Patents

Literature

50results about How to "Vibration effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

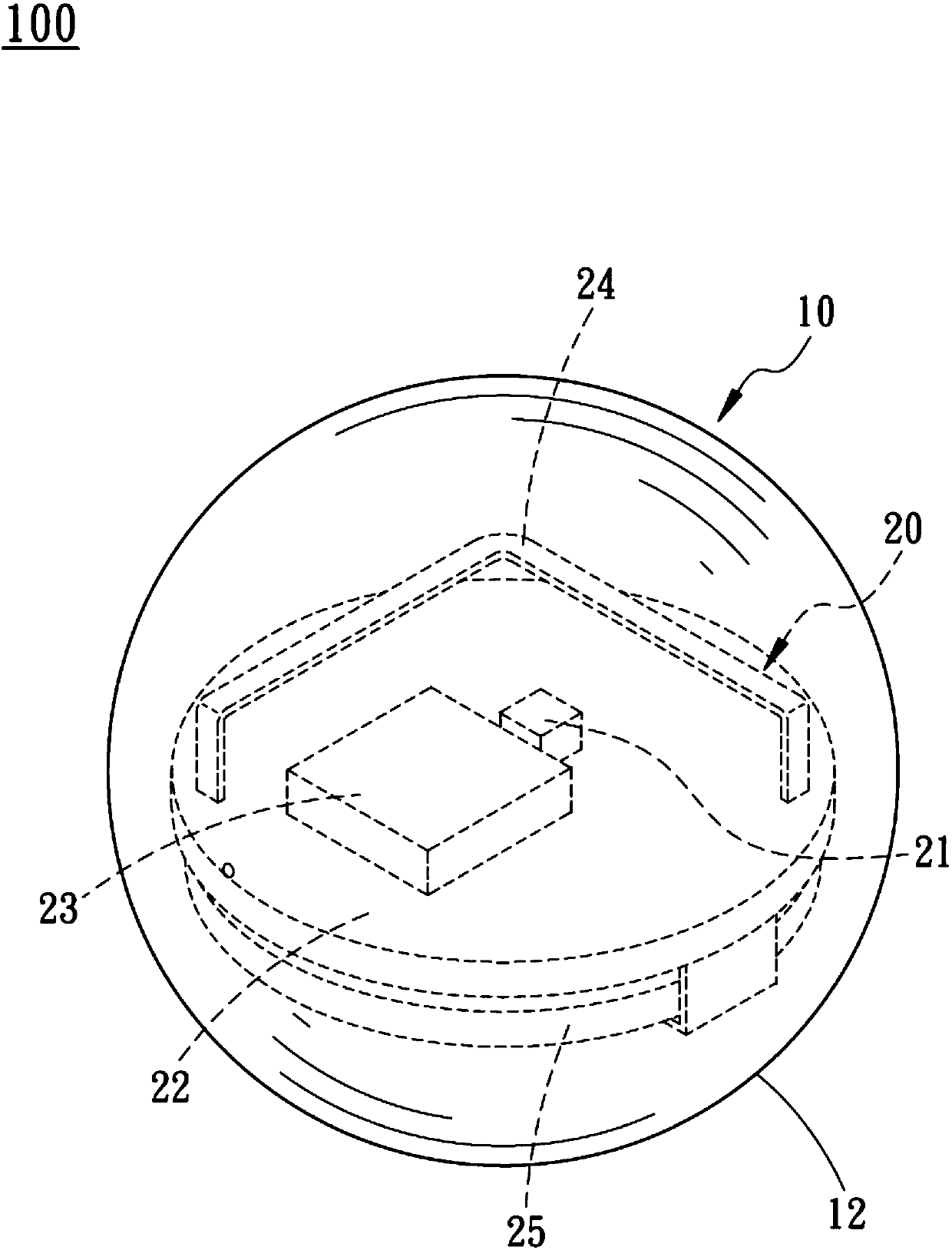

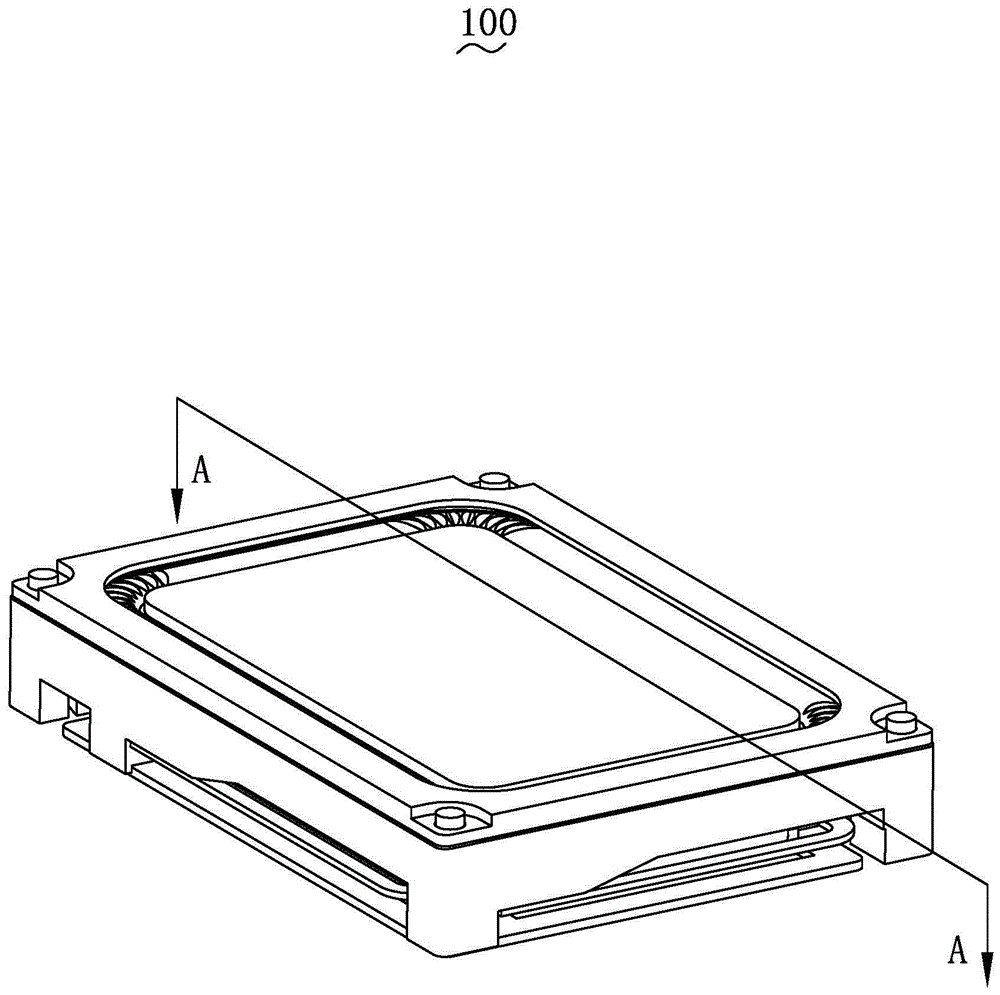

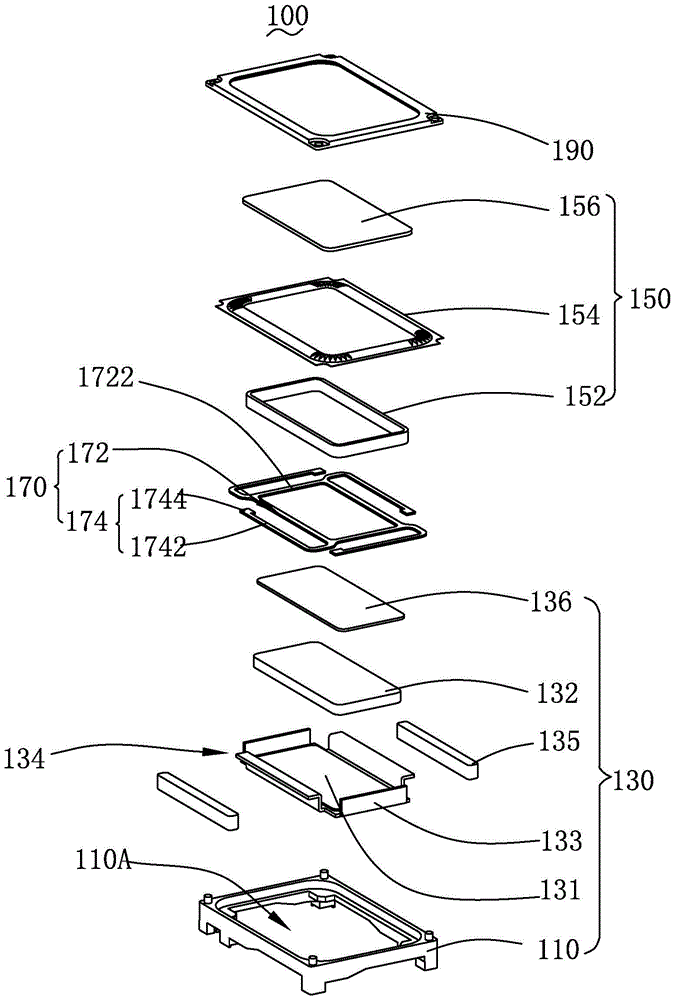

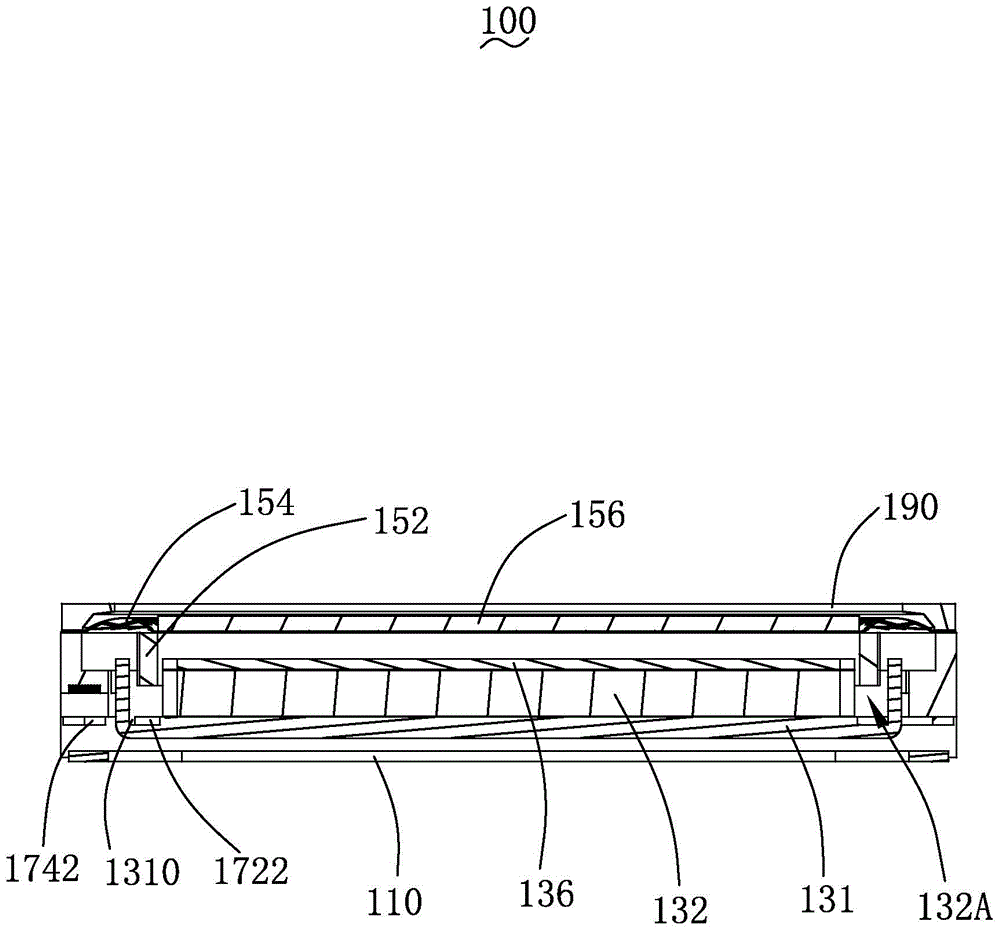

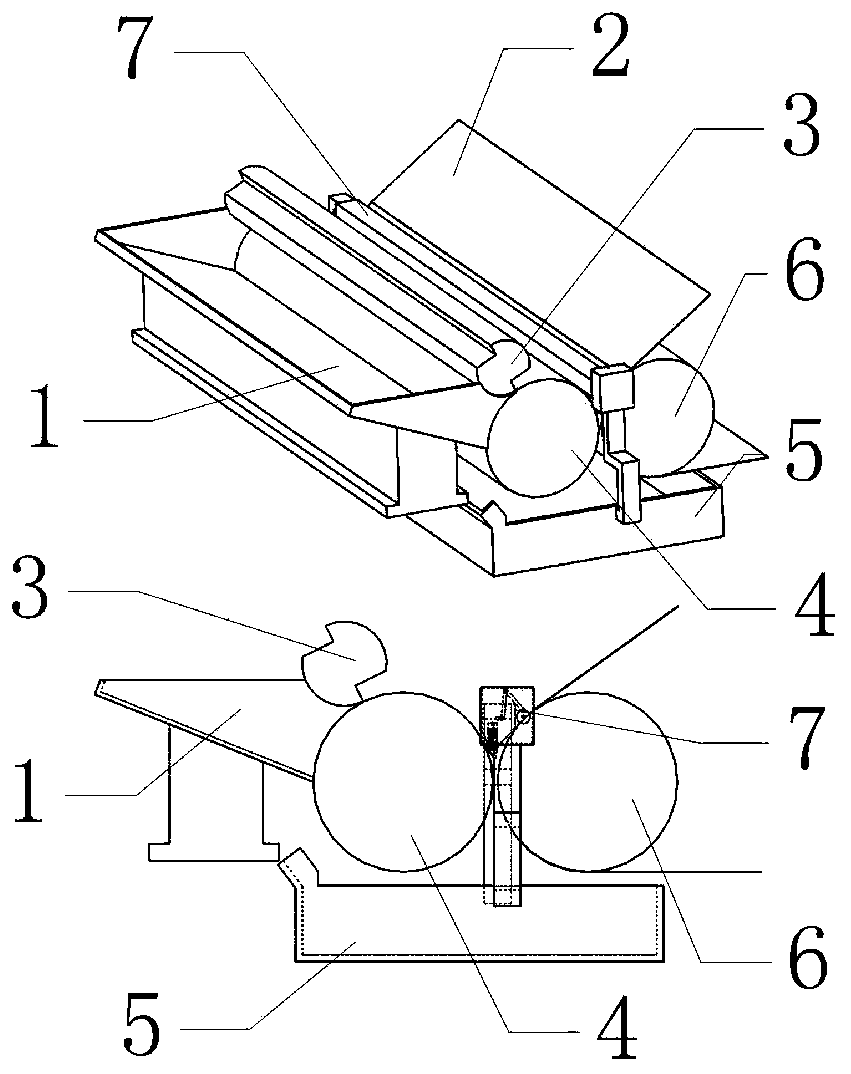

Micro Vibration Motor

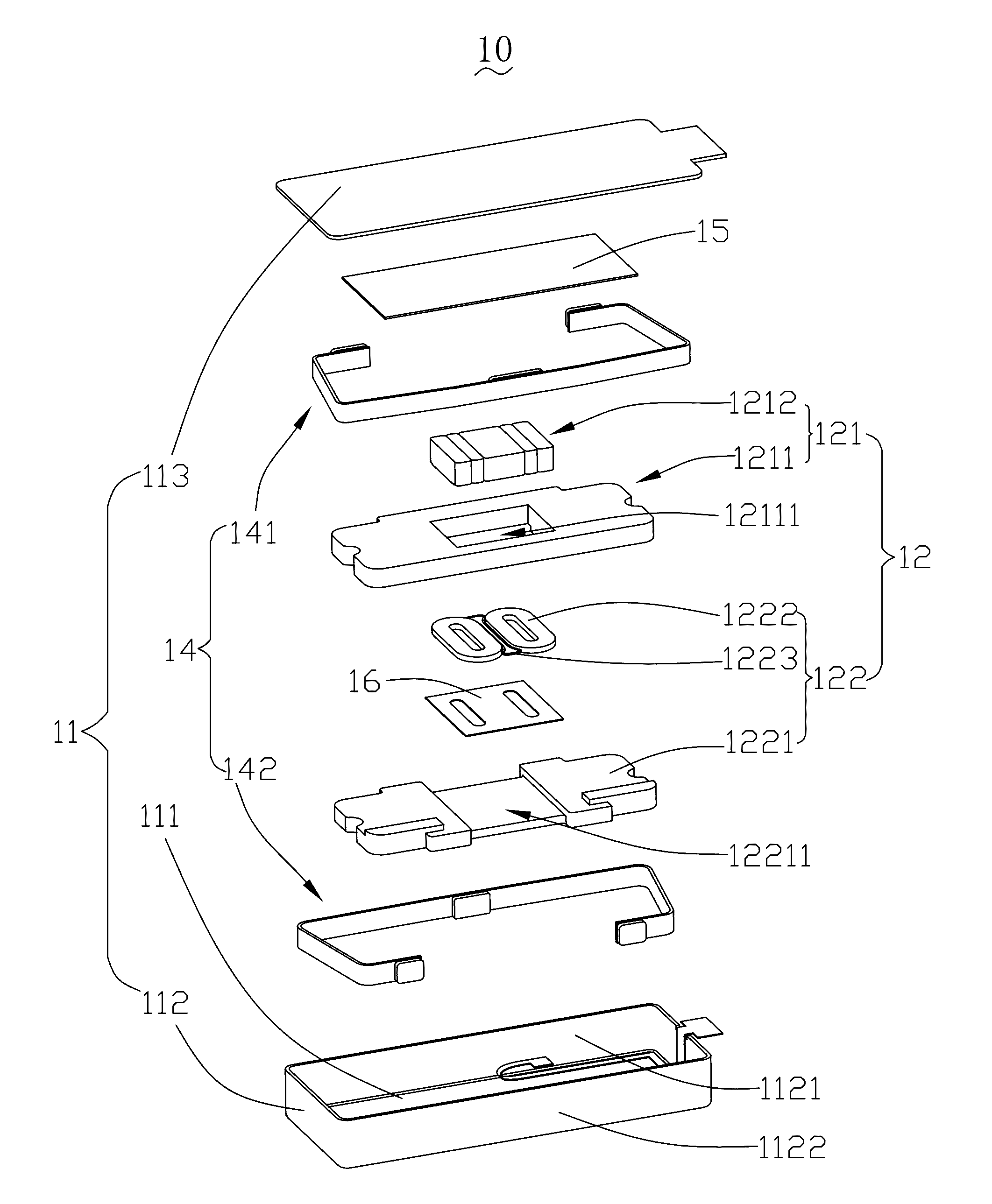

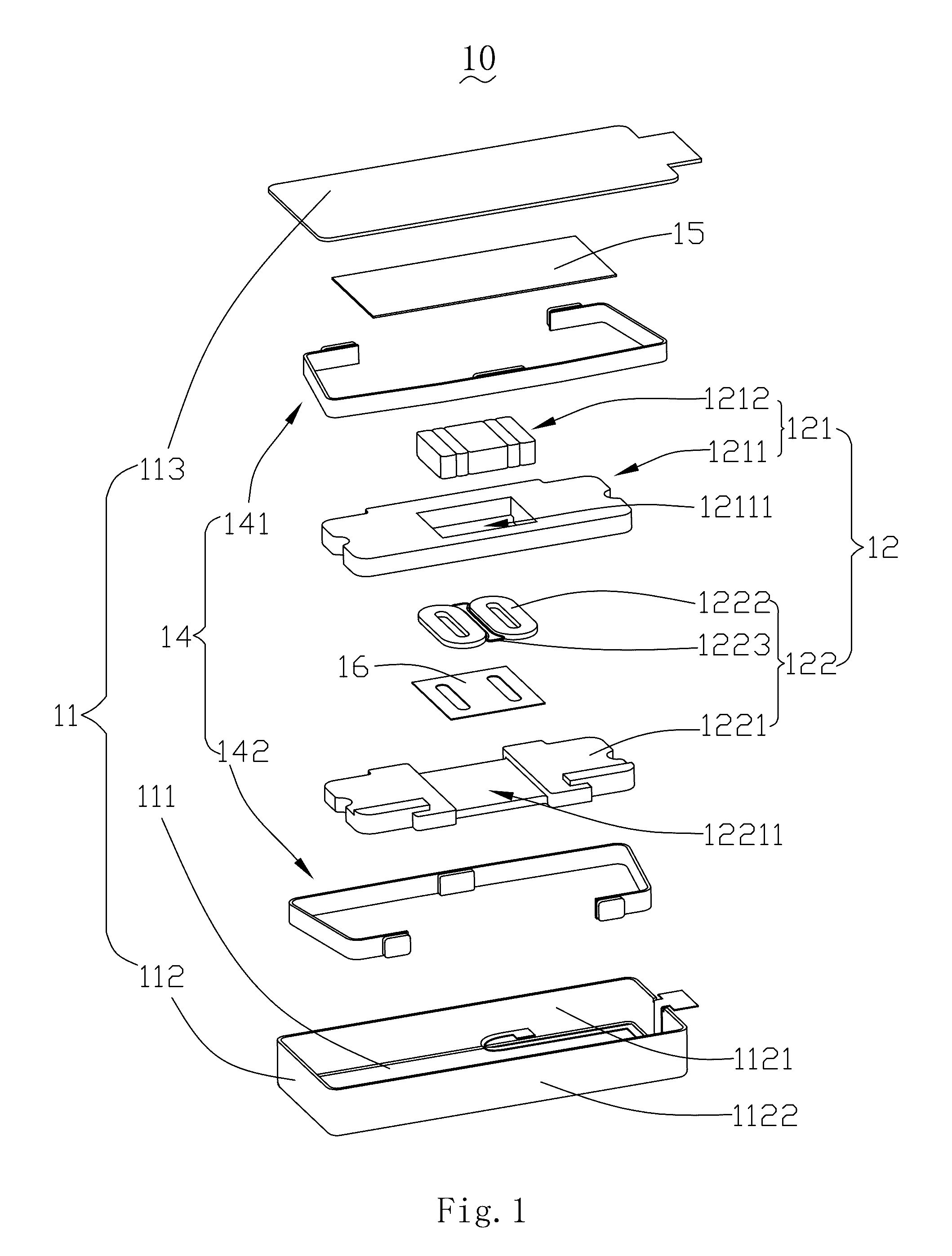

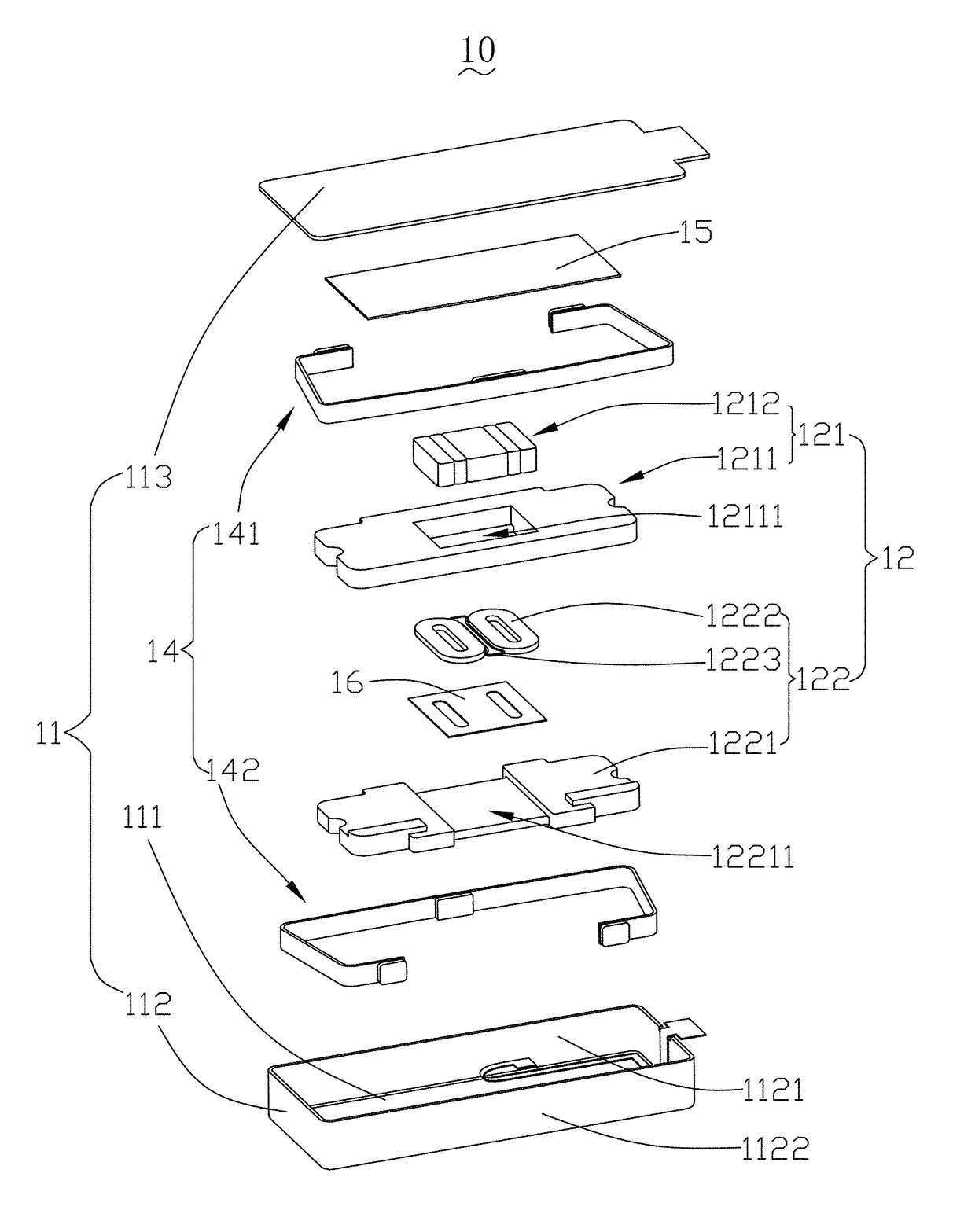

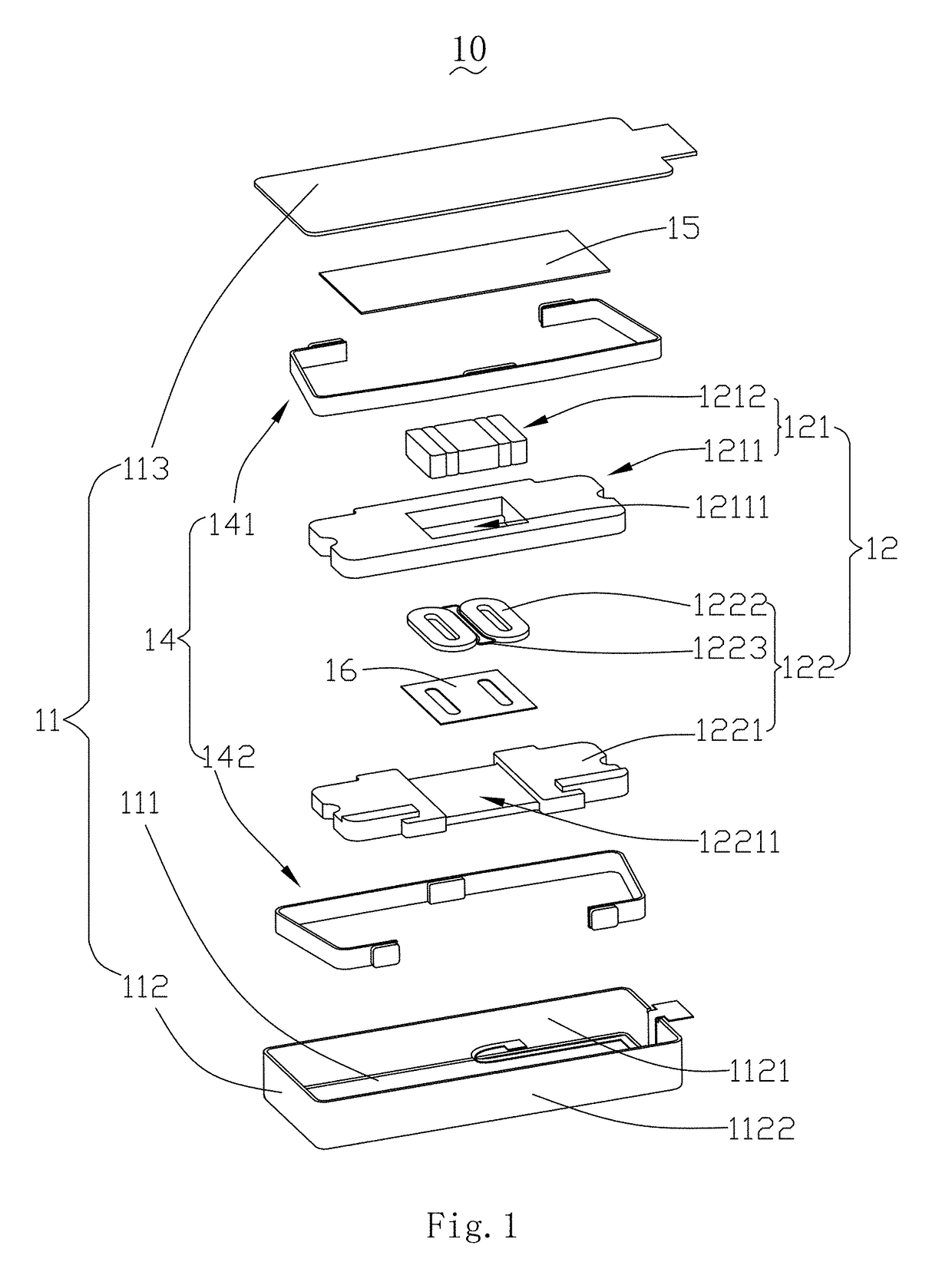

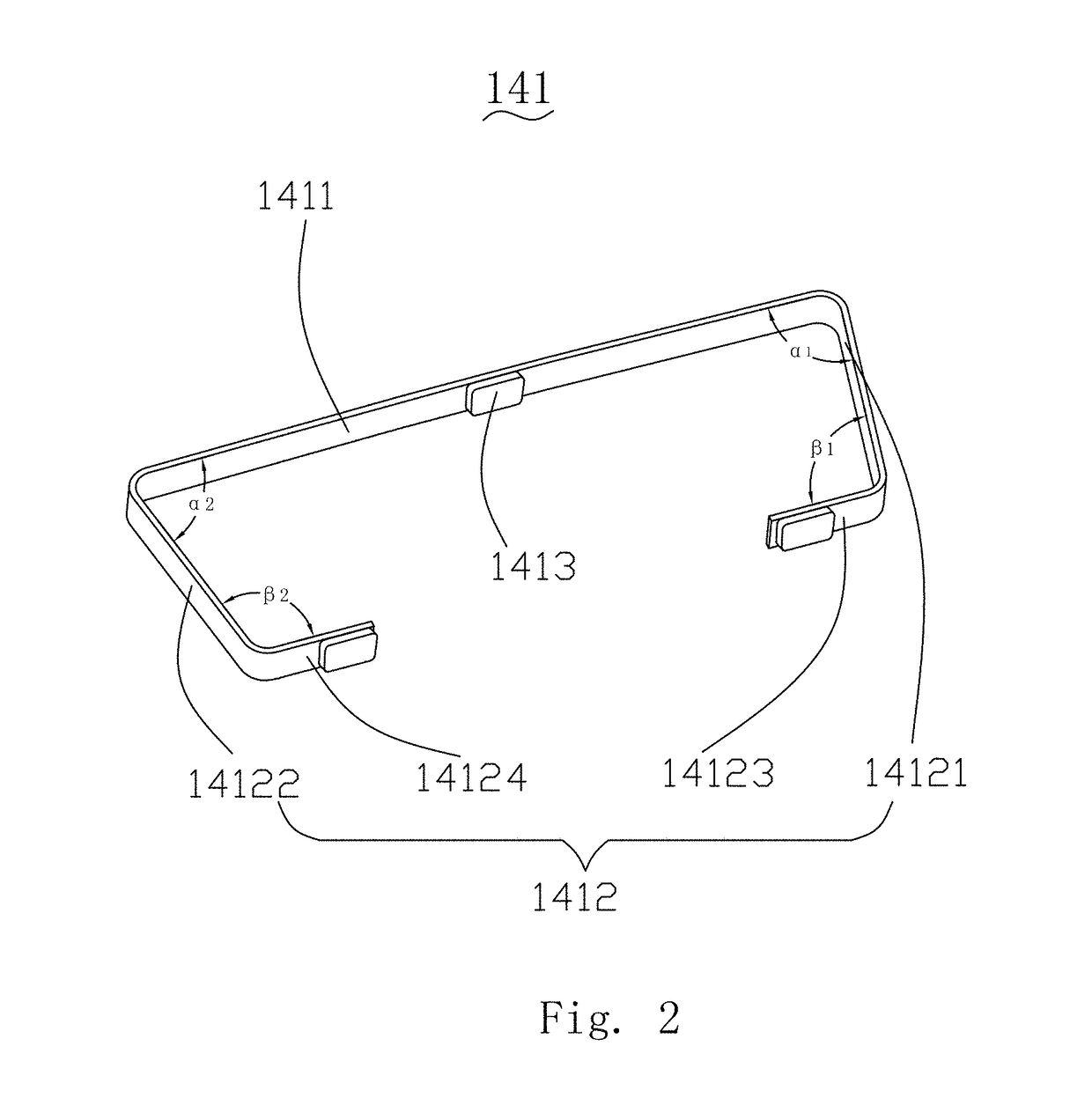

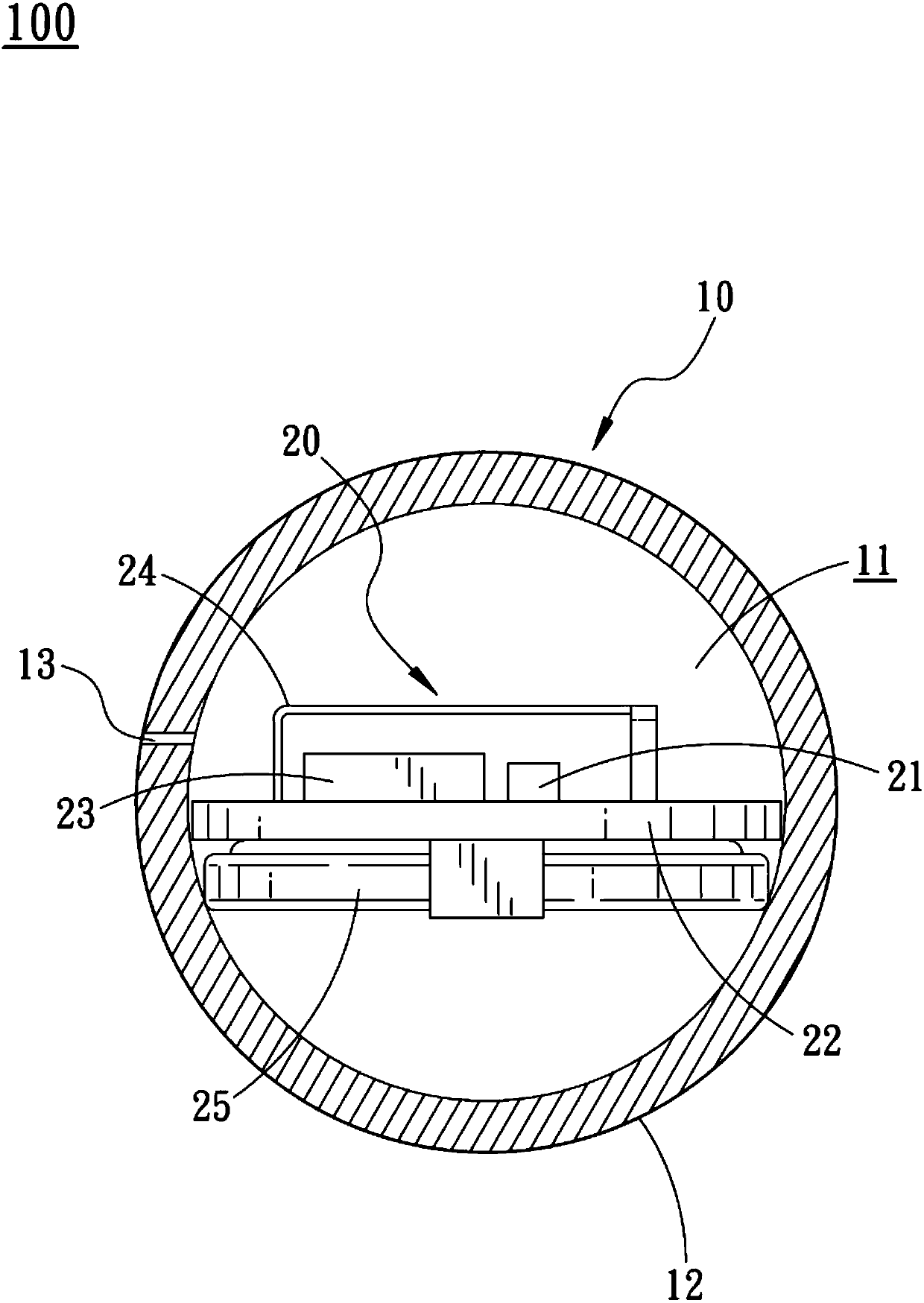

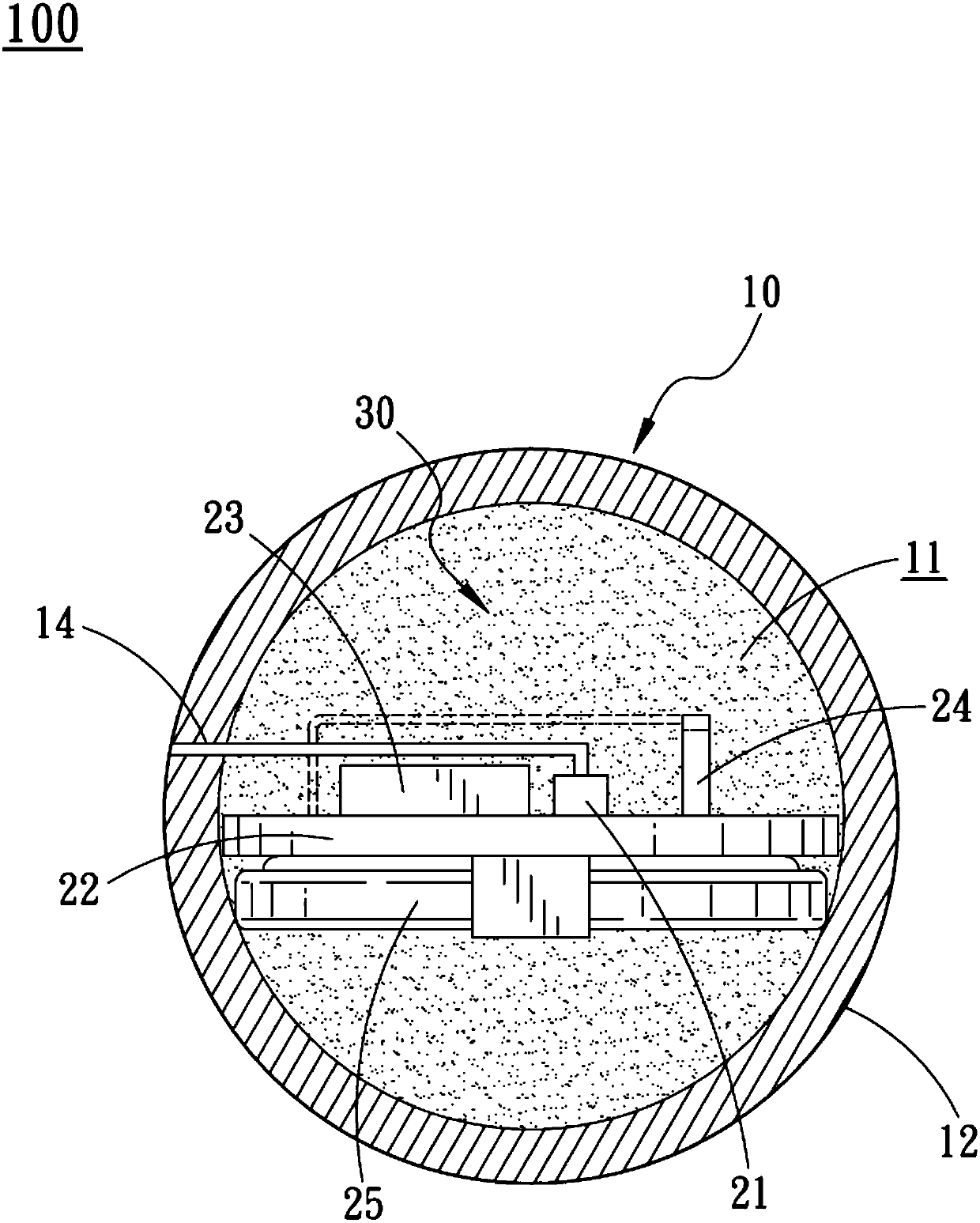

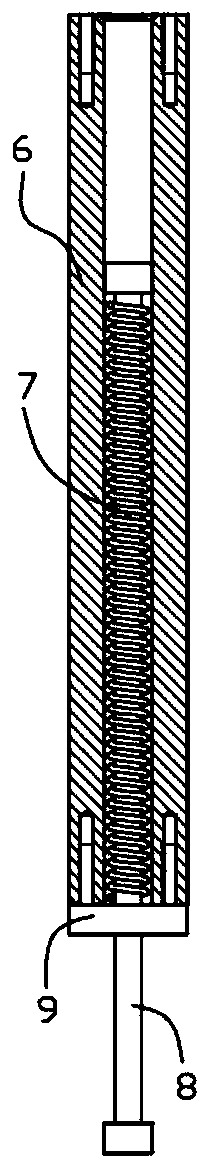

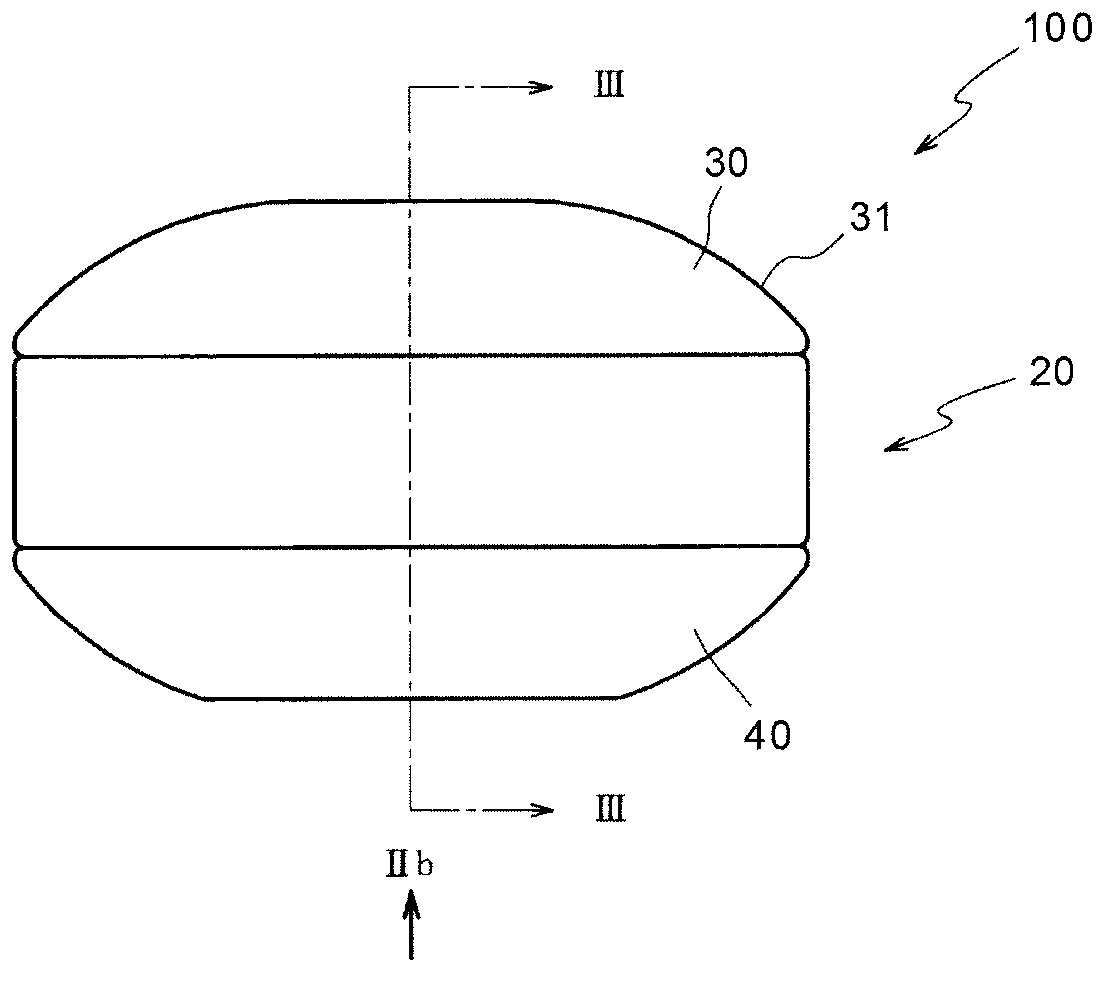

ActiveUS20170033657A1Vibration effectShorten assembly timeDynamo-electric machinesEngineeringElectric signal

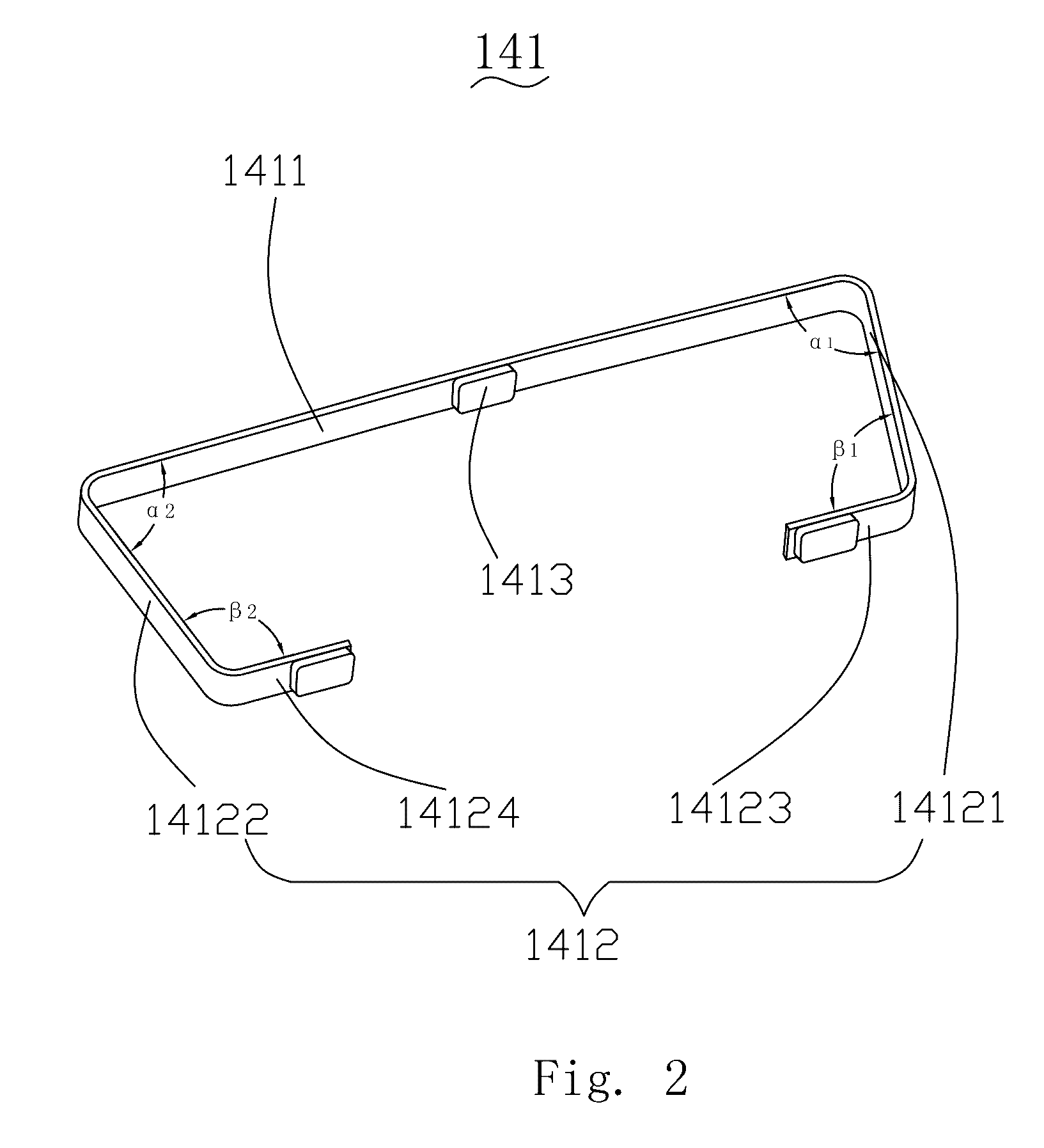

A micro vibration motor, includes: a housing having an accumulating space, an elastic support, a vibrator suspended in the accommodation space by the elastic support, and including an upper vibrator in which a magnet is accommodated and a lower vibrator which is parallel to the upper vibrator, the lower vibrator being provided with coils for driving the magnet to vibrate; and a FPC for providing electric signals. The upper vibrator and the lower vibrator are supported by the elastic support including a fixation part connecting with the housing and an annular elastic arm extending from two ends of the fixation part; and the vibrator is surrounded by at least one part of the annular elastic arm and one end of the annular elastic arm is connected to the vibrator.

Owner:AAC TECH PTE LTD

Micro vibration motor

ActiveUS9871432B2Vibration effectShorten assembly timeDynamo-electric machinesEngineeringElectric signal

A micro vibration motor, includes: a housing having an accumulating space, an elastic support, a vibrator suspended in the accommodation space by the elastic support, and including an upper vibrator in which a magnet is accommodated and a lower vibrator which is parallel to the upper vibrator, the lower vibrator being provided with coils for driving the magnet to vibrate; and a FPC for providing electric signals. The upper vibrator and the lower vibrator are supported by the elastic support including a fixation part connecting with the housing and an annular elastic arm extending from two ends of the fixation part; and the vibrator is surrounded by at least one part of the annular elastic arm and one end of the annular elastic arm is connected to the vibrator.

Owner:AAC TECH PTE LTD

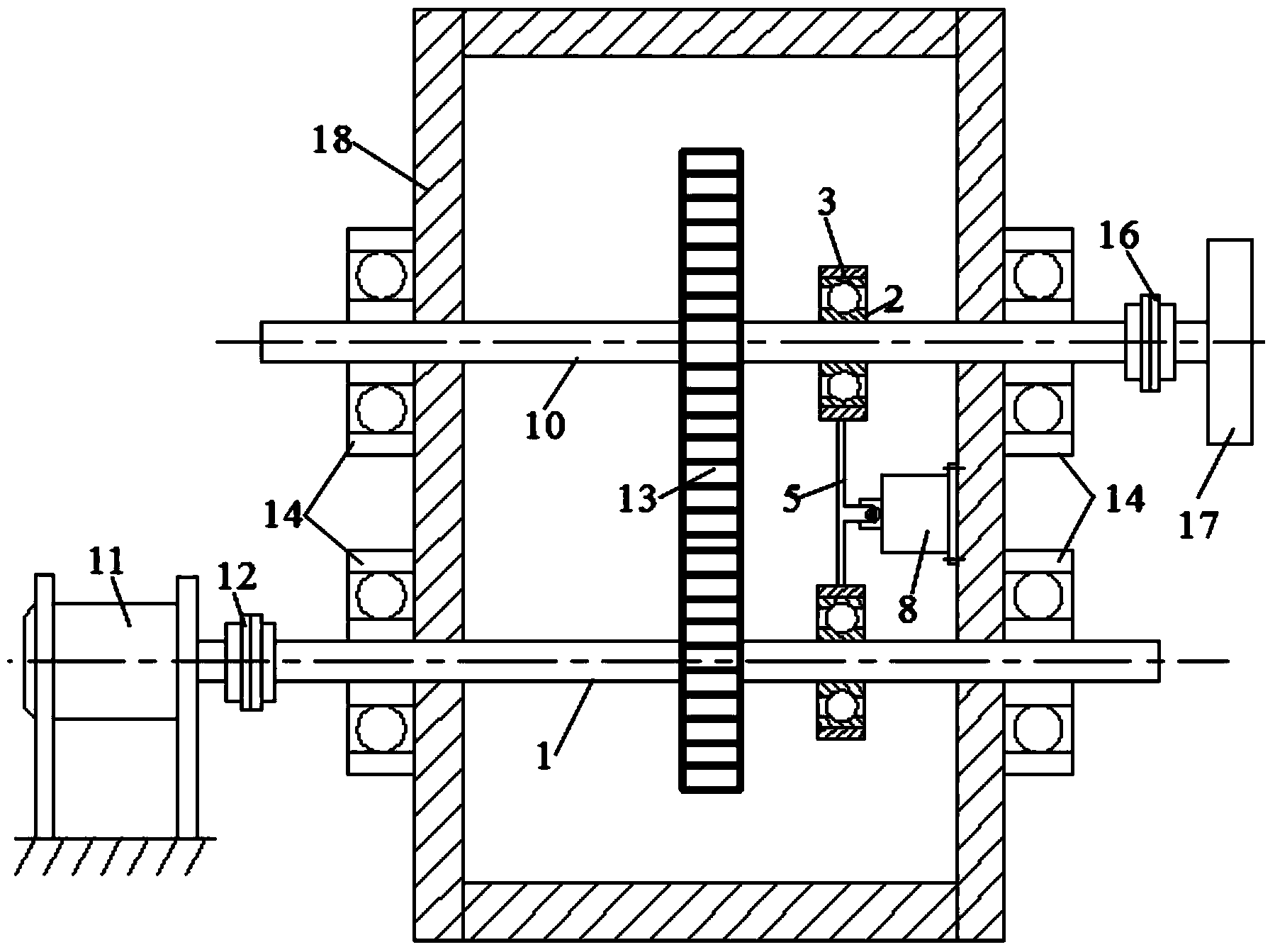

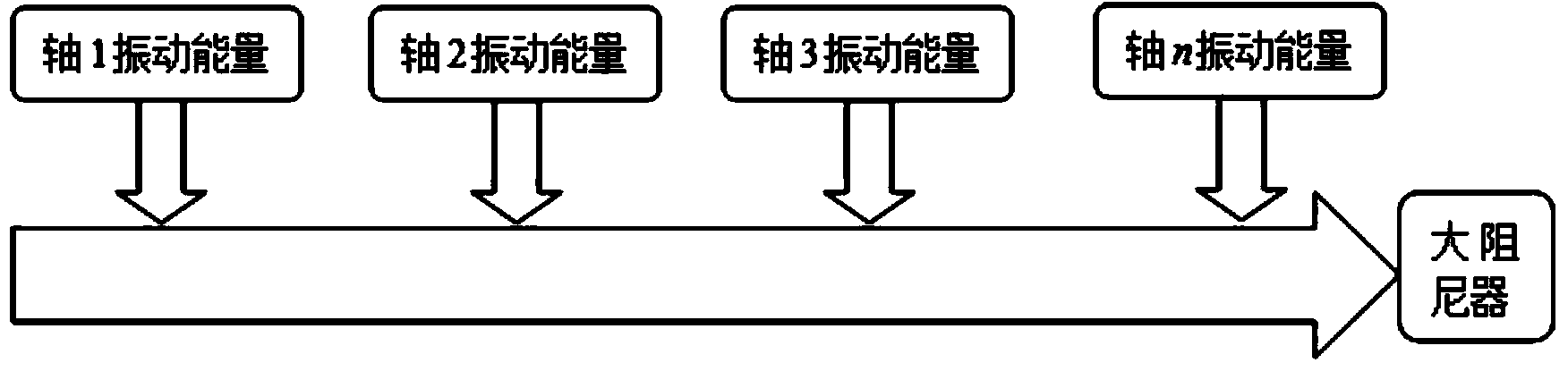

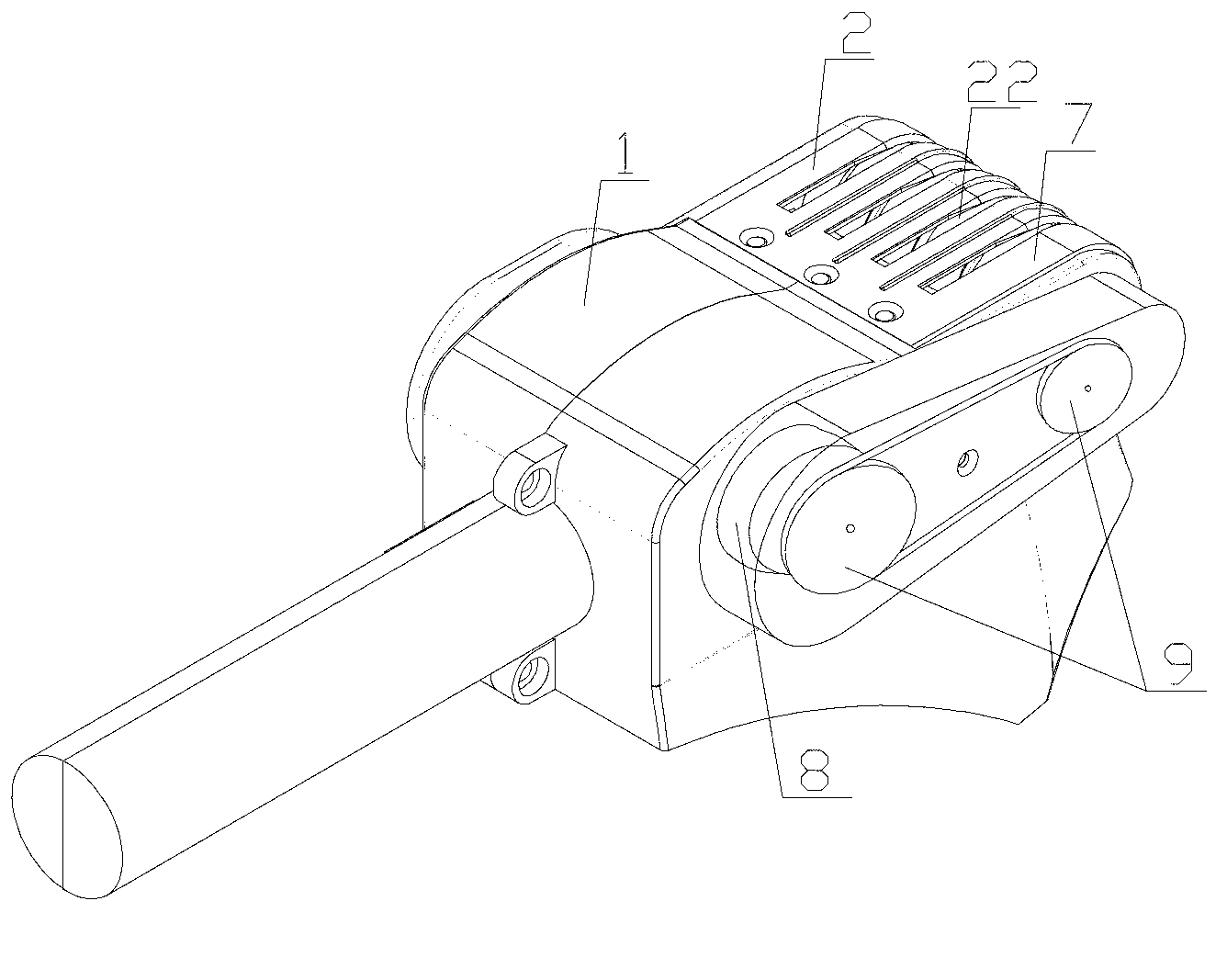

Composite damping device for vibration and noise reduction of gear shafting

ActiveCN103982635AFlexible spaceCompact structureGear vibration/noise dampingVibration suppression adjustmentsEngineeringVibration transmission

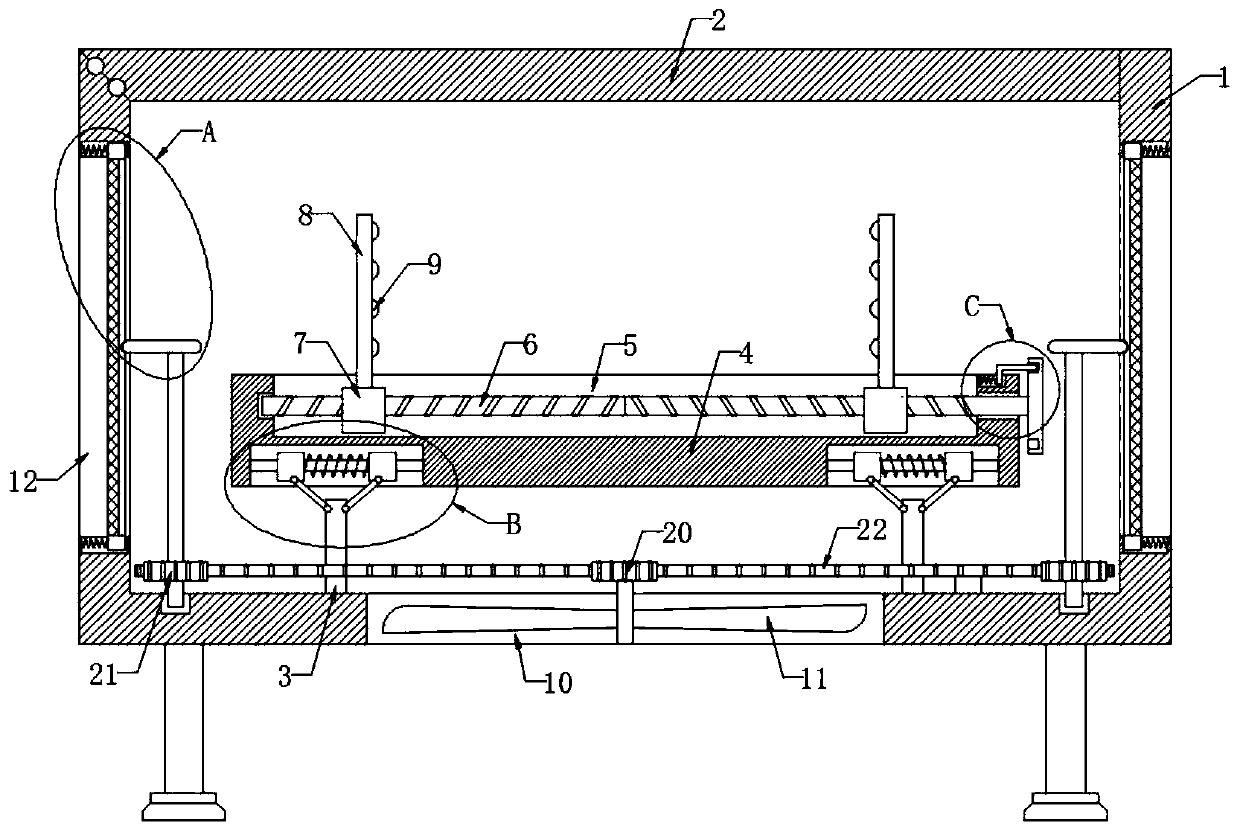

The invention relates to a composite damping device for vibration and noise reduction of gear shafting, which belongs to the technical field of damping devices. The composite damping device acts on each gear shaft through an auxiliary bearing, a clamp and a vibration transmission frame with a flexible structure, vibration, which is generated by some factors in a process of transmission, of a gear pair is transferred to the auxiliary bearing, and the clamp and the vibration transmission frame so as to drive a piston soaked in high-viscosity damping liquid to do shearing motion in the damping liquid, generate a damping force large enough and absorb and dissipate vibration energy, thereby suppressing bending vibration of the shaft. On one hand, internal excitation of the whole gear is reduced, on the other hand, vibration which is transferred to a gearbox body is attenuated. By virtue of the composite damping device disclosed by the invention, the vibration of frequency components due to meshing impact in the gear shafting can be simultaneously reduced, and a vibration frequency band is wide. The composite damping device has the advantages of simple structure, easiness in removal and installation, flexibility of installation position, no worn parts, long service life and the like.

Owner:BEIJING UNIV OF CHEM TECH

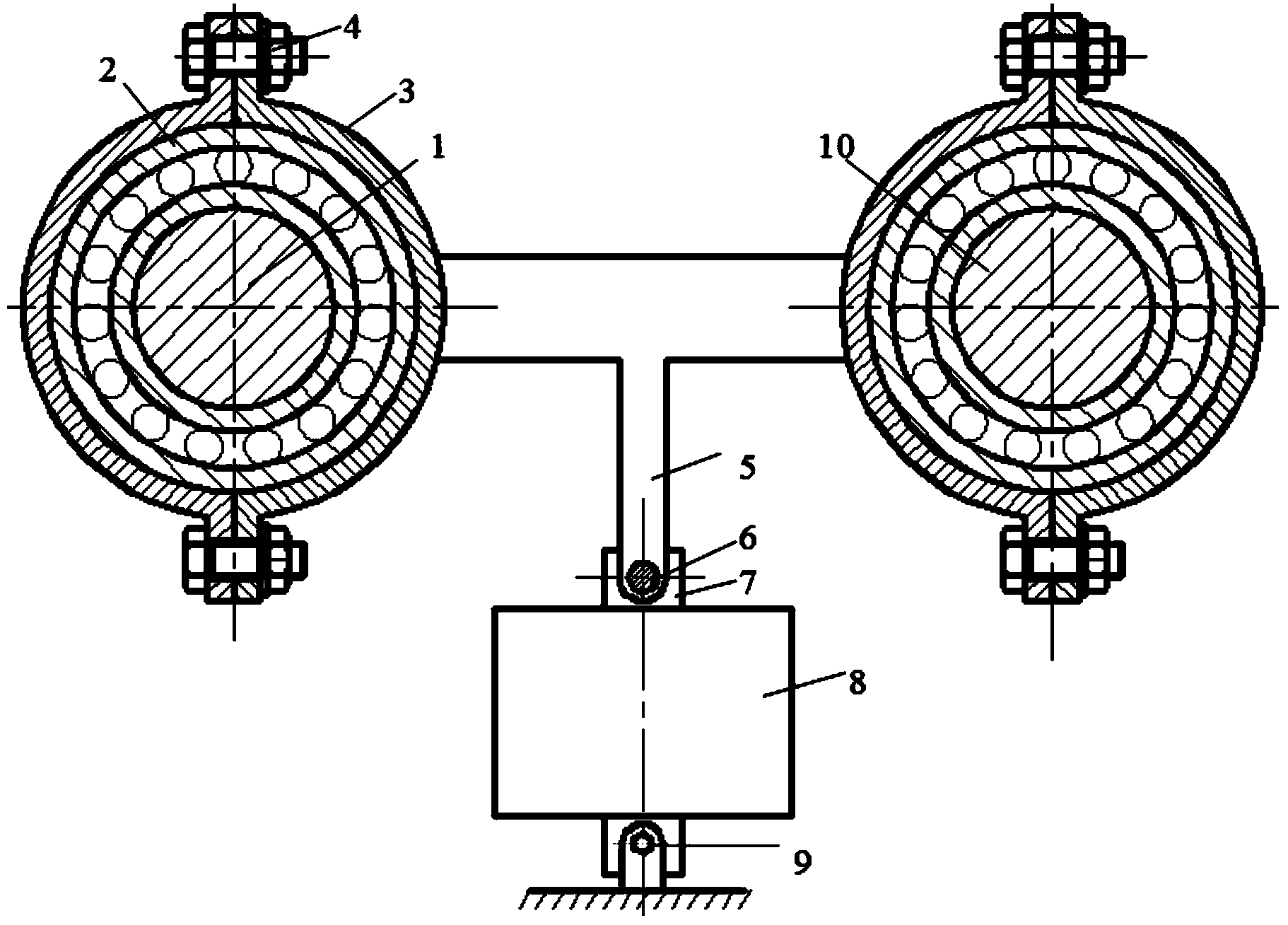

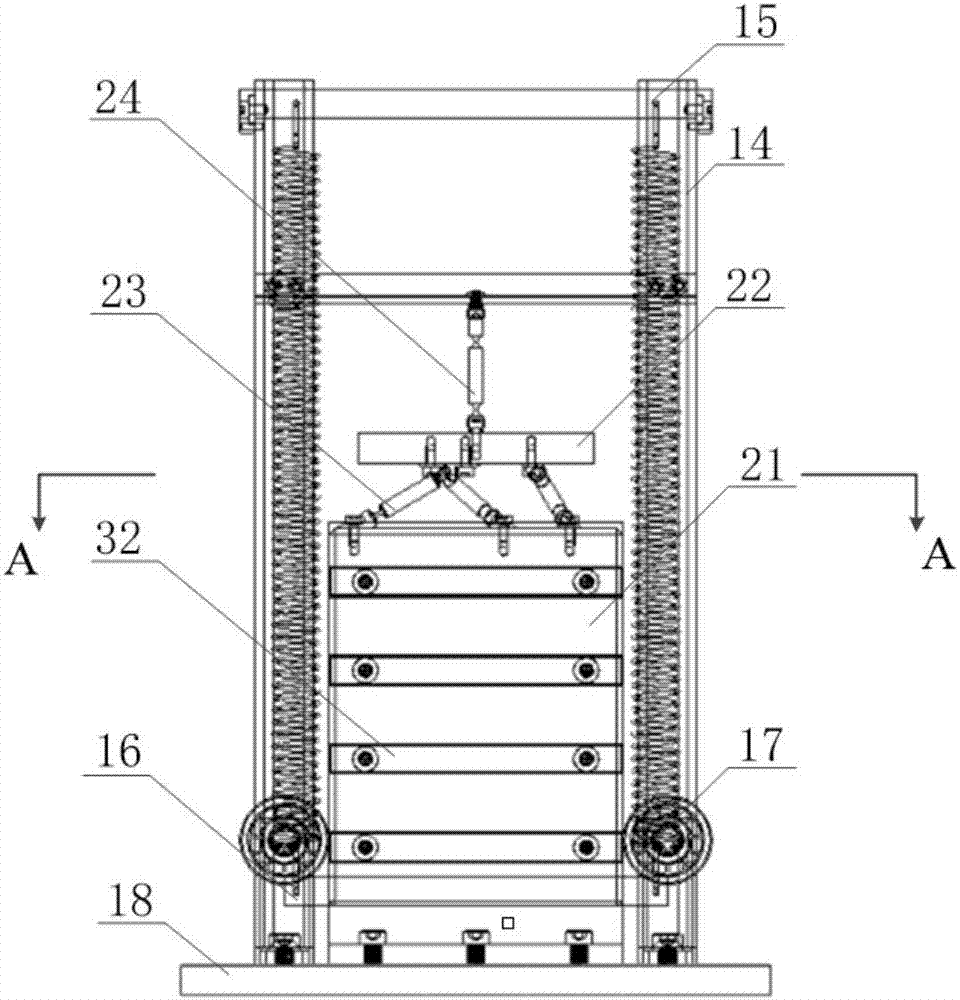

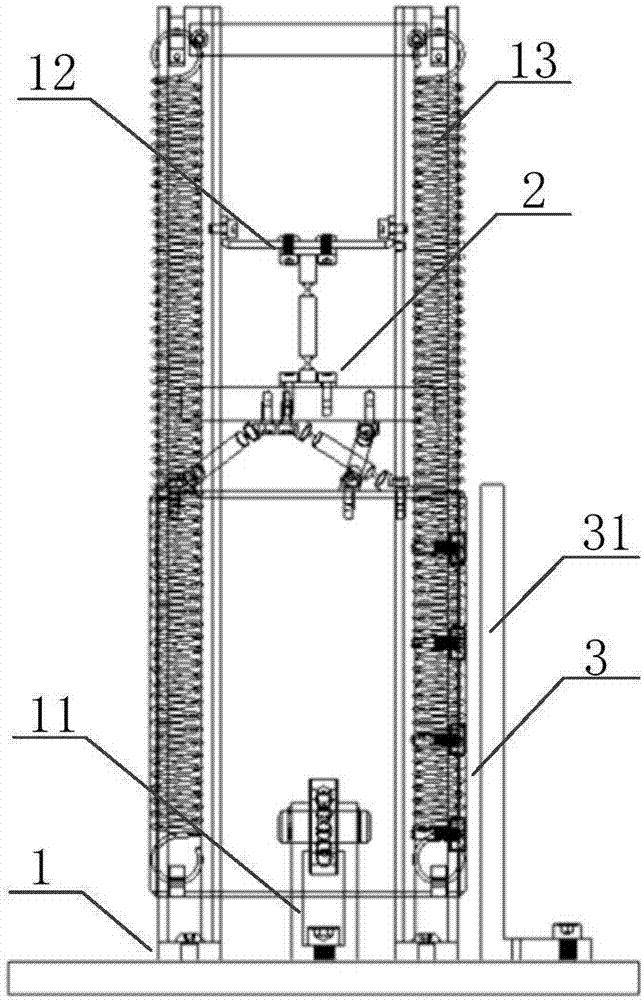

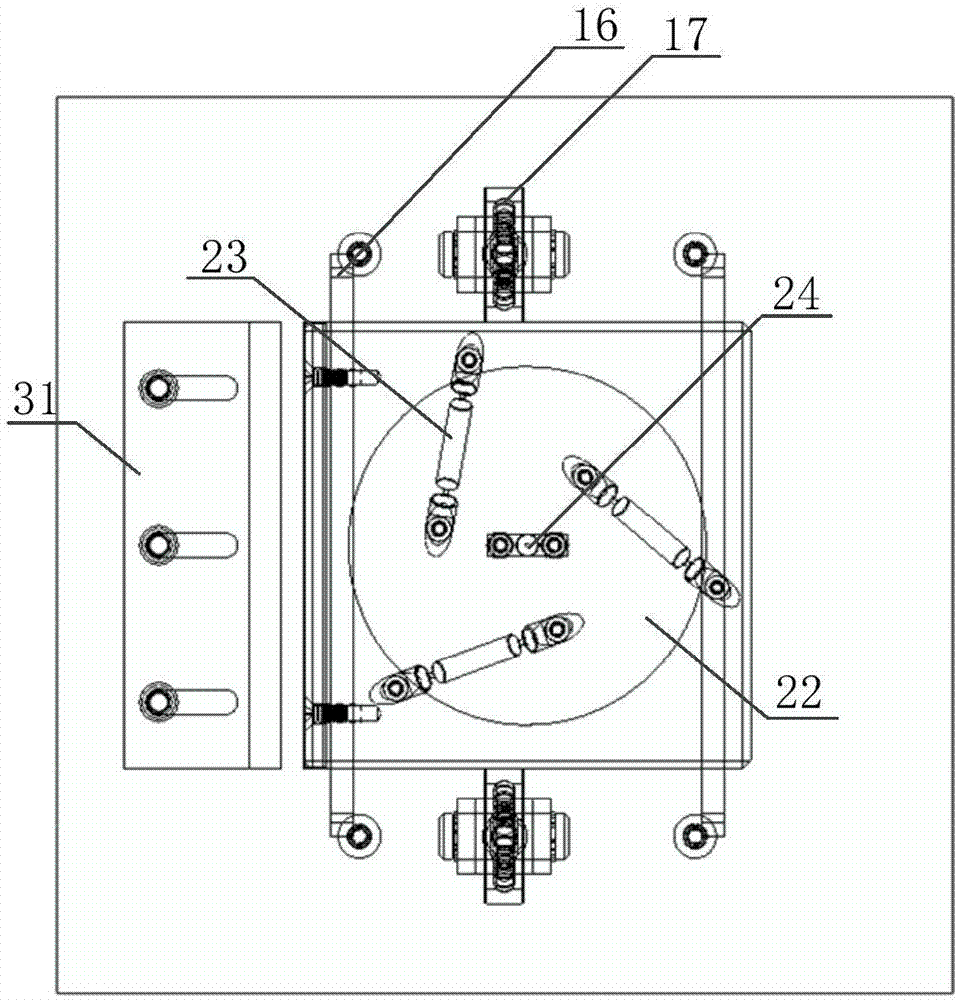

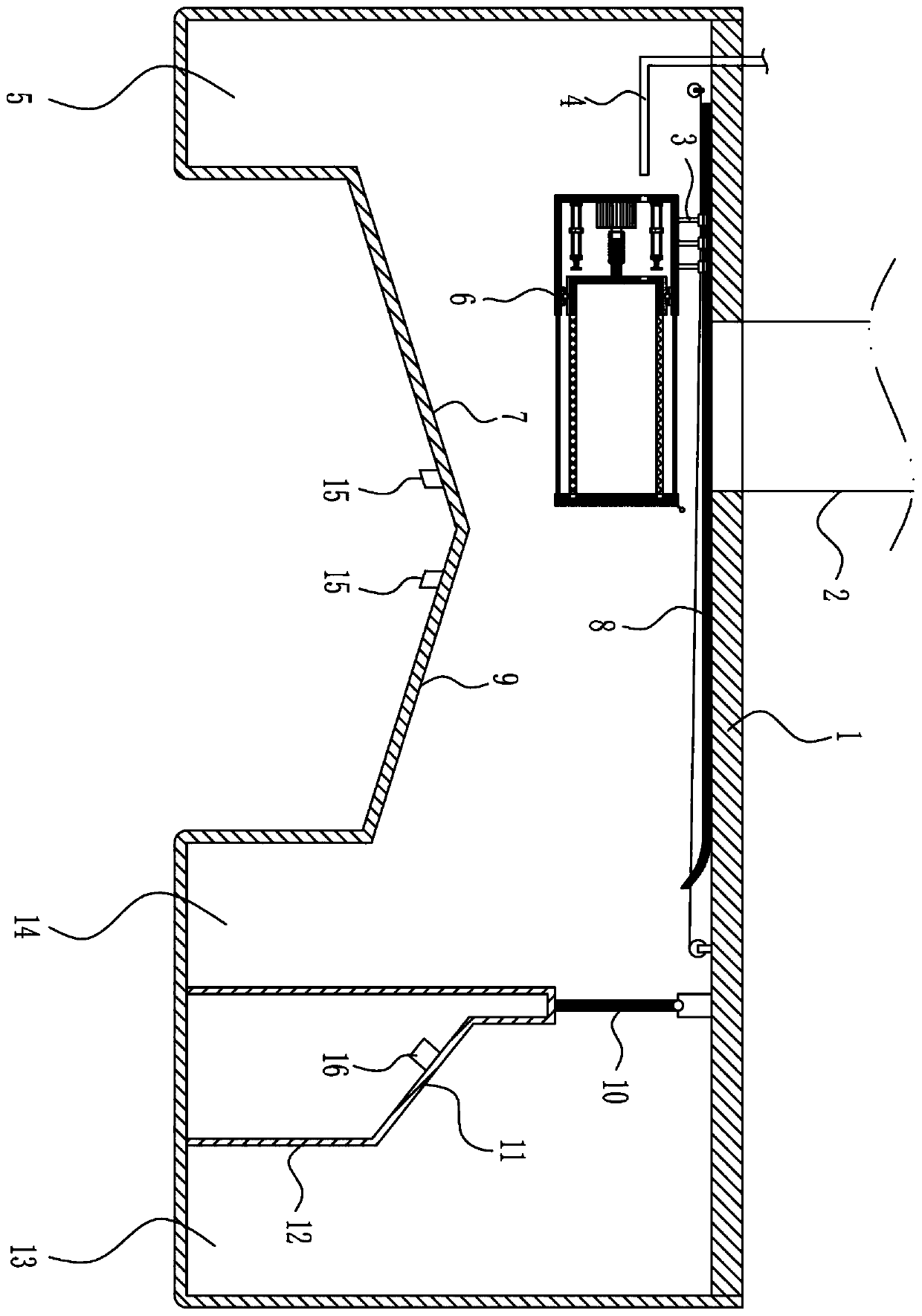

Permanent magnet type ultralow-frequency vertical tuned mass damper

ActiveCN107228147ASmall sizeSolve the problem of excessive static elongationNon-rotating vibration suppressionShock absorbersEngineeringFlywheel

The invention discloses a permanent magnet type ultralow-frequency vertical tuned mass damper. The permanent magnet type ultralow-frequency vertical tuned mass damper comprises an inertia mass system, an electromagnetic damping system and a support system, wherein the inertia mass system comprises a counterweight block, a flywheel, an inclined flexible hinge and a vertical flexible hinge; the electromagnetic damping system comprises a conductor plate and a permanent magnet; and the support system comprises a bearing bracket, a flexible hinge fixed plate, an extension spring, a bearing frame, an upper spring cross beam, a lower spring cross beam, a bearing and a base. A straight circular flexible hinge is adopted as a linear-rotary motion conversion mechanism; the space structure of the flexible hinge is well designed; and when the main structure is slowly and slightly vibrated, a small linear motion of the counterweight block can be effectively converted to a rotating motion of the flywheel, so that the problem of excessive static elongation of the spring of the ultralow-frequency vertical tuned mass damper is solved, and the vibration isolating performance of the tuned mass damper in the field of ultralow-frequency weak vibration is improved.

Owner:ZHEJIANG UNIV

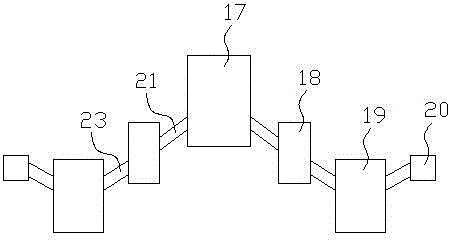

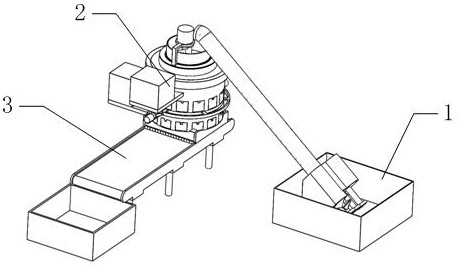

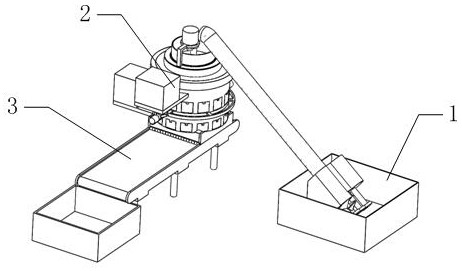

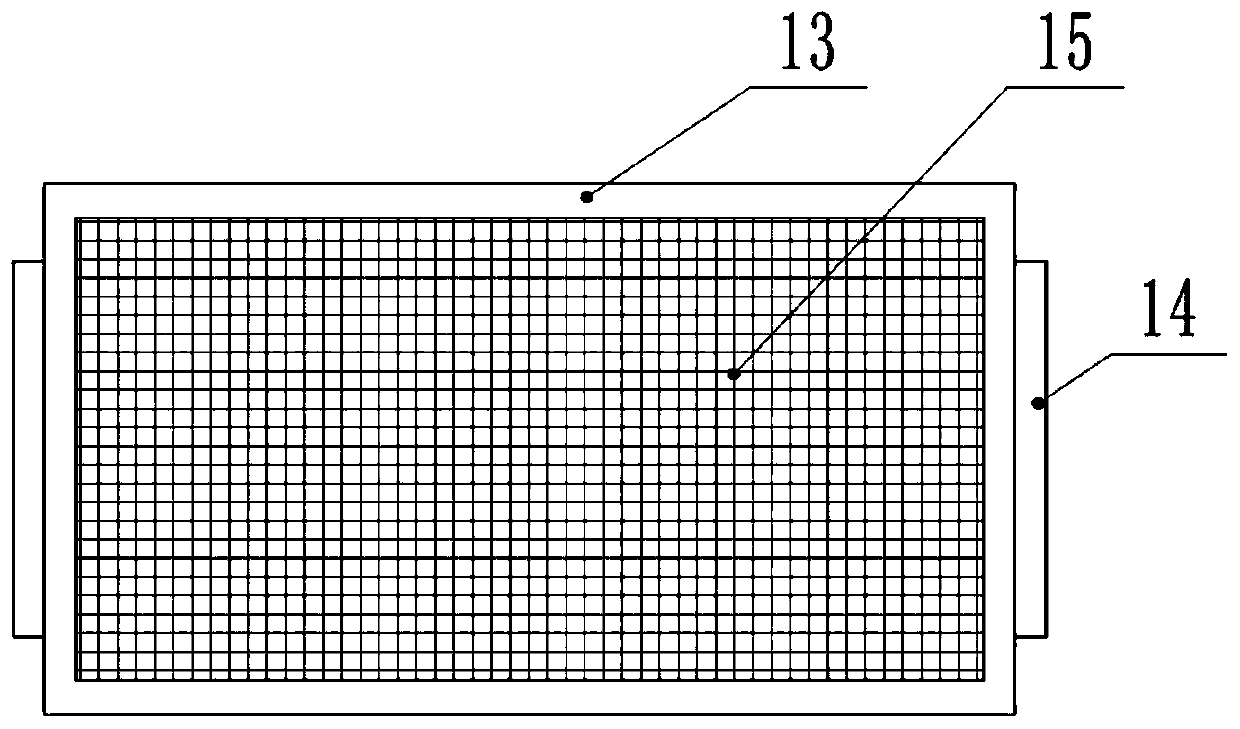

Integrated machine for grading production of anti-radiation mortar

ActiveCN105921248ASimple structureScreening boundaries are clearSievingDischarging apparatusRotational axisCrusher

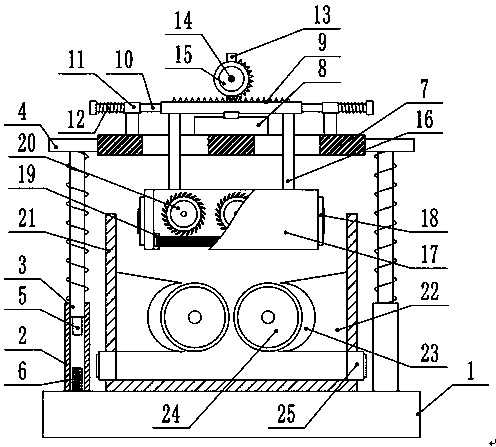

The invention relates to an integrated machine for grading production of anti-radiation mortar. The integrated machine comprises a screening and grading device connected to a crushing machine, a quantitative conveying device, a material mixing device and a raw material box, wherein the screening and grading device comprises a screening drum; a screen mesh is arranged at an upper part in the screening drum and a mounting tube is arranged at a bottom center of the screening drum; turnover shafts penetrating through the screening drum are arranged on the two sides of the screen mesh; the turnover shafts on the two sides are respectively mounted on a bearing pedestal and a turnover motor; partition plates are evenly arranged between the mounting tube and the screening drum; material collection cavities are formed between adjacent partition plates; a rotary cover is arranged above the mounting tube; a notch matched with the material collection cavity is formed in the rotary cover; the rotary cover is connected to a rotary shaft; and the rotary shaft is connected to a rotary motor. According to the screening and grading device, by screening by the simple screen mesh, the limit for screening is obvious, the structure is simple, meanwhile, the classified collection is facilitated, then the anti-radiation mortar of different grades is produced via the quantitative conveying device and the simple material mixing device, and further the economic effects are improved.

Owner:YIYANG JINYU BUILDING MATERIAL TECH CO LTD

Multi-directional horizontal movement type gravel screening device for concrete proportioning

InactiveCN107999385AAccelerateAvoid clogging holes with sand and gravelSievingScreeningDrive motorEngineering

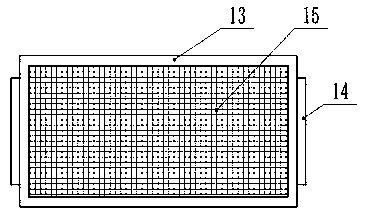

The invention discloses a multi-directional horizontal movement type gravel screening device for concrete proportioning. The device comprises a base, outer sleeve rods, inner sliding rods, a transverse plate, a driving motor, a special-shaped gear and a screening box. Magnets are arranged at the lower ends of the inner sliding rods. Electromagnets are arranged at the bottoms of the outer sleeve rods and matched with the magnets. The lower ends of connecting rods are connected with the screening box in a welded mode. An output shaft of the driving motor faces the front and is in interference fit with the special-shaped gear. The electromagnets are intermittently electrified and de-energized, thus, the screening box moves up and down intermittently, the vibration effect is achieved, the screening speed is greatly increased, and meanwhile, the situation that holes are blocked by gravels during screening is effectively avoided; the screening box slides leftwards and rightwards, thus, horizontal movement in the up-down direction and in the left-right direction is achieved, and the screening speed is further increased; and furthermore, compared with manual screening, more time and laborare saved, in addition, the structure is simple, the manufacturing cost is greatly reduced, and the practicability is high.

Owner:ZHENGZHOU MOORE ELECTRONICS INFORMATION TECH CO LTD

Soil sample crushing and screening device for soil restoration

InactiveCN109603968AAvoid cloggingVibration effectSievingScreeningManufacturing cost reductionSoil remediation

The invention discloses a soil sample crushing and screening device for soil restoration. The soil sample crushing and screening device comprises a fixing seat, an upper cover plate, a driving motor,a special-shaped gear, a screening box and a crushing box, the screening box is welded to the lower end of a connecting rod, a screen is arranged at the bottom of the screening box, and a plurality ofgroups of crushing wheels are further arranged inside the screening box. Intermittent electrification and power loss of an electromagnet are realized so that the screening box can move up and down intermittently, the vibration effect is achieved, the screening speed is greatly increased, and meanwhile, the situation that soil particles block holes during screening is effectively avoided; and thescreening box can slide left and right, so that up-down and left-right translation motion is realized, then the screening speed is further increased, meanwhile, compared with manual screening, time and labor are saved to the greater extent, moreover, the structure is simple, the manufacturing cost is greatly reduced, and the practicability is high.

Owner:刘艳姣

Controller system remotely controlling cluster robot by using non-specific foreign language voice

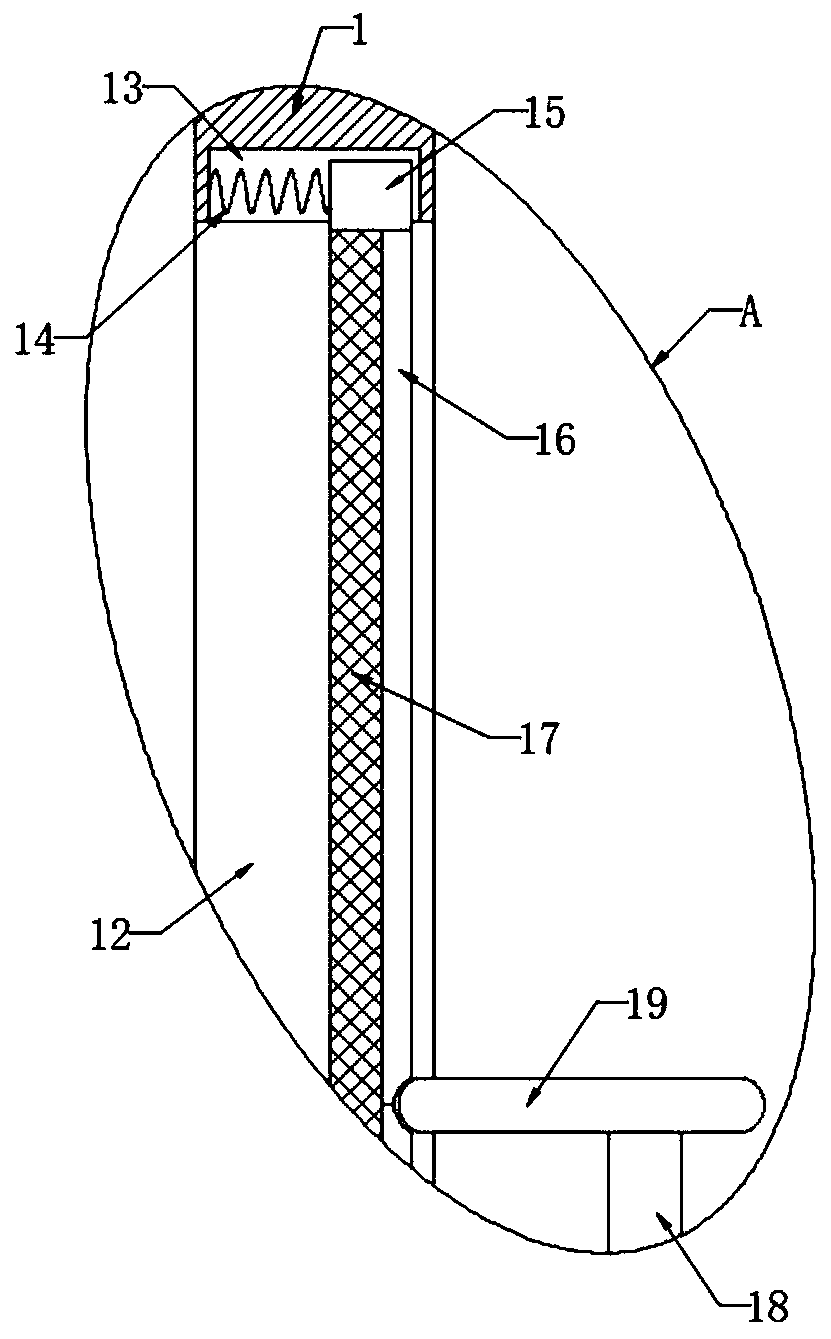

PendingCN111590635AWide range of applicationsEasy to install and disassembleManipulatorCooling/ventilation/heating modificationsComputer fanSwarm robotics

The invention discloses a controller system remotely controlling a cluster robot by using non-specific foreign language voice. The controller system comprises a shell, and the bottom of the interior of the shell is symmetrically and fixedly connected with two fixing rods; the upper ends of the two fixing rods are fixedly connected with a transverse plate through a vibration reduction mechanism; the upper end of the transverse plate is provided with a groove, and the inner wall of the groove is rotationally connected with a double-thread screw; and a clamping mechanism for clamping a controllerbody is installed on the double-thread screw. According to the controller system, by rotating the double-thread screw, two first slide blocks get close to each other, accordingly, clamping plates aredriven to slide, and controllers different in size can be clamped; the controller system is wide in application range and convenient to assemble and disassemble; through rotating of a cooling fan, vertical rods drive cams to rotate, the transverse plate fixedly connected to the inner wall of an annular frame is subjected to intermittent impact, dust on a filter screen is removed, and the situation that a large amount of dust is accumulated on the surface of the filter screen after the filter screen is used for a long time, and dissipation of heat in the controller is influenced is avoided.

Owner:HEILONGJIANG UNIV OF TECH +3

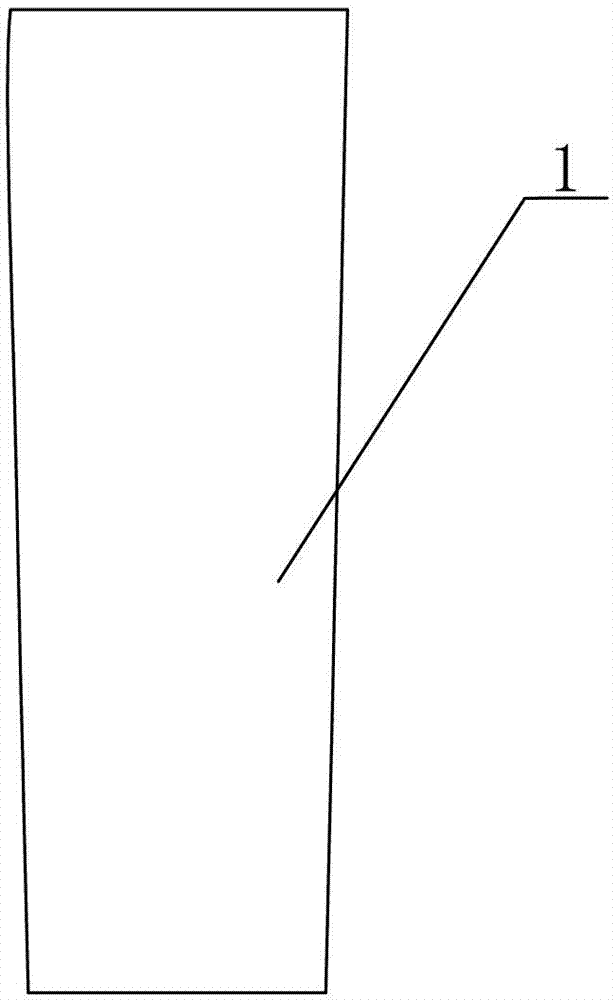

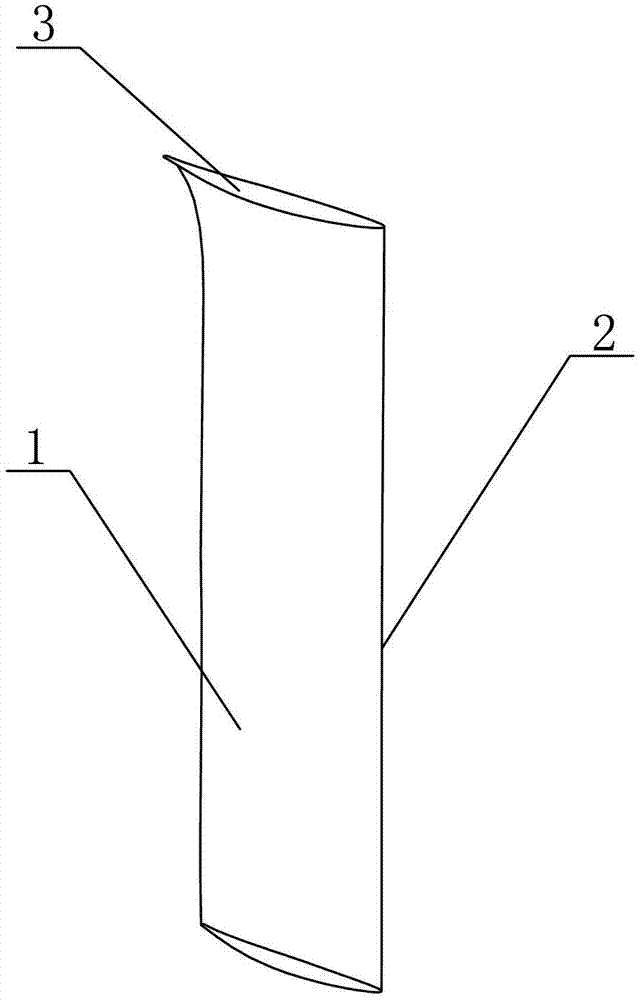

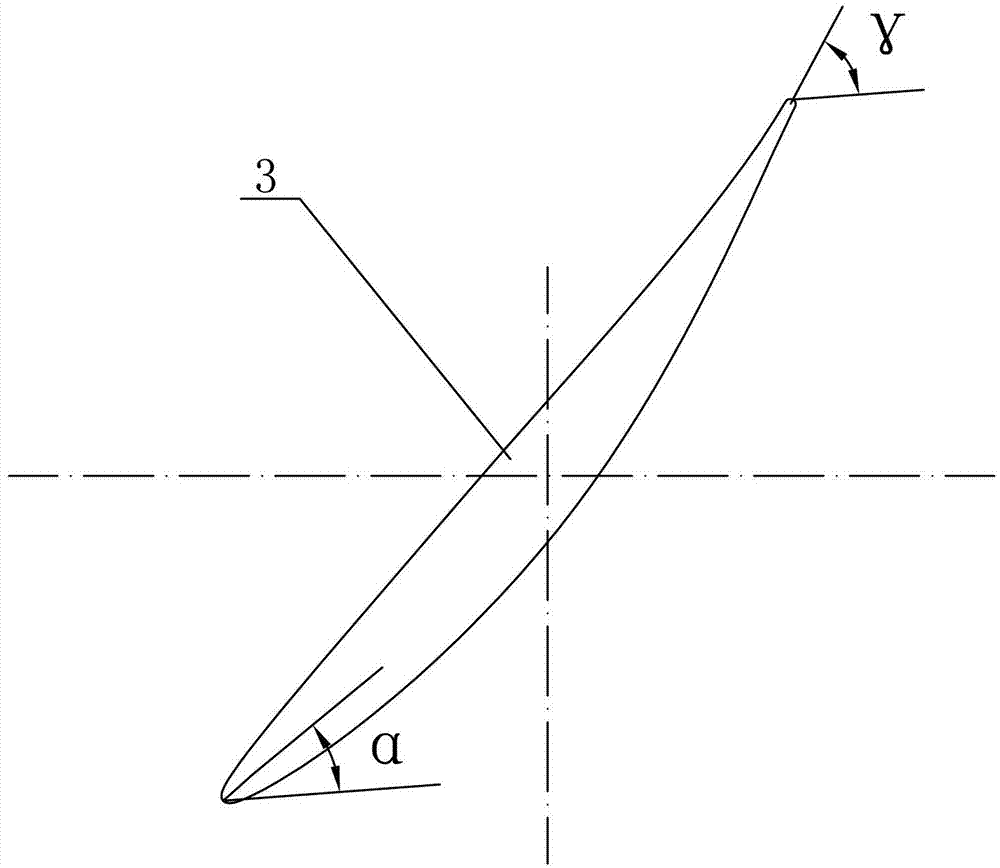

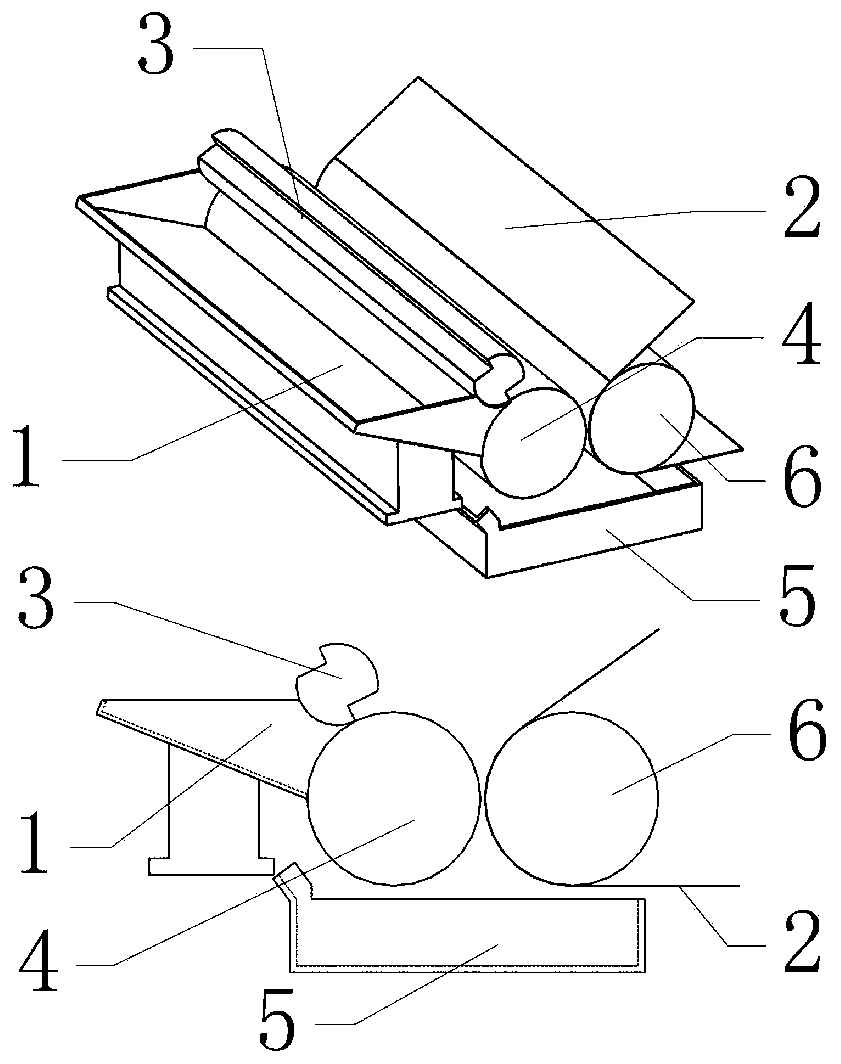

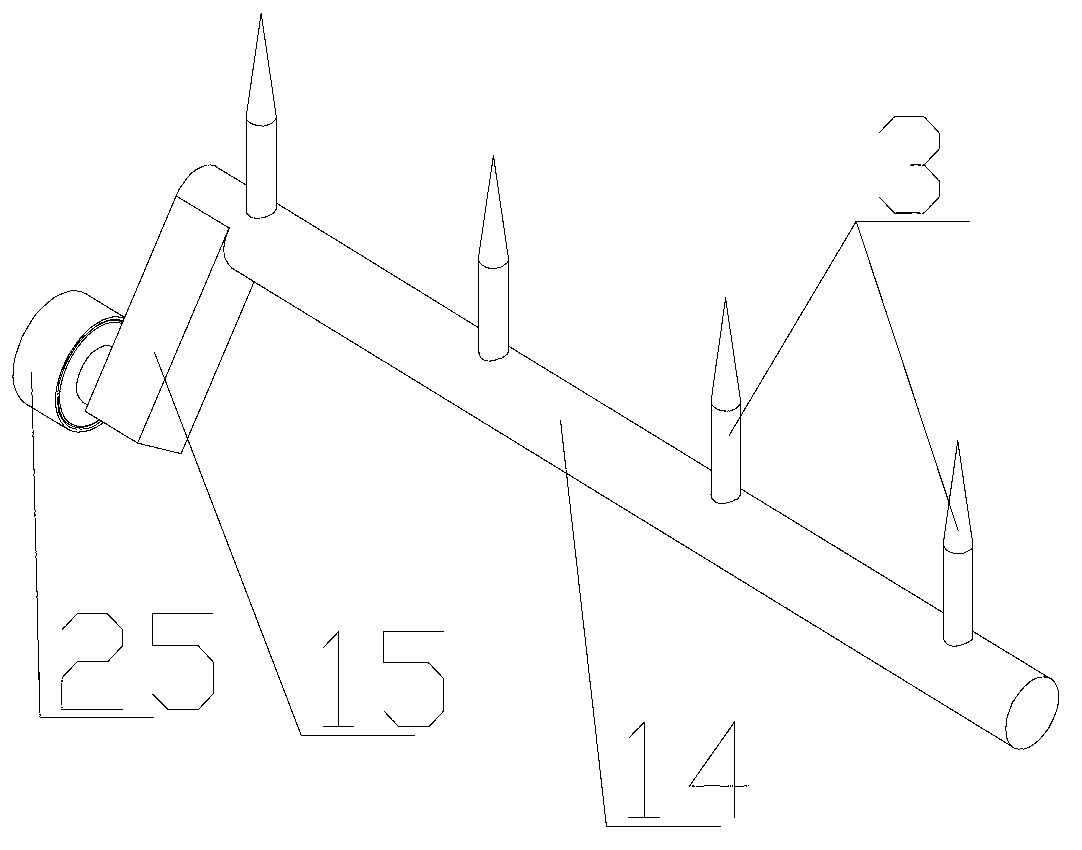

End-bend blade for improving working stability of gas compressor

InactiveCN102927050AInhibition of flow separationImprove job stabilityPump componentsPumpsAirflowEngineering

The invention discloses an end-bend blade for improving the working stability of a gas compressor, which relates to the end-bend blade and solves the problems that a guide blade of the traditional gas compressor is enlarged with the load, a positive angle of attack at the position close to the end wall is gradually increased, thus the gas compressor enters into a stall situation in advance, and the working stability of the gas compressor is poor. The end-bend blade comprises a guide blade (1), wherein the upper part of the guide blade (1) is an end-bend area (3), the end-bend area (3) is subjected to end bending along a track of a stacking line (2), the end-bend height of the end-bend area (3) is 7% of the total height of the guide blade (1), an inlet geometric angle of the guide blade (1) is linearly increased by 0-10 degrees along the blade height in an end-bend height area, and an end-bend blade profile at the upper end of the guide blade (1)shifts 0-7.53 mm towards one side of a suction surface relative to the middle part of the guide blade (1). According to the end-bend blade disclosed by the invention, the inflow and the outflow of airflow can be more in fit with a blade profile curve of the blade and can be matched with an angle of a main flow area of the gas compressor, and the working stability of the gas compressor can be increased. The end-bend blade disclosed by the invention is used in the gas compressor.

Owner:HARBIN TURBINE

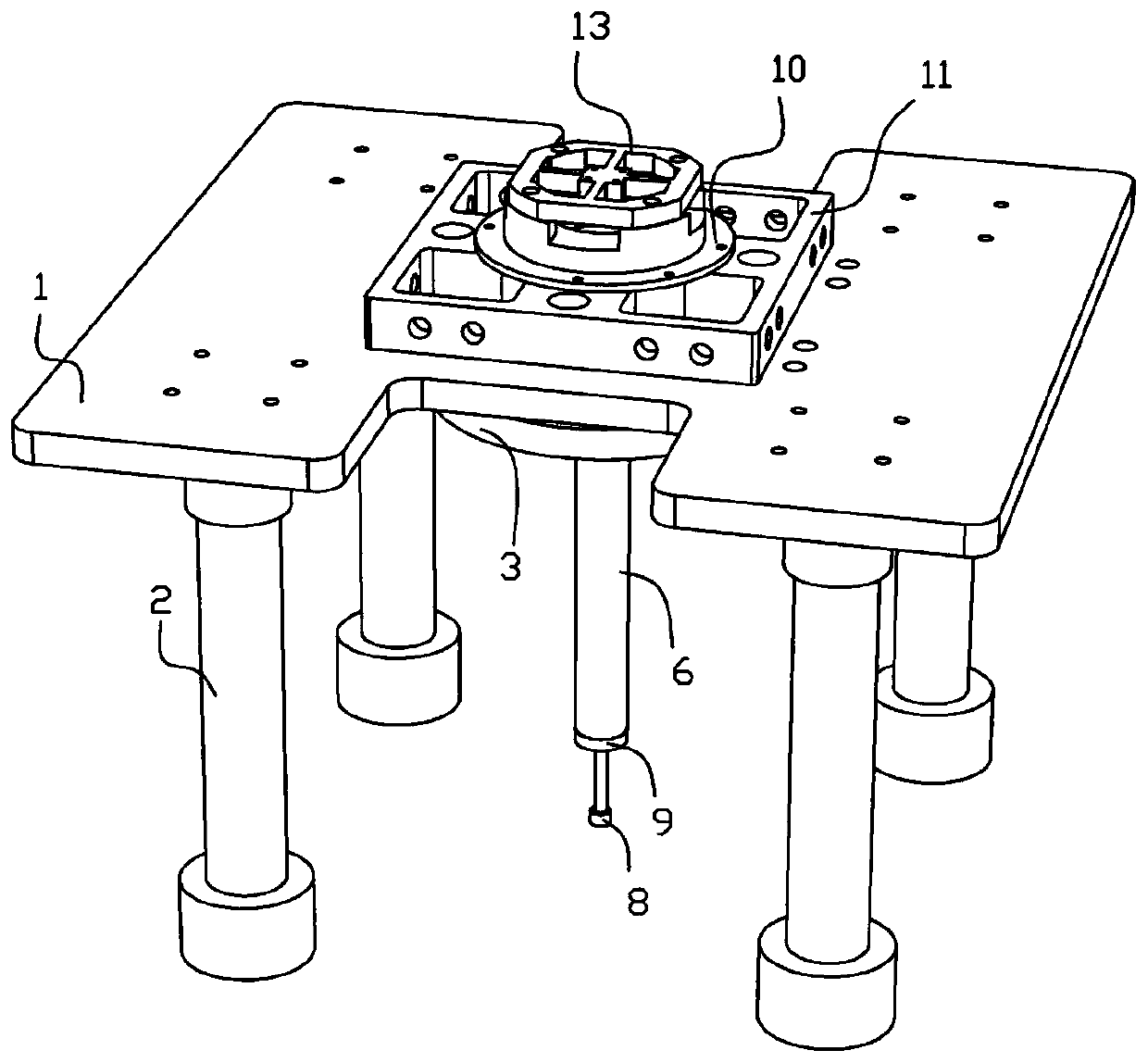

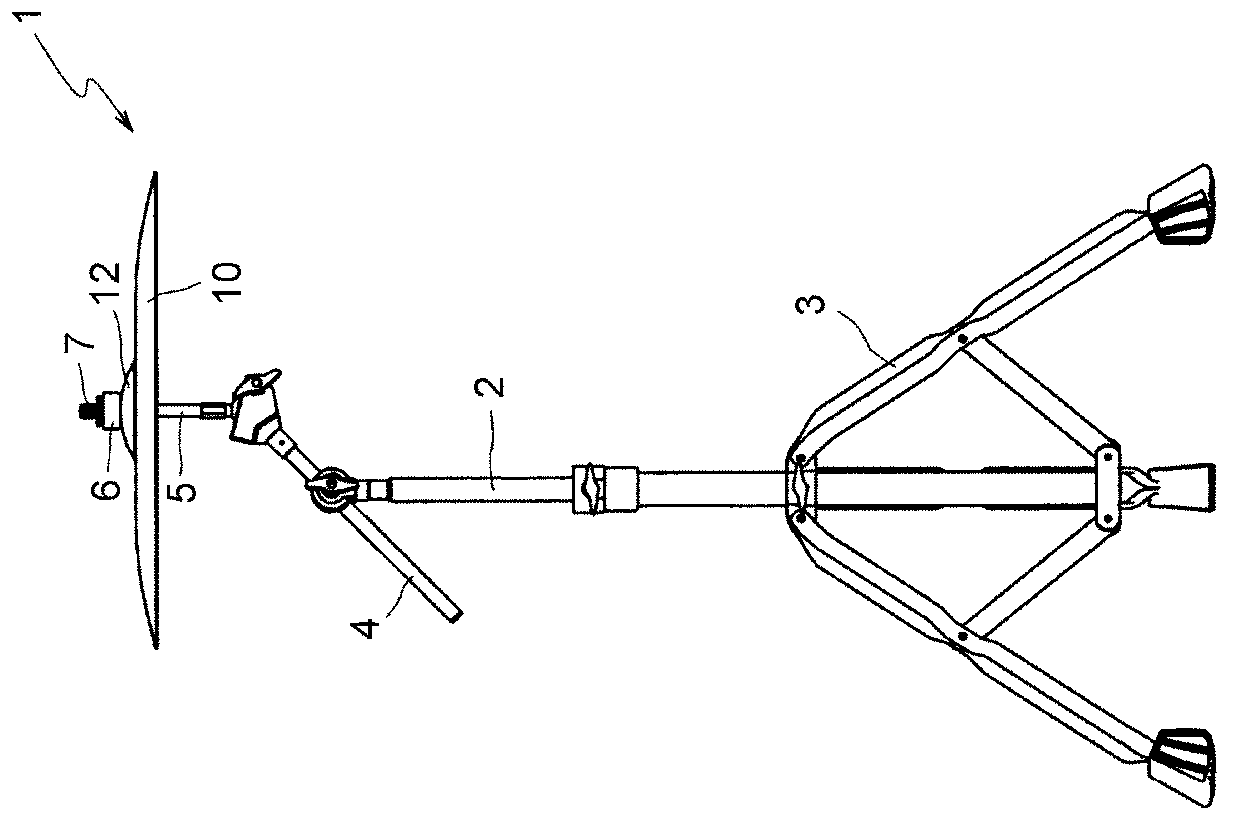

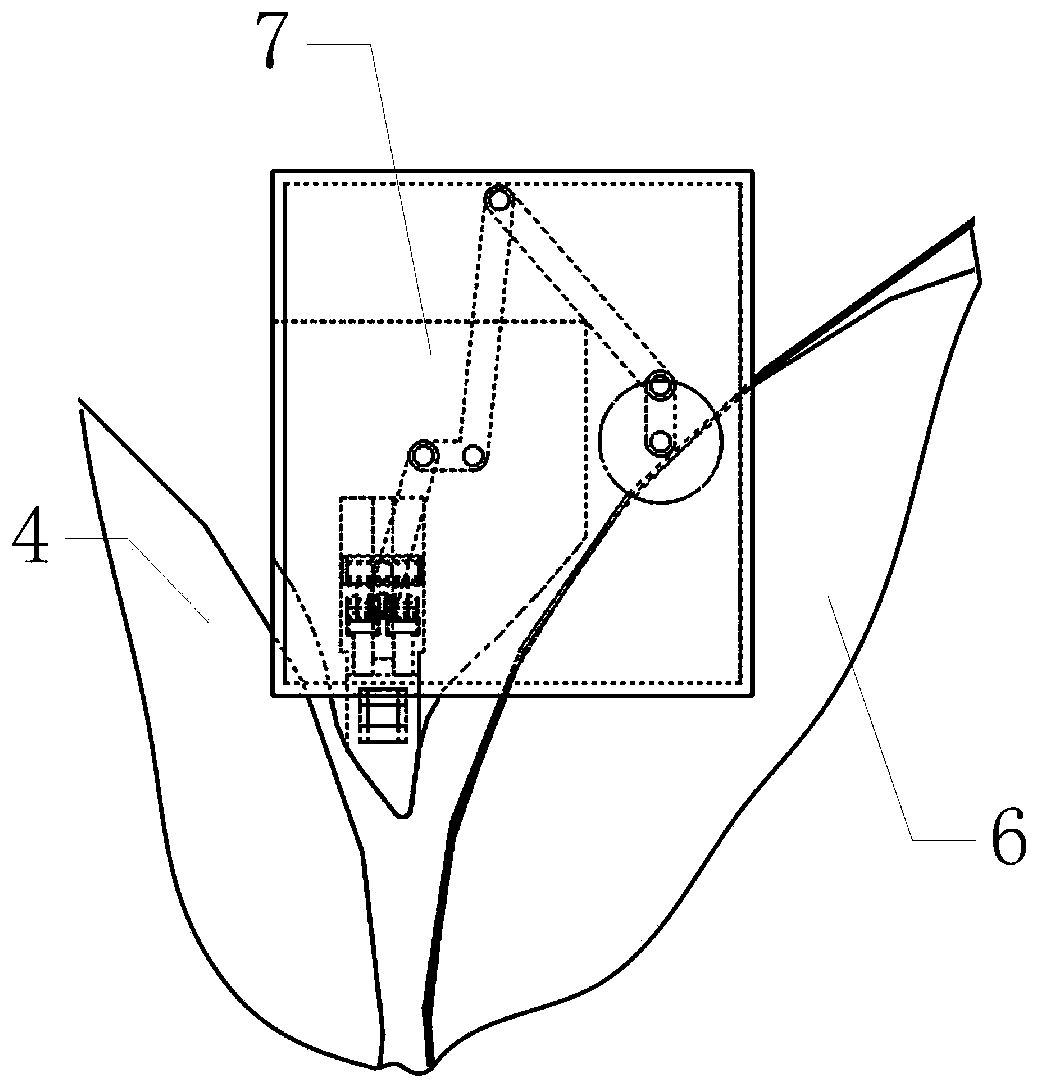

Tire pressure sensor with wheel balance function and wheel balance system

PendingCN107672389AReduce installation stepsQuick installationTyre measurementsWireless transmissionControl theory

The invention discloses a tire pressure sensor with the wheel balance function and a wheel balance system. The tire pressure sensor with the wheel balance function is used for a wheel which is provided with a wheel ring and a tire, air pressure space is formed between the tire and the wheel ring, and the wheel ring is provided with an air nozzle communicating with the air pressure space; the tirepressure sensor comprises a body and a sensing module, and the body is movably arranged in the air pressure space and is provided with accommodating space; the sensing module is arranged in the accommodating space, and a sensing unit of the sensing module is used for sensing the gas pressure in the air pressure space and producing a pressure signal; and a central processing unit of the sensing module receives the pressure signal, the pressure signal is outwards transmitted wirelessly through a wireless transmission unit of the sensing module. The tire pressure sensor with the wheel balance function can effectively reduce the vibration and shaking problem due to uneven wheel weight during wheel travelling so as to achieve the effect of wheel balance.

Owner:SHANGHAI VEI SHENG AUTO PARTS MFG CO LTD

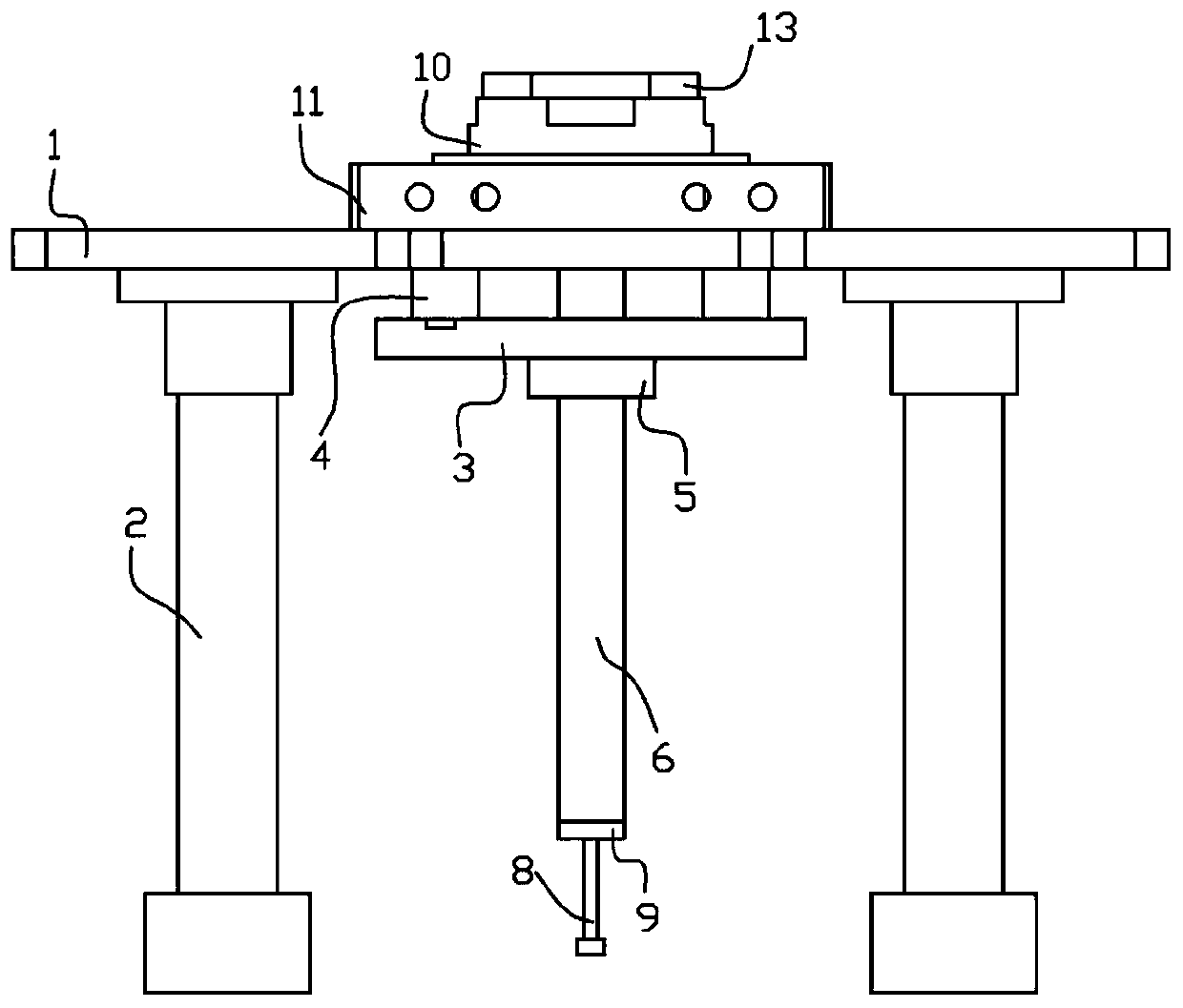

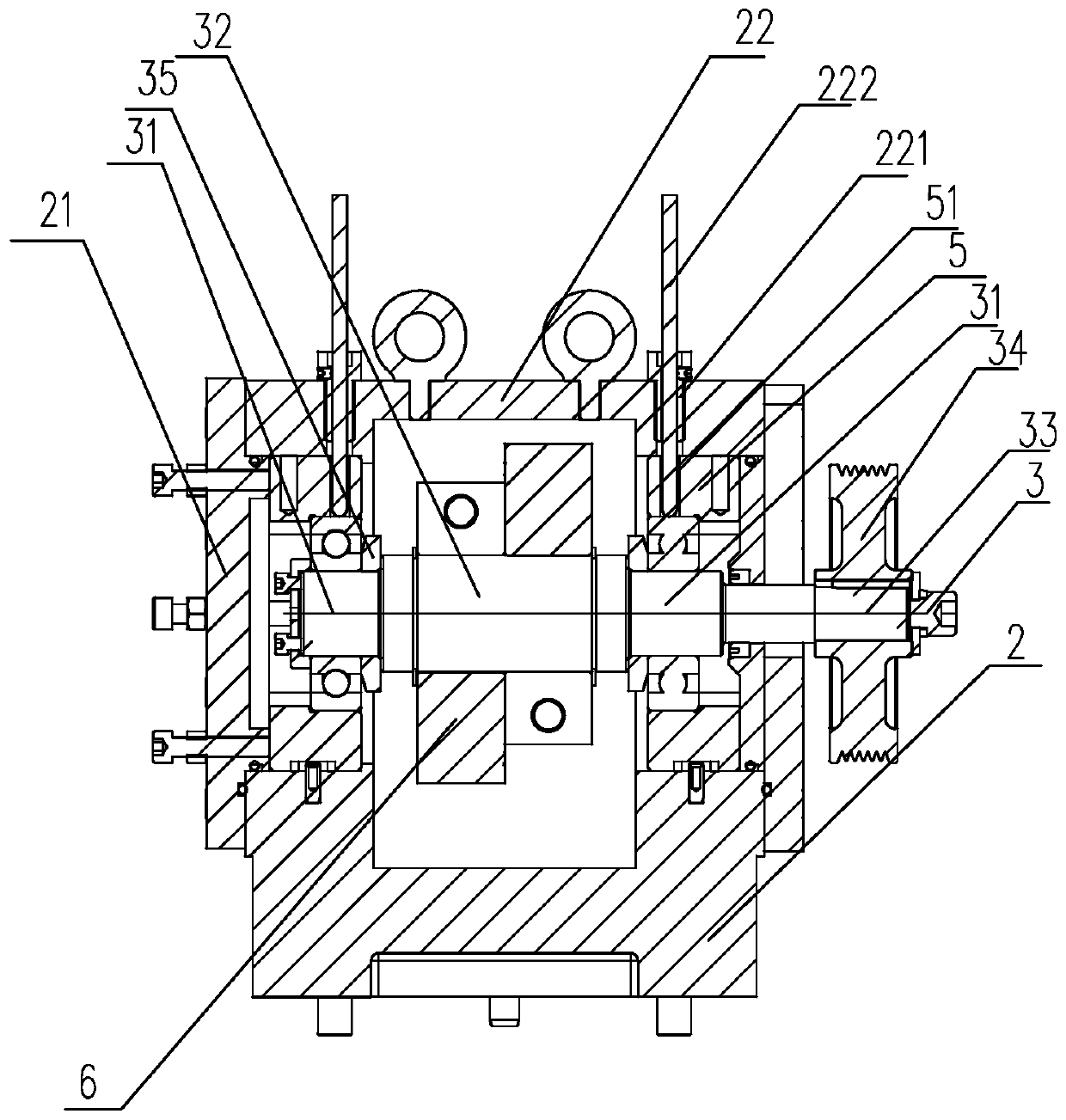

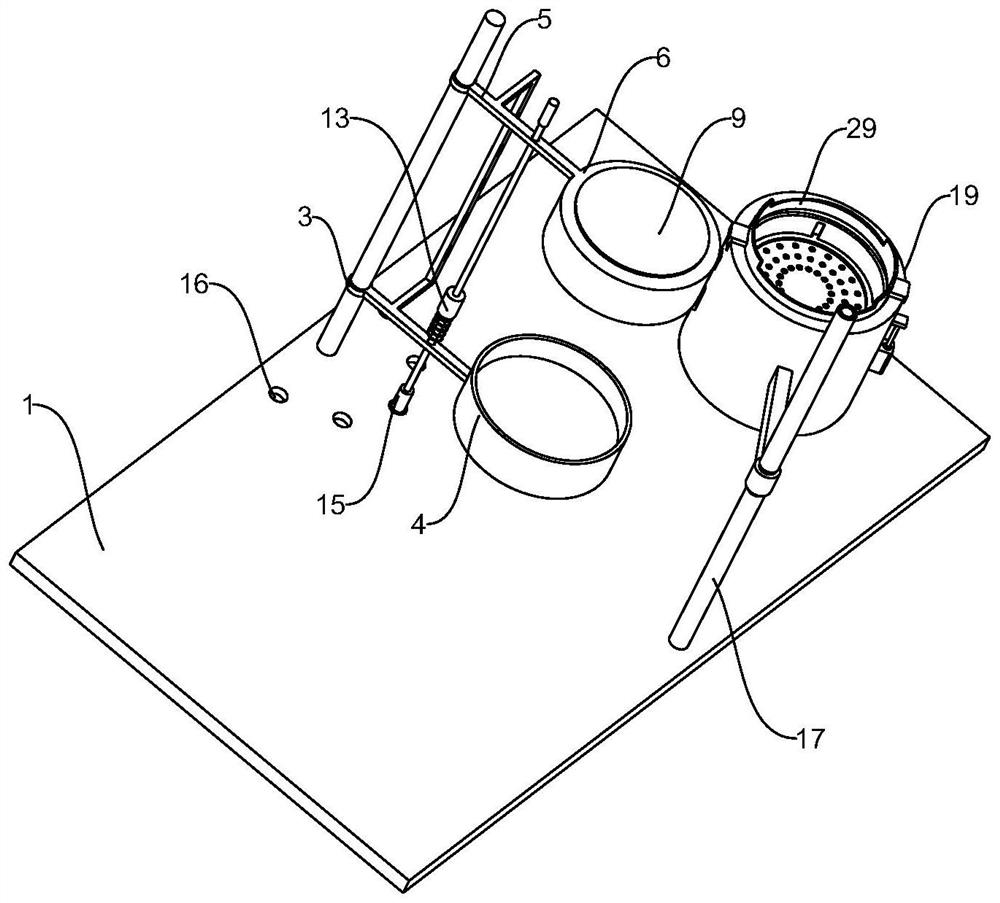

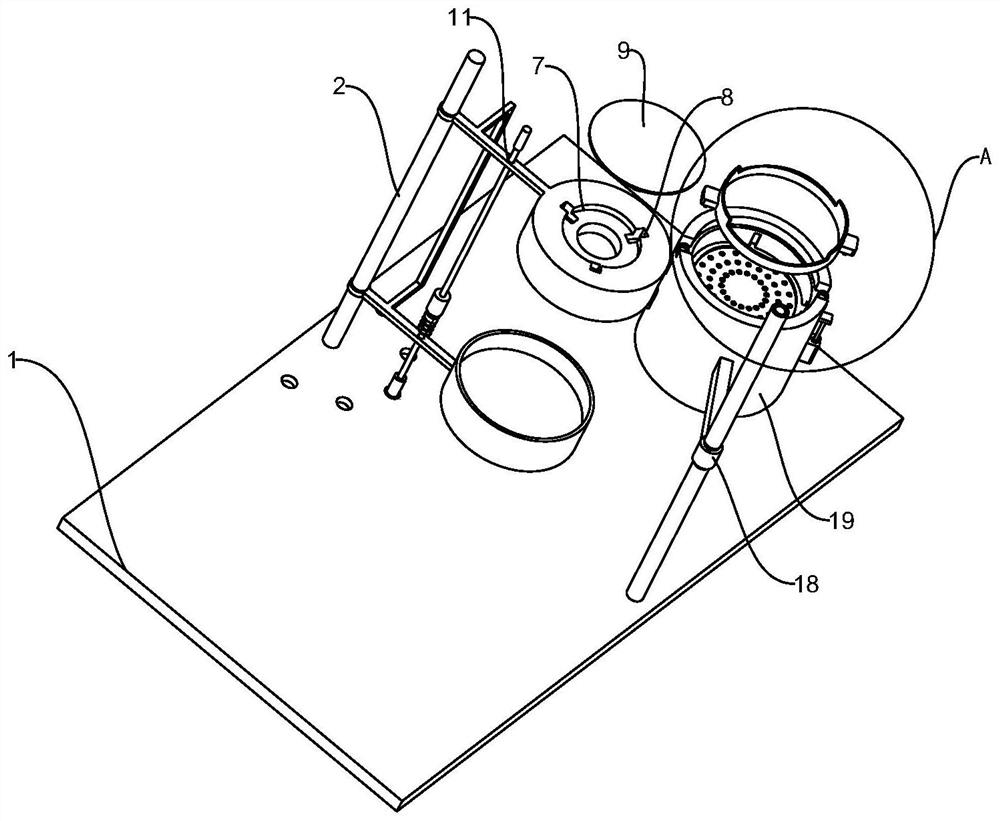

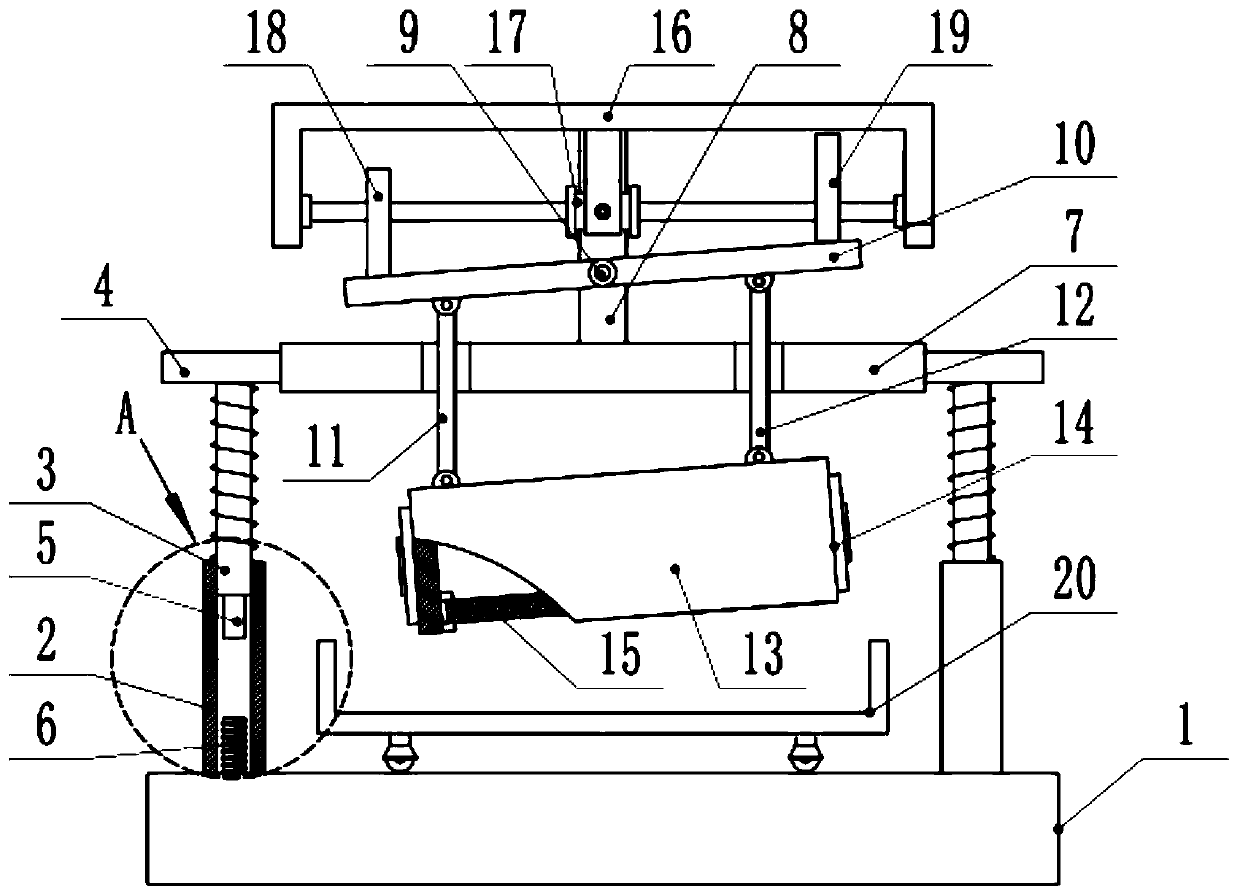

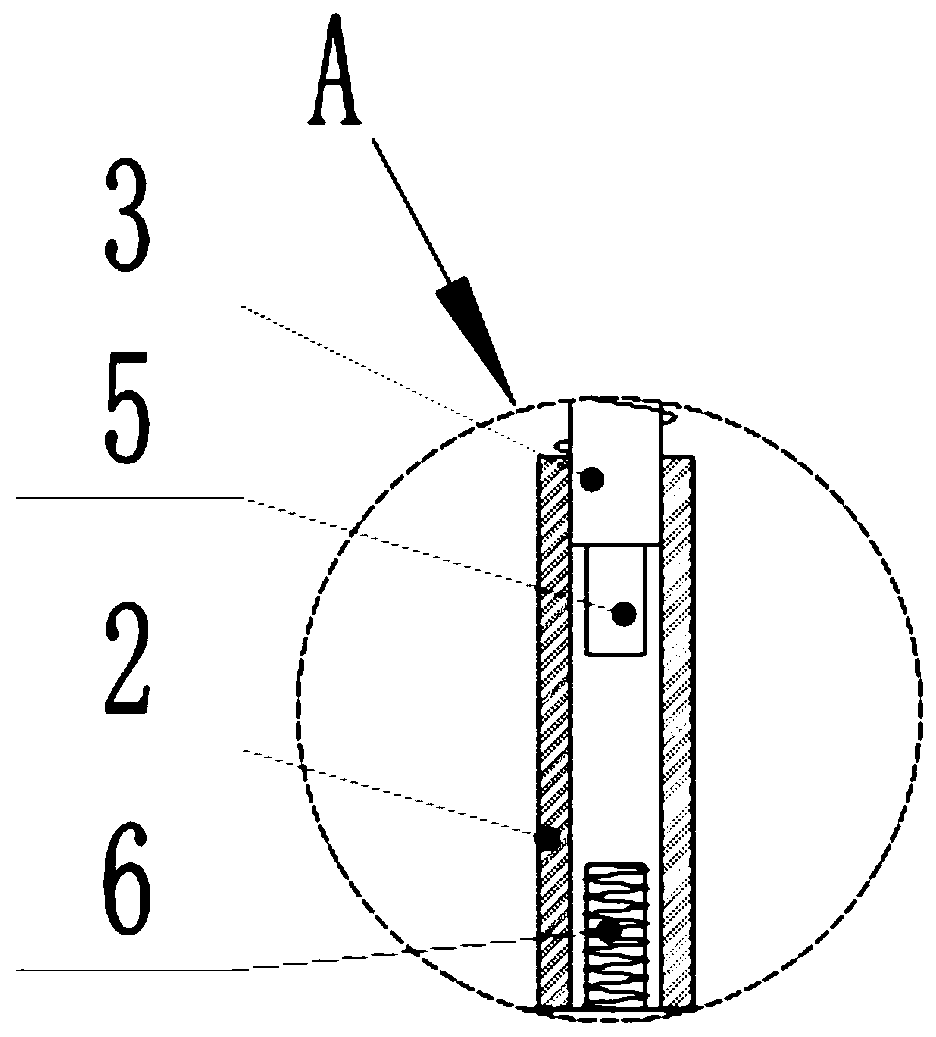

Six-dimensional force sensor dynamic calibration device and calibration method thereof

PendingCN111579152ASolve the size of the forceSolve the point of applicationForce/torque/work measurement apparatus calibration/testingClassical mechanicsControl theory

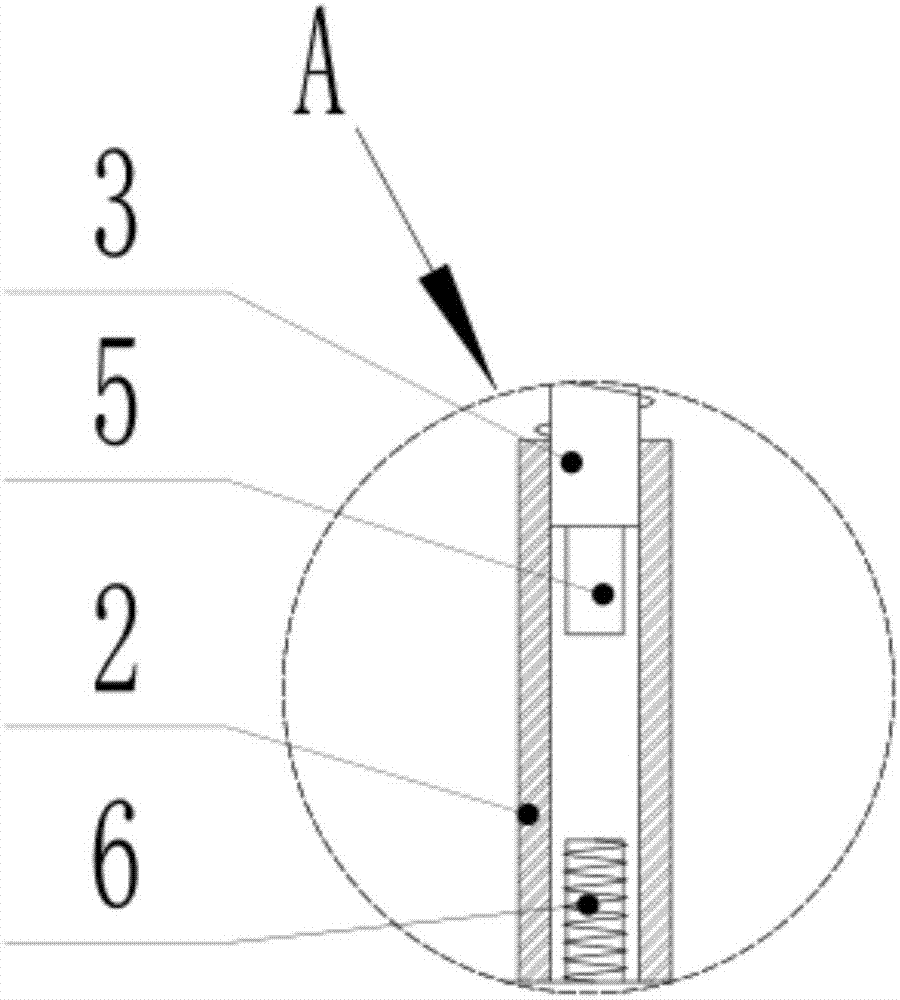

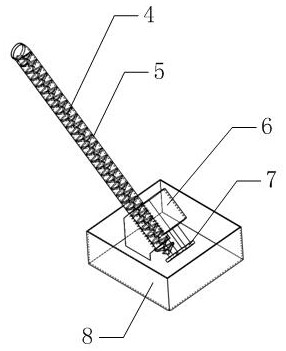

The invention discloses a six-dimensional force sensor dynamic calibration device and a calibration method thereof. The device comprises a calibration table, a pulse force loading device and a fixingdevice used for fixing a to-be-measured force sensor, the pulse force loading device is arranged below the table top of the calibration table, and a plurality of groups of positioning holes are formedin the table top of the calibration table and used for installing the fixing device in different directions. A through hole is formed in the middle of the calibration table, the pulse force loading device comprises a sleeve fixedly installed on the bottom face of the calibration table, a spring pull rod coaxially arranged in the sleeve and a spring connected to the spring pull rod in a sleeving mode, and the upper end of the spring pull rod and an end cover installed at the bottom end of the sleeve serve as spring seats at the two ends of the spring respectively. When the to-be-measured forcesensor is installed on the fixing device, the sensitive direction axis of the to-be-measured force sensor is located on the axis of the spring pull rod, and the axis is located in the calibration table through hole. Loading is carried out in a small ball impact mode, and the device has the advantages of being stable and controllable in loading force value, high in precision, good in repeatabilityand the like.

Owner:HEFEI UNIV OF TECH

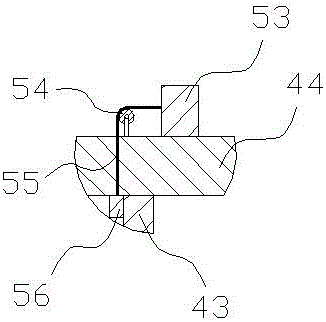

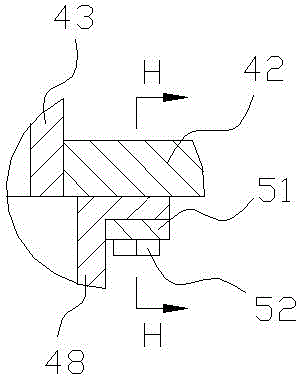

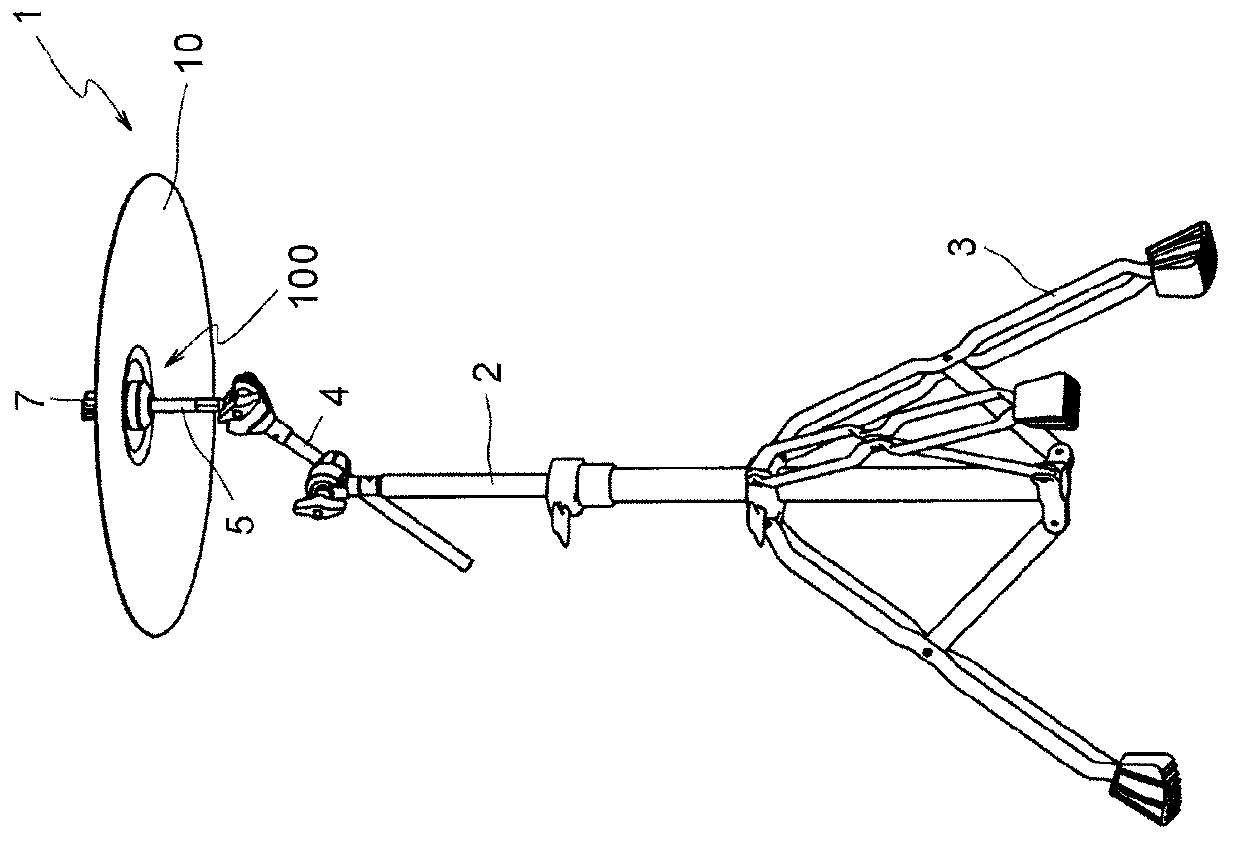

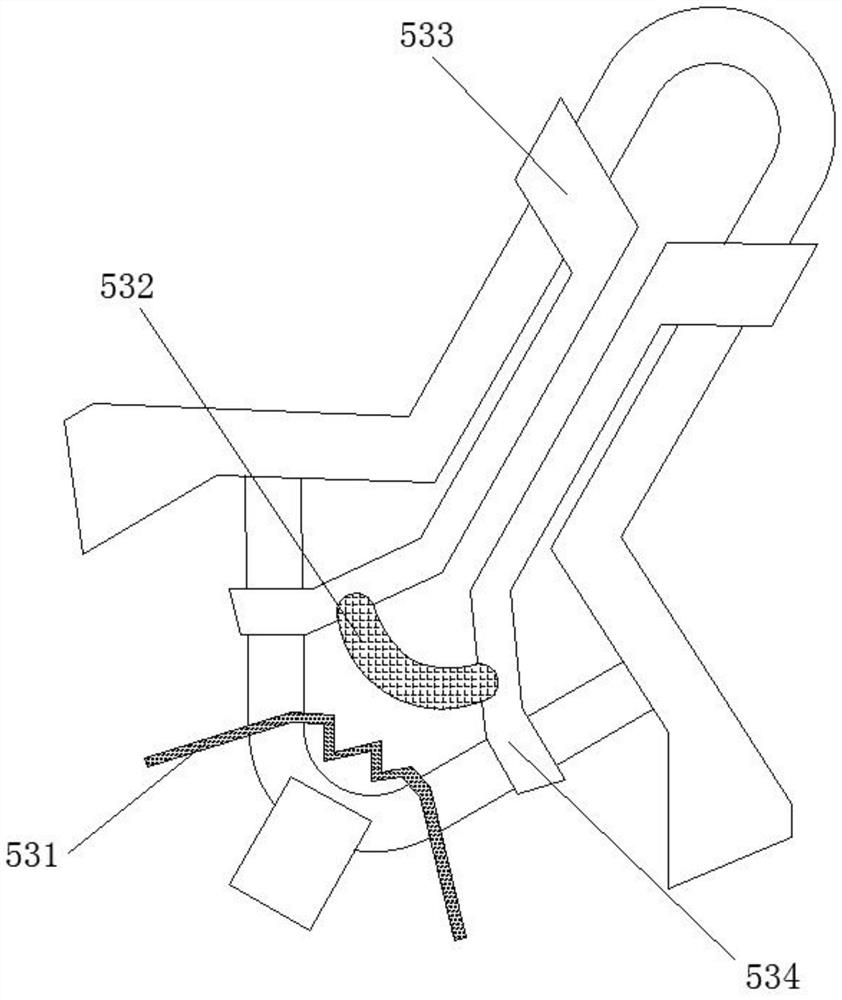

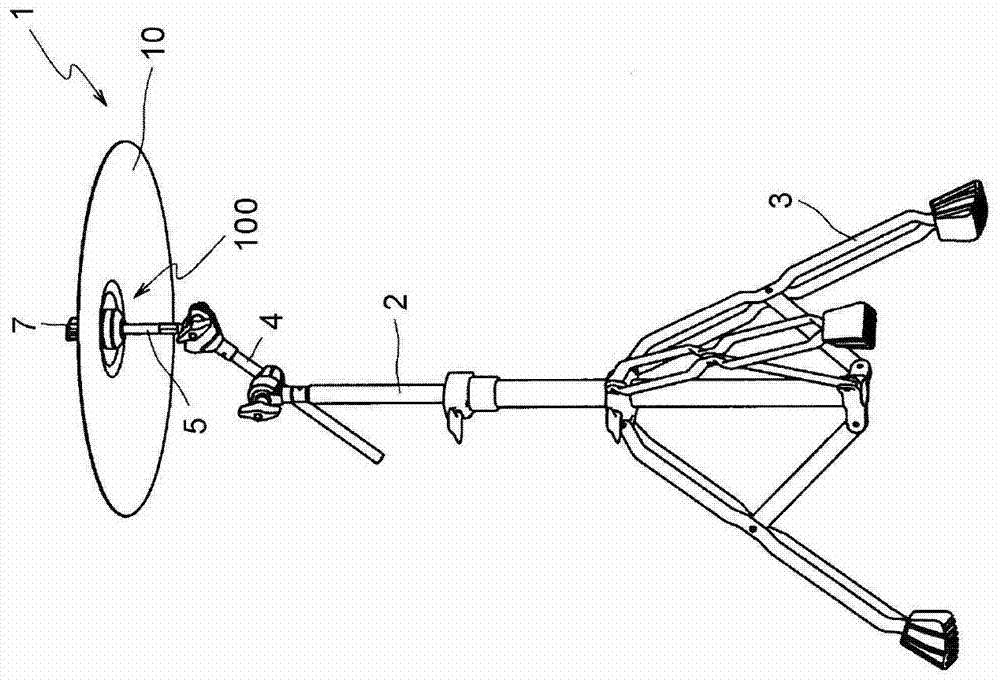

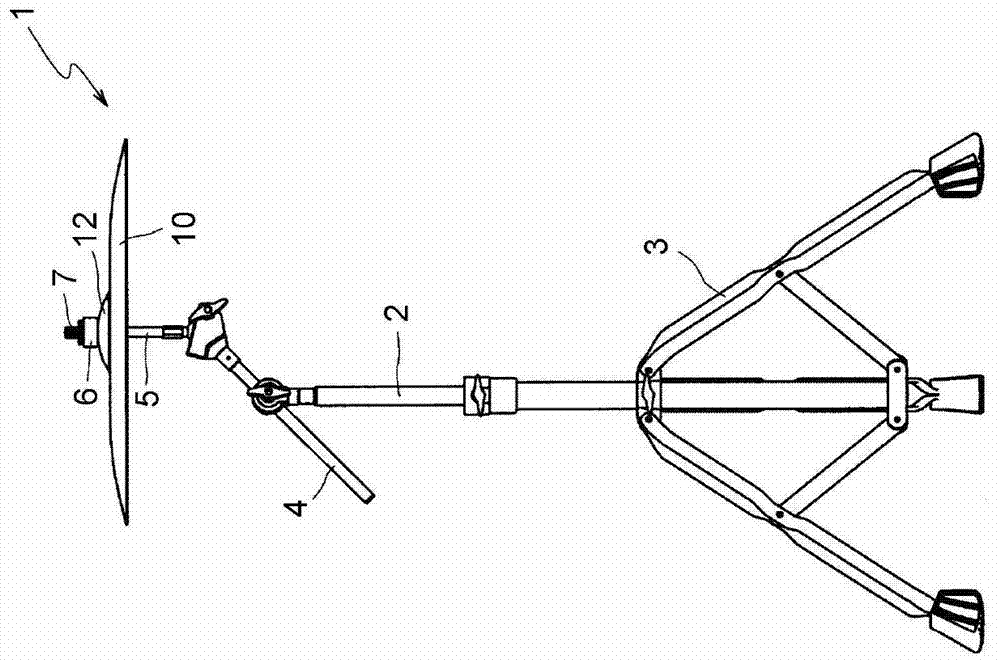

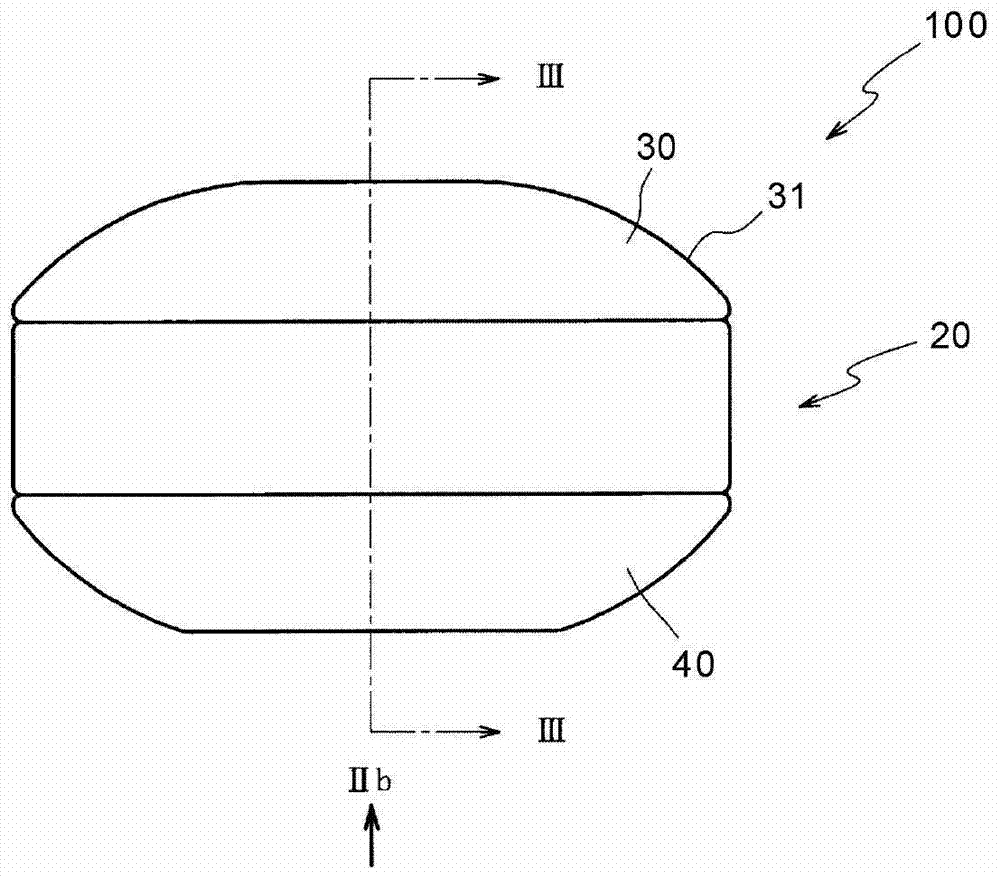

Cymbal pickup and stand provided with the same

InactiveCN103137111AVibration effectSmooth vibrationElectrophonic musical instrumentsPiezoelectric generatorEngineering

A cymbal pickup and a stand provided with the same are described. The cymbal pickup can stably detect vibration corresponding to striking to the cymbal, and prevent damage of sensors. A mounting part of the sensor uses an insert part to remain a space between a first abutting section and a second abutting section to be fixed, thereby preventing the first abutting section and the second abutting section to close to each other due to a fastening effect of fastening members, and furthermore preventing effects of a fastening force of the fastening members on detecting results of a piezoelectric sensor mounted on the first abutting section. Consequently, detecting results corresponding to the vibration of the mounting part of the sensor conveyed by the cymbal can be outputted. In addition, deformation of the piezoelectric sensor as the stroke cymbal tilts can be prevented, and thus damage of the piezoelectric sensor caused by strongly striking the cymbal can be prevented.

Owner:ROLAND CORP

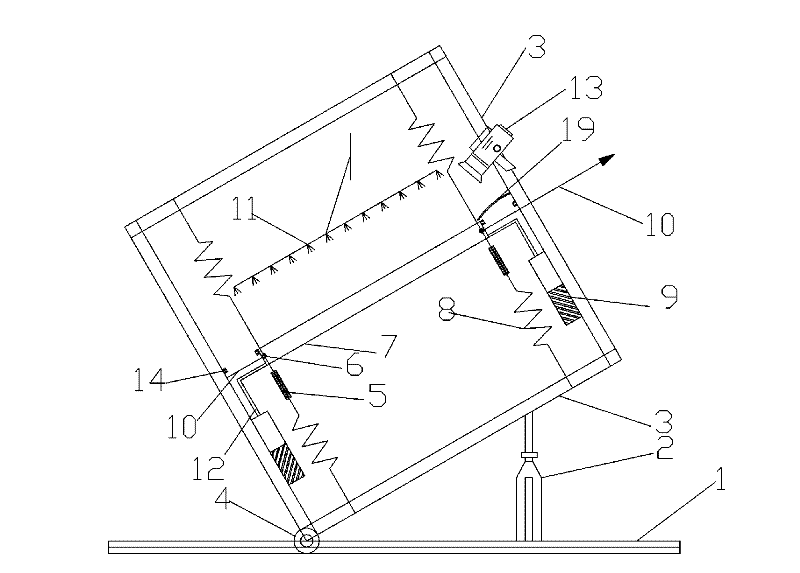

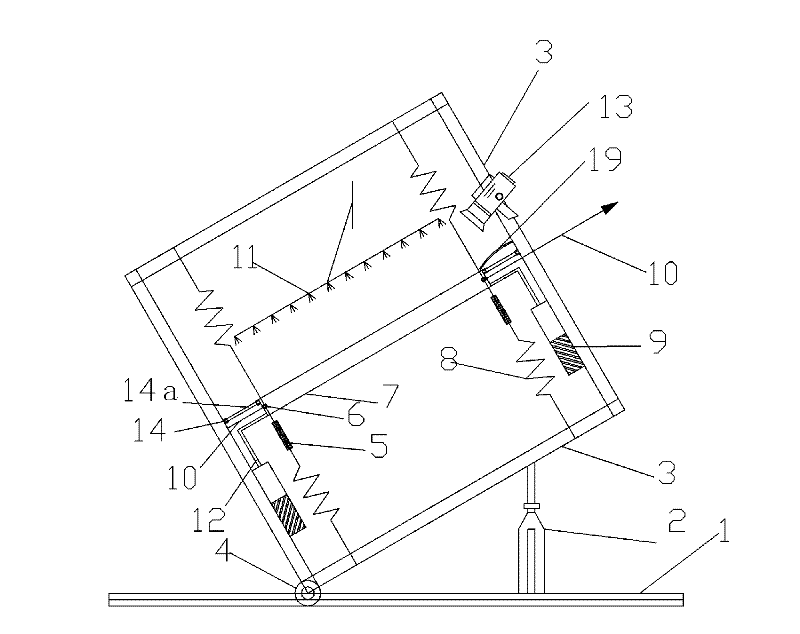

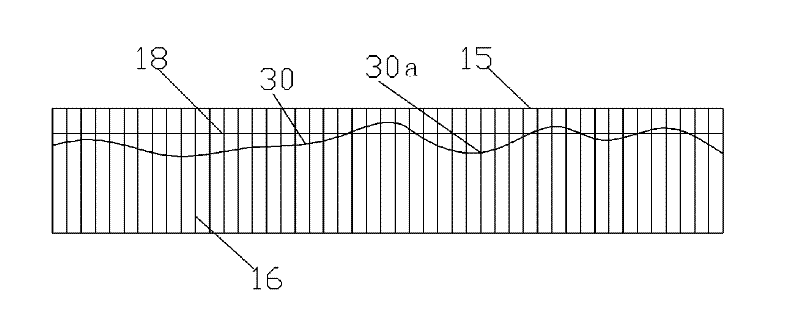

Simulation test device and method for waterway of cable-stayed bridge inhaul cable

InactiveCN102175421AAccurate mapping resultsSimple structureAerodynamic testingCable stayedAccuracy and precision

The invention relates to a simulation test device and a method for a waterway of a cable-stayed bridge inhaul cable. The device is characterized in that two ends of a test stayed cable are respectively connected to upper and lower borders of a quadrangular steel frame through upper and lower two suspension springs; an arch-shaped strain type sensor is serially connected in the lower suspension spring; the two ends of the stayed cable are provided with acceleration meters and are fixedly connected to connecting rods of dampers; the dampers are fixed on the side frame of the steel frame; one corner on the lower part of the steel frame is hinged with a turntable; a jack is arranged between the lower border of the steel frame and the turntable; a water injection device is arranged above the suspension cable; and a camera is arranged above the side frame of the steel frame. The device can be used for accurately testing the waterway of the cable-stayed bridge inhaul cable, is high in testing precision and has simple structure, thereby supplying reliable and objective accordance for studying the raining vibration phenomenon of the cable-stayed bridge and supplying reliable guarantee to the design and construction of the cable-stayed bridge.

Owner:SOUTHWEST JIAOTONG UNIV

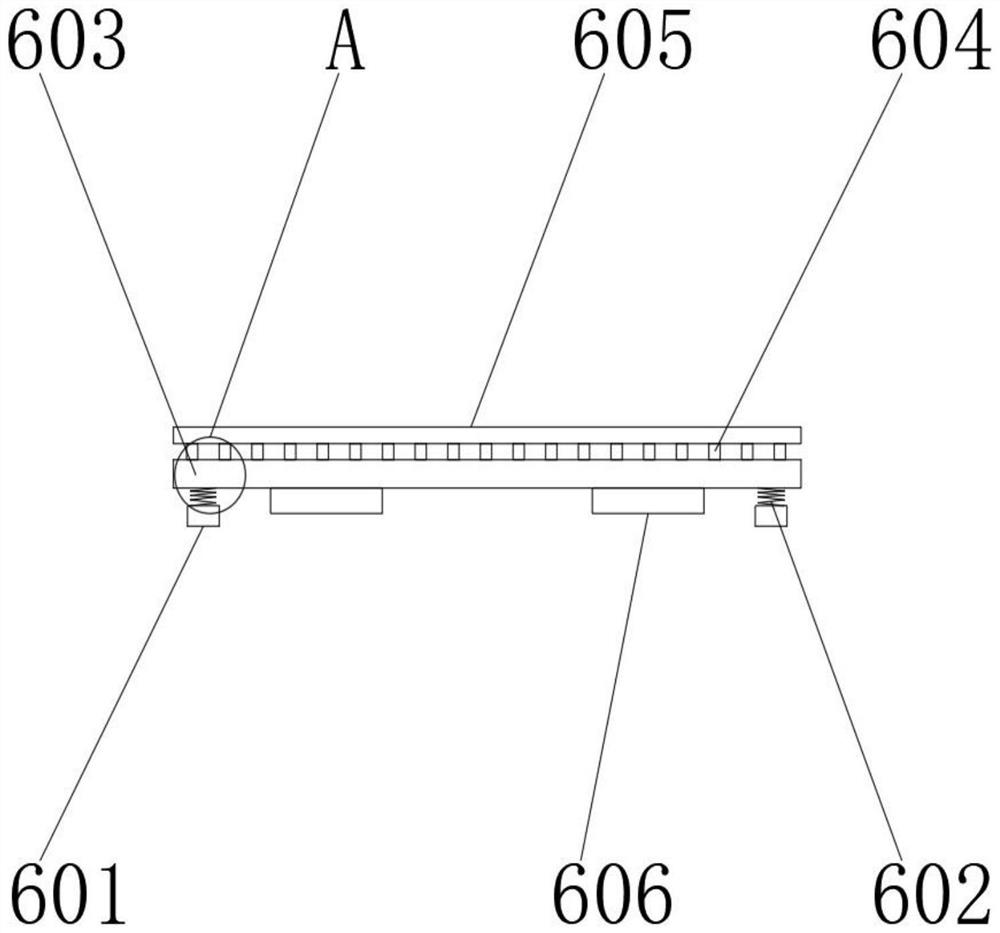

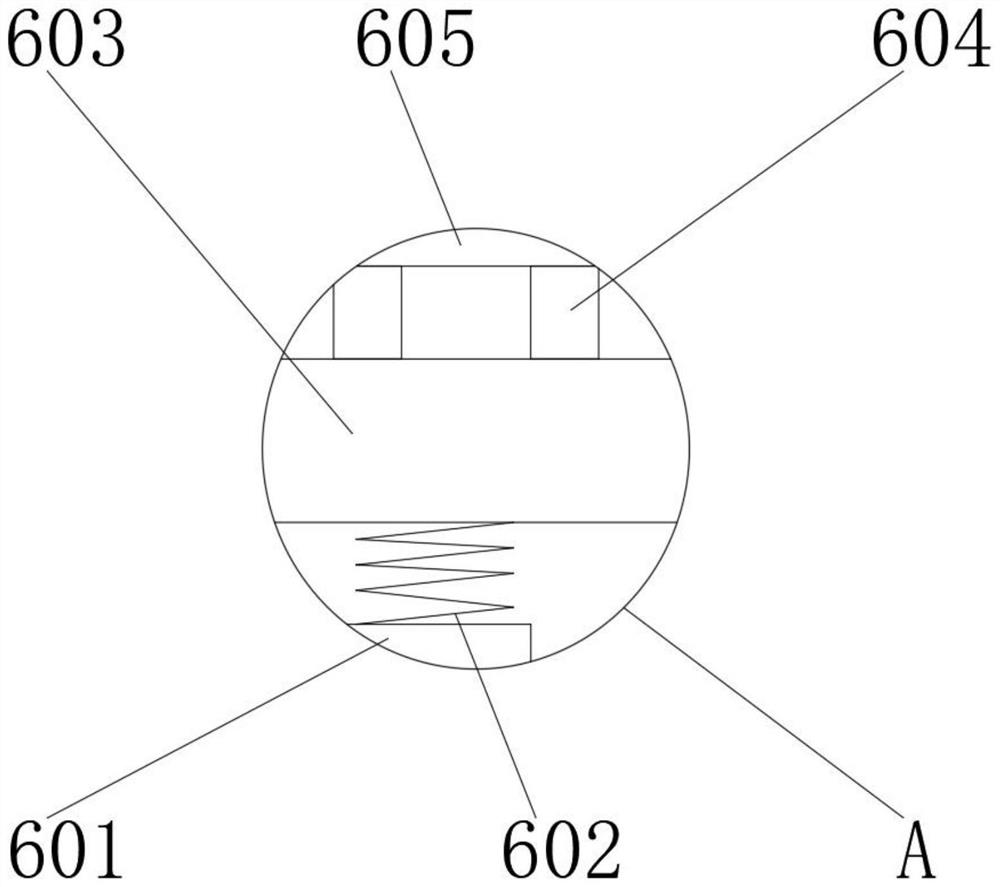

Coated plastic particle production device

The invention relates to the field of plastic particles, in particular to a coated plastic particle production device. The coated plastic particle production device is uniform in coating, capable of saving raw materials and high in work efficiency; in order to solve the technical problem, the coated plastic particle production device is provided and comprises a rack, a feeding cylinder, a first connecting rod, a feeding pipe, a coating mechanism, a moving mechanism, a second springback door and a partition frame; the feeding pipe and the feeding cylinder are arranged on the top of the rack, the feeding pipe extends into the rack, the moving mechanism is fixedly connected to the top in the rack, the moving mechanism is located below the feeding pipe, the output end of the moving mechanism is fixedly connected with the first connecting rod, and the bottom end of the first connecting rod is fixedly connected with the coating mechanism. The effects that inorganic particles can be evenly coated on plastic particles, raw materials are saved, labor force is saved, and work efficiency is high are achieved.

Owner:中山市立科硅胶制品有限公司

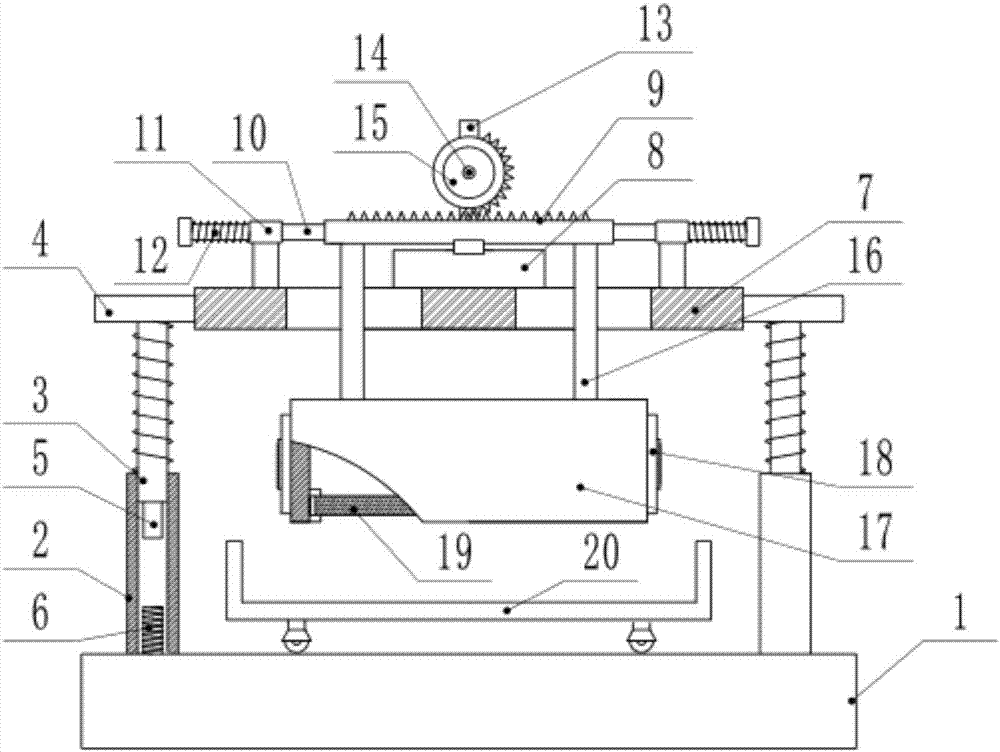

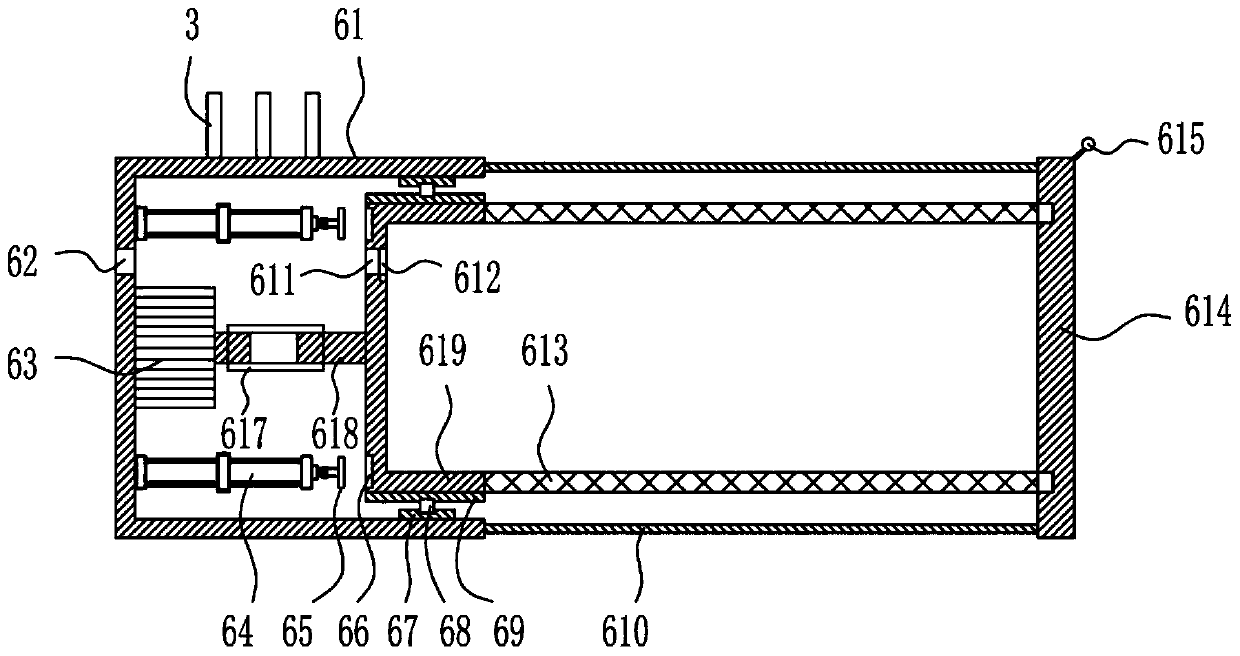

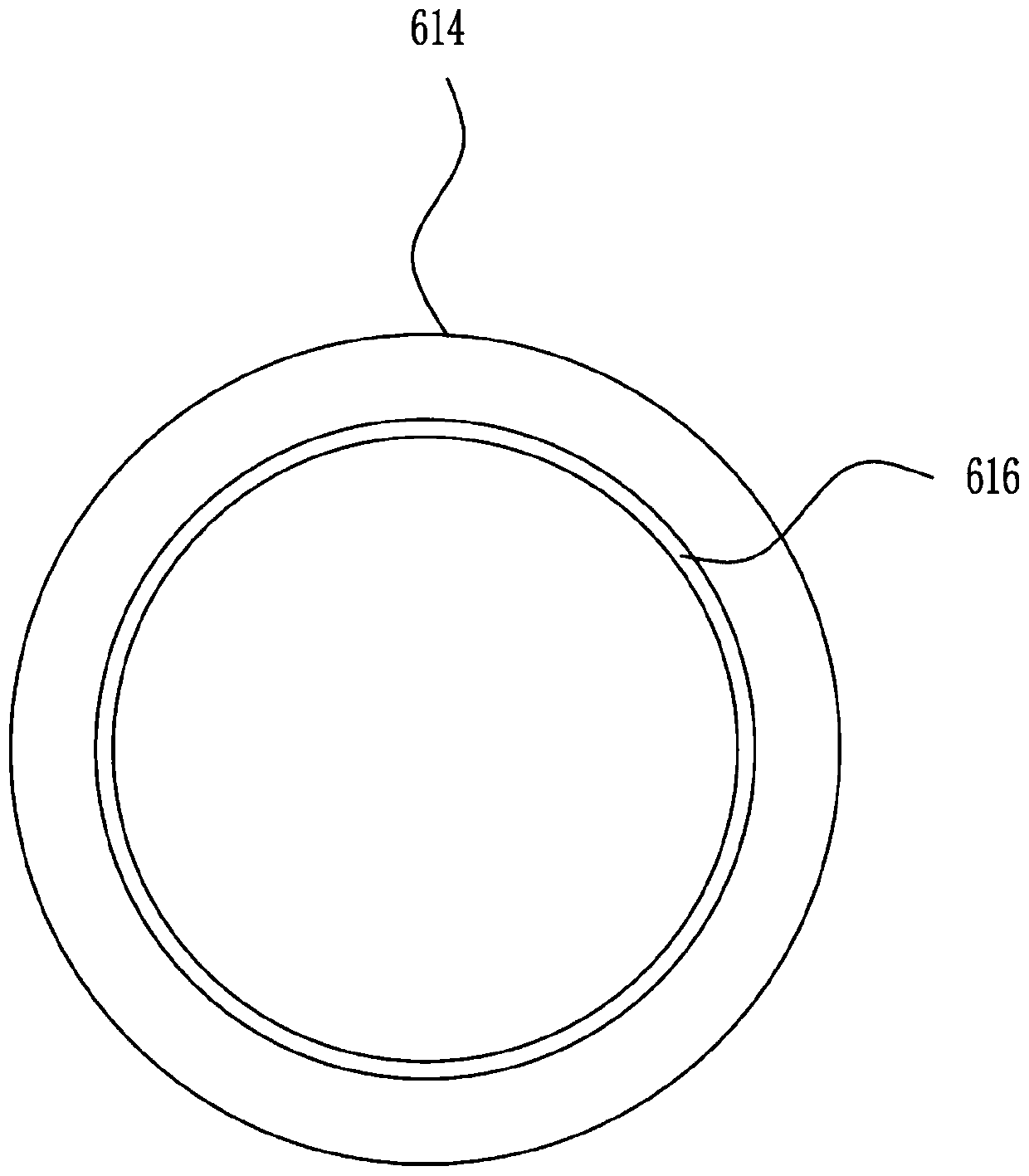

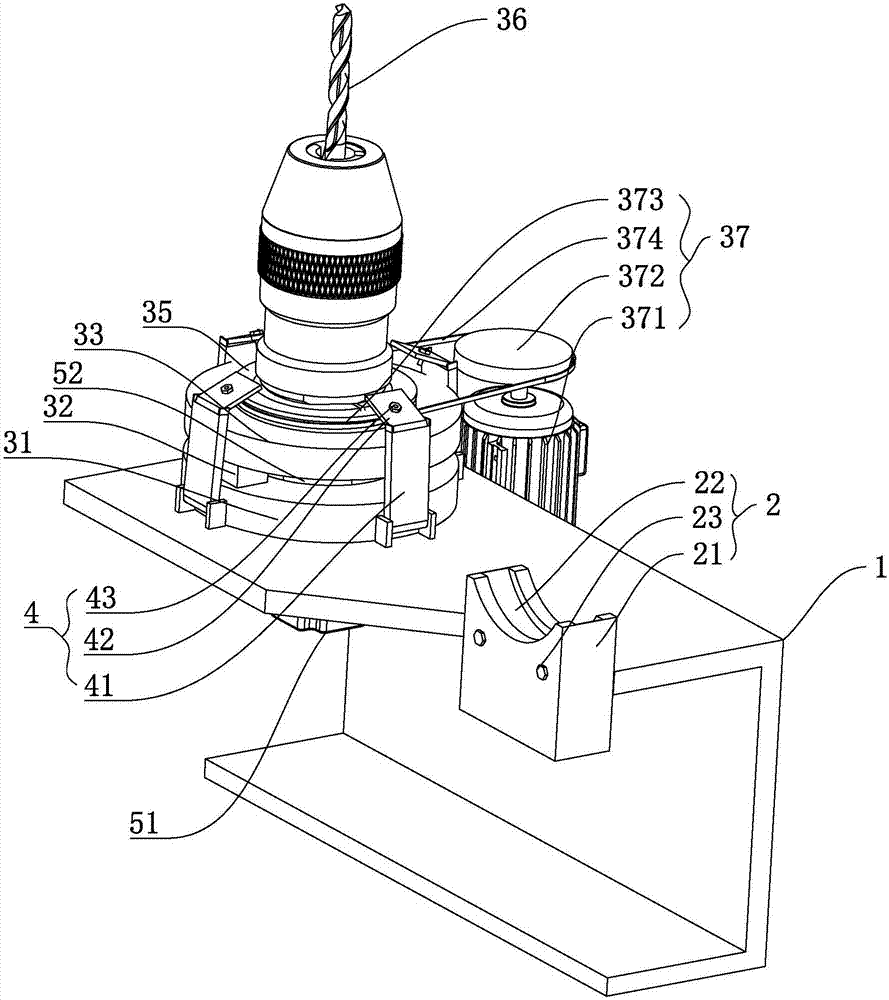

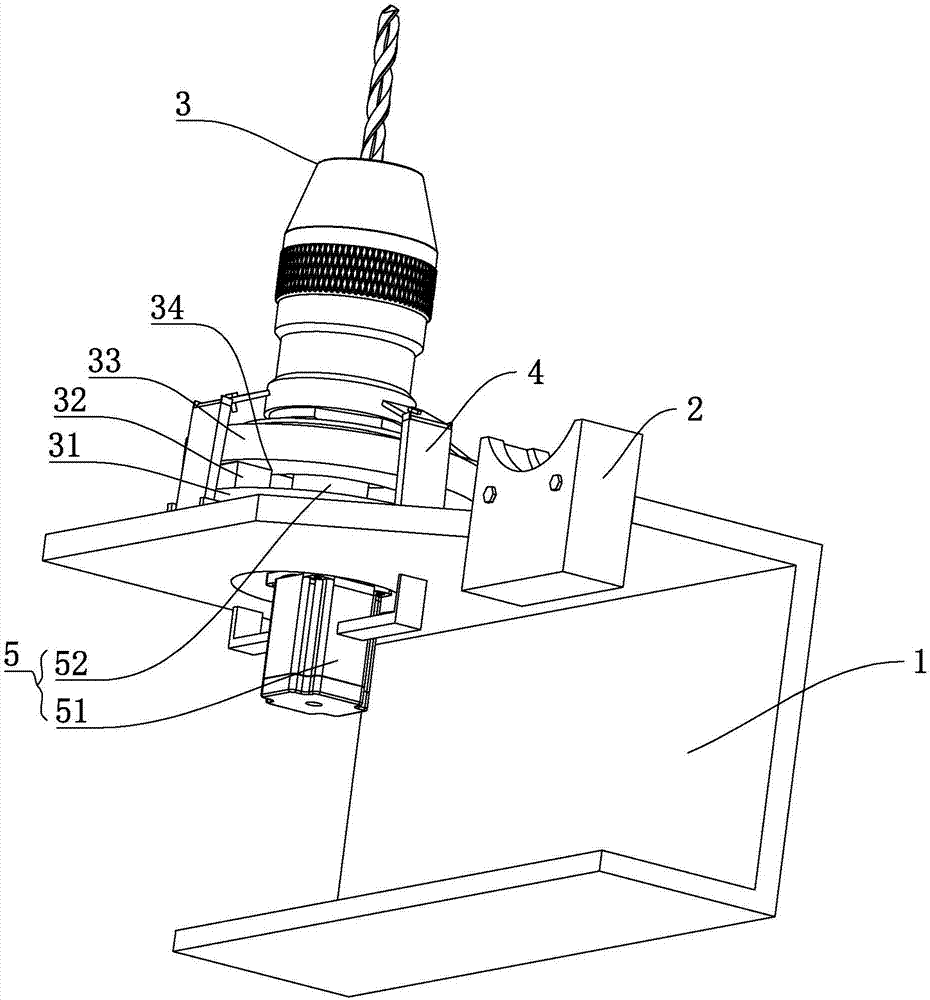

Vertical special drilling machine

PendingCN107570740AReduce the situation of not being able to see the drilling condition clearlySmooth rotationLarge fixed membersBoring/drilling componentsCushionDrilling machines

The invention discloses a vertical special drilling machine, and aims to provide a vertical special drilling machine with a drill bit facing upwards. The technical scheme of the vertical special drilling machine is characterized in that the vertical special drilling machine comprises a base; a supporting device is arranged on the base; a vertical upward drilling device is arranged on one side of the supporting device; the base is further provided with fixing devices for fixing the drilling device; and the drilling device comprises a cushion block fixed to the base, clamping blocks located on the cushion block and protruding upwards, a base plate arranged on the cushion block and matched with the cushion block, clamping grooves located in the base plate and matched with the clamping blocks,a bearing plate located on the base plate and rotationally connected with the base plate, the drill bit fixedly connected with the outer ring of the bearing plate and a driving device located on thebase and connected with the outer ring of the bearing plate.

Owner:无锡美高帝机械有限公司

Multifunctional loudspeaker

InactiveCN105681981AAvoid taking up spaceImprove performanceElectrical transducersLoudspeakersLoudspeakerMagnetic circuit

The present invention provides a multifunctional loudspeaker, which includes a basin frame with accommodating space, a spring piece connected to the basin frame, and a magnetic circuit system suspended in the basin frame through the spring piece, the magnetic circuit The system includes a lower clamping plate and a first magnet part and a second magnet part arranged on the lower clamping plate, at least one of the first magnet part and the second magnet part is a permanent magnet, and the second magnet part surrounds the The first magnet part is set and forms a magnetic gap with the first magnet part. The spring piece includes a connected elastic arm and a supporting arm. The elastic arm is fixed to the frame, and the supporting arm is accommodated in the In the magnetic gap and fixedly connected with the lower splint. The multifunctional loudspeaker provided by the present invention can save the space occupied by the magnetic circuit system by setting the support arm in the magnetic gap and fixing it on the lower splint, so that a larger magnetic circuit system can be provided, so that the Multi-function speakers perform better and have higher sensitivity.

Owner:AAC MICROTECH CHANGZHOU

Green and environment-friendly stone powder treatment device for machine-made sand production

The invention belongs to the technical field of stone powder treatment, and particularly relates to a green and environment-friendly stone powder treatment device for machine-made sand production. The green and environment-friendly stone powder treatment device for machine-made sand production comprises a feeding module, a treatment module and a transportation module. According to the green and environment-friendly stone powder treatment device for machine-made sand production provided by the invention, machine-made sand can directly fall to the upper side of a transportation mechanism in the stone powder removal process, and friction abrasion between the machine-made sand and the inner wall of a treatment shell is avoided. A filter ring designed in the invention can prevent stone powder from entering the upper end of a first channel to damage a first air pump. According to the green and environment-friendly stone powder treatment device for machine-made sand production provided by the invention, through the design of the width of a discharging hole, the machine-made sand falling from the discharging hopper falls in the radial direction of the treatment shell in a thin form, so that after the stone powder in the falling machine-made sand is blown by air in a first air pipe, most of the stone powder can enter a second channel from third air holes formed in a third channel in the treatment shell, the most of the stone powder in the machine-made sand can be ensured to be removed, and the quality of the machine-made sand is improved.

Owner:三亚城投众辉新型建材有限公司

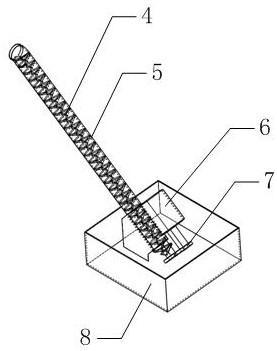

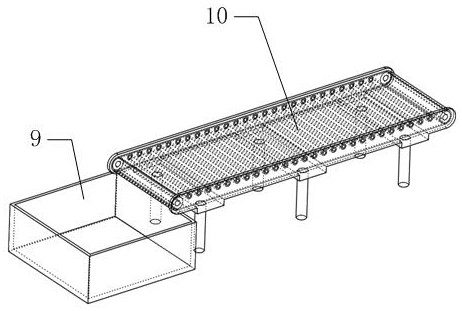

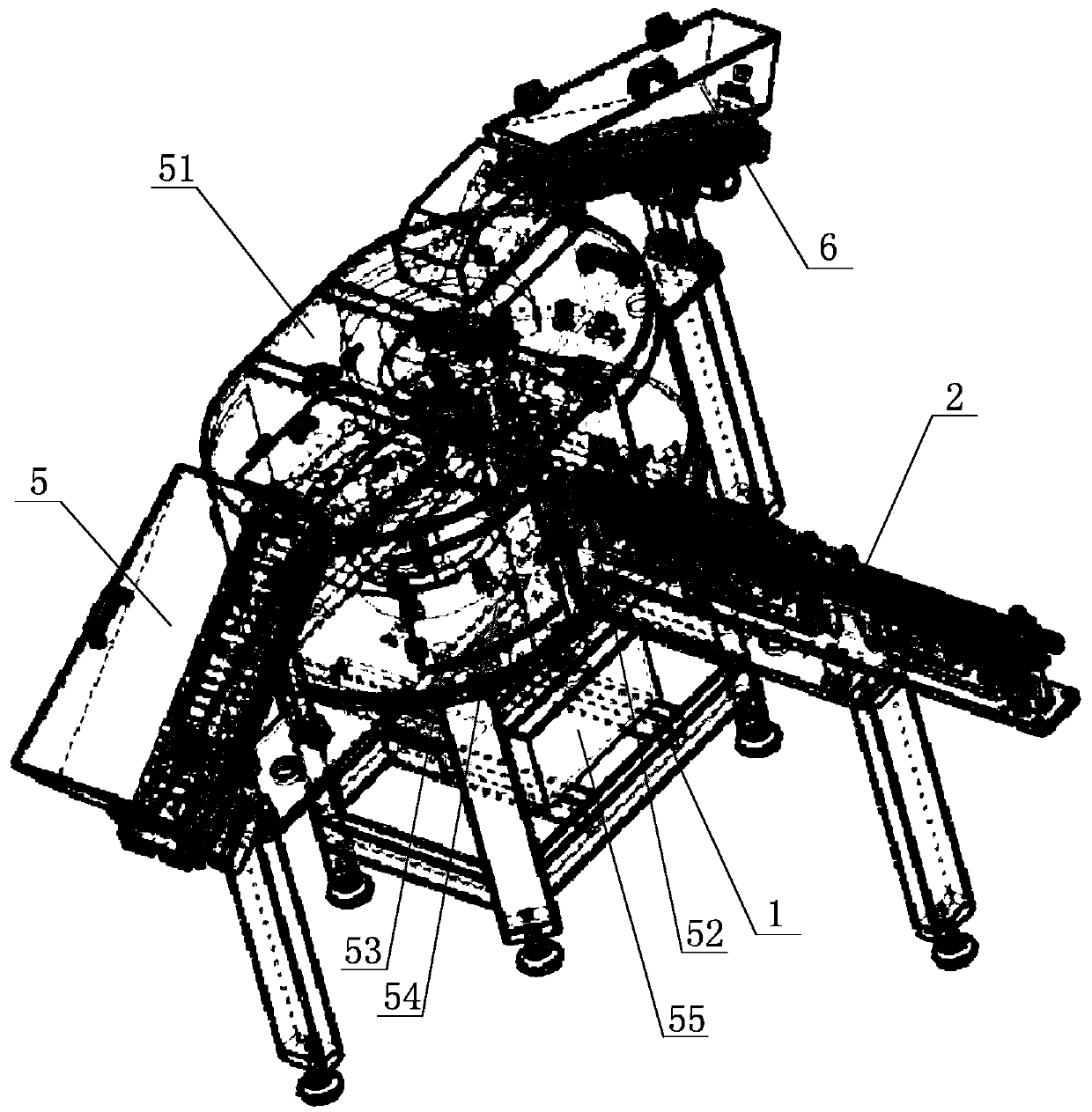

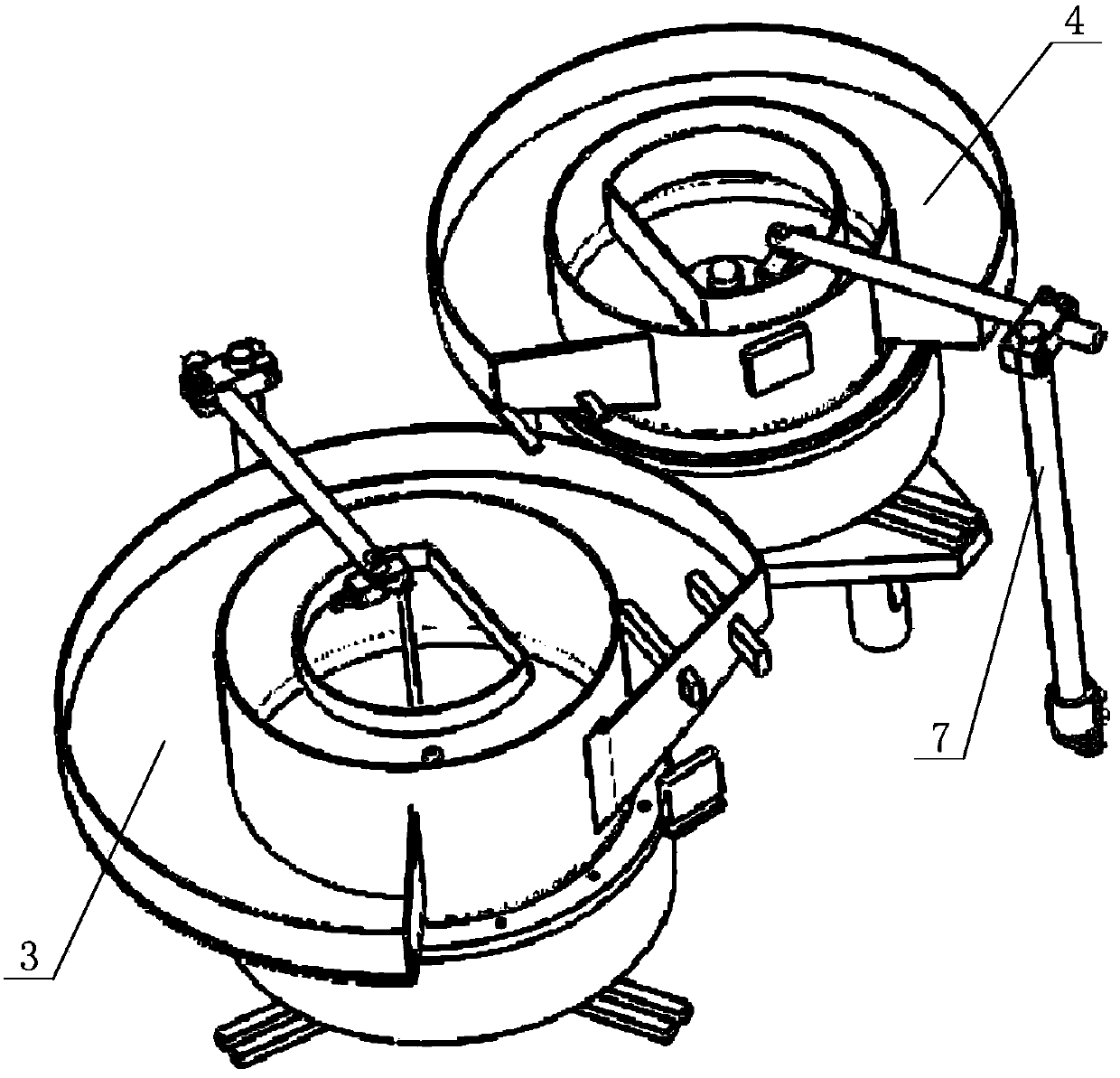

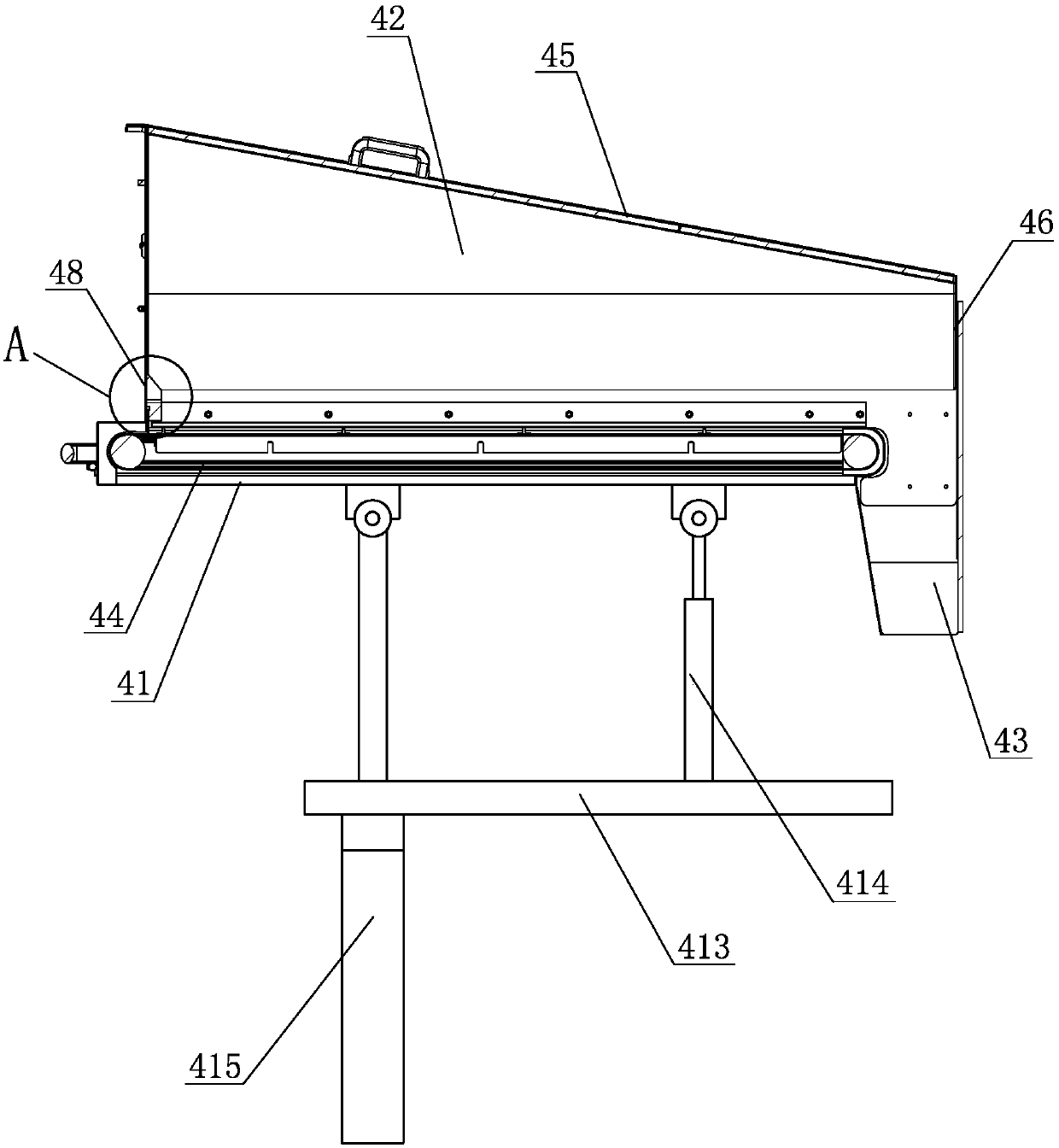

Automatic feeding equipment

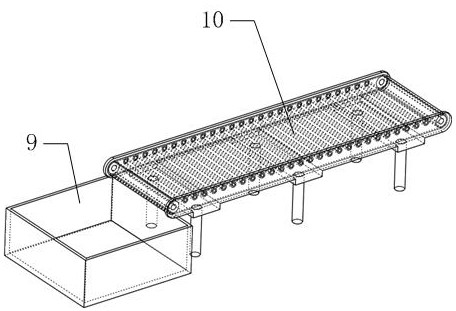

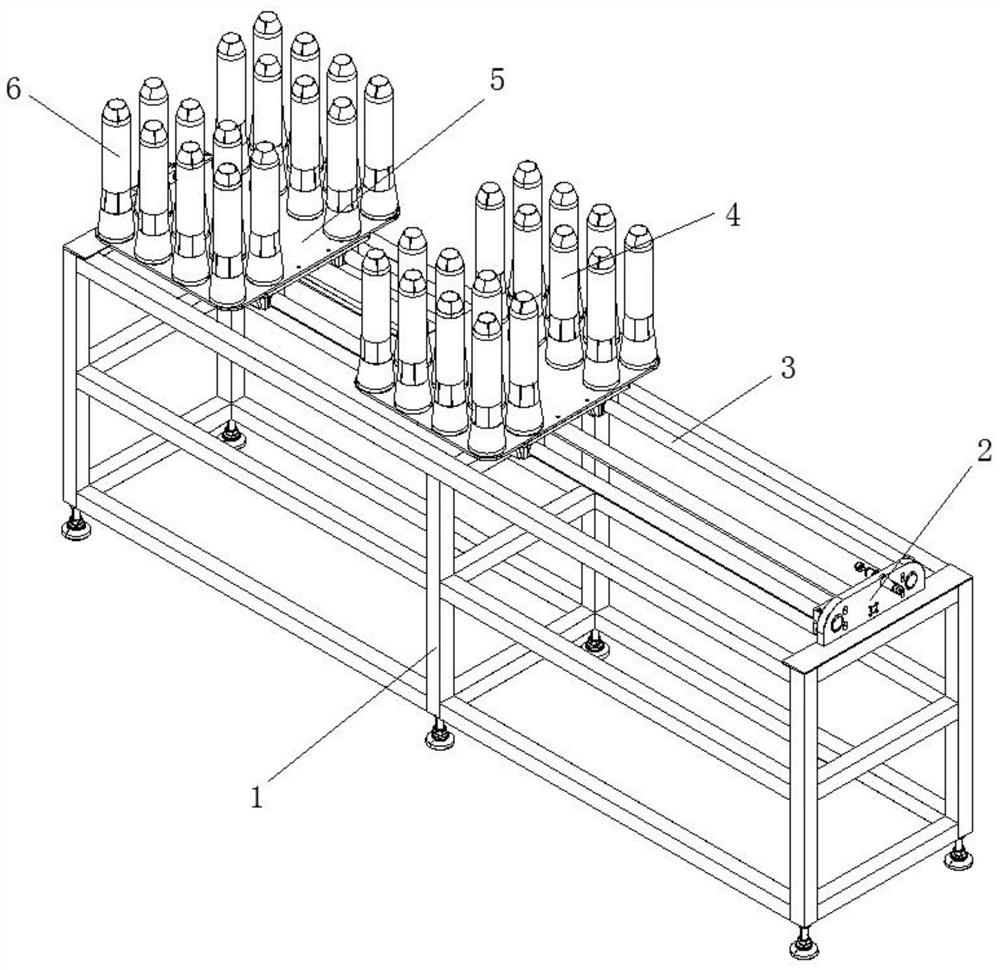

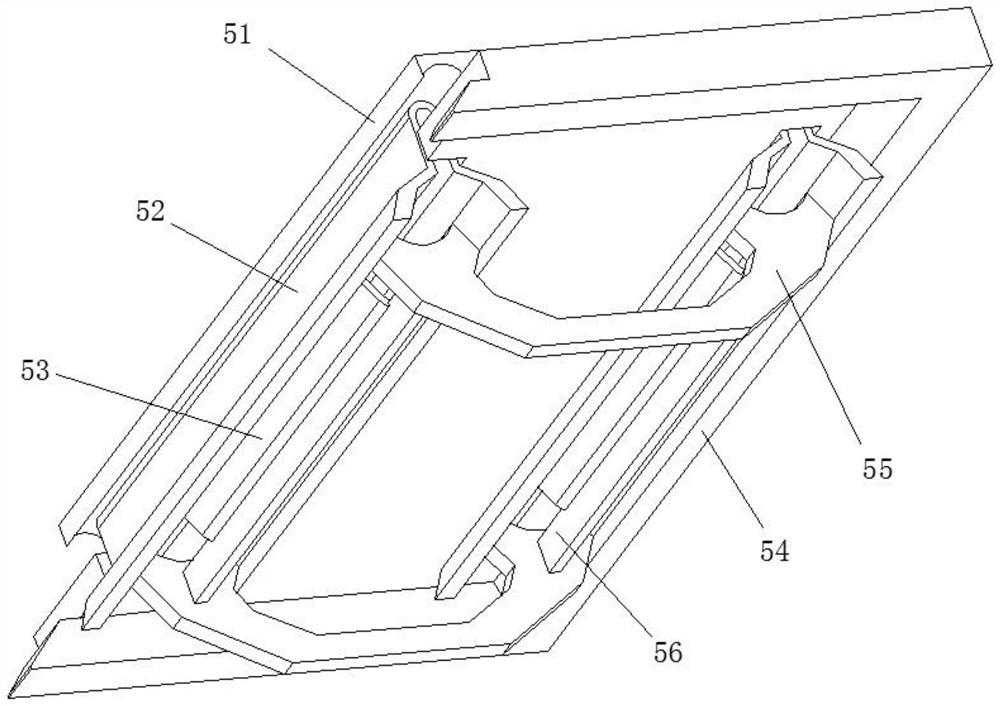

PendingCN107720179AReduce occupancyImprove feeding efficiencyCleaningLoading/unloadingMechanical engineeringElectrical and Electronics engineering

Owner:SUZHOU ITS IND TRANSFER SYST CO LTD

Roll coating device for lithium batteries

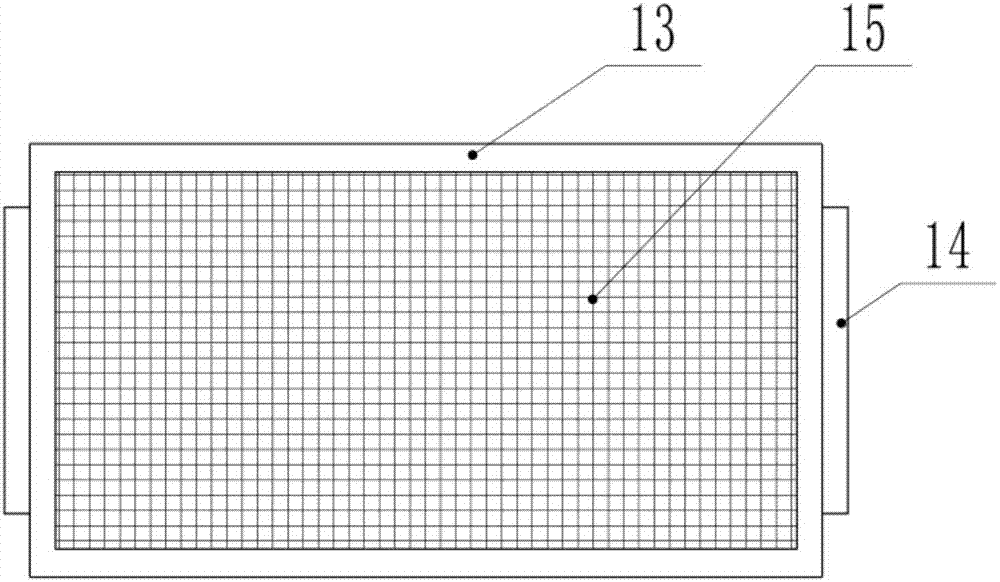

ActiveCN111530692AGuaranteed uniformityVibration effectLiquid surface applicatorsCoatingsChemistryComposite material

The invention belongs to the technical field of lithium batteries, and particularly relates to a roll coating device for the lithium batteries. The roll coating device for the lithium batteries comprises a liquid containing shell body, a scraper, a coating roller, a charging tray and a back roller. According to the roll coating device for the lithium batteries, a first removing block and a secondremoving block slide up and down, so that on the one hand, the effect that bubbles in slurry gathered at the upper end of a position where the outer circle face of the back roller and the outer circleface of the coating roller are close to each other are extruded is achieved, and on the other hand, the effect that the slurry is vibrated is achieved through movement of the two removing blocks, thebubbles in the vibrated slurry are extremely easy to discharge, and the phenomena that air entrainment exists and a plurality of tiny bubbles are exist on the surface of a coating due to a relativelylarge gap between the coating roller and the back roller and a relatively high coating speed in the coating process can be avoided to a certain extent; and in the sliding process of the bubble removing blocks, through the first removing block and the second removing block which are opposite in movement direction and alternately and sequentially installed in the same number, the stability of the pressure of slurry gathered at the upper ends of the position where the outer circle face of the back roller and the outer circle face of the coating roller are close to each other can be guaranteed, and the uniformity of the coating thickness is guaranteed.

Owner:深圳市鹏锦生混凝土有限公司

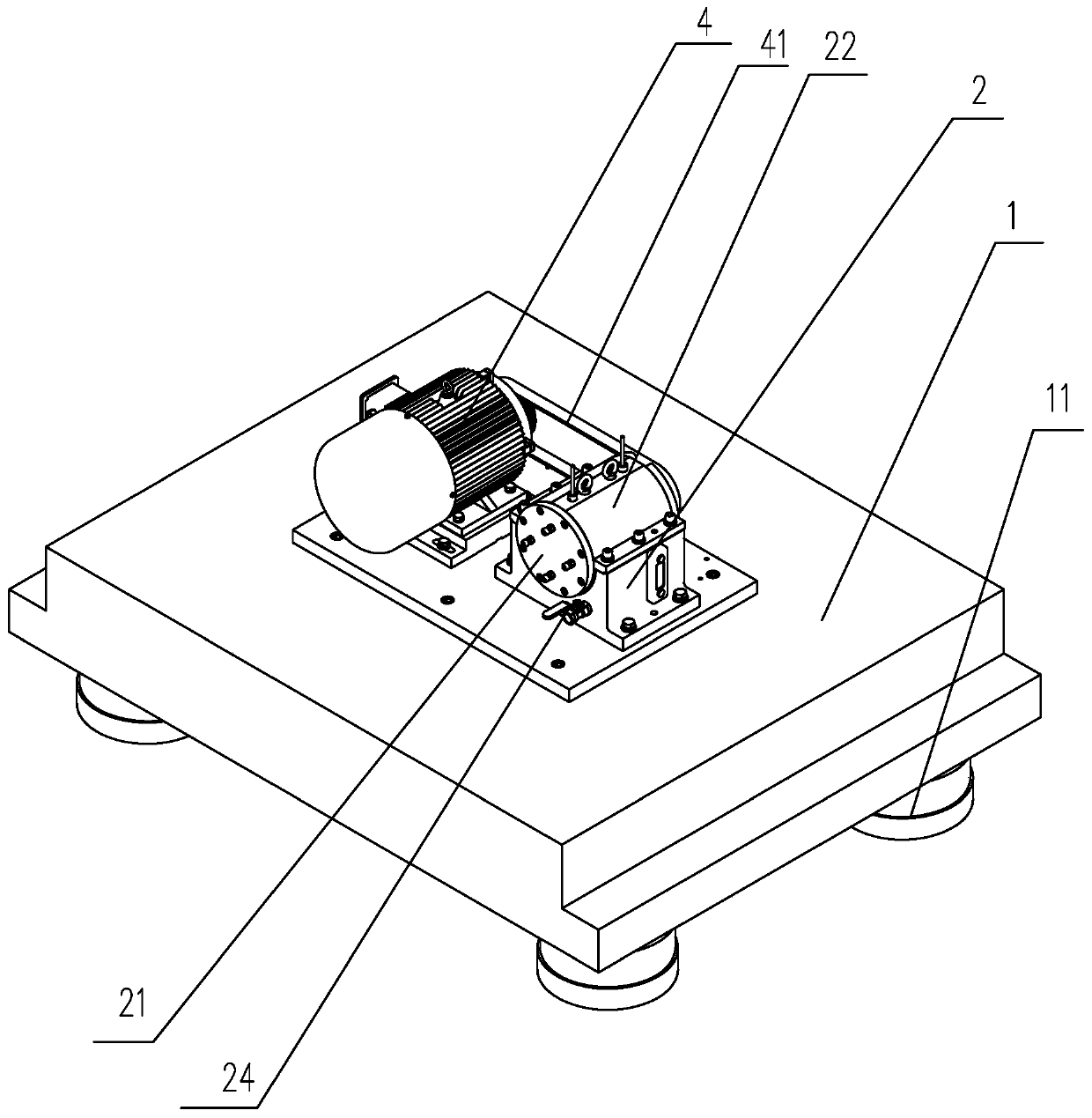

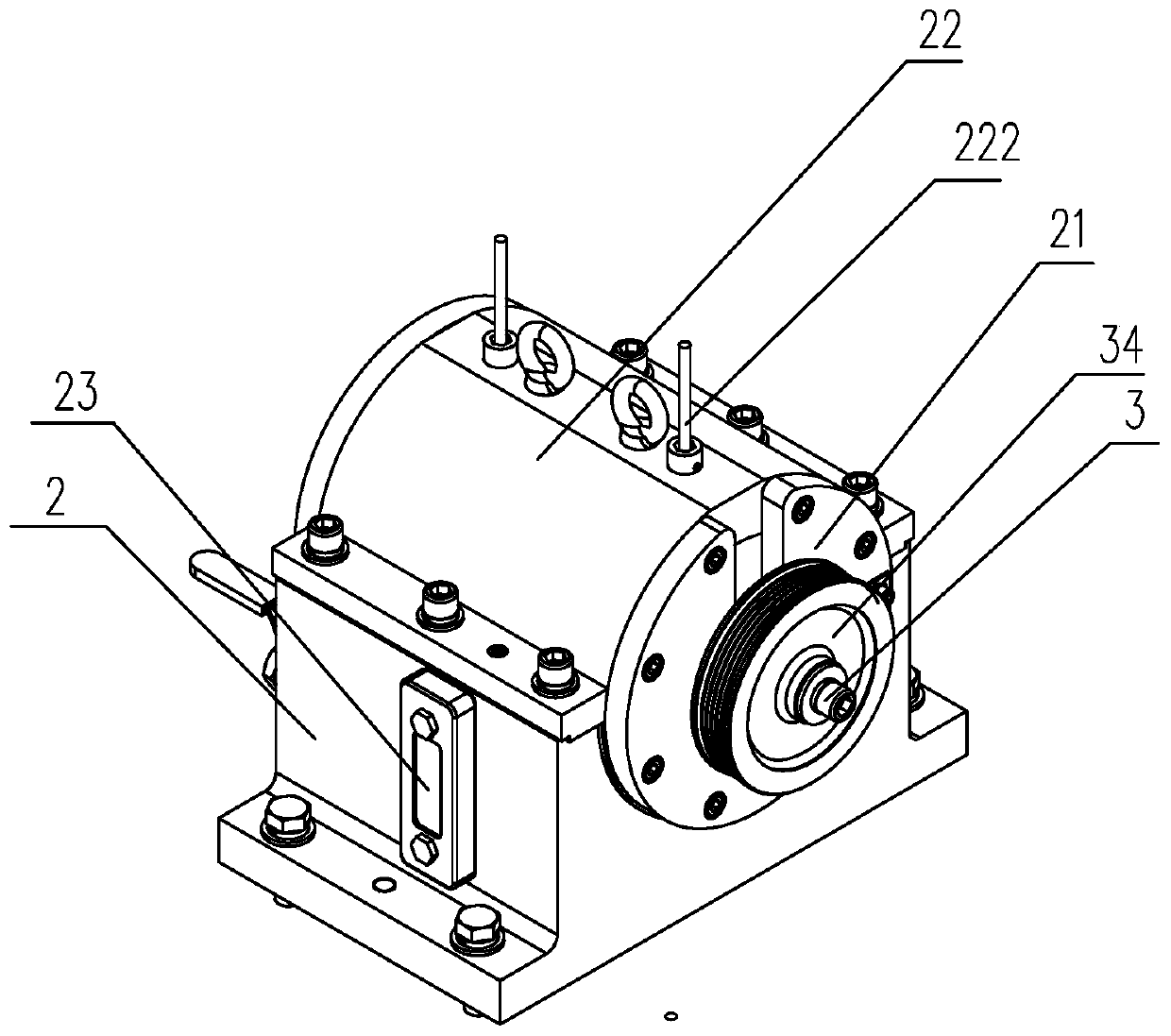

Bearing centrifugal testbed

The invention discloses a bearing centrifugal testbed. The bearing centrifugal testbed comprises a bearing seat, a driving motor, and a testing table for mounting a to-be-tested bearing; the testing table is arranged on the bearing seat, a mounting slot is formed on the testing table, a spindle is arranged in the mounting slot, the spindle is arranged in the mounting slot through a bush, and a positioning slot is arranged on the bush; the spindle comprises a testing part, a balance weight part and a transmission part; the testing part is arranged at a bush corresponding location, a base plateis arranged on the testing part, the positioning slot and the base plate are combined to form the locking on a to-be-tested bearing; the transmission part is arranged at the external of the testing table, a belt pulley is sleeved on the transmission part, the belt pulley is connected with a driving part output end through a belt to form the driving on the rotation of the spindle by the driving motor; the balance weight part is arranged in the mounting slot, and an eccentric block is arranged on the balance weight part. The testbed disclosed by the invention is simple in structure, capable of testing the capacity for bearing the rotating load by the outer ring of the bearing, and the testbed can provide a certain vibration effect, and the testing is closer to the working environment.

Owner:C&U CO LTD +2

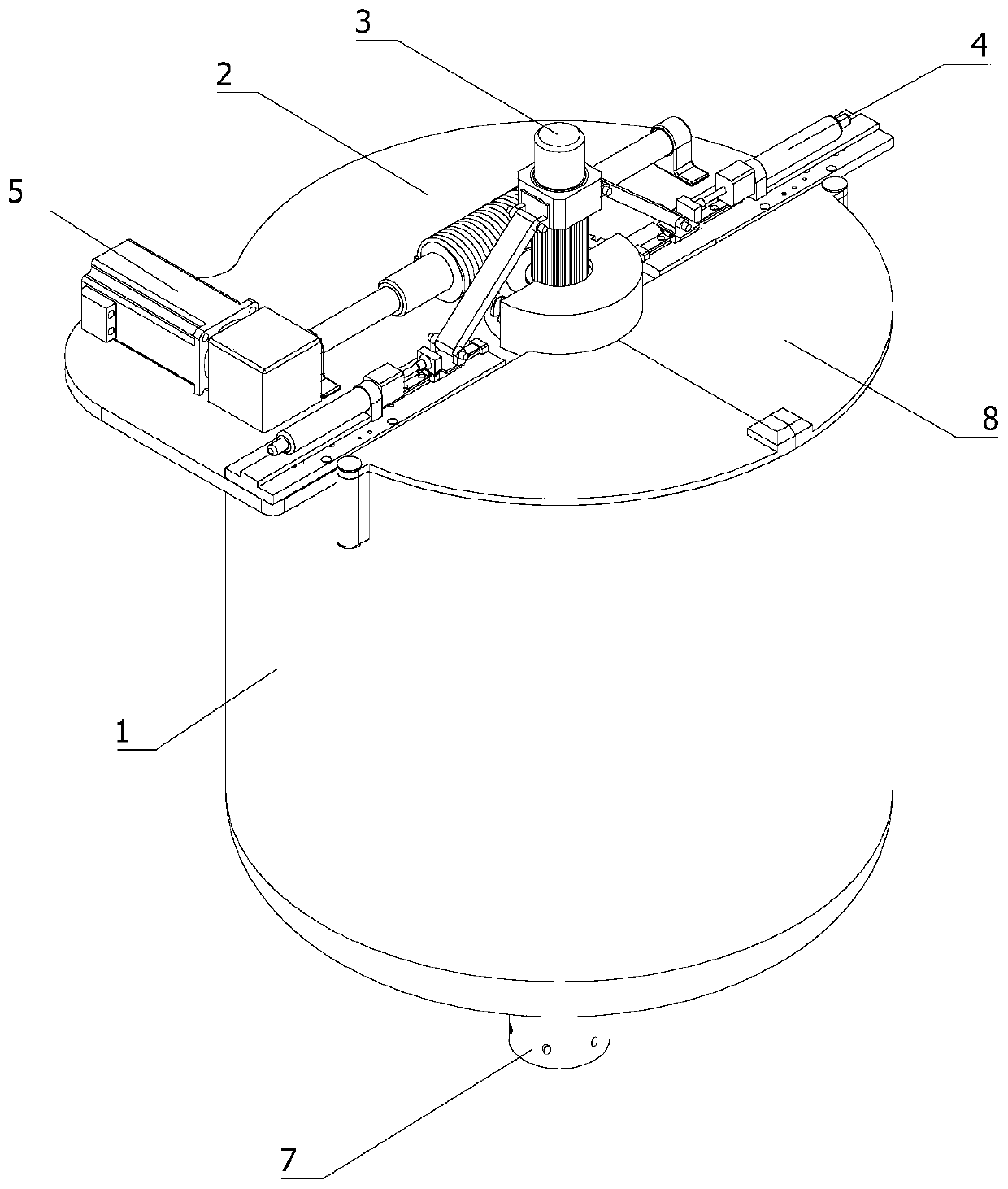

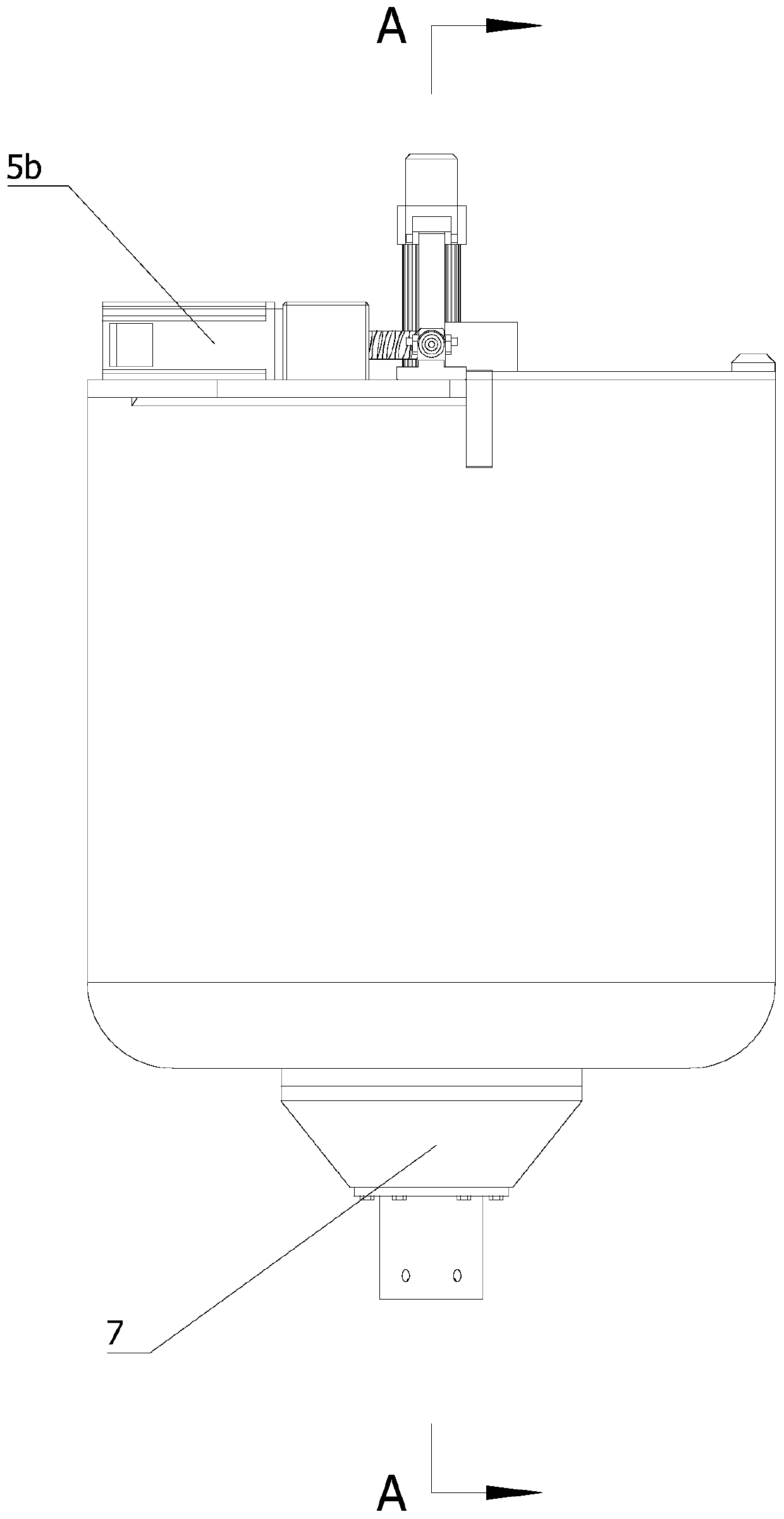

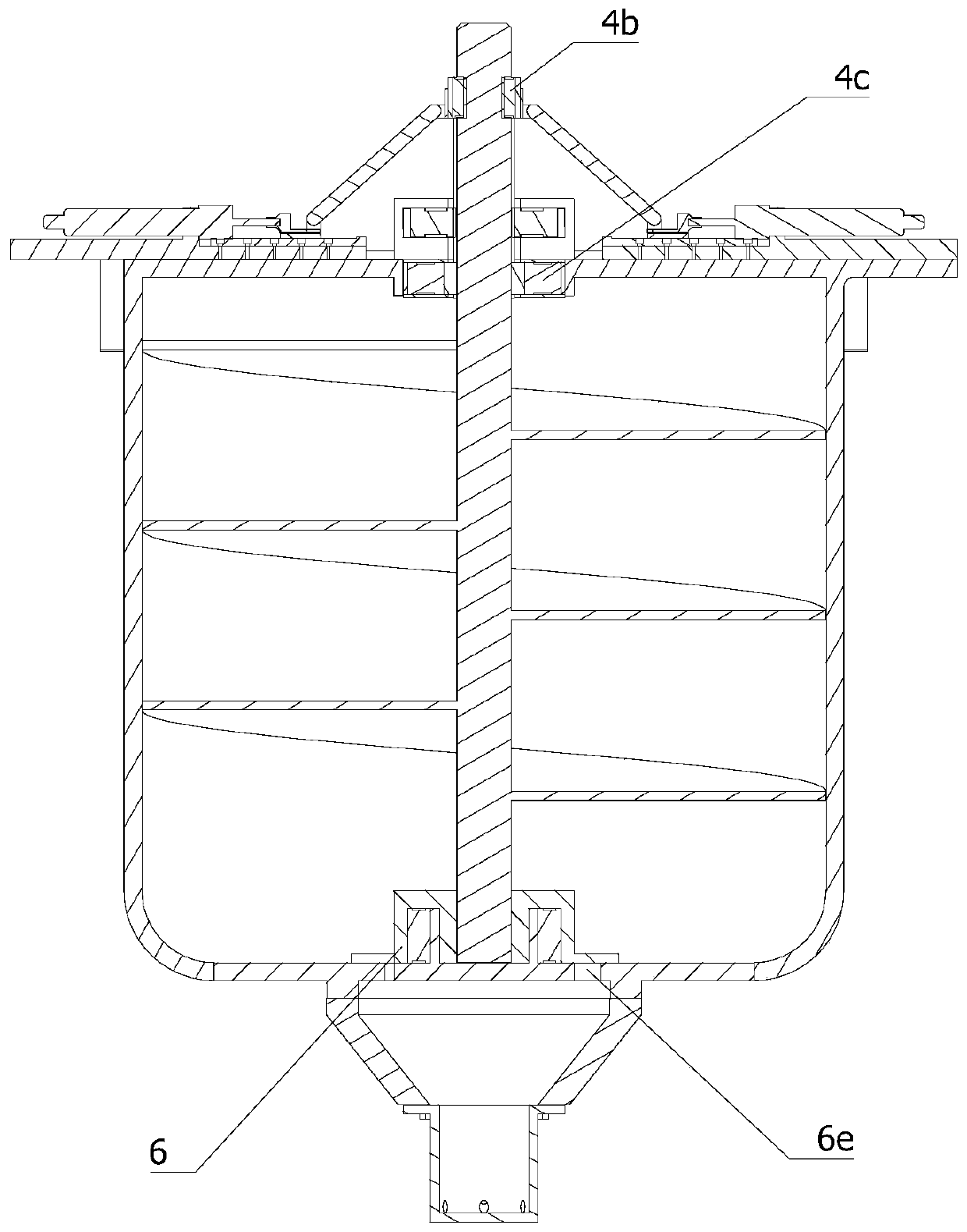

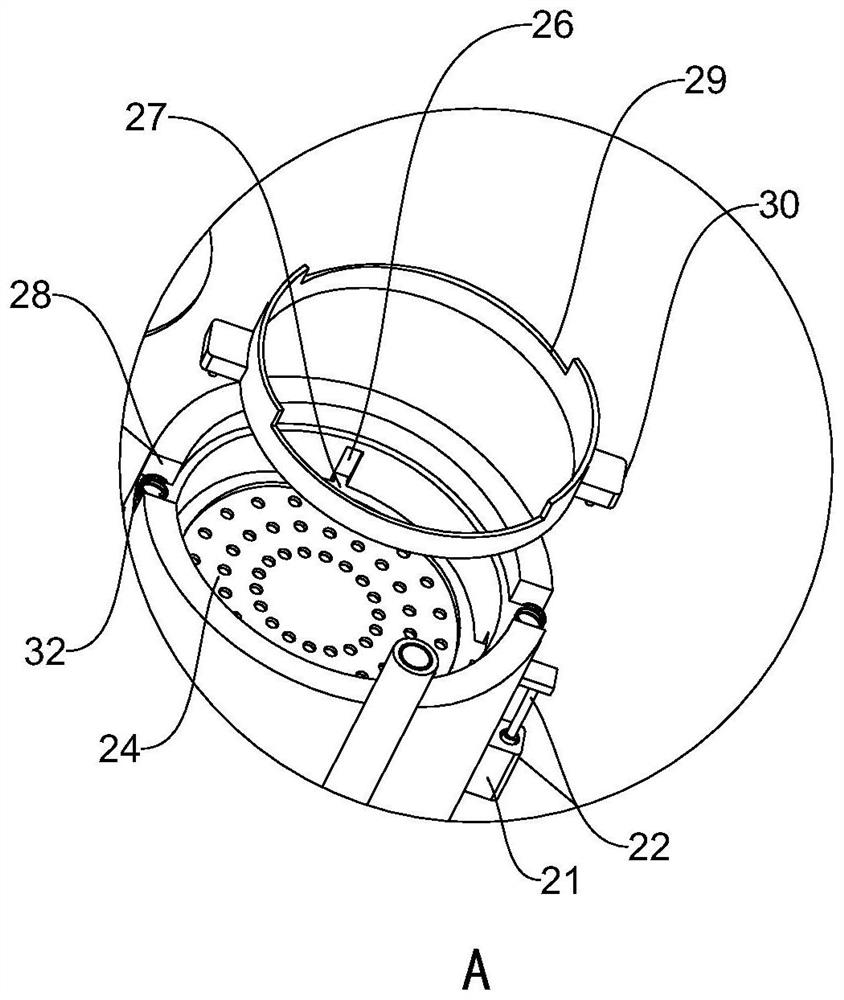

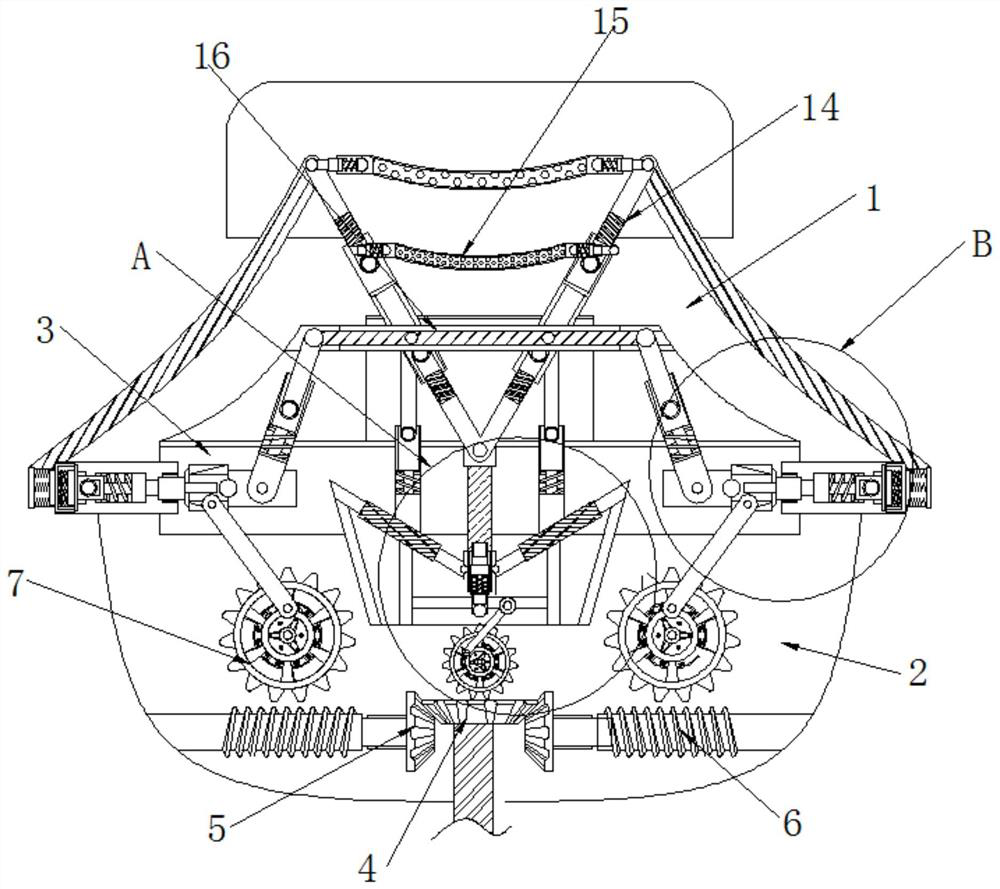

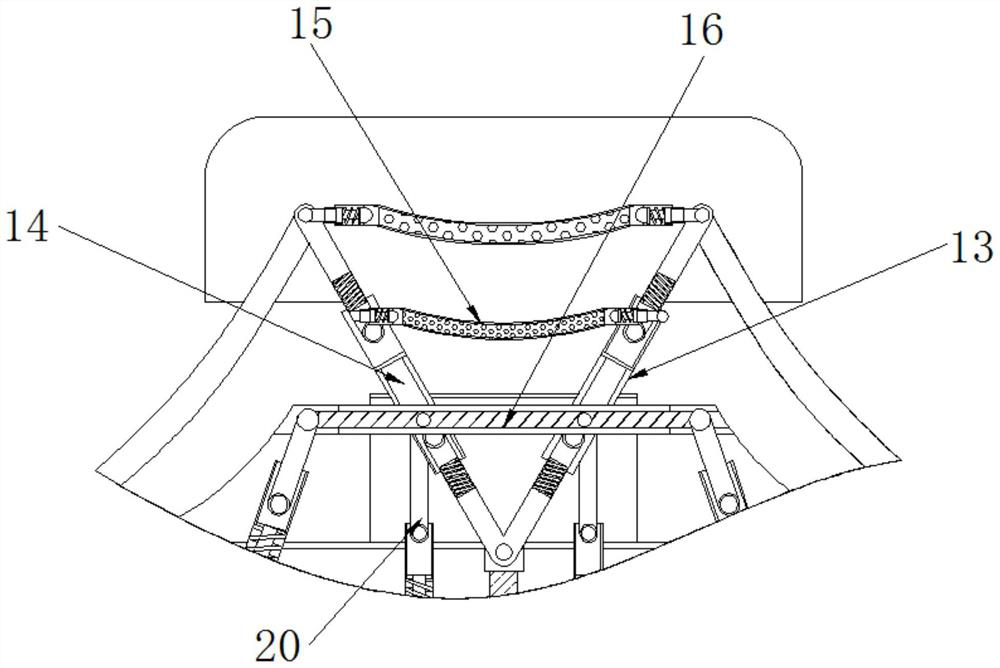

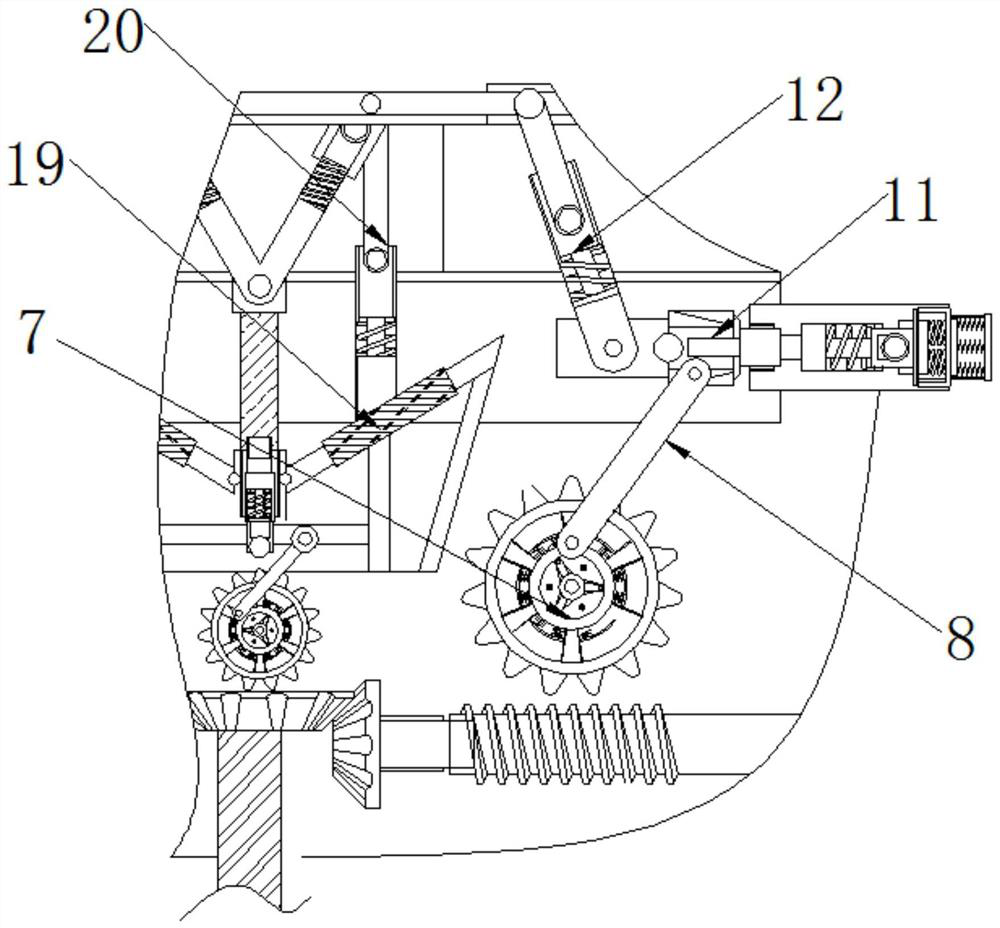

High-precision silver-copper rod semi-continuous casting equipment with stirring and vibration device

The invention relates to the technical field of a semi-continuous casting flow control device, in particular to high-precision silver-copper rod semi-continuous casting equipment with a stirring and vibration device. The equipment comprises a semi-continuous casting tundish, an end fixed frame, a rotating shaft, a lifting mechanism, a rotating mechanism, a flow adjusting mechanism, a graphite sleeve part, a top cover and a controller. The end fixed frame is mounted on the semi-continuous casting tundish. The rotating shaft is rotationally mounted on the end fixed frame. The lifting mechanism and the rotating mechanism are mounted on the end fixed frame. The output end of the lifting mechanism and the upper end of the rotating shaft are connected in a clamped manner. The output end of the rotating mechanism is engaged with the peripheral wall of the lifting mechanism. The work end of the rotating mechanism is arranged on the peripheral wall of the rotating shaft along the axis of the rotating shaft. The flow adjusting mechanism is mounted at the bottom of the semi-continuous casting tundish. The graphite sleeve part is mounted at the bottom end of the semi-continuous casting tundishand communicates with the interiorof the semi-continuous casting tundish. The top cover is arranged at the upper end f the semi-continuous casting tundish in a manner of being capable of being openedand closed. By means of the scheme, the property of forming materials is more excellent, the manual cost is reduced, and production efficiency is improved.

Owner:江苏环胜合金科技有限公司

Environment-friendly circulating high polymer material

The invention discloses an environment-friendly circulating polymer material which comprises the following components in parts by weight: 20 parts of polyurethane resin, 10 parts of water-soluble polymer, 1 part of polyester lubricant, 2 parts of linseed oil and 3 parts of peach gum. According to the device, a round rod is pulled upwards to enable a clamping block to be separated from a clamping groove, at the moment, a first rotating ring and a second rotating ring can be pushed, a collecting bin and an inlet bin rotate to the proper position with a first vertical rod as the circle center, then force on the round rod is released, and at the moment, under the action of a first spring, the clamping block moves and stretches into the clamping groove; therefore, the positions of the collecting bin and the inlet bin are fixed, the position of the filtering bin can be conveniently adjusted subsequently, the filtering bin is adjusted to be flush with the collecting bin and the inlet bin in the vertical direction, the high polymer materials processed into particles can fall into the filtering bin to be screened through an inlet of the inlet bin, and impurities and the like mixed in the materials can be filtered by the filter screen. Therefore, reprocessing of the material is facilitated, environmental protection is achieved, and pollution to the environment is reduced.

Owner:SUNRISE PACKAGING MATERIAL JIANGYIN CO LTD

Multi-stage screening device for red kiwifruit classification

ActiveCN112246611AImprove screening effectPlay a supporting roleSievingGas current separationGear wheelStructural engineering

The invention belongs to the technical field of screening, and particularly relates to a multi-stage screening device for red kiwifruit classification. The multi-stage screening device comprises a screening seat, a supporting seat is fixedly connected to the lower surface of the screening seat, a hollow pipeline is fixedly connected to the interior of the screening seat, and a first bevel gear isrotatably connected to the interior of the supporting seat; and second bevel gears are engaged with the left side and the right side of the first bevel gear correspondingly, threaded columns are rotatably connected to the side surfaces of the second bevel gears, rotating gears are engaged with the outer surfaces of the threaded columns, stretching rods are rotatably connected to the outer surfacesof the rotating gears, and a compression shaft is movably connected to the interior of the hollow pipeline. When the multi-stage screening device is used, the angle between V-shaped frames is regularly increased or decreased, meanwhile, the V-shaped frames drive screening nets to be in a contracted or unfolded state, and therefore at the moment, kiwi fruits on the surfaces of the screening nets can be screened to a certain degree; and the multiple screening nets with different hole diameters are arranged, so that multi-stage screening can be achieved.

Owner:湖南周生堂生物科技股份有限公司

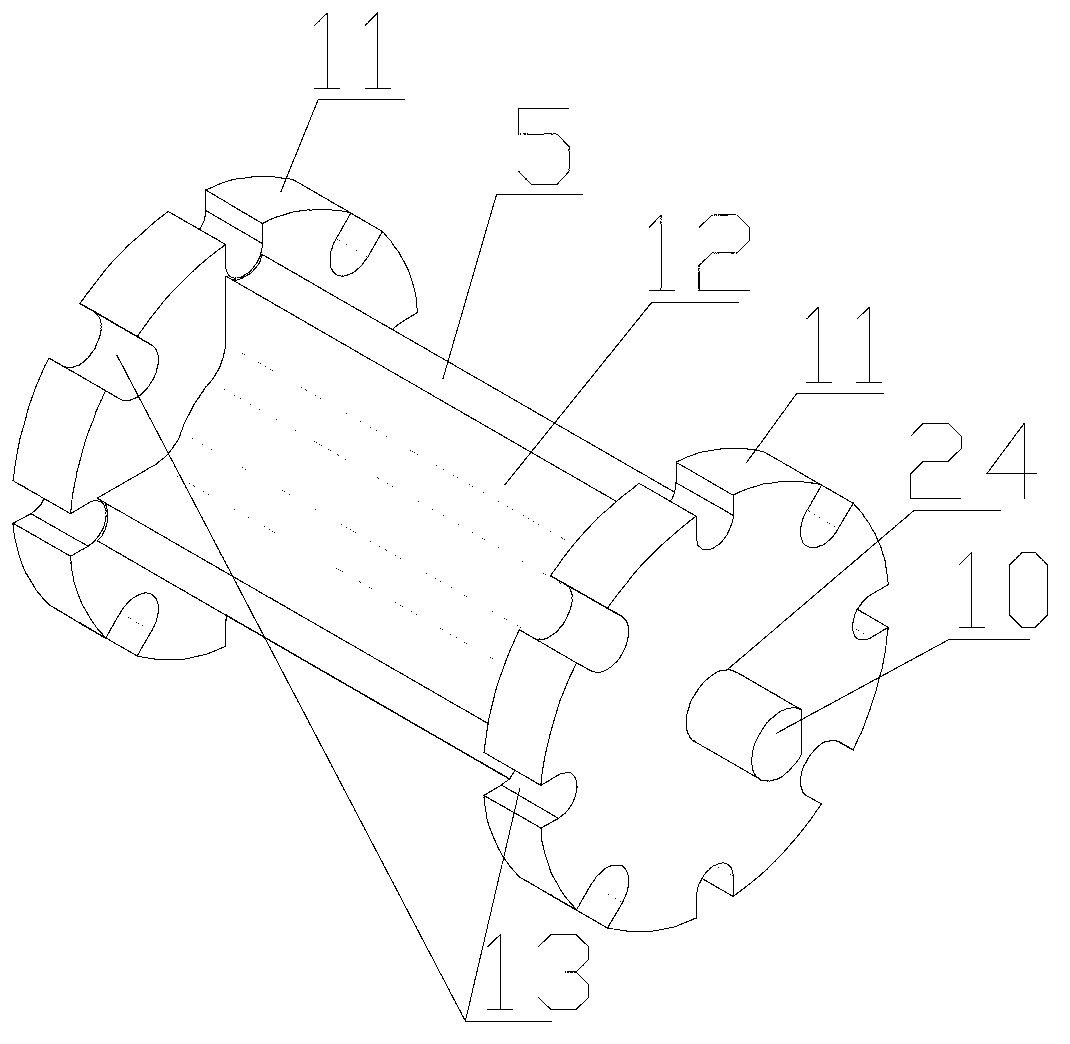

Cotton picker

InactiveCN103283399AReduce accumulationVibration effectPicking devicesAgricultural scienceAgricultural engineering

The invention discloses a cotton picker which comprises a shell and a drive component. A cotton picker nose is fixed on the shell. Cotton picking needles which are capable of automatically changing angles through crankshaft eccentric rotation during operation are disposed in the cotton picker nose. The cotton picker has the advantages that the cotton picker is simple in structure and convenient to use, cotton is efficiently picked by rotating the cotton picking needles, when the cotton picking needles rotate to picking positions, the cotton picking needles extend forwardly to pick cotton, when the cotton picking needles rotate to non-picking positions, the cotton picking needles reverses to discharge cotton / cotton flock, the problem that repeated bringing in and out of cotton / cotton flock increases probability of cotton flock accumulation and winding in the original cotton picker with cotton picking needles in fixed rotation, and the discharged cotton / cotton flock can be collected through a cotton outlet to complete cotton / cotton flock picking.

Owner:周芬

A stone powder processing device for green environmental protection machine-made sand production

The invention belongs to the technical field of stone powder treatment, and in particular relates to a stone powder treatment device for green and environmentally friendly machine-made sand production, which includes a feeding module, a processing module, and a transportation module. The upper side of the transport mechanism will not have friction and wear with the inner wall of the processing shell. The function of the filter ring designed in the present invention can prevent stone powder from entering the upper end of the first passage, causing damage to the first air pump. The invention makes the machine-made sand falling from the hopper fall in a relatively thin shape in the radial direction of the treatment shell through the design of the width of the feeding hole, so as to ensure that the stone powder in the falling machine-made sand is blown by the gas in the first air pipe , most of the stone powder can enter the second channel from the third air hole opened on the third channel on the treatment shell, so as to ensure that the stone powder in the machine-made sand can be mostly cleaned up and improve the quality of the machine-made sand.

Owner:三亚城投众辉新型建材有限公司

Cup sleeve taking-out and stacking tool

The invention discloses a cup sleeve taking-out and stacking tool, and releates to the technical field of injection molding manufacturing. The cup sleeve taking-out and stacking too comprises a rack, a station interchanging device is fixedly connected to the top of the rack, an electromagnetic valve driving air cylinder mechanism is fixedly connected to the interior of the station interchanging device, a base plate device is slidably connected to the top of the electromagnetic valve driving air cylinder mechanism, the top of the base plate device are correspondingly connected to a working station A and a working station B, and the base plate device comprises a cup joint pressing device. According to the cup sleeve taking-out and stacking tool, an electromagnetic signal is given to the electromagnetic valve driving air cylinder mechanism through the times which a manipulator takes out cup sleeves and completes the stacking of the working station A, when the working station B runs to the position of the working station A, the manipulator takes the cup sleeves and continues to stack the cup sleeves for the set times of the manipulator, after the stacking times of the working station B are completed, the manipulator sends a signal to the electromagnetic valve driving air cylinder mechanism to push the working station A to the original position, the manipulator continues to stack, and the process is circulated, so that the recycling effect of the device is achieved.

Owner:遵义遵道智造实业有限公司

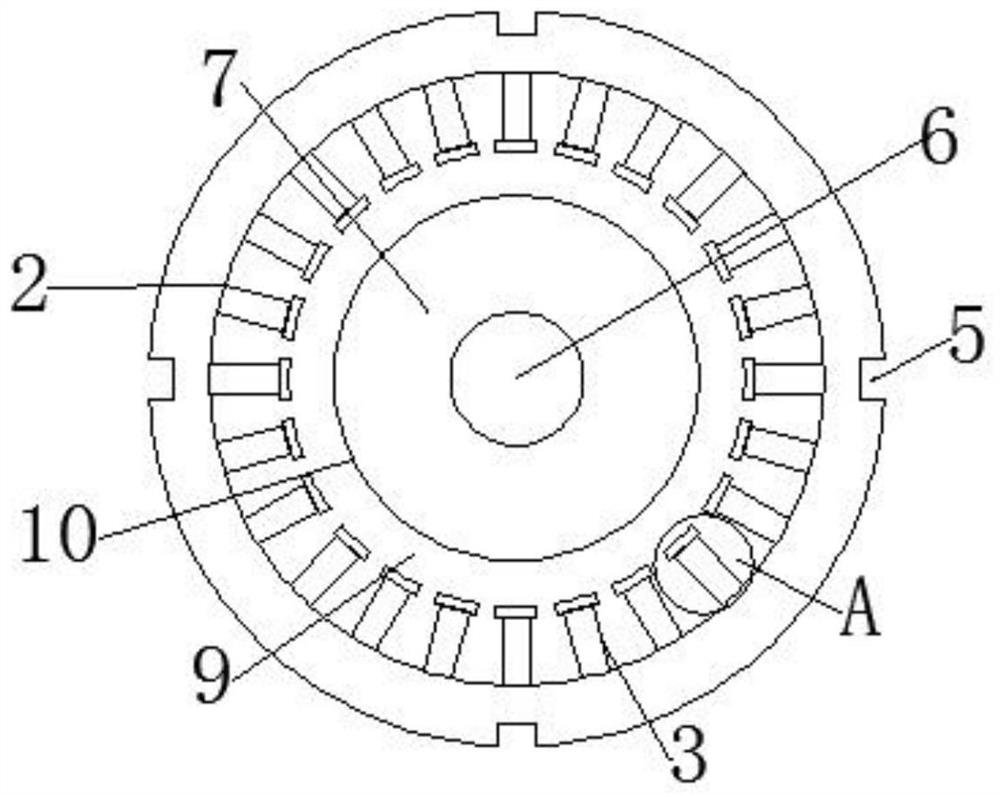

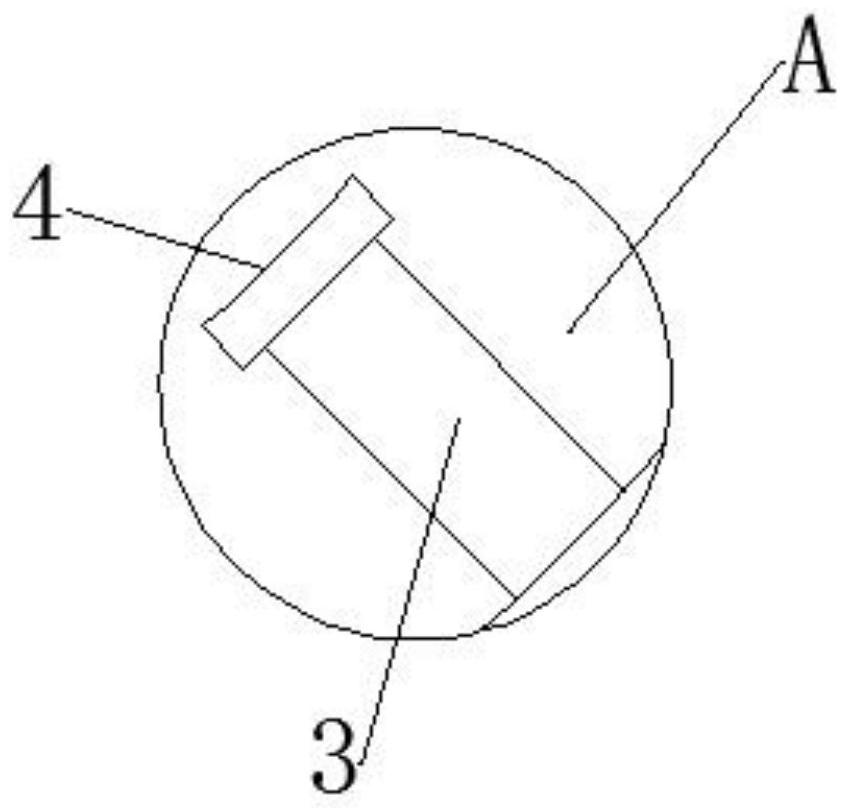

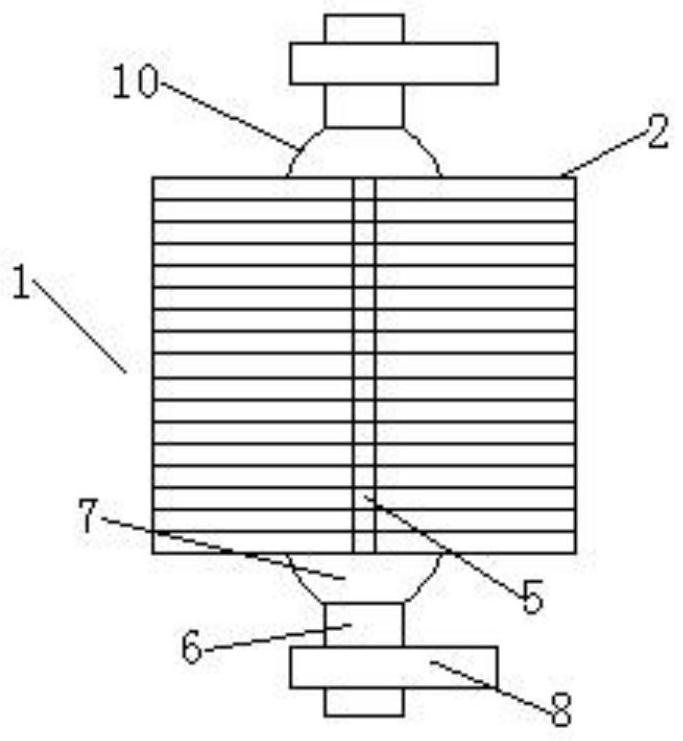

Stator structure of vibration motor

InactiveCN112653262AAchieve normal operationImprove cooling effectWindingsMagnetic circuit stationary partsEngineeringMechanical engineering

The invention discloses a stator structure of a vibration motor. The stator structure comprises a motor shell and a rotating shaft, wherein the rotating shaft is fixedly arranged in the motor shell, a rotor is coaxially and fixedly arranged on the rotating shaft, coils are fixedly arranged on the rotor, a stator is fixedly arranged in the motor shell, and is formed by stacking single stators, heat dissipation grooves are formed in the periphery of the single stator, a plurality of uniformly distributed winding posts are fixedly mounted in the single stator, the coils are fixedly mounted between the winding posts, and air channels are formed between the winding posts and the rotor. According to the invention, the operation of the motor is achieved through the stator and the rotor arranged in the motor shell; the stator is composed of a plurality of single stators, so that the heat dissipation performance of the stator is improved, and the contact area between the coil and the stator is increased; and the stator is cooled through the heat dissipation grooves formed in the single-piece stators, so that the coil is protected, the practicability of the device is improved, and the service life of the device is prolonged.

Owner:湖北恒高电子有限公司

Cymbal pickup and bracket including the cymbal pickup

InactiveCN103137111BVibration effectSmooth vibrationElectrophonic musical instrumentsInsertion stentEngineering

The present invention provides a pickup for cymbals capable of stably detecting vibrations corresponding to hitting a cymbal and preventing damage to a sensor, and a stand including the pickup for cymbals. The sensor mounting part keeps the distance between the first abutment part and the second abutment part fixed by the insertion part, so it can prevent the first abutment part and the second abutment part from being separated from each other by the fastening effect of the fastening member. The detection result of the piezoelectric sensor mounted on the first abutting portion can be avoided from being affected by the fastening force of the fastening member. Thereby, the detection result corresponding to the vibration of the sensor mounting part transmitted from the cymbal can be output. In addition, deformation of the piezoelectric sensor according to the inclination of the struck cymbal can be avoided, so that damage to the piezoelectric sensor caused by the strong hitting of the cymbal can be prevented.

Owner:ROLAND CORP

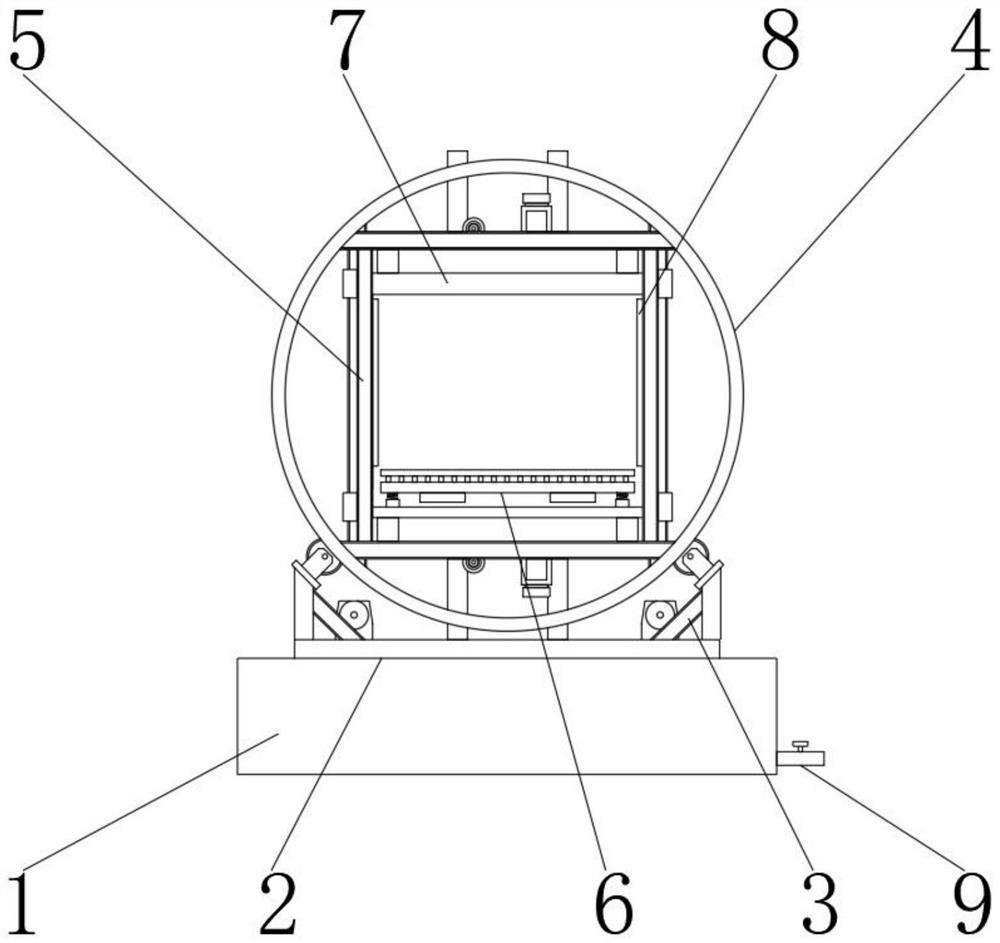

Large intelligent automatic water pouring machine

PendingCN114231709AEliminate mildew and odorSolve the problem of stagnant waterFurnace typesCleaning processes and apparatusElectric machineryMaterials processing

The invention discloses a large-scale intelligent automatic water pouring machine, and relates to the field of aluminum alloy disc-shaped material processing, the large-scale intelligent automatic water pouring machine comprises a water pool, a rack base is arranged on the outer surface of the upper end of the water pool, a driving device is arranged on the outer surface of the upper end of the rack base, and an annular frame is arranged on the outer surface of the upper end of the driving device; a square frame is arranged in the middle of the annular frame. According to the large-scale intelligent automatic water pouring machine, accumulated water in a cylinder can be smoothly discharged in the modes of automatic overturning for 90-degree hovering, 180-degree hovering, 270-degree hovering and the like, the problem of pipeline water accumulation is solved, the situation that the interior of the cylinder is mildewed and smelly due to the accumulated water is completely eradicated, fixation is firm during use, operation is convenient, workpieces can be conveniently moved, loaded and unloaded, and the working efficiency is improved. And the water shaking mechanism can achieve a vibration effect on the workpiece through a vibration motor during water pouring, water in the workpiece can be shaken out, the water pouring effect can be improved during use, and the use effect is better than that of a traditional mode.

Owner:GUANGZHOU HOTPOOL SANITARY WARE CO LTD

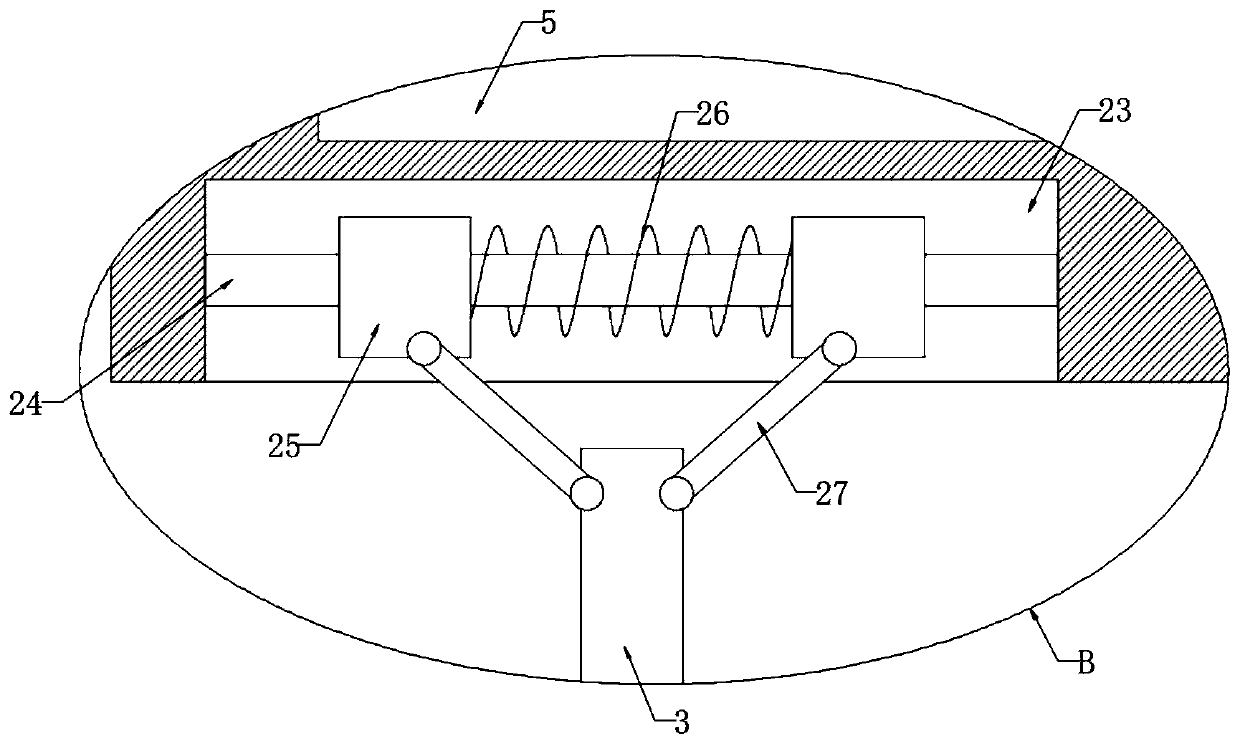

A vibrating and vibrating integrated sand and gravel screening device for concrete preparation

ActiveCN108127783BImprove turnoverAvoid cloggingClay processing apparatusElectric machineClassical mechanics

The invention discloses a vibration-swing integration type gravel sieving device for concrete preparation. The vibration-swing integration type gravel sieving device comprises a base, an outer sleeverod, an inner sliding rod, a transverse plate, a swing rod, a sieving box, a double-shaft motor, a left cam and a right cam, wherein the bottom of the outer sleeve rod is provided with an electromagnet, the electromagnet is matched with a magnet, a swing shaft is perpendicularly welded to the front side of a vertical column, the swing rod is mounted on the swing shaft in a rotating manner, a leftconnecting rod and a right connecting rod are separately hinged to the left and right parts of the lower side of the swing rod, and the left connecting rod and the right connecting rod vertically penetrate downwards through the transverse plate and are hinged to the sieving box in a contact manner. Through the intermittent power supply and outage of the electromagnet, the sieving box is driven tomove upwards and downwards intermittently, a vibrating effect is realized, the sieving speed is greatly increased, and at the same time, the condition that gravels block holes during sieving is effectively avoided; and through the leftward and rightward swing of the swing rod, the sieving box is driven to swing leftwards and rightwards, the flow rate of gravels in the sieving box is greatly increased, and the sieving speed is further increased.

Owner:江苏中能建材有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com