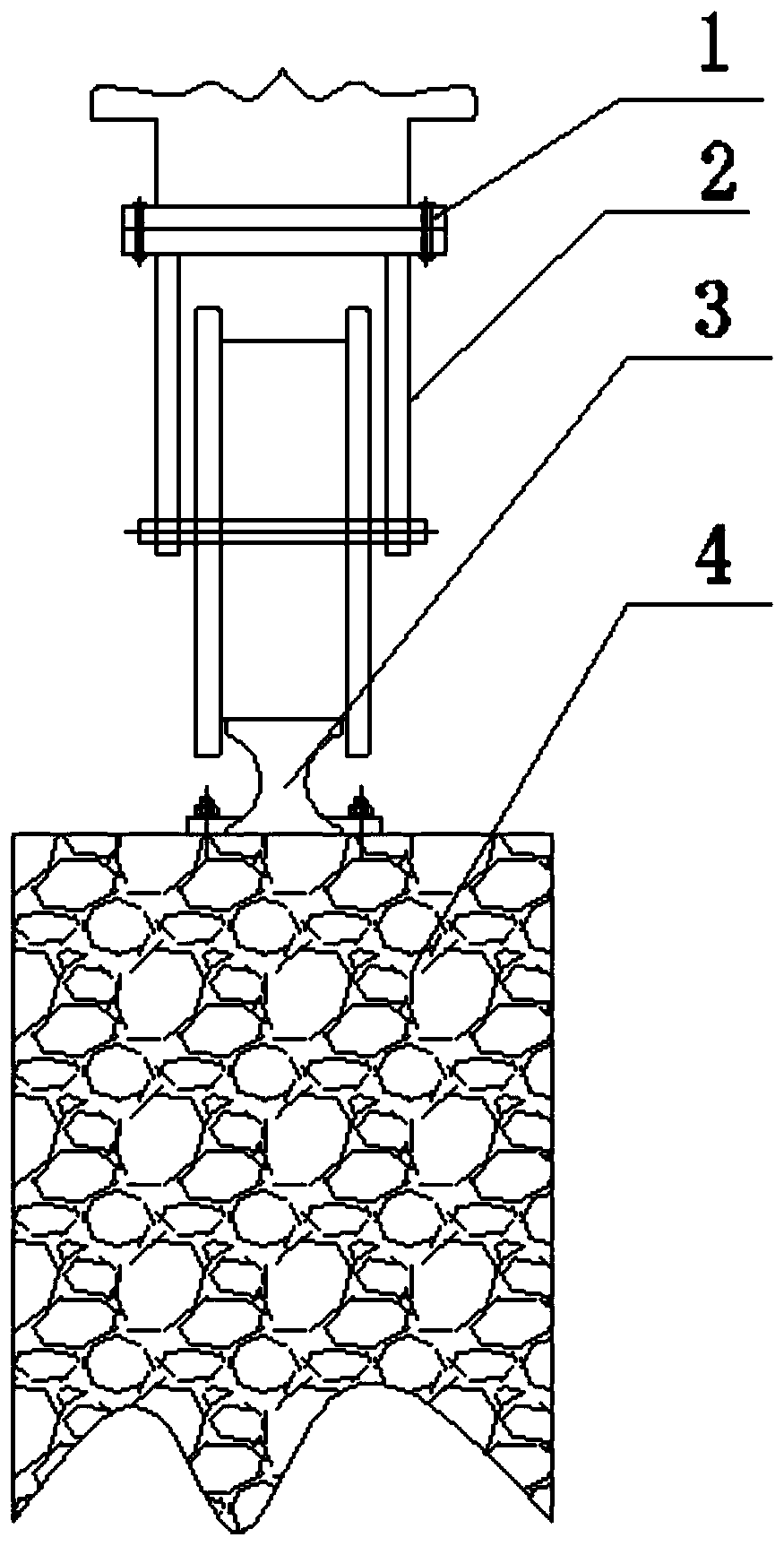

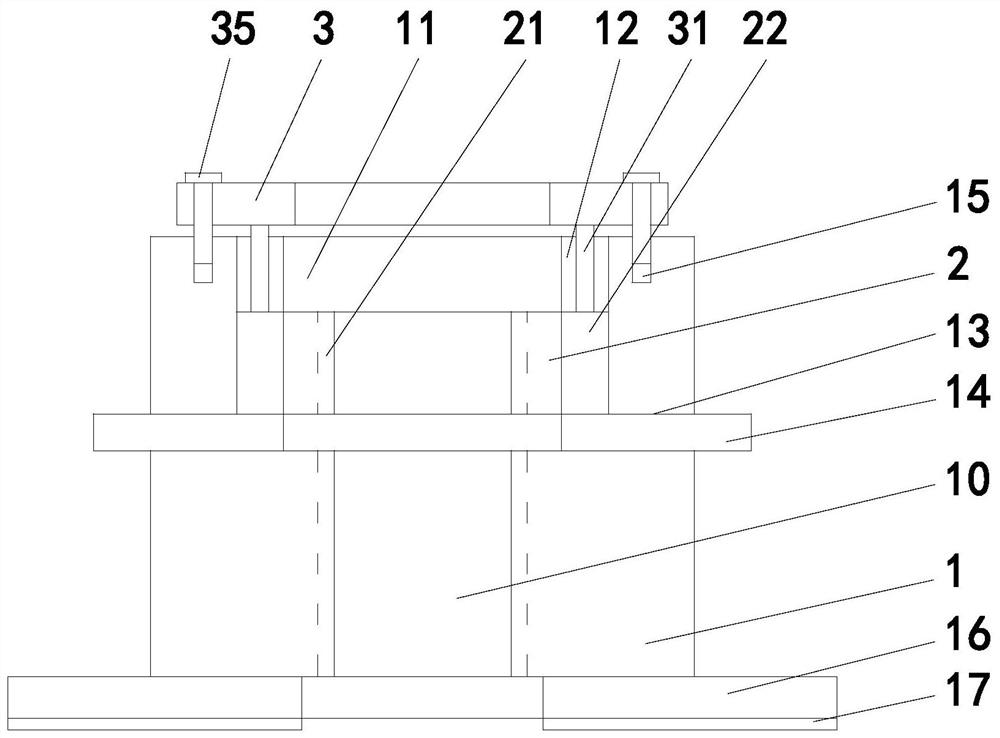

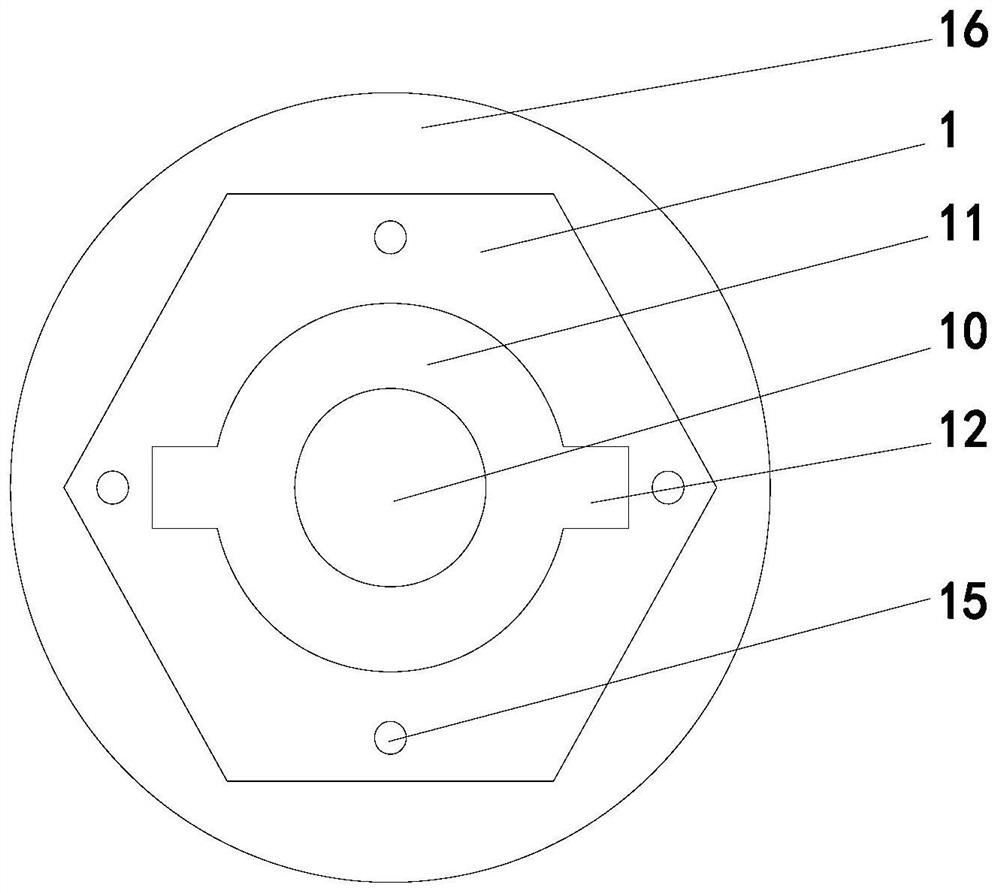

Intra-cavity mounting rack of inside deviation rectifying device

ActiveCN103912014ASimplified installation stepsSolve the installationArtificial islandsUnderwater structuresEngineeringWork productivity

The invention relates to an intra-cavity mounting rack of an inside deviation rectifying device, in particular to a mounting rack for mounting the inside deviation rectifying device in a joint cavity between two pipe joints and enabling the mounting of the inside deviation rectifying device to conform to the requirements of deviation rectifying in a pipe. The intra-cavity mounting rack comprises a rotary foundation support and a rotary beam mounted on the rotary foundation support, the rotary beam is provided with a sliding mounting base, one end of the rotary beam is hinged to the rotary foundation support, and the other end of the rotary beam is connected with a hoisting mechanism. According to the intra-cavity mounting rack, the rotary beam is provided with the sliding mounting base; the problem of mounting the inside deviation rectifying device in the joint cavity is solved, the device mounting process is simplified, the operating risk is lowered, and the working efficiency is improved.

Owner:CCCC FIRST HARBOR ENG +1

Debris blocking structure of cutting machine tool

InactiveCN106799640APrevent splashing aroundAvoid processing environmental pollutionMaintainance and safety accessoriesBroomEngineering

The invention discloses a debris blocking structure of a cutting machine tool. The debris blocking structure of the cutting machine tool comprises a worktable; a blocking cover is installed on the worktable, an opening for workpiece entering and existing is formed in the side edge of the blocking cover, an cavity is formed in the blocking cover, an annular collecting groove is formed in the bottom of the cavity, and the side edge of the collecting groove is connected with the side wall of the worktable; a telescopic arm movably penetrates through the top of the blocking cover and is installed above the worktable, and a cutting wheel is rotatably installed at the tail end of the telescopic arm; the air suction end of the draught fan is connected with the collecting groove; and a filtering net is installed on the collecting groove, and a gap is reserved between the filtering net and the bottom of the collection groove. During cutting, generated debris slides downwards along the inner wall of the metal debris till falling into the annular collecting groove; after cutting is completed, the collecting groove can be cleaned through simple tools such as a broom, meanwhile, the metal debris accumulated in the collection groove can be centrally recycled, and consequently secondary utilization can be achieved.

Owner:重庆市木越机械制造有限公司

Using method of fragment blocking device used for metal plate cutting

InactiveCN106799623AGuaranteed normal cuttingPrevent splashMaintainance and safety accessoriesEngineeringBroom

The invention discloses a using method of a fragment blocking device used for metal plate cutting. The using method comprises the following steps that a workpiece is pushed to a working table in a sliding manner, and a cutting wheel is in contact with the upper surface of the workpiece; the opening of a shielding cover is sealed, and the cutting wheel is started to cut the workpiece; during cutting, generated metal fragments start to slide down along the inner wall of a cavity and finally fall into a collecting groove, and the generated metal fragments are directly blocked by a sealing organ cover to prevent the metal fragments from catapulting into the movable part of a telescopic arm; when a rotary shaft makes diameter run-out, a spring is stressed with upward force to have compressive deformation, and within short time, the spring generates elastic force in the opposite direction to offset applied stress; the fine fragments falling at the bottom of the collecting groove are absorbed by the air suction end of a draught fan and are transmitted out of the shielding cover; the rest metal fragments are isolated on a filter screen; and after cutting, a broom and the like can be manually adopted to recycle the metal fragments with larger diameters in the collecting groove.

Owner:重庆市木越机械制造有限公司

Sweep collecting structure of machine tool machining

InactiveCN106799633AGuaranteed normal cuttingPrevent splashMaintainance and safety accessoriesEngineeringBlock match

The invention discloses a sweep collecting structure of machine tool machining. The sweep collecting structure comprises a worktable; a shielding cover is mounted on the worktable; an opening allowing a workpiece to enter and go out is formed in the side of the shielding cover; a cavity is formed in the shielding cover; an annular collecting groove is formed in the bottom of the cavity; and the side of the collecting groove is connected with the side wall of the worktable. A telescopic arm movably penetrates through the top of the shielding cover, and a cutting wheel is rotatably arranged at the tail end of the telescopic arm. A filter screen is mounted on the collecting groove, and a gap is reserved between the filter screen and the bottom of the collecting groove. The collecting groove is arranged obliquely in the circumferential direction of the bottom of the cavity, a sliding block matched with the collecting groove is slidably arranged at the end, in the high position, of the filter screen, and traction ropes are connected on the two sides of the sliding block correspondingly. At the time of cutting, produced metal sweeps start to slide downward along the inner wall of the cavity until falling into the annular collecting groove, and after cutting is finished, the collecting groove can be cleaned by simple tools such as a broom. Meanwhile, the metal sweeps accumulated in the collecting groove are intensively recycled to achieve secondary utilization.

Owner:重庆市木越机械制造有限公司

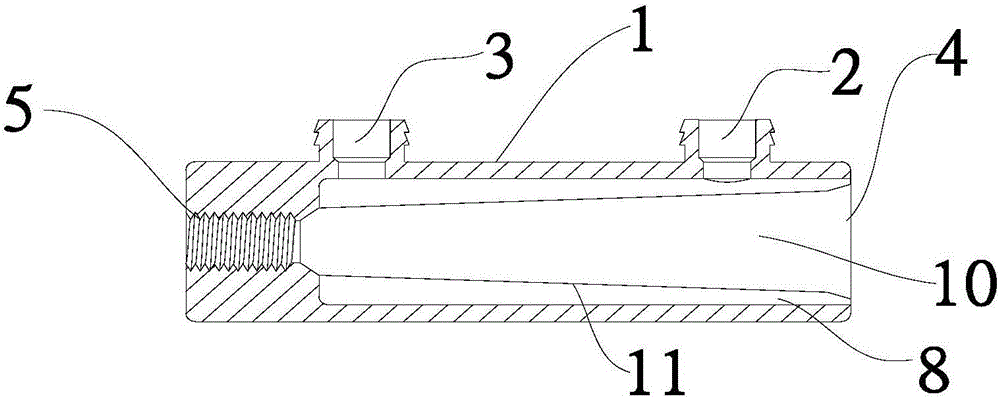

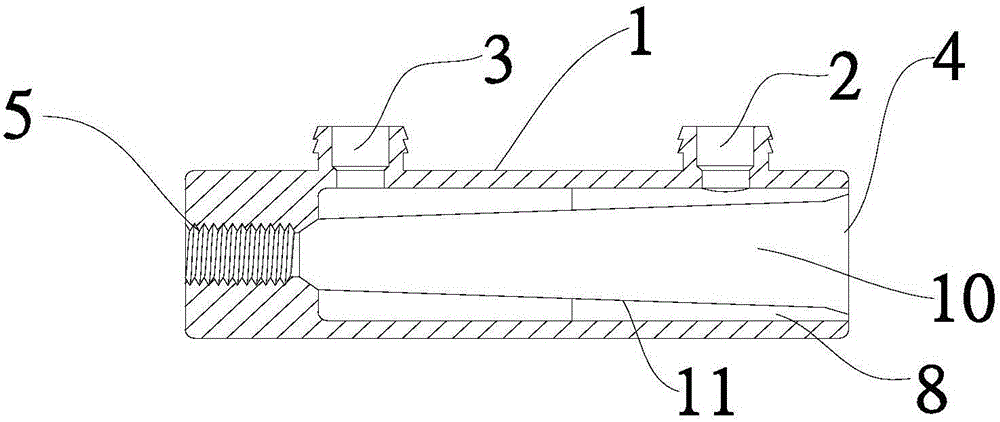

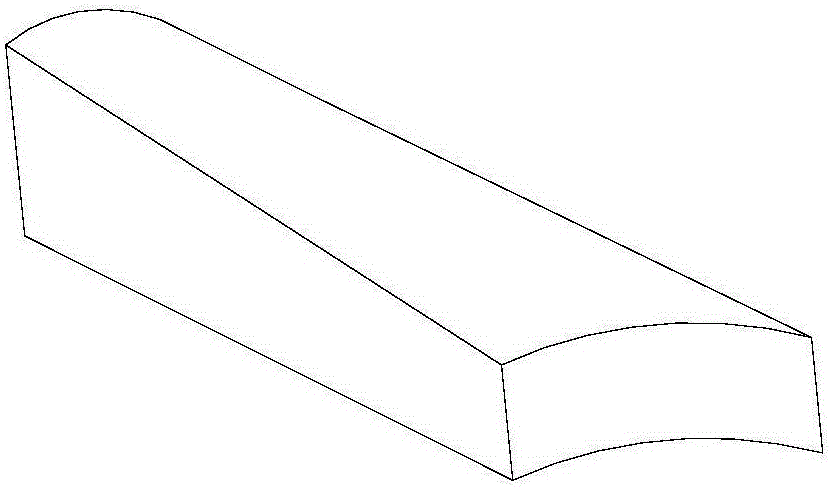

Grouting sleeve and pre-fabricated part

The invention belongs to the field of constructional engineering and particularly discloses a grouting sleeve and a pre-fabricated part.The grouting sleeve comprises a sleeve body, wherein a grouting opening and an exhaust port are formed in the sleeve body, one end of the sleeve body is open, the other end of the sleeve body serves as a connecting end, steel petals are arranged on the inner wall of the sleeve body, the thickness of the steel petals is gradually increased from the open end to the inside, and the width of the end, close to the connecting end, of each steel petal is greater than that of the end, close to the connecting end, of each steel petal.The arranged steel petals improve the overall rigidity of the sleeve body, the wall thickness of the sleeve body can be appropriately decreased on the premise that the rigidity is met, and materials are saved.In addition, grouted slurry form a locking-fixing structure matched with the sleeve inside and the steel pedals in the sleeve body, and the anchoring reliability of steel bars is remarkably improved.The accurate axial control and radial positioning of the steel bars can be achieved, and the positioning precision between the steel bars and the grouting sleeve can be ensured.

Owner:CHINA MINGSHENG DRAWIN TECH INVESTMENT CO LTD

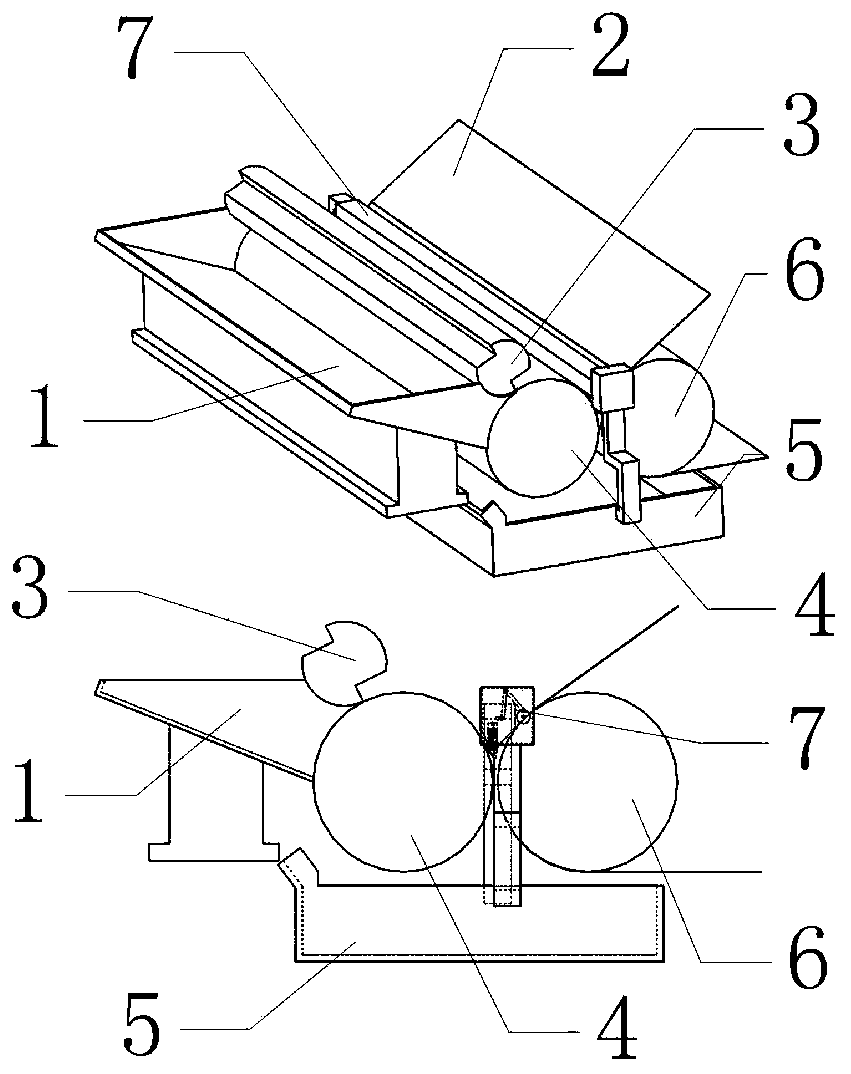

Roll coating device for lithium batteries

ActiveCN111530692AGuaranteed uniformityVibration effectLiquid surface applicatorsCoatingsChemistryComposite material

The invention belongs to the technical field of lithium batteries, and particularly relates to a roll coating device for the lithium batteries. The roll coating device for the lithium batteries comprises a liquid containing shell body, a scraper, a coating roller, a charging tray and a back roller. According to the roll coating device for the lithium batteries, a first removing block and a secondremoving block slide up and down, so that on the one hand, the effect that bubbles in slurry gathered at the upper end of a position where the outer circle face of the back roller and the outer circleface of the coating roller are close to each other are extruded is achieved, and on the other hand, the effect that the slurry is vibrated is achieved through movement of the two removing blocks, thebubbles in the vibrated slurry are extremely easy to discharge, and the phenomena that air entrainment exists and a plurality of tiny bubbles are exist on the surface of a coating due to a relativelylarge gap between the coating roller and the back roller and a relatively high coating speed in the coating process can be avoided to a certain extent; and in the sliding process of the bubble removing blocks, through the first removing block and the second removing block which are opposite in movement direction and alternately and sequentially installed in the same number, the stability of the pressure of slurry gathered at the upper ends of the position where the outer circle face of the back roller and the outer circle face of the coating roller are close to each other can be guaranteed, and the uniformity of the coating thickness is guaranteed.

Owner:深圳市鹏锦生混凝土有限公司

Chipping-blocking mechanism used for metal plate machining

InactiveCN106799644AGuaranteed normal cuttingPrevent splashMaintainance and safety accessoriesEngineeringBroom

The invention discloses a chipping-blocking mechanism used for metal plate machining. The chipping-blocking mechanism comprises a working table; a shielding cover is installed on the working table, an opening is formed in the side edge of the shielding cover, and a cavity is formed in the shielding cover; a collecting groove is formed at the bottom of the cavity, the side edge of the collecting groove is connected with the side wall of the working table, and a cutting wheel is rotatably installed at the tail end of a telescopic arm; the suction end of a draught fan is connected with a collecting groove, a filter screen is installed on the collecting groove, and a space is reserved between the filter screen and the bottom of the collecting groove; and limiting blocks are installed at the two ends of the working table, sunken portions can be formed in the opposite side walls of the two limiting blocks in the direction away from the center of the working table, and rubber protrusions are installed in the middles of the sunken portions. During cutting, produced metal chippings star downwards sliding in a smooth mode along the inner wall of the cavity till dropping into the annular collecting groove, and after cutting is finished, the collecting groove can be cleared through simple instruments such as a broom; and meanwhile, the metal chippings accumulated in the collecting groove are centrally recovered to achieve secondary using.

Owner:重庆市木越机械制造有限公司

Waste recovery device used after metal piece cutting

InactiveCN106799637AGuaranteed normal cuttingPrevent splashMaintainance and safety accessoriesBroomMetal

The invention discloses a waste recovery device used after metal piece cutting. The waste recovery device comprises a workbench. A shielding cover is mounted on the workbench. An opening allowing moving-in and moving-out of workpieces is formed in the side edge of the shielding cover. A cavity is formed in the shielding cover. An annular collection tank is arranged at the bottom of the cavity. The side edge of the collection tank is connected with the side wall of the workbench. A telescopic arm movably penetrates the top of the shielding cover and is arranged over the workbench. A cutting wheel is rotationally arranged at the tail end of the telescopic arm. A circular-truncated-cone-shaped sealed organ cover is arranged on the inner wall of the top end of the shielding cover. The movable end of the sealed organ cover is connected with the outer circumferential wall of the telescopic arm. By the adoption of the waste recovery device, metal chippings generated during cutting start to slide downwards along the inner wall of the cavity and do not stop sliding until the chippings fall into the annular collection tank; and after cutting is completed, the collection tank can be cleaned with simple tools such as a broom, meanwhile the metal chippings accumulated in the collection tank are recovered in a concentrated manner, and secondary utilization is achieved.

Owner:重庆市木越机械制造有限公司

Shielding device for machine tool cutting

InactiveCN106799642AGuaranteed normal cuttingPrevent splashMaintainance and safety accessoriesComing outEngineering

The invention discloses a shielding device for machine tool cutting. The shielding device comprises a workbench, a shielding hood is installed on the workbench, and an opening for coming in and coming out of a workpiece is formed in the side edge of the shielding hood. A cavity is formed in the shielding hood, an annular collecting groove is formed in the bottom of the cavity, and the side edge of the collecting groove is connected with the side wall of the workbench. A telescopic arm movably penetrates through the top of the shielding hood and is stored over the workbench, a cutting wheel is rotatably arranged at the tail end of the telescopic arm, the air suction ends of draught fans are connected with the collecting groove, filtering nets are installed on the collecting groove, gaps are reserved between the filtering nets and the bottom of the collecting groove, a sealing organ hood is arranged on the inner wall of the top end of the shielding hood, and the active end of the sealing organ hood is connected with the external circumference wall of the telescopic arm. During cutting, generated metal chippings begin to downwards slide along the inner wall of the cavity till the chippings fall into the annular collecting groove; after cutting is finished, the collecting groove can be cleaned through simple tools such as a broom; and meanwhile, the metal chippings accumulated in the collecting groove are intensively recovered, so that secondary utilization is achieved.

Owner:重庆市木越机械制造有限公司

Laser three-dimensional medical image acquisition device

InactiveCN112890778AEasy to useEasy to storeSurgical furnitureDiagnostic recording/measuringApparatus instrumentsImage acquisition

The invention belongs to the technical field of medical instruments, and particularly relates to a laser three-dimensional medical image acquisition device. The device comprises a storage box and a supporting box which is slidably connected to the outer wall of the bottom of the storage box, wherein a bottom plate is slidably connected to the inner wall of the bottom of the storage box, connecting columns are fixedly connected to the four corners of the top of the bottom plate, the same top plate is fixedly connected to the top ends of the four connecting columns, and a rotating shaft is rotatably connected to one side of the top of the bottom plate. Accordingly, by means of the storage box, the effect of facilitating storage of a laser three-dimensional image acquisition device body can be achieved, and the storage stability is good; meanwhile, the automatic door opening and closing function and the box door self-locking function are achieved, the convenience, practicability and safety are greatly improved, the automation degree is high, the manual operation steps are reduced, and time and labor are saved; and the use angle and height of the whole device can be adjusted, the adjustment flexibility is high, the precision is high, placement and use in different environments are facilitated, and use is convenient.

Owner:彭清莲

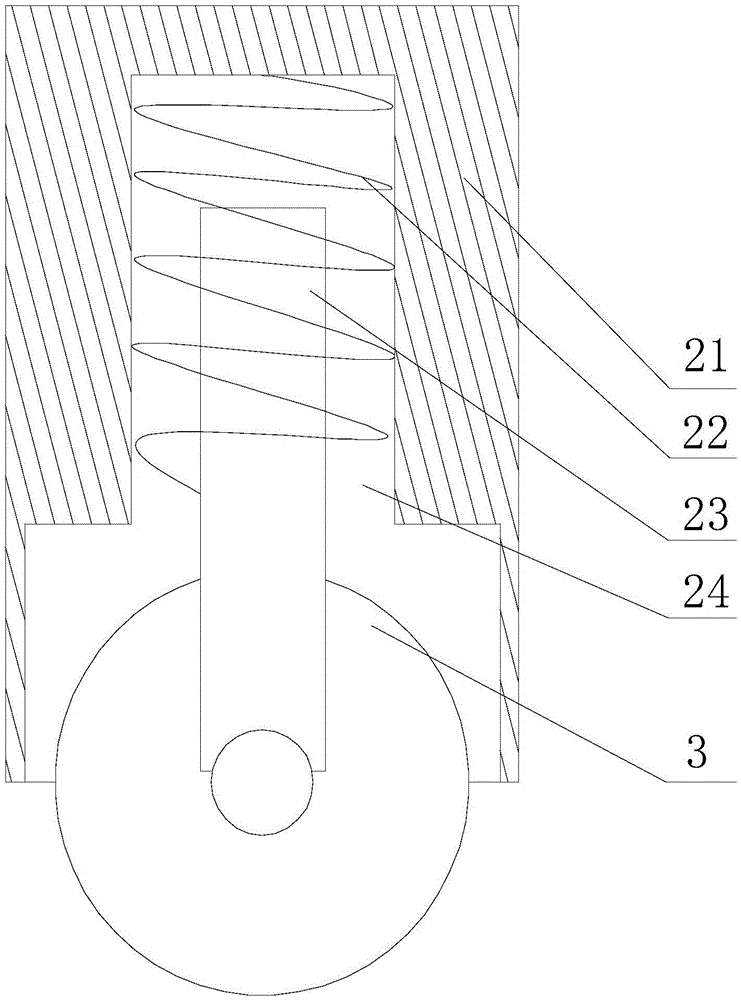

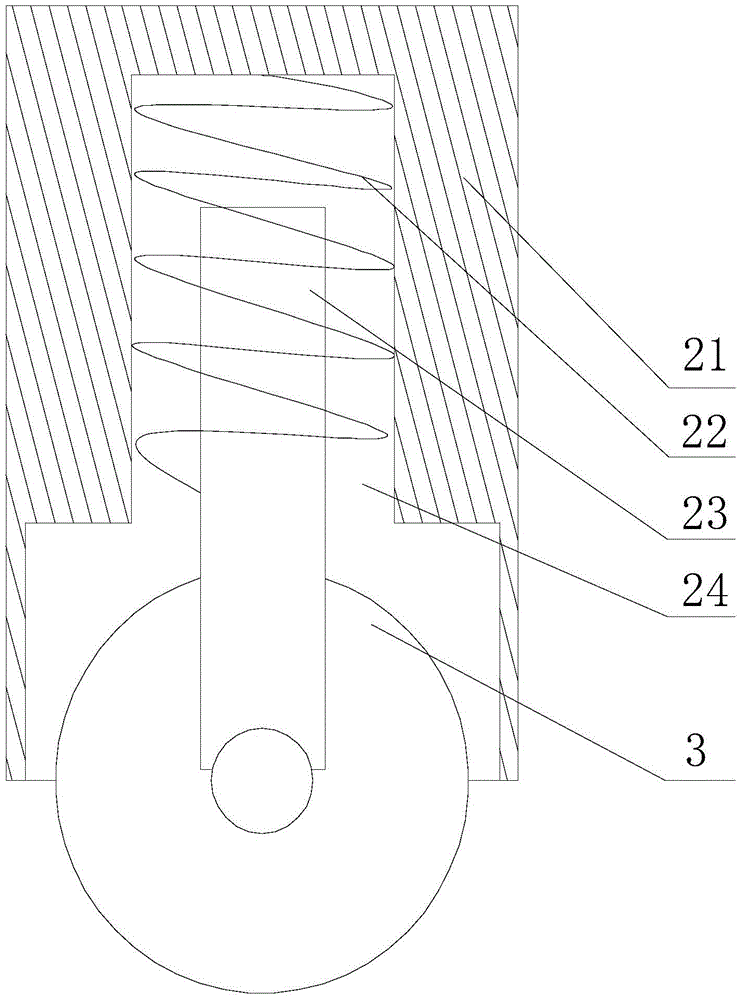

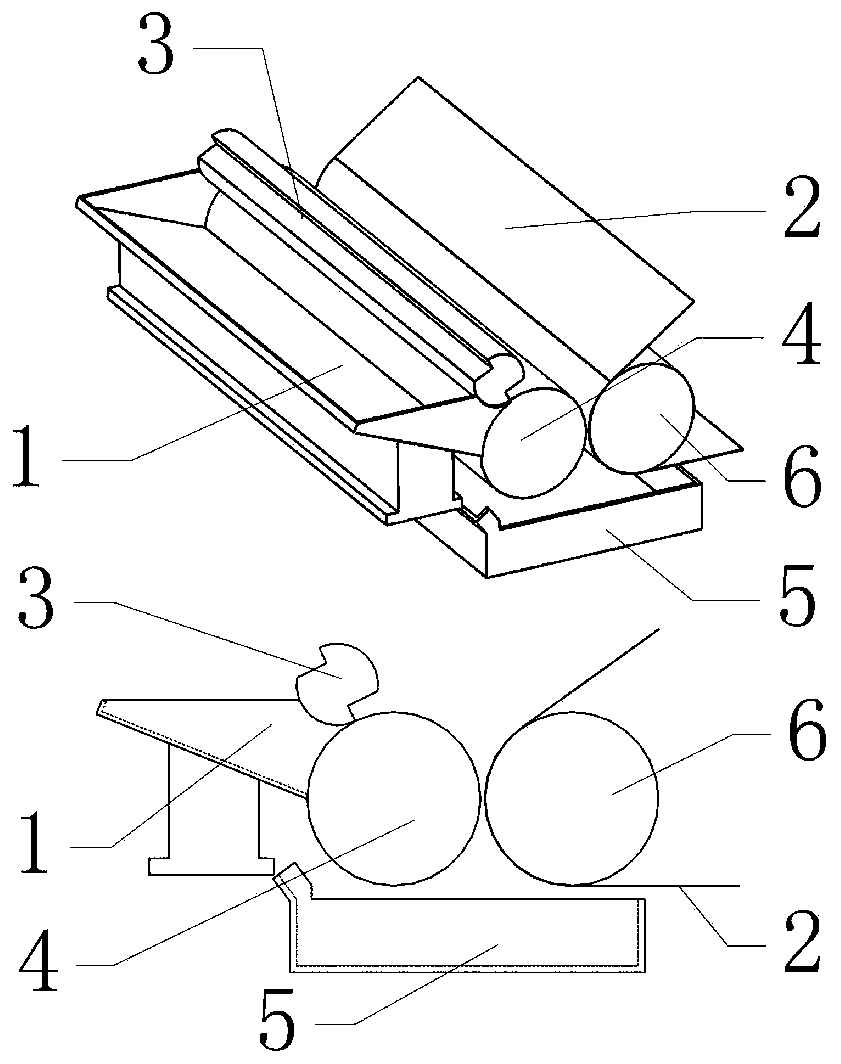

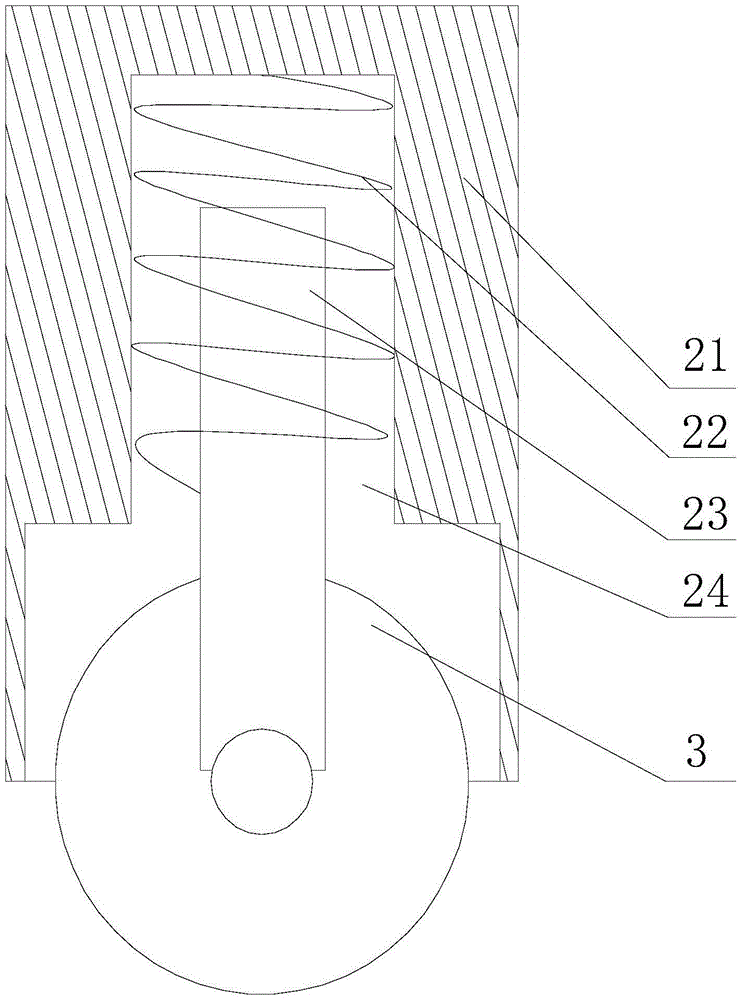

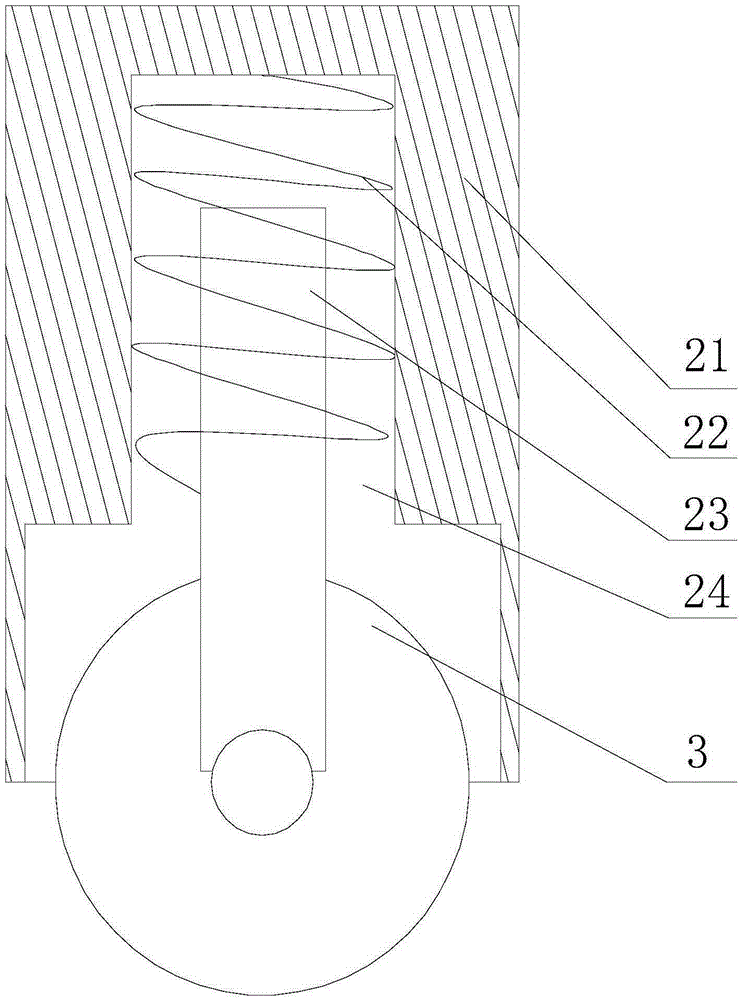

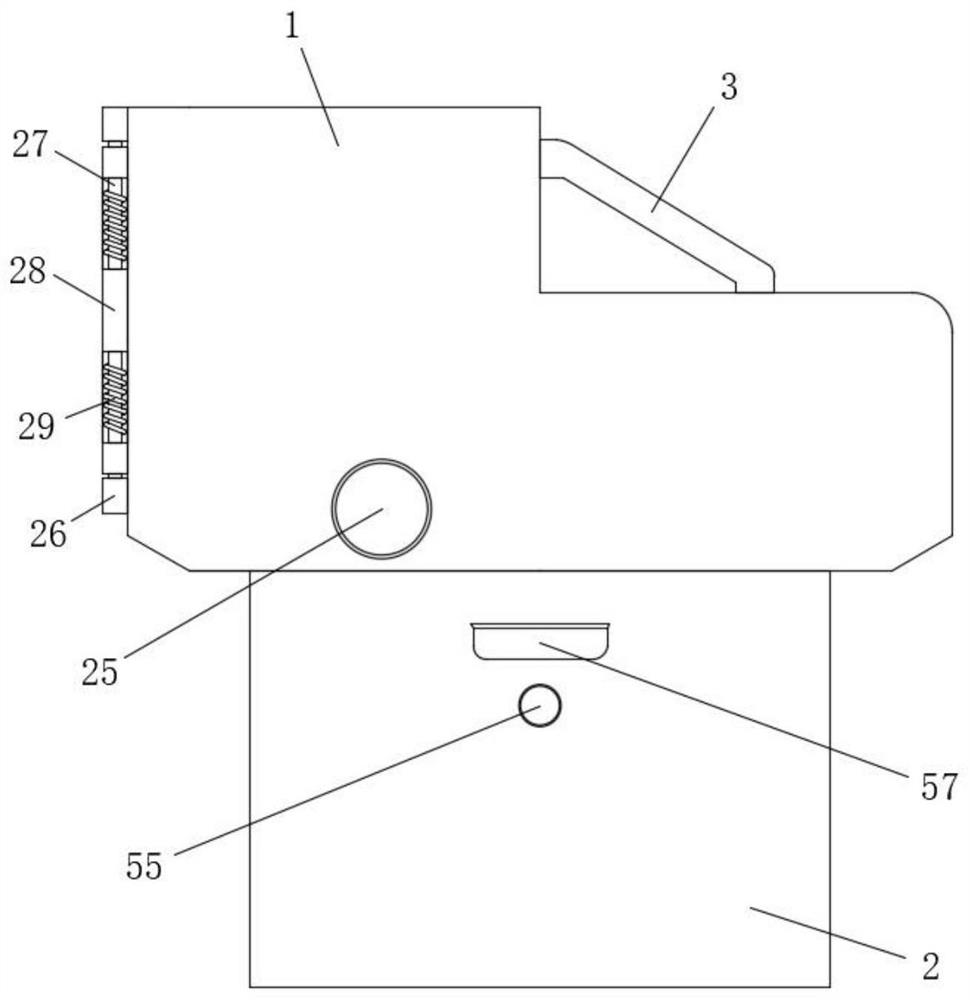

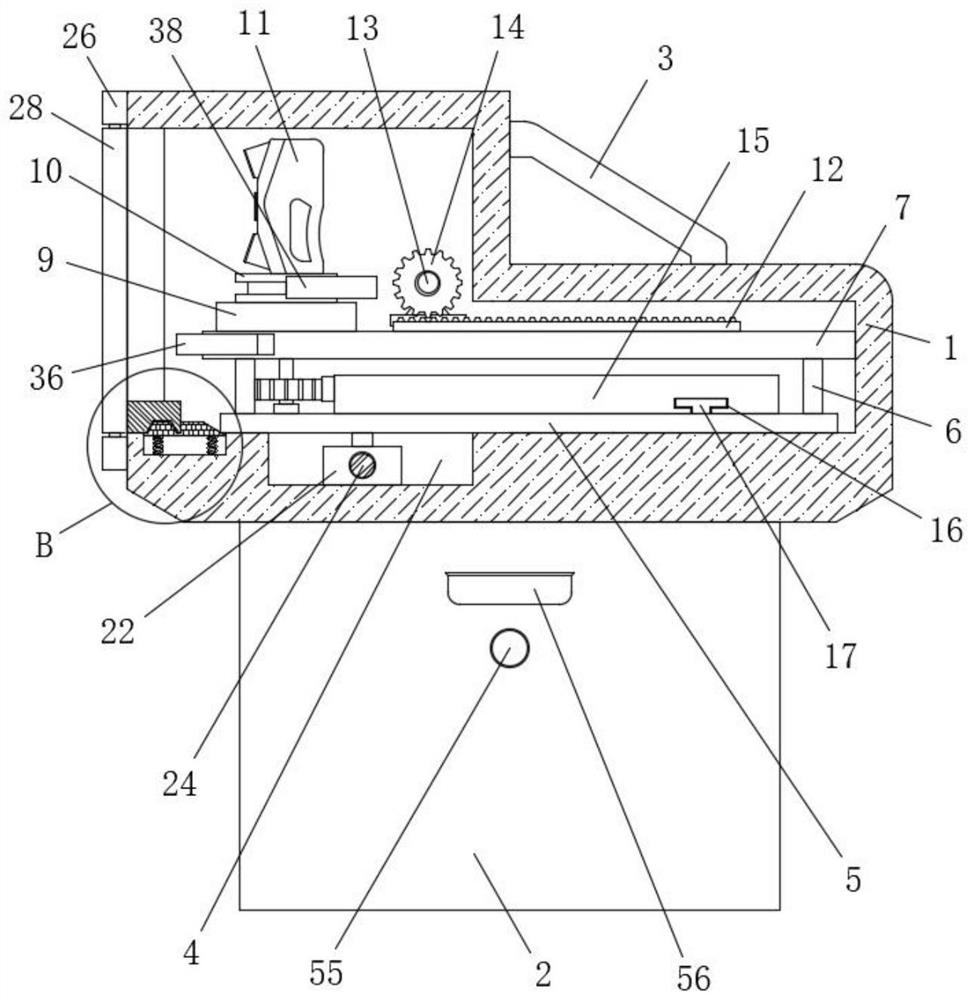

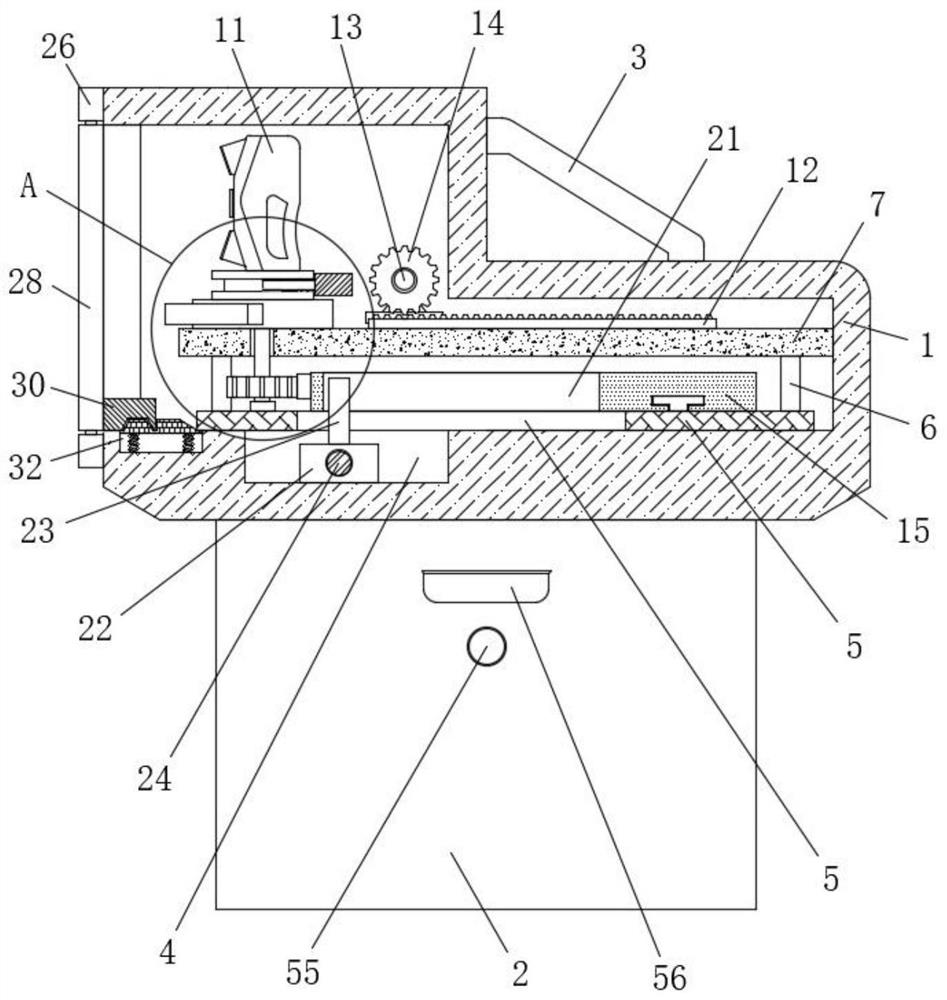

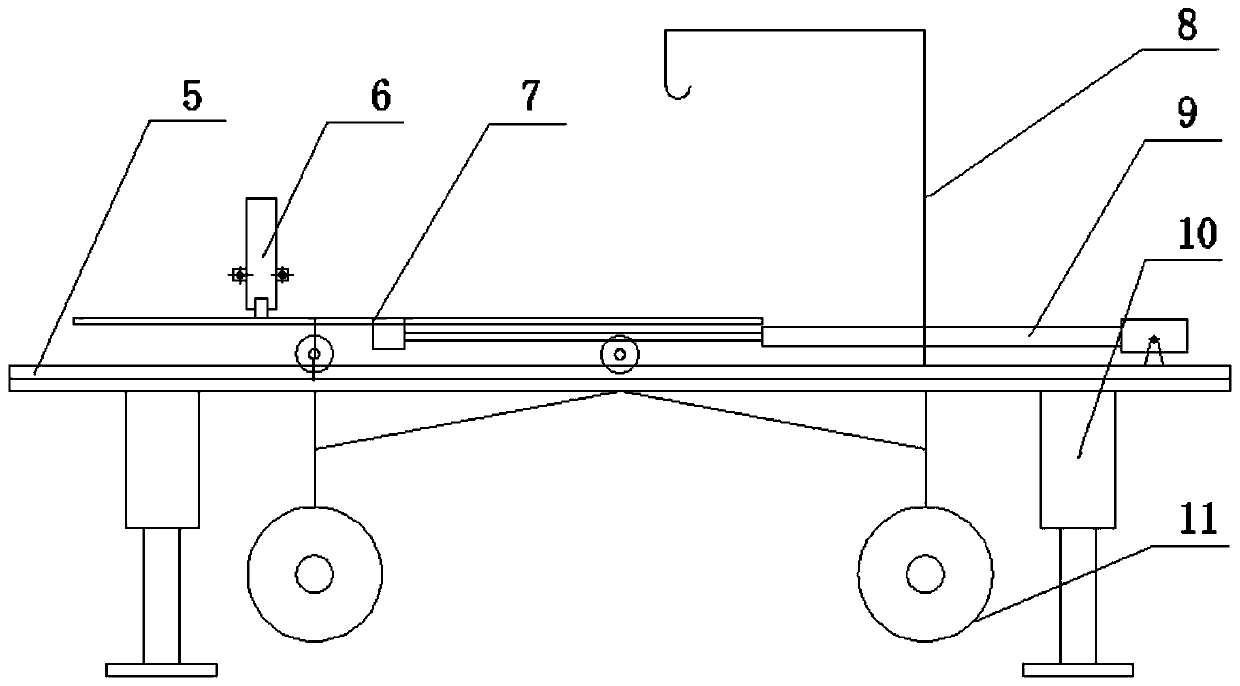

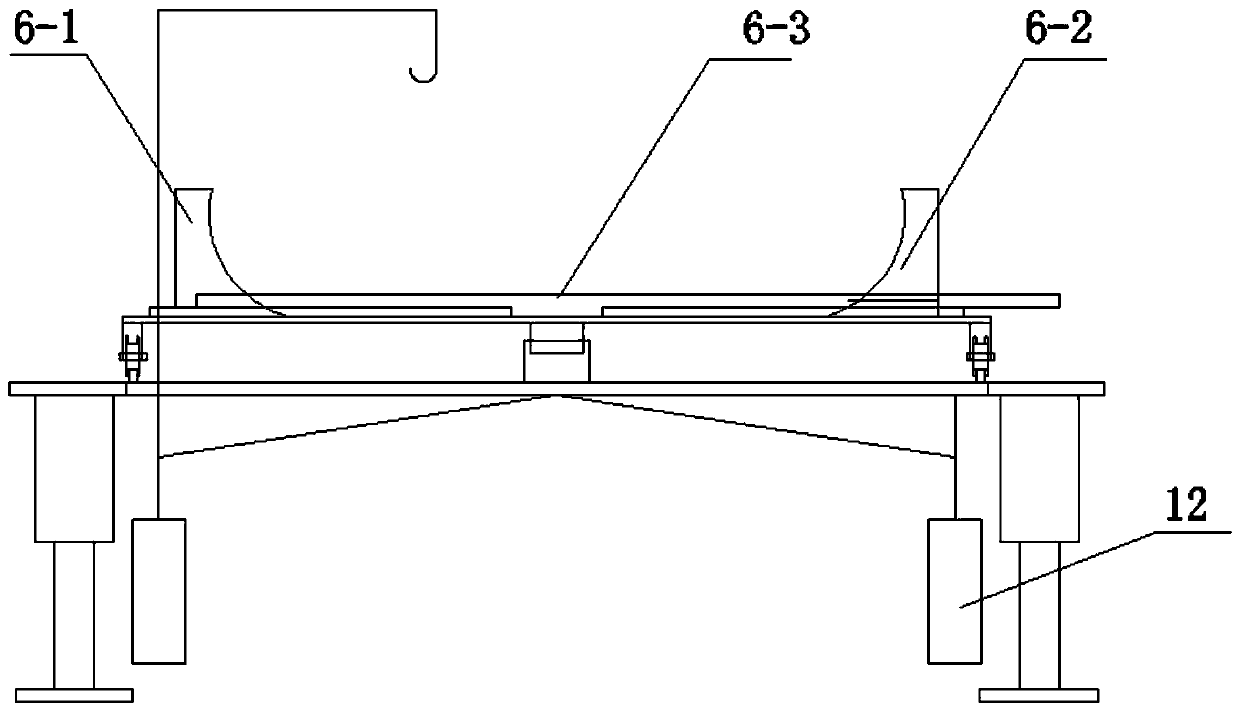

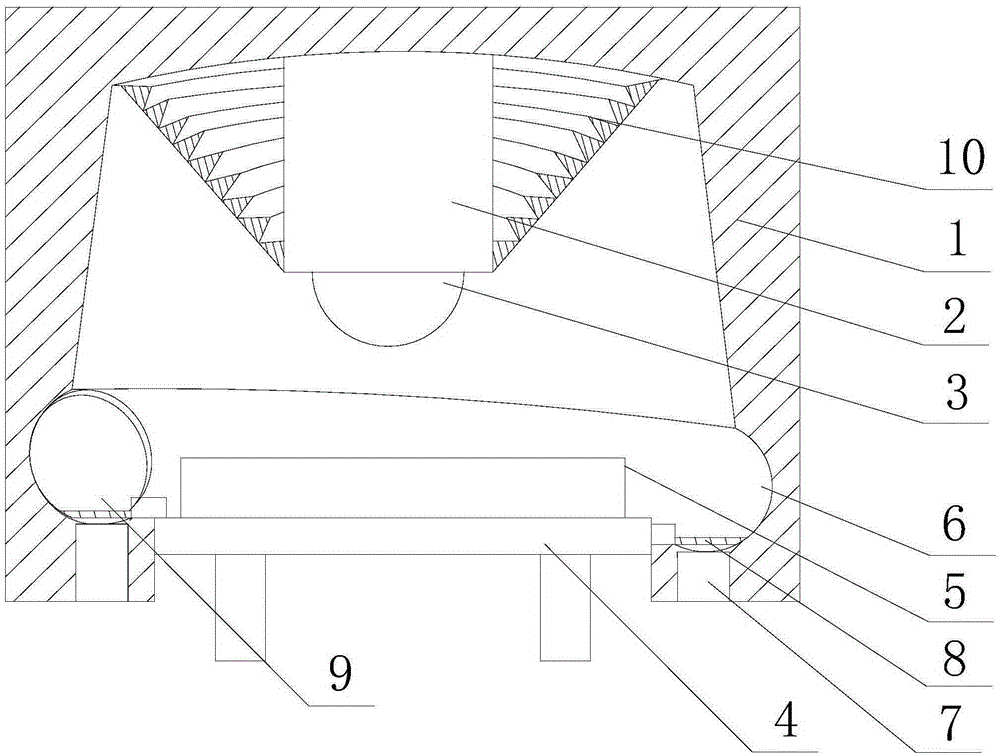

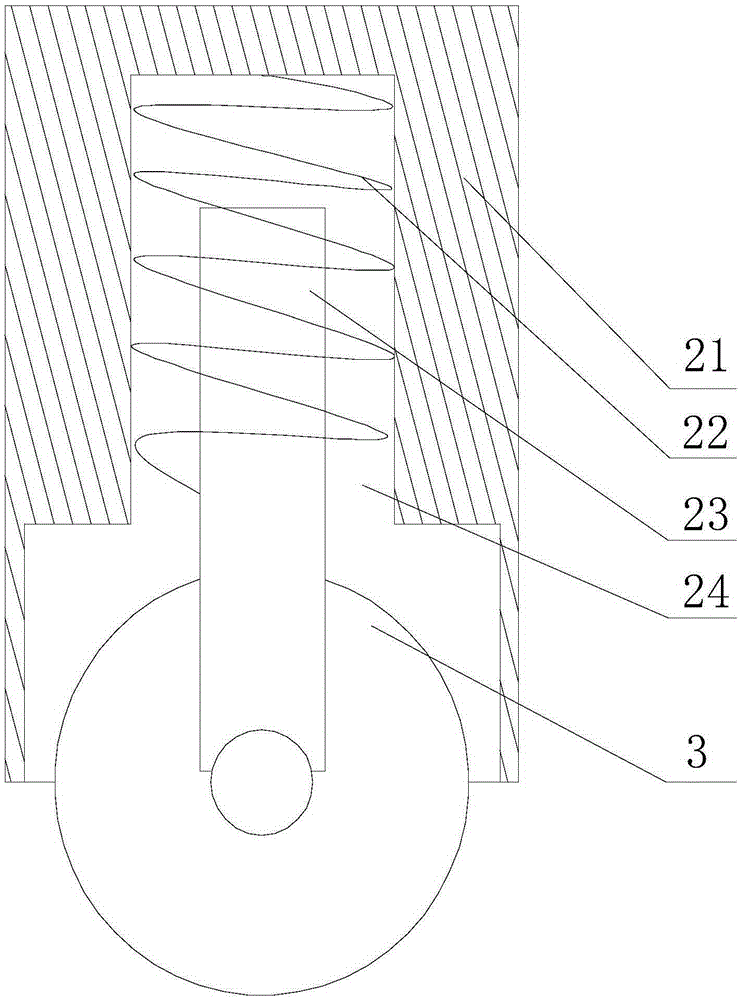

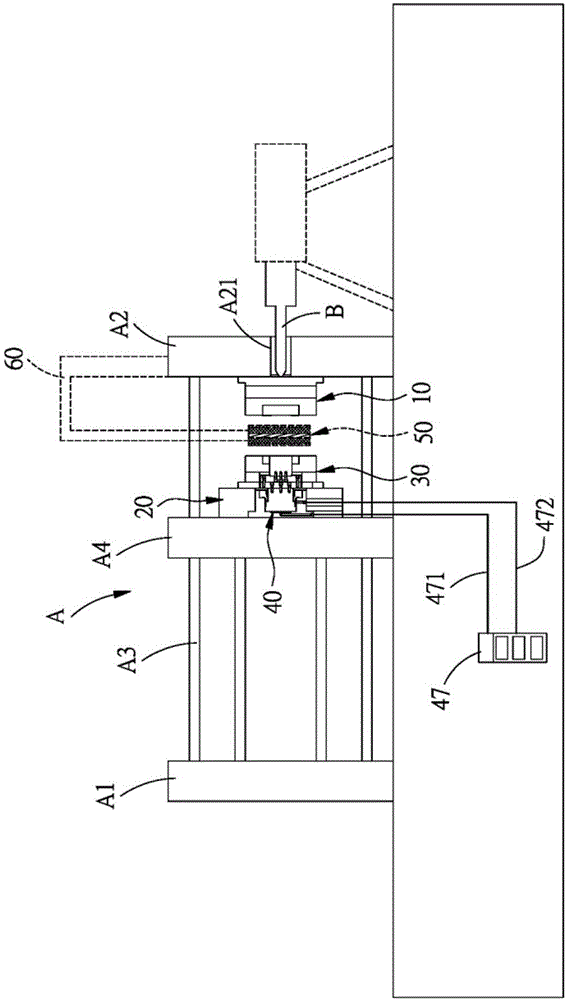

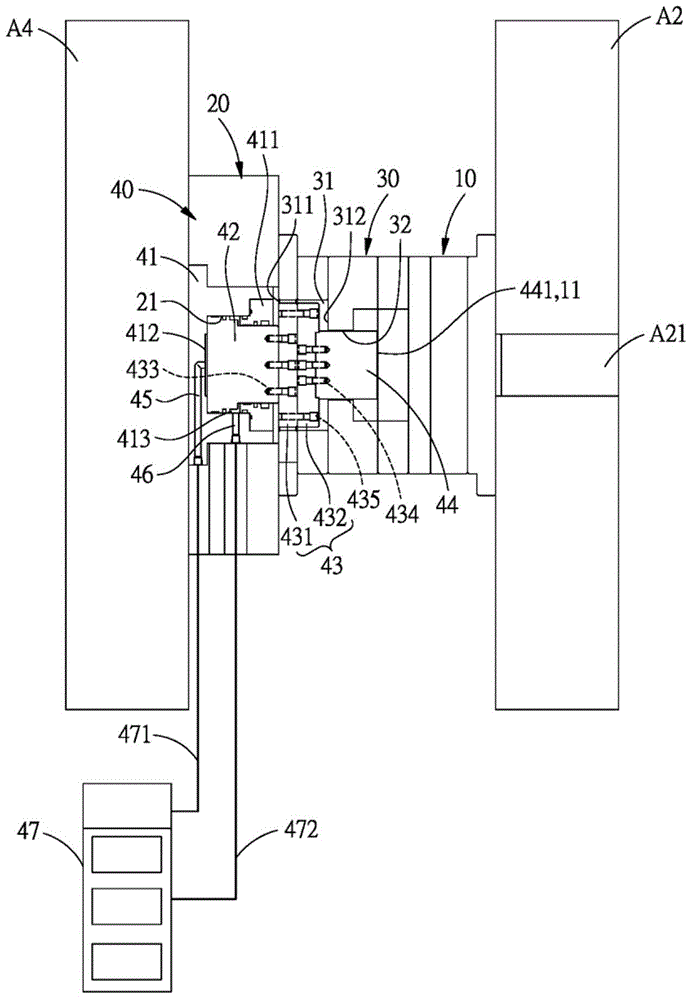

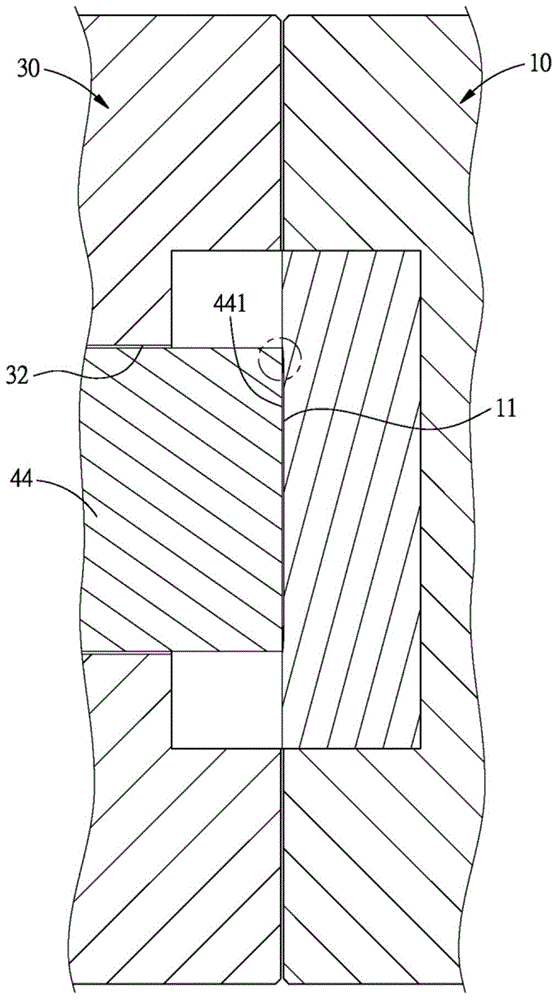

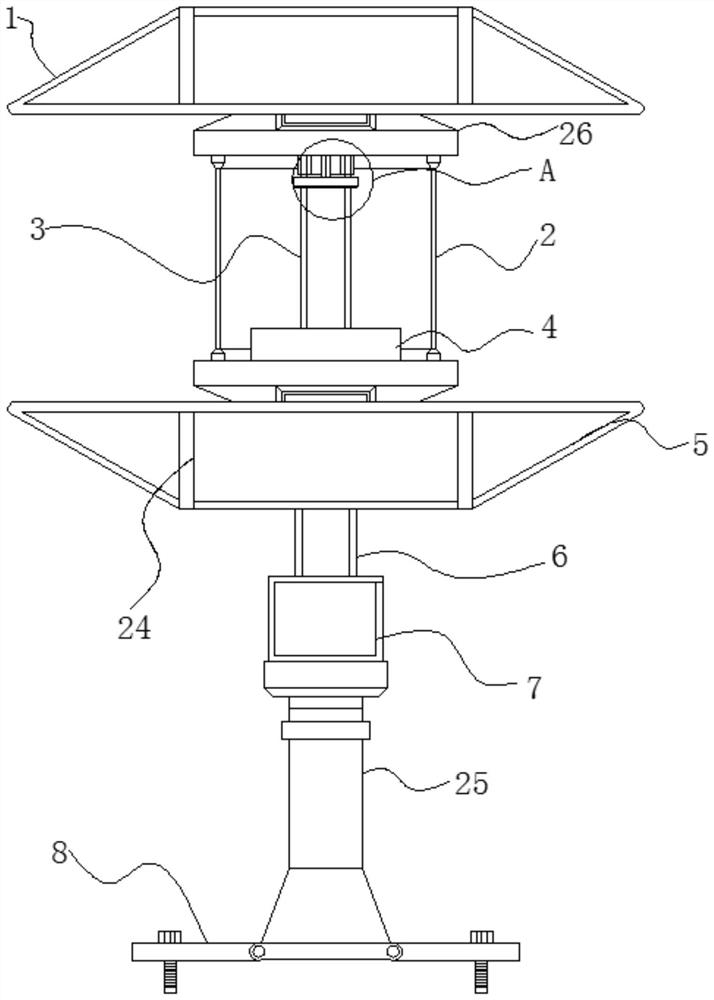

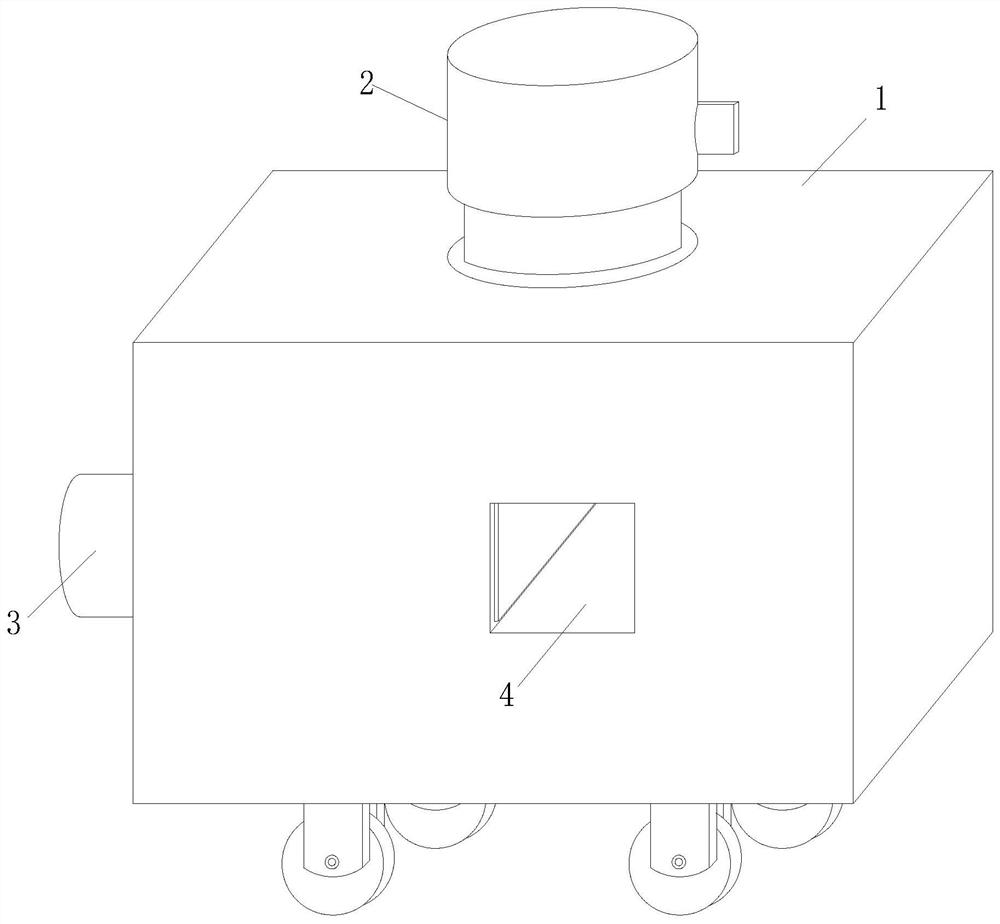

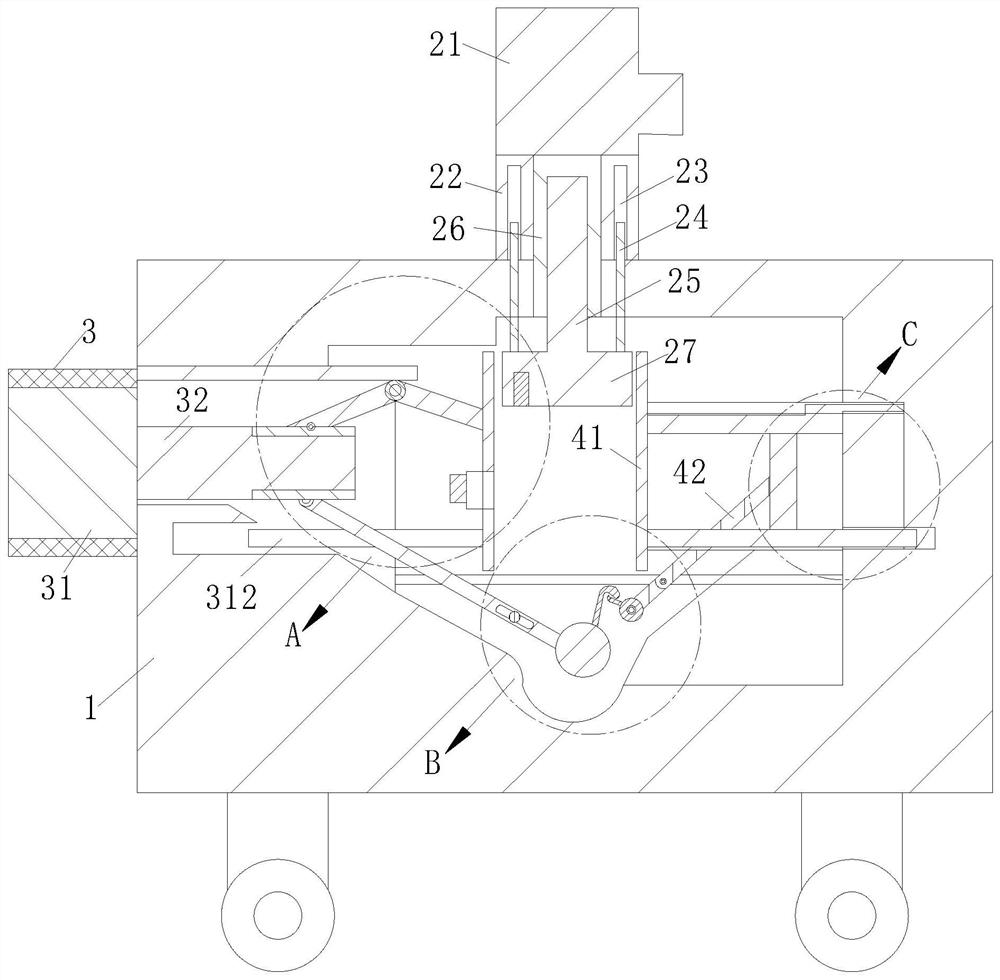

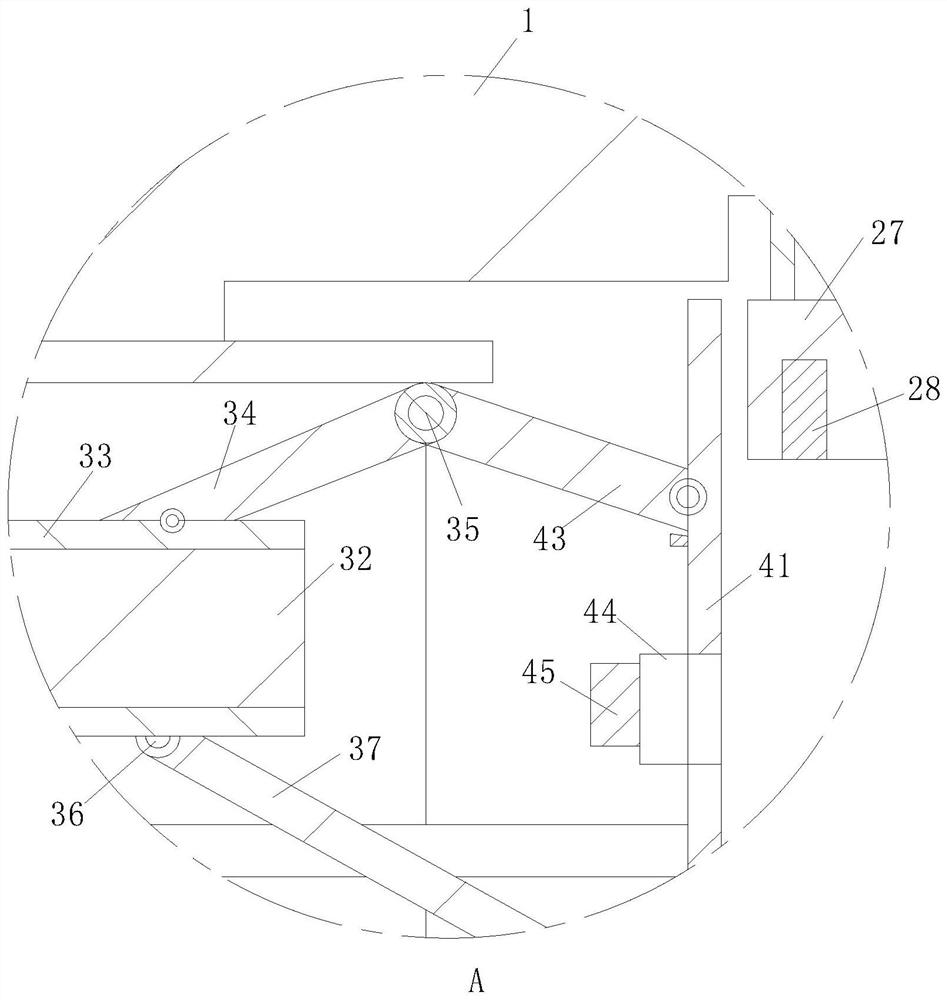

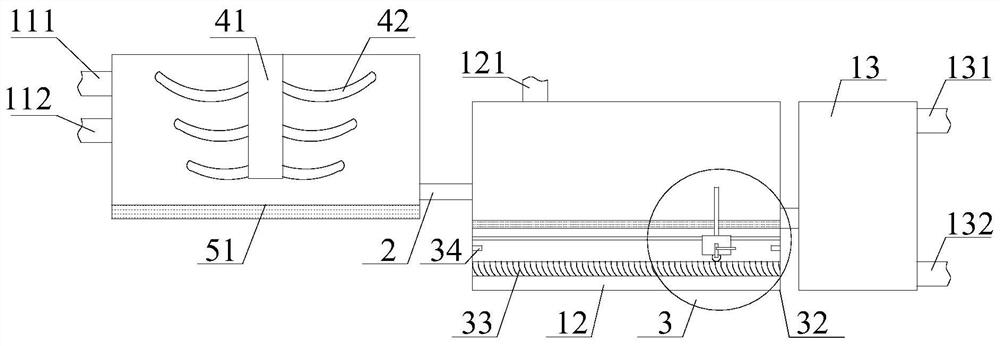

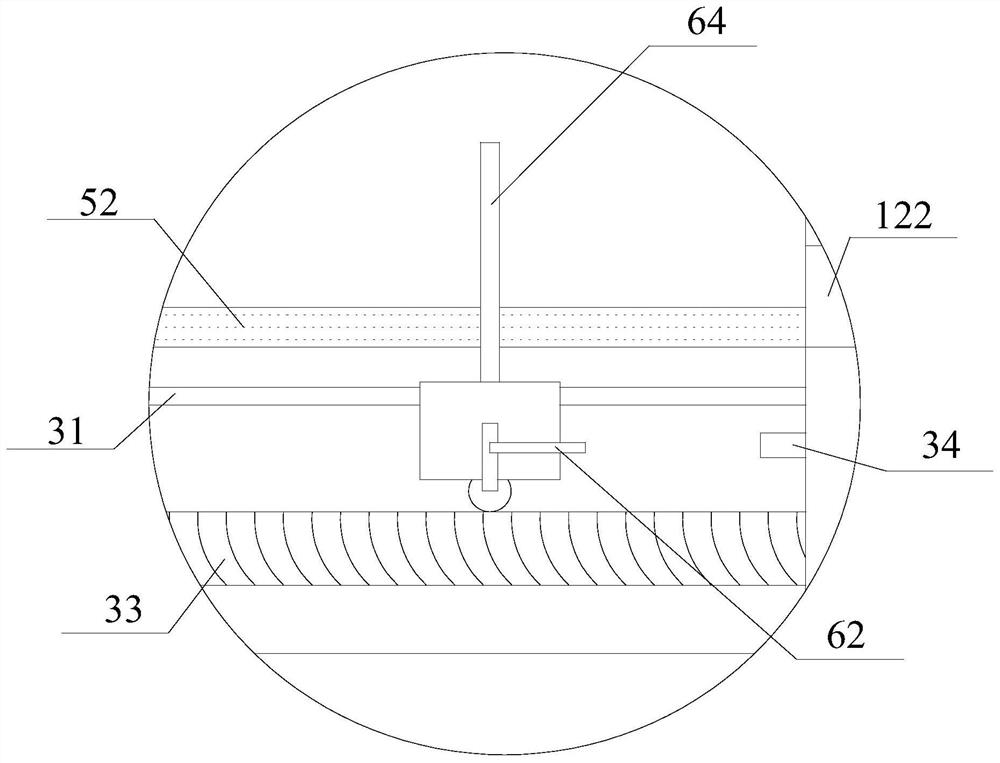

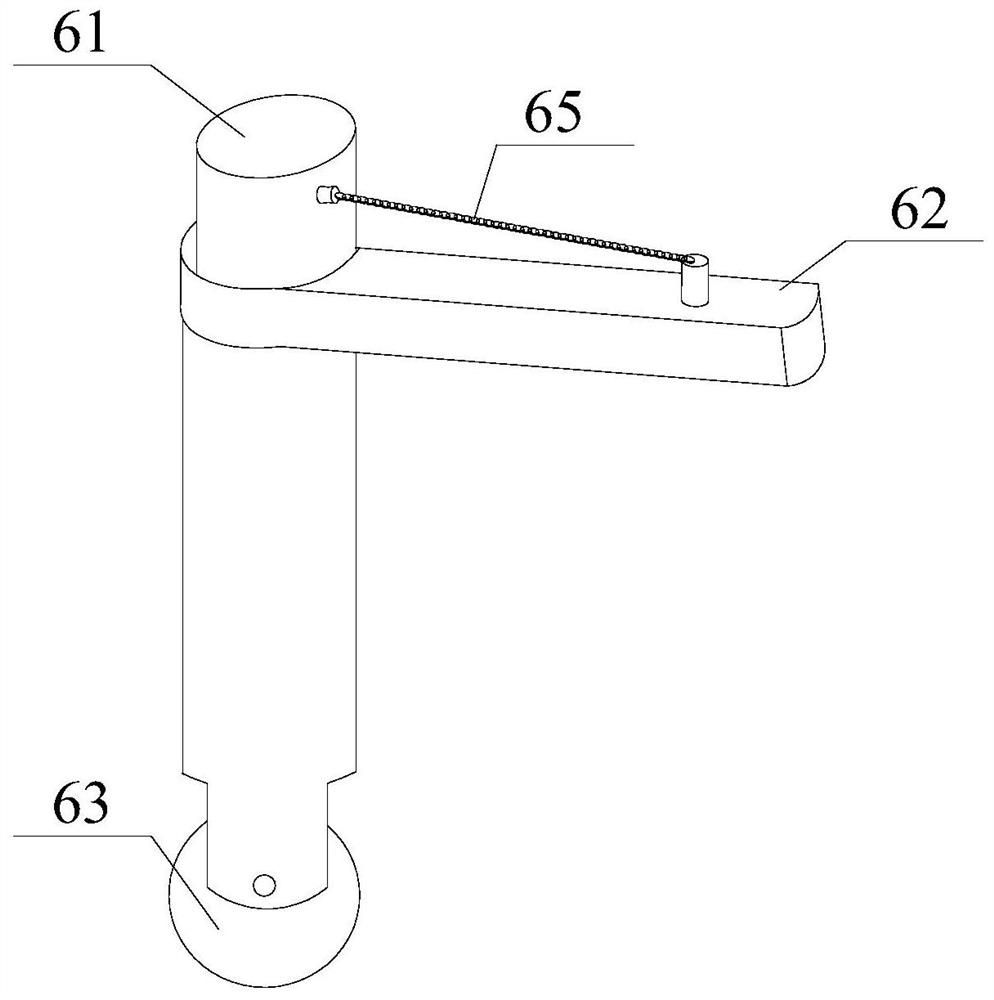

Rail trolley wheel set replacing tool

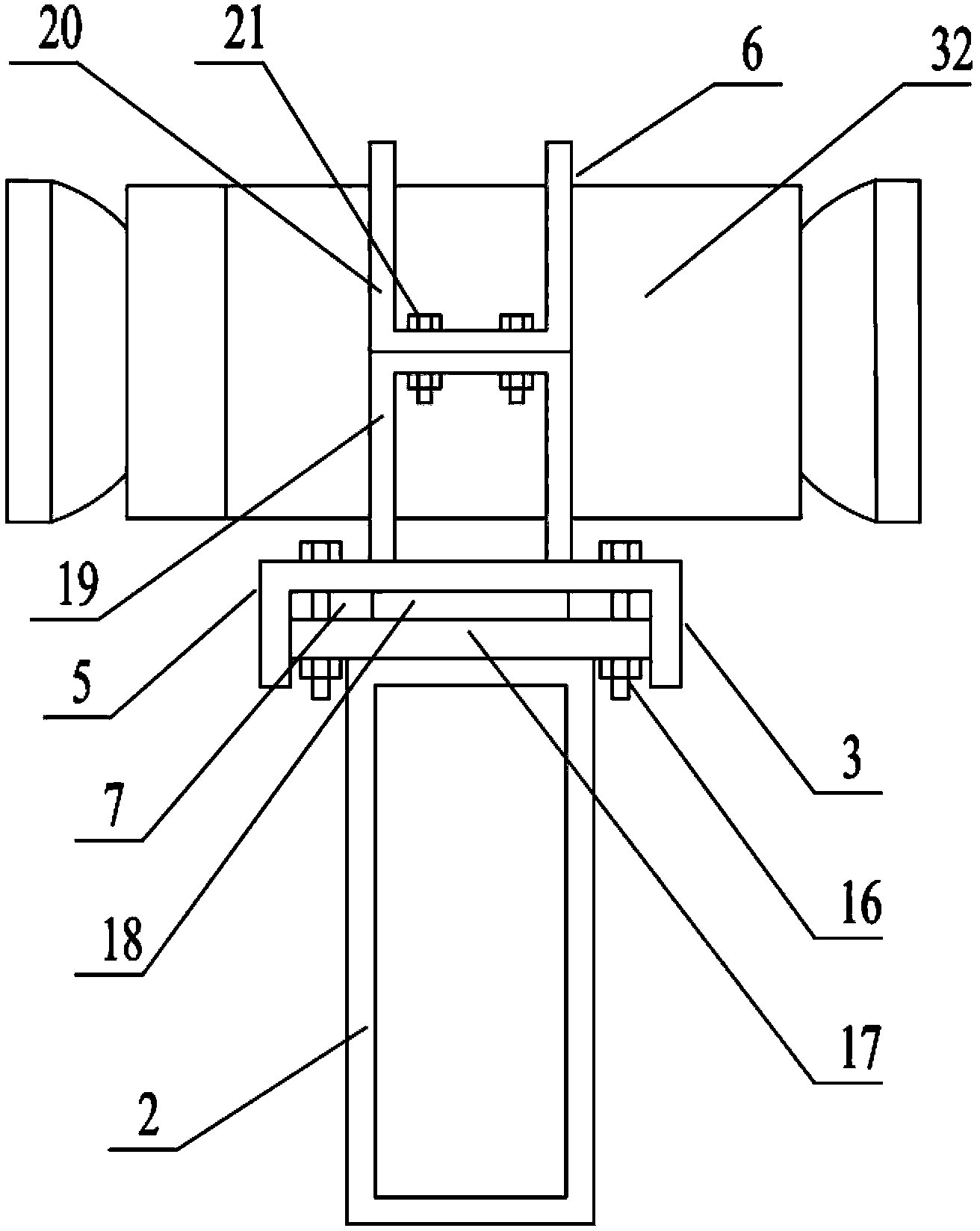

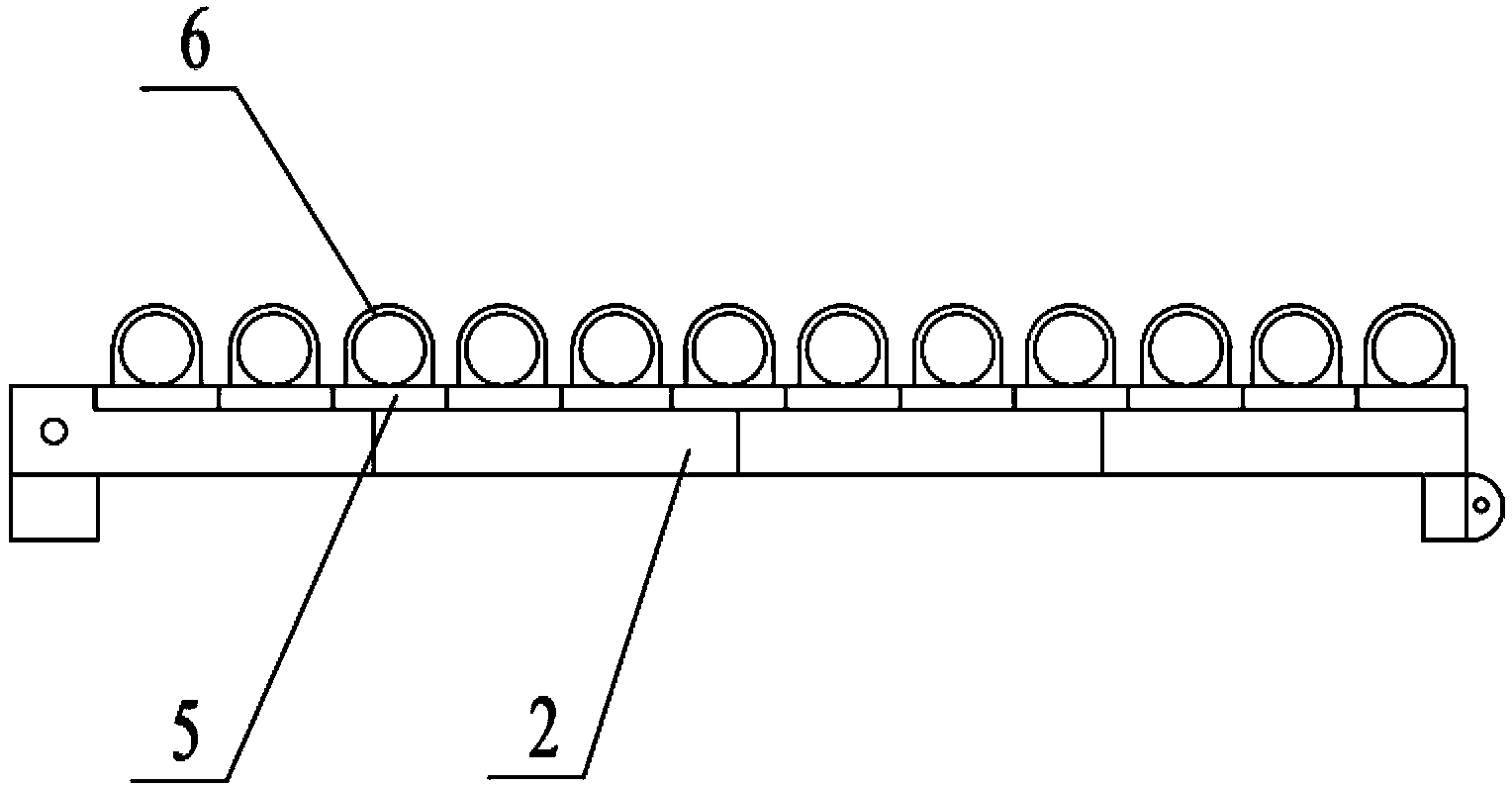

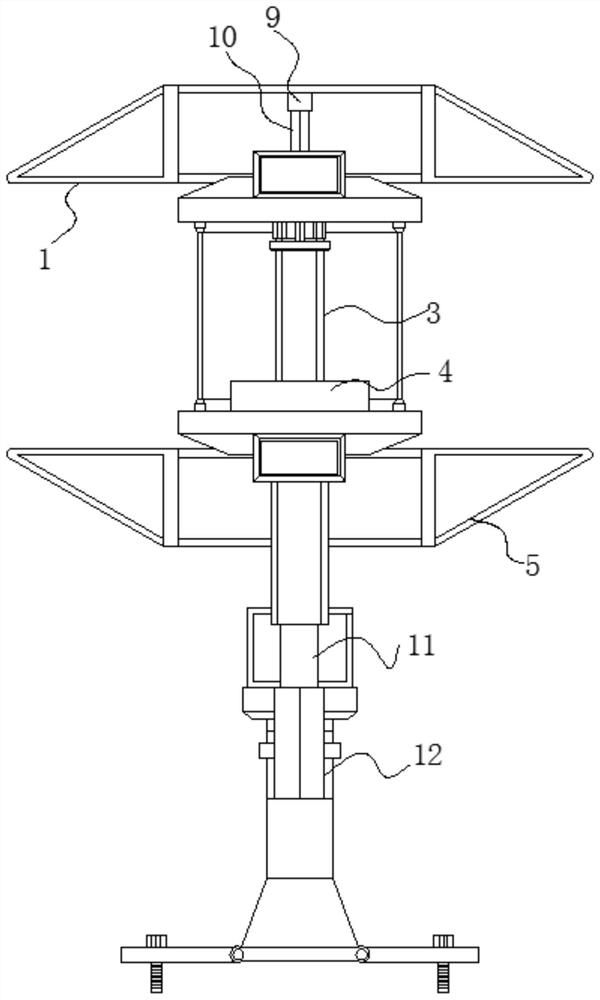

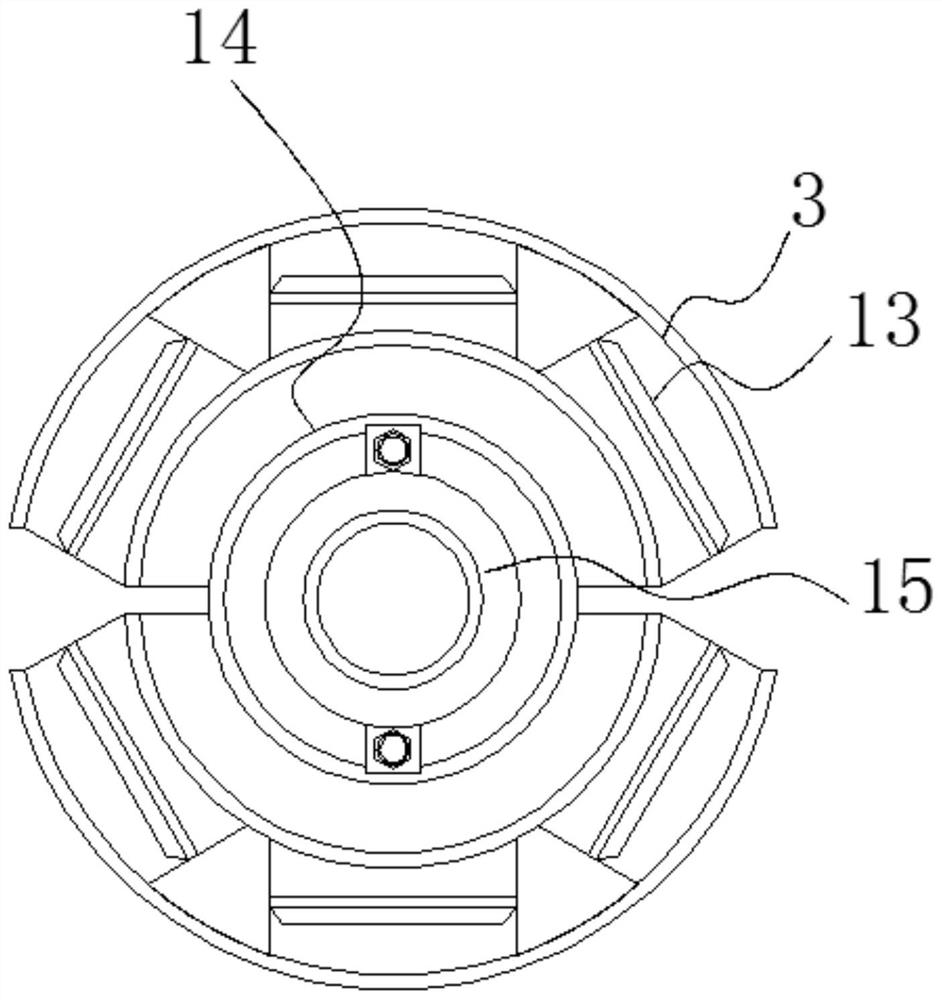

InactiveCN111516429AEnough room to moveRealize disassemblyWheel mounting apparatusLifting framesControl engineeringControl theory

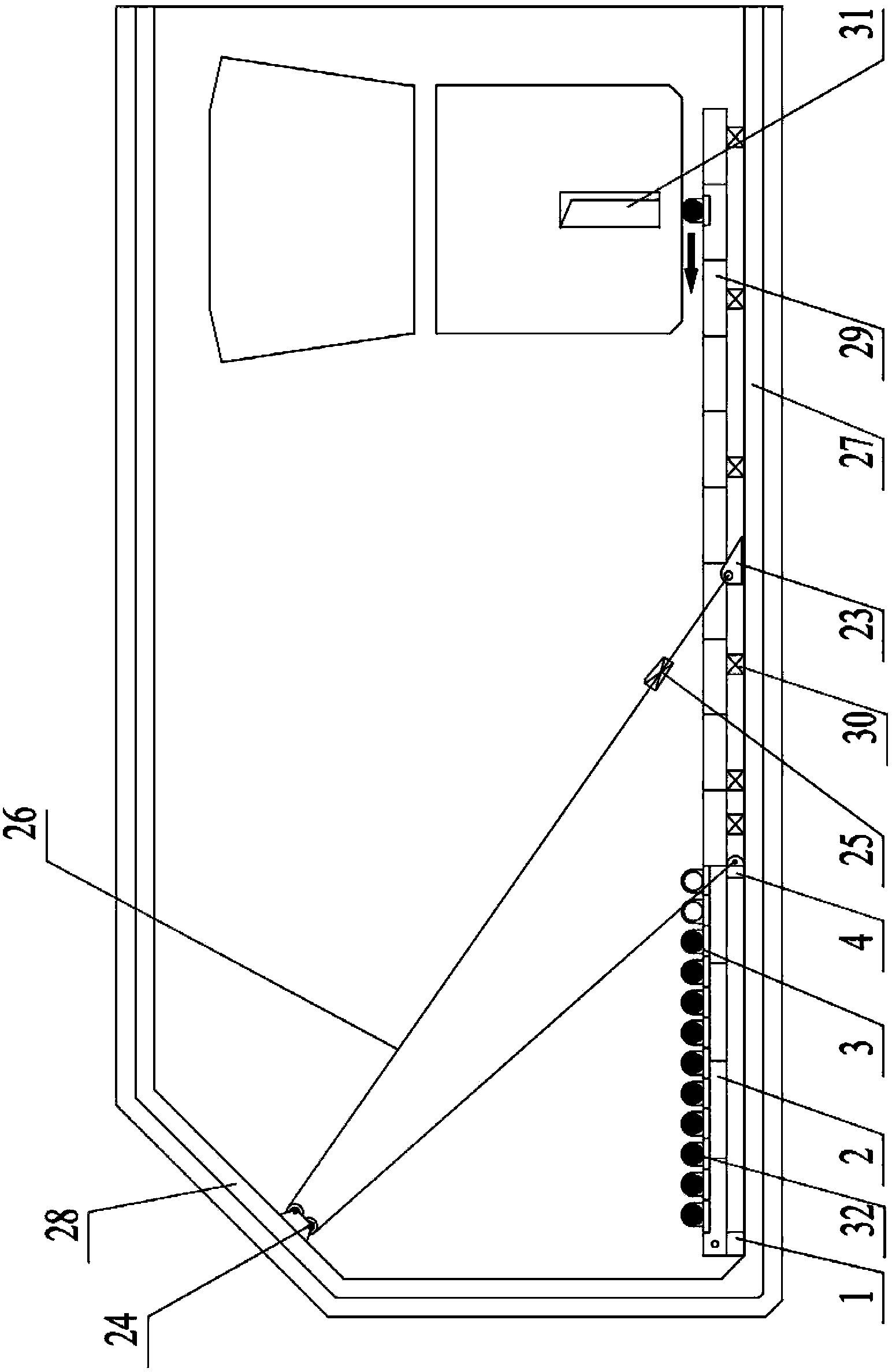

The invention discloses a rail trolley wheel set replacing tool which comprises a lifting device, a horizontal moving device and a wheel set tray; the wheel set tray is used for supporting a wheel setto be disassembled and assembled; the horizontal moving device is fixed to the lifting device; and the wheel set tray is fixed to the telescopic end of the horizontal moving device. When the wheel set needs to be disassembled, the height position of the horizontal moving device is adjusted through the lifting device, so that the bearing surface of the wheel set tray is located on the same plane with the lower surface of the wheel set to be disassembled; the wheel set tray is controlled to move towards the direction of the wheel set so as to lift up the wheel set; after a fixing piece on the wheel set is dismounted, a wheel set saddle is moved upwards, so that enough moving space can be ensured; and finally the wheel set is pulled out through the horizontal moving device. When the wheel set is assembled, the wheel set can be assembled through steps opposite to the above steps. Due to the fact that the wheel set is borne by the wheel set tray during disassembly and assembly, the stability of the position of the wheel set can be guaranteed, and then the safety of the disassembly and assembly of the wheel set is improved.

Owner:PANGANG GRP XICHANG STEEL & VANADIUM CO LTD

Protective device used for metal part cutting and machining

InactiveCN106799641AGuaranteed normal cuttingPrevent splashMaintainance and safety accessoriesMachiningMetal

The invention discloses a protective device for metal parts cutting and processing, which includes a worktable, on which a shielding cover is installed, an opening is arranged on the side of the shielding cover, a cavity is opened in the shielding cover, and a A collection tank, the side of the collection tank is connected with the side wall of the workbench, a cutting wheel is rotated at the end of the telescopic arm, the suction end of the fan is connected with the collection tank, and a filter screen is installed on the collection tank, and the filter screen and There is a gap between the bottoms of the collection tanks, and limit blocks are installed at both ends of the workbench. The opposite side walls of the two limit blocks are recessed away from the center of the workbench, and rubber protrusions are provided in the middle of the depression. When cutting, the generated metal debris starts to slide down along the inner wall of the cavity until it falls into the ring-shaped collection tank. After the chips are finished, the collection tank can be cleaned with a simple tool such as a broom, and the accumulation in the collection tank can be recovered in a concentrated manner. Metal scraps for secondary use.

Owner:重庆市木越机械制造有限公司

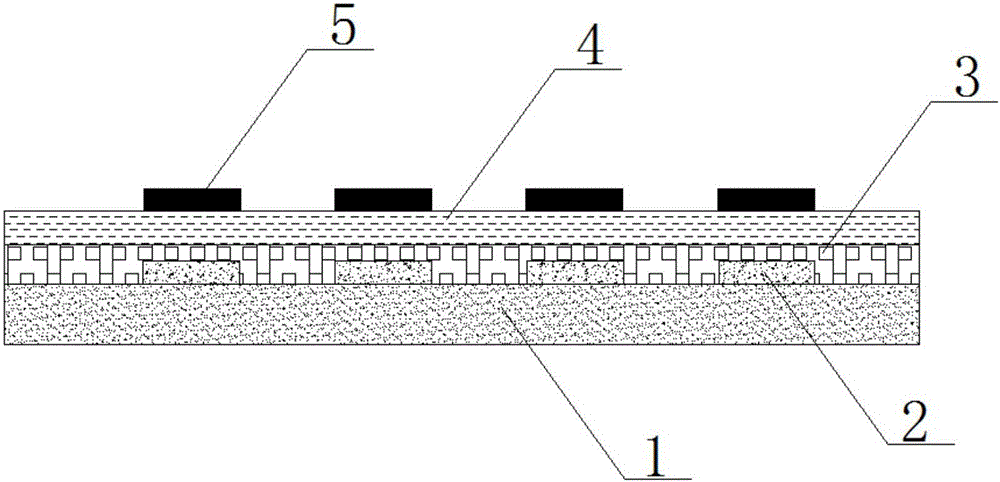

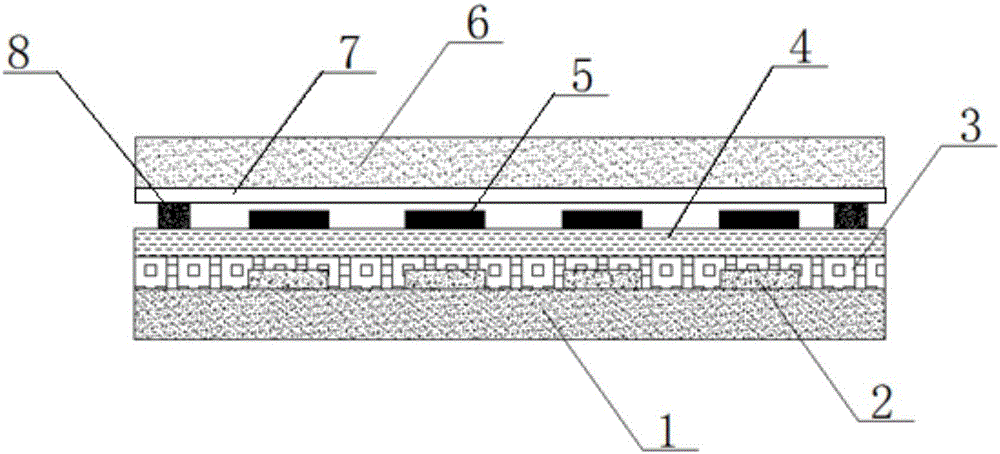

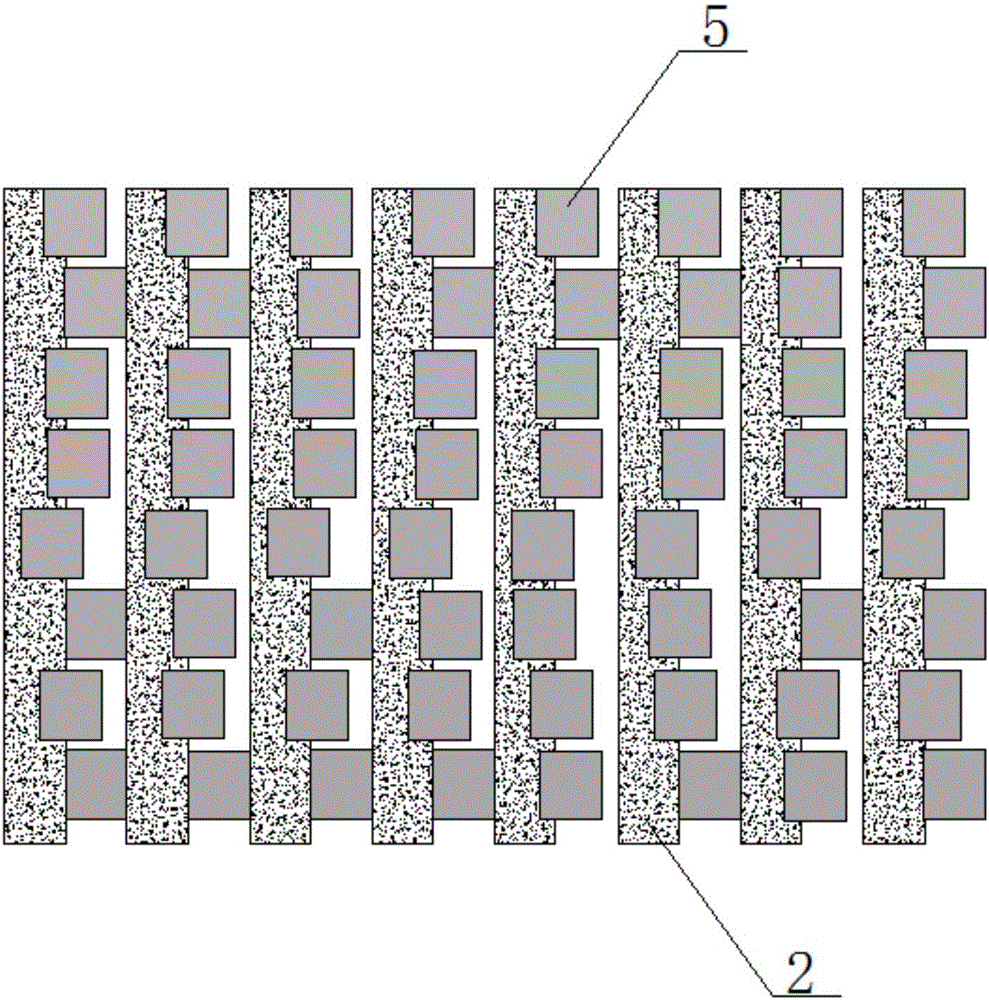

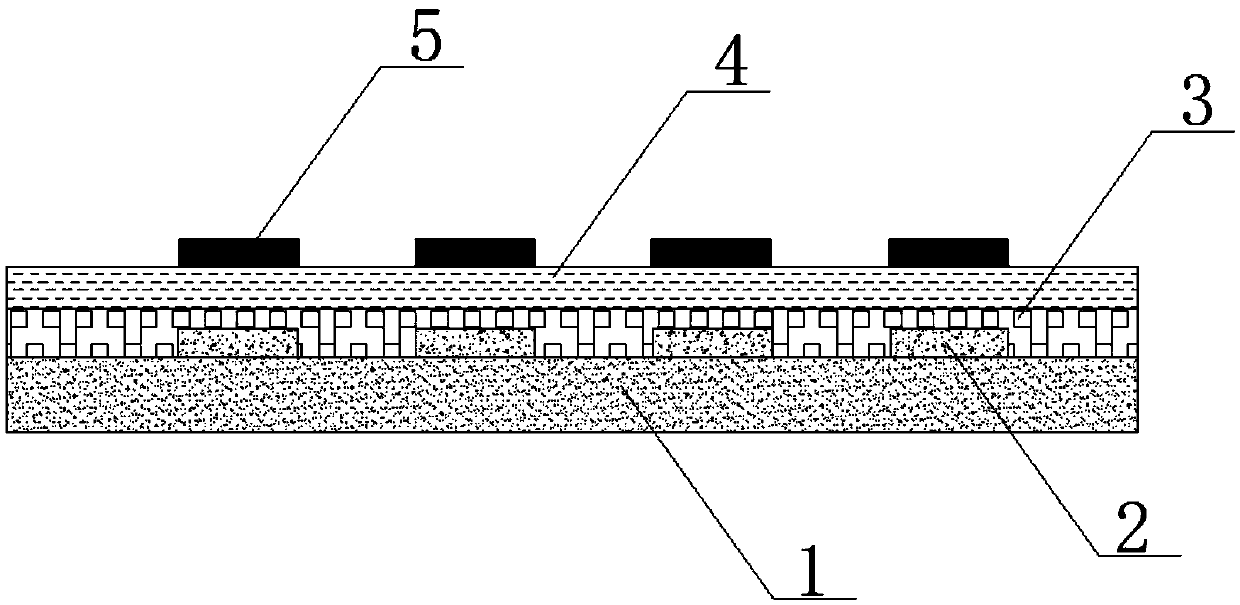

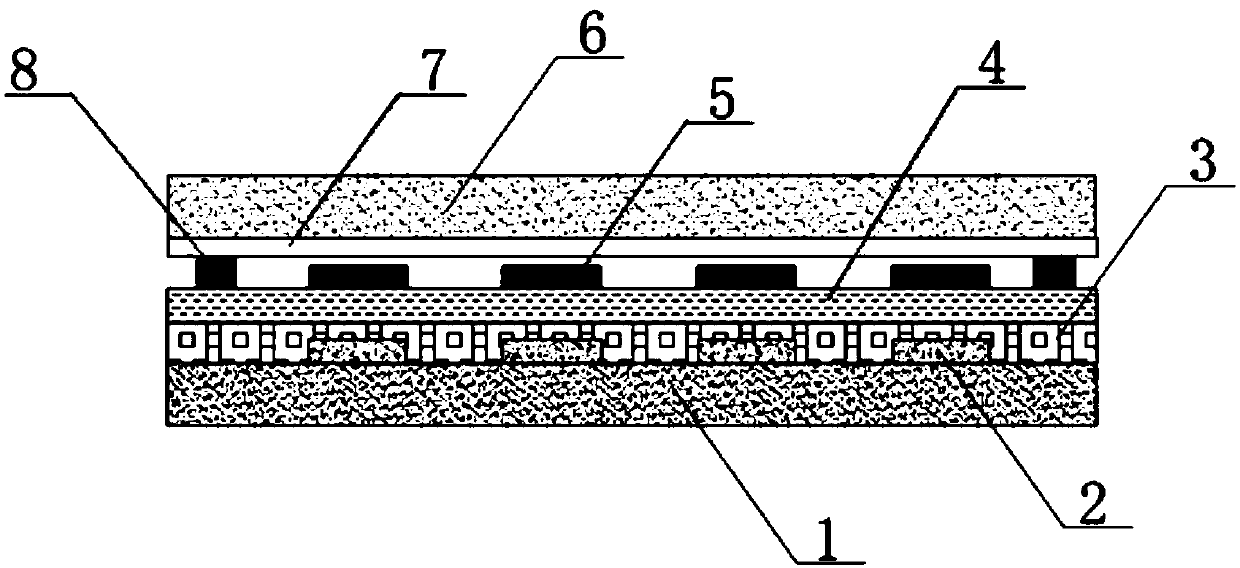

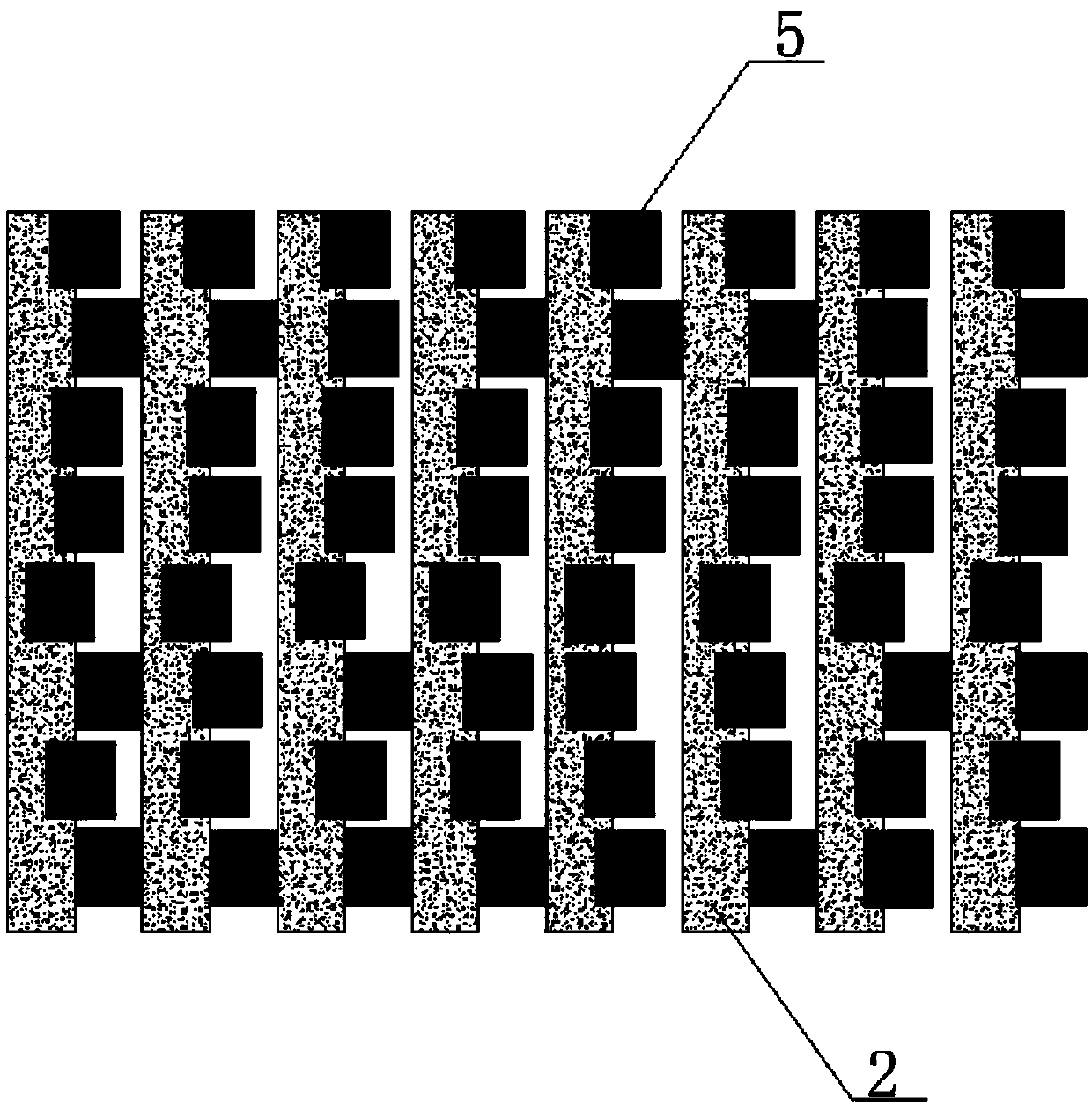

Micro-electro-mechanical system (MEMS) substrate, display unit containing same and intelligent display mirror

ActiveCN106125294ARealize the function of reflective displayBrightness adjustableOptical elementsGratingColor film

The application provides an MEMS substrate, a display unit containing the same and an intelligent display mirror. The MEMS substrate provided by the present invention is characterized by orderly comprising an array substrate, a raster for reflecting ambient light, an insulating layer, a color film photoresistor and an adjusting raster, wherein the adjusting raster can move, the array substrate is equipped with an MEMS raster drive circuit, and the overlapping area of the adjusting raster and the raster for reflecting ambient light is adjusted and controlled by the drive circuit, thereby realizing a function of MEMS reflective display. The display unit provided by the present invention comprises a packaging substrate packaged on the MEMS substrate, and a metal thin film which is coated on the lower end face of the packaging substrate and is used for reflecting the external ambient light. The display mirror provided by the present invention comprises a plurality of display units in array arrangement. According to the present invention, by utilizing an MEMS technology, the multifunctional application of the mirror and the reflective display is realized, the structure of the display mirror is simplified, and the thickness of the display mirror and the cost are reduced.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS TECH CO LTD

Metal scrap recycling mechanism of machine tool

InactiveCN106799632AGuaranteed normal cuttingPrevent splashMaintainance and safety accessoriesEngineeringBlock match

The invention discloses a metal scrap recycling mechanism of a machine tool. The metal scrap recycling mechanism comprises a worktable; a shielding cover is mounted on the worktable; an opening allowing a workpiece to enter and go out is formed in the side of the shielding cover; a cavity is formed in the shielding cover; an annular collecting groove is formed in the bottom of the cavity; and the side of the collecting groove is connected with the side wall of the worktable. A telescopic arm movably penetrates through the top of the shielding cover, and a cutting wheel is rotatably arranged at the tail end of the telescopic arm. A filter screen is mounted on the collecting groove, and a gap is reserved between the filter screen and the bottom of the collecting groove. The collecting groove is arranged obliquely in the circumferential direction of the bottom of the cavity, a sliding block matched with the collecting groove is slidably arranged at the end, in the high position, of the filter screen, and traction ropes are connected on the two sides of the sliding block correspondingly. At the time of cutting, produced metal scraps start to slide downward along the inner wall of the cavity until falling into the annular collecting groove, and after cutting is finished, the collecting groove can be cleaned by simple tools such as a broom. Meanwhile, the metal scraps accumulated in the collecting groove are intensively recycled to achieve secondary utilization.

Owner:重庆市木越机械制造有限公司

Mold cavity adjustment device of injection machine and adjustment method thereof

The invention provides a mold cavity adjustment device of an injection machine and an adjustment method thereof. An oil cylinder adjustment mechanism is arranged in an assembling and fixing base and a module on an injection machine movable template, after molds are closed and form a complete mold cavity, the mold cavity is filled with a material, then the oil cylinder adjustment mechanism adjusts and reduces mold cavity thickness so that after mold closing, the plastic has an enough flowing space and can uniformly fill the mold cavity, and then a thin object is cooled and molded after mold cavity thickness adjustment and reduction so that the limitation of thin object molding based on the injection machine is broken through.

Owner:KUNSHAN PAISHIDER OPTOELECTRONICS TECH

Broiler efficient high-yield breeding method

InactiveCN106973852ARestricted activitiesEnough room to moveFood processingAnimal feeding stuffFree rangeBran

The invention relates to a broiler efficient high-yield breeding method, and belongs to the technical field of poultry breeding. The breeding method comprises the specific steps of adopting open free range extensive breeding after greenhouse breeding of baby chicks finishes and epidemic prevention work is completed to 150 days, and adopting a breeding mode of cage-entry intensive breeding from 151 days of chickens, wherein fodder in the free range extensive breeding stage is prepared from pineapple bran, corn powder, peanut bran, sunflower seed meal, sesame, wheat skin, paddies, cavings, fish meal, bone (calcium) meal and saline water, and fodder in the cage breeding stage is prepared from the pineapple bran, the corn powder, the peanut bran, the sunflower seed meal, the sesame, the wheat skin, the paddies, the cavings, the fish meal, the bone meal and the saline water. The chicken bred in 180-200 days through the broiler efficient high-yield breeding method is fragrant in taste, thin in skin and soft in bone, less in subcutaneous fat and tender and smooth in meat feeling.

Owner:杜德贵

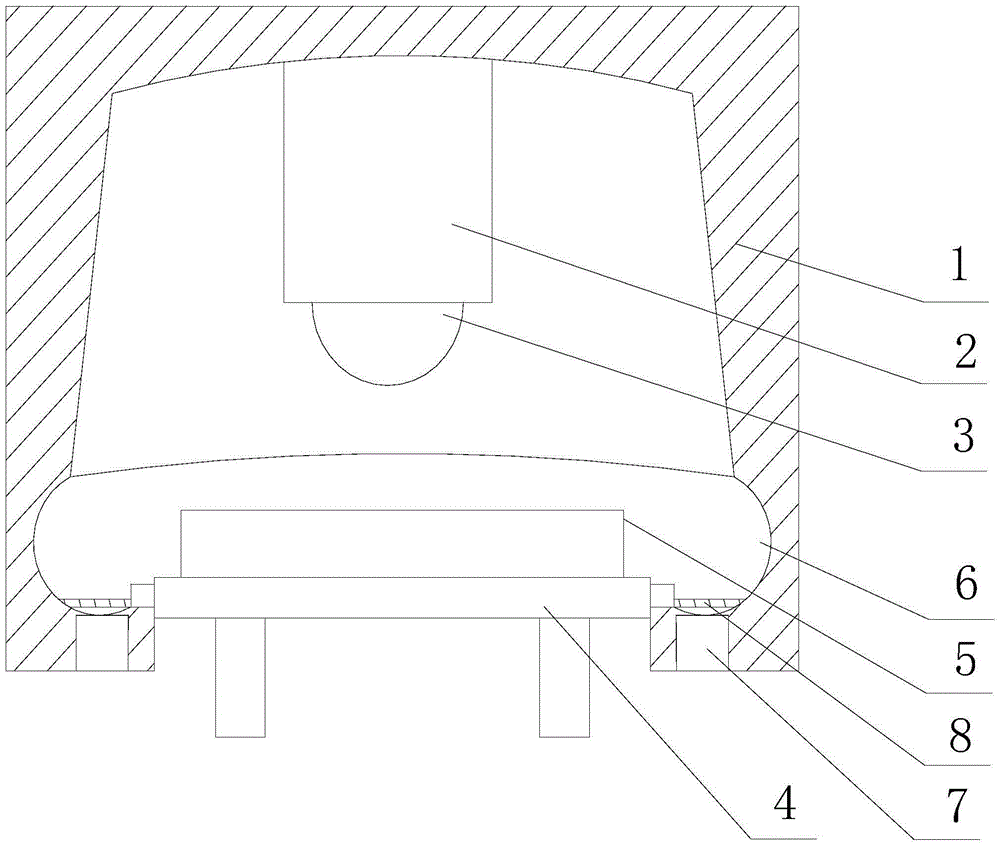

Grouting sleeve and prefabricated member

InactiveCN105781023AGuaranteed fullEnough room to moveBuilding reinforcementsArchitectural engineeringSlurry

The invention belongs to the field of constructional engineering, and particularly discloses a grouting sleeve and a prefabricated member. The grouting sleeve comprises a sleeve body, wherein the sleeve body is provided with a grouting port and an exhaust port; two ends of the sleeve body are open; fixing members are arranged in the middle of an inner cavity of the sleeve body; the inner wall of the sleeve body is provided with steel clacks; the thicknesses of the steel clacks gradually increase from the two ends to the middle of the sleeve body; the widths of the positions, which approach the fixing members, of the steel clacks are larger than the those of positions approaching end parts. The integral rigidity of the sleeve body is increased through the arrangement of the steel clacks of the grouting sleeve. In addition, poured slurry for grouting forms a fastening structure matched with an inner hollow part and the steel clacks of the sleeve in the sleeve body; the anchoring reliability of a steel bar is greatly improved; by using the grouting sleeve and the prefabricated member, the accurate axial control and radial positioning of the steel bar can be realized; the positioning accuracy between the steel bar and the grouting sleeve is guaranteed.

Owner:CHINA MINGSHENG DRAWIN TECH INVESTMENT CO LTD

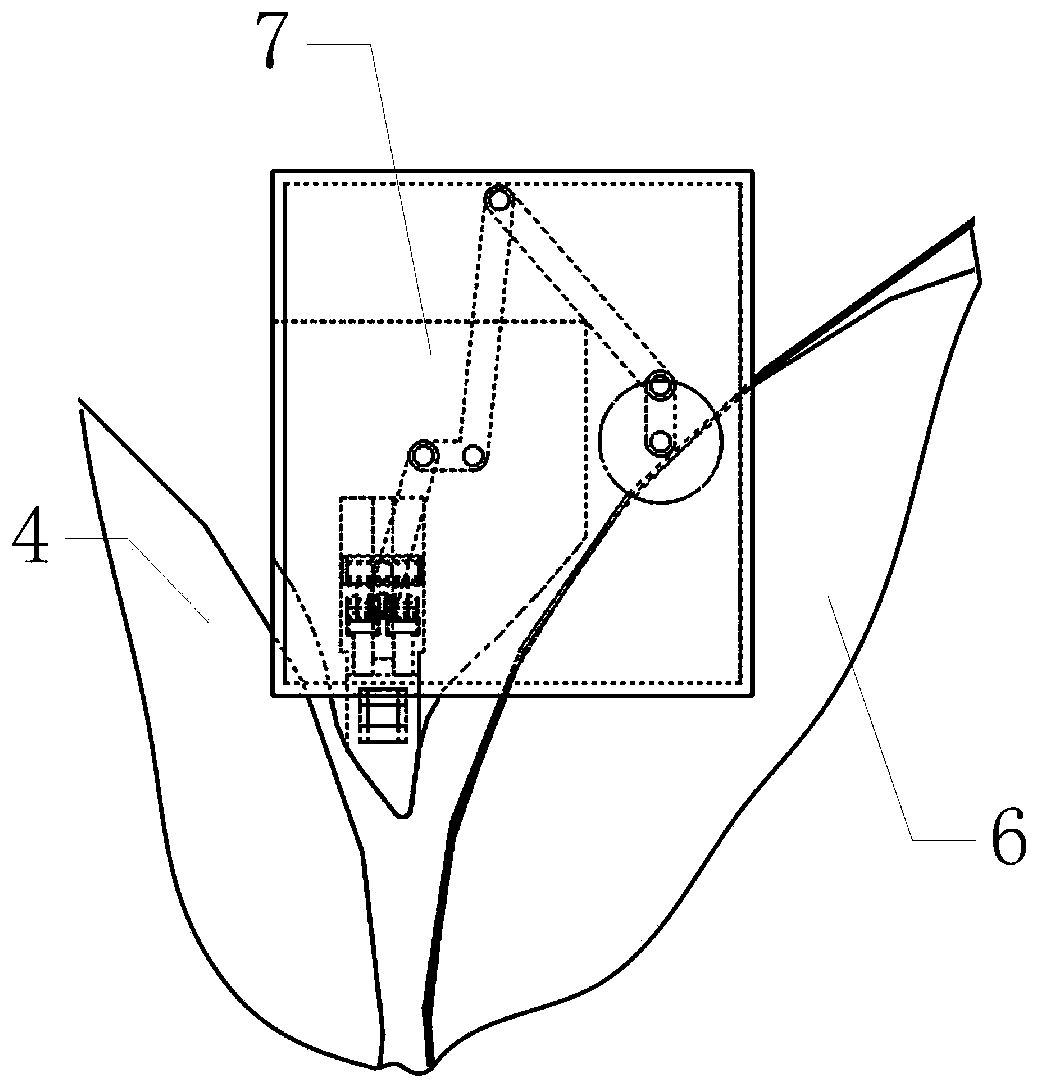

Intelligent monitoring and killing device for diptera insects

InactiveCN113142158AExtended service lifeAvoid damageInsect catchers and killersAnimal scienceZoology

The invention relates to an intelligent monitoring and killing device for diptera insects, which comprises a protective top plate, a cleaning mechanism and a visual detection head, wherein a connecting top is installed at the lower end of the outer portion of the protective top plate; the cleaning mechanism is fixedly mounted on the outer surface of the bottom of the connecting top, and a bottom plate is arranged outside the bottom of the cleaning mechanism in parallel; and the visual detection head is vertically installed at the center line of the connection top, and a protective cover is installed outside the visual detection head. The intelligent monitoring and killing device for the diptera insects has the beneficial effects that through the design of an annular structure of a connecting disc and cleaning cotton, and meanwhile, the connecting disc and the cleaning cotton are movably designed outside the protective cover, so that the cleaning cotton connected with the connecting disc can be driven to move up and down outside the protective cover under the action of a second hydraulic air rod to clean the outside of the protective cover, and the protective cover is effectively prevented from being exposed to the outside for a long time and being attached with dust to influence the monitoring of the visual detection head on the external environment.

Owner:郭继光

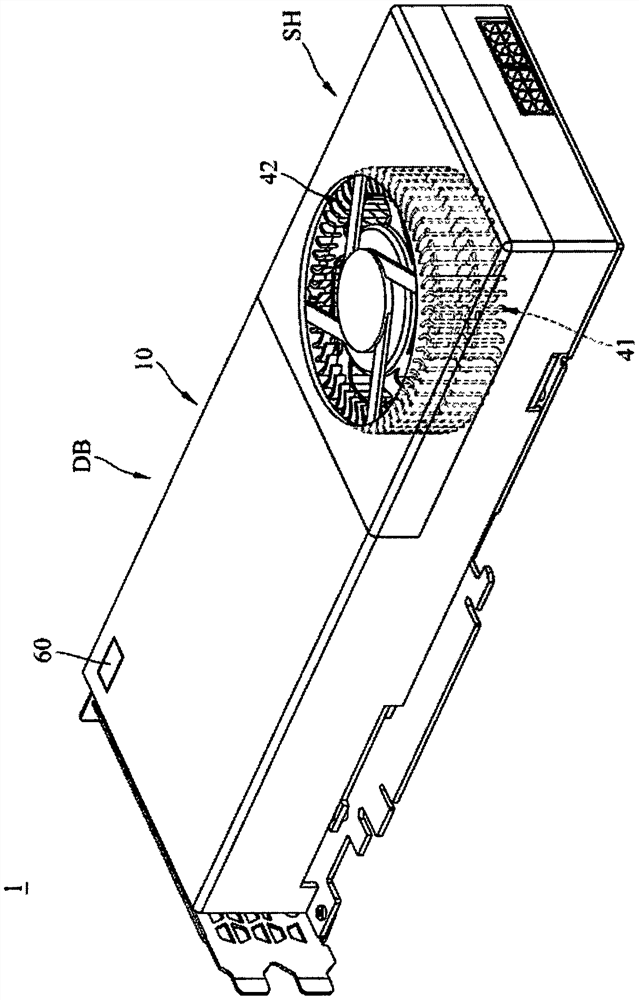

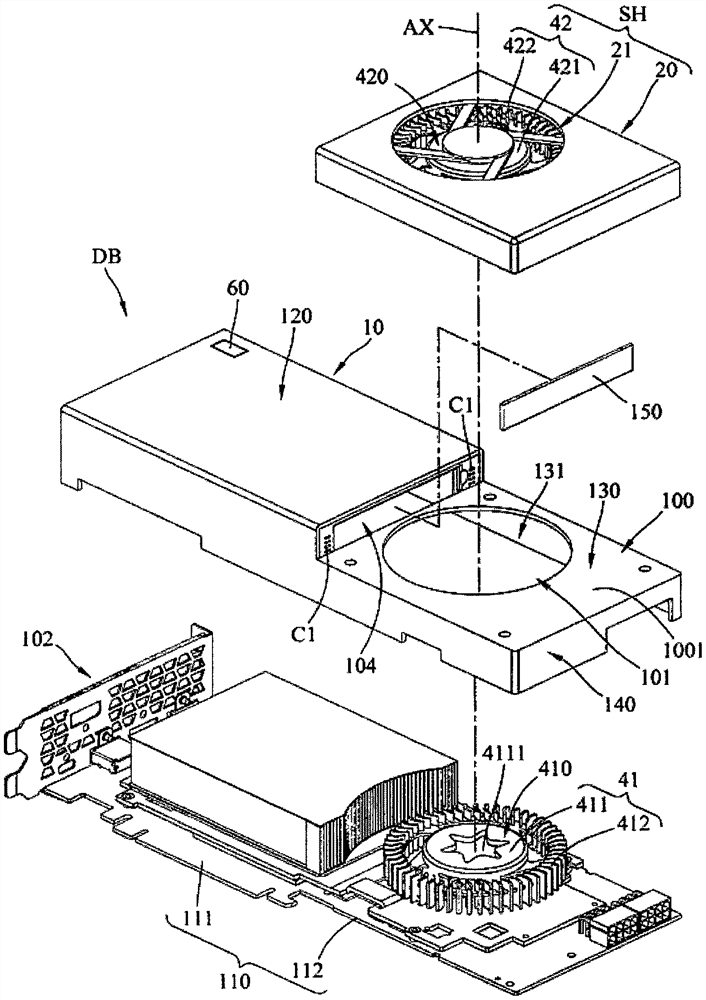

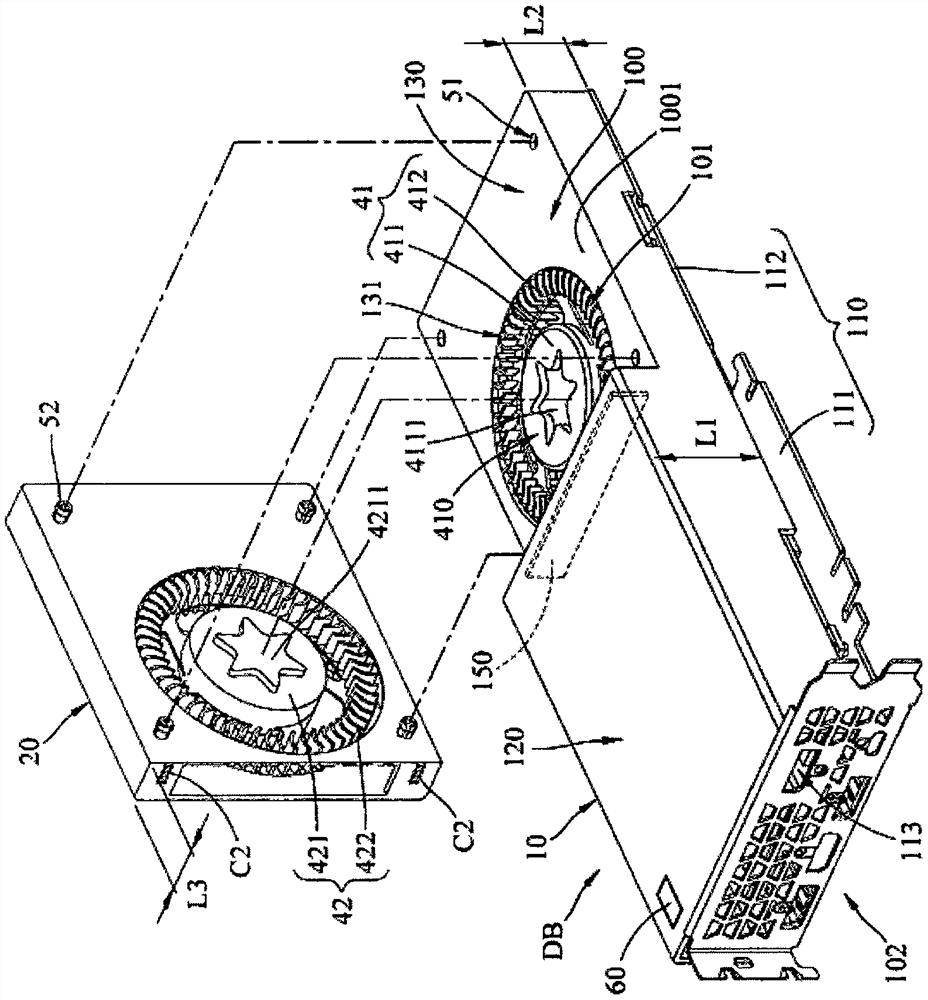

Electronic device

PendingCN113946195AEnough room to moveAvoid overall overheatingDigital processing power distributionEngineeringMechanical engineering

Owner:GIGA BYTE TECH CO LTD

Retaining and anti-loosening combined nut

The invention discloses a retaining and anti-loosening combined nut. The retaining and anti-loosening combined nut comprises a main nut, a movable ring, a pressing ring, side grooves and protruding strips, a mounting groove with an upward opening is formed in the main nut, a main threaded hole is formed in the bottom of the mounting groove, the inner diameter of the mounting groove is larger thanthe inner diameter of the main threaded hole, the mounting groove and the main threaded hole are coaxial with the main nut correspondingly, a plurality of vertically-arranged side grooves are formed in the side wall of the mounting groove and extend downwards to the bottom of the mounting groove from the top of the mounting groove, the movable ring is arranged in the mounting groove, the thicknessof the movable ring is smaller than the depth of the mounting groove, a plurality of protruding strips in one-to-one correspondence with the side grooves are arranged on the outer wall of the movablering, the protruding strips are embedded into the side grooves, and an internal thread is arranged on the inner wall of the movable ring. According to the retaining and anti-loosening combined nut, the pressing ring is matched with the movable ring, so that the main nut and a screw rod can be locked through the pressing ring after being tightened, and the combined nut has good retaining and anti-loosening performance.

Owner:海盐宏茂五金制品有限公司

A mems substrate, a display unit comprising a mems substrate, and an intelligent display mirror

The application provides an MEMS substrate, a display unit containing the same and an intelligent display mirror. The MEMS substrate provided by the present invention is characterized by orderly comprising an array substrate, a raster for reflecting ambient light, an insulating layer, a color film photoresistor and an adjusting raster, wherein the adjusting raster can move, the array substrate is equipped with an MEMS raster drive circuit, and the overlapping area of the adjusting raster and the raster for reflecting ambient light is adjusted and controlled by the drive circuit, thereby realizing a function of MEMS reflective display. The display unit provided by the present invention comprises a packaging substrate packaged on the MEMS substrate, and a metal thin film which is coated on the lower end face of the packaging substrate and is used for reflecting the external ambient light. The display mirror provided by the present invention comprises a plurality of display units in array arrangement. According to the present invention, by utilizing an MEMS technology, the multifunctional application of the mirror and the reflective display is realized, the structure of the display mirror is simplified, and the thickness of the display mirror and the cost are reduced.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

Metal piece grinding device

InactiveCN106799627AGuaranteed normal cuttingPrevent splashMaintainance and safety accessoriesArchitectural engineeringMetal debris

The invention discloses a metal piece grinding device. The metal piece grinding device comprises a worktable, a blocking cover is installed on the worktable, an opening for workpiece entering and existing is formed in the side edge of the blocking cover, an cavity is formed in the blocking cover, an annular collecting groove is formed in the bottom of the cavity, and the side edge of the collecting groove is connected with the side wall of the worktable; a telescopic arm movably penetrates through the top of the blocking cover and is installed above the worktable, and a cutting wheel is rotatably installed at the tail end of the telescopic arm; and the collecting groove is obliquely installed in the circumferential direction of the bottom of the cavity, a sliding block adapted to the colleting groove is slidably installed at the end, located at the higher position, of the collecting groove, and traction ropes are installed on the two sides of the sliding block correspondingly. During cutting, generated debris slides downwards along the inner wall of the metal debris till falling into the annular collecting groove; after cutting is completed, the collecting groove can be cleaned through simple tools such as a broom, meanwhile, the metal debris accumulated in the collection groove can be centrally recycled, and consequently secondary utilization can be achieved.

Owner:重庆市木越机械制造有限公司

An automated production equipment for LED packaging tubes

ActiveCN111554786BEnough room to moveEasy to moveSemiconductor/solid-state device manufacturingConveyor partsProcess engineeringPackaging Tube

The invention discloses an automatic production equipment for LED packaging tubes, which includes a casing, a drying mechanism is installed on the casing, a transmission mechanism is arranged on the casing, and a positioning mechanism is connected to the transmission mechanism. The positioning mechanism is located inside the casing, and the positioning mechanism is located below the drying mechanism; this device has the function of packaging multiple packaging tubes of the same specification at one time, and can also quickly perform packaging during packaging. Heat dissipation, the heat dissipation process will not affect the package tube for packaging. The transmission mechanism can drive two positioning plates to position the package tube at the same time. The die is sealed in the package tube. The function of the package is mainly to protect the die. The equipment is easy to operate and can quickly complete the packaging of multiple packaging tubes.

Owner:贵州中晟泰科智能技术有限公司

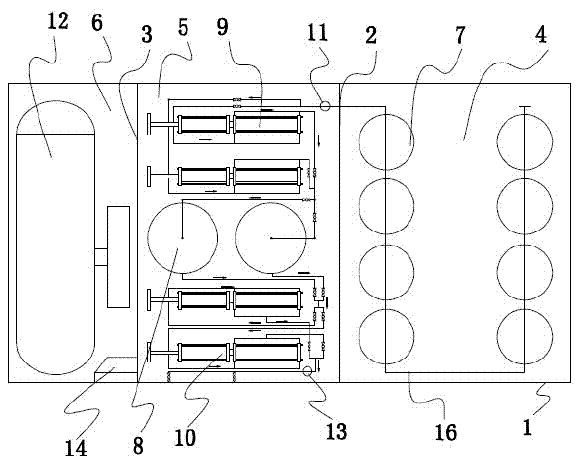

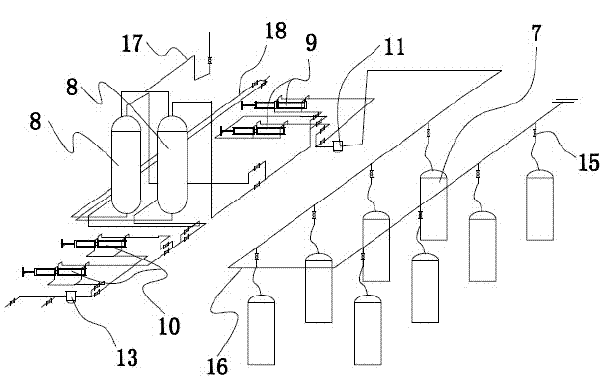

Unattended liquefied gas transmission station

InactiveCN102278595BCompact structureSmall footprintPipeline systemsVapor–liquid separatorEngineering

Owner:东莞市九丰化工有限公司

Intelligent enhanced production system and process of 1, 4-butanediol

PendingCN112457155AEnough room to moveChange directionOrganic compound preparationCarboxylic acid esters preparationProcess engineeringButanediol

The invention is applicable to the technical field of butanediol production, and provides an intelligent enhanced production system and process of 1, 4-butanediol, the system comprises reaction devices including a first reaction device, a second reaction device and a third reaction device; micro-interface generators comprise a first micro-interface generator and a second micro-interface generatorwhich are respectively positioned at the bottoms of the first reaction device and the second reaction device; a mixing and stirring device comprises a guide rod, a fixed shell, a power shaft and a steering device, the steering device comprises a fixed shaft, a rotating part and a guide wheel fixedly connected with the rotating part, the fixed shaft is connected with the end of the rotating part through an elastic part, a limiting part is arranged on the fixed shell, the rotating part is longer than the fixed shell, and an auxiliary rod is arranged on the rotating part; an intelligent control device comprises a strategy setting unit, a parameter control unit and a model setting unit. Therefore, the reaction efficiency and the working quality can be effectively improved, and the reaction parameters can be intelligently adjusted.

Owner:NANJING YANCHANG REACTION TECH RES INST CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com